Page 1

Application Note

Problem description

This case history came from

an electric utility engineer

assigned to maintain the power

systems for several small towns

in the western U.S. The eng ineer carries a Fluke 43B on

all trouble calls, because it

provides a graphical display

that allows customers to see

a “picture” of the problem.

The case history began

with a call from a local police

department. The officer

explained that the traffic light

at the main intersection of town

was randomly malfunctioning.

Sometimes it worked fine,

while other times it generated

unacceptably long delays in

one direction or the other.

Normally when a traffic light

fails, it will not work at all. In

this case, however, the problem

was intermittent. Therefore, the

engineer suspected the problem

was due to an interaction with

the power system, rather than

a failure within the traffic light

Malfunctioning

traffic light

From the Fluke Digital Library @ www.fluke.com/library

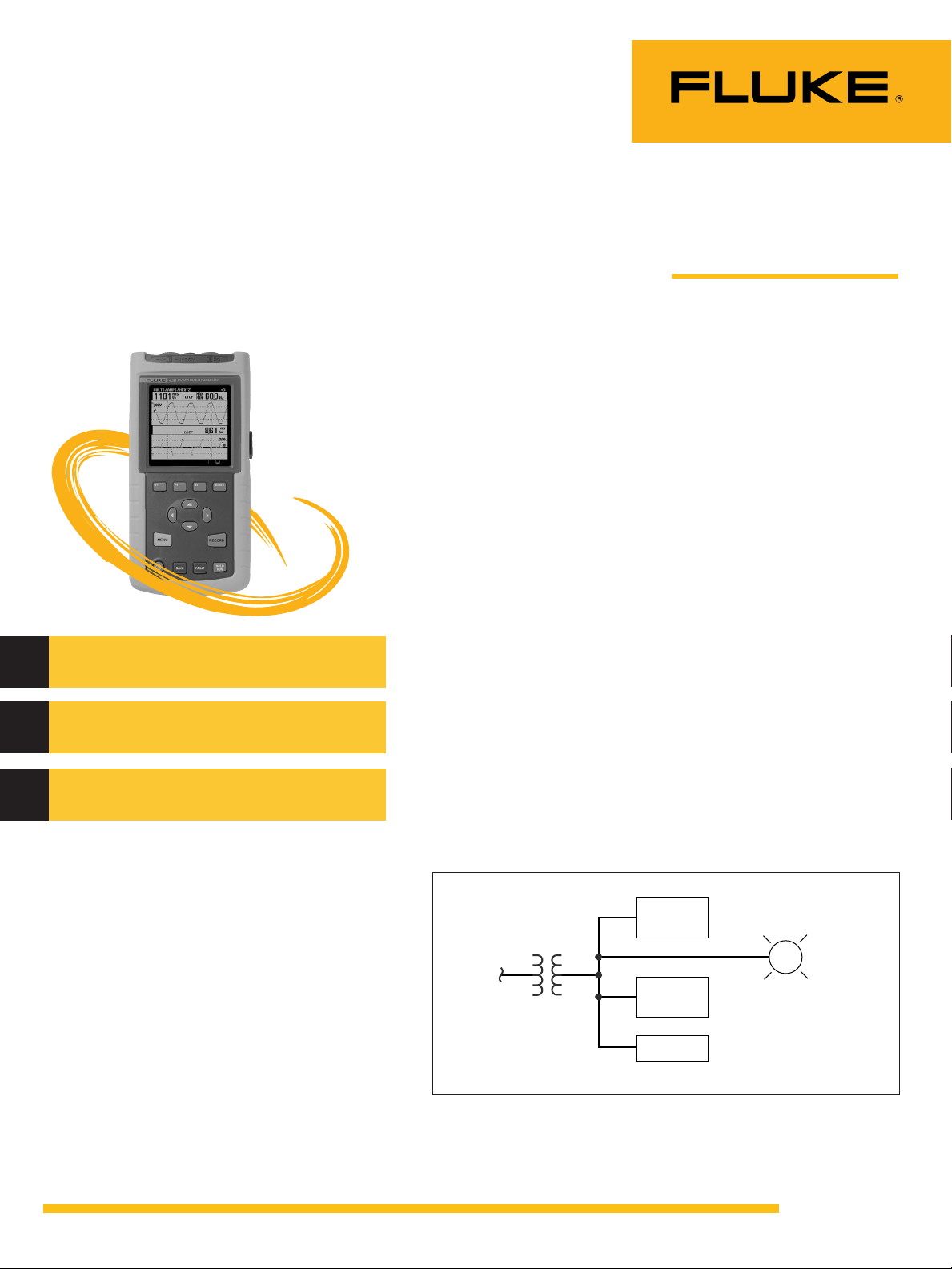

itself. The engineer’s investigation showed that three facilities

(a barbershop, a small café and

an automotive machine shop)

shared the transformer secondary that supplied power to the

traffic light. See Fig. 1.

One of the keys to troubleshooting a problem is determining what changed just prior

to the appearance of the problem. Visits to the barbershop

and café didn’t reveal anything

meaningful. The machine shop,

however, had a different story.

The shop had just installed a

new brake lathe they were

using to resurface brake drums

and rotors for cars and trucks.

The lathe was equipped with a

dc motor powered by a dc

adjustable speed drive.

Machine

Shop

Traffic

Light

Utility

Barber

Shop

Café

Fig. 1 One-line diagram showing power supplied to the traffic light

Operator: Electric utility engineer

Measuring tools: Fluke 43B Power

Quality Analyzer

Features used: Voltage, transient

capture

Power

Quality

Case

Study

Page 2

Fluke.Keeping your world

up and running.

Fluke Corporation

PO Box 9090, Everett, WA USA 98206

Fluke Europe B.V.

PO Box 1186, 5602 BD

Eindhoven, The Netherlands

For more information call:

In the U.S.A. (800) 443-5853 or

Fax (425) 446-5116

In Europe/M-East/Africa (31 40) 2 675 200 or

Fax (31 40) 2 675 222

In Canada (800)-36-FLU K E or

Fax (905) 890-6866

From other countries +1 (425) 446-5500 or

Fax +1 (425) 446-5116

Web access: http://www.fluke.com/

©2003 Fluke Corporation. All rights reserved.

Printed in U.S.A. 8/2003 2103520 A-ENG- N Rev A

Theory and analysis

Machine tool applications need

high torque at low speeds, and

dc motor/drive configurations

serve this need well. Thus,

machine tools commonly have

dc motors and drives. The input

rectifier circuit in a dc drive is

designed to provide variable

amounts of current to meet the

torque and speed requirements

of the motor. A commonly used

circuit configuration uses silicon

controlled rectifiers (SCRs) to

provide the variable current.

The SCR c ircuit produces

commutating spikes as one

rectifier is turned off before the

next rectifier is turned on. In

this case, the spikes generated

when the lathe was operating

were large enough to disrupt

the traffic light.

Solution

The engineer ordered a new

transformer and separate feeder

connection for the traffic light.

This new configuration

provided enough isolation to

keep things running normally.

Measurements

The engineer connected his

43B to the machine shop’s

service entrance, line-to-line

with “Transient Capture” mode

activated. The 43B recorded

large voltage spikes whenever

the lathe was operating. See

Fig. 2.

Fig. 2 Voltage spikes from a dc adjustable

speed drive

2 Fluke Corporation Power Quality Case Study: Malfunctioning traffic light

Loading...

Loading...