Page 1

33X

ClampMeters

Calibration Information

Introduction

XWWarning

To avoid electric shock or injury, do not perform the performance tests or

calibration procedures unless you are qualified to do so.

The information provided in this manual is for the use of qualified personnel

only.

The 33X Calibration Information provides the information necessary to verify the performance and adjust

the calibration of the Fluke 333, 334, 335, 336, and 337 ClampMeters, hereafter known as the Meter(s).

®

The following information is included in this document:

• Safety Information and International Electrical Symbols

• Specifications

• Replacing the Batteries

• Cleaning

• Performance Tests

• Calibration Adjustment

• User-Replaceable Parts and Accessories

• Warranty Statement

See the 33x Instruction Cards for complete operating instructions.

Contact Information

To contact Fluke, call:

1-888-99-FLUKE (1-888-993-5853) in USA

1-800-36-FLUKE (1-800-363-5853) in Canada

+31 402-675-200 in Europe

+81-3-3434-0181 Japan

+65-738-5655 Singapore

+1-425-446-5500 in other countries

For additional information about Fluke, its products, and services, visit Fluke’s web site at:

www.fluke.com

To register this product, go to register.fluke.com

PN 1618765 June 2001 Rev. 3, 4/06

© 2001-2006 Fluke Corporation. All rights reserved. Printed in U.S.A.

1

Page 2

33x

Calibration Information

Safety Information

XWWarnings and Precautions

To avoid possible electric shock or personal injury, and to avoid possible damage to the Meter

or the equipment under test, adhere to the following practices:

• Avoid working alone so assistance can be rendered.

• Never use the Meter on a circuit with voltages higher than 600 V or a frequency

higher than 400 Hz fundamental. The meter may be damaged.

• Do not use the Meter or test leads if they look damaged.

• Use extreme caution when working around bare conductors or bus bars. Contact

with the conductor could result in electric shock.

• Read the instruction card and safety sheet before use and follow all safety instructions.

• Use the Meter only as specified in the instruction card; otherwise, the Meter's safety

features may be impaired.

• Use caution when working with voltages above 60 V dc or 30 V ac. Such voltages

pose a shock hazard.

• Before using the Meter, inspect the case. Do not use the Meter if it is damaged. Look for

cracks or missing plastic. Pay particular attention to the insulation around the connectors.

• Verify the Meter’s operation by measuring a known voltage. Do not use the Meter if it

operates abnormally. Protection may be impaired. When in doubt, have the Meter serviced.

• Do not apply more than the rated current or voltage, as marked on the Meter.

• Use the proper terminals, function, and range for your measurements.

• Do not operate the Meter with the case (or part of the case) removed.

• When servicing the Meter, use only specified replacement parts.

International Electrical Symbols

The following international symbols appear in this document and on the Meter.

Y

W

T

M

)

P

J

F

B

;

N10140

s

~

Risk of electric shock

Risk of danger. Important Information. See manual.

Equipment protected by double or reinforced Insulation

Battery

Complies with U.S. and Canadian standards: UL61010B-1; CSA C22.2 No.1010.1-92

and amendment 2. Also complies with European standard EN 61010-2-032-04.

Conforms to EU directives

Earth

DC measurement

AC measurement

Conforms to relevant Australian standards

Inspected and licensed by TÜV Product Services

Do not dispose of this product as unsorted municipal waste. Contact Fluke or a qualified

recycler for disposal.

2

Page 3

ClampMeters

Specifications

Specifications

*These specifications apply

@ 23 °C ± 5 °C, in relative

humidity of 0 - 90%

?

(50 Hz/60 Hz)

Inrush Current Integration

Range 0 - 400.00 A 0 - 600.0 A 0 - 999.9 A

Accuracy 2 % ± 5 counts (50/60 Hz) 2 % ± 5 counts (10 - 100 Hz)

Crest

Factor

add 2% for

CF > 2

AC

response

Time

Range NA NA NA 0 - 600.0 A 0 - 999.9 A A

Accuracy NA NA NA 2 % ± 5 counts

Range 0 - 600.00 V K

Accuracy 1 % ± 5 counts

333

NA NA 2.4 @ 500 A

Avg Rms

NA 100 ms

334

2.0 @ 600 A

50/60 Hz

335

3 @ 500 A

2.5 @ 600 A

336

6 % ± 5 counts (10 - 400 Hz)

3 @ 500 A

2.5 @ 600 A

1.42 @ 1000 A

1 % ± 5 counts (20 - 100 Hz)

6 % ± 5 counts (100 - 400 Hz)

337

Range 0 - 600.0 V L

Accuracy 1 % ± 5 counts

e

Continuity R ≤ 30 Ω

Trigger Level:

10-100 Hz ≥ 5 A

5-10 Hz,

100-400 Hz > 10 A

Storage

Temperature

Operating

Temperature

Altitude 2500 m

EMC- instrument unspecified for use in EMC field ≥ 0.5 V/m

CAT III 600 V, Pollution Degree II:

CAT III equipment is designed to protect against transients in equipment in fixed-equipment installations, such as

distribution panels, feeders and short branch circuits, and lighting systems in large buildings.

Range 0 - 600.0 Ω 0 - 600.0 Ω

600 - 6000 Ω

Accuracy 1.5 % ± 5 counts

Range NA NA NA NA 5.0 - 400.0 Hz Hz-Amps Only

Accuracy NA NA NA NA 0.5 % ± 5 counts

-40 °C to 60 °C

-10 °C to 50 °C

*< 18 °C,> 28 °C add 0.1 x (specified accuracy)/°C

3

Page 4

33x

Calibration Information

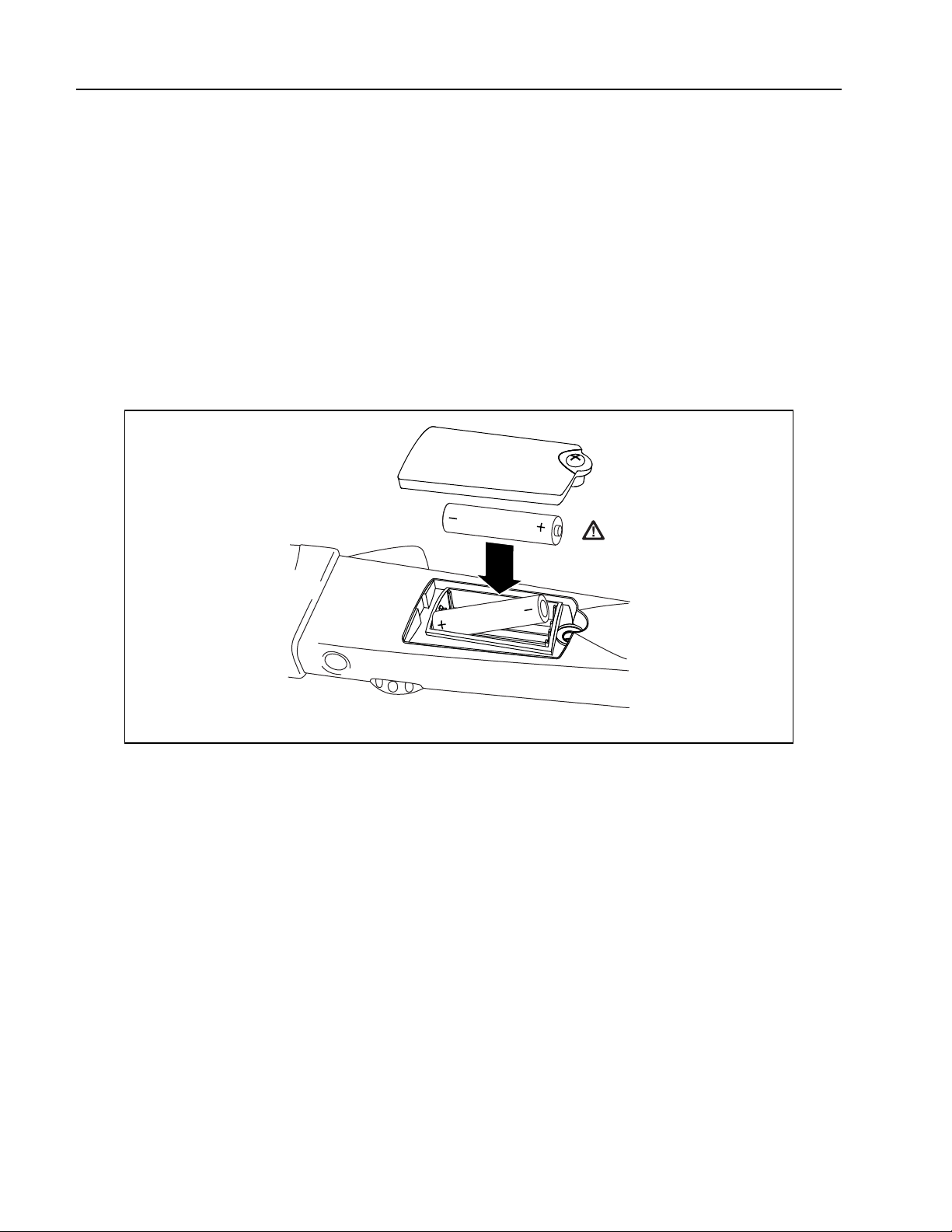

Replacing the Batteries

To avoid false readings, that could lead to possible electric shock or personal

injury, replace the batteries as soon as the low battery indicator (B) appears.

Disconnect the test leads before replacing the batteries.

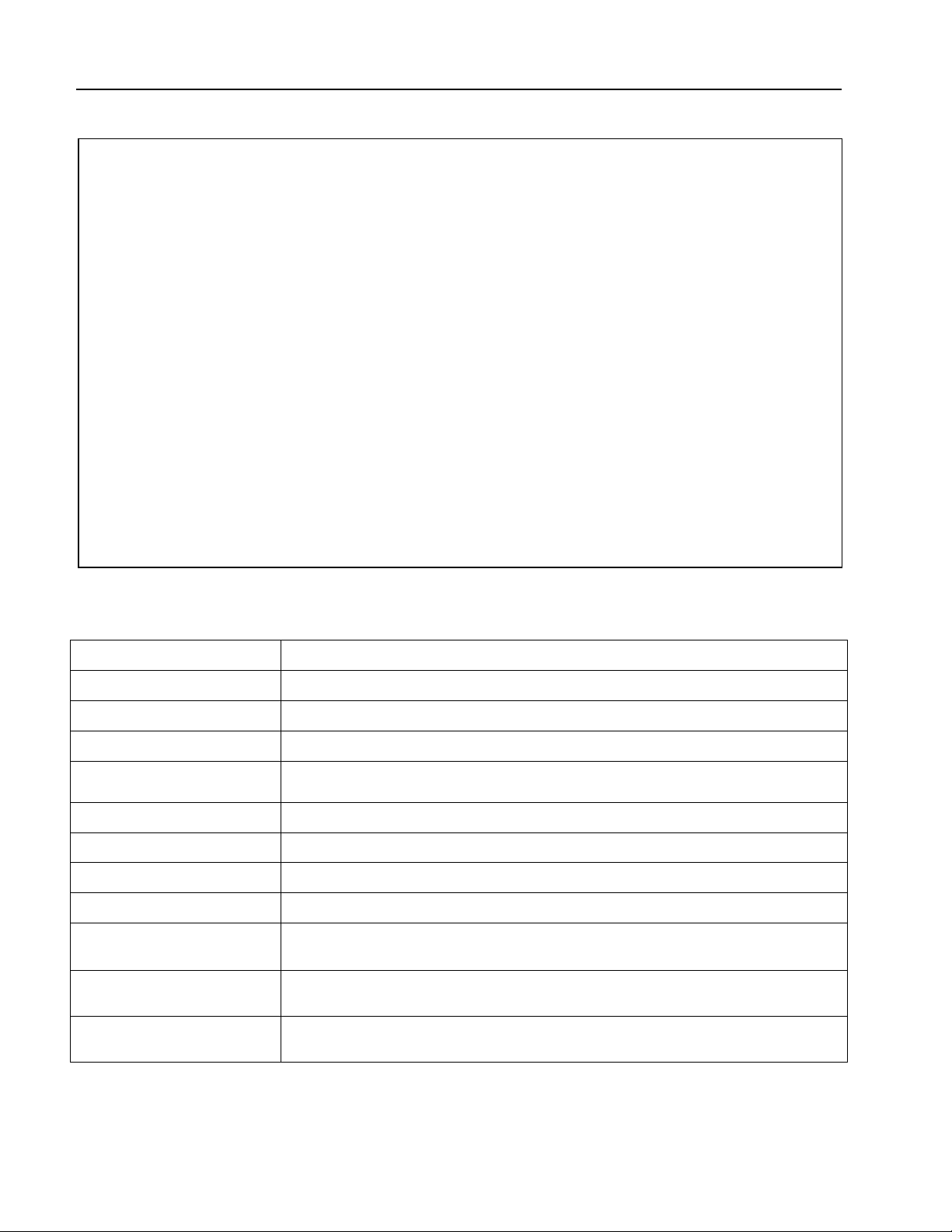

To replace the batteries (refer to Figure 1):

XWWarning

1. Turn the rotary switch to

OFF and remove the test leads from the terminals.

2. Loosen the battery compartment door screw, and remove the door from the case bottom.

3. Remove the batteries.

4. Replace the batteries with 2 new AA batteries.

5. Reattach the battery compartment door to the case bottom and tighten the screw.

Figure 1. Replacing the Batteries

Cleaning

XW Warning

To avoid electrical shock, remove any input signals before cleaning.

WCaution

To avoid damaging the Meter, do not use aromatic hydrocarbons or chlorinated

solvents for cleaning. These solutions will react with the plastics used in the

instruments.

Clean the instrument case with a damp cloth and mild detergent.

4

adc02f.eps

Page 5

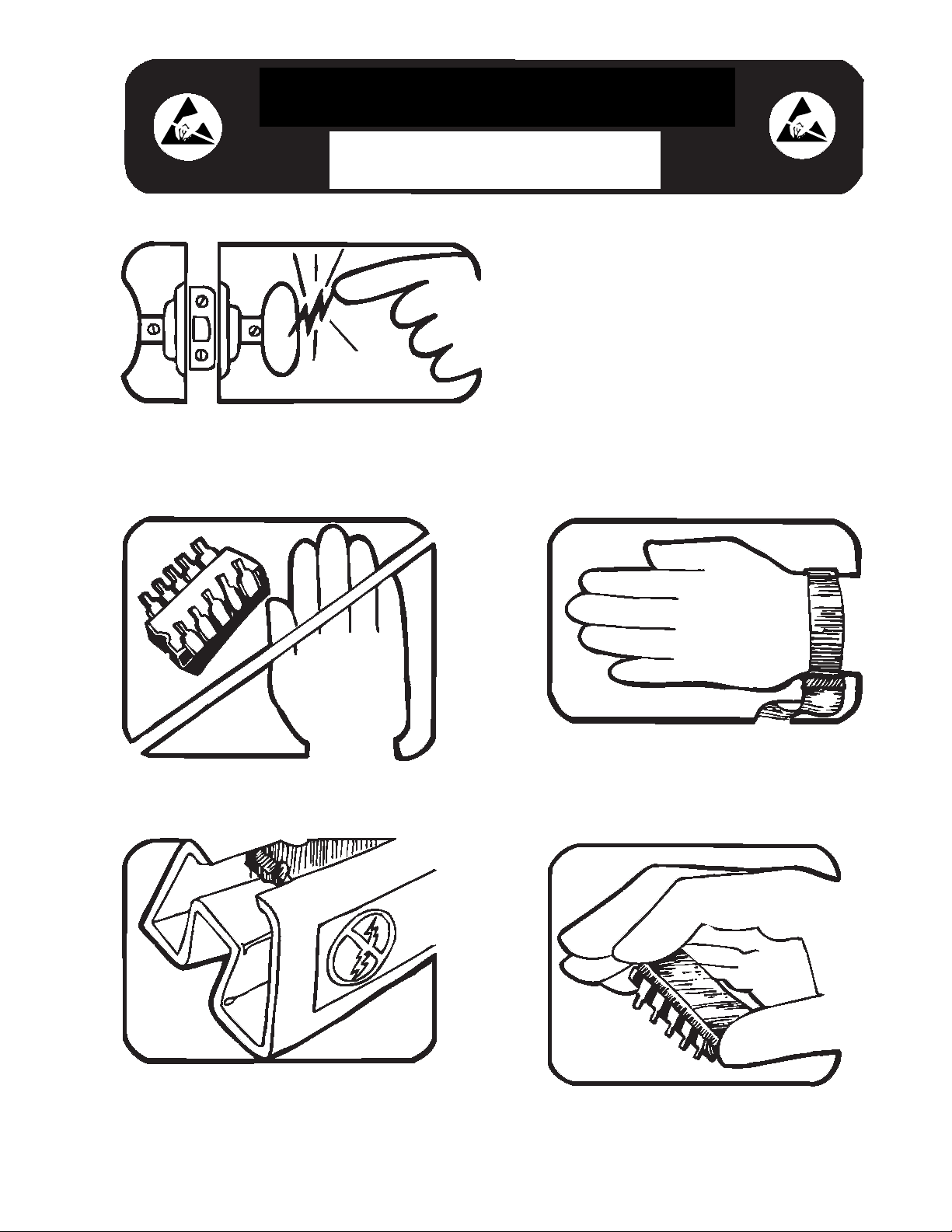

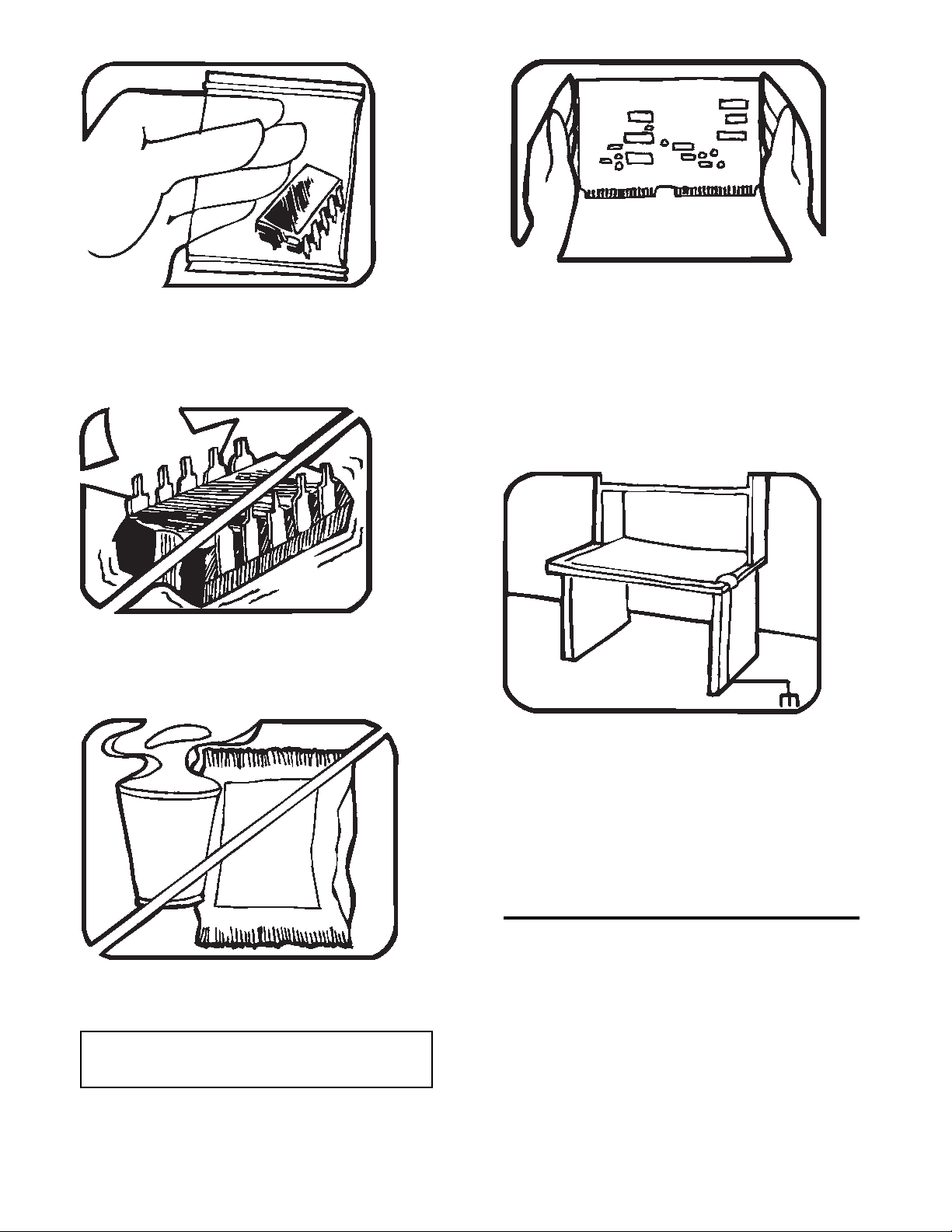

static awareness

A Message From

Fluke Corporation

Some semiconductors and custom IC's can be

damaged by electrostatic discharge during

handling. This notice explains how you can

minimize the chances of destroying such devices

by:

1. Knowing that there is a problem.

2. Learning the guidelines for handling them.

3. Using the procedures, packaging, and

bench techniques that are recommended.

The following practices should be followed to minimize damage to S.S. (static sensitive) devices.

1. MINIMIZE HANDLING

2. KEEP PARTS IN ORIGINAL CONTAINERS

UNTIL READY FOR USE.

3. DISCHARGE PERSONAL STATIC BEFORE

HANDLING DEVICES. USE A HIGH RESIS TANCE GROUNDING WRIST STRAP.

4. HANDLE S.S. DEVICES BY THE BODY.

Page 6

5. USE STATIC SHIELDING CONTAINERS FOR

HANDLING AND TRANSPORT.

6. DO NOT SLIDE S.S. DEVICES OVER

ANY SURFACE.

8. WHEN REMOVING PLUG-IN ASSEMBLIES

HANDLE ONLY BY NON-CONDUCTIVE

EDGES AND NEVER TOUCH OPEN EDGE

CONNECTOR EXCEPT AT STATIC-FREE

WORK STATION. PLACING SHORTING

STRIPS ON EDGE CONNECTOR HELPS

PROTECT INSTALLED S.S. DEVICES.

9. HANDLE S.S. DEVICES ONLY AT A

STATIC-FREE WORK STATION.

7. AVOID PLASTIC,VINYL AND STYROFOAM

IN WORK AREA.

PORTIONS REPRINTED

WITH PERMISSION FROM TEKTRONIX INC.

AND GERNER DYNAMICS, POMONA DIV.

Dow Chemical

10. ONLY ANTI-STATIC TYPE SOLDER SUCKERS SHOULD BE USED.

11. ONLY GROUNDED-TIP SOLDERING

IRONS SHOULD BE USED.

Page 7

ClampMeters

Performance Tests

Performance Tests

XWWarning

To avoid electric shock, do not perform the performance test procedures unless

the Meter is fully assembled.

The following performance tests verify the complete operation of the Meter and check the accuracy of

each meter function against the Meter’s specifications. If the Meter fails any part of the test, calibration

adjustment and/or repair is indicated.

In the performance tests, the Meter is referred to as the unit under test (UUT).

Table 1. Required Equipment

Equipment Recommended Model

AC Calibrator Fluke 5520A

Digital Multimeter (DMM) Any Fluke model

50-Turn Current Coil Fluke 5500A/Coil

Testing the Display

For models 334 - 337, test the display by turning the Meter on while holding down the INRUSH button.

Check all segments for clarity and contrast. The 333 is not equipped with this feature. Refer to Figure 2.

Figure 2. Testing the Display (337 is shown)

5

adc01f.eps

Page 8

33x

Calibration Information

Backlight Test

The 334, 335, 336, and 337 Clampmeters are equipped with a display backlight. To test the backlight,

press b. The backlight will come on and the unit will beep. To turn off the backlight, press b a second

time. Refer to Figure 3.

Figure 3. Testing the Backlight

Keypad Test

To test the keypad, turn the Meter on and push each button separately. Each button push will cause the

Meter to beep.

Preparing for the Performance Test

XWWarning

To avoid possible electric shock or personal injury:

• Do not perform the following procedures unless qualified to do so. Some

procedures involve the use of high voltages.

• Before handling the test connections and in between tests, make sure the

calibrator is in standby mode (STBY).

To prepare for the performance test:

1. Make sure that you have the required equipment, see Table 1.

2. Warm up the calibrator as required by its specifications.

3. Allow the temperature of the UUT to stabilize at room temperature ( 23 °C ± 5 °C [73 °F ± 9 °F] ).

adc03f.eps

6

Page 9

ClampMeters

Performance Tests

Performance Test Procedure

To test each of the Meter's functions and operating ranges, do the following:

1. Connect the source to the Meter's VΩ and COM input jacks.

2. Referring to Table 2, put the Meter in the desired function and range for each test.

3. Apply the indicated output from the source.

4. When using the amp function on the 5520A, make sure LCOMP on the 5520A is ON.

5. The reading on the Meter display should be within the low and high limits shown in the table.

6. Repeat steps 1-4 for each function and range in Table 2.

If the Meter fails to perform within the low-high range indicated for each test in Table 2, the Meter needs

to be calibrated and adjusted, or requires some repair.

Figure 4. 33x Amps/Hz Verification Setup

7

adc07f.eps

Page 10

33x

Calibration Information

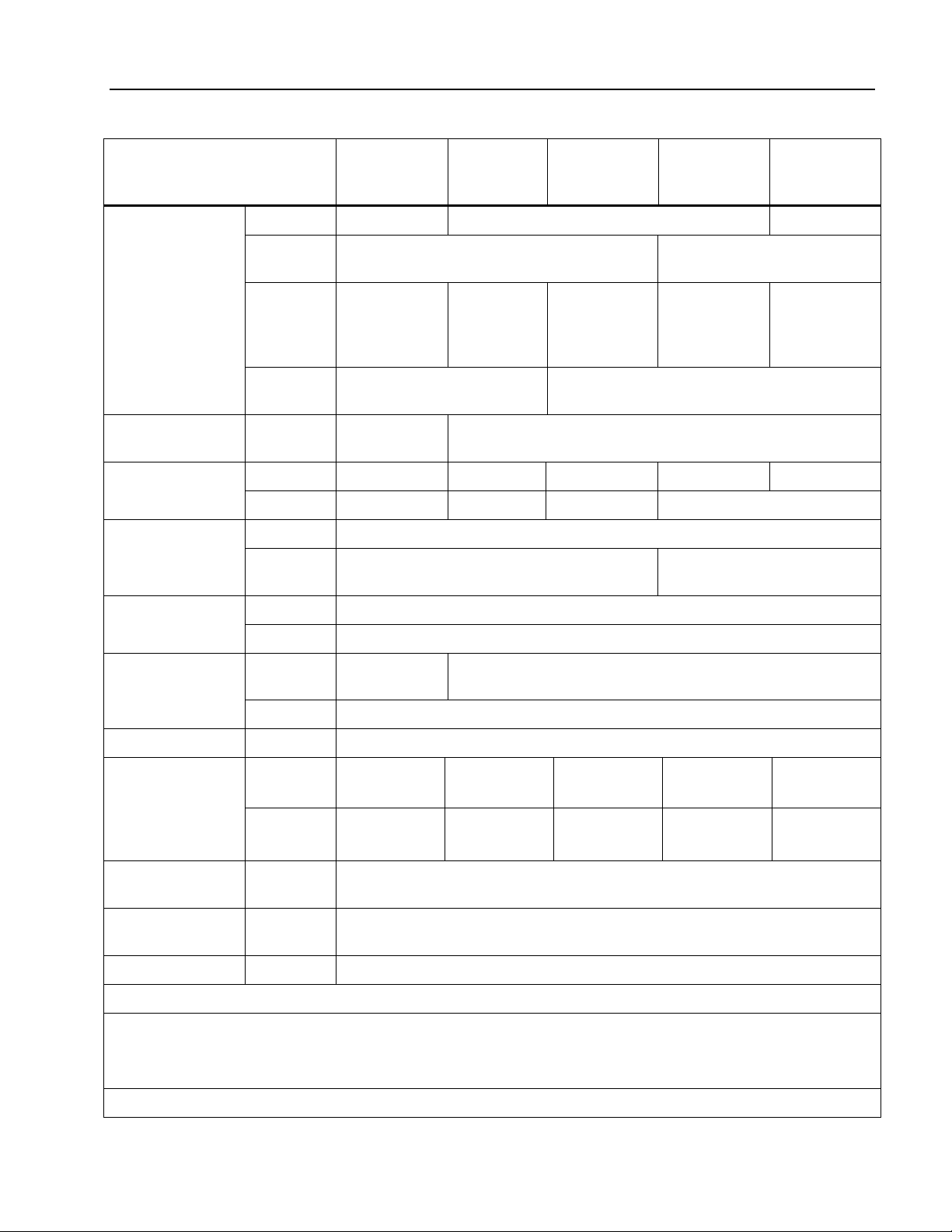

Table 2. Performance Tests 333, 334, 335

Test

(Switch Position)

20 V 50 Hz 19.3 V AC 20.7 V AC K

AC Volts

L

DC Volts

R

Continuity

Ohms

?

Amps AC

*INRUSH **5 A 60 Hz 4.4 A AC 5.6 A AC

600 V 50 Hz 593.5 V AC 606.5 V AC

20 V 19.3 V DC 20.7 V DC

-20 V -20.7 V DC -19.3 V DC

600 V 593.5 V DC 606.5 V DC

-600 V -606.5 V DC -593.5 V DC

25 Ω Beeper On

600 Ω 590.5 Ω 609.5 Ω e

6 KΩ (334, 335) 5905 Ω 6095 Ω

.4 A 50 Hz 19.1 A AC 20.9 A AC

4 A 50 Hz 195.5 A AC 204.5 A AC

10 A 50 Hz (333) 391.5 408.5

12 A 50 Hz (334, 335) 587.5 A AC 612.5 A AC

Meter Response

5520A Output Lower Limit Upper Limit

*The “INRUSH” button must be pressed after current is applied to the 50-turn coil.

**Display should bar (- - - -), then show reading with inrush light on (334, 335)

8

Page 11

ClampMeters

Table 2. Performance Tests 336, 337 (cont.)

Performance Tests

Test

(Switch Position)

K

AC Volts

L

DC Volts

R

Continuity

Ohms

?

Amps AC

Meter Response

5520A Output Lower Limit Upper Limit

20 V 50 Hz 19.3 V AC 20.7 V AC

600 V 50 Hz 593.5 V AC 606.5 V AC

600 V 400 Hz 563.5 V AC 636.5 V AC

600 V 400 Hz 563.5 V AC 636.5 V AC Min/Max (337)

20 V 400 Hz Reading does not change

20 V 19.3 V DC 20.7 V DC

-20 V -20.7 V DC -19.3 V DC

600 V 593.5 V DC 606.5 V DC

-600 V -606.5 V DC -593.5 V DC

25 Ω Beeper On

600 Ω 590.5 Ω 609.5 Ω e

6 KΩ 5905 Ω 6095 Ω

.4 A 50 Hz 19.1 A AC 20.9 A AC

4 A 50 Hz 195.5 A AC 204.5 A AC

10 A 50 Hz 187.5 A AC 212.5 A AC

12 A 50 Hz 587.5 A AC 612.5 A AC

18 A 50 Hz (337 only) 881.5 A AC 918.5 A AC

*INRUSH **5 A 60 Hz 4.4 A AC 5.6 A AC

A

DC Amps

*The “INRUSH” button must be pressed after current is applied to the 50-turn coil.

**Display should bar (- - - -), then show reading with inrush light on (334, 335)

0.0 A after button push -0.5 A DC 0.5 A DC

.4 A 19.1 A DC 20.9 A DC

-.4 A -20.9 A DC -19.1 A DC

12 A 587.5 A DC 612.5 A DC

-12 A -612.5 A DC -587.5 A DC

18 A (337) 881.5 A DC 918.5 A DC

-18 A (337) -918.5 A DC -881.5 A DC

5 A 10 Hz 9.4 Hz 10.6 Hz Frequency (337)

10 A 300 Hz 298.0 Hz 302.0 Hz

9

Page 12

33x

Calibration Information

Calibration Adjustment 333, 334, & 335

Use the following steps to adjust the calibration of the 333, 334, and 335 meters (refer to Figure 5):

1. Remove the 2 screw on the bottom of the Meter.

2. Lift off the top case.

3. Apply 600.0 V 50 Hz.

4. Adjust R12 until display reads within 1.0 V.

5. Apply 200.0 A 50 Hz (remove 600 Vac).

6. Adjust R15 until the display reads within 0.5 A.

7. Replace the top case.

8. Replace the case screws.

9. Verify the calibration by going through the performance test procedures.

10

Page 13

ClampMeters

Performance Tests

Figure 5. Calibration Adjustment Points (333-335)

adc05f.eps

11

Page 14

33x

Calibration Information

Calibration Adjustment 336 & 337

Use the following steps to adjust the calibration of the 336 and 337 meters (refer to Figures 5 and 6):

1. Remove the 2 screw on the bottom of the Meter.

2. Lift off the top case.

3. Apply 600.0 V 50 Hz.

4. Adjust R12 until the UUT display reads within 1.0 V.

5. Remove 600.0 V.

6. Change to the A DC Function.

7. Adjust R60 until the display reads within 2.0 A of 0 A DC.

8. Change to the A AC function.

9. Apply 100.0 A 50 Hz.

10. Note measurement with wire at top and bottom of jaw opening.

11. Adjust R9 until this difference is within 1.0 A.

12. Replace top case.

13. Open battery door and remove the batteries.

14. Apply 2.7 V to 3.2 V to battery terminals.

15. Change to AAC function.

16. Apply 600.0 A 50 Hz.

17. Adjust R61 until the display reads within 1.0 A.

18. Replace the batteries.

19. Verify the calibration by going through the Performance Test procedures.

12

Page 15

ClampMeters

Performance Tests

Figure 6. Calibration Adjustment Points 336-337

adc06f.eps

13

Page 16

33x

Calibration Information

Figure 7. Calibration Adjustment (336-337)

adc04f.eps

14

Page 17

ClampMeters

User-Replaceable Parts and Accessories

User-Replaceable Parts and Accessories

Item # Description Part No Qty

A

B

C

D

E

F

G

H

I

J

K

L

Not Shown

Not Shown

Not Shown

Not Shown

* WTo ensure safety, use exact replacement only.

** Fluke accessories are available from your authorized Fluke distributor.

Knob 1611630 1

Case Top (Model 333)

Case Top (Model 334)

Case Top (Model 335)

Case Top (Model 336)

Case Top (Model 337)

Button, Backlight (334-337) 1611585 1

Button, Hold 1611572 1

Screw, case (small) 1611682 1

Battery,1.5V,0-150MA, AA Alkaline 376756 2

Battery Door 1611653 1

Screw, Battery Door 1611694 1

Screw, case (large) 1611666 1

Input Recepticle Housing 1611648 1

Keypad (334,335)

Keypad (336)

Keypad (337)

TL75 Test Lead Set** 855705 1

Softcase 1587541 1

333, 334, 335, 336, and 337 Safety Sheet 1561546 1

333,334, and 335 Instruction Card

336 and 337 Instruction Card

Calibration Manual 1618765 1

1611439

1611442

1611456

1611474

1611488

1611597

1611611

1611627

1549865

1549876

adc08f.eps

1

1

1

1

1

1

1

1

1

1

Figure 8. User-Replaceable Parts and Accessories

15

Page 18

33x

Calibration Information

LIMITED WARRANTY AND LIMITATION OF LIABILITY

This Fluke product is warranted to be free from defects in material and workmanship under normal use and service. The warranty period is

three years and begins on the date of shipment. Parts, product repairs, and services are warranted for 90 days. This warranty extends only

to the original buyer or end-user customer of a Fluke authorized reseller, and does not apply to fuses, disposable batteries, or to any

product which, in Fluke's opinion, has been misused, altered, neglected, contaminated, or damaged by accident or abnormal conditions of

operation or handling. Fluke warrants that software will operate substantially in accordance with its functional specifications for 90 days

and that it has been properly recorded on non-defective media. Fluke does not warrant that software will be error free or operate without

interruption.

Fluke authorized resellers shall extend this warranty on new and unused products to end-user customers only but have no authority to

extend a greater or different warranty on behalf of Fluke. Warranty support is available only if product is purchased through a Fluke

authorized sales outlet or Buyer has paid the applicable international price. Fluke reserves the right to invoice Buyer for importation costs

of repair/replacement parts when product purchased in one country is submitted for repair in another country.

Fluke's warranty obligation is limited, at Fluke's option, to refund of the purchase price, free of charge repair, or replacement of a defective

product which is returned to a Fluke authorized service center within the warranty period.

To obtain warranty service, contact your nearest Fluke authorized service center to obtain return authorization information, then send the

product to that service center, with a description of the difficulty, postage and insurance prepaid (FOB Destination). Fluke assumes no risk

for damage in transit. Following warranty repair, the product will be returned to Buyer, transportation prepaid (FOB Destination). If Fluke

determines that failure was caused by neglect, misuse, contamination, alteration, accident, or abnormal condition of operation or handling,

including overvoltage failures caused by use outside the product’s specified rating, or normal wear and tear of mechanical components,

Fluke will provide an estimate of repair costs and obtain authorization before commencing the work. Following repair, the product will be

returned to the Buyer transportation prepaid and the Buyer will be billed for the repair and return transportation charges (FOB Shipping

Point).

THIS WARRANTY IS BUYER'S SOLE AND EXCLUSIVE REMEDY AND IS IN LIEU OF ALL OTHER WARRANTIES, EXPRESS OR

IMPLIED, INCLUDING BUT NOT LIMITED TO ANY IMPLIED WARRANTY OF MERCHANTABILITY OR FITNESS FOR A PARTICULAR

PURPOSE. FLUKE SHALL NOT BE LIABLE FOR ANY SPECIAL, INDIRECT, INCIDENTAL OR CONSEQUENTIAL DAMAGES OR

LOSSES, INCLUDING LOSS OF DATA, ARISING FROM ANY CAUSE OR THEORY.

Since some countries or states do not allow limitation of the term of an implied warranty, or exclusion or limitation of incidental or

consequential damages, the limitations and exclusions of this warranty may not apply to every buyer. If any provision of this Warranty is

held invalid or unenforceable by a court or other decision-maker of competent jurisdiction, such holding will not affect the validity or

enforceability of any other provision.

Fluke Corporation

P.O. Box 9090

Everett, WA 98206-9090

U.S.A.

Fluke Europe B.V.

P.O. Box 1186

5602 BD Eindhoven

The Netherlands

11/99

To register this product, go to register.fluke.com

16

Loading...

Loading...