Page 1

Earth/Ground Tester

Users Manual

®

1625

January 2006

© 2006 Fluke Corporation, All rights reserved. Printed in USA

All product names are trademarks of their respective companies.

Page 2

LIMITED WARRANTY AND LIMITATION OF LIABILITY

Each Fluke product is warranted to be free from defects in material and workmanship

under normal use and service. The warranty period is two years and begins on the date of

shipment. Parts, product repairs, and services are warranted for 90 days. This warranty

extends only to the original buyer or end-user customer of a Fluke authorized reseller,

and does not apply to fuses, disposable batteries, or to any product which, in Fluke's

opinion, has been misused, altered, neglected, contaminated, or damaged by accident or

abnormal conditions of operation or handling. Fluke warrants that software will operate

substantially in accordance with its functional specifications for 90 days and that it has

been properly recorded on non-defective media. Fluke does not warrant that software will

be error free or operate without interruption.

Fluke authorized resellers shall extend this warranty on new and unused products to enduser customers only but have no authority to extend a greater or different warranty on

behalf of Fluke. Warranty support is available only if product is purchased through a Fluke

authorized sales outlet or Buyer has paid the applicable international price. Fluke reserves the right to invoice Buyer for importation costs of repair/replacement parts when

product purchased in one country is submitted for repair in another country.

Fluke's warranty obligation is limited, at Fluke's option, to refund of the purchase price,

free of charge repair, or replacement of a defective product which is returned to a Fluke

authorized service center within the warranty period.

To obtain warranty service, contact your nearest Fluke authorized service center to obtain

return authorization information, then send the product to that service center, with a description of the difficulty, postage and insurance prepaid (FOB Destination). Fluke assumes no risk for damage in transit. Following warranty repair, the product will be returned to Buyer, transportation prepaid (FOB Destination). If Fluke determines that failure

was caused by neglect, misuse, contamination, alteration, accident, or abnormal condition

of operation or handling, including overvoltage failures caused by use outside the product’s specified rating, or normal wear and tear of mechanical components, Fluke will provide an estimate of repair costs and obtain authorization before commencing the work.

Following repair, the product will be returned to the Buyer transportation prepaid and the

Buyer will be billed for the repair and return transportation charges (FOB Shipping Point).

THIS WARRANTY IS BUYER'S SOLE AND EXCLUSIVE REMEDY AND IS IN LIEU OF

ALL OTHER WARRANTIES, EXPRESS OR IMPLIED, INCLUDING BUT NOT LIMITED

TO ANY IMPLIED WARRANTY OF MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE. FLUKE SHALL NOT BE LIABLE FOR ANY SPECIAL, INDIRECT,

INCIDENTAL OR CONSEQUENTIAL DAMAGES OR LOSSES, INCLUDING LOSS OF

DATA, ARISING FROM ANY CAUSE OR THEORY.

Since some countries or states do not allow limitation of the term of an implied warranty,

or exclusion or limitation of incidental or consequential damages, the limitations and exclusions of this warranty may not apply to every buyer. If any provision of this Warranty is

held invalid or unenforceable by a court or other decision-maker of competent jurisdiction,

such holding will not affect the validity or enforceability of any other provision.

Fluke Corporation

P.O. Box 9090

Everett, WA 98206-9090

U.S.A.

Fluke Europe B.V.

P.O. Box 1186

5602 BD Eindhoven

The Netherlands

11/99

Page 3

Table of Contents

Title Page

Introduction .......................................................................................... 1

Models and Accessories........................................................................ 3

Safety Instructions ................................................................................ 4

Qualified Staff .................................................................................. 5

Setup..................................................................................................... 5

Unpacking......................................................................................... 5

Checking the Scope of Delivery ....................................................... 5

General ................................................................................................. 6

Additional Accessories ......................................................................... 6

Assembly .............................................................................................. 7

Description of Functions....................................................................... 7

Measurement of Interference Voltage (UST) ..................................... 8

Measurement of Interference Frequency (FST).................................. 8

Measurement of Earthing Resistance (RE)........................................ 9

Selective Measurement of Earthing Resistance (RE A) ................ 9

Resistance Measurement (R~) .......................................................... 9

Low Resistance Measurement (RF)................................................. 9

Checking for Correct Measuring Connection ................................... 9

Beeper............................................................................................... 9

LO-BAT............................................................................................ 10

Specifications........................................................................................ 10

Measurement of Interference Voltage DC + AC (UST) ..................... 13

Measurement of Interference Frequency (FST).................................. 13

Earthing Resistance (RE)................................................................... 13

Selective Measurement of the Earthing Resistance (REA)............ 17

Resistance Measurement (R~) .......................................................... 18

Resistance Measurement (RF)......................................................... 19

Compensation of Lead Resistance (RK) ............................................ 20

Description of the Operating Elements ................................................. 21

Description of Display Elements ...................................................... 23

Procedure of Measurements.................................................................. 24

POWER ON Functions ................................................................. 25

Operation ...................................................................................... 26

Checking of Correct Measuring Connection (Socket Allocation). 30

Safety Control Measurements....................................................... 31

i

Page 4

1625

Users Manual

Measurement of Interference - Voltages and Frequencies................ 31

Measurement of Earthing Resistances.............................................. 32

Measurement of Soil Resistivity....................................................... 45

Measurement of Resistances ............................................................ 48

Changing of All Data Settings with Personalized CODE................. 51

Description of Displays........................................................................ 55

Care and Maintenance.......................................................................... 60

Replacing Batteries........................................................................... 61

Recalibration .................................................................................... 62

Storage.............................................................................................. 62

Specifications ....................................................................................... 64

Principle of Operation .......................................................................... 65

Purpose............................................................................................. 65

Operation.......................................................................................... 68

Applications ..................................................................................... 70

3-pole/4-pole Measurement of Earthing Resistance..................... 33

Measurement of Single Earth Electrode Resistances in

Mesh Operated Earthing Systems Using Selective Clamp

Method ......................................................................................... 36

3-pole/4-pole Measurement of Single Earth Electrode

Resistances ................................................................................... 37

Measurements on High Voltage Pylons........................................ 39

Correcting Clip-on Transformer Errors ........................................ 42

Compensation of Earth Electrode Connecting Lead..................... 44

Resistance Measurement (R~)...................................................... 48

Resistance Measurement (RF)..................................................... 49

Compensation of Measuring Lead Resistance.............................. 50

Storing a Code.............................................................................. 53

Deleting a Code............................................................................ 54

Settings on the Tester ................................................................... 69

Description of Displays................................................................ 72

ii

Page 5

List of Tables

Table Title Page

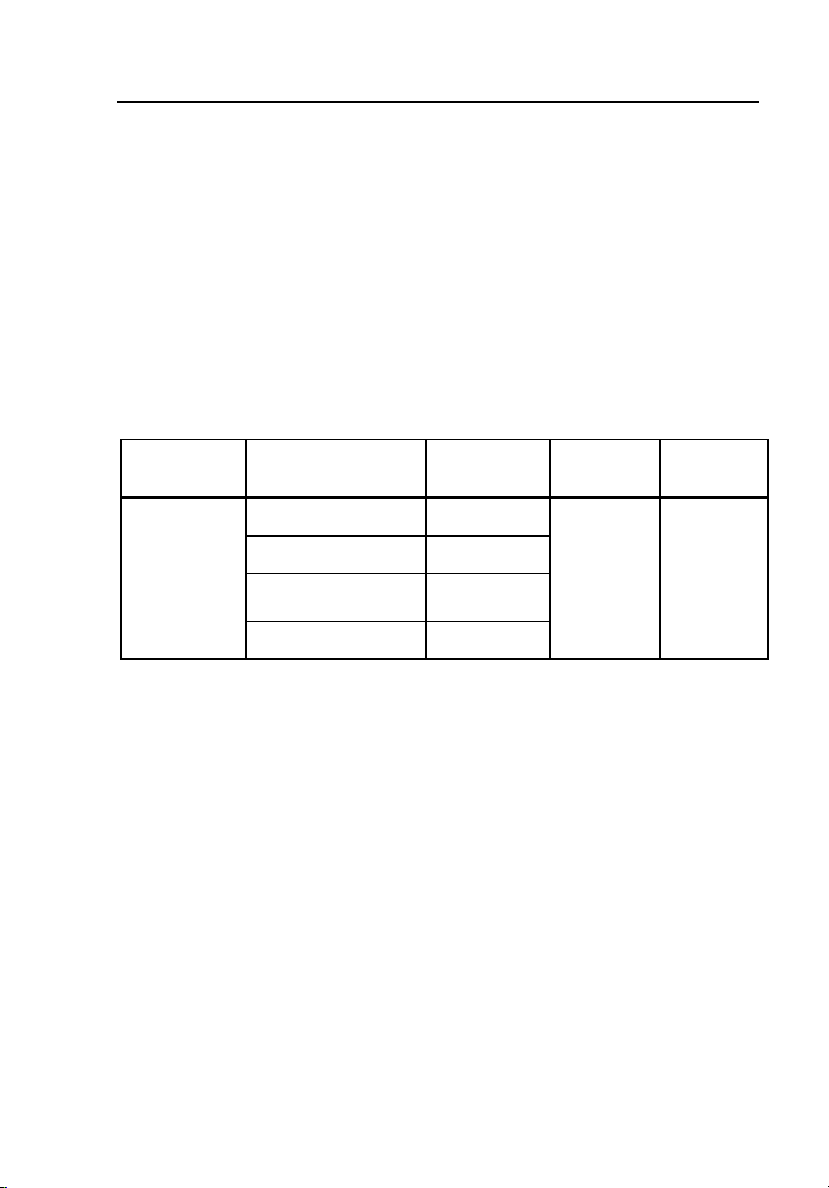

1. Models and Accessories................................................. 3

2. Electrical Measurement Specifications .......................... 14

3. Description of Displays.................................................. 56

iii

Page 6

1625

Users Manual

iv

Page 7

List of Figures

Figure Title Page

1. Fluke 1625 Earth/Ground Tester.................................... 2

2. Description of Functions ................................................ 8

3. Display ........................................................................... 10

4. Operating Elements........................................................ 21

5. Display Elements ........................................................... 23

6. Operational Modes ......................................................... 27

7. Measurement of Interference -

Voltages and Frequencies............................................... 32

8. Earthing Resistances Measurement - Method ................ 33

9. 3-pole/4-pole Measurement of Earthing Resistance -

Process............................................................................ 34

10. Earth Resistance - Maximum Permissible Value ........... 35

11. Measurement of Single Earth Electrode Resistances in

Mesh Operated Earthing Systems .................................. 36

12. 3-pole/4-pole Measurement of Single Earth

Electrode Resistances..................................................... 37

13. Measuring the Earthing Resistance without

Disengaging the Overhead Earth Wire........................... 40

14. Correcting Clip-on Transformer Errors.......................... 43

15. Compensation of Earth Electrode Connecting Lead ...... 44

16. Measurement of Soil Resistivity .................................... 45

17. Resistance Measurement (R~) ....................................... 48

18. Resistance Measurement (RF) ...................................... 49

19. Evaluation of Measured Value....................................... 50

20. Compensation of Measuring Lead Resistance ............... 51

v

Page 8

1625

Users Manual

vi

Page 9

Earth/Ground Tester

Introduction

At locations involving the generation, distribution and consumption of electrical energy, certain safety measures must be met in order to protect human life.

In many cases, these safety measures are national and international regulations

which must be checked regularly. Grounding, the connection of exposed conductive parts to the earth in case of a fault, represents the most fundamental

safety measure. There are requirements for grounding of transformers, high

and medium voltage power pylons, railway tracks, tanks, vats, foundations and

lightning protection systems.

The effectiveness of grounding systems should be checked using a ground test

instruments such as the 1625 which checks the effectiveness of connections to

the ground. The 1625 provides the perfect solution by combining the latest

technology into a compact, field-rugged and extremely easy to use instrument.

In addition to performing standard 3- and 4-pole ground resistance measurements, an innovative process accurately measures individual earth electrode

resistances in single and meshed earthed systems without disconnecting any

parallel electrodes. One specific application of this capability is quick and accurate measurement of power pylon grounds. The 1625 also incorporates

automatic frequency control (AFC) to minimize interference. Before measuring, the instrument identifies existing interference and selects a measurement

frequency to minimise its effect. The 1625 incorporates microprocessor controlled automatic measurements including checking probe hookup to ensure

that measurements are taken correctly. It measures all probe ground resistances

to ensure reliable, repeatable results. Probe resistance and auxiliary earth resistance are also measured and displayed.

1

Page 10

1625

Users Manual

Notes

• The terms earth and earthing also refer to ground and grounding

and is used interchangeably throughout this manual.

• For stakeless earth resistance measurements, the EI-1625 must

be purchased. (The EI-1625 comes standard with the 1625 Kit).

Refer to Appendix A for a complete set of operating information

including specifications.

• Selective measurements are described in the main section of this

manual.

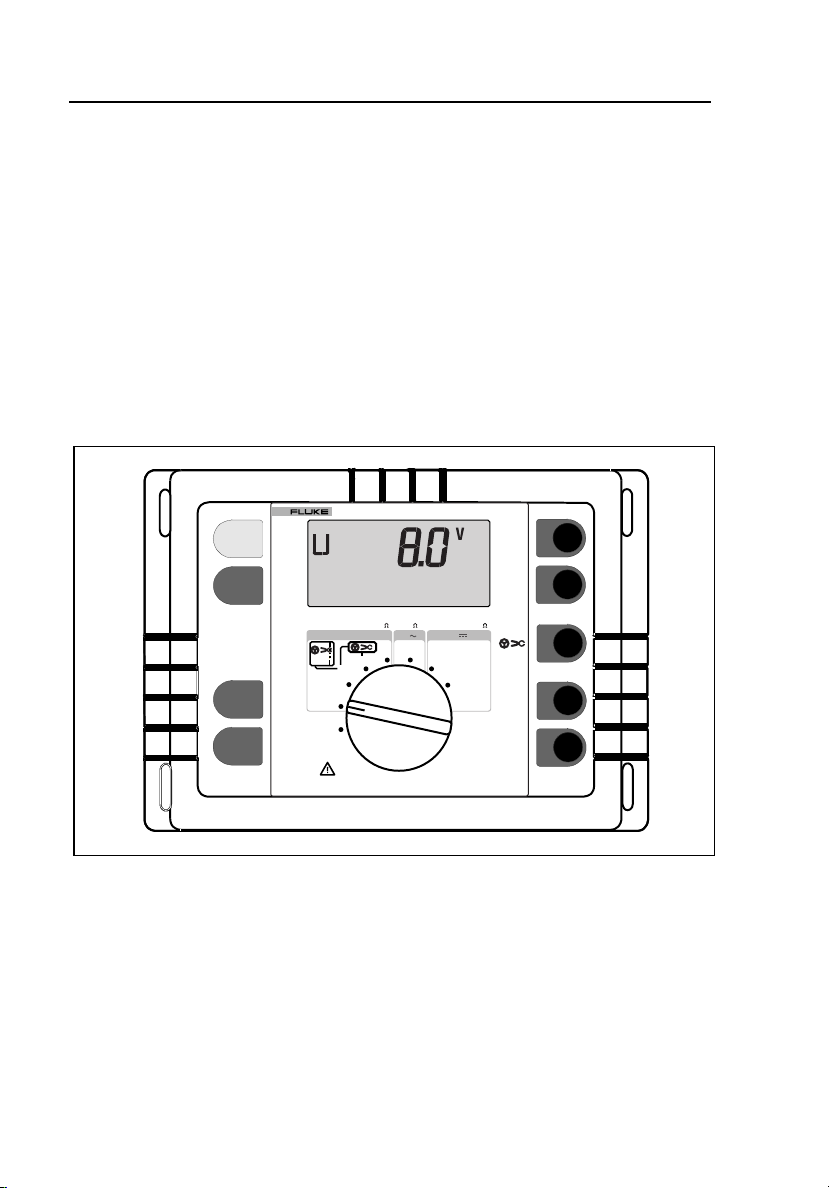

Figure 1 displays the Fluke 1625 Earth/Ground Tester:

EARTH / GROUND TESTER

1625

START

TEST

ST

H/C2

2

DISPLAY

MENU

CHANGE

ITEM

SELECT

Earth/Ground Resistance 300 k

RA

4

POLE

3

POLE

4

POLE

3

POLE

OFF

AC

Resistance

300 k

R

2

POLE

DC Low Resistance 3k

2

POLE

S/P2

R

4

POLE

ES/P1

E/C1

Figure 1. Fluke 1625 Earth/Ground Tester

edw001.eps

Page 11

Earth/Ground Tester

Models and Accessories

Models and Accessories

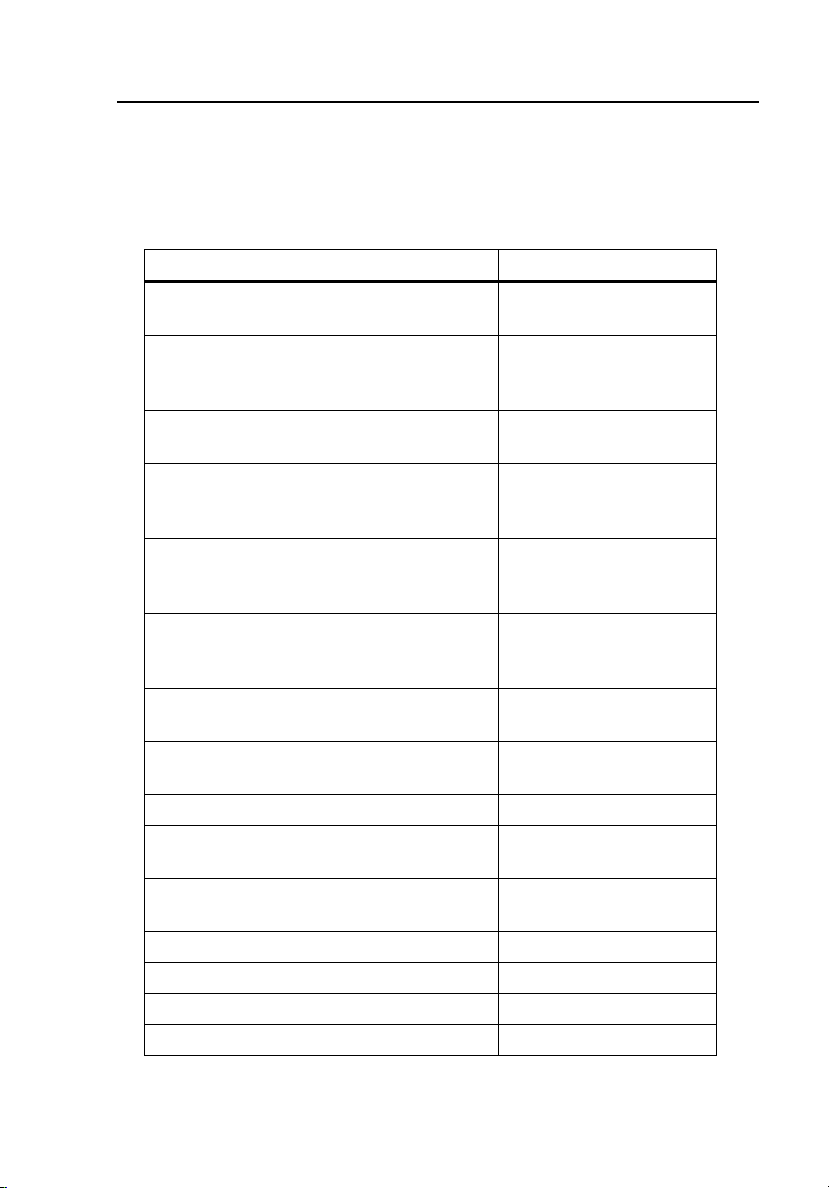

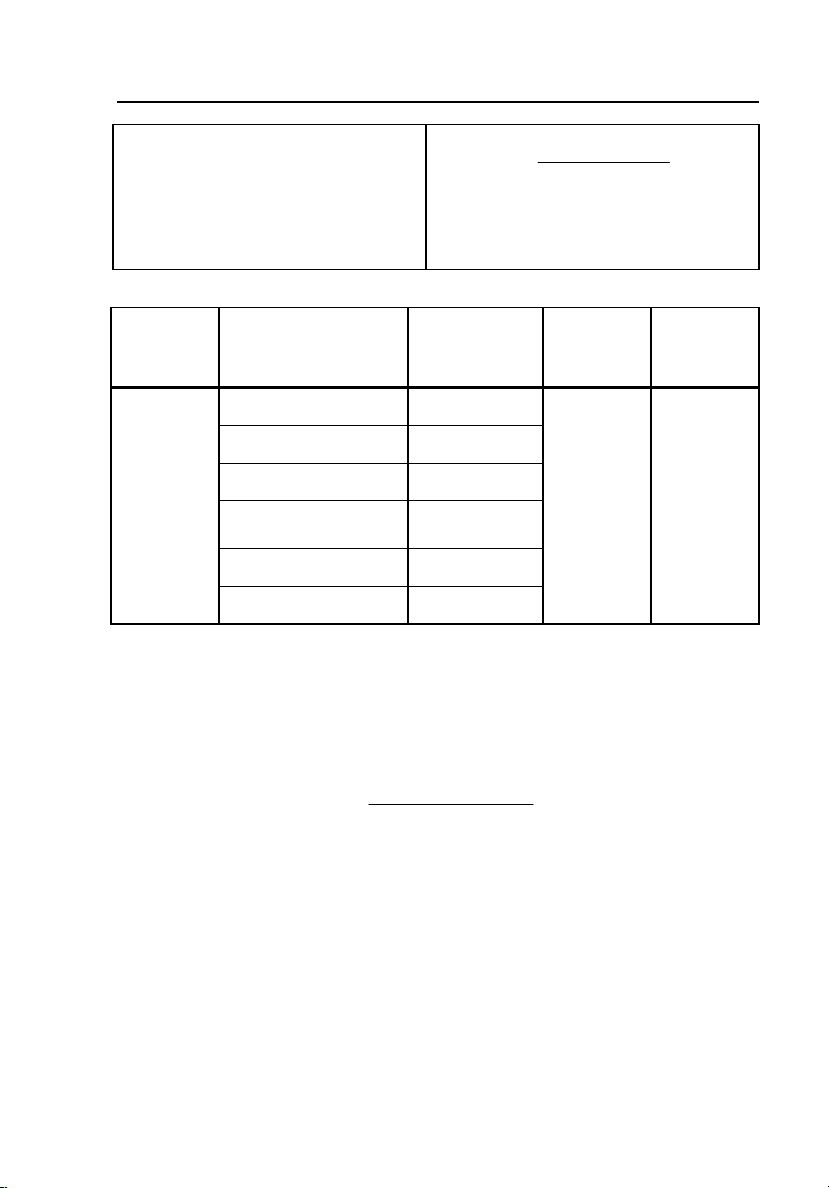

Table 1 lists the models and accessories.

Table 1. Models and Accessories

Description Item/Part Number

Earth Ground Tester - Basic

(Includes manual, 2 leads and 2 clips)

Earth Ground Tester - Fully Loaded

(Includes manual, 2 leads and 2 clips,

ES162P4, EI-1623)

Service Replacement Kit

(Includes 2 Leads, 2 Clips)

Stake Set for 3 Pole Measurement

(Includes three stakes, one 25 m cable

reel, one 50 m cable reel)

Stake set for 4 Pole Measurement

(Includes four stakes, two 25 m cable

reels, one 50 m cable reel)

Selective/Stakeless Clamp Set for

1625. (Includes EI-162X and EI162AC and 2-3 wire adapter cable)

Clip-on Current Transformer (sensing)

with shielded cable set

Shielded Cable (Used w/EI-162X

Clamp)

Clip-on Current Transformer (inducing) EI-162AC

12.7 Inch (320mm) Spilt Core Transformer

2-3 Wire Adapter Cable for 1625 for EI162AC Current Transformer

Earth Stake 2539121

Cable Reel w/25m Wire 2539100

Cable Reel w/50m Wire 2539117

1625 Users Manual 2560348

Fluke-1625

Fluke-1625 Kit

Fluke-162x-7001

ES-162P3

ES-162P4

EI-1625

EI-162X

2539195

EI-162BN

2577171

3

Page 12

1625

Users Manual

Safety Instructions

W Warning

This measuring equipment is only to be operated by qualified staff and in accord with its technical data in compliance with the safety precautions and instructions set forth

below. In addition, use of this equipment requires compliance with the legal and safety instructions pertaining to

the specific application in question. Similar precuations

apply to the use of accessories.

Caution

Operation of electrical equipment inevitably causes certain

parts of such equipment to carry dangerous voltage. Noncompliance with precautions may therefore cause major

physical or material damage.

Fault-free and reliable operation of this instrument requires suitable transport

and storage, setting-up and assembly, as well as care in operation and maintenance.

If there is reason to believe that risk-free operation is no longer possible, the

instrument should be switched off immediately and protected against accidental restarting. Risk-free operation shall be deemed to be no longer possible if

and when the instrument

• shows visible damage,

• fails to work in spite of functioning batteries,

• has been exposed for some time to unfavorable conditions ( e.g. stor-

age beyond the permissible climatic limits without adaptation to the

ambient climate, dewing etc.),

• has been exposed to major strain during transport ( e.g. been dropped

from some height without visible external damage etc.), or

• shows " E1 ... E5 " on the display.

4

Page 13

Earth/Ground Tester

Setup

Qualified Staff

Consists of persons familiar with the setting up, assembly, starting up and operation of the product and possess the qualifications required for such activities, such as

• training, instruction and/or authorization to perform the following op-

erations on circuits and equipment according to safety engineering

standards: switching on and off, disconnecting, earthing/grounding,

labeling;

• training or instructions according to safety engineering standards in

the care and main tenance of adequate safety equipment.

• training in rendering first aid.

Setup

Unpacking

Check delivery for damage during transport. Keep the packing material for

later transport and check scope of delivery.

Checking the Scope of Delivery

Upon unpacking immediately check the accessories for missing parts. The accessories supplied are listed on page 2.

Caution

Although the instrument is easy to operate please read

these operating instructions carefully for safety reasons

and in order to make optimum use of the instrument.

The measuring functions are only all activated when the instrument is connected.

5

Page 14

1625

Users Manual

General

Microprocessor controlled universal earth resistance meter with fully automated measuring frequency selection process as well as automatic testing of

probe- and auxiliary earth electrode resistances and possible interference voltages as per DIN IEC61557-5/EN61557-5.

• Measurement of interference voltage (U

• Measurement of interference frequency (F

• Measurement of probe resistance (R

• Measurement of auxiliary earth electrode resistance (R

• Measurement of earthing resistance 3pole, 4pole, (R

)

ST

)

ST

)

S

)

H

) with or without

E

using the external clip-on current transformer for selective measurement of single earthing branches in mesh operated earthing systems

A

• Resistance measurement 2pole with AC voltage (R~)

• Resistance measurement with DC voltage 2pole, 4pole, (RF)

With its various possibilities of measurement and the fully automated measuring sequence control (incl. automatic frequency control AFC), this instrument

offers the latest measuring technology in the field of earthing resistance measurements. By means of the selectable limit input with visual and accoustical

confirmation/error message and with the code programmable and customer

defined special functions, e.g. measuring voltage 20 V (for agricultural systems), earthing impedance R* (measuring frequency 55 Hz) switched on or off

etc., these instruments are individually programmable for use as a simple meter

as well as a high end fully automated measuring device.

Additional Accessories

An external current transformer with a transformation ratio between 80 and

1200:1 for the measurement of a single branch in mesh operated earthing systems is available as an option and enables the user to measure on high voltage

pylons without seperating the overhead earth wires or earth strips at the bottom

of the pylons and also to measure lightning protection systems without seperating the individual lightning protection wires.

6

Page 15

Earth/Ground Tester

Assembly

Assembly

The instrument is made up of two parts:

1. The base part which contains the measuring electronics.

2. The protective housing.

The functions are selected with the central rotary switch. Four rubber buttons,

which start measurements, read out supplementary measuring values and select

special functions, are located on the left hand side of the front panel. This design enables quick and clear one-hand operation.

The measured values are displayed on a liquid crystal display with correct

decimal point and unit. Various additional special characters indicate measuring mode, operating condition and error messages.

The auxiliary power supply consists of 6 x 1.5 V batteries (IEC R6 or LR6 or

type AA).

This device has been developed, designed and manufactured in compliance

with quality system DIN ISO 9001.

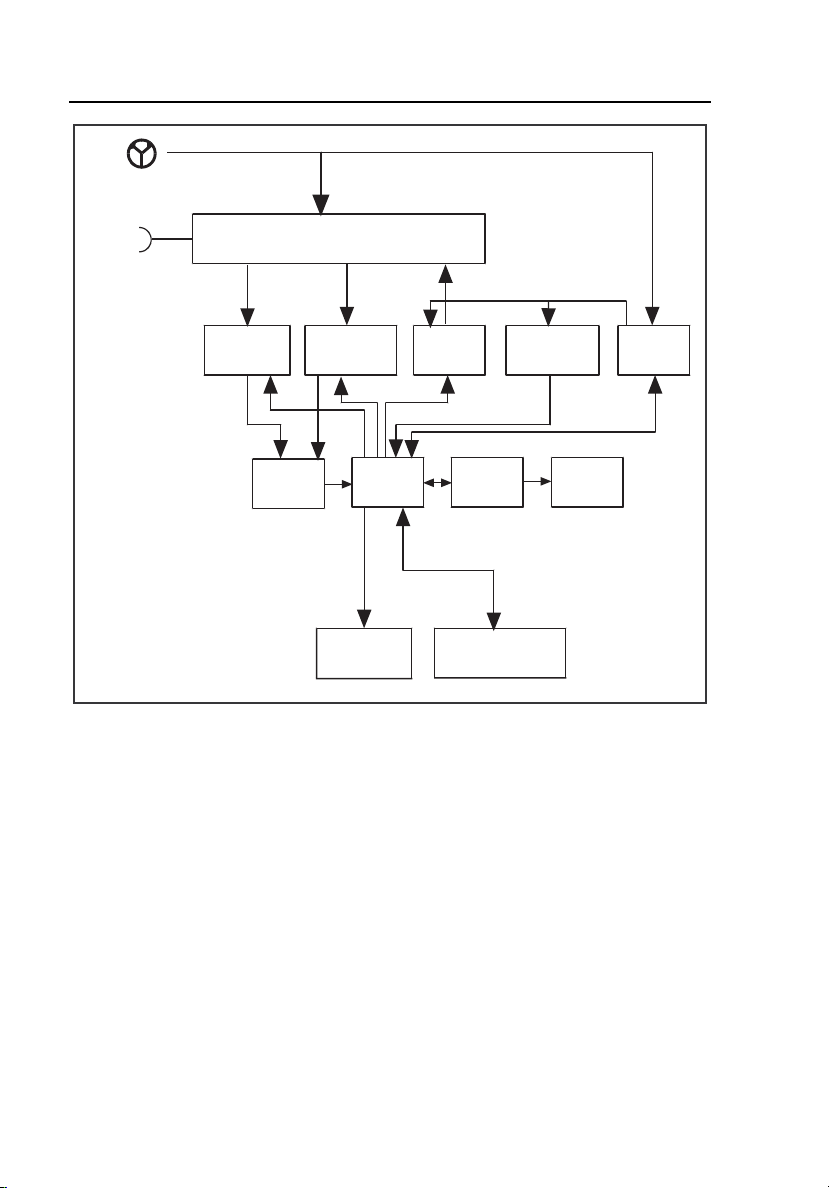

Description of Functions

The following flowchart presents a description of the functions of the 1625

Earth/Ground Tester.

7

Page 16

1625

Users Manual

EXT

H

S

ES

E

Switching

Voltage

measurement

ADC

Comp

Current

measurement

Processor

Relais

driver

Source

driver

Rotary selector

switch buttons

LCD

Undervoltage

detection

Display

Supply

voltage

edw003.eps

Figure 2. Description of Functions

Measurement of Interference Voltage (UST)

Fullwave rectification for DC and AC (DC without operational sign, AC signal

sinus calibrated for r.m.s. values). If limit values are exceeded no measurement

will be started.

Measurement of Interference Frequency (FST)

For interference voltage >1 V its frequency is derived from the period time.

8

Page 17

Earth/Ground Tester

Description of Functions

Measurement of Earthing Resistance (RE)

The earthing resistance is determined by a 3- or 4-pole current and voltage

measurement. The measuring voltage is a square pulse AC voltage with 48 /

20 V and a frequency of 94, 105, 111 or 128 Hz. The frequency can be selected

manually or automatically (AFC).

Selective Measurement of Earthing Resistance (RE

Measurement of a single earth electrode in a mesh operated (parallel) earthing

system. The current flowing through the single earth electrode is measured

with an external current transformer.

A

)

Resistance Measurement (R~)

The resistance is determined by a 2 pole current and voltage measurement. The

measuring voltage is a square pulse AC voltage with 20 V and a frequency of

94, 105, 111 or 128 Hz. The frequency can be selected manually or automatically (AFC).

Low Resistance Measurement (RF)

The resistance is determined by DC current and voltage measurement. 2- as

well as 4-pole measurement is possible. The short circuit current is > 200 mA.

The resistance of both current directions is measured and stored.

Checking for Correct Measuring Connection

The processor checks if the measuring lead is properly connected according to

the selected function via isolated, two piece contacts, inside of each 4 mm (banana) input socket, in combination with detection circuitry. A wrong or missing connection is indicated by an optical or acoustical signal.

Beeper

The built in beeper has two functions:

1. Giving messages if set limit values are exceeded.

2. Indicating dangerous conditions or maloperation.

Controlling is done by means of the microprocessor.

9

Page 18

1625

Users Manual

LO-BAT

Supervision of the battery charge status is done with a comparator circuit. Via

microprocessor, a drop in battery capacity down to typ. 10 % of its specified

value is indicated on the display with symbol LO-BAT.

Specifications

General: Microprocessor controlled, fully automated earth

measuring instrument with additional functions

Measuring function: interference voltage and frequency, earthing resis-

tance 3- and 4-pole with / without clip-on current

transformer, resistance 2-pole with AC, 2- and 4-pole

with DC

Display

(see Figure 4):

ST

4 digit (2999 Digit) - 7 segment liquid crystal display,

digit size 18 mm with supplementary signs and active

illumination.

edw004.eps

Figure 3. Display

10

Page 19

Earth/Ground Tester

Specifications

Operation: Central rotary switch and function keys

Working temperature range: -10 °C … +50 °C

Operating temperature range: 0 °C … +35 °C

Nominal temperature range: 18 °C … +28 °C

Storage temperature range: -30 °C … +60 °C

Note

The chart of four temperature ranges for the instrument exist to satisfy European Standards requirements; the instrument can be used

over the full Working temperature range by using the temperature coefficient to calculate accuracy at the ambient temperature of use.

Temperature coefficient: ± 0.1 % of range / Kelvin

Operating errors: refer to operating temperature range and RH

< 20 RE, RS < 100 RE

The maximum percentage operating error within the measurement range does

not exceed ± 30 % with the measured value as fiducial value, as determined in

accordance with TABLE 1.

The operating error applies under the rated operating conditions given in

IEC1557-1 and the following:

• injection of series interference voltages with system frequencies of

400 Hz, 60 Hz, 50 Hz, 16

2

/3 Hz or with d.c. voltage respectively

across the terminals E (ES) and S. The r.m.s. value of the series interference voltage shall be 3 V;

• resistance of the auxiliary earth electrode and of the probes: 0 to 100 x

but ≤ 50 kΩ;

R

A

• system voltages between 85 % and 110 % of the nominal voltage and

between 99 % and 101 % of the nominal system frequency for measuring equipment with a mains supply and/or measuring equipment deriving its output voltage directly from the distribution system.

Limits of error: refer to nominal temperature range

Climate class: C1 (IEC 654-1), -5 °C...+45 °C, 5 %...95 % RH

Type of protection: IP 56 for case, IP 40 for battery door according to

EN 60529

11

Page 20

1625

Users Manual

Max voltage:

Urms = 0 V

Sockets ” E ES S H " to each other in any com-

EMC (Emission Immunity):

Quality standard: developed, designed and manufactured to comply

External field influence:

Auxiliary power: 6 x 1,5 V alkali-manganese-batteries (IEC

Battery life span: with IEC LR6/type AA: typ. 3000 measurements

with IEC LR6/type AA : typ. 6000 measurements

Dimensions: 240 mm (W) x 220 mm (D) x 90 mm ( H )

Weight: ≤ 1.1 kg without accessories

Wsocket A to socket EFGH

bination, max. Urms= 250 V (pertains to misuse)

IEC 61326-1:1997 Class A

with DIN ISO 9001

complies with DIN 43780 (8/76)

LR6 or type AA )

(RE+R

(RE + R

≤ 1 kΩ)

H

>10 kΩ)

H

≤ 5.5 kg incl. accessories and batteries in carrying

case

Case material: NORYL, shock -and scratch proof thermoplast

12

Page 21

Earth/Ground Tester

Specifications

Measurement of Interference Voltage DC + AC (UST)

Measuring method: fullwave rectification

Measuring

Range

1…50 V 0.0…50 V 0.1 V DC/AC

Display

Range

Resolu-

tion

Frequency

Range

45…400 Hz

sine

Limits of Er-

ror

± (5% of

reading +5

digit)

Measuring sequence: approx. 4 measurements /s

Internal resistance:

Max. overload:

approx. 1.5 MΩ

U

= 250 V

rms

Measurement of Interference Frequency (FST)

Measuring method: Measurement of oscillation period of the interfer-

ence voltage

Measuring

Range

16.0 … 400

Hz

Display Range Resolution Range

16.0…299.9…99

9 Hz

0.1 … 1 Hz 1 V …

50 V

Limits of

Error

± (1% v. mv

+2 digit)

Earthing Resistance (RE)

Measuring method: current and voltage measurement with probe

as IEC61557-5

Open circuit voltage: 20 / 48 V, AC

Short circuit current: 250 mA AC

Measuring frequency: 94 , 105 , 111 , 128 Hz selected manually or

automatic.(AFC) 55 Hz in function R*

Noise rejection: 120 dB ( 16 2/3, 50 , 60, 400 Hz )

Max. overload: U

13

= 250 V

rms

Page 22

1625

Users Manual

Intrinsic Er-

ror or Influ-

ence Quan-

tity

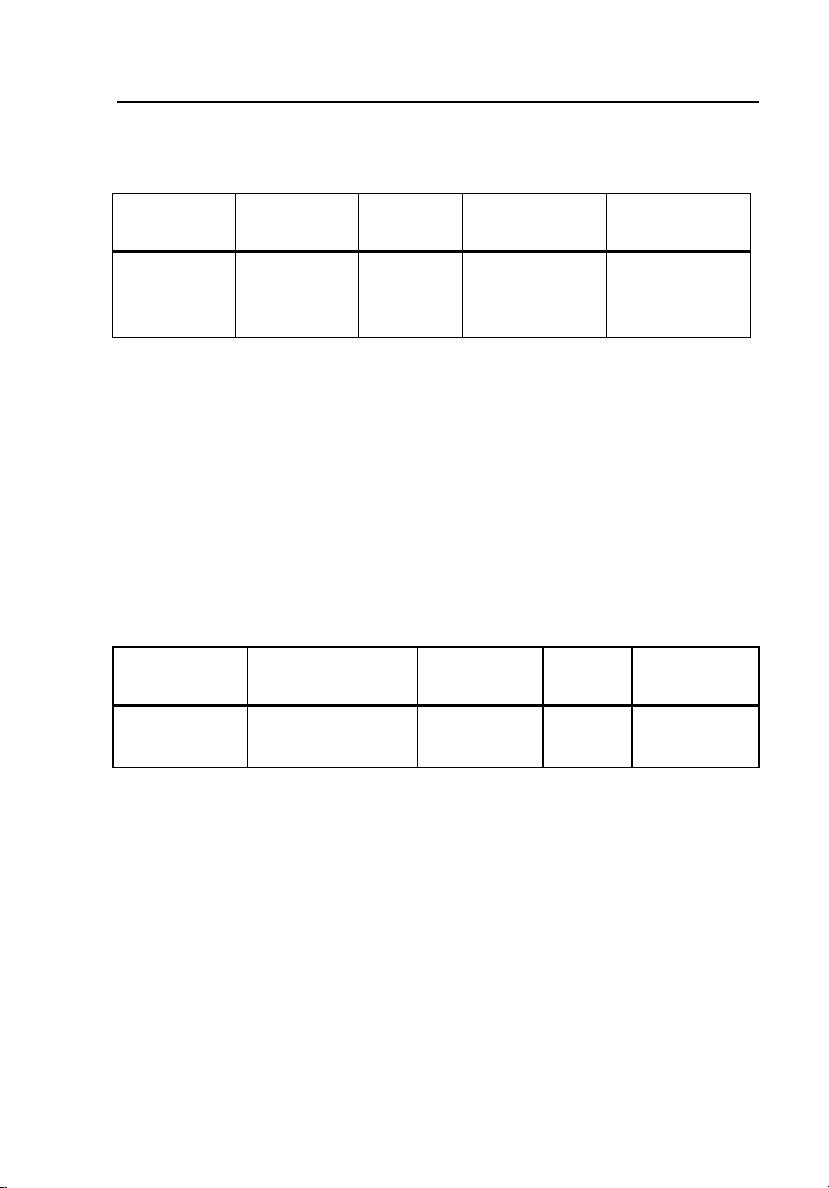

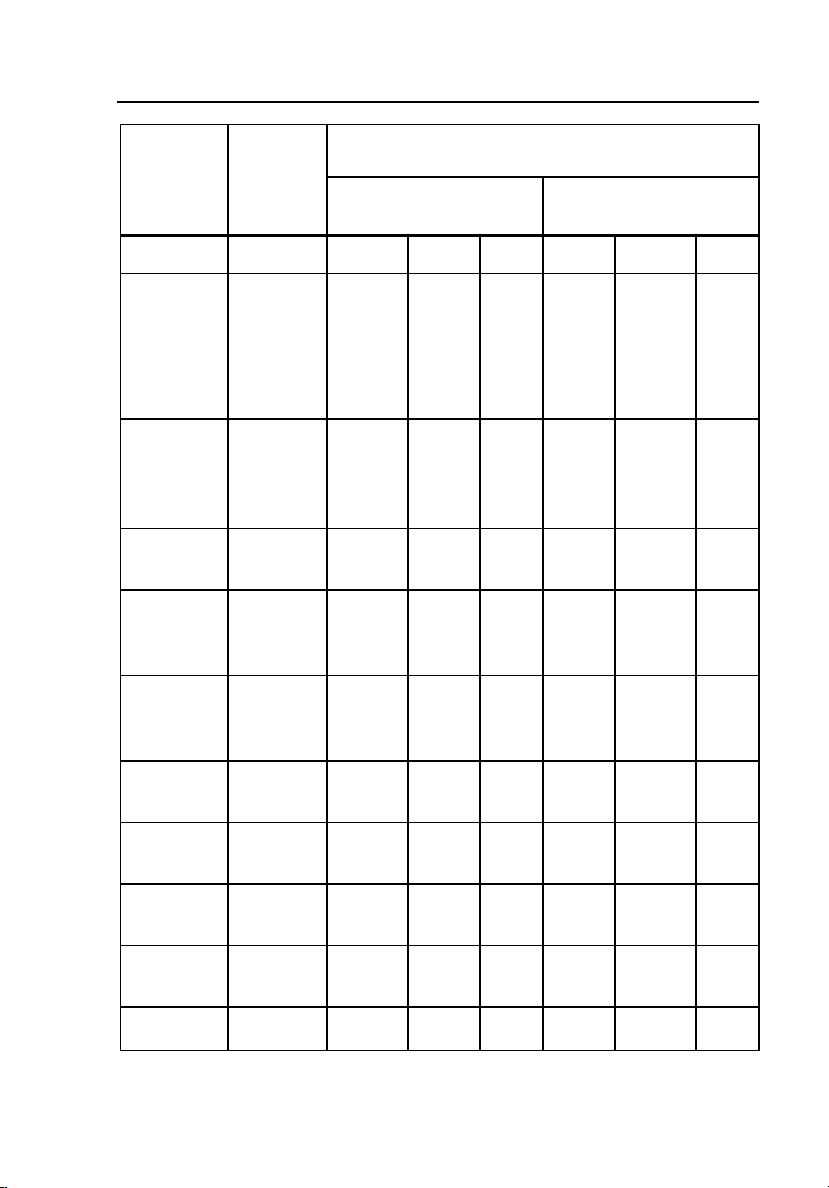

Table 2. Electrical Measurement Specifications

Requirements

Reference Con-

ditions or Speci-

fied Operating

Range

Designation

Code

or Test in Ac-

cordance with

the Relevant

Parts of

IEC 1557

Type

of

Test

Intrinsic error Reference condi-

A Part 5, 6.1 R

tions

Position Reference posi-

E1 Part 1, 4.2 R

tion

± 90°

Supply voltage

At the limits

stated by the

E2 Part 1, 4.2,

4.3

manufacturer

Temperature 0 °C and 35 °C E3 Part 1, 4.2 T

Series interference volt-

See 4.2 and 4.3 E4 Part 5, 4.2,

4.3

age

Resistance

of the probes

and auxiliary

0 to 100 x R

but ≤ 50 kΩ

A

E5 Part 5, 4.3 T

earth electrodes

System frequency

99 % to 101 % of

the nominal fre-

E7 Part 5, 4.3 T

quency

System voltage

85 % to 110 % of

the nominal volt-

E8 Part 5, 4.3 T

age

R

T

Operating

error

14

Part 5, 4.3 R

282726252423222

15,1( EEEEEEEEAB +±=

1

Page 23

Earth/Ground Tester

Specifications

A = intrinsic error

En = variations

R = routine test

T = type test

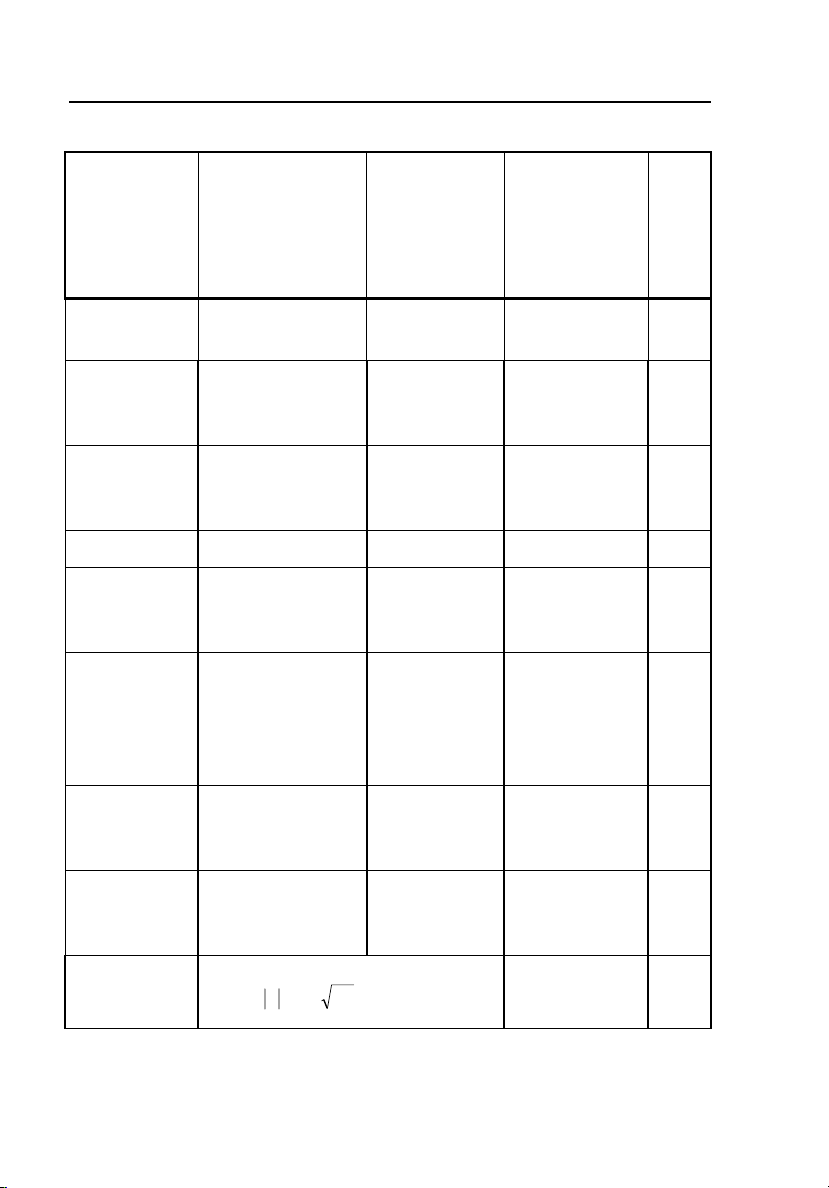

[]

%B ±=

B

valuefiducial

100% x

Measuring

Range

0.001 Ω...2.999 Ω 0.001 Ω

3.00 Ω...29.99 Ω 0.01 Ω

0.020 Ω 30.0 Ω...299.9 Ω 0.1 Ω

300 kΩ 0.300 kΩ...2.999 kΩ 1 Ω

3.00 kΩ...29.99 kΩ 10 Ω

30.0 kΩ...299.9 kΩ 100 Ω

Display Range Resolution

Instrinsic

Error

± ( 2 % of

mv +2 digit )

Max. Op-

erating

Error

± ( 5% of

mv +5

digit )

Measuring time: typ. 8 sec. with a fixed frequency

30 sec. max. with AFC and complete cycle of all

measuring frequencies

Additional error because of

probe-and auxiliary earth

electrode resistance:

Measuring error of RH and

RR

SH

R

E

typ. 10 % of

)2000(

Ω+

RRR ++

6

−

HsE

+××

digits

5%1025.1

RS:

Max. probe resistance: ≤ 1 M Ω

Max. auxiliary earth elec-

≤ 1 M Ω

trode resistance:

Automatic check if error is kept within the limits required by IEC61557-5.

If after a measurement of probe-, auxiliary earth electrode- and earthing resistance, a measurement error of higher than 30 % is assumed because of the in-

15

Page 24

1625

R

Users Manual

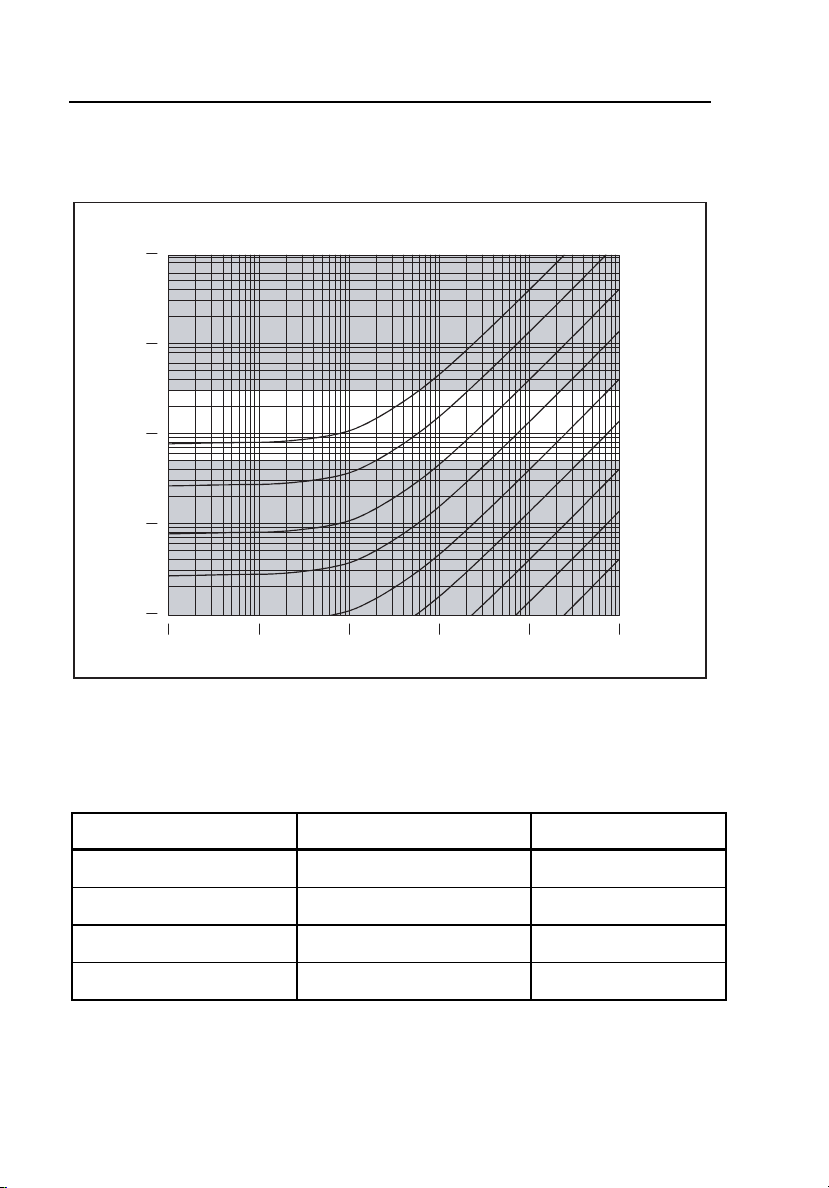

fluencing conditions (see diagramm), the display shows a warning symbol W

and a notice that RS or RH are too high.

F

%0001

%001

%01

%1

0

%1,

1 01

k

1 00

k01

3

k001

0001000

E

00

H

=R/R

3

0

01

3

0

01

3

1

3,0

S

M

1

edw005.eps

Automatic switchover of measuring resolution in dependence to auxiliary earth

electrode resistance R

:

H

RH with Umeas = 48 V RH with Umeas = 20 V Resolution

< 300 Ω < 250 Ω 1 mΩ

< 6 kΩ < 2,5 kΩ 10 mΩ

< 60 kΩ < 25 kΩ 100 mΩ

< 600 kΩ < 250 kΩ 1 Ω

16

Page 25

Earth/Ground Tester

Specifications

Selective Measurement of the Earthing Resistance

(R

A

)

E

Measuring method: Current and voltage measurement with probe as per

EN61557-5 and current measurement in the individual

branch with additional current transformer (patent applied for).

Open circuit volt-

20 / 48 V AC

age:

Short circuit current: 250 mA AC

Measuring frequency:

94, 105, 111, 128 Hz selected manually or automatically (AFC), 55 Hz (R

*

)

Noise rejection: 120 dB (16 2/3 , 50 , 60 , 400 Hz)

Max. overload: max. Urms = 250 V (measurement will not be started)

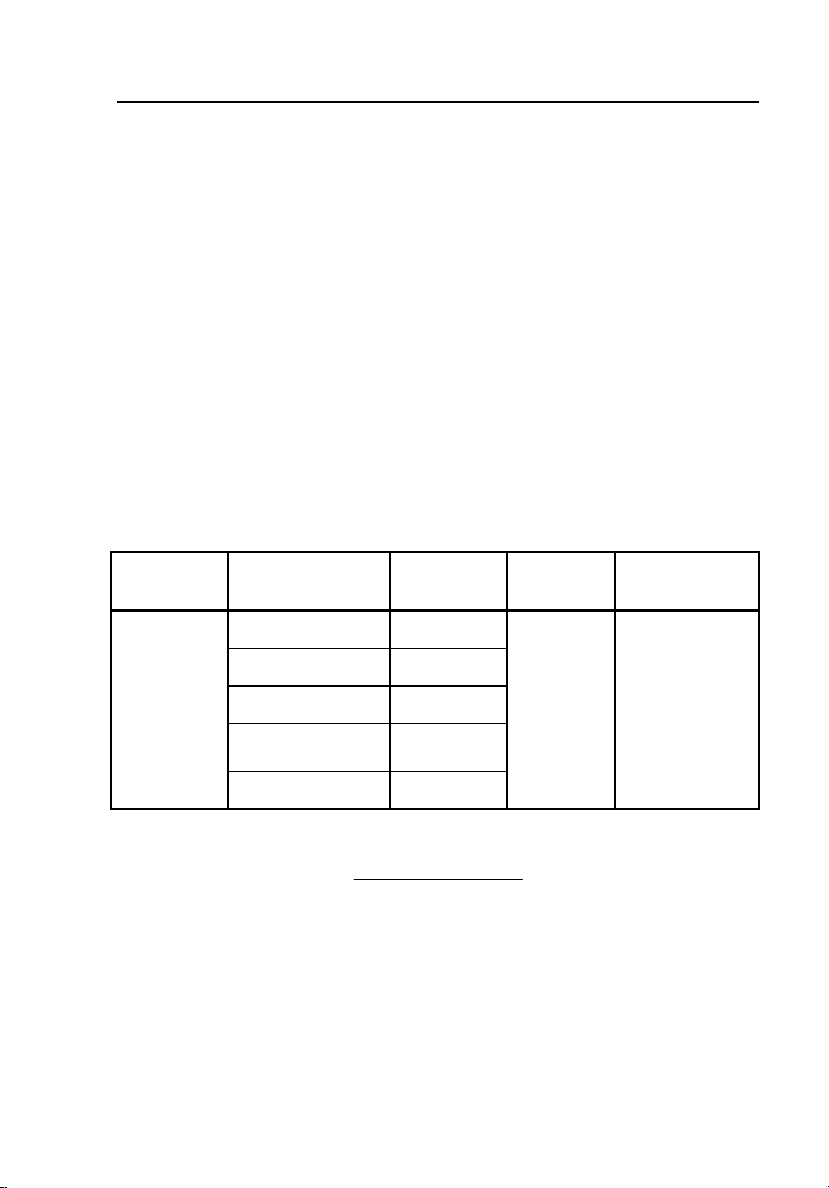

Measuring

Range

0.001...2.999 Ω 0.001 Ω

3.00...29.99 Ω 0.01 Ω

0.020 Ω... 30.0...299.9 Ω 0.1 Ω

30 kΩ 0.300...2.999 kΩ 1 Ω

3.00...29.99 kΩ 10 Ω

Display Range Resolution

Intrinsic

Error *

± (7 % of

m.v. +2

digit)

Operating

Error *

± (10% of m.v.

+5 digit)

* With recommended current clamps / transformers.

Additonal error because

of probe- and auxiliary

earth typ.electrode resis-

RR

R

SH

ETOTAL

)2000(

Ω+

6

−

+××

digits

5%1025.1

tance:

Measuring error of RH

and RS:

Measuring time:

typ.of 10% of

RRR ++

HSETOTAL

typ. 8 sec. with a fixed frequency 30 sec.max.

with AFC and complete cycle of all measuring

frequencies

17

Page 26

1625

Users Manual

Minimal current in single

0.5 mA with transformer (1000:1)

branch to be measured:

Max. interference current

through transformer:

0.1 mA with transformer (200:1)

3 A with a transformer (1000:1)

Resistance Measurement (R~)

Measuring method: current and voltage measurement

Measuring voltage: 20 V AC, square pulse

Short circuit current: > 250 mA AC

Measuring frequency: 94, 105, 111, 128 Hz selected manually or auto-

matically (AFC)

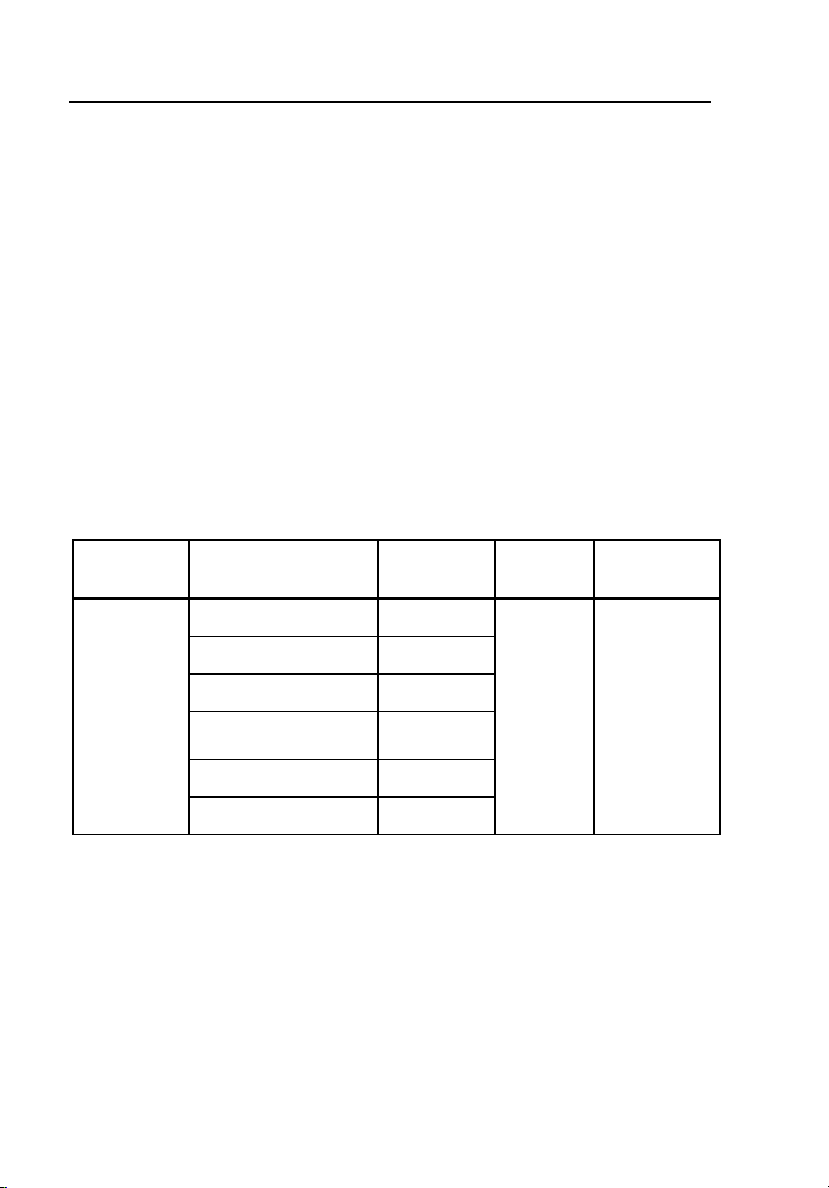

Measuring

Range

0.001 Ω ... 2.999 Ω 0.001 Ω

3.0 Ω ... 29.99 Ω 0.01 Ω

0.020 Ω... 30 Ω ... 299.9 Ω 0.1 Ω

300 kΩ 300 Ω ... 2999 Ω 1 Ω

Display Range Resolution

Intrinsic

Error

± ( 2 %

of m.v.

+2 digit )

Operating

Errors

± ( 5% of m.v.

+5 digit )

3.0 kΩ ... 29.99 kΩ 10 Ω

30.0 kΩ ... 299.9 kΩ 100 Ω

Measuring time: typ. 6 sec.

Max. interference voltage: 24 V, with higher voltages measurement will not

be started

Max overload: Urms max. = 250 V

18

Page 27

Earth/Ground Tester

Specifications

Resistance Measurement (RF)

Measuring method: current- voltage measurement as per IEC61557-4

possible

Open circuit voltage: 20 V DC

Short circuit current: 200 mA DC

Formation of measured

value:

with 4-pole measurement wires on H, S, ES can

be extended without additional error.

Resistances >1 Ω in wire E can cause additional

error of 5m Ω/Ω.

Measuring

Range

0.001 Ω ... 2.999 Ω 0.001 Ω

0.020 Ω 3.0 Ω ... 29.99 Ω 0.01 Ω

3 kΩ 30.0 Ω ... 299.9 Ω 0.1 Ω

300 Ω ... 2999 Ω 1 Ω

Display Range Resolution Intrinsic

Error

±( 2 % of

m.v. +2

digit)

Operating

Error

±( 5% of

m.v. +5

digit)

Measuring sequence: approx. 2 measurements/s

Measuring time: typ. 4 sec. incl. reversal of polarity (2 pole or 4

pole)

Max. interference voltage: ≤ 3 V AC or DC, with higher voltages measure-

ment will not be started

Max inductivity: 2 Henry

Max. overload: Urms = 250 V

19

Page 28

1625

Users Manual

Compensation of Lead Resistance (RK)

Compensation of lead resistance (RK) can be

switched on in functions R

A, R~ , and R F 2pole

Formation of measured value:

3pole, RE 4pole

E

R

* Value of setpoint entry R

display

= R

measured

- R

compensated

*

= 0.000Ω, vari-

K

able from 0.000…29.99 Ω by means of

measuring adjustment.

20

Page 29

Earth/Ground Tester

Description of the Operating Elements

Description of the Operating Elements

Figure 4 illustrates the operating elements described below.

6

EARTH / GROUND TESTER

2

3

4

START

TEST

DISPLAY

MENU

CHANGE

ITEM

SELECT

1625

Earth/Ground Resistance 300k

RA

4

POLE

3

POLE

4

POLE

3

POLE

OFF

AC

Resistance

300k

R

2

POLE

DC Low Resistance 3k

R

2

POLE

4

POLE

ES/P1

H/C2

S/P2

8

9

7

E/C1

10

5

1

rear side

12

13

11

edw006.eps

Figure 4. Operating Elements

A Central rotary switch to select measuring function or switch ON/OFF

B "START TEST"-button to start the set measuring function.

C "DISPLAY MENU"-button to call corresponding supplementary values.

21

Page 30

1625

Users Manual

D "CHANGE ITEM" button to change the set point entry values.

E "SELECT" button to select the digit to be changed.

F Display unit, liquid crystal digits, 18 mm high with automatic decimal

point as well as active illumination.

G Connecting socket H (auxiliary earth electrode) (4 mm ø) also usable

with safety measuring lead

H Connecting socket G (probe) (4 mm ø) also usable with safety measuring

lead.

I Connecting socket for an ext. clip-on current transformer (optional).

W Warning

No voltage permissable to sockets EFGH.

J Connecting socket F (earthing probe) (4 mm ø) also usable with safety

measuring lead. Potential pick off with 4-pole earthing measurement.

K Connecting socket E (earth electrode) (4 mm ø) also usable with safety

measuring lead.

W Attention

Do not open or close the instrument with force!

L Battery compartment for: 6 x IEC LR6 batteries or type AA batteries.

W Warning

Disconnect all leads before opening the instrument!

M Screws to fasten the battery compartment

22

Page 31

Earth/Ground Tester

Description of the Operating Elements

Description of Display Elements

The display (Figure 5) is divided into four display elements:

1. Digital display of measured value

2. Measuring function field to display measuring function

3. Unit field: V, Ω, kΩ, Hz

4. Special characters for operator guidance

2 3

Figure 5. Display Elements

1

4

Description of display symbols:

U

Interference voltage (AC + DC)

ST

F

Frequency of interference voltage

ST

F

Frequency of measuring voltage

M

U

Measuring voltage limit 20/48 V

M

R

Earthing resistance

E

R

Auxiliary earth electrode resistance

H

R

Probe resistance

S

R

Compensation resistance

K

R

, R2 Low voltage measurement with polarity indication

1

edw008.eps

23

Page 32

1625

Users Manual

R ~ AC- resistance

*

Earthing impedance (measuring frequency 55 Hz)

R

AFC Automatic-frequency-control

TEST Measuring sequence in process

LIMIT Limit value

> LIMIT Limit value exceeded

EFGH Socket recognition

B Recognition of current transformer socket

} Message of an exceeded limit with beeper

LO-BAT Battery voltage too low, replace batteries.

REMOTE Interface ( optional ) active - button operation locked

C Measuring circuit ( E-S,E-H ) interrupted or measured value

instable

W Warning

Refer to Operating Instructions.

Procedure of Measurements

W Warning

Use the instrument on voltage free systems only.

1. Set measuring function with the central rotary switch 1

2. Connect instrument without measuring lead connected START is

omitted

3. Start measurement with "START TEST" button.

4. Read out measured value.

For optimum performance and utilization of the device observe the following

points:

24

Page 33

Earth/Ground Tester

Procedure of Measurements

POWER ON Functions

During switching on of the instrument with the central rotary switch it is possible to access certain operating conditions by pressing certain button combinations:

a) Standard mode

If the device is put into operation without further button control, it switches

into a battery saving condition (Stand by-display "---") approx. 50 seconds

after the termination of a measurement, or after a button push or turn of the

rotary switch. Pressing the "DISPLAY MENU" reactivates the instrument; the

"old" measured values can be read out again. After 50 min. of stand by the

Display is turned off completely. Instrument is reactivated with ON / OFF on

the rotary switch

b) Stand by disable

A simultaneous push of buttons "DISPLAY MENU" and "CHANGE ITEM"

during switching on prevents the instrument from being switched off automatically (Stand by). The battery saving mode is reactivated with ON / OFF on the

central rotary switch.

c) Prolonged displaytest

By keeping the "DISPLAY MENU" button pressed during switching on, the

display test can be prolonged for any length of time. Return to the standard

operation mode by pressing any button or turning of the central rotary switch.

d) Number of software version

By keeping the "SELECT" button pressed during the switch on sequence, the

number of the software version is indicated on the display. By pressing the

"DISPLAY MENU" button a switch over to the last calibration date is possible. This display sequence is terminated by turning the central rotary switch or

pressing the "START TEST" button.

Display format: SOFTWARE-version: X. X X

Date of calibration: M M . J J

Note

At delivery the date of calibration is set to 0.00. Only after the first

recalibration a proper date is indicated.

25

Page 34

1625

Users Manual

e) Activation of display illumination

By keeping the "CHANGE ITEM" button pressed during the switch on sequence the display illumination is activated. Illumination fades away automatically if the instrument is switched to"Stand by" and, together with the instrument, is switched on again by pressing any button. The instrument is switched

off with ON/OFF on the central rotary switch exclusively.

Operation

The measuring functions have two initial operational modes: the Control loop

and the Measuring loop (see Figure 6).

26

Page 35

Earth/Ground Tester

Procedure of Measurements

CONTROL LOOP

POWER ON

Function

SELECT MEASURING

FUNTION WITH

CENTRAL ROTARY

SWITCH

1 X DISPLAY

SET VALUE OR

VOLTAGE

MEASUREMENT

1 X CHANGE 1 X SELECT

QUICK

SWITCHOVER,

SET VALUE

DIGIT/DECIMAL POINT

SPOT SELECTION

ON/OFF

LIMIT

MEASURING LOOP

1 X START

MEASUREMENT

DISPLAY, MEASURED VALUE

OR SUPPLEMENTARY VALUE

1 X DISPLAY

1 X CHANGE

INCREASE SELECTED

SPOT (DIGIT/DECIMAL

POINT) BY 1

edw009.eps

Figure 6. Operational Modes

27

Page 36

1625

Users Manual

Control Loop

After turning the function rotary switch, the voltage display mode is reached.

Pushing "DISPLAY MENU" now calls up the control loop. According to the

selected measuring function, different setting values can be displayed and

changed in the control loop. The "DISPLAY MENU" button switches between

the different set values inside a contiuous loop. The "SELECT" button selects

the decimal point to be changed. Pushing the "CHANGE ITEM" button the

instrument either switches between certain set values or increases the decimal

point selected with "SELECT" by 1.

After parmeter setting has been finished the next display can be called with

"DISPLAY MENU" or the measurement can be started with "START TEST".

Depending on the selected function, the following parameters can be displayed

or changed:

Function Parameter Setting Range Remarks

U

F

RE

3pole

U

and RK 0.000 Ω ... 29.99 Ω in position RE

R

RE

4pole

Sound) is activated with

R* On/Off only if activated

display only

ST

display only

ST

FM (AFC/94/105/111/128) Hz

48 V/20 V selectable to 20 V

M

with CODE

3pole only *

LIMIT 0.000 Ω ... 999 kΩ only if activated

E

with CODE

}(warning On/Off only if R

CODE

with CODE

U ST display only RE

F ST display only

LIMIT

E

28

Page 37

Earth/Ground Tester

Procedure of Measurements

A U

and RK 0.000 Ω ... 29.99 Ω in position RE

4pole

A

}(warning- On / Off only if RE LIMIT

sound) is activated with

R* On / Off only if activated

48 V/20 V selectable to 20 V

M

with CODE

3pole only *

I ( ratio ) 80 ... 1200 display only RE

RE LIMIT 0.000 Ω ... 999 kΩ only if activated

with CODE

CODE

with CODE

* (see Compensation of Earth Electrode Connecting Lead)

Function Parameter Setting Range Remarks

U

F

F

R~ RK 0.000 Ω ... 29.99 Ω

R ~ LIMIT 0.000 Ω ... 999 kΩ only if activated

}(warning- On / Off only if R ~ LIMIT

sound) is activated with

RF U

2pole F ST display only

and RK 0.000 Ω ... 29.99 Ω

4pole R LIMIT 0.000 Ω ... 9,99 kΩ only if activated

}(warning -

display only

ST

display only

ST

(AFC/94/105/111/128) Hz

M

with CODE

CODE

display only

ST

with CODE

On / Off only if R LIMIT is

sound)

activated with

CODE

29

Page 38

1625

Users Manual

Measuring Loop

This loop is entered by pressing the "START TEST" button. After releasing

"START TEST" the last measured value stays on the display. By repeated

pressing of the "DISPLAY MENU" button all supplementary values can be

called. If a measured value exceeds or falls below the pre-set limit, the limit

can be displayed as well (with "DISPLAY MENU"). In that case the measured

value is diplayed with a flashing "LIMIT" whereas the limit value is displayed

with a steady "LIMIT"-symbol.

Inside the measuring loop parameters cannot be changed.

Further possibilities of button operation:

Warning sound (}) cancel with "DISPLAY MENU" (with display switchover)

or with "CHANGE ITEM" or "SELECT" button (without display switchover).

Checking of Correct Measuring Connection (Socket Allocation)

The instrument implements an automatic check, corresponding to the measurement selected, to see if the correct input sockets are used.

The display symbols EFGH and B

as shown in Figure 4.

From the way the symbols are displayed, the validity of the connected wiring

can be concluded by the following features:

• socket incorrectly wired (or, by mistake, not wired): corresponding

symbol flashes.

• socket correctly wired: corresponding symbol is steady active

• socket with no connection: corresponding symbol is blank

30

are assigned to a specific socket

Page 39

Earth/Ground Tester

Procedure of Measurements

Safety Control Measurements

Before each measurement the instrument automatically checks the measuring

conditions and, while simultaneously displaying the kind of error, prevents

measurements from being started under the following conditions:

• excessive voltage on the sockets (> 24 V in RE and R~; > 3 V in

RF)

• wrong or incomplete connection

• Problems during the measuring sequence (display "E1 ... E5") see

display description in the section ‘Procedure of Measurements’.

• Battery voltage too low ( display LO-BAT )

Measurement of Interference - Voltages and Frequencies

This measuring function detects possible interference voltages and their frequencies. This function is automatically active in every switch position before

an earthing or resistance measurement. If the pre-set limit values are exceeded,

the interference voltage is indicated as too high and a measurement automatically prevented .The frequency of an interference voltage is only measurable if

the level of this intereference voltage is higher than 1 V. See Figure 7.

Bring central rotary switch in desired position, read out measured value of interference voltage, measured value of interference frequency is displayed with

"DISPLAY".

31

Page 40

1625

Users Manual

START

TEST

DISPLAY

MENU

Earth/Ground Resistance 300k

4

POLE

CHANGE

ITEM

3

POLE

OFF

SELECT

EARTH / GROUND TESTER

1625

RA

4

POLE

3

POLE

Resistance

300k

2

H/C2

S/P2

AC

DC Low Resistance 3k

R

R

POLE

2

POLE

4

POLE

ES/P1

E/C1

Auxiliary

earth

Earth

Probe

electrode

electrode

>20 m >20 m

Figure 7. Measurement of Interference - Voltages and Frequencies

edw010.eps

Measurement of Earthing Resistances

This instrument is equipped with a 3 pole as well as a 4 pole resistance measurement which renders measurements of resistances of earthing systems possible, as well as measurements of the soil resistivity of geological strata. A specific description of the different applications is given further on in this manual.

As a special function, the instrument offers measurements with an external

current transformer, with which a measurement of single resistance branches in

interlinked networks (lightning protection and high voltage pylons with cabling) can be performed without seperating parts of the system.

To ensure most feasible interference suppression during measurements, the

instrumen t is equipped with 4 measuring frequencies (94 Hz, 105 Hz,

111 Hz, 128 Hz), with automatic switch over if necessary (AFC - Automatic

Frequency Control). The corresponding measuring frequency used for a specific measurement can be called and displayed with "DISPLAY MENU" after

the measurement. Additionally, one of the four measuring frequencies can be

selected and permanently set in special cases. In that case, in order to stabilize

the display, an average measurement can be carried out for up to 1 minute by

keeping the ”START TEST" button pressed.

To determine the earthing impedance (R

close to the mains frequency (55 Hz) is carried out. At the activation of R*

through user's code, this measuring frequency is activated automatically.

*

) a measurement with a frequency

32

Page 41

Earth/Ground Tester

Procedure of Measurements

To keep the instrument as simple as possible at the time of delivery, all special

functions, such as LIMIT input, BEEPER programming, measurement of

earthing impedance (R

*

) etc, are not activated at delivery. They can be activated with personalized user's code (see "Changing of all Pre-set Data with

Personalized Code"). Refer to Figure 8.

G

I

E

E

RE

E

U

Umeas.

I

S

S

RS

H

H

H

R

edw011.eps

Figure 8. Earthing Resistances Measurement - Method

3-pole/4-pole Measurement of Earthing Resistance

This measuring function measures earthing and earth dissipation resistances of

single earth electrodes, foundation earth electrodes and other earthing systems

by using 2 earth spikes. See Figure 9.

33

Page 42

1625

Users Manual

START

TEST

DISPLAY

MENU

Earth/Ground Resistance 300k

4 POLE

CHANGE

ITEM

3 POLE

OFF

SELECT

EARTH / GROUND TESTER

1625

RA

4 POLE

3 POLE

Resistance

300k

2 POLE

H/C2

S/P2

AC

DC Low Resistance 3k

R

R

2 POLE

4 POLE

ES/P1

E/C1

4 pole

Auxiliary

earth

Earth

Probe

electrode

electrode

>20 m >20 m

Figure 9. 3-pole/4-pole Measurement of Earthing Resistance - Process

edw012.eps

1. Turn central rotary switch to position "RE 3pole" or "RE 4pole"

The instrument is to be wired according to picture and notices given

on the display.

A flashing of the sockets symbols EFGH or A, points to an

incorrect or incomplete connection of the measuring lead.

2. Press "START TEST" button

Now a fully automated test sequence of all relevant parameters like

auxiliary earth electrode, probe- and earth electrode resistance, is implemented and finished with the display of the result R

3. Read out measured value R

4. Call R

and RH with "DISPLAY MENU".

S

E

.

E

Remarks for the setting of earth spikes:

Before setting the earth spikes for probe and auxiliary earth electrode make

sure that the probe is set outside the potential gradient area of earth electrode

and auxiliary earth electrode (also see “The Influence of Potential Gradient

areas on Earth Resistance Measurement”). Such a condition is normally

reached by allowing a distance of > 20 m between the earth electrode and the

earth spikes as well as of the earth spikes to each other.

34

Page 43

Earth/Ground Tester

Procedure of Measurements

An accuracy test of the results is made with another measurement following

repositioning of the auxiliary earth electrode or probe. If the value stays the

same, the distance is sufficient. If the measured value changes, probe or auxiliary earth electrode must be repositioned until the measured value R

stays

E

constant.

Spike wires should not run too close to each other.

3-pole measurement with longer earth electrode connecting leads

Use one of the accessory cable drums as earth electrode connecting lead. Spool

off cable completely and compensate line resistance as described in “Compensation of Earth Electrode Connecting Lead”.

Time average measurement:

If there is a warning "measured value unstable" (see “Procedures of Measurement”, “Description of display”) after a test sequence, most likely it is caused

by strong interference signals (e.g. unsteady noise voltage).Nevertheless, to get

reliable values, the instrument offers the possibility of averanging over a

longer period.

1. Select a fixed frequency (see “Control loop” in “Operation”)

2. Keep the "START TEST" button pressed until the warning "measured

value unstable" disappears. Max. averaging time is approx. 1 min.

Evaluation of measured value:

Figure 10 shows the maximum permissible value of the Earth resistance which

will not exceed a permissible limit value, taking into account the maximum

usage error.

Desired Values

10

0

5

10

20

20

50

50

100

100

200

200

500

1000

1000

500

Measured Values

3000 3152

2000

2999

edw013.eps

Figure 10. Earth Resistance - Maximum Permissible Value

35

Page 44

1625

Users Manual

Measurement of Single Earth Electrode Resistances in Mesh Operated Earthing Systems Using Selective Clamp Method

This measuring method has been created to measure single earth electrodes in

permanently wired or mesh operated systems (e.g. lightning protection system

with several electrodes or high voltage pylons with earth cabling etc.). By

measuring the actual current flow through the earth electrode, this special

measuring method provides the unique possibility to measure selectively only

this particular resistance by means of a clip-on transformer (accessory). Other

parallel resistances applied are not taken into account and do not distort the

measuring result.

A disconnection of the earth electrode before the measurement is therefore no

longer necessary.

I

I

3

RE

RE

1

RE

2

3

RE3 =

Figure 11. Measurement of Single Earth Electrode Resistances in Mesh

Operated Earthing Systems

G

I

Z

tr

U

A

meas.

I

3

=

U

V

RS

meas.

tr

U

meas.

Aux. Earth

Probe

Electrode

RH

I

.

Z

edw014.eps

36

Page 45

Earth/Ground Tester

Procedure of Measurements

Errors of the current transformer can be corrected as described in “Correcting

Clip-on Transformer Error”.

3-pole/4-pole Measurement of Single Earth Electrode Resistances

See Figure 12.

EARTH / GROUND TESTER

1625

START

TEST

DISPLAY

MENU

Earth/Ground Resistance 300k

4 POLE

CHANGE

ITEM

3 POLE

OFF

SELECT

H/C2

S/P2

AC

Resistance

300k

DC Low Resistance 3k

RA

R

R

2 POLE

4 POLE

2 POLE

3 POLE

4 POLE

ES/P1

E/C1

4 Pole

Probe

Auxiliary

earth

electrode

Earth

electrode

>20 m >20 m

edw015.eps

Figure 12. 3-pole/4-pole Measurement of Single Earth Electrode Resis-

tances

Turn central rotary switch to position "A RE 3pole" or "A RE 4pole".

The instrument is to be wired according to picture and notices given on the

display.

A flashing of the sockets symbols EFGH or A, points to an incorrect

or incomplete connection of the measuring lead.

Fix clip-on transformer around the earth electrode to be measured.

Make sure that the clip-on transformation ratio set on the instrument corresponds to the clip-on transformer used. Change settings if necessary (see

“Changing of all Data Settings with Personalised CODE”)

37

Page 46

1625

Users Manual

Note

The ratio that is preset from factory is correct for the EI162X sensing

clamp

Press "START TEST" button.

Now a fully automated test sequence of all relevant parameters like auxiliary

earth electrode, probe- and earth electrode resistance, is implemented and finished with the display of the result R

1. Read out measured value R

2. Call R

and RH with "DISPLAY MENU".

S

.

E

E

Remarks for the Setting of Earth Spikes

Before setting the earth spikes for probe and auxiliary earth electrode make

sure that the probe is set outside the potential gradient of earth electrode and

auxiliary earth electrode (see also 12.5). Such a condition is normally reached

by allowing a distance of >20 m between the earth electrode and the earth

spikes as well as to the earth spikes to each other. An accuracy test of the results is made by another measurement following repositioning of the auxiliary

earth electrode or probe. If the value stays the same, the distance is sufficient.

If the measured value changes, probe or auxiliary earth electrode must be repositioned until the measured value RE stays constant.

Spikes wires should not run too close.

3-pole Measurement with Longer Earth Electrode Connecting Leads

1. Use one of the accessory cable drums as earth electrode connecting

lead.

2. Spool off cable completely and compensate line resistance as described in “Compensation of Earth Electrode Connecting Lead”.

Time Average Measurement

If there is a warning "measured value unstable" (see “Description of Displays”,

Procedure of Measurements) after a test sequence, most likely it is caused by

strong interference signals (e.g. unsteady noise voltage). Nevertheless, to get

38

Page 47

Earth/Ground Tester

Procedure of Measurements

reliable values, the instrument offers the possibility of averaging over a longer

period.

1. Select a fixed frequency (see "Control loop", Operation)

2. Keep the "START TEST" button pressed until the warning "measured

value unstable" disappears. Max. averaging time is approx. 1 min.

Measurements on High Voltage Pylons

Measuring the Earthing Resistance without Disengaging

the Overhead Earth Wire Using the Selective Clamp

Method

The measurement of the earth resistance of a single high voltage pylon usually

requires the overhead earth wire to be disengaged (lifted off) or the seperation

of the earthing system from the pylon construction. Otherwise false reading of

the resistance of the pylon earth electrode are liable to occur because of the

parallel circuit of the other pylons connected to each other by an overhead

earth wire.

The new measuring method employed in this instrument - with its external

current transformer to measure the true current flowing through the earth electrode - allows measurements of earth electrode resistances without disconnection of the earthing system or disengaging the overhead earth wire.

As all four pylon stubs are connected to the foundation earth of the pylon, the

measuring current I

is divided into five components according to the pre-

meas

sent resistances involved.

One part flows via pylon construction to the overhead earth wire and further to

the parallelly circuited pylon earthing resistances.

The other four current components (I

The addition of all currents result in a current I

... I4) flow via the individual pylon foots.

1

going through the earthing

E

resistance, i.e. the resistance of the "composite"earth electrode to the soil.

If the current transformer is fixed to each pylon stub, one after the other, four

resistances have to be measured which show a behaviour inversely proportional to the corresponding current components I

... I4. The feeding point of

1

the measuring current is to be left unchanged to avoid a change in the current

distribution.

39

Page 48

1625

Users Manual

Accordingly, these equivalent resistances are displayed as:

U

meas

=

R

Ei

Therefore the earthing resistance R

li

of the pylon is determined as a parallel

E

circuit of the individual equivalent resistances:

R

=

E

1

+++

EARTH / GROUND TESTER

1625

START

TEST

DISPLAY

MENU

Earth/Ground Resistance 300k

3

4

POLE

CHANGE

ITEM

3

POLE

OFF

SELECT

H/C2

S/P2

AC

Resistance

300k

DC Low Resistance 3k

RA

R

R

2

POLE

4

POLE

2

POLE

POLE

4

POLE

ES/P1

E/C1

1111

RRRR

4321

EEEE

4 Pole

Probe

>20 m >20 m

Figure 13. Measuring the Earthing Resistance without Disengaging the

edw016.eps

Overhead Earth Wire

1. Turn central rotary switch to position “ARE 3pole" or ARE

4pole". The instrument is to be wired according to picture and notices

given on the display.

Auxiliary

earth

electrode

A flashing of the sockets symbols EFGH or B, points to an

incorrect or incomplete connection of the measuring lead.

2. Apply current transformer to the pylon stub. Make sure that the transformation ratio set on the instrument corresponds to the current transformer used. Change settings if necessary (see “Changing of All Data

Settings with Personalised CODE”)

40

Page 49

Earth/Ground Tester

Procedure of Measurements

3. Press “START TEST” button

Now a fully automated test sequence of all relevant parameters like

auxiliary earth electrode, probe- and earth electrode resistance, is implemented and finishes with the display of the result R

4. Read out measured value R

5. Call R

and RH with “DISPLAY MENU”.

S

E

.

E

Notices for the setting of earth spikes:

Before setting the earth spikes for probe and auxiliary earth electrode make

sure that the probe is set outside the potential gradient of earth electrode and

auxiliary earth electrode (see also “The Influence of Potential Gradient Areas

on Earth Resistance Measurement”). Such a condition is normally reached by

allowing a distance of >20 m between the earth electrode and the earth spikes

as well as to the earth spikes to each other. An accuracy test of the results is

made with another measurement after repositioning of auxiliary earth electrode

or probe. If the result is the same, the distance is sufficient. If the measured

value changes, probe or auxiliary earth electrode must be repositioned until the

measured value R

remains constant. Spike wires should not run too close.

E

1. Apply current transformer to next pylon stub.

2. Repeat measuring sequence.

Current feeding point of measuring current (alligator clip) and the polarity of

the split core current transformer has to be left unchanged.

After values of R

R

has to be calculated:

E

R

=

E

of all pylon foots are determined, the actual earth resistance

Ei

1

+++

1111

RRRR

4321

EEEE

Note

If the displayed R

value is negative despite correct orientation of the

E

current transformer, a part of the measuring current is flowing upwards into the tower body. The earthing resistance, thus coming into

effect, correctly calculates, if the individual equivalent resistances

(under observation of their polarity) are inserted into the equation

above.

41

Page 50

1625

Users Manual

Time average measurement:

If there is a warning "measured value unstable" (see "Description of displays",

Procedure of Measurement) after a test sequence, most likely it is caused by

strong interference signals (e.g. unsteady noise voltage).

Nevertheless, to get reliable values, the instrument offers the possibility of

averanging over a longer period.

1. Select a fixed frequency (see "Control loop", Operation)

2. Keep the "START TEST" button pressed until the warning "measured

value unstable" disappears. Max. averaging time is approx. 1. min.

Measuring Earthing Impedance with 55 Hz (R*)

For the calculation of short circuit currents in power supply plants, the complex earthing impedance is important. Direct measurement is possible under

the following conditions:

Phase angle at 50 Hz: 30 °... 60 ° inductive

auxiliary earth electrode (ohmic): >100 • Z

E

Measuring process:

The measurement of the earthing impedance (R

*

) is only possible if it is activated by putting in a personalized user's code (see "Change of Setup Data with

Personalized Code"). If this measuring function is activated, in every measurement of the four RE positions, the earthing impedance R* is displayed before all other measured values.

Correcting Clip-on Transformer Errors

If the measurement of an earthing resistance by means of a clip-on transformer

results in a significantly different value as if measured without the clip-on, the

deviation may be due to the tolerances of the clip-on current transformer. This

error can be corrected by fine tuning the clip-on transformation ratio (basic

settings 1000:1). This correction applies to the transformer current range it was

performed with. For other ranges a different correction may be necessary.

1. Connect a low Ohm resistor (approx. 1 Ohm - in the range you want

to correct) as described in the picture below.

42

Page 51

Earth/Ground Tester

Procedure of Measurements

EARTH / GROUND TESTER

1625

START

TEST

DISPLAY

MENU

CHANGE

ITEM

SELECT

Earth/Ground Resistance 300k

RA

3

POLE

4

POLE

3

POLE

OFF

AC

Resistance

300k

R

2

POLE

4

POLE

DC Low Resistance 3k

R

2

POLE

4

H/C2

S/P2

POLE

ES/P1

E/C1

Figure 14. Correcting Clip-on Transformer Errors

edw017.eps

2. Turn central rotary switch to position "A RE 3pole".

3. Press "START TEST"-button and note result of RE value.

4. Connect clip-on transformer.

EARTH / GROUND TESTER

1625

START

TEST

DISPLAY

MENU

CHANGE

ITEM

SELECT

Earth/Ground Resistance 300k

RA

3

POLE

4

POLE

3

POLE

OFF

Resistance

300k

2

4

POLE

AC

R

POLE

DC Low Resistance 3k

2

POLE

H/C2

S/P2

R

4

POLE

ES/P1

E/C1

edw018.eps

5. Turn central rotary switch to position "A RE 3pole".

6. Press "START TEST" again.

If the thus measured value R

deviates from the RE value determined without

E

clip-on transformer by more than 5 %, adjust the clip-on transformation ratio

(tr) correspondingly:

)(

troldtrnew

E

×=

E

−

−

merontransforwithclipR

)(

meronTransfprpwithoutcliR

43

Page 52

1625

Users Manual

Example:

Your clip-on transformer has a transformation ratio of tr = 1000:1. The measurement without clip-on transformer results in a value R

clip-on transformer a value of R

= 1.175 Ω is measured.

E

The deviation thus reads (1.175 - 0.983) Ω= + 0.192 Ω and referring to R

= 0.983 Ω . With a

E

=

E

0.983 Ω an error evolves as following:

Ω

192.0

%100 +=

×

Ω

983.0

%5.19

The new transformation ratio to be set calculates:

1000 =×=trnew

175.1

1195

983.0

Compensation of Earth Electrode Connecting Lead

If the line resistance to the earth electrode can not be ignored, a compensation

of the connecting lead resistance to the earth electrode is possible. Proceed as

described below:

Measuring process:

EARTH / GROUND TESTER

1625

START

TEST

DISPLAY

MENU

Earth/Ground Resistance 300k

RA

4

POLE

3

POLE

4

POLE

CHANGE

ITEM

3

POLE

OFF

SELECT

Figure 15. Compensation of Earth Electrode Connecting Lead

Resistance

300k

2

H/C2

S/P2

AC

DC Low Resistance 3k

R

R

POLE

2

POLE

4

POLE

ES/P1

E/C1

Auxiliary

Earth

electrode

earth

electrode

edw019.eps

1. Turn central rotary switch to position "RE 3pole".

2. Wire instrument according to picture.

44

Page 53

Earth/Ground Tester

Procedure of Measurements

3. Call display R

with "DISPLAY MENU" button.

K

4. Implement compensation with "START TEST" button.

The compensation resistance is displayed only for as long as the "START

TEST" button is kept pressed. After releasing the "START TEST" button the

measured value is stored and the measuring instrument returns to the standard

settings at the beginning of the measurement so that a succeeding measurement

of the earthing resistance can be implemented by pressing "START TEST"

again. Thereafter, R

is subtracted from the actual measured value.

K

If the compensation value has to be reset to the basic setting (0.000 Ω), the

compensation sequence has to be implemented with an open (disconnected)

measuring lead or turn the switch to the next position and back.

Measurement of Soil Resistivity

The soil resistivity is the geological and physical quantity for calculation and

design of earthing systems. The measuring procedure applied below uses the

method developed by Wenner (F.Wenner, A method of measuring earth resistivity; Bull. National Bureau of Standards, Bulletin 12 (4), Paper 258, S 478496; 1915/16).

EARTH / GROUND TESTER

1625

START

TEST

DISPLAY

MENU

Earth/Ground Resistance 300k

RA

4

POLE

3

POLE

4

POLE

CHANGE

ITEM

3

POLE

OFF

SELECT

AC

Resistance

300k

R

2

POLE

DC Low Resistance 3k

2

POLE

H/C2

S/P2

R

4

POLE

ES/P1

E/C1

edw020.eps

Figure 16. Measurement of Soil Resistivity

45

Page 54

1625

π

ρ

Users Manual

1. Four earth spikes of the same length are positioned into the soil in an

even line and with the same distance "a" to each other. The earth

spikes should not be hammered in deeper than a maximum of 1/3 of

"a".

2. Turn central rotary switch to position "R

4pole".

E

The instrument is to be wired according to picture and notices given

on the display.

A flashing of the sockets symbols EFGH or B, points to an

incorrect or incomplete connection of the measuring lead.

3. Push "START TEST" button.

4. Read out measured value R

From the indicated resistance value R

.

E

, the soil resistivity calculates according

E

to the equation:

=

ρ

...... mean value of soil resistivity (Ωm)

E

R

...... measured resistance (Ω)

E

Ra..2

EE

a ...... probe distance (m)

The measuring method according to Wenner determines the soil resistivity

down to a depth of approx. the distance "a" between two earth spikes. By increasing "a", deeper strata can be measured and checked for homogenity. By

changing "a" several times, a profile can be measured from which a suitable

earth electrode can be determined.

According to the depth to be measured, "a" is selected between 2 m and 30 m.

This procedure results in curves depicted in the graph below.

46

Page 55

Earth/Ground Tester

Procedure of Measurements

2