Page 1

®

Fluke 433/434

Three Phase Power Quality Analyzer

Users Manual

EN

August 2004

© 2004 Fluke Corporation, All rights reserved. Printed in the Netherlands

All product names are trademarks of their respective companies.

Page 2

Page 3

Table of Contents

Chapter Title Page

General Aspects.............................................................................................. 1-1

Introduction........................................................................................................1-1

Limited Warranty & Limitation of Liability......................................................1-2

Declaration of Conformity.................................................................................1-3

Shipment Note ...................................................................................................1-4

Contacting a Service Center...............................................................................1-5

Safety Information: Read First...........................................................................1-5

About This Manual .......................................................................................... 2-1

Introduction........................................................................................................2-1

Users Manual Contents......................................................................................2-1

Features Of Fluke 433/434.............................................................................. 3-1

Introduction........................................................................................................3-1

General Measurements ......................................................................................3-1

Measuring modes to investigate details .............................................................3-2

Basic Operations and Menu Navigation ....................................................... 4-1

Introduction........................................................................................................4-1

Tilt Stand and Hang Strap..................................................................................4-1

Powering the Analyzer.......................................................................................4-2

Display Brightness.............................................................................................4-3

Locking the keyboard ........................................................................................4-3

Menu Navigation ...............................................................................................4-4

Display Contrast ................................................................................................4-4

Reset to Factory Defaults...................................................................................4-4

Display Information......................................................................................... 5-1

Introduction........................................................................................................5-1

Phase Colors ......................................................................................................5-2

i

Page 4

Fluke 433/434

Users Manual

Screen Types......................................................................................................5-2

Screen information common for all screen types...............................................5-2

Input Connections........................................................................................... 6-1

Introduction........................................................................................................6-1

Input Connections ..............................................................................................6-1

Scope Waveform and Phasor ........................................................................ 7-1

Introduction........................................................................................................7-1

Scope Waveform................................................................................................7-1

Scope Phasor......................................................................................................7-2

Tips and Hints....................................................................................................7-2

Volts/Amps/Hertz ............................................................................................ 8-1

Introduction........................................................................................................8-1

Table ..................................................................................................................8-1

Trend..................................................................................................................8-2

Tips and Hints....................................................................................................8-3

Dips & Swells................................................................................................... 9-1

Introduction........................................................................................................9-1

Trend..................................................................................................................9-3

Events Tables.....................................................................................................9-4

Tips and Hints....................................................................................................9-5

Harmonics........................................................................................................ 10-1

Introduction........................................................................................................10-1

Bar Graph Screen...............................................................................................10-1

Table ..................................................................................................................10-3

Trend..................................................................................................................10-3

Tips and Hints....................................................................................................10-4

Power & Energy............................................................................................... 11-1

Introduction........................................................................................................11-1

Table ..................................................................................................................11-1

Trend..................................................................................................................11-3

Tips and Hints....................................................................................................11-4

Flicker 12-1

Introduction........................................................................................................12-1

Table ..................................................................................................................12-1

Trend..................................................................................................................12-3

Tips and Hints....................................................................................................12-4

Unbalance ........................................................................................................ 13-1

Introduction........................................................................................................13-1

Table ..................................................................................................................13-1

Trend..................................................................................................................13-2

Phasor ................................................................................................................13-3

Tips and Hints....................................................................................................13-3

ii

Page 5

Contents (continued)

Transients ........................................................................................................ 14-1

Introduction........................................................................................................14-1

Waveform Display.............................................................................................14-1

Tips and Hints....................................................................................................14-3

Inrush Currents ............................................................................................... 15-1

Introduction........................................................................................................15-1

Inrush Trend Display .........................................................................................15-1

Tips and Hints....................................................................................................15-4

Power Quality Monitoring............................................................................... 16-1

Introduction........................................................................................................16-1

Power Quality Main Screen ...............................................................................16-4

Events Table ......................................................................................................16-5

Trend Display ....................................................................................................16-6

Bar Graph Screen...............................................................................................16-7

Cursor and Zoom ............................................................................................ 17-1

Introduction........................................................................................................17-1

Cursor on Waveform Displays...........................................................................17-1

Cursor on Trend Displays ..................................................................................17-2

From Events Table to Trend Display with Cursor On. ......................................17-3

Cursor on Bar graph Displays............................................................................17-4

Setting up the Analyzer .................................................................................. 18-1

Introduction........................................................................................................18-1

General Settings.................................................................................................18-3

FUNCTION PREFerences.................................................................................18-7

USER PREFerences...........................................................................................18-11

Limits Adjustments............................................................................................18-13

Using Memory, Printer, and PC ..................................................................... 19-1

Introduction........................................................................................................19-1

Using memory....................................................................................................19-1

Use of Printer and PC ........................................................................................19-3

Tips and Maintenance..................................................................................... 20-1

Introduction........................................................................................................20-1

Cleaning the Analyzer and its Accessories ........................................................20-1

Storing the Analyzer ..........................................................................................20-1

Keeping the Battery in Good Condition ............................................................20-1

Installation of Options in Fluke 433 ..................................................................20-1

Parts and Accessories.........................................................................................20-2

Troubleshooting.................................................................................................20-3

Specifications.................................................................................................. 21-1

Introduction........................................................................................................21-1

Electrical Measurements....................................................................................21-2

Trend Recording ................................................................................................21-11

Wiring Combinations.........................................................................................21-12

Display...............................................................................................................21-13

iii

Page 6

Fluke 433/434

Users Manual

Memory..............................................................................................................21-13

Printers and Interface .........................................................................................21-14

Power Supply and Battery Charger....................................................................21-14

Mechanical.........................................................................................................21-15

Environmental....................................................................................................21-15

Electro Magnetic Compatibility (EMC) ............................................................21-16

Safety .................................................................................................................21-16

iv

Page 7

Introduction

This chapter informs you about a number of general and important aspects concerning the

Fluke 433/434 Three Phase Power Quality Analyzer (hereafter referred to as ‘Analyzer’).

This concerns:

• Warranty and Liability Conditions.

• Declaration of Conformity.

• Shipment Note: Survey of items that should be included in your Analyzer Kit.

• Contacting a Service Center.

• Safety Information: Read First!

Chapter 1

General Aspects

1-1

Page 8

Fluke 433/434

Users Manual

Limited Warranty & Limitation of Liability

Each Fluke product is warranted to be free from defects in material and workmanship

under normal use and service. The warranty period is three years for the Analyzer and

one year for its accessories. The warranty period begins on the date of shipment. Parts,

product repairs and services are warranted for 90 days. This warranty extends only to the

original buyer or end-user customer of a Fluke authorized reseller, and does not apply to

fuses, disposable batteries or to any product which, in Fluke's opinion, has been misused,

altered, neglected or damaged by accident or abnormal conditions of operation or

handling. Fluke warrants that software will operate substantially in accordance with its

functional specifications for 90 days and that it has been properly recorded on nondefective media. Fluke does not warrant that software will be error free or operate

without interruption.

Fluke authorized resellers shall extend this warranty on new and unused products to enduser customers only but have no authority to extend a greater or different warranty on

behalf of Fluke. Warranty support is available if product is purchased through a Fluke

authorized sales outlet or Buyer has paid the applicable international price. Fluke reserves

the right to invoice Buyer for importation costs of repair/replacement parts when product

purchased in one country is submitted for repair in another country.

Fluke's warranty obligation is limited, at Fluke's option, to refund of the purchase price,

free of charge repair, or replacement of a defective product which is returned to a Fluke

authorized service center within the warranty period.

To obtain warranty service, contact your nearest Fluke authorized service center or send

the product, with a description of the difficulty, postage and insurance prepaid (FOB

Destination), to the nearest Fluke authorized service center. Fluke assumes no risk for

damage in transit. Following warranty repair, the product will be returned to Buyer,

transportation prepaid (FOB Destination). If Fluke determines that the failure was caused

by misuse, alteration, accident or abnormal condition of operation or handling, Fluke

will provide an estimate of repair costs and obtain authorization before commencing the

work. Following repair, the product will be returned to the Buyer transportation prepaid

and the Buyer will be billed for the repair and return transportation charges (FOB

Shipping Point).

THIS WARRANTY IS BUYER'S SOLE AND EXCLUSIVE REMEDY AND IS IN

LIEU OF ALL OTHER WARRANTIES, EXPRESS OR IMPLIED, INCLUDING BUT

NOT LIMITED TO ANY IMPLIED WARRANTY OF MERCHANTABILITY OR

FITNESS FOR A PARTICULAR PURPOSE. FLUKE SHALL NOT BE LIABLE FOR

ANY SPECIAL, INDIRECT, INCIDENTAL OR CONSEQUENTIAL DAMAGES OR

LOSSES, INCLUDING LOSS OF DATA, WHETHER ARISING FROM BREACH OF

WARRANTY OR BASED ON CONTRACT, TORT, RELIANCE OR ANY OTHER

THEORY.

Since some countries or states do not allow limitation of the term of an implied warranty,

or exclusion or limitation of incidental or consequential damages, the limitations and

exclusions of this warranty may not apply to every buyer. If any provision of this

Warranty is held invalid or unenforceable by a court of competent jurisdiction, such

holding will not affect the validity or enforceability of any other provision.

1-2

Fluke Corporation, P.O. Box 9090, Everett, WA 98206-9090 USA, or

Fluke Industrial B.V., P.O. Box 90, 7600 AB, Almelo, The Netherlands

Page 9

General Aspects

Declaration of Conformity 1

Declaration of Conformity

Declaration of Conformity

for

Fluke 433/434

Three Phase Power Quality Analyzers

Manufacturer

Fluke Industrial B.V.

Lelyweg 1

7602 EA Almelo

The Netherlands

Statement of Conformity

Based on test results using appropriate standards,

the product is in conformity with

Electromagnetic Compatibility Directive 89/336/EEC

Low Voltage Directive 73/23/EEC

Sample tests

Standards used:

EN 61010-1 2nd edition

Safety Requirements for Electrical Equipment for Measurement, Control,

and Laboratory Use

EN 61326 – 2002

Electrical equipment for

Measurement Control and Laboratory use

EMC requirements

The tests have been performed in a typical configuration.

This Conformity is indicated by the symbol

, i.e. “Conformité Européenne”.

1-3

Page 10

Fluke 433/434

Users Manual

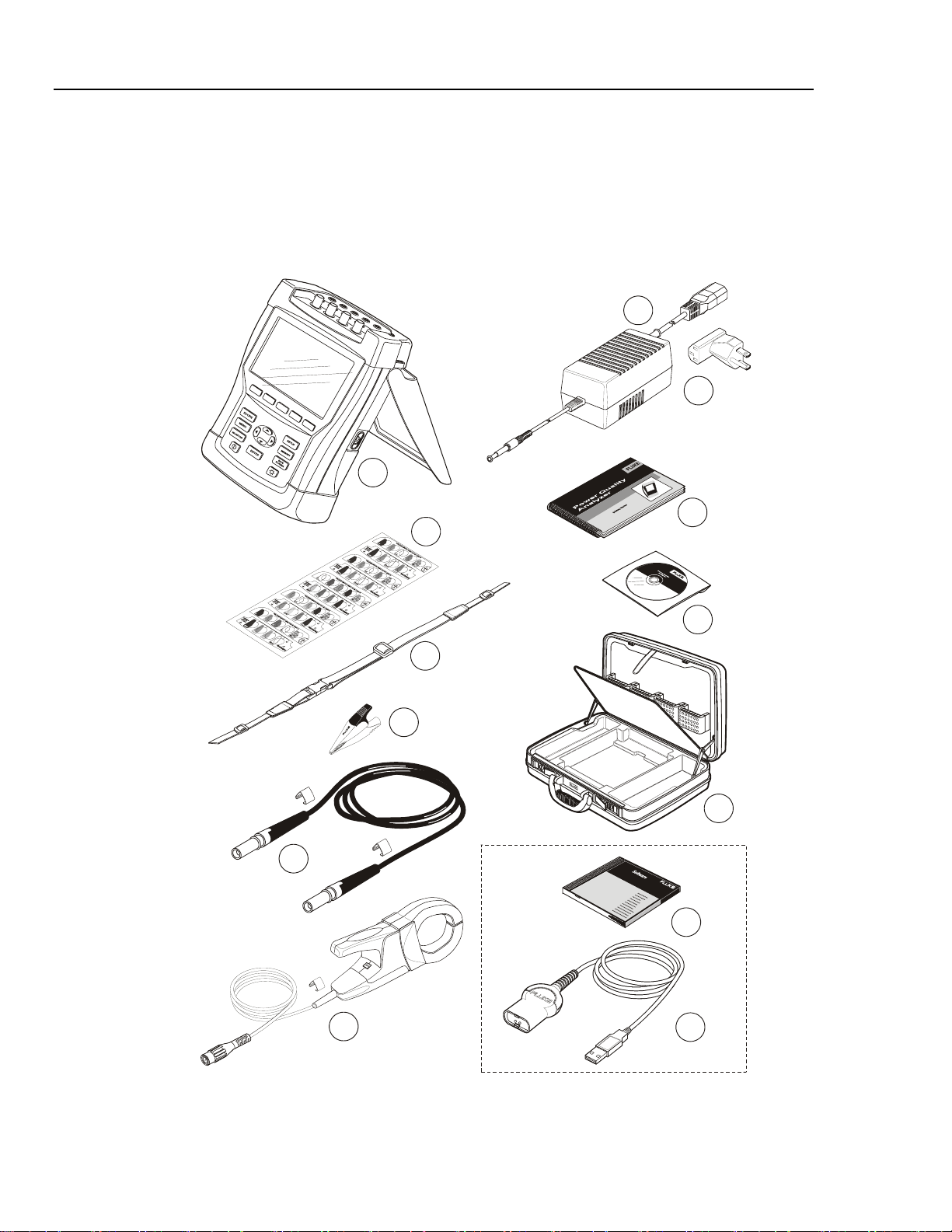

Shipment Note

The following items are included in your Analyzer Kit:

Note:

When new, the Analyzer’s rechargeable NiMH battery is not charged.

Refer to Chapter 4 – Powering the Analyzer.

7

F

1

F

2

F

3

F

4

F

5

1

8

9

2

10

3

4

(5x)

11

5

(5x)

Fluke 434

12

1-4

6

(4x)

13

Figure 1-1. Contents of Analyzer Kit

Page 11

General Aspects

Contacting a Service Center 1

# Description

1 Power Quality Analyzer

2 Decal Set for Input Sockets

3 Hang Strap

4 Alligator Clips. Set of 5

5 Test Leads, 2.5 m. Set of 5

6 AC Current Clamps 400 A (1 mV/A) and 40 A (10 mV/A) switcheable. Set of 4

7 Battery Charger / Power Adapter

8 Line Plug Adapter (country dependent)

9 Getting Started Manual

10 CD ROM with Users Manual and Getting Started Manual (multi-language)

11 Hard Case

12 CD ROM with FlukeView® Software for Windows®, standard for Fluke 434. Optional for Fluke 433

13 Optical Cable for USB, standard for Fluke 434. Optional for Fluke 433

Contacting a Service Center

To locate a Fluke authorized service center, visit us on the World Wide Web at:

www.fluke.com

or call Fluke using any of the phone numbers listed below:

+1-888-993-5853 in the U.S. and Canada

+31-40-2675200 in Europe

+1-425-446-5500 from other countries

Safety Information: Read First

The Fluke 433/434 Three Phase Power Quality Analyzer complies with:

• ANSI/ISA S82.01-1994.

• EN/IEC61010-1 2

Cat IV, Pollution Degree 2.

• CAN/CSA-C22.2 No.61010-1-04 (including approval).

Use the Analyzer and its accessories only as specified in the Users Manual. Otherwise,

the protection provided by the Analyzer and its accessories might be impaired.

nd

edition 1000 V Measurement Category III, 600 V Measurement

A Warning identifies conditions and actions that pose hazard(s) to the user.

A Caution identifies conditions and actions that may damage the Analyzer.

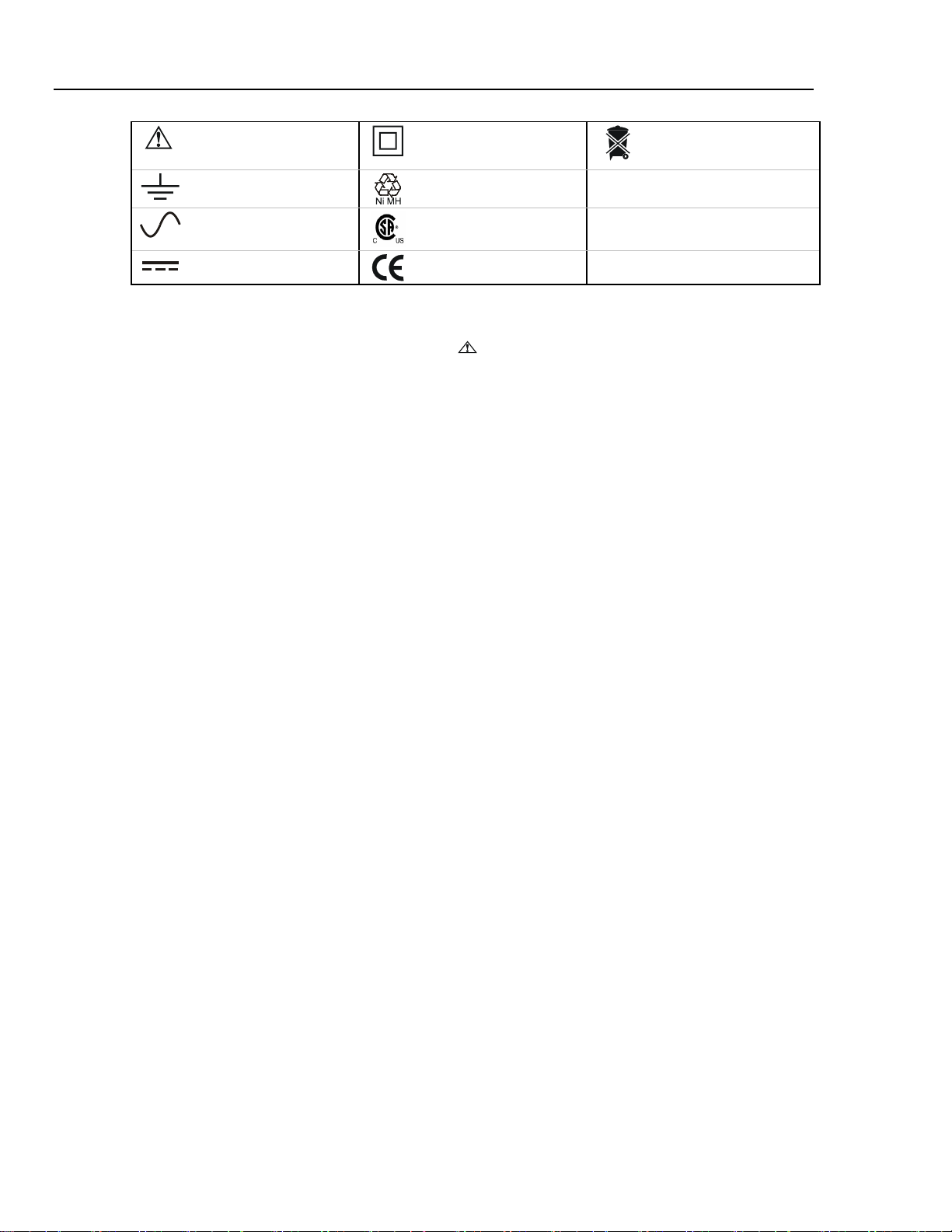

The following international symbols are used on the Analyzer and in this manual:

1-5

Page 12

Fluke 433/434

Users Manual

See explanation in

manual

Earth

Alternating Current

Direct Current

Double Insulation

(Protection Class)

Recycling information

Safety Approval

Conformité Européenne

Disposal information

Warning

To avoid electrical shock or fire:

• Review the entire manual before use of the Analyzer and its

accessories.

• Avoid working alone.

• Do not operate the Analyzer around explosive gas or vapor.

• Use only insulated current probes, test leads and adapters as

supplied with the Analyzer, or indicated as suitable for the

Fluke 433/434 Analyzer.

• Before use, inspect the Analyzer, voltage probes, test leads

and accessories for mechanical damage and replace when

damaged. Look for cracks or missing plastic. Pay special

attention to the insulation surrounding the connectors.

• Remove all probes, test leads and accessories that are not in

use.

• Always connect the Battery Charger / Power Adapter first to

the AC outlet before connecting it to the Analyzer.

• Use the ground input only to ground the Analyzer and do not

apply any voltage.

• Do not apply input voltages above the rating of the instrument.

• Do not apply voltages in excess of the marked ratings of the

voltage probes or current clamps.

• Do not use exposed metal BNC or banana plug connectors.

• Do not insert metal objects into connectors.

• Use only the power supply, Model BC430 (Battery Charger /

Power Adapter).

• Before use check that the selected/indicated voltage range on

the BC430 matches the local line power voltage and frequency

(refer to figure below). If necessary set the slider switch of the

BC430 to the correct voltage.

• For the BC430 use only AC line plug adapters or AC line cords

that comply with local safety regulations.

1-6

Page 13

General Aspects

Safety Information: Read First 1

Slider switch on BC430 Battery Charger / Power Adapter to select line power voltage:

115V 230V

Max. Input Voltage at Voltage Banana Inputs to Ground:

Input A (L1), B (L2), C (L3), N to Ground: 1000 V Cat III, 600 V Cat IV.

Max. Voltage at Current BNC Inputs (See marking):

Input A (L1), B (L2), C (L3), N to Ground: 42 V peak.

Voltage ratings are given as “working voltage”. They should be read as V ac rms

(50-60 Hz) for AC sinewave applications and as V dc for DC applications.

Measurement Category IV refers to the overhead or underground utility service of an

installation. Cat III refers to distribution level and fixed installation circuits inside a

building.

If Safety Features are Impaired

If the Analyzer is used in a manner not specified by the manufacturer, the protection

provided by the Analyzer may be impaired.

Before use, inspect the test leads for mechanical damage and replace damaged test leads!

If the Analyzer or its accessories appear to be impaired or not functioning properly, do

not use it and send it in for repair.

Note

To accommodate connection to various line power sockets, the BC430

Battery Charger / Power Adapter is equipped with a male plug that must be

connected to a line plug adapter appropriate for local use. Since the

Charger is isolated, you can use line plug adapters with or without a

protective ground terminal.

The 230 V rating of the BC430 is not for use in North America. A line plug

adapter complying with the applicable National Requirements may be

provided to alter the blade configurations for a specific country.

1-7

Page 14

Fluke 433/434

Users Manual

1-8 2-1

Page 15

Introduction

This Users Manual gives full and comprehensive information on how to use the Fluke

433 and 434 Three Phase Power Quality Analyzers effectively and in a safe manner.

Read it carefully to learn about safe use of the Analyzer and its accessories and to take

full advantage of all measuring modes.

The Analyzer is also supplied with a printed Getting Started Guide which provides basic

information and can be used as a quick reference.

Users Manual Contents

• Introduction: Title, Table of Contents.

• Chapter 1. General Aspects: Warranty and Liability, Declaration of Conformity,

Shipment Note, Contacting a Service Center, Safety information.

• Chapter 2. Overview of manual contents.

Chapter 2

About This Manual

• Chapter 3. Summary of measuring modes and how to use them in a logical order.

• Chapter 4. Basic operations: Tilt Stand and Hang Strap, Powering, Display

adjustment, Keyboard Locking, Reset, Menu Navigation.

• Chapter 5. Display information: Screen types, General Screen Information, Screen

Symbols.

• Chapter 6. Input Connections: Use of voltage and current probes.

• Chapter 7 ... 16. Explanation of measuring functions with tips & hints:

- Scope Waveform & Phasor (7),

- Volts/Amps/Hertz (8),

- Dips & Swells (9),

- Harmonics (10),

- Power & Energy (11),

- Flicker (12),

- Unbalance (13),

- Transients (14),

- Inrush Currents (15),

- Power Quality Monitoring (16).

• Chapter 17. Cursor and Zoom: how to investigate measurement details.

Page 16

Fluke 433/434

Users Manual

• Chapter 18. Setting up the Analyzer: a comprehensive explanation of adjustments to

customize measurements.

• Chapter 19. Using Memory, printer and PC: how to save, recall and delete

screenshots and data formats. How to make hard copies of measurement results and

setup of communication with PC.

• Chapter 20. Tips and Maintenance: Cleaning, Storage, Batteries, Replaceable parts,

Troubleshooting.

• Chapter 21. Specifications: Electrical, Mechanical, and Safety characteristics.

• Index.

2-2

Page 17

Features Of Fluke 433/434

Introduction

The Analyzer offers an extensive and powerful set of measurements to check power

distribution systems. Some give a general impression of power system performance.

Others are used to investigate specific details. This chapter gives an overview on how to

perform measurements in a logical order.

The measuring modes are described in detail in Chapter 7 to 16. Each measuring mode is

explained in a separate chapter.

Fluke 434 has additional features such as Interharmonics, Transients, Energy

Usage, extra memory to store Screens and Data, FlukeView software, and an optical

isolated interface cable. In Fluke 433 these functions can be installed optionally. If

not installed, they are shown in the menus in grey color.

General Measurements

To check if voltage leads and current clamps are connected correctly, use Scope

Waveform and Scope Phasor. The clamps are marked with an arrow to facilitate proper

signal polarity. Chapter 6 Input Connections explains how to make connections.

Chapter 3

To get a general impression of the quality of a power system use MONITOR. The

MONITOR key displays a screen with Bar Graphs that show quality aspects of the phase

voltages. A Bar Graph changes from green to red if the related aspect does not meet the

limits. Six different sets of limits can be chosen: a number of them are user

programmable. One of these sets are the limits according to the EN50160 norm. For each

quality aspect submenus with detailed information are attainable via the function keys F1

... F5.

Numerical data is shown by Volts/Amps/Hertz. For this press the MENU key. Then

select Volts/Amps/Hertz and press F5 – OK to display a table with the present values of

voltages (rms and peak), currents (rms and peak), frequency and Crest Factors per phase.

Press F5 – TREND so display the course over time of these values.

3-1

Page 18

Fluke 433/434

Users Manual

Measuring modes to investigate details

Phase voltages. Should be close to the nominal value. Voltage waveforms must be a sine

wave that is smooth and free from distortion. Use Scope Waveform to check the

waveform shape. Use Dips & Swells to record sudden voltage changes. Use Transients

mode to capture voltage anomalies.

Phase currents. Use Volts/Amps/Hertz and Dips & Swells to check current/voltage

relations. Use Inrush Current to record sudden current increases like motor inrush.

Crest Factor. A CF of 1.8 or higher means high waveform distortion. Use Scope

Waveform to see waveform distortion. Use Harmonics mode to identify harmonics and

THD (Total Harmonic Distortion).

Harmonics. Use Harmonics mode to check for voltage and current harmonics and THD

per phase. Use Trend to record harmonics over time.

Flicker. Use Flicker to check short and long term voltage flicker and related data per

phase. Use Trend to record these values over time.

Dips & Swells. Use Dips & Swells to record sudden voltage changes as short as half a

cycle.

Frequency. Should be close to nominal value. Frequency is normally very stable. Select

Volts/Amps/Hertz to display frequency. The course of frequency over time is recorded in

the Trend screen.

Unbalance. Each phase voltage should not differ more than 1 % from the average of the

three. Current unbalance should not exceed 10 %. Use Scope Phasor or Unbalance mode

to investigate unbalances.

3-2

Page 19

Chapter 4

Basic Operations and Menu Navigation

Introduction

This chapter deals with a number of general aspects of the Analyzer’s operation:

• Tilt Stand and Hang Strap

• Powering the Analyzer

• Display Brightness

• Locking the keyboard

• Menu navigation

• Display Contrast

• Reset to Factory Defaults

Tilt Stand and Hang Strap

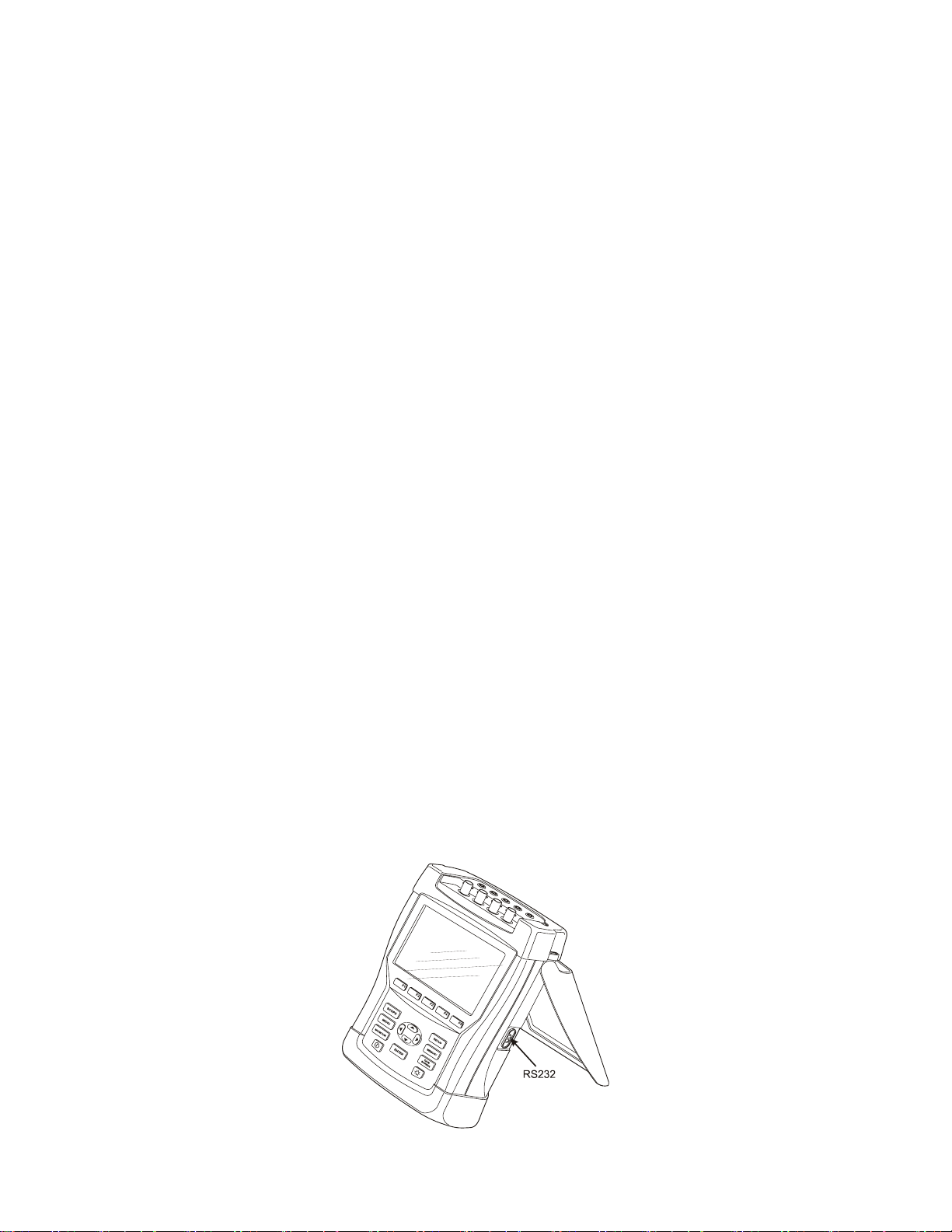

The Analyzer has a tilt stand that allows viewing the screen at an angle when placed on a

flat surface. With the tilt stand folded out, the optical RS-232 port can be accessed at the

right side of the Analyzer as shown in the figure.

Figure 4-1. Tilt stand and location of RS-232 interface

4-1

Page 20

Fluke 433/434

Users Manual

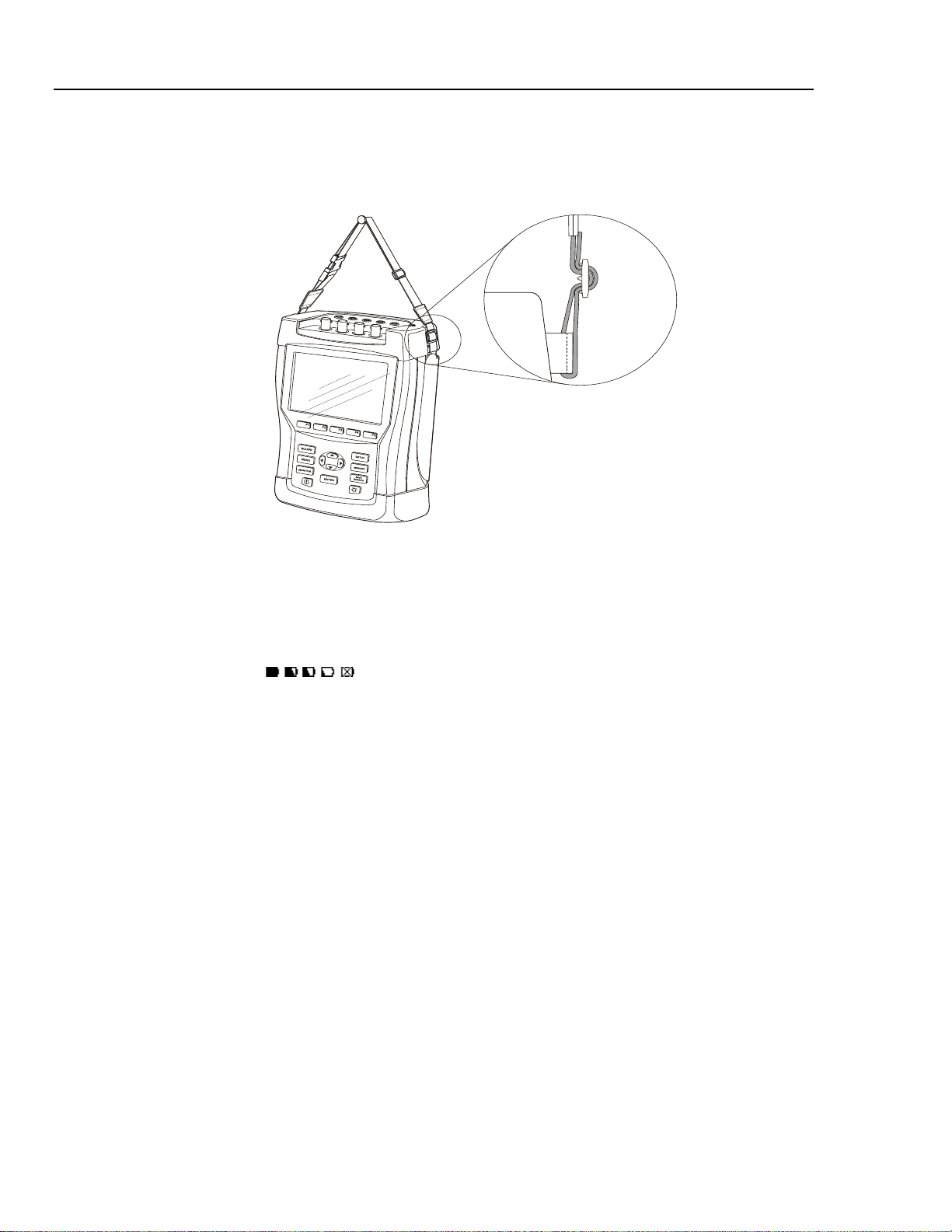

A hang strap is supplied with the Analyzer. The figure below shows how to attach the

strap correctly to the Analyzer.

Figure 4-2. Fixing the hang strap

Powering the Analyzer

The Analyzer has a built-in rechargeable NiMH battery that can power it for more than 6

hours when fully charged. When powered by the battery, the battery condition symbol in

the screen header indicates the charge condition. This symbol ranges from fully charged

to empty:

When empty allow the batteries to fully charge with the Battery Charger/Power Adapter

model BC430. A full charge takes about 4 hours with the Analyzer turned off. When

turned-on charging takes much longer.

No damage will occur if the charger is connected for long periods, e.g. over the weekend.

The Analyzer automatically switches to trickle charging. At delivery the battery may be

empty and it is recommended to charge it before use.

Concerning the use of the Battery Charger/Power Adapter bear the following in mind:

• Use only the supplied Battery Charger/Power Adapter model BC430.

• Before use check that the BC430 voltage and frequency match the local line power

range.

If necessary set the slider switch of BC430 to the correct voltage.

• Connect the Battery Charger to the ac outlet.

.

4-2

• Connect the battery charger to the POWER ADAPTER input on the top side of the

Analyzer.

• To avoid overheating of the battery during charging, do not exceed the allowable

ambient temperature as given in the specifications.

Page 21

Basic Operations and Menu Navigation

Caution

To prevent decrease of battery capacity, charge it at least twice

a year.

Power On/Off:

Display Brightness 4

To save battery power, the Analyzer display turns off automatically when no keys are

operated during a certain time. This time is adjustable.

When a key is operated, the display turns on again.

For the adjustment of Auto-off time see Chapter 18, USER PREFerences.

Press to power up or down with the last setup configuration.

The welcome screen shows what Analyzer settings are

currently in use. At power on a single beep can be heard.

Display Brightness

Press repeatedly to dim/brighten the backlight.

Keep pressed during 5 seconds for extra brightness for

better visibility in strong sunlight.

Low brightness saves battery power.

Locking the keyboard

The keyboard can be locked to prevent unwanted operation during unattended

measurements:

ENTER

Press for 5 seconds to lock or unlock the keyboard.

4-3

Page 22

Fluke 433/434

Users Manual

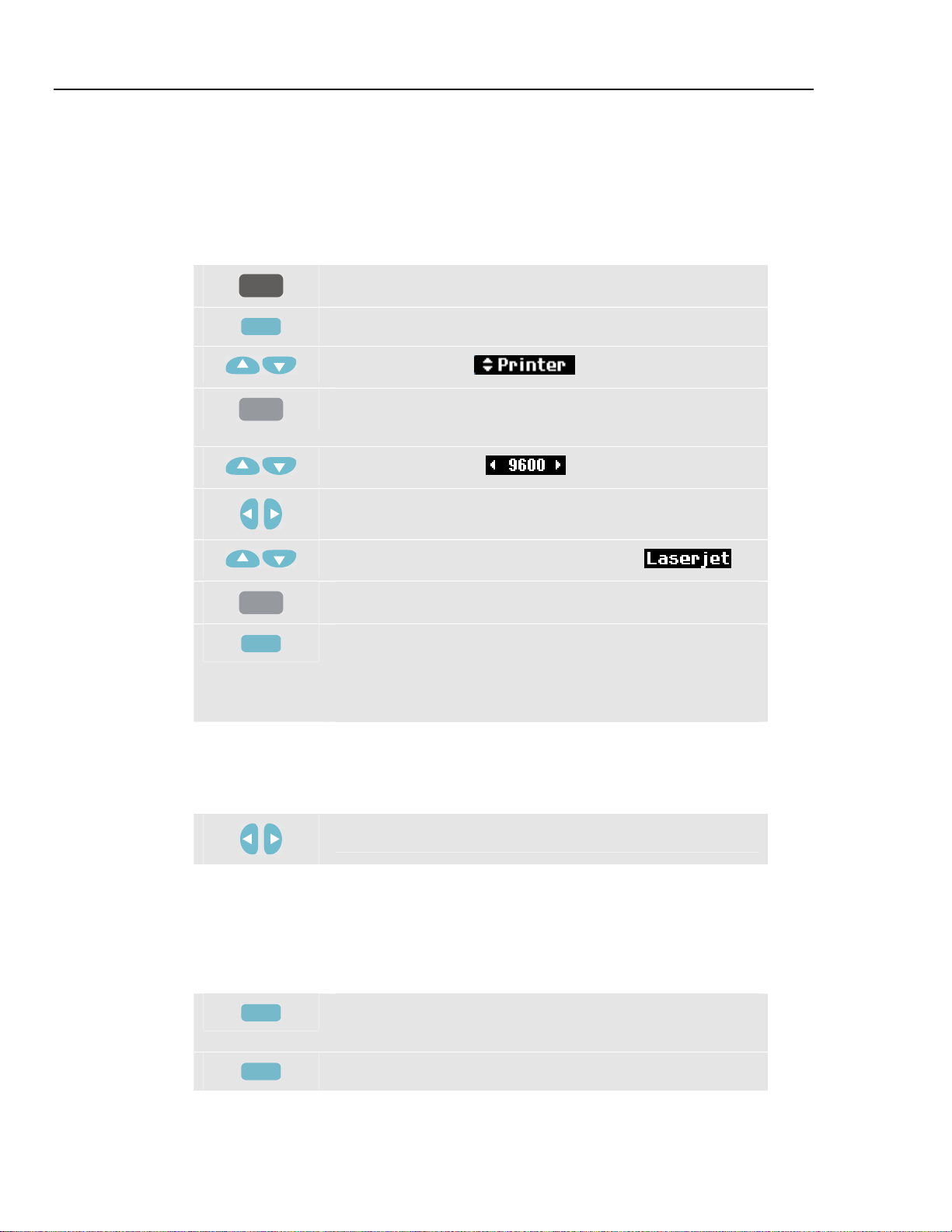

Menu Navigation

Most of the Analyzer functions are menu operated. Arrow keys are used to navigate

through menus. The Function keys F1 ... F5 and the ENTER key are used to make

selections. Active Function key selections are highlighted with a black background.

How to use the menus is illustrated in the example below on how to adjust the Analyzer

for use with a certain printer type.

SETUP

ENTER

ENTER

F4

The SETUP menu pops up.

Submenu SETUP USER PREF appears.

Highlight Printer: .

The PRINTER submenu appears. In this menu you can

adjust printer type and baudrate.

Highlight baudrate: .

Adjust the required transmission speed.

Highlight the Printer type you want to use: .

F5

Press to confirm the selection.

Press to return to the next higher menu SETUP USER

PREF. This menu is the starting point for many adjustments

such as Display Contrast Adjustment and Reset to Factory

Defaults.

4-4

Display Contrast

Use submenu SETUP USER PREF as a starting point. How to get there is explained

above under Menu Navigation:

Adjust the Display Contrast to your personal taste.

Reset to Factory Defaults

Proceed as follows to reset the Analyzer to factory default settings. Bear in mind that

recorded data and adjustments will be lost.

Use submenu SETUP USER PREF as a starting point. How to get there is explained

above under Menu Navigation:

F1

F5

Press to start the reset to default settings. Because of the risk

of unwanted erasure of data, a confirm menu pops up.

Press to confirm the reset.

Page 23

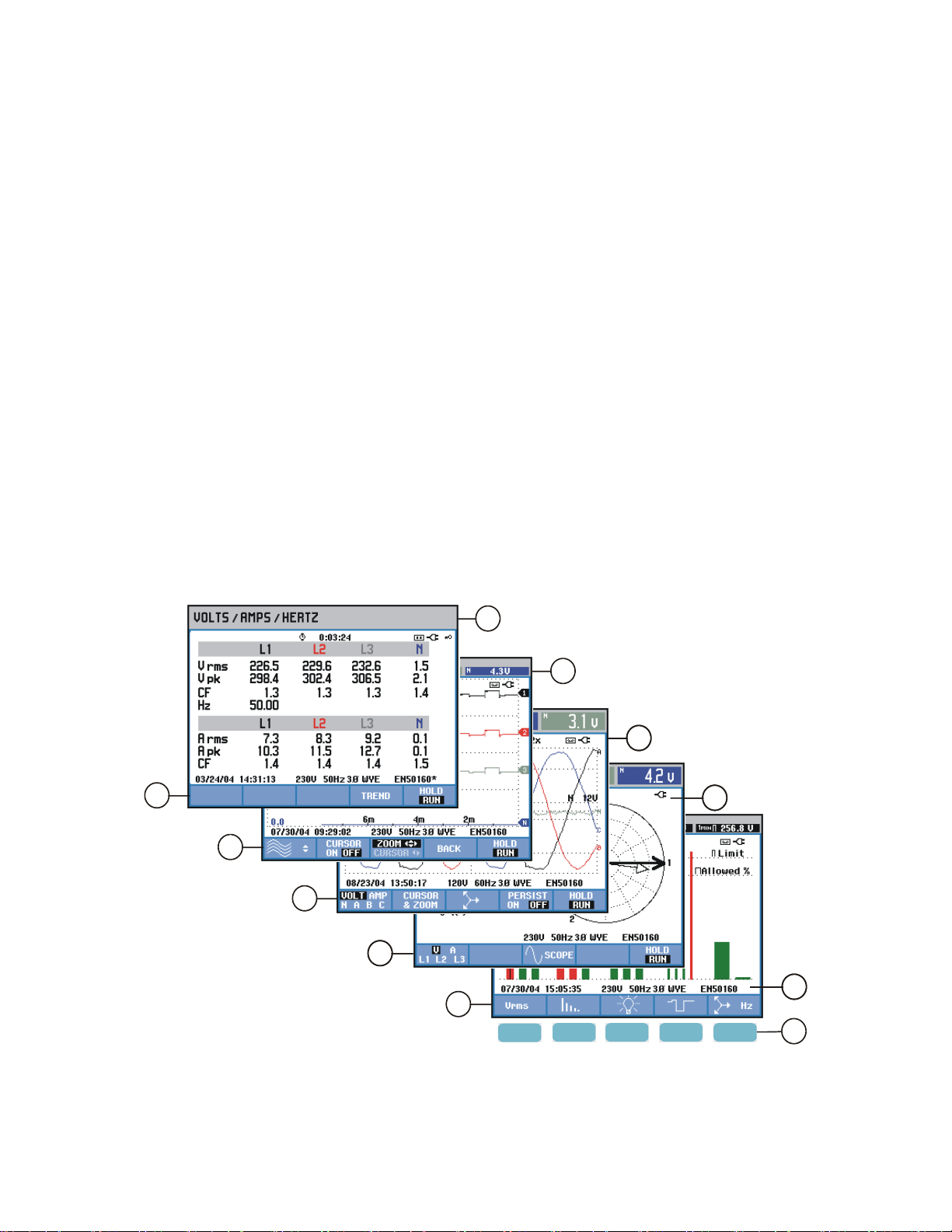

Introduction

A

The Analyzer uses five different screen types to present measuring results in the most

effective way. The features these screens have in common are explained in this chapter.

Details that are specific for a certain measuring mode are presented in the chapter

explaining that mode. The figure below gives an overview of the screen types 1 .. 5;

common features are explained under A ... F.

Chapter 5

Display Information

B

C

1

2

3

44

5

F1

Figure 5-1. Survey of Display Types

5-1

F2 F3 F4 F5

D

E

F

Page 24

Fluke 433/434

Users Manual

Phase Colors

Screen Types

Measuring results belonging to different phases are presented with individual colors. If

for a certain phase voltage and current are displayed simultaneously, the voltage color has

a dark tone and the current has a light tone. The set of phase colors can be chosen via the

SETUP key and function key F4 – USER PREF. For detailed information see Chapter 18.

Below you will find a brief description of each screen type and its purpose. The

measuring mode it is used for is given as well as the manual chapter with detailed

information. Bear in mind that the amount of screen information depends on the number

of phases and the wiring configuration. Refer to Figure 5-1, item 1 ... 5.

Table screen: gives an instantaneous overview of a big number of

1

important numerical measuring values. Used for: Volts/Amps/Hertz

(Chapter 8), Dips & Swells (Chapter 9), Harmonics (Chapter 10),

Power & Energy (Chapter 11), Flicker (Chapter 12), Unbalance

(Chapter 13), and Power Quality Monitoring (Chapter 16).

Trend screen: this type of screen is related to a table screen. Trend

2

shows the course over time of measuring values from the table. After

selection of a measuring mode, the Analyzer starts recording all

readings in the table. Used for: Volts/Amps/Hertz (Chapter 8), Dips &

Swells (Chapter 9), Power & Energy (Chapter 11), Flicker (Chapter

12), and Inrush Currents (Chapter 15).

Waveform screen: shows voltage and current waveforms as displayed

3

on an oscilloscope. Channel A (L1) is reference channel and 2 complete

cycles starting at 0 volt are displayed. The nominal voltage and

frequency determine the measuring grid size. Used for: Scope

Waveform (Chapter 7) and Transients (Chapter 14).

Phasor screen: shows the phase relation between voltages and currents

4

in a vector diagram. The vector of reference channel A (L1) points to

the positive horizontal direction. The A (L1) amplitude is also reference

for the measuring grid size. Used for: Scope Phasor (Chapter 7) and

Unbalance (Chapter 13).

Bar Graph screen: shows the density of each measuring parameter as a

5

percentage by means of a Bar Graph. Used for: Harmonics (Chapter 10)

and Power Quality Monitor (Chapter 16).

Screen information common for all screen types

Refer to Figure 5-1, item A ... F.

A

Measuring mode: the active measuring mode is shown in the screen

header.

Measuring values: main numerical measuring values. Background

B

colors differ per phase and for voltage or current. If Cursor is on, the

values at the Cursor are shown.

5-2

Page 25

Display Information

Screen information common for all screen types 5

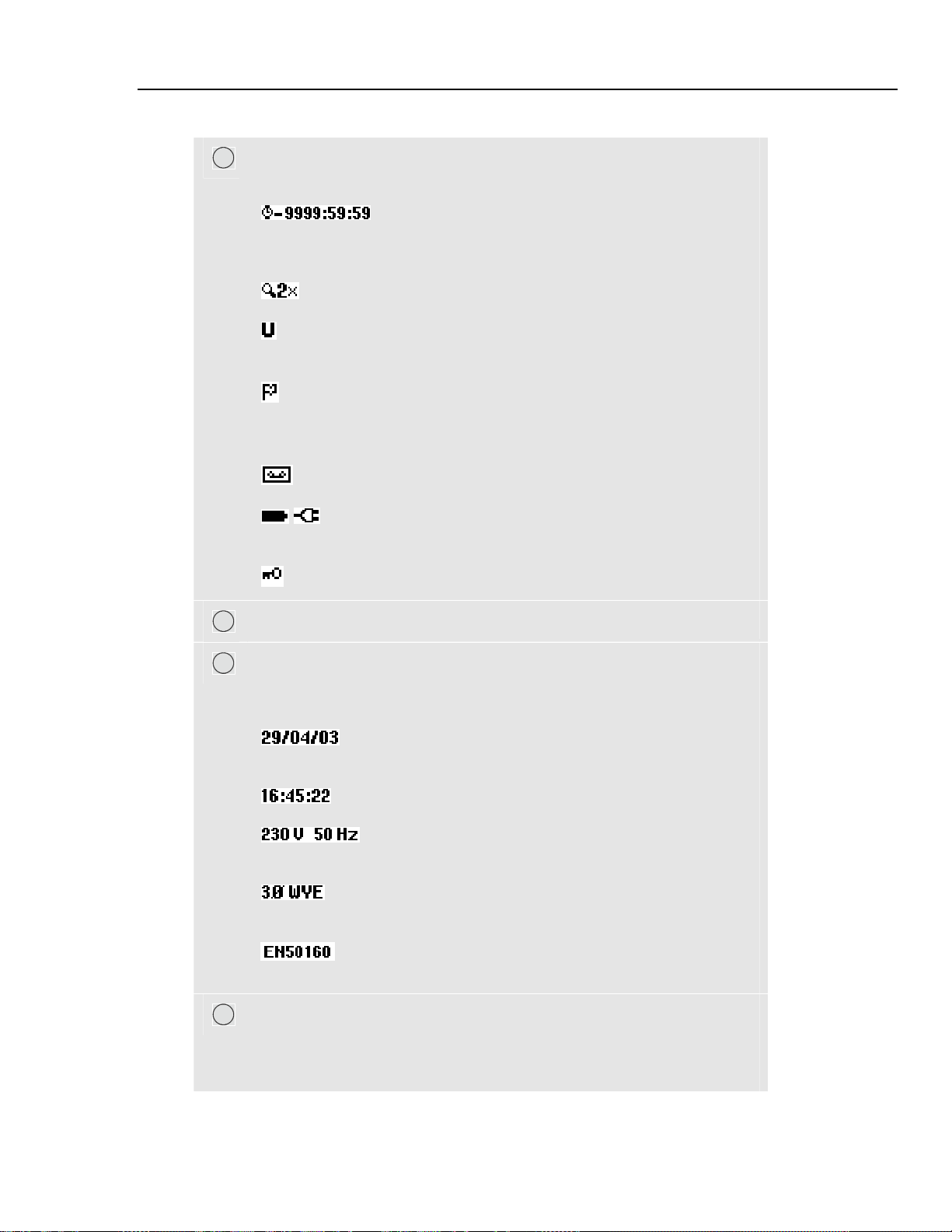

Status indicators. The following symbols may appear on the screen to

C

show the state of Analyzer and measurements:

Time that a measurement has been going on. Format:

hours, minutes, seconds. When waiting for a timed start, time counts

down with prefix -.

Horizontal ZOOM on.

Measurement may be unstable. E.g. applicable for frequency

readout during absence of voltage at reference phase A (L1).

Indicates according to IEC61000-4-30 flagging convention that a

dip, swell or interruption has occurred during the displayed aggregation

interval. Indicates that an aggregated value may not be reliable.

Recording of measurement data is on.

Battery/Line power indication. During battery operation the

battery charge condition is displayed.

Keyboard locked. Press ENTER 5 seconds to unlock/unlock.

Main area with measuring data: features are explained under 1 ... 5.

D

Status line: following information appears on the screen. How to adjust

E

these items is explained in Chapter 18 – General Settings. Following

information is given:

Date of Analyzer’s real time clock. Date format may be

month-day-year or day-month-year.

Time of day or cursor time.

Nominal line voltage and frequency: are a reference for

the measurements.

Number of phases and wiring configuration for the

measurement.

Name of the limits used for the power quality MONITOR,

dips, swells, interruptions, rapid voltage changes.

Softkey text area: softkey functions that can be selected with F1 ... F5

F

are indicated in white. Functions currently not available are indicated in

gray. Active Function key selections are highlighted with a black

background.

5-3

Page 26

Fluke 433/434

Users Manual

5-4 6-1

Page 27

Introduction

This chapter explains how to make connection to the power distribution system under test

and how to adjust the Analyzer settings.

Check that the Analyzer setup meets the characteristics of the system under test and the

accessories that are used. This concerns:

• wiring configuration

• nominal frequency

• nominal voltage

• properties of voltage leads and current clamps

The actual setup is shown in the welcome screen that appears after power up. To change

the setup, refer to Chapter 18.

Chapter 6

Input Connections

Input Connections

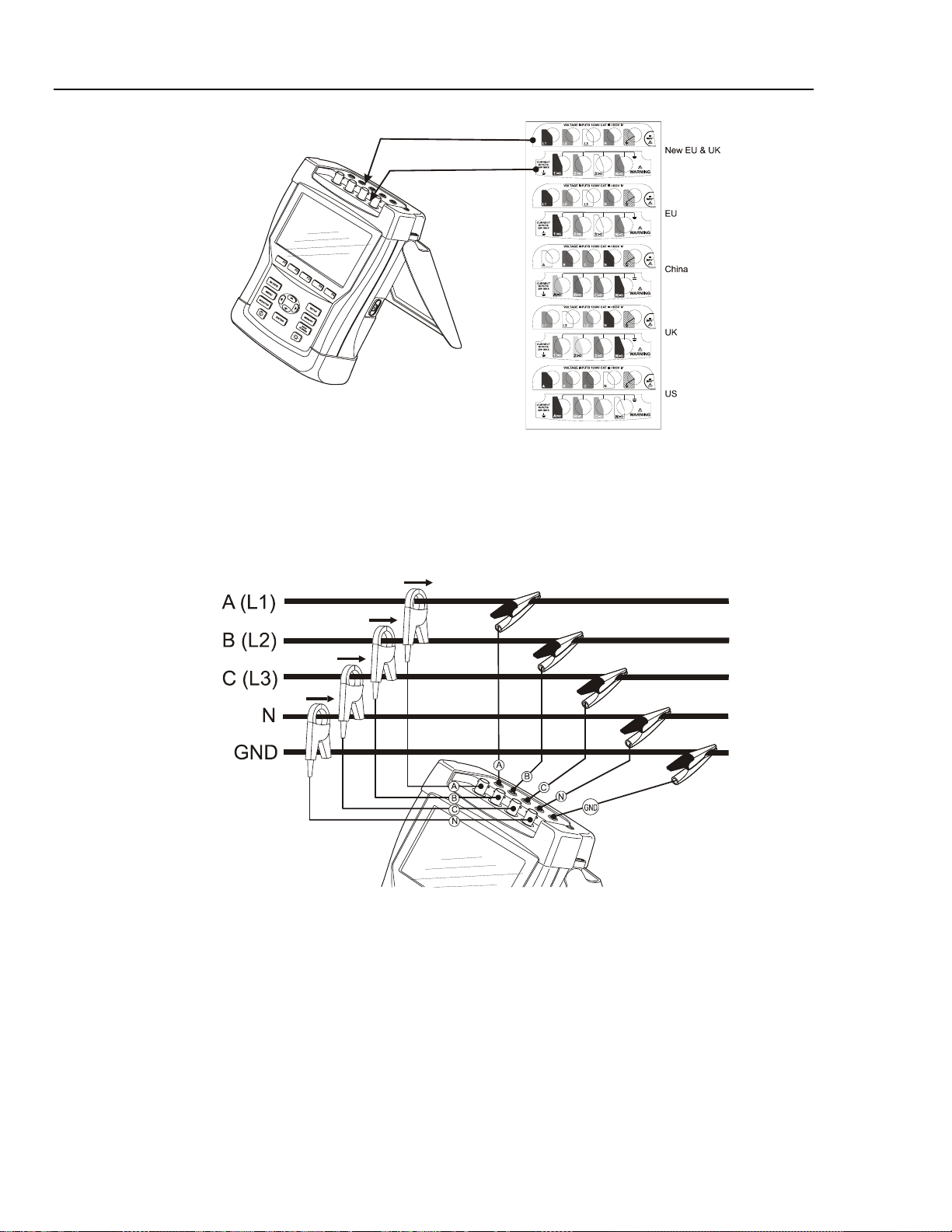

The Analyzer has 4 BNC-inputs for current clamps and 5 banana-inputs for voltages.

Self-adhesive decals are supplied corresponding to wiring color codes used in the USA,

Continental Europe, the UK, and China. Stick the decals that fit to your local wiring

codes around the current and voltage inputs as shown in Figure 6-1.

Page 28

Fluke 433/434

Users Manual

Figure 6-1. Mounting the decals for voltage and current inputs

De-energize power systems before making connections whenever possible. Avoid

working alone and work according to the warnings listed in Chapter 1, Safety

Information.

For a 3-phase system make the connections as shown in Figure 6-2.

Figure 6-2. Connection of Analyzer to 3-phase distribution system

First put the current clamps around the conductors of phase A (L1), B (L2), C (L3), and

N(eutral). The clamps are marked with an arrow indicating the correct signal polarity.

Next make the voltage connections: start with Ground and then in succession N, A (L1),

B (L2), and C (L3). For correct measuring results, always connect the Ground input.

Always double-check the connections. Make sure that current clamps are secured and

completely closed around the conductors.

6-2

For single phase measurements, use current input A (L1) and the voltage inputs Ground,

N(eutral), and phase A (L1).

A (L1) is the reference phase for all measurements.

Page 29

Input Connections

Input Connections 6

Before making any measurements, set the Analyzer up for the line voltage, frequency,

and wiring configuration of the power system you want to measure. This is explained in

Chapter 18, General Settings.

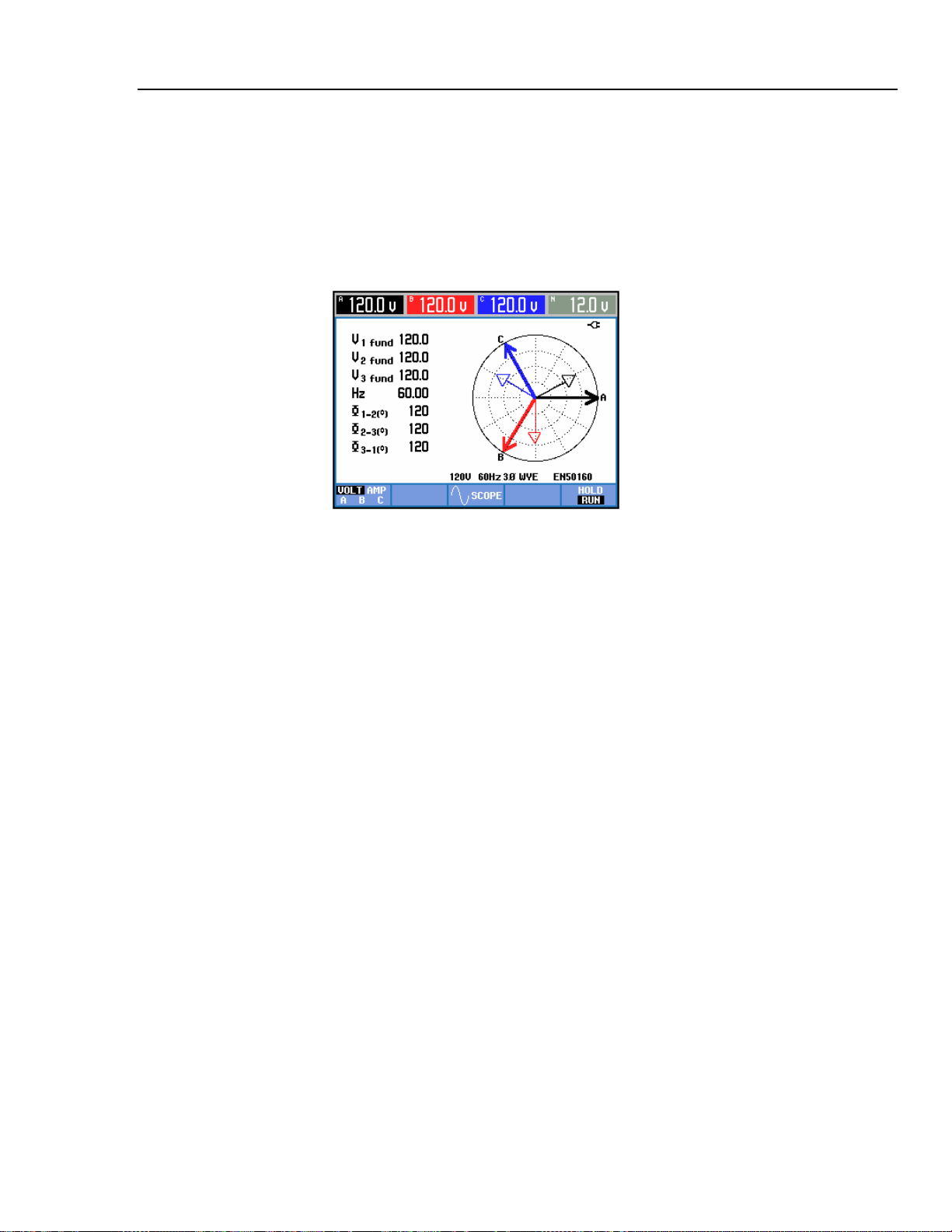

Scope Waveform and Phasor display are useful to check if voltage leads and current

clamps are connected correctly. In the vector diagram the phase voltages and currents A

(L1), B (L2), and C (L3) should appear in sequence when observing them in clockwise

direction as shown in the example in Figure 6-3.

Figure 6-3. Vector diagram for correctly connected Analyzer

6-3

Page 30

Fluke 433/434

Users Manual

6-4

Page 31

Introduction

Scope mode shows voltages and currents in the power system under test by means of

waveforms or vector diagram. Also numerical values are shown such as phase voltages,

phase currents, frequency, and phase angles between voltages and currents.

Scope Waveform

To access the Scope Waveform screen:

Chapter 7

Scope Waveform and Phasor

c

The Scope Waveform screen offers an oscilloscope style of display of voltage and/or

current waveforms with a fast update rate. The screen header shows the related rms

voltage/current values (12 or 10 cycle rms acc. to IEC61000-4-30). As a default 2

waveform periods are displayed. Channel A (L1) is the reference channel and 2 complete

cycles starting at 0 volt are displayed.

Available function keys:

SCOPE

F1

F2

F3

Selection of waveform set to be displayed: V displays all

voltages, A displays all currents. A (L1), B (L2), C (L3), N

(neutral) give simultaneous display of phase voltage and

current for the selected phase.

Access to submenu for Cursor and Zoom operation.

Access to the Phasor screen. For description see below.

7-1

Page 32

Fluke 433/434

Users Manual

F4

F5

Cursor. When the Cursor is on, the waveform values at the Cursor are displayed in the

screen header. Positioning the Cursor across the left or right screen end brings the next

screen out of a maximum of 6 within viewing area.

Zoom. Allows you to expand or shrink the display vertically and horizontally to view

details or to see the complete graph within the screen area. Zoom and Cursor are operated

by the arrow keys and are explained in Chapter 17.

Offset and Span of waveforms are preadjusted for a good display in almost all cases. This

is based upon Nominal Voltage (Vnom) and Current range (A Range).

If desired, you can change them. The adjustment menu is reached via the SETUP key and

function key F3 - FUNCTION PREF. See Chapter 18, FUNCTION PREFerences.

Scope Phasor

To access the Phasor screen:

d

F3

PERSISTence ON memorizes all waveform variations on

screen.

Switch between HOLD and RUN of screen update.

The Phasor screen displays the phase relation between voltages and currents in a vector

diagram. The vector of reference channel A (L1) points in the positive horizontal

direction. Additional numerical values are fundamental phase voltage, frequency, and

phase angles. The screen header shows rms voltage and/or current values.

Available function keys:

F1

F3

F5

Tips and Hints

Scope Waveform gives a clear view of current and voltage waveform shapes. Voltage

waveforms in particular should be smooth and sinusoidal. If you see voltage distortion, it

is a good idea to check the harmonics display. The rms voltages and frequency should be

close to their nominal values.

Waveform and Phasor display are also useful to check if voltage leads and current clamps

are connected correctly. In the vector diagram the phase voltages and currents L1 (A), L2

(B), and L3 (C) should appear in sequence when observing them in clockwise direction.

Selection of additional data to be displayed: all voltages, all

currents, or voltage and current phase by phase.

Return to the Scope Waveform.

Switch between HOLD and RUN of screen update.

7-2

Page 33

Introduction

Volts/Amps/Hertz displays a table with important numerical measuring values. The

related Trend screen shows the changes over time of all values in the table.

Table

To access the VOLTS/AMPS/HERTZ Table screen:

Chapter 8

Volts/Amps/Hertz

c

MENU

d

ENTER

The table gives an overview of voltages and currents in all phases. Also frequency and

Crest Factors are shown. The Crest Factor CF indicates the amount of distortion: a CF of

1 means no distortion and higher than 1.8 means high distortion. Use this screen to get a

first impression of power system performance before examining the system in detail with

other measuring modes. The number of columns in the table depends on the power

system configuration.

The figures in the table are present values that may update constantly. Changes in these

values over time are recorded as soon as the measurement is turned on. The recording is

visible in the Trend screen.

8-1

Page 34

Fluke 433/434

Users Manual

Available function keys:

F4

Access to the Trend screen. For description see below.

Trend

To access the VOLTS/AMPS/HERTZ Trend screen:

All values in the table are recorded, but the Trends from each row in the table are

displayed one at a time. Press Function key F1 to assign the up/down arrow keys to row

selection.

The traces build up from the right side. Readings in the header correspond to the most

recent values plotted on the right.

Available function keys:

e

F5

Switch between HOLD and RUN of screen update.

Switching from HOLD to RUN invokes a menu to select

immediate (NOW) or TIMED start time which allows you

to define start and duration of the measurement.

F4

F1

Assign up/down arrow keys to select a row from the table

for Trend display.

8-2

F2

F3

F4

F5

Cursor on/off.

Assign the arrow keys to Cursor or Zoom operation.

Return to table screen.

Switch between HOLD and RUN of screen update.

Switching from HOLD to RUN invokes a menu to select

immediate (NOW) or TIMED start time which allows you

to define start and duration of the measurement.

Cursor. When the Cursor is on, the Trend values at the Cursor are displayed in the screen

header. Moving the Cursor off the left or right side of the screen brings the next of six

screens into the viewing area.

Zoom. Allows you to expand or shrink the display vertically or horizontally to view

details or to fit a complete graph within the screen area. Zoom and Cursor are operated by

the arrow keys and explained in Chapter 17.

Offset and Span of the Trends are preset for a good display in most cases, but they are

adjustable. The adjustment menu is reached via the SETUP key and function key F3 FUNCTION PREF. See Chapter 18, FUNCTION PREFerences.

Page 35

Volts/Amps/Hertz

Tips and Hints 8

Tips and Hints

Voltage and frequency should be close to the nominal values of for example 120 V, 230

V, 480 V, 60 Hz, or 50 Hz.

The voltages and currents in the table can e.g. be used to check if power applied to a 3phase induction motor is in balance. Voltage unbalance causes high unbalanced currents

in stator windings resulting in overheating and reduced motor life. Each of the phase

voltages should not differ more than 1 % from the average of the three. Current

unbalance should not exceed 10 %. In case of too high unbalance, use other measuring

modes to further analyze the power system.

A Crest Factor close to 2.0 indicates high distortion. CF = 2.0 can e.g. be found if you

measure the current drawn by rectifiers that only conduct at the sine wave top.

8-3

Page 36

Fluke 433/434

Users Manual

8-4 9-1

Page 37

Introduction

Dips & Swells records Dips, Interruptions, Rapid Voltage Changes, and Swells.

Dips (Sags) and Swells are fast deviations from the normal voltage. Magnitude may be

ten up to hundreds of volts. Duration may vary from a half cycle to a few seconds as

defined in EN61000-4-30. The Analyzer allows you to choose nominal or sliding

reference voltage. A sliding reference voltage uses measured values filtered with a 1minute time constant.

During a dip the voltage drops; during a swell the voltage rises. In three phase systems a

dip begins when the voltage on one or more phases drops below the dip threshold and

ends when all phases are equal to or above the dip threshold plus hysteresis. The trigger

conditions for dips and swells are threshold and hysteresis. Dips and swells are

characterized by duration, magnitude, and time of occurrence. Figure 9-1 and 9-2 explain

this.

Chapter 9

Dips & Swells

Figure 9-1. Characteristics of a voltage dip

Page 38

Fluke 433/434

Users Manual

Figure 9-2. Characteristics of a voltage swell

During an Interruption the voltage sinks well below its nominal value. In three phase

systems an interruption begins when the voltage on all phases are below threshold and

ends when one phase is equal to or above the interruption threshold plus hysteresis. The

trigger conditions for interruptions are threshold and hysteresis. Interruptions are

characterized by duration, magnitude and time of occurrence. Figure 9-3 explains this.

INTERRUPTION-INT-

NOMINAL

VOLTAGE

HYSTERESIS

THRESHOLD

duration

time

0 VOLT

Figure 9-3. Characteristics of a voltage interruption

magnitude

Rapid voltage changes are quick transitions of the RMS voltage between two steadystates. Rapid voltage changes are captured based on steady voltage tolerance, steady time,

minimum step detected, and minimum rate (%/s). Figure 9-4 explains this.

9-2

Page 39

Dips & Swells

RAPID VOLTAGE CHANGE - CHG-

VOLTAGE

TOLERANCE

VOLTAGE

STEP

VOLTAGE

TOLERANCE

STEADY TIME

VOLTAGE STEP

TRANSITION TIME

Trend 9

In addition to the voltage, current is also recorded. This allows you to see cause and

effect of deviations. Function key F4 – EVENTS accesses event tables where voltage

events are listed in sequence.

Trend

To access to the Dips & Swells Trend screen:

c

d

STEADY TIME

Figure 9-4. Characteristics of a rapid voltage change

MENU

TIME

TRANSITION

TIME

e

ENTER

For the main screen all configured voltage and current channels are recorded to allow

viewing of cause and effect of deviations. Not all channels are displayed simultaneously.

Press function key F1 to assign the arrow keys to select the set of trends to be displayed.

9-3

Page 40

Fluke 433/434

Users Manual

The screen builds up from the right side of the screen and the corresponding values are

displayed in the screen header.

Available function keys:

F1

Assign up/down arrow keys to select the voltage or current

channels to be displayed.

F2

F3

F4

F5

Cursor on/off.

Assign the arrow keys to Cursor or Zoom operation.

Access to Events tables.

Switch between HOLD and RUN of screen update.

Switching from HOLD to RUN invokes a menu to select

immediate (NOW) or TIMED start time which allows you

to define start and duration of the measurement.

Cursor. When the Cursor is on, the Trend values at the Cursor are displayed in the screen

header. Moving the Cursor off the left or right side of the screen brings the next of six

screens into the viewing area.

Zoom. Allows you to expand or shrink the display vertically or horizontally to view

details or to fit a complete graph within the screen area. Zoom and Cursor are operated by

the arrow keys and are explained in Chapter 17.

Offset and Span of the Trends are preset for a good display in most cases. This is based

upon Nominal Voltage (Vnom) and Current range (A range). If desired, you can adjust

Offset and Span. The adjustment menu is reached via the SETUP key and function key

F3 - FUNCTION PREF. See Chapter 18, FUNCTION PREFerences.

Event criteria such as threshold, hysteresis and others are preset, but they may be

adjusted. The adjustment menu is reached via the SETUP key and limits setup. See

Chapter 18, Limits Adjustments.

Events Tables

To access the Dips & Swells Events Tables:

f

The Events table lists all threshold crossings of phase voltages. Thresholds according to

international standards or user-definable thresholds can be used. Threshold adjustment is

reached via the SETUP key and Limits. For detailed information see Chapter 18, Limits

Adjustments.

In Normal mode major event characteristics are listed: start time, duration, and voltage

magnitude. Detail shows details of threshold crossings per phase.

F4

9-4

Page 41

Dips & Swells

Tips and Hints 9

The following Abbreviations and Symbols are used in the tables:

Abbreviation Description Symbol Description

CHG Rapid Voltage Change Rising voltage edge

DIP Voltage Dip Falling voltage edge

INT Voltage Interruption

SWL Voltage Swell

Available function keys:

F3

Switch between NORMAL and DETAILED event table.

F4

F5

Tips and Hints

The occurrence of Dips (Sags) and Swells may indicate a weak power distribution

system. In such a system voltage will change considerably when a big motor or a welding

machine is switched on or off. This may cause lights to flicker or even show visible

dimming. It may cause reset and loss of data in computer systems and process controllers.

By monitoring the voltage and current trend at the power service entrance, you can find

out if the cause of the voltage dip is inside or outside the building. The cause is inside the

building (downstream) when voltage drops while current rises; it is outside (upstream)

when both voltage and current drop.

Return to Trend screen.

Access Trend screen with Cursor on and positioned on the

highlighted event.

This event can be selected with the up/down arrow keys

9-5

Page 42

Fluke 433/434

Users Manual

9-6 10-1

Page 43

Introduction

Harmonics measures and records harmonics and interharmonics (Fluke 434) up to the

th

. Related data such as DC components, THD (Total Harmonic Distortion), and K-

50

factor are measured. Harmonics are periodic distortions of voltage, current, or power

sinewaves. A waveform can be considered as a combination of various sinewaves with

different frequencies and magnitudes. The contribution of each of these components to

the full signal is measured. Readings can be given as a percentage of the fundamental, or

as a percentage of all harmonics combined. Results may be viewed in a Bar Graph

display, a table, or a Trend display. Harmonics are often caused by non-linear loads such

as DC power supplies in computers, TV’s and adjustable speed motor drives. Harmonics

can cause transformers, conductors, and motors to overheat.

Bar Graph Screen

To access to the Harmonics Bar Graph screen:

Chapter 10

Harmonics

c

d

MENU

Page 44

Fluke 433/434

Users Manual

e

ENTER

The Bar Graph display shows the percentage contribution of each of the components

related to the full signal. A signal without distortion should show a 1

fundamental) at 100 % while the others are at zero: in practice this will not occur because

there always is a certain amount of distortion resulting in higher harmonics.

A pure sinewave becomes distorted when higher frequency components are added to it.

Distortion is represented by the THD percentage. The display can also show the

percentage of the DC component and the K-factor. The K-factor is a number that

quantifies potential losses in transformers due to harmonic currents. Higher order

harmonics influence the K-factor more than low order harmonics.

The table below shows the number of Bar Graphs displayed simultaneously in one

screen:

Harmonics Harmonics & Interharmonics

All phase display 1 ... 12 1 ... 6

st

harmonic (= the

Single phase display 1 ... 50 1 ... 25

The left/right arrow keys are used to position the Cursor on a particular bar. The screen

header will show for that bar phase identifier, harmonic number, frequency, and phase

angle. If not all bars are shown on the screen, you can bring the next set within the

viewing area by moving the Cursor off the left or right end of the screen. The up/down

arrow keys are used for vertical zoom: 100 %, 50 %, 20 %, 10 %, or 5 % at full scale can

be selected. Using the SETUP key and function key F3 - FUNCTION PREF you can

choose harmonics display as a percentage of the fundamental voltage (%f) or the total of

harmonic voltages (%r). For detailed information see Chapter 18, FUNCTION

PREFerences.

Available function keys:

F1

Selection of harmonics type: Voltage, Current, or Real

Power (Watt). Power harmonics can have positive and

negative polarity.

F2

Selection of waveform set to be used: A (L1), B (L2), C

(L3), N (neutral) or ALL

F3

F4

Access the table screen.

Interharmonics display on/off (Fluke 434 only).

10-2

F5

Switch between HOLD and RUN of screen update.

Switching from HOLD to RUN invokes a menu to select

immediate (NOW) or TIMED start time which allows you

to define start and duration of the measurement.

Page 45

Harmonics

Table10

Table

To access the Harmonics Table screen:

f

The table display shows 8 measurements per phase. Using the SETUP key and function

key F3 - FUNCTION PREF you can choose the table contents. For detailed information

see Chapter 18, FUNCTION PREFerences.

Available function keys:

F3

F3

Return to Bar Graph screen.

Trend

To access the Harmonics Trend screen:

Trend shows how harmonics vary over time: Cursor and Zoom can be used to investigate

details. All values in the table are recorded, but the Trends from each row in the table are

displayed one at a time. Press function key F1 to assign the arrow keys to row selection.

Using the SETUP key and function key F3 - FUNCTION PREF you can choose

harmonics display as a percentage of fundamental voltage (%f) or of the total of

harmonic voltages (%r, total Vrms). Also the table contents can be selected in this menu.

For detailed information see Chapter 18, FUNCTION PREFerences.

g

F4

F5

Access the Trend screen. For description see below.

Switch between HOLD and RUN of screen update.

Switching from HOLD to RUN invokes a menu to select

immediate (NOW) or TIMED start time which allows you

to define start and duration of the measurement.

F4

Available function keys:

F1

Assign up/down arrow keys to select a row from the table

for Trend display.

F2

Cursor on/off.

10-3

Page 46

Fluke 433/434

Users Manual

F3

F4

F5

Assign arrow keys to Cursor or vertical Zoom operation.

Return to table screen.

Switch between HOLD and RUN of screen update.

Switching from HOLD to RUN invokes a menu to select

immediate (NOW) or TIMED start time which allows you

to define start and duration of the measurement.

Tips and Hints

The harmonic number indicates the harmonic frequency: the first harmonic is the

fundamental frequency (60 or 50 Hz), the second harmonic is the component with two

times the fundamental frequency (120 or 100 Hz), and so on. The harmonics sequence

can be positive (+), zero (0), or negative (-). The table below gives an overview.

Order 1st 2nd 3rd 4th 5th 6th

Frequency

60 Hz

50 Hz

Sequence + - 0 + - 0

Order 7th 8th 9th 10th 11th ...

Frequency

420 Hz

350 Hz

120 Hz

100 Hz

480 Hz

400 Hz

180 Hz

150 Hz

540 Hz

450 Hz

240 Hz

200 Hz

600 Hz

500 Hz

300 Hz

250 Hz

660 Hz

550 Hz

360 Hz

300 Hz

...

Sequence + - 0 + -

Positive sequence harmonics try to make a motor run faster than the fundamental;

negative sequence harmonics try to make the motor run slower than the fundamental. In

both cases the motor looses torque and heats up. Harmonics can also cause transformers

to overheat. Even harmonics disappear if waveforms are symmetrical, i.e. as equally

positive and negative.

Zero sequence current harmonics add in Neutral conductors. This can cause overheating

of these conductors.

Distortion. Current distortion is to be expected in a system with non-linear loads like DC

power supplies. When the current distortion starts to cause voltage distortion (THD) of

more than 5 %, this signals a potential problem.

K-factor: this is an indication of the amount of harmonic currents and can help in

selecting transformers. Use the K-factor along with KVA to select a replacement

transformer to handle non-linear, harmonics-rich loads.

...

10-4

Page 47

Introduction

Power & Energy displays a table with all important power parameters. The related Trend

screen shows the changes over time of all measuring values in the table.

Fluke 434 can also display energy usage and offers verification of energy meters with a

pulse contact. For power calculations you can choose Fundamental or Full.

FUNDamental considers voltage and current only at the fundamental frequency (60 or 50

Hz) for power calculations; FULL uses the full frequency spectrum (True rms voltage

and current). Selection is made using the SETUP key and function key F3 - FUNCTION

PREF. For detailed information see Chapter 18, FUNCTION PREFerences.

Table

To access the Power & Energy table screen:

Chapter 11

Power & Energy

c

d

11-1

MENU

Page 48

Fluke 433/434

Users Manual

e

ENTER

The table displays power data for each phase and in total: real or active power (kW),

apparent power (kVA, the product of rms voltage and current), reactive power (kVAR,

the reactive component of apparent power caused by phase shift between AC current and

voltage in inductors and capacitors), power factor (PF, the ratio of real power to apparent

power for the total rms including harmonics), displacement power factor (DPF or cos ϕ,

the ratio of real power to apparent power for fundamental), and the 12 or 10 cycle rms

values of current and voltage.

Symbols indicate if a load is capacitive (

) or inductive ( ).

A popup table with energy usage by phase and in total can be activated on the Fluke 434

by pressing the F3 – ENERGY softkey. The table shows real energy (kWh), apparent

energy (kVAh), and reactive energy (kVARh) The energy measurement starts when

Power & Energy is started. The readout can be reset with function key F5.

By a using TIMED start of the measurement, the Fluke 434 can be used to measure

energy usage during a predefined period of time. TIMED start can be adjusted when

switching from HOLD to RUN with function key F5. Temporarily Close ENERGY to

make function key F5 available for HOLD/RUN operation.

Pulse count mode counts pulses like those available at the pulse output of certain types of

energy meters. This can be used to as a quick test for revenue meter error. The pulse

output is measured by means of an Optical Isolated Trigger Probe that is connected

between the pulse output and the Analyzer’s optical RS-232 interface. Figure 11-1 shows

the measuring setup. The energy usage (kWh) per pulse must be set in advance. The

adjustment menu is reached via the SETUP key and function key F3 – FUNCTION

PREF. See Chapter 18, FUNCTION PREFerences.

11-2

Figure 11-1. Verification of an energy meter with pulse output

Page 49

Power & Energy

Trend11

To access the Energy popup table:

f

F3

Available function keys:

F2

Pulse count mode on/off.

Trend

To access the Power & Energy Trend screen:

g

F3

F4

F5

Switch Energy screen on/off.

Access Trend screen. For description see below.

Switch between HOLD and RUN of screen update.

Switching from HOLD to RUN invokes a menu to select

immediate (NOW) or TIMED start time which allows you

to define start and duration of the measurement.

If Energy is displayed, the readout can be reset with F5.

F4

The figures in the table are instantaneous values that update constantly. Changes in these

values over time are recorded whenever the measurement is active. All values in the table

are recorded, but the Trends from each row in the table are displayed one at a time. Press

function key F1 to assign the arrow keys to row selection.

The traces build up from the right side. The readings in the header correspond to the most

recent measurements plotted on the right.

In addition to TIMED start of energy usage measurement, the Analyzer can measure

average power during an adjustable time window. Electricity suppliers often bill

industrial customers upon the highest average energy usage during a specified time

window. For this demand interval a period of 15 minutes is common.

For any setting besides OFF horizontal scaling of the trend is fixed so that each data point

corresponds with Max, Min, and Average usage during the interval. The demand interval

can be adjusted between 1 ... 60 minutes or to OFF. The adjustment menu is reached via

the SETUP key and function key F3 – FUNCTION PREF. See Chapter 18, FUNCTION

11-3

Page 50

Fluke 433/434

Users Manual

PREFerences. With the demand interval set to OFF the Trend functions as usual with

automatic horizontal scaling.

Available function keys:

F1

Assign up/down arrow keys to select a row from the table

for Trend display. The selected row is displayed in the

screen header.

F2

F3

F4

F5

Cursor. When the Cursor is on, the Trend values at the Cursor are displayed in the screen

header. Moving the Cursor off the left or right side of the screen brings the next of six

screens into the viewing area.

Zoom. Allows you to expand or shrink the display vertically or horizontally to view

details or to fit a complete graph within the screen area. Zoom and Cursor are operated by

the arrow keys and explained in Chapter 17.

Offset and Span are preset for a good display in most cases. This is based upon Nominal

Voltage (Vnom) and Current range (A range). If desired, you can adjust Offset and Span.

The adjustment menu is reached via the SETUP key and function key F3 - FUNCTION

PREF. See Chapter 18, FUNCTION PREFerences.

Tips and Hints

Power mode can be used to record apparent power (kVA) of a transformer over several

hours. Look at the Trend and find out if there are times that the transformer is overloaded.

You can transfer loads to other transformers, stagger the timing of loads, or if necessary

replace the transformer with a larger one.

Cursor on/off.

Assign the arrow keys to Cursor or Zoom operation.

Return to table screen.

Switch between HOLD and RUN of screen update.

Switching from HOLD to RUN invokes a menu to select

immediate (NOW) or TIMED start time which allows you

to define start and duration of the measurement.

11-4

Interpretation of Power Factor when measured at a device:

• PF = 0 to 1: not all supplied power is consumed, a certain amount of reactive power

is present. Current leads (capacitive load) or lags (inductive load).

• PF = 1: all supplied power is consumed by the device. Voltage and current are in

phase.

• PF = -1: device generates power. Current and voltage are in phase.

• PF = -1 to 0: device is generating power. Current leads or lags.

If you see negative power or power factor readings and you are connected to a load,

check to make sure the arrows on your current clamps are pointing towards the load.

Reactive power (VAR) is most often due to inductive loads such as motors, inductors,

and transformers. Installation of correction capacitors can correct for inductive VAR’s.

Be sure to check with a qualified engineer before adding PF-correction capacitors,

especially if you measure current harmonics in your system.

Page 51

Introduction

Flicker quantifies the luminance fluctuation of lamps caused by supply voltage variations.

The algorithm behind the measurement meets EN61000-4-15 and is based on a

perceptual model of the human eye / brain sensory system. The Analyzer converts

duration and magnitude of voltage variations into an ‘annoyance factor’ caused by the

resulting flicker of a 60 W lamp. A high flicker reading means that most people would

find the luminance changes irritating. The voltage variation can be relatively small. The

measurement is optimized to lamps powered by 120 V / 60 Hz or 230 V / 60 Hz. Flicker

is characterized per phase by the parameters shown in a table. The related Trend screen

shows the changes in all measuring values in the table.

After you have switched to Flicker, a settling time of about 10 seconds will

pass before the measurement is started. During this time the U (Unstable)

symbol shows in the screen header. Moreover the timer counts down from –

10 seconds. Flicker measurement has no unstable period when used with a

timed start.

Chapter 12

Flicker

Note

Table

To access the Flicker table screen:

c

12-1

MENU

Page 52

Fluke 433/434

Users Manual

d

e

ENTER

Flicker is characterized by: short term severity Pst (measured over 1 min for fast

feedback), short term severity Pst (measured over 10 min) and a long term severity Plt

(measured over 2 hours). This data and also the related D-parameters Dc, Dmax, and TD

(acc. to EN61000-3-3) are displayed in the table.

A popup table can be switched on to show the peak values of the D-parameters that

occurred during the measurement. You can reset the stored D-parameters to zero with

Function key F5.

To access the popup table with peak D-parameters:

f

F2

Pst and Plt are parameters showing flicker over a certain period of time. Momentary

flicker is shown in the PF5 submenu and is reached via Function key F3. Flicker PF5 is

displayed as a fast Trend plot.

Available function keys (popup table must be off):

F2

F3

F4

F5

Activate the popup screen with maximum D-parameters.

Access PF5 Trend screen.

Access Trend screen. For description see below.

Switch between HOLD and RUN of screen update.

Switching from HOLD to RUN invokes a menu to select

immediate (NOW) or TIMED start time which allows you

to define start and duration of the measurement.

12-2

Page 53

Flicker

Trend12

Trend

To access Flicker Trend screen:

g

The parameters in the table update over time. They are recorded whenever the

measurement is on. Trend displays the changes in these values over time. All values in

the table are recorded, but the Trends from each row in the table are displayed one at a

time. Press function key F1 to assign the arrow keys to row selection. The Trend display

may consist of 6 screens.

PF5 displays a fast Trend plot in one screen and is reached via a menu to define expected

measurement duration and Immediate or Timed measurement start. Two vertical marker

lines are used to indicate a Pst period on the PF5 trend.

F4

Available function keys:

F1

Assign up/down arrow keys to select a row from the table

for Trend display. The selected row is displayed in the

screen header.

F2

F3

F4

F5

Cursor on/off.

Assign the arrow keys to Cursor or Zoom operation.

Return to table screen.

Switch between HOLD and RUN of screen update.

Switching from HOLD to RUN invokes a menu to select

immediate (NOW) or TIMED start time which allows you