187/189

®

True RMS Multimeter

Calibration Manual

PN 1584337

November 2000 Rev.1, 6/02

© 2000-2002 Fluke Corporation. All rights reserved. Printed in U.S.A.

All product names are trademarks of their respective companies.

LIFETIME L IMITED WARRANTY

Each Fluke 20, 70, 80, 170 and 180 Series DMM will be free from defec t s in material and workmanship for its lifetime. As

used herein, “lifetime” is defined as seven years after Fluke discontinues m anuf acturing the product, but the warranty period

shall be at least ten years from the date of purchase. Thi s warranty does not cover fuses, disposable batteri es, damage

from neglect, misus e, contamination, alteration, accident or abnormal condi tions of operation or handling, inc l udi ng failures

caused by use outside of the product’s specifi cations, or normal wear and tear of mechanical components. This warranty

covers the original purchas er onl y and i s not transferable.

For ten years from the date of purchase, this warranty als o covers the LCD. Thereafter, f or the lifetime of the DMM, Fluke

will replace the LCD for a fee based on then current c omponent acquisition costs.

To establish original ownership and prove date of purchase, please complete and return the registration card

accompanying the product, or register your product on http://www.fluke.com. Fluke will, at its option, repair at no charge,

replace or refund the purchase price of a defective product purchas ed t hrough a Fl uke authorized sales outlet and at the

applicable international pric e. Fl uke reserves the right to c harge for importation costs of repai r/replacement parts if t he

product purchased in one country i s sent for repair elsewhere.

If the product is defective, contact your nearest Fluke authorized service center to obtain return aut hori zation information,

then send the product to that service center, with a description of the diffi culty, postage and insurance prepaid (FOB

Destination). Fluke assumes no ris k for damage in transit. Fluke will pay return transportation for product repaired or

replaced in-warranty. Before making any non-warrant y repair, Fluke will estimate cost and obtain authorization, then

invoice you for repair and return transportation.

THIS WARRANTY IS Y O UR ONLY REMEDY. NO OTHER WARRANT IES, SUCH AS FIT NESS FOR A PARTICULAR

PURPOSE, ARE EXPRESSED OR IMPLIED. FLUKE SHALL NOT BE LIABLE FOR ANY SPECIAL, INDIRECT,

INCIDENTAL OR CONSEQUENTIAL DAMAGES OR LOSSES, INCLUDING LOSS OF DATA, ARISING FROM ANY

CAUSE OR THEORY. AUTHORIZED RESELLERS ARE NOT AUTHORIZED TO EXTEND ANY DIFFERENT

WARRANTY ON FLUKE’S BEHA LF. Since some states do not allow the exclusion or li m i t ation of an implied warranty or

of incidental or consequential damages, this limitation of liability may not apply to you. I f any provision of this warranty is

held invalid or unenforceable by a court or other decis ion-maker of competent jurisdiction, such holding will not affect the

validity or enforceability of any other provision.

2/02

Fluke Corporation Fluke Europe B.V.

P.O. Box 9090 P.O. Box 1186

Everett, WA 98206-9090 5602 BD Eindhoven

U.S.A. The Netherlands

Table of Contents

Title Page

Introduction....................................................................................................... 1

Contacting Fluke ............................................................................................... 1

Precautions and Safety Information.................................................................. 2

International Symbols........................................................................................ 2

Safety Information............................................................................................. 3

Specifications .................................................................................................... 4

Accuracy ....................................................................................................... 4

Feature Summary.......................................................................................... 4

Basic Specifications .......................................................................................... 5

Detailed Accuracy Specifications ..................................................................... 6

Frequency Counter Sensitivity.......................................................................... 9

Burden Voltage (A, mA, µA)............................................................................ 9

Input Characteristics.......................................................................................... 9

Required Equipment.......................................................................................... 10

Basic Maintenance ............................................................................................ 11

Opening the Meter Case................................................................................ 11

Removing and Reinserting the Circuit Board Assembly.............................. 11

Replacing the LCD........................................................................................ 12

Reassembling the Meter Case....................................................................... 13

Testing Fuses (F1 and F2)............................................................................. 13

Replacing Fuses ............................................................................................ 14

Replacing the Batteries................................................................................. 14

Cleaning........................................................................................................ 15

Performance Tests............................................................................................. 16

Testing the Display ....................................................................................... 16

Backlight Test............................................................................................... 16

Current Terminal Sensing Test..................................................................... 16

Keypad Test .................................................................................................. 17

Verification of the IR Communication Port.................................................. 17

Testing Temperature..................................................................................... 17

Testing Voltage, Current, Resistance, Capacitance and Diode Functions.... 18

Calibration......................................................................................................... 21

Keypad Interface........................................................................................... 21

General Procedure......................................................................................... 22

Special Requirements.................................................................................... 23

Calibration Inputs.......................................................................................... 23

i

187/189

Calibration Manual

Remote Interface........................................................................................... 25

Temperature Calibration............................................................................... 25

Setup......................................................................................................... 25

Procedure.................................................................................................. 26

Re-Programming Serial Number or Model Number..................................... 26

Parts and Accessories........................................................................................ 27

ii

List of Tables

Table Title Page

1. International Symbols............................................................................................ 2

2. Required Tools and Equipment............................................................................. 10

3. Temperature Test Input and Display..................................................................... 17

4. Performance Test Steps ......................................................................................... 18

5. Calibration Inputs .................................................................................................. 23

iii

187/189

Calibration Manual

iv

List of Figures

Figure Title Page

1. Removing LCD Mask to Access LCD................................................................... 12

2. Testing the Current Fuses...................................................................................... 14

3. Battery and Fuse Replacement .............................................................................. 15

4. Display Test........................................................................................................... 16

5. Locating Recessed Calibration Button.................................................................. 21

6. Calibration Display................................................................................................ 22

7. Replacement Parts and Accessories....................................................................... 28

v

187/189

Calibration Manual

vi

Introduction

To avoid shock or injury, do not perform the verificati on t est s

or calibration procedures described in this manual unless you

are qualified to do so.

The information provided in this document is for the use of

qualified personnel only.

The 187 & 189 Multimeters contain parts t hat can be damaged

by static discharge.

Follow the standard practices for handling static sensitive

devices.

The information in this manual deals with the Fluke Models 187 & 189 True RMS

Multimeters, (hereafter referred to as “the meter”). Information provided includes:

• Precautions and safety information

• Specifications

• Basic maintenance (cleaning, replacing the battery and fuses)

• Performance test procedures

• Calibration and calibration adjustment procedures

• Accessories and replaceable parts

W Warning

Caution

For complete operating instructions, refer to the Model 187 & 189 Users Manual located

on the 187/189 CD ROM.

Contacting Fluke

To order accessories, receive assistance, or locate the nearest Fluke distributor or Service

Center, call:

USA: 1-888-99-FLUKE (1-888-993-5853)

Canada: 1-800-36-FLUKE (1-800-363-5853)

Europe: +31 402-678-200

Japan: +81-3-3434-0181

Singapore: +65-738-5655

Anywhere in the world: +1-425-446-5500

Address correspondence to:

Fluke Corporation Fluke Europe B.V.

P.O. Box 9090, P.O. Box 1186,

Everett, WA 98206-9090 5602 BD Eindhoven

USA The Netherlands

Visit us on the World Wide Web at: www.fluke.com

1

187/189

Calibration Manual

Precautions and Safety Information

International Symbols

WWarning

If this product is used in a manner not specif ied by the

manufacturer, the protection provided by the equipment may

be impaired.

Read the “Safety Information” page before servicing this product.

In this manual, a Warning identifies conditions and actions that pose hazard(s) to the

user; a Caution identifies conditions and actions that may damage the Meter or the test

instruments.

International symbols used on the Meter and in this manual are explained in Table 1.

Table 1. International Symbols

Symbol Meaning Symbol Meaning

Alternating current Earth ground

Direct current

Alternating or direct current Conforms to European Union

Refer to the manual. Important

information.

Inspected and licensed by TÜV

Product Services.

Battery

Conforms to VDE Standards

Fuse

directives

Conforms to relevant Canadian

Standards Association directives

Double insulated

Underwriters Laboratories, Inc.

2

Safety Information

WWarnings and Precautions

To avoid possible electric shock or personal injury, follow these guidelines:

Do not use the Meter if it is damaged. Before you use the Meter, inspect the case.

•

Look for cracks or missing plastic. Pay particular attention to the insulation

surrounding the connectors.

Inspect the test leads for damaged insulation or exposed metal. Check the test

•

leads for continuity. Replace damaged test leads before you use the Meter.

Do not use the Meter if it operates abnormally. Protection may be impaired. When

•

in doubt, have the Meter serviced.

Do not operate the Meter around explosive gas, vapor, or dust.

•

Do not apply more than the rated voltage, as marked on the Meter, between

•

terminals or between any terminal and earth ground.

Before use, verify the Meter’s operation by measuring a known voltage.

•

When measuring current, turn off circuit power before connecting the Meter in the

•

circuit. Remember to place the Meter in series with the circuit.

True RMS Multimeter

Safety Information

When servicing the Meter, use only specified replacement parts.

•

Use caution when working above 30 V ac rms, 42 V peak, or 60 V dc. Such

•

voltages pose a shock hazard.

Avoid working alone.

•

When using the probes, keep your fingers behind the finger guards on the probes.

•

Connect the common test lead before you connect the live test lead. When you

•

disconnect test leads, disconnect the live test lead first.

Remove test leads from the Meter before you open the battery door.

•

Do not operate the Meter with the battery door or portions of the cover removed or

•

loosened.

To avoid false readings, which could lead to possible electric shock or personal

•

injury, replace the batteries as soon as the low battery indicator (M) appears.

Use only type AA batteries, properly installed in the Meter case, to power the

•

Meter.

Caution

To avoid possible damage to the Meter or to the equipment under test, follow these

guidelines:

• Disconnect circuit power and discharge all high-voltage capacitors before testing

resistance, continuity, diodes, or capacitance.

• Use the proper terminals, function, and range for your measurements.

• Before measuring current, check the Meter's fuses and turn power OFF to the

circuit before connecting the Meter to the circuit.

3

187/189

Calibration Manual

Specifications

Accuracy

Feature Summary

Dual Digital Displays

Analog Bar Graph

Backlight with 2 brightness levels Bright white backlight for clear readings in poorly lighted areas

Fast Autorange Meter automatically selects best range - instantly

AC+DC true rms, ac rms specified

to 100 kHz

dBm, dBV User selectable impedance references for dBm

AutoHOLD Holds readings on display

Continuity / Open test Beeper sounds for resistance readings below threshold, or to

Fast Bar Graph 51 segments for peaking and nulling

Duty cycle / Pulse width Measure signal on or off time in % or milliseconds

MIN MAX Mode

FAST MN MX with 24-hour time

stamp

Closed-Case Calibration No internal adjustments needed

Battery / Fuse Access Door Battery or fuse replaceable without voiding calibration

Hi-Impact Overmolded Case Protective holster features

Accuracy is specified for a period of one year after calibration, at 18 °C to 28 °C (64 °F

to 82 °F), with relative humidity to 90 %. Accuracy specifications are given as:

± ( [ % of reading ] + [ number of least significant digits ] )

AC mV, AC V, AC µA, AC mA, and AC A specifications are ac-coupled, true rms and are

valid from 5 % of range to 100 % of range. AC crest factor can be up to 3.0 at full-scale, 6.0

at half-scale, except the 3000 mV and 1000 V ranges where it is 1.5 at full scale, 3.0 at halfscale.

Feature Description

Primary: 50,000 counts

Secondary: 5,000 count

Bar graph: 51 segments, updates 40 times/second

Choices for AC only, AC and DC dual display, or AC+DC

readings

indicate a momentary open circuit

Record maximum, minimum, and average values.

24-hour clock for MAX or MIN, elapsed time for AVG.

FAST MN MX captures peaks to 250 µsec.

4

Basic Specifications

Function Ranges/Description

DC Voltage 0 to 1000 V

AC Voltage, true RMS 2.5 mV to 1000 V – 100 kHz bandwidth

Basic Accuracy DC voltage: 0.025 %

AC voltage: 0.4 %

DC Current 0 to 10 A (20 A for 30 seconds)

AC Current, true RMS 25 µA to 10 A (20 A for 30 seconds)

Resistance 0 to 500 MΩ

Conductance 0 to 500 nS

Capacitance 0.001 nF to 50 mF

Diode Test 3.1 V

Temperature −200 °C to 1350 °C (−328 °F to 2462 °F)

Frequency 0.5 Hz to 1000 kHz

LOGGING Intervals

(Model 189 only)

SAVE Readings

(Model 189 only)

At least 288 intervals may be stored. Up to 700 unstable event values (see

AutoHold) are automatically added to LOGGING memory for viewing only

through optional PC software. Additional intervals will be logged up to 995 if

the signal is stable.

Up to 100 readings may be saved by the user in a memory separate from

LOGGING memory. These readings may be viewed using VIEW MEM.

True RMS Multimeter

Basic Specifications

5

187/189

Calibration Manual

Detailed Accuracy Specifications

Function Range Resolution

AC mV

AC V

dBV −52 to −6 0.01 dB 0.1 dB 0.2 dB 0.5 dB 0.5 dB 1.4 dB

1. For the 5,000 count mode, div i de the number of least signifi cant digits (counts) by 10.

2. A residual reading of 8 to 180 digits with leads shorted, will not affect st at ed accuracy above 5 % of range.

Accuracy is specified for a period of one year after calibration, at 18 °C to 28 °C (64 °F

to 82 °F), with relative humidity to 90 %. Accuracy specifications are given as:

± ( [ % of reading ] + [ number of least significant digits ] )

AC mV, AC V, AC µA, AC mA, and AC A specifications are ac coupled, true rms and

are valid from 5 % of range to

100 % of range. AC crest factor can be up to 3.0 at full-scale, 6.0 at half-scale except the

3000 mV and 1000 V ranges where it is 1.5 at full scale, 3.0 at half-scale.

Accuracy

45 Hz-

1 kHz

1, 2

50.000 mV 0.001 mV 0.4 % + 40 2 % + 80 5 % + 40 5.5 % + 40 15 % + 40

500.00 mV 0.01 mV 0.4 % + 40 2 % + 80 5 % + 40 5.5 % + 40 8 % + 40

3000.0 mV 0.1 mV 0.4 % + 40 2 % + 80 0.4 % + 40 1.5 % + 40 8 % + 40

1, 2

5.0000 V 0.0001 V 0.4 % + 40 2 % + 80 0.4 % + 40 1.5 % + 40 8 % + 40

50.000 V 0.001 V 0.4 % + 40 2 % + 80 0.4 % + 40 1.5 % + 40 8 % + 40

500.00 V 0.01 V 0.4 % + 40 2 % + 80 0.4 % + 40 Not

1000.0 V 0.1 V 0.4 % + 40 2 % + 80 0.4 % + 40 Not

−6 to +34 0.01 dB 0.1 dB 0.2 dB 0.1 dB 0.2 dB 0.8 dB

+34 to +60 0.01 dB 0.1 dB 0.2 dB 0.1 dB Not

20 Hz-

45 Hz

1 kHz-

10 kHz

10 kHz-

20 kHz

specified

specified

specified

20 kHz-

100 kHz

Not

specified

Not

specified

Not

specified

Accuracy

45 Hz-

Function Range Resolution

AC µA 500.00 µA 0.01 µA 0.75 % + 20 1 % + 20 0.75 % + 20 6 % + 40

5,000.0 µA0.1 µA 0.75 % + 5 1% + 5 0.75 % + 10 2 % + 40

AC mA 50.000 mA 0.001 mA 0.75 % + 20 1% + 20 0.75 % + 20 9 % + 40

400.00 mA 0.01 mA 0.75 % + 5 1% + 5 1.5 % + 10 4 % + 40

AC A 5.0000 A 0.0001 A 1.5 % + 20 1.5% + 20 6 % + 40 Not specified

10.000 A

1. 10 A continuous up to 35 °C, l ess than 10 minutes 35 °C to 55 °C. 20 A overl oad for 30 seconds maximum.

1

0.001 A 1.5 % + 5 1.5% + 5 5 % + 10 Not specified

1 kHz

20 Hz-

45 Hz

1 kHz-

20 kHz

20 kHz-

100 kHz

6

True RMS Multimeter

Detailed Accuracy Specifications

Accuracy Accuracy Dual Display AC or AC+DC

20 Hz-

Function Range Resolution DC

DC mV 50.000 mV 0.001 mV 0.1% + 20 6 % + 40

45 Hz

2 % + 80 0.5 % + 40

45 Hz -

1 kHz

1 kHz-

20 kHz

500.00 mV 0.01 mV 0.03 % + 2

3000.0 mV 0.1 mV 0.025 % + 5 2 % + 40

DC V 5.0000 V 0.0001 V 0.025 % + 10

50.000 V 0.001 V 0.03 % + 3

500.00 V 0.01 V 0.1 % + 2

1000.0 V 0.1 V 0.1 % + 2

2

2

2

2

Not specified

Not specified

DC µA 500.00 µA 0.01 µA 0.25 % + 20 1 % + 20 1.0 % + 20 2 % + 40

5,000 µA0.1 µA 0.25 % + 2 1 % + 10 0.75 % + 10 2 % + 40

DC mA 50.000 mA 0.001 mA 0.15 % + 10 1 % + 20 0.75 % + 20 2 % + 40

400.00 mA 0.01 mA 0.15 % + 2 1 % + 10 1 % + 10 3 % + 40

DC A 5.0000 A 0.0001 A 0.5 %+ 10 2 % + 20 2 % + 20 6 % + 40

10.000 A

1. 10 A continuous up to 35 °C, l ess than 10 minutes 35 °C to 55 °C. 20 A overload for 30 seconds maximum.

2. 20 counts in dual display DC or AC+DC.

3. See AC conversions not es for AC mV and V

1

0.001 A 0.5 %+ 2 1.5 % + 10 1.5 % + 10 5 % + 10

3

Function Range Resolution Accuracy

Resistance

1

500.00 Ω 0.01 Ω 0.05 % + 10

3

5.0000 kΩ 0.0001 kΩ 0.05 % + 2

50.000 kΩ 0.001 kΩ 0.05 % + 2

500.00 kΩ 0.01 kΩ 0.05 % + 2

5.0000 MΩ 0.0001 MΩ 0.15 % + 4

30.000 MΩ 0.001 MΩ 1 % + 4

100.0 MΩ 0.1 MΩ 3 % + 2

500.0 MΩ 0.1 MΩ 10 % + 2

2

2

4

4

Conductance 50.00 nS 0.01 nS 1 % + 10

1. For the 5,000 count mode, div i de the number of least signifi cant digits (counts) by 10.

2. For relative humidity great er than 70 %, resistance ac curacy is 0.5 % over 1 MΩ and 2.5 % over 10 MΩ.

3. Using relative mode (REL ∆) to zero residual reading.

4. To ensure stated accurac y, switch to conductance mode and verify that the open circuit reading is les s than

0.10 nS.

7

187/189

Calibration Manual

Capacitance

Diode Test

1. For the 5,000 count mode, div i de the number of least signifi cant digits (counts) by 10.

2. For film capacitor or bet ter, using Relative mode (REL ∆) to zero residual on 1.000 nF and 10.00 nF ranges.

3. Least significant digit not active abov e 10 m F .

Function Ranges Resolution Accuracy

2

1.000 nF 0.001 nF 2% + 5

10.00 nF 0.01 nF 1 % + 5

100.0 nF 0.1 nF

1.000 µF 0.001 µF

10.00 µF 0.01 µF

100.0 µF 0.1 µF

1,000 µF 1 µF

10.0 mF 0.01 mF

50.00 mF 0.01 mF

1

3.1000 V 0.0001 V 2 % + 20

3

3 % + 10

Function Range Resolution Accuracy

Frequency 500.00 Hz 0.01 Hz

1

± (0.0050 % + 1)

5.0000 kHz 0.0001 kHz

50.000 kHz 0.001 kHz

999.99 kHz 0.01 kHz

Duty Cycle 10.00% to 90.00 % 0.01 % ± ((voltage range/input voltage) X 300

counts)

Pulse Width 499.99 ms 0.01 ms ± (3 % X (voltage range/input voltage) + 1

count)

5,6

5,6

999.9 ms 0.1 ms

Temperature −200 to +1350 °C0.1 °C ± ( 1% of reading + 1 °C)

−328 to +2462 °F0.1 °F ± ( 1% of reading + 1.8 °F)

MIN MAX

AVG

Response: 100 ms to 80 % Specified accuracy ± 12 counts for

changes > 200 ms in duration. (± 40

2,3

2,3

counts in AC for changes > 350 ms and

inputs > 25 % of range)

FAST MN MX 250 µs

4

Specified accuracy ±100 counts up to

5,000 count (full range) reading. For higher

peak readings (to 20,000 counts),

specified accuracy ± 2% of reading.

1. Reading will be 0.00 for signals below 0.5 Hz.

2. Accuracy spec i fication is relativ e t o the user-adjustable temperature of fset, and assumes ambi ent temperature

stable to ± 1 °C.

3. For ambient temperature changes of ± 5 °C, rated accuracy appl i es after 1 hour.

4. For repetitive peaks; 2.5 ms for single events . Use DC function settings below 20 Hz. 50 mV range not speci f i ed.

5. Frequency greater than 5 Hz, ex cept for VDC, 500 mVDC and 3000 mVDC functions; 0.5 Hz to 1 k Hz . Signals

centered around trigger levels.

6. Range/input ratios also appl y to current functions. 500 counts or 5 % for 10 A ranges.

8

Frequency Counter Sensitivity

Frequency Counter Sensitivity

Approximate VAC

Sensitivity (RMS Sine

Input

Range

15 Hz -

100 kHz

50 mV 5 mV 10 mV 1 MHz -5 mV & 5 mV 1 MHz

500 mV 20 mV 20 mV 1 MHz 5 mV & 65 mV 1 MHz

3000 mV 500 mV 2000 mV 800 kHz 140 mV & 200 mV 90 kHz

5 V 0.5 V 2.0 V 950 kHz 1.4 V & 2.0 V 14 kHz

50 V 5 V 5.0 V 1 MHz 0.5 V & 6.5 V > 400 kHz

500 V 20 V 20 V 1 MHz 5 V & 65 V > 400 kHz

1000 V 100 V 100 V > 400 kHz 5 V & 65 V > 400 kHz

1. Maximum input = 10 x Range (1000 V m ax). Noise at low frequencies and am pl i tudes may affect ac curacy.

2. Useable at reduced sensiti vity to 0.5 Hz and 1000 kHz.

3. Typical frequency bandwidt h wi t h full scale (or maximum 2 X 10

Wave)

2

1

500 kHz

2

VAC

Bandwidth

Approximate

3

VDC Trigger

Levels

7

V-Hz product) RMS sine wave.

1

VDC Bandwidth

True RMS Multimeter

3

Burden Voltage (A, mA, µA)

Function Range Burden Voltage (typical)

mA - µA 500.00 µA

102 µV / µA

5,000 µA 102 µV / µA

50.000 mA 1.8 mV / mA

400.00 mA 1.8 mV / mA

A 5.0000 A 0.04 V / A

10.000 A 0.04 V / A

Input Characterist ics

Function Input Impedance (Nominal)

Volts, mV 10 MΩ, < 100 pF

Common Mode Rejection Ratio Normal Mode Rejection

DC Volts, mV >100 dB at dc, 50 Hz or 60 Hz ±0.1% >90 dB at 50 Hz or 60 Hz ± 0.1%

AC Volts, mV > 90 dB dc to 60 Hz

Full-Scale Voltage

Open Circuit Test Voltage To 5 MΩ 30 MΩ + nS

Ohms < 5 V 500 mV 3.1 V

Diode Test < 5 V 3.1000 V

Typical Short-Circuit Current

500 Ω 5 kΩ 50 kΩ 500 kΩ 5 MΩ 30 MΩ

Ohms 1 mA 100 µA 10 µA 1 µA 0.1 µA 0.1 µA

Diode Test 1 mA typical

9

187/189

Calibration Manual

Required Equipment

Required equipment is listed in Table 2. If the recommended models are not available,

equipment with equivalent specifications may be used.

Repairs or servicing should be performed only by qualified personnel.

Table 2. Required Equipment

Equipment Required Characteristics

Calibrator AC Voltage Range: 0-1000 Vac

Accuracy: + 0. 1 %

Frequency Range: 20 Hz – 100 kHz

Accuracy: +3 %

DC Voltage Range: 0-1000 Vdc

Accuracy: + 0.006 %

Current Range: 0-10A

Accuracy: AC mA - +0.18 %

AC A - + 0.38 %

Frequency range: 1 kHz – 20 kHz

DC mA - + 0.06 %

DC A - + 0.125 %

Frequency Source: 500 Hz-20 kHz

Accuracy: + 0.00125 %

Amplitude: 1 Volt

Accuracy: + 5 %

Ohms Range: 0 Ω - 50 MΩ

Accuracy: + 0.0125 %

Recommended

Model

Fluke 5520A

10

Capacitance Range: 110.0 nF & 11.00

µF

Accuracy: +0. 25%

Temperature Range: -10 to 350 °C

Accuracy: 0.3 %

Thermocouple Adapter

Accessory

K-type Thermocouple K-type, mini-plug on both ends N/A

Serial Cable, Infrared/W IR

Cable Adapter

87/89-IV, 187/189

Service Software

K-type Fluke 80AK

Fluke P/N 1590638

Fluke P/N 676152

Basic Maintenance

To avoid electrical shock or personal injury, remove the t est

leads and any input signals before opening the case or

replacing the battery or fuses. To prevent damage or injury,

install ONLY batteries or fuses specifi ed f or t hi s product.

Opening the Meter Case

To avoid unintended circuit shorting, always place the

uncovered Meter assembly on a protective surface. When the

case of the Meter is open, circuit connect ions are exposed.

To open the Meter case, do the following:

True RMS Multimeter

Basic Maintenance

WWarning

Caution

1. Disconnect test leads from any live source, turn the rotary switch to

remove the test leads from the front terminals.

2. Remove the battery door by using a flat-blade screwdriver to turn the battery door

fasteners 1/4-turn counterclockwise.

3. The case bottom is secured to the case top by four screws, one at each corner.

Remove the screws with a Phillips-head screwdriver.

4. Pull the two halves of the case apart.

Removing and Reinserting the Circuit Board Assembl y

The circuit board assembly must be removed to access and replace the LCD.

Caution

The circuit board is extremely susceptible to contamination.

Handle it by the input receptacle, fuse clips or edges of the

board only. You can use clean surgical gloves to help avoi d

contamination.

1. Open the Meter case and remove the case bottom to access the circuit board.

2. Remove the two Phillips-head screws securing the circuit board to the case top and

lift it out carefully to avoid contamination.

3. To reinsert the circuit board, simply place it into the case top with the LCD display

showing through the window.

OFF, and

4. Carefully replace the two Phillips-head screws that connect the circuit board to the

case top.

Caution

Do not over-torque the two Phillips-head screws when you

reconnect the circuit board to the case top. Doi ng so may

create shielding problems and cause the Meter to give incorrect

readings.

11

187/189

Calibration Manual

Replacing the LCD

If you need to replace the LCD, you will find it easier to leave the LCD assembly

attached to the circuit board and access the LCD by removing the LCD mask from the

front of the LCD assembly.

1. Remove the circuit board as described under “Removing and Reinserting the Circuit

Board Assembly.”

2. Carefully insert the tip of a thin screwdriver under the LCD mask at the top of the

display as shown in Figure 1.

LCD Mask

LCD

Figure 1. Removing LCD Mask to Access LCD

aau05f.eps

3. Lift up the LCD mask gently with the screwdriver blade to loosen the mask from the

assembly. Be careful to press upward, not inward toward the LCD. By hand, tilt the

LCD mask upward to release.

4. Replace the LCD. The LCD must be centered on the platform between the brackets

before you replace the LCD mask. If the LCD is improperly aligned, the display may

show missing segments or meaningless readings.

5. Reattach the LCD mask by pressing it over the LCD until it snaps into place.

12

Reassembling the Meter Case

To reassemble the Meter case, do the following:

True RMS Multimeter

Basic Maintenance

1. Verify that the rotary switch is in the

2. Reinsert the circuit board by placing it into the case top with the LCD showing

through the window. Carefully replace the two Phillips-head screws that connect the

circuit board to the case top.

Do not over-torque the two Phillips-head screws when you

reconnect the circuit board to the case top. Doi ng so may

create shielding problems and cause the Meter to give incorrect

readings.

3. Hold the Meter face down and place the case bottom on the case top. Make sure the

backlight cable located on the back of the LCD assembly is not caught between the

case halves.

4. Reinstall the four screws and the battery door.

5. Secure the battery door by turning the fasteners 1/4-turn clockwise.

6. Go to the “Performance Test” section in this document, and perform the procedures

described.

Testing Fuses (F1 and F2)

Before measuring current, test the appropriate fuse as shown in Figure 2. If the tests give

readings other than those shown, have the Meter serviced.

OFF position.

Caution

WWarning

To avoid electrical shock or personal injury, remove the t est

leads and any input signals before replacing the battery or

fuses. To prevent damage or injury, install ONLY specified

replacement fuses with the amperage, volt age, and speed

ratings shown in the specifications.

13

187/189

Calibration Manual

Replace F2 if " or "

displayed

Replacing Fuses

To avoid electrical shock, remove the test leads and any input

signals before replacing the battery or fuses. To prevent damage or

injury, INSTALL ONLY specified fuses and bat t eri es.

Replace F1 if " or "

displayed

189

LOGGING MULTIMETER

AutoHOLD

HOLD

FAST MN MX

MIN MAX

LOGGING

REL

CANCEL

Hz

%

SETUP

nS

ac+dc

mV

ac+dc

V

dB

mV

dB

V

OFF

A

mA

10A MAX

A

FUSED

400mA

FUSED

A

ac+dc

ac+dc

VIEW

CLEAR MEM

TEMPERATURE

COM

V

CAT

1000V

YES

ms

SAVE

RANGE

NO

F

C

A

mA

A

A

mA

ac+dc

A

mA

OFF

A

mA

10A MAX

A

FUSED

400mA

FUSED

AutoHOLD

HOLD

CANCEL

Hz

%

SETUP

nS

ac+dc

mV

ac+dc

V

dB

mV

dB

V

A

ac+dc

ac+dc

VIEW

CLEAR MEM

TEMPERATURE

COM

V

CAT

1000V

189

LOGGING MULTIMETER

FAST MN MX

MIN MAX

LOGGING

REL

YES

ms

SAVE

RANGE

NO

F

C

A

mA

A

A

mA

ac+dc

A

mA

ach038f.eps

Figure 2. Testing the Current Fuses

WWarning

To replace the fuses, refer to Figure 3 and do the following:

1. Turn the rotary switch to

2. Remove the battery access door by using a standard-blade screwdriver to turn the

battery door fasteners one-quarter turn counterclockwise.

3. Remove either fuse by gently prying one end loose, then lifting the fuse out of the

fuse contacts.

4. Install ONLY specified fuses.

5. Reinstall the battery door. Secure the door by turning the fasteners one-quarter turn

clockwise.

Replacing the Batteries

The Meter is powered by four AA batteries (NEDA 15A or IEC LR6).

Be sure to observe proper polarity when replacing batteries.

Incorrect battery polarity may seriously damage the Met er.

OFF and remove the test leads from the terminals

Caution

14

To replace the batteries, refer to Figure 3 and do the following:

True RMS Multimeter

Basic Maintenance

1. Turn the rotary switch to

OFF and remove the test leads from the terminals.

2. Remove the battery door by using a standard-blade screwdriver to the turn the

battery door fasteners one-quarter turn counterclockwise.

3. Replace the batteries, observing proper polarity. Replace the battery door and secure

it by turning the fasteners one-quarter turn clockwise.

Cleaning

Periodically wipe the case with a damp cloth and mild detergent. Do not use abrasives or

solvents.

Dirt or moisture in the input terminals can affect readings and can falsely activate the

Input Alert™ feature. Clean the terminals as follows:

1. Turn the Meter off and remove all test leads.

2. Shake out any dirt that may be in terminals.

3. Soak a new swab with alcohol. Clean each terminal with the swab.

F2

F1

tc037f.eps

Figure 3. Battery and Fuse Replacement

WWarning

To avoid electrical shock or damage to the Meter, never all ow

water inside the case. To avoid damaging the housing, never

apply solvents to the Meter.

15

187/189

Calibration Manual

Performance Tests

Testing the Display

The following performance tests will ensure that the Meter is in proper operating

condition and will check the accuracy of each meter function against its specifications.

To perform the tests you will need a Fluke 5520A Calibrator or equipment meeting the

minimum specification given in Table 1.

If the Meter fails any of these tests, it needs calibration adjustment or repair.

Push down the Q button and simultaneously turn the Meter on. Compare the display

with the example in Figure 4. Check all segments for clarity and contrast.

Backlight Test

To test the backlight, press the T button twice. Note that the backlight comes on at two

different intensity levels.

Current Terminal Sensing Test

This test determines whether or not the Input Alert™ beeper is functioning properly.

Before conducting this test, make sure the beeper is not disabled in setup.

1. Turn the rotary switch to the AC V function. Press the backlight button twice to turn

the backlight to the highest intensity.

2. Turn the rotary switch to all functions, except current functions. Note that the beeper

does not come on.

3. Turn the rotary switch to the DC mA position. Insert a test lead into the mA

terminal. Note that the beeper does not emit a continuous chirp.

As the test lead is inserted, the Meter may produce a single chirp. This is

acceptable.

Figure 4. Display Test

aau02f.eps

Note

Note

16

Keypad Test

To test the keypad, turn the Meter to AC V and push each button separately. Each button

push should cause the Meter to beep.

True RMS Multimeter

Performance Tests

Reset the Meter by turning it

Off, and then back On.

Verification of the IR Communication Port

Note

If you are using MET/CAL to do performance testing, it is not necessary to

perform this verification test.

1. Connect the Infrared Serial Cable to the com port of a PC.

2. Connect the Infrared Serial Cable to the IR Cable Adapter and insert into the

187/189 accessory mount so that it is flush with the IR adapter window. Turn the

Meter rotary switch to DC V.

3. Install Fluke 87/89-IV, 187/189 Service Software, P/N 676152.

4. Apply 1 V dc to the VeG terminal.

5. The display reading should appear in text box of PC.

Note

If the PC indicates that the Meter is not connected, ensure that the com

port is correct and that the IR Serial Cable and adapter is aligned with the

IR window.

Testing Temperature

Connect K-type thermocouple and Fluke 80Ak to the temperature input on the Meter.

Connect the other end to the 5520A TC output. Allow connections to stabilize for 30

seconds before proceeding.

1. Turn the rotary switch to the temperature function.

2. Set the 5520A for K-type thermocouple and an output of 23 °C.

3. Enter the Meter Setup mode (press yellow button, then backlight button).

4. Adjust the temperature offset until the temperature on the Meter primary display

matches the 5520A output temperature (23 °C). Use the blue shift button and

backlight button to advance digit. Use the up and down arrow keys to edit digit.

5. Enter an offset value by pressing the yellow button, then the backlight button.

6. Exit Setup mode by pressing the yellow button, then the

CANCEL button.

7. Perform the steps in Table 3.

Table 3. Temperature Test Input and Display

Input

Lower Limit Upper Limit

-10.0 °C -11.1 °C -8.9 °C

0.0 °C -1.0 °C1.0 °C

350.0 °C 345.0 °C 355.0 °C

Display

17

187/189

Calibration Manual

Testing Voltage, Current, Resistance, Capacitance and Diode Functions

Step Function Range

1 AC V 5.0000 V 0.25 V 100 kHz 0.2260 0.2740

2 AC V 5.0000 V 5 V 20 kHz 4.9210 5.0790

3 AC V 5.0000 V 5 V 100 kHz 4.5960 5.4040

4 AC V 50.000 V 50 V 700 Hz 49.760 50.240

5 AC V 50.000 V 50 V 20 kHz 49.210 50.790

6 AC V 50.000 V 50 V 100 kHz 45.960 54.040

7 AC V 500.00 V 500 V 65 Hz 497.60 502.40

8 AC V 1000.0 V 500 V 65 Hz 494.0 506.0

9 AC mV 50.000 2.5 mV 100 kHz 2.085 2.915

10 AC mV 50.000 50 mV 20 kHz 47.210 52.790

11 AC mV 50.000 50 mV 100 kHz 42.460 57.540

12 AC mV 500.00 mV 500 mV 10 kHz 474.60 525.40

13 AC mV 3000.0 mV 3 V 20 kHz 2951.0 3049.0

14 AC mV 3000.0 mV 3 V 100 kHz 2756.0 3244.0

15 Frequency 50.000 kHz 1 V 20 kHz 19.998 20.002

16 Duty Cycle 3.0000 V 2.2 Vp-p,

17 DC V 5.0000 V short -0.0010 0.0010

18 DC V 5.0000 V 5 V 4.9977 5.0023

19 DC V 5.0000 V -5 V -4.9977 -5.0023

20 DC V 50.000 V -50 V -49.982 -50.018

21 DC V 500.00 V -500 V -499.48 -500.52

22 DC V 1000.0 V -500 V -499.3 -500.7

1. Do not rely on autoranging for all tests. Some test steps will require manual ranging.

2. Must allow for source and meter settling before recording reading.

3. Wait at least 60 seconds for source and meter to sett l e bef ore recording reading.

4. Using Relative Mode (REL) to z ero residual reading (apply 0 Ω and allow UUT to settle for 45 seconds before

To verify the accuracy of Meter functions, do the following.

1. Connect the Calibrator to the VeG and COM inputs on the Meter.

2. Turn the rotary switch to the function listed in each step.

3. Apply the input from the steps listed in Table 4.

4. Compare the reading on the Meter display with the display reading in Table 4.

5. If the display reading falls outside of the range shown in Table 4, the Meter does not

meet specification.

6. Repeat steps 2 through 4 for the remaining inputs shown in Table 4.

Table 4. Performance Test Steps

2

Upper

Limit

pushing REL).

Display

1

Input Level

@30%

Sq. wave

Frequency or

Model

500 Hz

Lower

Limit

21.82 38.18

18

True RMS Multimeter

Performance Tests

Table 4. Performance Test Steps (cont.)

Display

Step Function Range

1

Input Level Frequency

Lower

Limit

23 AC&DC 50.000 V 50 V 20 kHz 48.960 51.040

24 DC mV 50.000 0 mV

3

-0.020 +0.020

25 DC mV 50.000 50 mV 49.930 50.070

26 DC mV 50.000 -50 mV -49.930 -50.070

27 DC mV 500.00 mV 0 V -0.02 0.02

28 DC mV 500.00 mV 500 mV 499.83 500.17

29 DC mV 3000.0 mV +2 V 1999.0 2001.0

30 DC mV 3000.0 mV -3 V -2998.7 -3001.3

31 AC+DC 3000.0 mV 1 V 20 kHz 976.0 1024.0

Connect 5520A for 2 Wire Comp

32 Ohms 500.00 Ω 0 Ω

4

-0.10 0.10

33 Ohms 500.00 Ω 500 Ω 499.65 500.35

34 Ohms 5.0000 kΩ 5 kΩ 4.9973 5.0027

35 Ohms 50.000 kΩ 50 kΩ 49.973 50.027

36 Ohms 500.00 kΩ 500 kΩ 499.73 500.27

37 Ohms 5.0000 MΩ 5 MΩ 4.9921 5.0079

38 Ohms 30.000 MΩ 30 MΩ 29.696 30.304

39 Ohms 500.0 100 MΩ 89.8 110.2

Remove 2 Wire Comp

40 nS 50.00 nS open -0.10 +0.10

41 nS 50.00 nS 100 MΩ 9.80 10.20

Remove Test Leads from UUT

42 Capacitance 1.100 nF open <0.070

43 Capacitance 110.0 nF 0.1 uF 98.5 101.5

44 Capacitance 11.00 uF 5 uF 4.90 5.10

45 Diode Test 3.1000 V 1 kΩ 0.9000 1.1000

2

Upper

Limit

46 AC mA 50.000 mA 2.5 mA 1 kHz 2.461 2.539

47 AC mA 500.00 mA 329 mA 10 kHz 323.96 334.04

48 AC uA 500.00 uA 500 uA 1 kHz 496.05 503.95

1. Do not rely on autoranging for all tests. Some test steps will require manual ranging.

2. Must allow for source and meter settling before recording reading.

3. Wait at least 60 seconds for source and meter to sett l e bef ore recording reading.

4. Using Relative Mode (REL) to z ero residual reading (apply 0 Ω and allow UUT to settle for 45 seconds before

pushing REL).

19

187/189

Calibration Manual

Step Function Range

49 AC uA 5000.0 uA 1.5 mA 1 kHz 1488.2 1511.8

50 DC mA 50.000 mA 0 A -0.010 0.010

51 DC mA 50.000 mA 50 mA 49.915 50.085

52 DC mA 50.000 mA -50 mA -49.915 -50.085

53 DC mA 500.00 mA -329.00 mA -328.49 -329.51

54 DC uA 500.00 uA 500 uA 498.55 501.45

55 DC uA -500.00 uA -500 uA -498.55 -501.45

56 DC uA 5000 uA -5 mA -4987.3 -5012.7

57 DC uA 500.00 uA 0 A -0.2 0.2

58 AC A 5.0000 A 250 mA 1 kHz 0.2442 0.2558

Table 4. Performance Test Steps (cont.)

1

Input Level

Frequency or

Model

Lower

Limit

Display

2

Upper

Limit

59 AC A 5.0000 A 250 mA 20 kHz 0.2310 0.2690

60 DC A 5.0000 A 0 A -0.0010 0.0010

61 DC A 5.0000 A 5 A 4.9740 5.0260

62 DC A -5.0000 A -5 A -4.9740 -5.0260

63 DC A 10.000 A -6 A -5.968 -6.032

64 AC A 10.000 A 6 A 1 kHz 5.905 6.095

1. Do not rely on autoranging for all tests. Some test steps will require manual ranging.

2. Must allow for source and meter settling before recording reading.

3. Wait at least 60 seconds for source and meter to sett l e bef ore recording reading.

4. Using Relative Mode (REL) to z ero residual reading (apply 0 Ω and allow UUT to settle for 45 seconds before

pushing REL).

20

Calibration

Calibrate the Meter once a year to ensure that it performs to specifications.

Before you begin the calibration procedure, locate the recessed calibration button on the

back of the Meter, underneath the accessory mount. It is inside a small opening covered

by a seal. Carefully puncture the seal with a calibration tool to access the calibration

button. See Figure 5.

True RMS Multimeter

Calibration

Keypad Interface

To start the calibration procedure, turn the rotary switch to the DC mV position, then

press and hold the recessed calibration button on the back of the Meter for one second.

This places the Meter in calibration mode as shown on the display in Figure 6. The unit

will remain in the calibration mode until the rotary switch is moved to the

Calibration Button

aau04f.eps

Figure 5. Locating Recessed Calibration Button

OFF position.

21

187/189

Calibration Manual

Function indicator

UP button

moves to the

next step

Calibration step number Input signal required Calibration mode indicator

Figure 6. Calibration Display

Autoranging

is disabled

for calibration

aau01f.eps

General Procedure

A sequence of signal inputs is required for each function that must be calibrated. The

secondary display shows the required input next to the step number for that function.

The primary display shows the value being measured. The measurement is likely to be

slightly different from the applied signal, because it may be showing an uncalibrated

measurement. The general calibration procedure is as follows:

1. Move the rotary switch to the function that you are calibrating.

2. Apply the input signal indicated by the secondary display.

3. Wait for the measurement on the primary display to settle out to its final value.

4. Press the

5. Repeat steps 2 through 4 until the secondary display shows

the calibration procedure for this function is complete. New constants will not be

recorded until secondary display shows

6. If there are more functions to be calibrated, move the rotary switch to the appropriate

function, and continue from step one. Otherwise, turn the rotary switch to the

position to exit calibration.

DC mV calibration affects the calibration of ALL functions and AC mV

will affect all AC functions.

If the accuracy of the calibration source is more than approximately

15 % from the nominal value required for the cal point, then the factory

default cal constants will automatically be used instead of source value.

In this case, the Meter may not pass the verification test and may

require re-calibration.

UP button to proceed to the next step. The Meter records a new constant.

End. This indicates that

End.

OFF

Note

22

Special Requirements

DC mV calibration will affect the calibration of all other functions. Therefore, the DC

mV function must be calibrated before calibrating any other function. Similarly, AC mV

must be calibrated before any AC function, but after DC mV. The remaining functions

may be calibrated in any order.

Temperature calibration need only be performed if one of the following components are

replaced during the course of repair: U4 A/D chip, U10 EEPROM, or U100 Reference

Junction Sensor. Temperature is calibrated by making an external temperature

measurement and entering the result into the instrument for calculation of the calibration

constant. The calibration constant is then stored in calibration memory. This is done

using the serial interface. See “Temperature Calibration” section.

When you replace the U10 EEPROM, you must also re-enter the serial number and

model number for the Meter. See “Reprogramming Meter Serial Number and Model

Number” section.

Calibration Inputs

Table 5 lists the input values required for each calibration step.

The column indicating time to settle does not include calibrator settling

time.

True RMS Multimeter

Calibration

Note

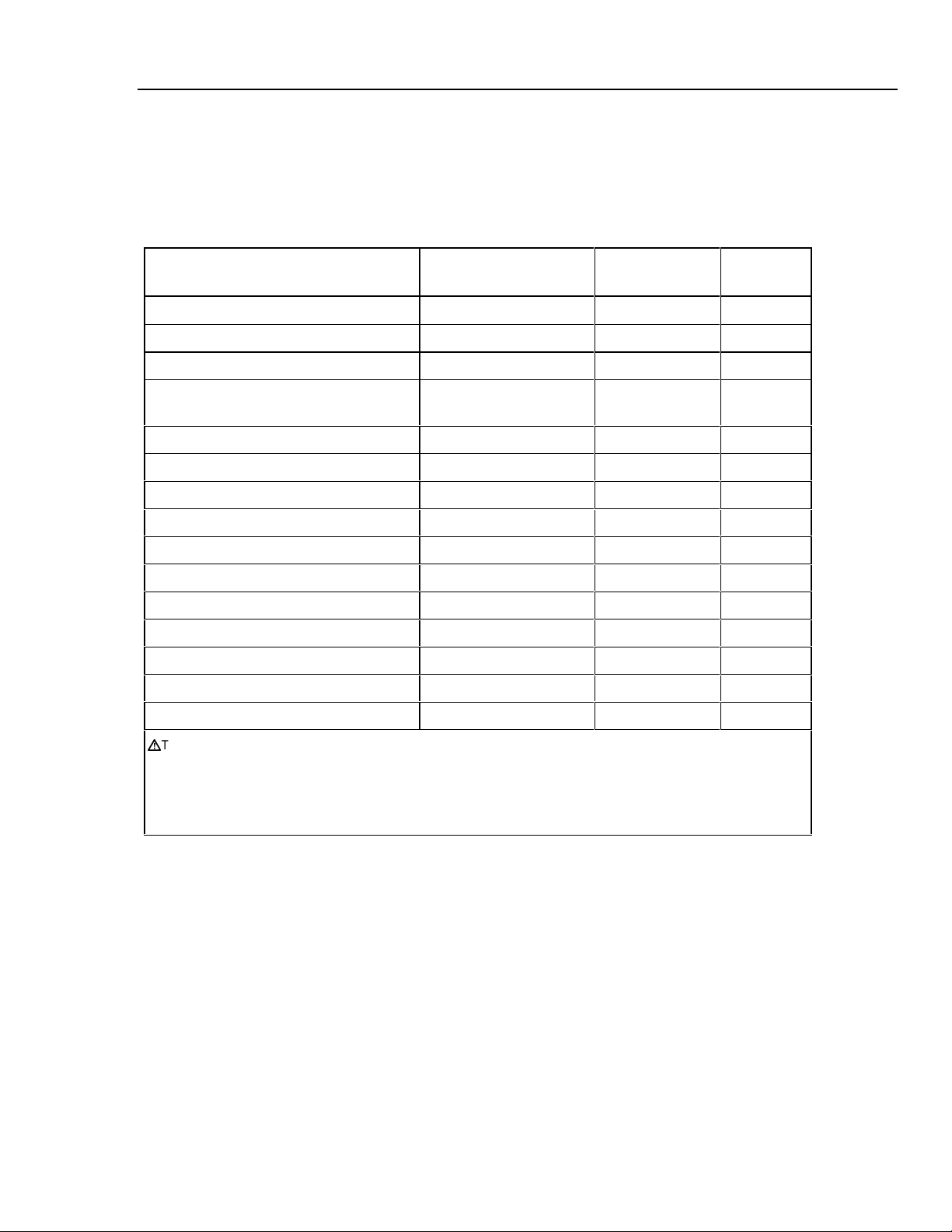

Table 5. Calibration Inputs

Step Value Frequency Time to Settle (In Seconds)

DC mV

10 mV DC 16

2 50 mV DC 16

3 300 mV DC 7

4 500 mV DC 7

5 3000 mV DC 1

Temperature

10 1

AC mV

1 700 mV 700 Hz 7

2 400 mV 700 Hz 7

3 100 mV 700 Hz 7

4 50 mV 700 Hz 7

5 3000 mV 700 Hz 7

1. Use 5520A 2-Wire Comp.

2. Zero ohms must use the sam e calibrator and test leads as al l ot her ohm cal points.

Do not bypass the calibrator with a s horting bar for the zero ohms step.

3. Because of capacitive c oupling, readings will be affected by movement of t he leads or

operator. Put fingers on UP but ton and wait for display reading to s ettle before pushing.

23

187/189

Calibration Manual

Table 5. Calibration Inputs (cont.)

Step Value Frequency Time to Settle (In Seconds)

AC V

1 5 V 700 Hz 7

2 50 V 700 Hz 7

3 500 V 700 Hz 7

4 500 V 700 Hz 7

DC V

15V DC 7

2 50 V DC 7

3 500 V DC 7

4 500 V DC 7

1

Ohms

120 Ohms 16

Ohms

AC uA

DC uA

AC mA

DC mA

2 500 Ohms 16

35k Ohms 7

4 50k Ohms 7

5 500k Ohms 7

6 5M Ohms 7

7 30M ohms 1

3

3

1 500 uA 700 Hz 7

2 5000 uA 700 Hz 7

1 500 uA DC 16

2 5000 uA DC 7

1 50 mA 700 Hz 7

2 400 mA 700 Hz 7

24

1 50 mA DC 16

2 400 mA DC 7

1. Use 5520A 2-Wire Comp.

2. Zero volts and ohms must use the same calibrator and tes t l eads as all other volt and ohm c al

points.

Do not bypass the calibrator with a s horting bar for the zero volts or ohm s step.

3. Because of capacitive c oupling, readings will be affected by movement of t he leads or

operator. Put fingers on UP but ton and wait for display reading to s ettle before pushing.

Step Value Frequency Time to Settle (In Seconds)

AC A

DC A

1. Use 5520A 2-Wire Comp.

2. Zero volts and ohms must use the same calibrator and tes t l eads as all other volt and ohm c al

points.

Do not bypass the calibrator with a s horting bar for the zero volt or ohm s t ep.

3. Because of capacitive c oupling, readings will be affected by movement of t he leads or

operator. Put fingers on UP but ton and wait for display reading to s ettle before pushing.

Remote Interface

You can perform semi-automated calibration with the remote interface using MET/CAL

software.

True RMS Multimeter

Calibration

Table 5. Calibration Inputs (cont.)

1 5 A 700 Hz 7

2 5 A 700 Hz 7

15 A DC 16

25 A DC 7

Temperature Calibration

Required equipment:

• Fluke 87/89-IV, 187/189 Service Software, Fluke P/N 676152

• Infrared Serial Cable Kit, Fluke P/N 1590638

• IBM compatible PC

• Fluke 80T-150U with accuracy certified to +0.2 °C

• Fluke 8060A Digital Multimeter

The following procedure is only required if the Meter has been repaired by

replacing one of the following components: A/D, U4, Reference Junction

Sensor, U100 or EEPROM, U10.

Setup

Prior to beginning the procedure, turn the rotary switch OFF. Let the Meter stabilize in a

constant ambient temperature for 30 minutes. This allows the internal reference junction

sensor and input terminals to stabilize to the same temperature.

Connect the IR Serial Cable to the serial com port of the PC. Install the 87/89-IV,

187/189 Service Software.

Note

25

187/189

Calibration Manual

Procedure

While the rotary switch is in the OFF position, insert the certified 80T-150 probe into the

Meter’s

makes firm contact with the bottom of the terminal. Measure and record the

COM terminal (same temperature as reference junction). Make sure the probe tip

COM

terminal temperature in units of 1/100 °C. Do not convert this number to Fahrenheit,

even if the Meter is using the Fahrenheit scale for its display output.

Turn the rotary switch to the temperature position. It does not matter whether the Meter

is in calibration mode. On the Service Software menu screen, click

Enter the measured temperature value in the text box and click

C Ref. Junction

°

OK. This sends the

.

recorded reference junction temperature to the Meter through the IR Serial Cable.

Although the temperature calibration is not yet complete, it is safe at this point to turn

the Meter off if the need arises. Doing so will not invalidate the previous steps.

To complete the temperature calibration, the DC mV function must be calibrated.

After DC mV calibration is complete:

1. Turn the rotary switch to the temperature position. Put the Meter in calibration mode

by pressing the recessed button on the back of the Meter.

The secondary display, which normally shows the required input, displays zero. In

this case, no input is required.

2. Press the

UP button.

This sends the calculated temperature constants to EEPROM, and completes the

temperature calibration.

3. Continue calibrating the other functions, or turn the rotary switch to the

position to exit calibration.

Re-Programming Serial Number or Model Number

When the U10 EEPROM is replaced, you must also reenter the serial number and model

number for the Meter. Do this as follows:

1. Connect the IR Serial Cable to the serial com port of the PC. Install 87/89-IV,

187/189 Service Software (Fluke P/N 676152).

2. Turn the Meter rotary switch to any function.

3. On the Service Software menu screen, click

EEPROM. Enter the serial number from

the back of the Meter in the text box and click

Yes or No in the model menu box.

OFF

OK. To enter the model number, click

26

Parts and Accessories

Replacement parts and accessories are listed in Table 6 and identified in Figure 7 by the

reference designator.

Table 6. Replacement Parts and Accessories

Reference

Description

Access Door, Battery / Fuse MP14 1589387 1

Tilt-Stand MP8 659026 1

Accessory Mount MP9 658424 1

Designators Part Number Qty

True RMS Multimeter

Parts and Accessories

WFuse, 0.44 A (44/100 A, 440 mA),

F1 943121 1

1000 V, FAST

WFuse, 11 A,1000 V FAST F2 803293 1

Battery, 1.5 V, 0-15 mA, AA Alkaline H8, H9, H10, H11 376756 4

Fasteners, Battery / Fuse Access Door H12, H13 948609 2

Screws, Phillip-Head H4, H5, H6, H7 832246 4

AC70A Alligator Clip (Black) MP38 738047 1

AC70A Alligator Clip (Red) MP39 738120 1

TL71 Right-Angle Test Lead Set MP34 802980 1

LCD 4.5 Digit Multiplexed DS1 688181 1

Connector, Elastomeric, LCD to PWB

Getting Started Manual (TM1-TM5) See Note Below

1

MP30, MP31 690883 2

2

5

CD-ROM (Contains Users Manual) (TM6) 1576992 1

W

To ensure safety, use ex act replacement only.

1. Order replacement connectors separately when ordering a replacement LCD.

2. Getting Started Manual P Ns: English=1547486; French, German, Italian, Dutch=1555282; Dani sh, Finnish,

Norwegian, Swedish=1555307; French, Spani sh, Portuguese=1555294; Simpli fied Chinese, Traditional Chinese,

Korean, Japanese,Thai=1555318

27

187/189

Calibration Manual

MP31

DS1

MP38

MP30

MP39

F1

F2

H5

H4

H7

28

MP34

MP9

H6

H8,9,10,11

MP14

H13

H12

MP8

Figure 7. Replacement Parts and Accessories

aau03f.eps

Loading...

Loading...