Page 1

1620A “DewK”

Thermo-Hygrometer

January 2003 Rev. 1, 3/13

© 2003-2013 Fluke Corporation. All rights reserved. Specifications are subject to change without notice.

All product names are trademarks of their respective companies.

User’s Guide

Page 2

LIMITED WARRANTY AND LIMITATION OF LIABILITY

Each Fluke product is warranted to be free from defects in material and workmanship under normal use and

service. The warranty period is one year and begins on the date of shipment. Parts, product repairs, and

services are warranted for 90 days. This warranty extends only to the original buyer or end-user customer of

a Fluke authorized reseller, and does not apply to fuses, disposable batteries, or to any product which, in

Fluke's opinion, has been misused, altered, neglected, contaminated, or damaged by accident or abnormal

conditions of operation or handling. Fluke warrants that software will operate substantially in accordance with

its functional specifications for 90 days and that it has been properly recorded on non-defective media. Fluke

does not warrant that software will be error free or operate without interruption.

Fluke authorized resellers shall extend this warranty on new and unused products to end-user customers

only but have no authority to extend a greater or different warranty on behalf of Fluke. Warranty support is

available only if product is purchased through a Fluke authorized sales outlet or Buyer has paid the

applicable international price. Fluke reserves the right to invoice Buyer for importation costs of

repair/replacement parts when product purchased in one country is submitted for repair in another country.

Fluke's warranty obligation is limited, at Fluke's option, to refund of the purchase price, free of charge repair,

or replacement of a defective product which is returned to a Fluke authorized service center within the

warranty period.

To obtain warranty service, contact your nearest Fluke authorized service center to obtain return

authorization information, then send the product to that service center, with a description of the difficulty,

postage and insurance prepaid (FOB Destination). Fluke assumes no risk for damage in transit. Following

warranty repair, the product will be returned to Buyer, transportation prepaid (FOB Destination). If Fluke

determines that failure was caused by neglect, misuse, contamination, alteration, accident, or abnormal

condition of operation or handling, including overvoltage failures caused by use outside the product’s

specified rating, or normal wear and tear of mechanical components, Fluke will provide an estimate of repair

costs and obtain authorization before commencing the work. Following repair, the product will be returned to

the Buyer transportation prepaid and the Buyer will be billed for the repair and return transportation charges

(FOB Shipping Point).

THIS WARRANTY IS BUYER'S SOLE AND EXCLUSIVE REMEDY AND IS IN LIEU OF ALL OTHER

WARRANTIES, EXPRESS OR IMPLIED, INCLUDING BUT NOT LIMITED TO ANY IMPLIED WARRANTY

OF MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE. FLUKE SHALL NOT BE LIABLE

FOR ANY SPECIAL, INDIRECT, INCIDENTAL, OR CONSEQUENTIAL DAMAGES OR LOSSES,

INCLUDING LOSS OF DATA, ARISING FROM ANY CAUSE OR THEORY.

Since some countries or states do not allow limitation of the term of an implied warranty, or exclusion or

limitation of incidental or consequential damages, the limitations and exclusions of this warranty may not

apply to every buyer. If any provision of this Warranty is held invalid or unenforceable by a court or other

decision-maker of competent jurisdiction, such holding will not affect the validity or enforceability of any other

provision.

Fluke Corporation

P.O. Box 9090

Everett, WA 98206-9090

U.S.A.

Fluke Europe B.V.

P.O. Box 1186

5602 BD Eindhoven

The Netherlands

11/99

To register your product online, visit register.fluke.com

Page 3

Table of Contents

1 Before You Start . . . . . . . . . . . . . . . . . . . . . . . . . . 1

1.1 Symbols Used . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

1.2 Safety Information . . . . . . . . . . . . . . . . . . . . . . . . . . 2

1.2.1 Warnings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

1.2.2 Cautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

1.3 Authorized Service Centers. . . . . . . . . . . . . . . . . . . . . . 3

2 Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

3 Specifications and Environmental Conditions . . . . . . . . . . 9

3.1 Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

3.2 Environmental Conditions. . . . . . . . . . . . . . . . . . . . . . 10

4 Quick Start . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

4.1 Unpacking . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

4.2 Use Proper Care . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

4.3 Learn About the Features and Components . . . . . . . . . . . . . 11

4.4 Install the Battery . . . . . . . . . . . . . . . . . . . . . . . . . . 11

4.5 Connect the Sensor . . . . . . . . . . . . . . . . . . . . . . . . . 12

4.6 Connect the Power Source . . . . . . . . . . . . . . . . . . . . . 12

4.7 Switch the Power On . . . . . . . . . . . . . . . . . . . . . . . . 12

4.8 Measure Temperature . . . . . . . . . . . . . . . . . . . . . . . . 12

5 Parts and Controls . . . . . . . . . . . . . . . . . . . . . . . . 13

5.1 Front Panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

5.2 Top Panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

5.3 Right Side Panel. . . . . . . . . . . . . . . . . . . . . . . . . . . 14

5.4 Left Side Panel . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

5.5 Back Panel. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

5.6 Quick Buttons . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

5.7 Configurations. . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

5.8 Accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

6 General Operation . . . . . . . . . . . . . . . . . . . . . . . . 19

6.1 DC Power Source . . . . . . . . . . . . . . . . . . . . . . . . . . 19

i

Page 4

6.2 Battery. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

6.3 Sensor Configuration . . . . . . . . . . . . . . . . . . . . . . . . 20

6.4 Power Switch . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

6.5 Power On Self-Test . . . . . . . . . . . . . . . . . . . . . . . . . 20

6.6 Display Contrast. . . . . . . . . . . . . . . . . . . . . . . . . . . 20

6.7 Display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

6.8 Alarm Screen . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

6.9 Measuring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

6.10 Unit of Temperature . . . . . . . . . . . . . . . . . . . . . . . . . 21

6.11 Recording Measurements . . . . . . . . . . . . . . . . . . . . . . 21

6.12 Sensors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

6.12.1 Sensor Accuracy . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

7 Menu Functions. . . . . . . . . . . . . . . . . . . . . . . . . . 25

7.1 Channel Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

7.1.1 Channel Setting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

7.1.2 Sensor ID . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

7.1.3 Sensor Lock . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

7.1.4 Sensor Cal. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

7.2 Display Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

7.2.1 Display Setting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

7.2.2 Display Layout . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

7.2.3 Field Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

7.2.4 Graph Scale . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

7.2.5 Display Reset . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

7.3 Data Menu. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

7.3.1 Data Record . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

7.3.1.1 Record Setting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

7.3.1.2 Data View . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

7.3.1.3 Data Print . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

7.3.1.4 Data Storage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

7.3.1.5 Data Clear . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

7.3.2 Daily Stats. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

7.3.2.1 Stats Setting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

7.3.2.2 Stats View . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

7.3.2.3 Stats Print . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

7.3.2.4 Stats Reset . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

7.3.2.5 Stats Clear . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

7.4 Alarm Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

7.4.1 Alarm Setting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

7.4.2 Sensor Alarm . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

7.4.3 System Alarm . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

7.4.4 Alarm View . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

7.5 System Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

7.5.1 System Setting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

7.5.2 Date Time . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

ii

Page 5

7.5.3 Comm Setting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

7.5.3.1 Serial . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

7.5.3.2 RF (optional) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

7.5.3.3 LAN . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

7.5.4 Password . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

7.5.5 System Info . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

8 Digital Communications Interface . . . . . . . . . . . . . . . 69

8.1 Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 69

8.1.1 Serial RS-232 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 69

8.1.2 RF Wireless (optional) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 70

8.1.3 LAN . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 70

8.1.4 Command Syntax . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 70

8.2 Commands . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 71

8.2.1 Alarm Commands. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 80

8.2.1.1 ALARm:BATTery? . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 80

8.2.1.2 ALARm:BATTery:ENABle? . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 80

8.2.1.3 ALARm:BATTery:ENABle <bool> . . . . . . . . . . . . . . . . . . . . . . . . . . 80

8.2.1.4 ALARm:BEEP:ENABle?. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 80

8.2.1.5 ALARm:BEEP:ENABle <bool> . . . . . . . . . . . . . . . . . . . . . . . . . . . . 80

8.2.1.6 ALARm:CLEar . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 81

8.2.1.7 ALARm:DATE:FIRSt? . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 81

8.2.1.8 ALARm:DATE:LAST? . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 81

8.2.1.9 ALARm:DISPlay:ENABle? . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 81

8.2.1.10 ALARm:DISPlay:ENABle <bool> . . . . . . . . . . . . . . . . . . . . . . . . . . . 81

8.2.1.11 ALARm:PORT? . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 82

8.2.1.12 ALARm:PORT <bool> . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 82

8.2.1.13 ALARm:PORT:ENABle?. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 82

8.2.1.14 ALARm:PORT:ENABle <bool> . . . . . . . . . . . . . . . . . . . . . . . . . . . . 82

8.2.1.15 ALARm:POWer? . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 82

8.2.1.16 ALARm:POWer:ENABle? . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 82

8.2.1.17 ALARm:POWer:ENABle <bool> . . . . . . . . . . . . . . . . . . . . . . . . . . . 83

8.2.1.18 ALARm:RHUMidity<chn>:LOWer? . . . . . . . . . . . . . . . . . . . . . . . . . 83

8.2.1.19 ALARm:RHUMidity<chn>:LOWer:ENABle?. . . . . . . . . . . . . . . . . . . . . 83

8.2.1.20 ALARm:RHUMidity<chn>:LOWer:ENABle <bool> . . . . . . . . . . . . . . . . . 83

8.2.1.21 ALARm:RHUMidity<chn>:LOWer:LIMit? [MIN|MAX|DEF] . . . . . . . . . . . . 83

8.2.1.22 ALARm:RHUMidity<chn>:LOWer:LIMit <float>|MIN|MAX|DEF . . . . . . . . . 84

8.2.1.23 ALARm:RHUMidity<chn>:RATE? . . . . . . . . . . . . . . . . . . . . . . . . . . 84

8.2.1.24 ALARm:RHUMidity<chn>:RATE:ENABle? . . . . . . . . . . . . . . . . . . . . . 84

8.2.1.25 ALARm:RHUMidity<chn>:RATE:ENABle <bool>. . . . . . . . . . . . . . . . . . 84

8.2.1.26 ALARm:RHUMidity<chn>:RATE:LIMit? [MIN|MAX|DEF] . . . . . . . . . . . . 85

8.2.1.27 ALARm:RHUMidity<chn>:RATE:LIMit <float>|MIN|MAX|DEF . . . . . . . . . . 85

8.2.1.28 ALARm:RHUMidity<chn>:SENSor? . . . . . . . . . . . . . . . . . . . . . . . . . 85

8.2.1.29 ALARm:RHUMidity<chn>:SENSor:ENABle? . . . . . . . . . . . . . . . . . . . . 85

8.2.1.30 ALARm:RHUMidity<chn>:SENSor:ENABle <bool> . . . . . . . . . . . . . . . . 86

8.2.1.31 ALARm:RHUMidity<chn>:UPPer? . . . . . . . . . . . . . . . . . . . . . . . . . . 86

8.2.1.32 ALARm:RHUMidity<chn>:UPPer:ENABle? . . . . . . . . . . . . . . . . . . . . . 86

8.2.1.33 ALARm:RHUMidity<chn>:UPPer:ENABle <bool> . . . . . . . . . . . . . . . . . 86

8.2.1.34 ALARm:RHUMidity<chn>:UPPer:LIMit? [MIN|MAX|DEF] . . . . . . . . . . . . 86

8.2.1.35 ALARm:RHUMidity<chn>:UPPer:LIMit <float>|MIN|MAX|DEF. . . . . . . . . . 87

8.2.1.36 ALARm:TEMPurature<chn>:LOWer? . . . . . . . . . . . . . . . . . . . . . . . . . 87

8.2.1.37 ALARm:TEMPurature<chn>:LOWer:ENABle? . . . . . . . . . . . . . . . . . . . . 87

8.2.1.38 ALARm:TEMPurature<chn>:LOWer:ENABle <bool> . . . . . . . . . . . . . . . . 87

8.2.1.39 ALARm:TEMPurature<chn>:LOWer:LIMit? [MIN|MAX|DEF] . . . . . . . . . . . 88

8.2.1.40 ALARm:TEMPurature<chn>:LOWer:LIMit <float>|MIN|MAX|DEF . . . . . . . . 88

8.2.1.41 ALARm:TEMPurature<chn>:RATE? . . . . . . . . . . . . . . . . . . . . . . . . . 88

8.2.1.42 ALARm:TEMPurature<chn>:RATE:ENABle? . . . . . . . . . . . . . . . . . . . . 88

8.2.1.43 ALARm:TEMPurature<chn>:RATE:ENABle <bool>. . . . . . . . . . . . . . . . . 89

8.2.1.44 ALARm:TEMPurature<chn>:RATE:LIMit? [MIN|MAX|DEF]. . . . . . . . . . . . 89

8.2.1.45 ALARm:TEMPurature<chn>:RATE:LIMit <float>|MIN|MAX|DEF . . . . . . . . . 89

iii

Page 6

8.2.1.46 ALARm:TEMPurature<chn>:SENSor? . . . . . . . . . . . . . . . . . . . . . . . . 89

8.2.1.47 ALARm:TEMPurature<chn>:SENSor:ENABle? . . . . . . . . . . . . . . . . . . . 90

8.2.1.48 ALARm:TEMPurature<chn>:SENSor:ENABle <bool>. . . . . . . . . . . . . . . . 90

8.2.1.49 ALARm:TEMPurature<chn>:UPPer? . . . . . . . . . . . . . . . . . . . . . . . . . 90

8.2.1.50 ALARm:TEMPurature<chn>:UPPer:ENABle? . . . . . . . . . . . . . . . . . . . . 90

8.2.1.51 ALARm:TEMPurature<chn>:UPPer:ENABle <bool> . . . . . . . . . . . . . . . . 90

8.2.1.52 ALARm:TEMPurature<chn>:UPPer:LIMit? [MIN|MAX|DEF] . . . . . . . . . . . 91

8.2.1.53 ALARm:TEMPurature<chn>:UPPer:LIMit <float>|MIN|MAX|DEF. . . . . . . . . 91

8.2.1.54 ALARm:TIME:FIRSt? . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 91

8.2.1.55 ALARm:TIME:LAST?. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 91

8.2.2 Measurement Commands . . . . . . . . . . . . . . . . . . . . . . . . . . . . 92

8.2.2.1 CALCulate:AVERage:CLEar. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 92

8.2.2.2 CALCulate<chn>:DEWPoint? . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 92

8.2.2.3 CALCulate<chn>:HINDex? . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 92

8.2.2.4 CALCulate<chn>:PARameter<num>:AVERage<type>? . . . . . . . . . . . . . . . 92

8.2.2.5 CALCulate[<chn>]:PARameter[<num>]:AVERage[<type>]:CLEar . . . . . . . . . 92

8.2.2.6 CALCulate[<chn>]:PARameter[<num>]:AVERage[<type>]:DATA? . . . . . . . . . 93

8.2.2.7 CALCulate[<chn>]:PARameter<num>:AVERage<type>:TYPE?. . . . . . . . . . . 93

8.2.2.8 CALCulate<chn>:PARameter<num>:RATE? . . . . . . . . . . . . . . . . . . . . . 93

8.2.2.9 CALCulate[<chn>]:PARameter[<num>]:RATE:TIME? [MIN|MAX|DEF]. . . . . . 93

8.2.2.10 CALCulate[<chn>]:PARameter[<num>]:RATE:TIME <num>|MIN|MAX|DEF . . . 93

8.2.2.11 CALCulate[<chn>]:PARameter<num>:RESolution? [MIN|MAX|DEF] . . . . . . . 94

8.2.2.12 CALCulate[<chn>]:PARameter<num>:RESolution <num>|MIN|MAX|DEF. . . . . 94

8.2.2.13 FETCh? [<chn>] . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .94

8.2.2.14 FORMat:TDST:STATe? . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 95

8.2.2.15 FORMat:TDST:STATe <bool> . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 95

8.2.2.16 MEASure? [<chn>] . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 95

8.2.2.17 READ? [<chn>]. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 96

8.2.3 Data Commands. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 96

8.2.3.1 DATa:DSTatistics:ENABle? . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 96

8.2.3.2 DATa:DSTatistics:ENABle <bool>. . . . . . . . . . . . . . . . . . . . . . . . . . . 96

8.2.3.3 DATa:DSTatistics:HOUR? [MIN|MAX|DEF] . . . . . . . . . . . . . . . . . . . . . 97

8.2.3.4 DATa:DSTatistics:HOUR <num>|MIN|MAX|DEF . . . . . . . . . . . . . . . . . . 97

8.2.3.5 DATa:DSTatistics:RENable? . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 97

8.2.3.6 DATa:DSTatistics:RENable <bool> . . . . . . . . . . . . . . . . . . . . . . . . . . 97

8.2.3.7 DATa:DSTatistics:RHOur? [MIN|MAX|DEF] . . . . . . . . . . . . . . . . . . . . . 97

8.2.3.8 DATa:DSTatistics:RHOur <num>|MIN|MAX|DEF . . . . . . . . . . . . . . . . . . 98

8.2.3.9 DATa:DSTatistics:RECord:BTIMe? [<num>] . . . . . . . . . . . . . . . . . . . . . 98

8.2.3.10 DATa:DSTatistics:RECord:CLEar . . . . . . . . . . . . . . . . . . . . . . . . . . . 98

8.2.3.11 DATa:DSTatistics:RECord:COUNt? [<MAX>] . . . . . . . . . . . . . . . . . . . . 98

8.2.3.12 DATa:DSTatistics:RECord:DATE? [<num>]. . . . . . . . . . . . . . . . . . . . . . 98

8.2.3.13 DATa:DSTatistics:RECord:ETIMe? [<num>] . . . . . . . . . . . . . . . . . . . . . 99

8.2.3.14 DATa:DSTatistics:RECord:FIND? (<year>,<month>,<day>) . . . . . . . . . . . . . 99

8.2.3.15 DATa:DSTatistics:RECord:VALue? <num>,<chn>,<type> . . . . . . . . . . . . . . 99

8.2.3.16 DATa:RECord:CLEar . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 99

8.2.3.17 DATa:RECord:FEED:RHUMidity<chn>? . . . . . . . . . . . . . . . . . . . . . . . 99

8.2.3.18 DATa:RECord:FEED:RHUMidity<chn> <bool> . . . . . . . . . . . . . . . . . . . 100

8.2.3.19 DATa:RECord:FEED:TEMPerature<chn>? . . . . . . . . . . . . . . . . . . . . . 100

8.2.3.20 DATa:RECord:FEED:TEMPerature<num> <bool> . . . . . . . . . . . . . . . . . 100

8.2.3.21 DATa:RECord:FREE? . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 100

8.2.3.22 DATa:RECord:OPEN? . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 101

8.2.3.23 DATa:RECord:OPEN [(<year>,<month>,<day>,<hour>,<minute>,<sec

ond>)[,(<year>,<month>,<day>,<hour>,<minute>,<second>)]] . . . . . . . . . . . . . . . . 101

8.2.3.24 DATa:RECord:READ? [<num>] . . . . . . . . . . . . . . . . . . . . . . . . . . . 101

8.2.3.25 DATa:RECord:TIME? [MIN|MAX|DEF] . . . . . . . . . . . . . . . . . . . . . . . 102

8.2.3.26 DATa:RECord:TIME <num>|MIN|MAX|DEF . . . . . . . . . . . . . . . . . . . . 102

-

8.2.4 Measurement Control Commands. . . . . . . . . . . . . . . . . . . . . . . 102

8.2.4.1 INITiate . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 102

8.2.4.2 INITiate:CONTinuous? . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 102

8.2.4.3 SENSor:AVERage? . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 102

8.2.4.4 SENSor:AVERage <bool> . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 102

8.2.4.5 SENSor<chn>:LOCK? . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 103

8.2.4.6 SENSor<chn>:LOCK <bool>. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 103

8.2.4.7 SENSor<chn>:IDENtification? . . . . . . . . . . . . . . . . . . . . . . . . . . . . 103

iv

Page 7

8.2.4.8 SENSor<chn>:IDENtification <str> . . . . . . . . . . . . . . . . . . . . . . . . . 103

8.2.4.9 SENSor<chn>:STATe? . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 104

8.2.4.10 TRIGger:TIMer? [MIN|MAX|DEF] . . . . . . . . . . . . . . . . . . . . . . . . . 104

8.2.4.11 TRIGger:TIMer <num>|MIN|MAX|DEF. . . . . . . . . . . . . . . . . . . . . . . 104

8.2.5 Channel Commands . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 105

8.2.5.1 ROUTe:CLOSe? <chn> . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 105

8.2.5.2 ROUTe:CLOSe <chn> . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 105

8.2.5.3 ROUTe:OPEN? <chn> . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 105

8.2.5.4 ROUTe:OPEN <chn> . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 105

8.2.6 Calibration Commands . . . . . . . . . . . . . . . . . . . . . . . . . . . . 105

8.2.6.1 CALibrate<chn>:ALERt? . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 106

8.2.6.2 CALibrate<chn>:ALERt <bool> . . . . . . . . . . . . . . . . . . . . . . . . . . . 106

8.2.6.3 CALibrate<chn>:DATE:CALibrate? . . . . . . . . . . . . . . . . . . . . . . . . . 106

8.2.6.4 CALibrate<chn>:DATE:CALibrate (<year>,<month>,<day>). . . . . . . . . . . . 106

8.2.6.5 CALibrate<chn>:DATE:DUE? . . . . . . . . . . . . . . . . . . . . . . . . . . . . 106

8.2.6.6 CALibrate<chn>:DATE:DUE (<year>,<month>,<day>). . . . . . . . . . . . . . . 107

8.2.6.7 CALibrate<chn>:EXPired? . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 107

8.2.6.8 CALibrate<chn>:PARameter:OFFSet<num>? . . . . . . . . . . . . . . . . . . . . 107

8.2.6.9 CALibrate<chn>:PARameter:OFFSet<num> <float> . . . . . . . . . . . . . . . . 107

8.2.6.10 CALibrate<chn>:PARameter:SCALe<num>? . . . . . . . . . . . . . . . . . . . . 107

8.2.6.11 CALibrate<chn>:PARameter:SCALe<num> <float> . . . . . . . . . . . . . . . . 108

8.2.7 System Commands . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 108

8.2.7.1 *IDN? . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 108

8.2.7.2 *OPT? . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 108

8.2.7.3 *RST. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 108

8.2.7.4 SYSTem:BEEP . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 109

8.2.7.5 SYSTem:BOOT:VERSion? . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 109

8.2.7.6 SYSTem:ERRor? . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 109

8.2.7.7 SYSTem:CODE:VERSion? . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 109

8.2.7.8 SYSTem:VERSion? . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 109

8.2.7.9 UNIT:TEMPerature? . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 109

8.2.7.10 UNIT:TEMPerature <unit> . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 110

8.2.8 Communication Interface Commands. . . . . . . . . . . . . . . . . . . . . 110

8.2.8.1 SYSTem:COMMunicate:RADio:CHANnel? . . . . . . . . . . . . . . . . . . . . . 110

8.2.8.2 SYSTem:COMMunicate:RADio:CHANnel <num> . . . . . . . . . . . . . . . . . 110

8.2.8.3 SYSTem:COMMunicate:RADio:ENABle?. . . . . . . . . . . . . . . . . . . . . . 110

8.2.8.4 SYSTem:COMMunicate:RADio:ENABle <bool> . . . . . . . . . . . . . . . . . . 110

8.2.8.5 SYSTem:COMMunicate:RADio:INSTrument? . . . . . . . . . . . . . . . . . . . 110

8.2.8.6 SYSTem:COMMunicate:RADio:INSTrument <num> . . . . . . . . . . . . . . . . 110

8.2.8.7 SYSTem:COMMunicate:RADio:MODem? . . . . . . . . . . . . . . . . . . . . . 110

8.2.8.8 SYSTem:COMMunicate:RADio:MODem <num> . . . . . . . . . . . . . . . . . . 110

8.2.8.9 SYSTem:COMMunicate:RADio:OPTion? . . . . . . . . . . . . . . . . . . . . . . 111

8.2.8.10 SYSTem:COMMunicate:RADio:PAN?. . . . . . . . . . . . . . . . . . . . . . . . 111

8.2.8.11 SYSTem:COMMunicate:RADio:PAN <num> . . . . . . . . . . . . . . . . . . . . 111

8.2.8.12 SYSTem:COMMunicate:RADio:SIGNal? . . . . . . . . . . . . . . . . . . . . . . 111

8.2.8.13 SYSTem:COMMunicate:RADio:SNUMber?. . . . . . . . . . . . . . . . . . . . . 111

8.2.8.14 SYSTem:COMMunicate:SERial:BAUD? [MIN|MAX|DEF]. . . . . . . . . . . . . 111

8.2.8.15 SYSTem:COMMunicate:SERial:BAUD <baud>|MIN|MAX|DEF. . . . . . . . . . 111

8.2.8.16 SYSTem:COMMunicate:SERial:FDUPlex? . . . . . . . . . . . . . . . . . . . . . 111

8.2.8.17 SYSTem:COMMunicate:SERial:FDUPlex <bool>. . . . . . . . . . . . . . . . . . 112

8.2.8.18 SYSTem:COMMunicate:SERial:FEED? . . . . . . . . . . . . . . . . . . . . . . . 112

8.2.8.19 SYSTem:COMMunicate:SERial:FEED <bool> . . . . . . . . . . . . . . . . . . . 112

8.2.8.20 SYSTem:COMMunicate:SERial:LINefeed? . . . . . . . . . . . . . . . . . . . . . 112

8.2.8.21 SYSTem:COMMunicate:SERial:LINefeed <bool> . . . . . . . . . . . . . . . . . 112

8.2.8.22 SYSTem:COMMunicate:SERial:TIMe? [MIN|MAX|DEF] . . . . . . . . . . . . . 112

8.2.8.23 SYSTem:COMMunicate:SERial:TIMe <num>|MIN|MAX|DEF . . . . . . . . . . 113

8.2.8.24 SYSTem:COMMunicate:SOCKet:ADDRess? . . . . . . . . . . . . . . . . . . . . 113

8.2.8.25 SYSTem:COMMunicate:SOCKet:ADDRess <addr> . . . . . . . . . . . . . . . . 113

8.2.8.26 SYSTem:COMMunicate:SOCKet:COMMand? . . . . . . . . . . . . . . . . . . . 113

8.2.8.27 SYSTem:COMMunicate:SOCKet:DHCP? . . . . . . . . . . . . . . . . . . . . . . 113

8.2.8.28 SYSTem:COMMunicate:SOCKet:DHCP <bool> . . . . . . . . . . . . . . . . . . 113

8.2.8.29 SYSTem:COMMunicate:SOCKet:ENABle? . . . . . . . . . . . . . . . . . . . . . 113

8.2.8.30 SYSTem:COMMunicate:SOCKet:ENABle <bool> . . . . . . . . . . . . . . . . . 113

8.2.8.31 SYSTem:COMMunicate:SOCKet:GATeway? . . . . . . . . . . . . . . . . . . . . 114

v

Page 8

8.2.8.32 SYSTem:COMMunicate:SOCKet:GATeway <addr>. . . . . . . . . . . . . . . . . 114

8.2.8.33 SYSTem:COMMunicate:SOCKet:HTML? . . . . . . . . . . . . . . . . . . . . . . 114

8.2.8.34 SYSTem:COMMunicate:SOCKet:MAC?. . . . . . . . . . . . . . . . . . . . . . . 114

8.2.8.35 SYSTem:COMMunicate:SOCKet:MASK? . . . . . . . . . . . . . . . . . . . . . . 114

8.2.8.36 SYSTem:COMMunicate:SOCKet:MASK <addr> . . . . . . . . . . . . . . . . . . 114

8.2.8.37 SYSTem:KLOCkout? . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 114

8.2.8.38 SYSTem:KLOCkout <bool> . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 114

8.2.8.39 SYSTem:POWer:BATTery? . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 114

8.2.9 Date and Time Commands . . . . . . . . . . . . . . . . . . . . . . . . . . 115

8.2.9.1 SYSTem:DATE?. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 115

8.2.9.2 SYSTem:DATE (<year>,<month>,<day>) . . . . . . . . . . . . . . . . . . . . . . 115

8.2.9.3 SYSTem:DATE:FORMat? [MIN|MAX|DEF] . . . . . . . . . . . . . . . . . . . . 115

8.2.9.4 SYSTem:DATE:FORMat <num>|MIN|MAX|DEF. . . . . . . . . . . . . . . . . . 115

8.2.9.5 SYSTem:DECimal:FORMat? [MIN|MAX|DEF]. . . . . . . . . . . . . . . . . . . 116

8.2.9.6 SYSTem:DECimal:FORMat <num>|MIN|MAX|DEF . . . . . . . . . . . . . . . . 116

8.2.9.7 SYSTem:TIME?. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 116

8.2.9.8 SYSTem:TIME (<hour>,<minute>,<second>) . . . . . . . . . . . . . . . . . . . . 116

8.2.9.9 SYSTem:TIME:DAYLight? [MIN|MAX|DEF]. . . . . . . . . . . . . . . . . . . . 117

8.2.9.10 SYSTem:TIME:DAYLight <num>|MIN|MAX|DEF . . . . . . . . . . . . . . . . . 117

8.2.9.11 SYSTem:TIME:FORMat? [MIN|MAX|DEF] . . . . . . . . . . . . . . . . . . . . 117

8.2.9.12 SYSTem:TIME:FORMat <num>|MIN|MAX|DEF . . . . . . . . . . . . . . . . . . 117

8.2.10 Password Commands . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 117

8.2.10.1 SYSTem:PASSword:ALARm? . . . . . . . . . . . . . . . . . . . . . . . . . . . . 118

8.2.10.2 SYSTem:PASSword:ALARm <bool> . . . . . . . . . . . . . . . . . . . . . . . . 118

8.2.10.3 SYSTem:PASSword:CDISable . . . . . . . . . . . . . . . . . . . . . . . . . . . . 118

8.2.10.4 SYSTem:PASSword:CENable <pass> . . . . . . . . . . . . . . . . . . . . . . . . 118

8.2.10.5 SYSTem:PASSword:CENable:STATe? . . . . . . . . . . . . . . . . . . . . . . . . 118

8.2.10.6 SYSTem:PASSword:COMM?. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 119

8.2.10.7 SYSTem:PASSword:COMM <bool> . . . . . . . . . . . . . . . . . . . . . . . . . 119

8.2.10.8 SYSTem:PASSword:NEW <pass>|DEF . . . . . . . . . . . . . . . . . . . . . . . 119

8.2.10.9 SYSTem:PASSword:RECord? . . . . . . . . . . . . . . . . . . . . . . . . . . . . 119

8.2.10.10 SYSTem:PASSword:RECord <bool> . . . . . . . . . . . . . . . . . . . . . . . . . 119

8.2.10.11 SYSTem:PASSword:SENSor? . . . . . . . . . . . . . . . . . . . . . . . . . . . . 119

8.2.10.12 SYSTem:PASSword:SENSor <bool> . . . . . . . . . . . . . . . . . . . . . . . . . 120

8.2.10.13 SYSTem:PASSword:STATistics? . . . . . . . . . . . . . . . . . . . . . . . . . . . 120

8.2.10.14 SYSTem:PASSword:STATistics <bool> . . . . . . . . . . . . . . . . . . . . . . . 120

8.2.10.15 SYSTem:PASSword:TIME? . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 120

8.2.10.16 SYSTem:PASSword:TIME <bool> . . . . . . . . . . . . . . . . . . . . . . . . . . 120

8.2.11 Status Commands . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 121

8.2.11.1 *CLS. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 121

8.2.11.2 *ESE? . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 121

8.2.11.3 *ESE <num>|MIN|MAX|DEF . . . . . . . . . . . . . . . . . . . . . . . . . . . . 121

8.2.11.4 *ESR? . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 121

8.2.11.5 *SRE? . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 122

8.2.11.6 *SRE <num>|MIN|MAX|DEF . . . . . . . . . . . . . . . . . . . . . . . . . . . . 122

8.2.11.7 *STB? . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 122

8.2.11.8 *TST? [<bool>] . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 123

8.2.11.9 STATus:ALARm? . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 125

8.2.11.10 STATus:ALARm:CONDition? . . . . . . . . . . . . . . . . . . . . . . . . . . . . 125

8.2.11.11 STATus:ALARm:ENABle? . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 126

8.2.11.12 STATus:ALARm:ENABle <num>|MIN|MAX|DEF . . . . . . . . . . . . . . . . . 126

8.2.11.13 STATus:MEASure? . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 126

8.2.11.14 STATus:MEASure:CONDition? . . . . . . . . . . . . . . . . . . . . . . . . . . . 127

8.2.11.15 STATus:MEASure:ENABle? . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 127

8.2.11.16 STATus:MEASure:ENABle <num>|MIN|MAX|DEF . . . . . . . . . . . . . . . . 127

8.2.11.17 STATus:OPERation? . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 128

8.2.11.18 STATus:OPERation:CONDition? . . . . . . . . . . . . . . . . . . . . . . . . . . . 128

8.2.11.19 STATus:OPERation:ENABle? . . . . . . . . . . . . . . . . . . . . . . . . . . . . 129

8.2.11.20 STATus:OPERation:ENABle <num>|MIN|MAX|DEF . . . . . . . . . . . . . . . . 129

8.2.11.21 STATus:QUEStionable? . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 129

8.2.11.22 STATus:QUEStionable:CONDition? . . . . . . . . . . . . . . . . . . . . . . . . . 130

8.2.11.23 STATus:QUEStionable:ENABle? . . . . . . . . . . . . . . . . . . . . . . . . . . 130

8.2.11.24 STATus:QUEStionable:ENABle <num>|MIN|MAX|DEF . . . . . . . . . . . . . . 130

8.2.12 Date and Time Formats . . . . . . . . . . . . . . . . . . . . . . . . . . . . 131

vi

Page 9

9 Calibration Procedure . . . . . . . . . . . . . . . . . . . . . 133

9.1 Equipment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 133

9.2 Preparation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 133

9.3 Calibration Points . . . . . . . . . . . . . . . . . . . . . . . . . 133

9.4 Temperature and Humidity Measurement Errors . . . . . . . . . 134

9.5 Temperature and Humidity Adjustments . . . . . . . . . . . . . 135

10 Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . 137

11 Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . 139

11.1 Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . 139

11.1.1 Incorrect temperature or humidity reading . . . . . . . . . . . . . . . . . . 139

11.1.2 Missing or Scattered Graph Data . . . . . . . . . . . . . . . . . . . . . . . 139

11.1.3 Blank screen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 139

11.1.4 Error message at power up. . . . . . . . . . . . . . . . . . . . . . . . . . . 139

11.1.5 Self-Test Error Messages . . . . . . . . . . . . . . . . . . . . . . . . . . . 140

11.1.6 Start-up Error Messages . . . . . . . . . . . . . . . . . . . . . . . . . . . 140

11.1.7 Error Messages during Normal Operation. . . . . . . . . . . . . . . . . . . 141

11.2 Downloading Recorded Data . . . . . . . . . . . . . . . . . . . 141

11.3 CE Comments . . . . . . . . . . . . . . . . . . . . . . . . . . . 142

11.3.1 EMC Directive . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 142

11.3.1.1 Immunity Testing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 142

11.3.1.2 Emission Testing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 143

11.3.2 Low Voltage Directive (Safety) . . . . . . . . . . . . . . . . . . . . . . . . 143

11.3.3 RF Certification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 143

11.3.3.1 United States. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 143

11.3.3.2 Canada . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 144

11.3.3.3 Europe . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 144

11.4 Frequently Asked Questions . . . . . . . . . . . . . . . . . . . 144

vii

Page 10

Figures

Figure 1 Front Panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Figure 2 Top Panel. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Figure 3 Right and Left Side View . . . . . . . . . . . . . . . . . . . . . . . . 15

Figure 4 Back Panel (RF option shown). . . . . . . . . . . . . . . . . . . . . . 17

Figure 5 Main Display. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Figure 6 Main Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Figure 7 Channel Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Figure 8 Channel Setting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Figure 9 Sensor ID. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Figure 10 Sensor Lock . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Figure 11 Sensor Cal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Figure 12 Sensor Channel Select . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Figure 13 Display Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Figure 14 Display Setting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Figure 15 Display Layout . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Figure 16 Field Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Figure 17 Graph Scale . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Figure 18 Graph Scale , Select Zone . . . . . . . . . . . . . . . . . . . . . . . . 37

Figure 19 Display Reset. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

Figure 20 Data Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Figure 21 Data Record . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

Figure 22 Record Setting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

Figure 23 Data View, Begin Time. . . . . . . . . . . . . . . . . . . . . . . . . . 42

Figure 24 Data View, Numeric Format . . . . . . . . . . . . . . . . . . . . . . . 42

Figure 25 Data Print. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

Figure 26 Data Clear . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

Figure 27 Data Storage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

Figure 28 Daily Stats . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

Figure 29 Stats Setting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

Figure 30 Stats View . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

Figure 31 Stats Print . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

Figure 32 Stats Clear . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

Figure 33 Stats Reset . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

Figure 34 Alarm. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

Figure 35 Alarm Setting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

Figure 36 Sensor Alarm. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

Figure 37 System Alarm . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

Figure 38 Alarm View . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

Figure 39 System Menu. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

Figure 40 System Setting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

viii

Page 11

Figure 41 Date Time . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

Figure 42 Comm Setting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

Figure 43 Serial . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

Figure 44 RF Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

Figure 45 Lan Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64

Figure 46 Password . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 66

Figure 47 System Info . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

Figure 48 Serial Cable Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . 69

ix

Page 12

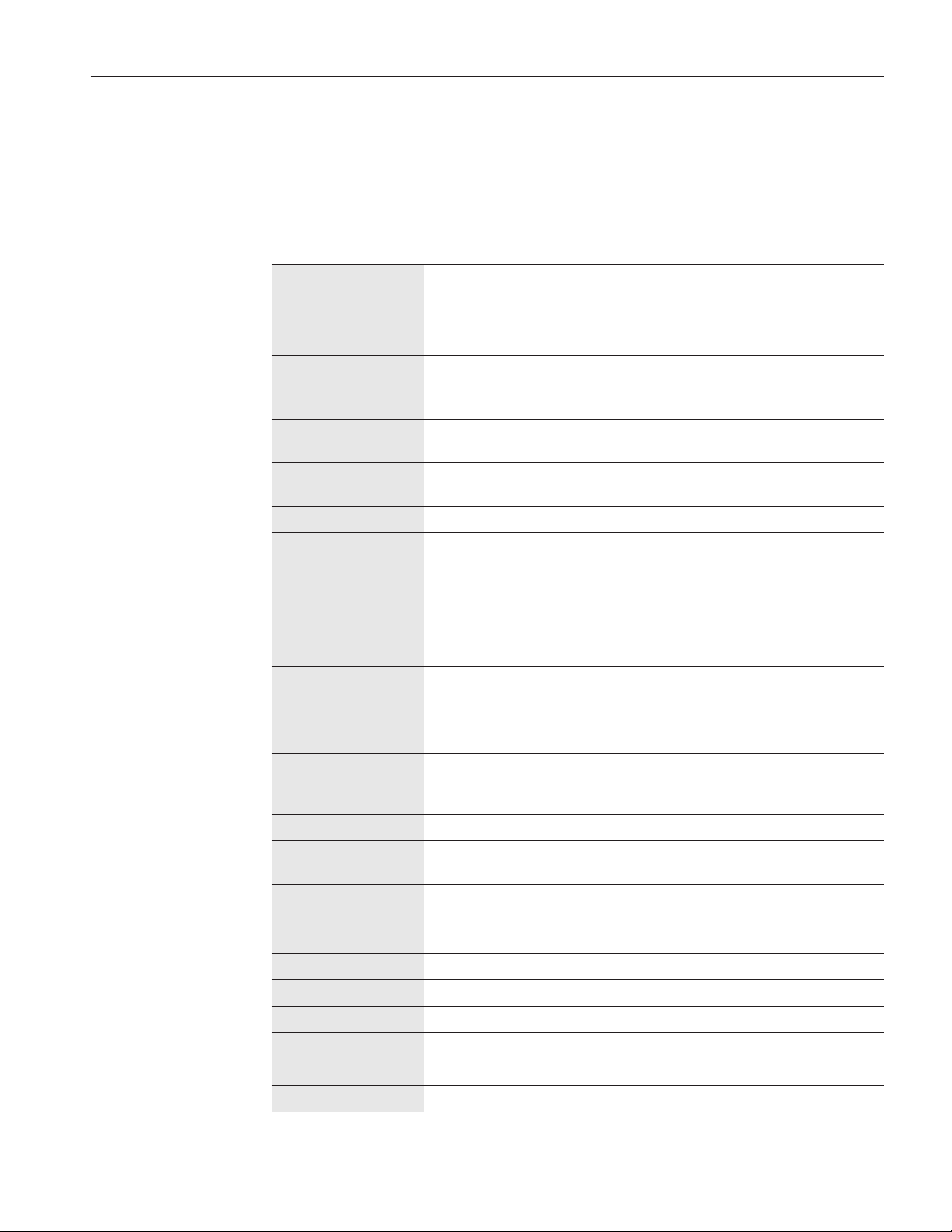

Tables

Table 1 International Electrical Symbols . . . . . . . . . . . . . . . . . . . . . 1

Table 2 Statistics Zone Field Types. . . . . . . . . . . . . . . . . . . . . . . . 34

Table 3 Approximate Data Storage Capacity . . . . . . . . . . . . . . . . . . . 41

Table 4 Alphabetical List Commands . . . . . . . . . . . . . . . . . . . . . . 72

Table 4 Alphabetical List Commands continued . . . . . . . . . . . . . . . . . 73

Table 4 Alphabetical List Commands continued . . . . . . . . . . . . . . . . . 74

Table 4 Alphabetical List Commands continued . . . . . . . . . . . . . . . . . 75

Table 4 Alphabetical List Commands continued . . . . . . . . . . . . . . . . . 76

Table 4 Alphabetical List Commands continued . . . . . . . . . . . . . . . . . 77

Table 4 Alphabetical List Commands continued . . . . . . . . . . . . . . . . . 78

x

Page 13

1 Before You Start

1.1 Symbols Used

Table 1 lists the International Electrical Symbols. Some or all of these symbols

may be used on the instrument or in this manual.

Table 1 International Electrical Symbols

Symbol Description

AC (Alternating Current)

AC-DC

1 Before You Start

Symbols Used

Battery

CE Complies with European Union Directives

DC (Direct Current)

Double Insulated

Electric Shock

Fuse

PE Ground

Hot Surface (Burn Hazard)

Read the User’s Manual (Important Information)

Off

On

1

Page 14

1620A “DewK” Thermo-hygrometer

User’s Guide

Symbol Description

Canadian Standards Association

OVERVOLTAGE (Installation) CATEGORY II, Pollution Degree 2 per IEC1010-1 re

fers to the level of Impulse Withstand Voltage protection provided. Equipment of

OVERVOLTAGE CATEGORY II is energy-consuming equipment to be supplied from

the fixed installation. Examples include household, office, and laboratory appliances.

C-TIC Australian EMC Mark

The European Waste Electrical and Electronic Equipment (WEEE) Directive

(2002/96/EC) mark.

1.2 Safety Information

Use this instrument only as specified in this manual. Otherwise, the protection

provided by the instrument may be impaired.

The following definitions apply to the terms “Warning” and “Caution”.

• “Warning” identifies conditions and actions that may pose hazards to the

user.

• “Caution” identifies conditions and actions that may damage the instru-

ment being used.

-

1.2.1

Warnings

To avoid personal injury, follow these guidelines.

•

DO NOT use this unit in environments other than those listed in the

User's Guide.

•

Follow all safety guidelines listed in the User's Guide.

•

Calibration equipment should only be used by trained personnel.

•

The AC adapter can present safety concerns if misused or damaged. To

avoid the risk of electric shock or fire, do not use the AC adapter outdoors

or in a dusty, dirty, or wet environment. If the cord, case, or plug of the

adapter is damaged in any way, discontinue its use immediately and have

it replaced.

•

Never disassemble the AC adapter. Use only the AC adapter provided

with the instrument or equivalent adapter recommended by the manufac

turer of this instrument.

•

The AC adapter has circuits with high voltage inside that could present

danger of electrical shock or fire if exposed. If the AC adapter is damaged

in any way or becomes hot, discontinue its use immediately, disconnect it

from any AC supply, and have it replaced. Do not attempt to open, repair,

or continue using a damaged or defective AC adapter.

-

2

Page 15

1 Before You Start

Authorized Service Centers

The instrument battery can present danger if not handled properly. To

•

avoid the risk of exposure to dangerous substances or explosion, immedi

ately remove the battery and discontinue use if it leaks or becomes dam

aged. Never allow the battery to be shorted, heated, punctured, or

dropped. If the instrument is physically damaged, immediately remove

the battery to insure that it does not become shorted. While removed from

the instrument, store the battery in a location so that it will not come into

contact with metal or fluids that might short circuit the battery and where

it is safe from excessive temperatures.

Used batteries must be disposed of properly. Check your local regulations

•

for additional information. Never dispose of batteries in fire which may

result in explosion with the possibility of personal injury or property dam

age.

-

-

-

1.2.2

Cautions

• If the instrument is dropped, struck, or handled in a way that causes inter-

nal or external physical damage, immediately unplug the AC adapter, remove the battery, discontinue use, and contact an Authorized Service

Center. Do not attempt to disassemble or repair the instrument, battery, or

AC adapter. Refer repairs or replacement components to an Authorized

Service Center.

• The instrument and sensors are sensitive and can be easily damaged. Al-

ways handle these devices with care. DO NOT allow them to be dropped,

struck, stressed, or overheated.

• Sensors are fragile devices which can be damaged by mechanical shock,

overheating, and exposure to fluids. Damage may not be visibly apparent

but can cause drift, instability, and loss of accuracy. Observe the following

precautions:

• DO NOT allow sensors to be dropped, struck, or stressed.

•

DO NOT overheat sensors beyond their recommended temperature range.

•

Keep the sensors clean and away from fluids and dust.

1.3 Authorized Service Centers

Please contact one of the following authorized Service Centers to coordinate

service on your Hart product:

Fluke Corporation, Hart Scientific Division

799 E. Utah Valley Drive

American Fork, UT 84003-9775

USA

Phone: +1.801.763.1600

3

Page 16

1620A “DewK” Thermo-hygrometer

User’s Guide

Telefax: +1.801.763.1010

E-mail: support@hartscientific.com

Fluke Nederland B.V.

Customer Support Services

Science Park Eindhoven 5108

5692 EC Son

NETHERLANDS

Phone: +31-402-675300

Telefax: +31-402-675321

E-mail: ServiceDesk@fluke.nl

Fluke Int'l Corporation

Service Center - Instrimpex

Room 2301 Sciteck Tower

22 Jianguomenwai Dajie

Chao Yang District

Beijing 100004, PRC

CHINA

Phone: +86-10-6-512-3436

Telefax: +86-10-6-512-3437

E-mail: xingye.han@fluke.com.cn

Fluke South East Asia Pte Ltd.

Fluke ASEAN Regional Office

Service Center

60 Alexandra Terrace #03-16

The Comtech (Lobby D)

118502

SINGAPORE

Phone: +65 6799-5588

Telefax: +65 6799-5588

E-mail: antng@singa.fluke.com

When contacting these Service Centers for support, please have the following

information available:

4

Page 17

Model Number

•

Serial Number

•

Voltage

•

Complete description of the problem

•

1 Before You Start

Authorized Service Centers

5

Page 18

Page 19

2 Introduction

Fluke’s Hart Scientific Division’s 1620A is a low-cost, high-accuracy, digital

thermo-hygrometer. Its unique combination of features makes it suitable for a

wide variety of applications from laboratory to industrial ambient measure

ment. Features of the thermo-hygrometer include:

Two channels measure ambient temperature to ±0.125 C and %RH to

•

±1.5%

Two sensor capability (second sensor optional), each measuring tempera

•

ture and relative humidity; each is detachable, cable-extendable, and inter

changeable, with self-contained calibration; each may be assigned a

unique 16-character identification

Display resolution is user selectable up to 0.001 C and 0.01% RH

•

• On-board memory holds up to 400,000 time/date-stamped readings

• Serial RS-232 interface for reading measurements and access to settings

2 Introduction

-

-

-

• Ethernet LAN interface provides TCP/IP communicatins and embedded

HTML web page for reading measurements over a network

• Optional wireless RF 802.15.4 (ZigBee) for remote operation

• Visual and audio alarms for various alarm or fault conditions, alarm out-

put port

• May be wall mounted or set on a bench top

• Detachable sensors contain their own calibration data for easy

recalibrations

• Optional software logs in real-time or shows graphical/statistical data

• Password protection of settings

• Large LCD displays temperature and humidity data graphically, numeri-

cally, and statistically; 16 pre-defined, user-changeable screen setups

•

Power 12 VDC from external 110-240 VAC to DC converter

•

Uses a standard 9V battery backup to allow continued measuring during

power interruptions

7

Page 20

Page 21

3 Specifications and Environmental Conditions

3 Specifications and Environmental

Conditions

3.1 Specifications

Temperature Range 0°C to 50°C

Temperature Accuracy

(“H” Model)

16°C to 24°C (60.8°F to 75.2°F): ±0.125°C (±0.225°F) [calibrated]

0°C to 16°C (32°F to 60.8°F): ±0.5°C (±0.9°F) [uncalibrated typical]

24°C to 50°C (75.2°F to 122°F): ±0.5°C (±0.9°F) [uncalibrated typical]

Specifications

Temperature Accuracy

(“S” Model)

Delta Temperature

Accuracy

Temperature Display

Resolution

RH Range 0% to 100% RH

RH Accuracy

(“H” Model)

RH Accuracy

(“S” Model)

Delta Humidity

Accuracy

RH Display Resolution User selectable up to 0.01% (0.1% recorded)

Inputs Two sensors, each measuring temperature and relative humidity; each is de

Display 240 x 128 graphics monochrome LCD, displays temperature and humidity data

Memory 400,000 typical individual time-stamped readings

15°C to 35°C (59°F to 95°F): ±0.25°C (±0.45°F) [calibrated]

0°C to 15°C (32°F to 59°F): ±0.5°C (±0.9°F) [uncalibrated typical]

35°C to 50°C (95°F to 122°F): ±0.5°C (±0.9°F) [uncalibrated typical]

±0.025°C (±0.045°F) for ±1°C (±1.8°F)

changes within 15°C to 35°C (59°F to 95°F)

User selectable up to 0.001°C (0.01°C recorded)

20% to 70% RH: ±1.5% RH (calibrated)

0% to 20% RH, 70% to 100% RH: ±3% RH (uncalibrated, typical)

20% to 70% RH: ±2% RH (calibrated)

0% to 20% RH, 70% to 100% RH: ±3% RH (uncalibrated, typical)

±1.0% for ±5% changes within 20% to 70% RH

tachable, cable-extendable, and interchangeable, with self-contained calibration; each may be assigned a unique 16-character identification

graphically, numerically, and statistically; 16 pre-defined, user-changeable

screen set-ups are included

Alarms Visual and audio alarms for temperature, temperature rate, RH, RH rate, and

fault conditions

Alarm port output 0 V normal, 11 to 12 V active, sources up to 20mA, 2.5mm, two-conductor sub

miniature plug

Communications RS-232, Ethernet LAN, 802.15.4 (ZigBee) wireless (optional)

Ethernet 10 Base-T, 100 Base-TX, IP, TCP, DHCP, Ping, HTTP, HTML

Wireless Range 30 m (100 ft) typical unobstructed

Enclosure The DewK may be wall-mounted (hardware included) or set on a benchtop

Power 12 V DC from external 100-240 V AC power supply

Battery Backup Standard 9V battery to allow continued measuring during power disruptions

Operating Range 0°C to 50°C

-

9

Page 22

1620A “DewK” Thermo-hygrometer

User’s Guide

Size (DewK)HxWxD 125 x 211 x 51 mm (4.9 x 8.3 x 2.0 in)

Size (Probes) 79 mm H x 19 mm dia. (3.1 x 0.75 in)

Weight 0.7kg(1.5lb.)

3.2 Environmental Conditions

Although the instrument has been designed for optimum durability and trou

ble-free operation, it must be handled with care. The instrument should not be

operated in an excessively dusty, dirty, or wet environment. Maintenance and

cleaning recommendations can be found in the Maintenance section of this

manual.

For full accuracy, operate the instrument within the calibrated temperature

•

and relative humidity range of the sensors.

1620A DewK

Operating Temperature: 0°C to 50°C (32°F to 122°F)

•

• Relative Humidity: 0% to 70% RH

2626-H/S

• Operating Temperature: 0°C to 50°C (32°F to 122°F)

• Relative Humidity: 0% to 100% RH

AC Adapter

• Operating Temperature: 0°C to 40°C (32°F to 104°F)

• Relative Humidity: 5% to 90% non-condensing de-rating from 40°C lin-

early to 50% at 70°C

10

General to all

•

Pressure: 75 kPa-106 kPa

•

Vibration should be minimized

•

Altitude less than 2,000 meters

•

Indoor use only

Page 23

4 Quick Start

This section briefly explains the basics of setting up and operating your

thermo-hygrometer.

4.1 Unpacking

Carefully unpack the thermo-hygrometer and inspect the instrument to make

sure all components are present and in satisfactory condition. Verify that the

following items are present:

1620A Thermo-Hygrometer

•

AC adapter and power cord

•

• Serial cable

• Manual

• Report of calibration

4 Quick Start

Unpacking

• Wall mount bracket

• Sensor

• 9V battery

If all items are not present, call your Hart Scientific Authorized Service Center.

See Section 1.3.

4.2 Use Proper Care

First and most important is to understand the safety issues related to the

thermo-hygrometer. Carefully read Section 1.2, Safety Information.

The thermo-hygrometer and sensors used with it are sensitive instruments that

can be easily damaged. Always handle these devices with care. DO NOT allow

them to be dropped, struck, stressed, or over-heated.

4.3 Learn About the Features and Components

Familiarize yourself with the features and accessories of the thermo-hygrome

ter by reading Section 5, Parts and Controls.

-

4.4 Install the Battery

To maintain uninterrupted measurement when power outages occur, you must

install the included battery into the rear battery compartment. A standard 9V al

kaline battery (NEDA 1604A or IEC 6LR61) is recommended. With a fresh al

kaline battery installed, the thermo-hygrometer will continue to measure and

record temperature and relative humidity during a power outage for up to 16

-

-

11

Page 24

1620A “DewK” Thermo-hygrometer

User’s Guide

hours, typically. However, without external power, the display will be

inoperable.

4.5 Connect the Sensor

The sensor for channel 1 connects to the socket at the top-right, and the sensor

for channel 2, if used, connects to the socket on the right side. Either sensor

may be used with an optional extension cable up to 100 feet (30 meters) in

length.

4.6 Connect the Power Source

The thermo-hygrometer draws power from the provided power adapter. Plug

the adapter into a wall outlet of the appropriate voltage and insert the DC plug

into the DC power input of the thermo-hygrometer.

4.7 Switch the Power On

Power is turned on and off with the power switch located below the stand on

the back panel. To switch the power on, toggle the power switch to the ‘ ’

position. To switch power off, toggle the power switch to the ‘ ’ position.

The instrument takes a few seconds to power up, initialize, and begin normal

operation. A self-test is performed, displaying the channel configuration and

status of the system, calibration, % battery power, memory, and buttons. If the

thermo-hygrometer calibration has expired and the alert message is enabled, the

user is notified and must press the Enter button to continue initialization. If an

error message is displayed on power up see Section 11, Troubleshooting.

4.8 Measure Temperature

After initialization, the temperature and relative humidity measurements for the

enabled channels are displayed. If recording is enabled, the measurements will

be automatically stored in memory. The display can be configured to display

the measurements in a variety of numerical and graphical formats. For informa

tion on the various modes of operation of the thermo-hygrometer, see Section

7, Menu Functions.

-

12

Page 25

5 Parts and Controls

The functions of the various features of the thermo-hygrometer are described

below.

5.1 Front Panel

The front panel buttons Enter/Menu, Up/Down/Left/Right Arrows, and Exit are

used to select and alter the functions of the thermo-hygrometer (see Figure 1).

5 Parts and Controls

Front Panel

Figure 1 Front Panel

The buttons have different functions depending on whether the main screen or

the menu system is displayed.

The functions of each of the buttons from the main screen are as follows:

Enter/Menu - This button is used to display the menu options.

Exit - This button is used to display the alarm window. With the alarm window

displayed the Exit button can be used to return to the main screen while preserving the alarm eve

events and return to the main screen.

lr - These buttons are used to move among enabled display layouts.

ud - These buttons are used to adjust the display contrast, u fordarkerand

d for lighter.

The functions of each of the buttons within the menu system are as follows:

nts or the Enter button can be used to clear the alarm

13

Page 26

1620A “DewK” Thermo-hygrometer

User’s Guide

Enter/Menu - This button is used to select a menu item, to accept a choice, or

save changes to a parameter.

Exit - This button is used to return from a menu or window or cancel changes

to a parameter. Pressing the Exit button for a second or so returns from most

any menu, menu function, or window back to the main screen.

ud - These buttons are used to move among menu items or parameters.

When editing some numeric or alpha-numeric parameters, these buttons are

used to change a digit or character.

lr - These buttons are used to change a value or option when editing a pa

rameter. When editing some numeric or alpha-numeric parameters, these but

tons are used to move among digits or characters.

5.2 Top Panel

The top panel contains the port for attaching the sensor for Channel 1. An optional extension cable may be used to allow the sensor to be placed in a remote

location.

Figure 2 Top Panel

-

-

14

5.3 Right Side Panel

The right side panel contains the port for attaching the sensor for Channel 2.

Page 27

5 Parts and Controls

Left Side Panel

An optional extension cable may be used to allow the sensor to be placed in a

remote location.

Figure 3 Right and Left Side View

5.4 Left Side Panel

The left side panel consists of, from top to bottom, the RS-232 port, Ethernet

LAN port, alarm port, and DC power socket.

RS-232 Port - The RS-232 port can be used to connect the instrument to a com

puter and remotely control and retrieve data from the instrument using a serial

RS-232 interface (see Sections 7.5.3.1 and 8). The jack accepts a 3.5 mm min

iature stereo plug.

LAN Port - This RJ45 socket allows the instrument to be connected to an

Ethernet IP computer network to remotely control and retrieve data from the in

strument (see Sections 7.5.3.3 and 8). The port has two LED indicators. The

-

-

-

15

Page 28

1620A “DewK” Thermo-hygrometer

User’s Guide

bottom LED indicates link state: off for no connection, amber for 10 Mbps, and

green for 100 Mbps. The top LED indicates link activity: off for no activity,

amber for half duplex, and green for full duplex.

Alarm Port - The alarm port allows external alarm indicators to be connected to

the instrument and activated when an alarm event occurs (see Section 7.4.1).

The port outputs 0V when inactive and 12V DC (up to 20 mA) when active.

The jack accepts a 2.5 mm two-conductor subminature plug (Switchcraft

#850). The sleeve of the plug is ground and the tip is positive.

DC Power Socket - The DC plug from the AC adapter plugs into the 12V DC

power socket to power the instrument. The jack accepts a 5.5 mm miniature

power plug (Switchcraft #S760). The outer conductor is ground and the inner

conductor is positive. The instrument may draw up to 0.5A.

5.5 Back Panel

The back panel contains the stand, power switch, battery compartment, and

product information, including serial number.

Stand - The stand can be used to prop up the thermo-hygrometer on a flat

surface.

Battery Compartment - The battery compartment holds a 9V alkaline battery

used as a backup power source to maintain continuous measurement during a

power outage (see Section 6.2, Battery).

Power Switch - The power switch turns the power on and off to the thermo-hygrometer, including power from the battery. Before disconnecting the AC

adapter from the instrument, switch the power off to prevent draining the

backup battery.

16

Page 29

5 Parts and Controls

Quick Buttons

Serial Label - The serial label shows the instrument model and serial number.

Figure 4 Back Panel (RF option shown)

5.6 Quick Buttons

When the main screen is displayed, the buttons have the following functions:

Enter/Menu - This button is used to display the menu options.

Exit - This button is used to display the alarm window. With the alarm window

displayed the Exit button can be used to return to the main screen while preserving the alarm events or the Enter button can be used to clear the alarm

events and return to the main screen.

lr - These buttons are used to move among enabled display layouts.

ud - These buttons are used to adjust the display contrast, u fordarkerand

d for lighter.

5.7 Configurations

•

Model 1620A-H includes a 1620A-H Thermo-Hygrometer readout, a

high accuracy sensor (Model 2626-H), a thermo-hygrometer readout wall

mount bracket, power supply (Model 2361), and an RS-232 cable.

•

Model 1620A-S includes a 1620A-S Thermo-Hygrometer readout, a stan

dard accuracy sensor (Model 2626-S), a thermo-hygrometer readout wall

mount bracket, power supply (Model 2361), and an RS-232 cable.

-

17

Page 30

1620A “DewK” Thermo-hygrometer

User’s Guide

5.8 Accessories

The following accessories are available to compliment either the high accuracy

or standard thermo-hygrometer readout.

2626-S Spare Sensor/Standard Accuracy

•

2627-S Spare Sensor Kit includes a standard accuracy probe (2626-S),

•

sensor case (2607), sensor wall mount bracket (2630), and 25-foot (7.6 m)

extension cable (2628)

2626-H Spare Sensor/High Accuracy

•

2627-H Spare sensor Kit includes a high accuracy sensor (2626-H), sen

•

sor case (2607), sensor wall mount bracket (2630), and 25-foot (7.6 m)

extension cable (2628)

2607 Spare Sensor Protective Case

•

• 2628 Extension cable, 25-foot (7.6 m)

2629 Extension cable, 50-foot (15.2 m)

•

-

• 2630 Sensor wall mount bracket

• 9328 Protective Case (includes space for a 1620A Thermo-Hygrometer,

two sensors, RS-232 cable, and power cord)

• 2361 Spare Power Supply, 100-240 VAC to 12 VDC

• 9936A LogWare III, single-PC license

• 9936A-L1 License, LogWare III, 1-pack

• 9936A-L5 License, LogWare III, 5-pack

• 9936A-L10 License, LogWare III, 10-pack

• 9936A-LST License, LogWare III, site

• 9936A-UPG Software, 9936A Upgrade from v1.X

•

2633-RF Option, Factory Installed Wireless, Dewk (Model 2633-USB or

Model 2633-232 receiver required to communicate with this option)

•

2633-USB Receiver, USB to wireless (requires 2633-RF)

•

2633-232 Receiver, RS-232 to wireless (requires 2633-RF)

18

Page 31

6 General Operation

6 General Operation

DC Power Source

This section explains basic operation of the thermo-hygrometer. Detailed oper

ation of the thermo-hygrometer is explained in Sections 7 and 8. Section 7 ex

plains the menu structure and the functions available in the menu structure and

Section 8 explains the communications interface for operating the thermo-hy

grometer remotely.

6.1 DC Power Source

The thermo-hygrometer requires 12V DC to operate. The AC adapter is pro

vided to produce the DC power from an AC mains supply.

Caution: For CE compliance and for proper performance, use only the

AC adapter shipped with the instrument by Hart Scientific. If the AC

adapter needs to be replaced, contact Hart Scientific Authorized Service

Center. The AC adapter has circuits with high voltages inside that could

present danger of electric shock or fire if exposed. If the AC adapter is

damaged in any way or becomes hot, discontinue use immediately, disconnect the adapter from any AC supply, and replace the adapter. Do not attempt to open, repair, or continue using a damaged or defective AC

adapter.

-

-

-

-

The DC output from the AC adapter plugs into the 12 V DC power input on the

left side of the instrument (see Figure 3 on page 15).

6.2 Battery

The thermo-hygrometer uses a 9V battery to maintain continuous measurement

and recording during power outages. The recommended battery type is a stan

dard 9V alkaline battery (NEDA 1604A or IEC 6LR61). During a power out

age, or when the AC adapter is disconnected, the display will be inoperable but

measuring will continue if the 9V battery is installed. If the alarm is enabled,

the beeper will sound periodically to alert the user of the loss of external power.

With a fresh alkaline battery, measuring will continue during a power outage

for typically about 16 hours. During normal operation, the battery charge is

regularly checked, and if the low battery alarm is enabled, the user will be

alerted when the battery charge drops below approximately 50%. The battery

charge level can be viewed with a display layout that includes a stat type zone

with one of the fields set to BATT. To prevent inadvertent battery drain, remem

ber to switch the power switch off when external power is disconnected and the

thermo-hygrometer is not in use.

To install or replace the battery, follow these steps:

1. Switch the power off and unplug the DC power cord.

-

-

-

19

Page 32

1620A “DewK” Thermo-hygrometer

User’s Guide

2. Turn the thermo-hygrometer over to access the rear battery compartment.

Press down slightly on the battery cover and slide it out to remove it.

3. Remove the old battery if one is in place by lifting it up at the bottom

and pulling it out.

4. Slide the new battery in at an angle, observing the proper polarity so the

terminals mate correctly, then press the bottom of the battery down into

the holder.

5. Replace the battery cover.

6. Replace the DC power cord and switch the power on.

Used batteries must be disposed of properly. See Section 1.2.1, Warnings.

6.3 Sensor Configuration

The thermo-hygrometer can be used with one or two sensors of either type attached at either of the two ports. Extension cables can be used with the sensors

to allow the sensors to be placed at remote locations. The extension cables can

be up to 30m (100 ft.) in length. When a sensor is attached, the thermo-hygrometer detects the sensor automatically, reads its calibration parameters, and

begins to measure if the channel is enabled (see Section 6.9, Measuring).

6.4 Power Switch

To operate the thermo-hygrometer, slide the rear power switch to the ON ( )

position. When the thermo-hygrometer is not being used, slide the power

switch to the OFF ( ) position before disconnecting the power source to

preserve the battery.

6.5 Power On Self-Test

When power is turned on, the thermo-hygrometer performs a self-test, checking

the system, sensors, sensor calibration parameters, memory, and buttons. If an

error occurs, an error message is displayed. See Section 11, Troubleshooting

for additional information on error messages.

6.6 Display Contrast

If the display appears too dark or too light, you can use the u and d buttons

at the main screen to adjust the contrast. The contrast can also be adjusted from

the DISPLAY SETTING menu (see Section 7.2.1, Display Setting).

20

Page 33

6.7 Display

The thermo-hygrometer display is originally configured with six default display

layouts enabled. The user can enable and configure any of the 16 display lay

outs to show a variety of data in numerical or graphical format (see Section

7.2.2, Display Layout). Enabled display layouts can be quickly selected from

the main screen using the l and r buttons.

6.8 Alarm Screen

The Alarm Screen can be accessed from the main screen by pressing Exit or by

entering the Alarm Menu (see Section 7.4, Alarm Menu). If enabled, the alarm

screen will appear automatically when an alarm event occurs. When an alarm is

displayed the event can be either hidden by pressing Exit or cleared by pressing

Enter.

6.9 Measuring

6 General Operation

Display

-

The thermo-hygrometer will automatically make measurements on enabled

channels at the set period when a sensor is attached. Channels are enabled using the CHANNEL SETTING function in the CHANNEL menu (see Section

7.3.1.1, Record Setting). The measurement period is also set with this function.

6.10 Unit of Temperature

The thermo-hygrometer is capable of displaying temperature in Celsius (C) or

Fahrenheit (F). The unit of temperature applies to temperature measurements

on either channel that are displayed, recorded, or printed. Recorded data is

viewed or printed with the currently set unit of temperature. The unit of temperature is set using the DISPLAY SETTING function in the DISPLAY menu

(see Section 7.2.1, Display Setting) or the SYSTEM SETTING function in the

SYSTEM menu (see Section 7.5.1, System Setting).

6.11 Recording Measurements

The thermo-hygrometer will automatically record measurements on enabled

channels at the set period. Recording is enabled using the RECORD SETTING

function in the DATA RECORD sub-menu in the DATA menu (see Section

7.3.1.1, Record Setting). The record period is also set with this function.

6.12 Sensors

The standard-accuracy sensor and high-accuracy sensor are used to measure

temperature and relative humidity. The sensors attach to the thermo-hygrometer

by plugging into the top or side panel of the instrument.

21

Page 34

1620A “DewK” Thermo-hygrometer

User’s Guide

The sensor contains a memory device that stores information about the sensor

and automatically transfers this data to the thermo-hygrometer when the sensor

is attached. This ensures that the settings used to measure and calculate temper

ature and humidity always match the sensor being used.

-

Caution: Sensors are fragile devices that can be easily damaged by me

chanical shock, overheating, and exposure to fluids or dust. Damage may

not be visibly apparent but nevertheless can cause drift, instability, and

loss of accuracy. Observe the following precautions:

DO NOT allow sensors to be dropped, struck, or stressed.

•

DO NOT overheat sensors beyond their recommended temperature range.

•

DO NOT expose sensors to harmful vapors, fumes, dust, or condensation.

•

• DO NOT allow sensors to come into direct contact with any fluids.

6.12.1 Sensor Accuracy

To achieve full accuracy with the thermo-hygrometer sensors, a few precautions should be noted.

First, consider that the sensor actually measures its own temperature, not necessarily the temperature of the air around it. Ideally, the sensor's temperature will

be the same as the air, but they might be different under less than ideal

conditions.

One such condition is when there is a source of radiated heat that is "seen" by

the sensor. Radiated heat tends to heat up the sensor higher than the air around

it (try shining a flashlight on the sensor from some distance away). Some

sources of radiated heat to avoid are incandescent lamps, space heaters, and

other high-temperature devices. If such objects cannot be eliminated, consider

using a heat shield between the heat source and the thermo-hygrometer sensor.

-

22

The sensor can also be heated by warm objects close by, perhaps a wall that is

slightly warmer than the air in the room or even another sensor placed next to

it. For best results, allow adequate distance between the sensor and any objects

that might be at a different temperature than the air.

Other considerations relate to the self-heating of the sensor. Since the sensor

contains electronic circuits that release a small amount of heat, the sensor will

naturally be slightly warmer than the air around it. The calibration of the sensor

takes this self-heating into account and compensates for it. But, factors that al

-

ter the natural self-heating can cause errors in the measurement.

Self-heating does depend somewhat on the velocity of the air around the sensor.

The sensor is calibrated in nearly still air. Different air velocities can cause dif

ferences in the measured temperature of the sensor: as much as ±0.06°C for ve

locities ranging from 0 to 10 cm/s. High velocities can cause even greater errors

that can be as large as 0.15°C below the temperature measured at low veloci

-

-

Page 35

6 General Operation

Sensors

ties. Thus, it is recommended that the sensor be located where there is minimal

air currents.

The self-heating of the sensor could also be altered by nearby objects that insu

late the sensor from the air. Keep adequate air space around the sensor.

The self-heating of the sensor takes a few minutes to stabilize after the power to

the thermo-hygrometer is switched on or the sensor is attached. For best results,

allow 15 minutes for the sensor to settle after applying power.

The sensor takes some time to respond to large changes in temperature or hu

midity, such as, for instance, when the sensor is brought from a cold or humid

location to a warm or dry one. Depending on the difference, the sensor can take

several minutes to more than an hour to reach full accuracy after conditions

have changed.

Finally, moisture condensing within the sensor can cause erroneous or invalid

measurements. Condensation can occur if the sensor is brought from a warm,

high-humidity environment to a colder temperature. This can be avoided by

first moving the sensor into low-humidity air at the same temperature for about

30 minutes before it is placed at the lower temperature. If condensation does

occur, the sensor should recover once it dries out. This may take several hours.

-

23

Page 36

Page 37

7 Menu Functions

7 Menu Functions

Figure 5 Main Display

Selecting the Enter/Menu button from the front panel accesses the main menu

of the thermo-hygrometer. The main menu consists of the submenus: CHAN-

NEL, DISPLAY, DATA, ALARM,andSYSTEM. Most of the menu options

may be password-protected to prevent them from being changed (see Section

7.5.4, PASSWORD)

Figure 6 Main Menu

25

Page 38