Page 1

1594A/1595A

Super-Thermometer

Technical Guide

159X____tgeng0000

Page 2

Limited Warranty & Limitation of Liability

Each product from Fluke Corporation (“Fluke”) is warranted to be free from defects in material and workmanship under normal use and service. The warranty period is one year(s) for the thermometer. The warranty

period begins on the date of the shipment. Parts, product repairs, and services are warranted for 90 days. The

warranty extends only to the original buyer or end-user customer of a Fluke authorized reseller, and does

not apply to fuses, disposable batteries or to any other product, which in Fluke’s opinion, has been misused,

altered, neglected, or damaged by accident or abnormal conditions of operation or handling. Fluke warrants

that software will operate substantially in accordance with its functional specications for 90 days and that it

has been properly recorded on non-defective media. Fluke does not warrant that software will be error free or

operate without interruption. Fluke does not warrant calibrations on the Super-Thermometer.

Fluke authorized resellers shall extend this warranty on new and unused products to end-user customers only

but have no authority to extend a greater or different warranty on behalf of Fluke. Warranty support is available if product is purchased through a Fluke authorized sales outlet or Buyer has paid the applicable international price. Fluke reserves the right to invoice Buyer for importation costs of repairs/replacement parts when

product purchased in one country is submitted for repair in another country.

Fluke’s warranty obligation is limited, at Fluke’s option, to refund of the purchase price, free of charge repair,

or replacement of a defective product which is returned to a Fluke authorized service center within the warranty period.

To obtain warranty service, contact your nearest Fluke authorized service center or send the product, with a

description of the difculty, postage, and insurance prepaid (FOB Destination), to the nearest Fluke authorized

service center. Fluke assumes no risk for damage in transit. Following warranty repair, the product will be

returned to Buyer, transportation prepaid (FOB Destination). If Fluke determines that the failure was caused

by misuse, alteration, accident or abnormal condition or operation or handling, Fluke will provide an estimate

or repair costs and obtain authorization before commencing the work. Following repair, the product will be

returned to the Buyer transportation prepaid and the Buyer will be billed for the repair and return transporta-

tion charges (FOB Shipping Point).

THIS WARRANTY IS BUYER’S SOLE AND EXCLUSIVE REMEDY AND IS IN LIEU OF ALL OTHER WARRANTIES, EXPRESS OR IMPLIED, INCLUDING BUT NOT LIMITED TO ANY IMPLIED WARRANTY OF MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE. FLUKE SHALL NOT BE LIABLE FOR ANY

SPECIAL, INDIRECT, INCIDENTAL. OR CONSEQUENTIAL DAMAGES OR LOSSES, INCLUDING LOSS OF

Fluke Corporation

799 E. Utah Valley Drive • American Fork, UT 84003-9775 • USA

Phone: +1.801.763.1600 • Telefax: +1.801.763.1010

E-mail: support@hartscientic.com

www.hartscientific.com

Specications subject to change without notice. • Copyright © 2008 • Printed in USA

Page 3

Table of Contents

1 Before You Start .................................................................................... 1

1.1 Symbols Used ............................................................................................................1

1.2 Safety Information ......................................................................................................1

1.2.1 WARNINGS .......................................................................................................................1

1.2.2 CAUTIONS ........................................................................................................................2

1.3 Authorized Service Centers .......................................................................................2

2 Introduction and Specications .......................................................... 5

2.1 Introduction ................................................................................................................5

2.2 Specifications ............................................................................................................5

2.2.1 General ..............................................................................................................................5

2.2.2 Primary Specifications.......................................................................................................6

2.2.2.1 Resistance Ratio Accuracy.......................................................................................................6

2.2.2.2 Resistor Stability .......................................................................................................................6

2.2.2.3 Absolute Resistance Accuracy.................................................................................................7

2.2.2.4 Measurement Current Accuracy ...............................................................................................7

2.2.3 Ancillary Specifications ..................................................................................................... 8

2.2.3.1 Temperature Measurement Noise .............................................................................................8

2.2.3.2 Relative Measurement Current Accuracy .................................................................................8

2.2.4 General Specifications ...................................................................................................... 9

2.2.5 Applying the Specifications ..............................................................................................9

2.2.5.1 Introduction ...............................................................................................................................9

2.2.5.2 How the Super-Thermometer Measures ...................................................................................9

2.2.5.3 Example 1: Measuring an SPRT .............................................................................................10

2.2.5.4 Example 2: Calibrating an SPRT .............................................................................................12

2.2.5.5 Example 4: Measuring a 100 Ω PRT .......................................................................................13

2.2.5.6 Example 5: Measuring a 10 kΩ Thermistor ............................................................................14

3 Preparation for Operation ................................................................... 15

3.1 Unpacking and Inspection ......................................................................................15

3.2 Instruction Manuals ..................................................................................................15

3.3 Line Voltage and Fuses ...........................................................................................15

3.4 Connecting to Line Power ........................................................................................16

3.5 Placement and Rack Mounting ................................................................................16

4 Front and Rear Panel Features .......................................................... 17

4.1 Introduction ..............................................................................................................17

4.2 Front Panel Features ................................................................................................17

4.2.1 Measurement Inputs .......................................................................................................17

4.2.2 USB Connection .............................................................................................................. 17

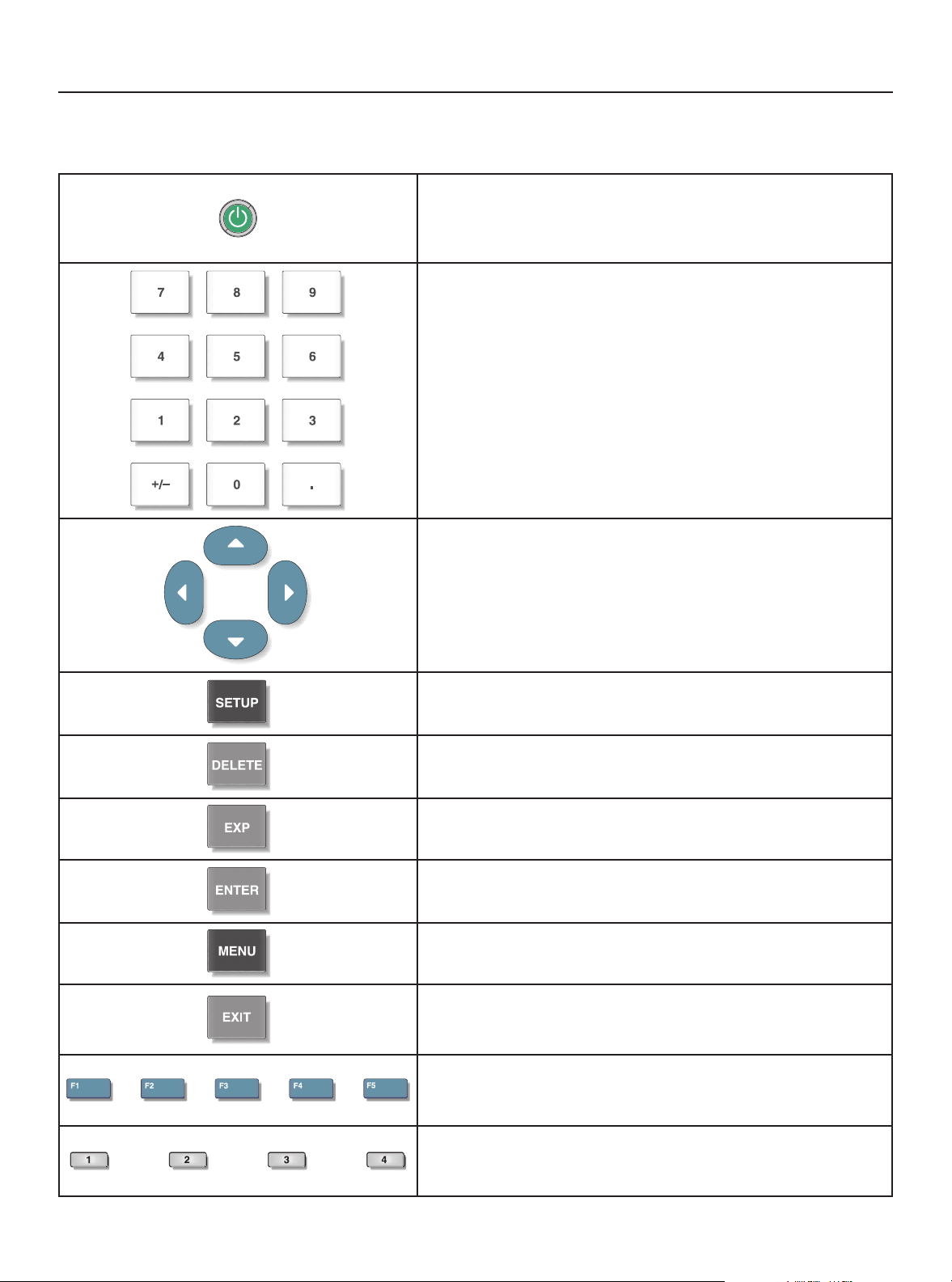

4.2.3 Front Panel Keys .............................................................................................................18

4.2.3.1 Front Panel Display .................................................................................................................19

4.3 Rear Panel Features ................................................................................................20

4.3.3.1 External Resistor Inputs ..........................................................................................................20

4.3.1 Scanner Connection ........................................................................................................20

4.3.2 Future Peripheral Connection .........................................................................................21

4.3.3 Remote Operation Connections ...................................................................................... 21

4.3.4 Line Voltage Connection .................................................................................................22

iii

Page 4

1594A/1595A Super-Thermometer

4.3.5 Earth Ground Connection ...............................................................................................22

5 Menus and Screens ............................................................................ 23

5.1 Introduction ..............................................................................................................23

5.2 Changing Settings ...................................................................................................23

5.3 Password Protection ................................................................................................24

5.4 Menu Navigation ......................................................................................................24

5.5 Menu System ...........................................................................................................24

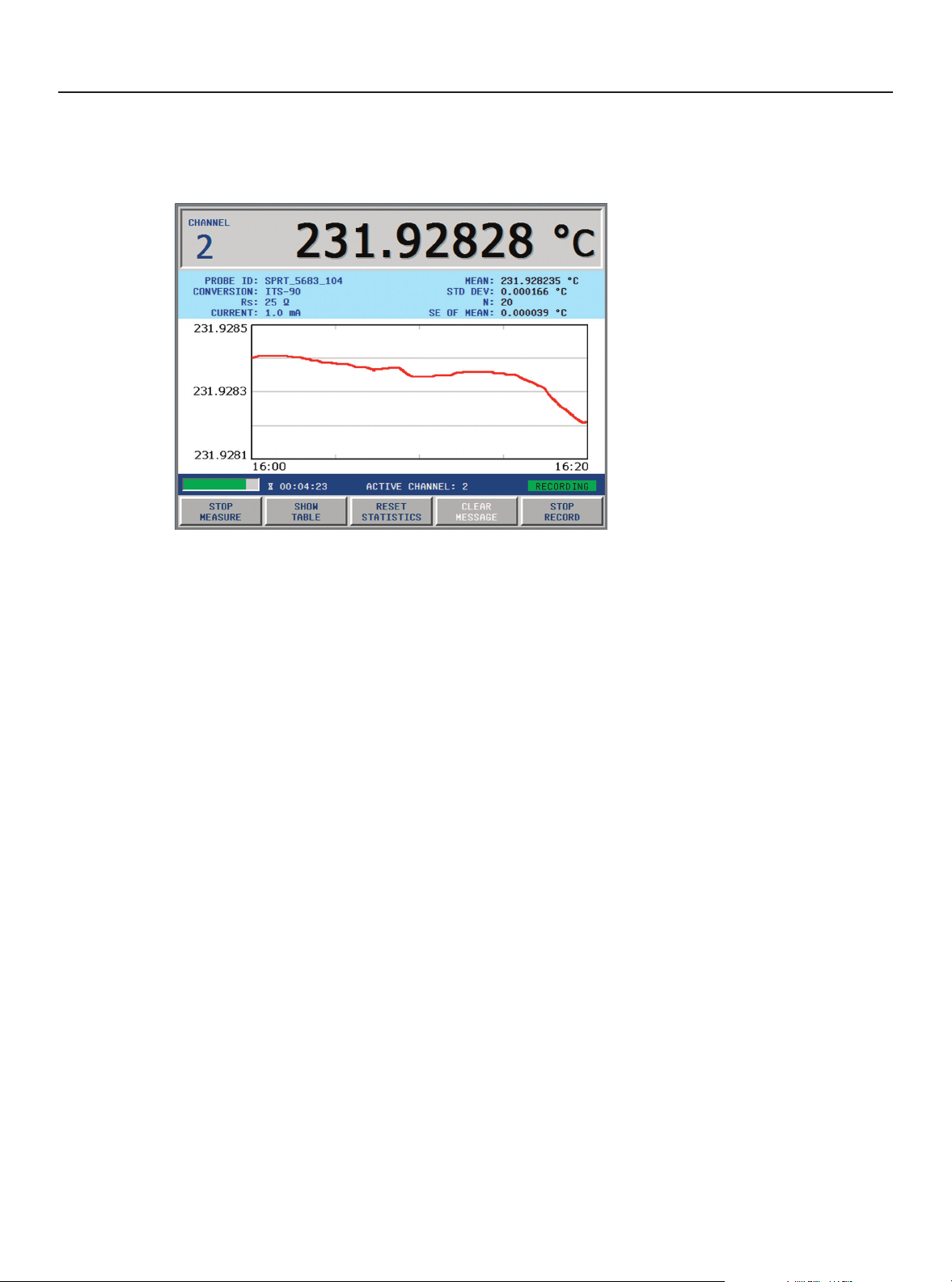

5.6 Measurement Screen ...............................................................................................25

5.6.1 Channel Measurement Display .......................................................................................26

5.6.2 Channel Summary Section .............................................................................................. 26

5.6.3 Statistics Fields ...............................................................................................................27

5.6.4 Data/Graph Section .........................................................................................................27

5.6.5 Status and Alert Section .................................................................................................. 27

5.6.6 START/STOP MEASUREMENT (F1) ................................................................................28

5.6.7 SHOW TABLE/GRAPH (F2) ............................................................................................. 28

5.6.8 RESET STATISTICS (F3) ..................................................................................................28

5.6.9 CLEAR GRAPH/CLEAR MESSAGE (F4) .........................................................................28

5.6.10 START/STOP RECORD (F5) ...........................................................................................28

5.7 Main Menu ...............................................................................................................28

5.7.1 CHANNEL SETUP (F1) .................................................................................................... 29

5.7.1.1 ASSIGN PROBE (F1) ..............................................................................................................29

5.7.1.2 CHANNEL SETTINGS (F2)......................................................................................................30

5.7.2 PROBE MENU (F2) .......................................................................................................... 34

5.7.2.1 ADD PROBE (F1) ...................................................................................................................34

5.7.2.2 COPY PROBE (F2) ..................................................................................................................36

5.7.2.3 EDIT PROBE (F3) ....................................................................................................................36

5.7.2.4 READ PROBE (F4) ..................................................................................................................37

5.7.2.5 MANAGE PROBES (F5) .........................................................................................................37

5.7.3 MEASURE MENU (F3) ..................................................................................................... 38

5.7.3.1 SCAN SETTINGS (F1) .............................................................................................................39

5.7.3.2 TIMING SETTINGS (F2) ..........................................................................................................39

5.7.3.3 DIGITAL FILTER (F3) ...............................................................................................................41

5.7.3.4 RECORDING MENU (F4) ........................................................................................................41

5.7.3.5 ZERO-POWER MEASUREMENT (F5) .....................................................................................43

5.7.4 DISPLAY MENU (F4) .......................................................................................................46

5.7.4.1 USER SETTINGS (F1) .............................................................................................................47

5.7.4.2 FIELD SETTINGS (F2) ............................................................................................................48

5.7.4.3 STATISTICS SETTINGS (F3) ....................................................................................................49

5.7.4.4 GRAPH SETTINGS (F4) ..........................................................................................................49

5.7.4.5 TEMPERATURE UNIT (F5) ......................................................................................................50

5.7.5 SYSTEM MENU (F5) ........................................................................................................ 50

5.7.5.1 TIME DATE (F1) ......................................................................................................................50

5.7.5.2 REMOTE INTERFACE (F2) ......................................................................................................51

5.7.5.3 CONFIG (F3) ...........................................................................................................................52

5.7.6 RECALL CONFIG (F2) ..................................................................................................... 53

5.7.7 DELETE CONFIG (F3) ..................................................................................................... 54

5.7.7.1 PASSWORD (F4) .....................................................................................................................54

5.7.7.2 CALIBRATION (F5) .................................................................................................................55

6 Getting Started .................................................................................... 57

6.1 Powering on the Super-Thermometer ......................................................................57

iv

Page 5

6.2 User Settings Screen ...............................................................................................57

6.3 Connecting a Probe or Resistor ...............................................................................58

7 Making Measurements ....................................................................... 61

7.1 Introduction ..............................................................................................................61

7.2 Measuring a Temperature Probe .............................................................................61

7.3 Scanning Multiple Temperature Probes ...................................................................62

7.4 Measuring Resistance Ratio ....................................................................................62

7.5 Configuring an External Reference Resistor ............................................................62

7.6 Making A Zero-Power Measurement .......................................................................63

8 Remote Operation ............................................................................... 65

8.1 Introduction ..............................................................................................................65

8.2 Configuring the Network (LAN) Port ........................................................................65

8.2.1 Hardware Mac Address ..................................................................................................66

8.2.2 Selecting Dynamic Host Configuration Protocol (DHCP) ................................................66

8.2.3 Setting a Static Internet Protocol (IP) Address ................................................................66

8.2.4 Setting the LAN Gateway Address .................................................................................67

8.2.5 Setting the LAN Subnet Mask .........................................................................................67

8.2.6 Setting the Host Name ....................................................................................................67

8.3 Using the Web Interface ..........................................................................................68

8.4 Configuring the USB Port.........................................................................................68

8.5 Configuring the RS-232 Serial Port ..........................................................................69

8.6 Configuring the IEEE-488 Port .................................................................................69

8.7 Interface Commands ...............................................................................................70

8.7.1 Command Syntax ............................................................................................................ 70

8.7.2 List of Commands ...........................................................................................................70

8.7.3 Descriptions of Commands ............................................................................................. 74

8.7.3.1 *CLS ........................................................................................................................................74

8.7.3.2 *ESE <value> ..........................................................................................................................74

8.7.3.3 *ESR? ......................................................................................................................................74

8.7.3.4 *IDN? ......................................................................................................................................75

8.7.3.5 *RST ........................................................................................................................................75

8.7.3.6 *SRE <value> .........................................................................................................................75

8.7.3.7 *STB? ......................................................................................................................................76

8.7.3.8 CAL:DATE <year>,<month>,<day> .......................................................................................76

8.7.3.9 CAL:PAR:LIN<n> <value> .....................................................................................................76

8.7.3.10 CAL:PAR:RES<n> <value> ....................................................................................................76

8.7.3.11 CAL:PAR:ZERO <value> ........................................................................................................76

8.7.3.12 CALC<n>:AVER:ALL? ............................................................................................................77

8.7.3.13 CALC<n>:AVER:AVER? ..........................................................................................................77

8.7.3.14 CALC[<n>]:AVER:CLEA .........................................................................................................77

8.7.3.15 CALC:AVER:COUN <value> ..................................................................................................77

8.7.3.16 CALC<n>:AVER:MAX? ...........................................................................................................78

8.7.3.17 CALC<n>:AVER:MIN? ............................................................................................................78

8.7.3.18 CALC<n>:AVER:SDEV? ..........................................................................................................78

8.7.3.19 CALC<n>:AVER:SEM? ...........................................................................................................79

8.7.3.20 CALC<n>:AVER:SPR? ............................................................................................................79

8.7.3.21 CALC<n>:AVER:SSIZ? ...........................................................................................................79

8.7.3.22 CALC:AVER:TCON NORM|MOV .............................................................................................79

8.7.3.23 CALC:DELT:CHAN <channel> ...............................................................................................79

v

Page 6

1594A/1595A Super-Thermometer

8.7.3.24 CALC<n>:DELT:DATA? ...........................................................................................................80

8.7.3.25 CALC:DELT:MODE OFFS|CHAN .............................................................................................80

8.7.3.26 CALC:DELT:OFFS <value> .....................................................................................................80

8.7.3.27 CALC<n>:TYPE TEMP|RES|RAT .............................................................................................80

8.7.3.28 DATA:REC:ALL <boolean> .....................................................................................................80

8.7.3.29 DATA:REC:FILE <name> ........................................................................................................81

8.7.3.30 DATA:REC:MEM INT|USB|BOTH .............................................................................................81

8.7.3.31 DATA:REC[:STAT] <boolean> .................................................................................................81

8.7.3.32 DISP:ALER:CLEA ....................................................................................................................81

8.7.3.33 DISP:ALER[:READ]? ...............................................................................................................81

8.7.3.34 DISP:DATE:FORM YMD|DMY|MDY .........................................................................................81

8.7.3.35 DISP:DEC:FORM PER|COMM ................................................................................................81

8.7.3.36 DISP:FIEL:FEED<n>? ............................................................................................................81

8.7.3.37 DISP:FIEL:MEM <n> ..............................................................................................................82

8.7.3.38 DISP:FIEL:MEM<n1>:FEED<n2> <feed> .............................................................................82

8.7.3.39 DISP:HELP <boolean> ...........................................................................................................82

8.7.3.40 DISP:LANG ENGLISH|CHINESE|JAPANESE|SPANISH|GERMAN|FRENCH|RUSSIAN ...........82

8.7.3.41 DISP:TEMP:DIG <digits> ........................................................................................................82

8.7.3.42 DISP:WARN:DUE <boolean> .................................................................................................82

8.7.3.43 DISP:WARN:ITS <boolean> ...................................................................................................83

8.7.3.44 FETC? <channel> ...................................................................................................................83

8.7.3.45 INIT:CONT <boolean> ............................................................................................................83

8.7.3.46 INIT:STOP:BEEP <boolean> ...................................................................................................83

8.7.3.47 INIT:STOP:DUR <value> .........................................................................................................83

8.7.3.48 INIT:STOP[:STAT] <boolean> .................................................................................................84

8.7.3.49 INIT:STOP:TIME?.....................................................................................................................84

8.7.3.50 INP<n>:CURR <current> .......................................................................................................84

8.7.3.51 INP<n>:CURR:DATA? .............................................................................................................84

8.7.3.52 INP<n>:CURR:STAN <boolean> ............................................................................................84

8.7.3.53 INP:PROB:ADD <id> ..............................................................................................................84

8.7.3.54 INP:PROB:COUN? ..................................................................................................................85

8.7.3.55 INP:PROB:DEL <id> ...............................................................................................................85

8.7.3.56 INP:PROB:FIRS? .....................................................................................................................85

8.7.3.57 INP<n>:PROB:IDEN <id> ......................................................................................................85

8.7.3.58 INP:PROB:NEXT?....................................................................................................................85

8.7.3.59 INP:PROB:PAR <id>,<name>,<value> ..................................................................................86

8.7.3.60 INP:PROB:TEST? <id>,<resistance> .....................................................................................87

8.7.3.61 INP:REAR<n>:RS:IDEN <id>|VAR|NONE ...............................................................................87

8.7.3.62 INP:RS:ADD <id> ...................................................................................................................88

8.7.3.63 INP:RS:COUN? .......................................................................................................................88

8.7.3.64 INP:RS:DEL <id> ....................................................................................................................88

8.7.3.65 INP:RS:FIRS? ..........................................................................................................................88

8.7.3.66 INP<n>:RS:IDEN <id>|VAR|NONE .........................................................................................88

8.7.3.67 INP:RS:NEXT? .........................................................................................................................89

8.7.3.68 INP:RS:OVEN:STAB? ..............................................................................................................89

8.7.3.69 INP:RS:PAR <id>,<name>,<value> .......................................................................................89

8.7.3.70 INP<n>:RS:ROUT <source> ..................................................................................................89

8.7.3.71 ROUT:CLOS <channel> .........................................................................................................90

8.7.3.72 ROUT:CLOS:STAT? .................................................................................................................90

8.7.3.73 ROUT:SCAN <channel list> ....................................................................................................90

8.7.3.74 ROUT:SCAN:ADD <channel list> ...........................................................................................91

8.7.3.75 ROUT:SCAN:ALT <boolean> ..................................................................................................91

8.7.3.76 ROUT:SCAN:DEL <channel list> ............................................................................................91

8.7.3.77 ROUT:SCAN:REF <channel> ..................................................................................................91

8.7.3.78 ROUT:SCAN:REP <value> ......................................................................................................91

8.7.3.79 ROUT:SCAN:STAT <boolean> ................................................................................................92

vi

Page 7

8.7.3.80 SENS:APER[:DISP] <time> .....................................................................................................92

8.7.3.81 SENS:APER:PRES NORM|PREC|FAST|LONG ........................................................................92

8.7.3.82 SENS:APER:SAMP <time> .....................................................................................................92

8.7.3.83 SENS:AVER1[:STAT] <boolean> .............................................................................................92

8.7.3.84 SENS:AVER2[:STAT] <boolean> .............................................................................................93

8.7.3.85 SENS:AVER2:COUN <count> ................................................................................................93

8.7.3.86 SENS:AVER2:CLEA .................................................................................................................93

8.7.3.87 SENS[<n>][:FRES]:DATA? ......................................................................................................93

8.7.3.88 SENS[<n>]:RRAT:DATA? .........................................................................................................93

8.7.3.89 STAT:OPER? ............................................................................................................................94

8.7.3.90 STAT:OPER:COND? ................................................................................................................94

8.7.3.91 STAT:OPER:ENAB <value> .....................................................................................................94

8.7.3.92 STAT:QUES? ............................................................................................................................94

8.7.3.93 STAT:QUES:COND? ................................................................................................................94

8.7.3.94 STAT:QUES:ENAB <value> .....................................................................................................94

8.7.3.95 SYST:BEEP[:IMM] ...................................................................................................................95

8.7.3.96 SYST:BEEP:KEY <boolean> ...................................................................................................95

8.7.3.97 SYST:BEEP:ALER <boolean> .................................................................................................95

8.7.3.98 SYST:CODE:VERS? .................................................................................................................95

8.7.3.99 SYST:COMM:GPIB:ADDR <value> .........................................................................................95

8.7.3.100 SYST:COMM:GPIB[:STAT] <boolean> ....................................................................................95

8.7.3.101 SYST:COMM:GPIB:TERM LIN|RET .........................................................................................95

8.7.3.102 SYST:COMM:SER:BAUD <value> ..........................................................................................95

8.7.3.103 SYST:COMM:SER:LIN <boolean> ..........................................................................................95

8.7.3.104 SYST:COMM:SOCK:ADDR <IP address> ..............................................................................95

8.7.3.105 SYST:COMM:SOCK:CONT OFF|ON|QUER.............................................................................96

8.7.3.106 SYST:COMM:SOCK:DHCP <boolean> ...................................................................................96

8.7.3.107 SYST:COMM:SOCK:GAT <IP address> .................................................................................96

8.7.3.108 SYST:COMM:SOCK:KEEP <seconds> ...................................................................................96

8.7.3.109 SYST:COMM:SOCK:MAC?......................................................................................................97

8.7.3.110 SYST:COMM:SOCK:MASK <IP address> ..............................................................................97

8.7.3.111 SYST:COMM:SOCK:NAME <name> ......................................................................................97

8.7.3.112 SYST:COMM:USB[:STAT] <boolean> .....................................................................................97

8.7.3.113 SYST:CONF:CHAN? ................................................................................................................97

8.7.3.114 SYST:CONF:SCAN? ................................................................................................................97

8.7.3.115 SYST:DATE <year>,<month>,<day> ......................................................................................97

8.7.3.116 SYST:ERR? ..............................................................................................................................98

8.7.3.117 SYST:KLOC <boolean> ..........................................................................................................98

8.7.3.118 SYST:PASS:CDIS .....................................................................................................................98

8.7.3.119 SYST:PASS:CEN <password> ................................................................................................98

8.7.3.120 SYST:PASS:CEN:STAT? ...........................................................................................................99

8.7.3.121 SYST:PASS:GROU:MEAS <boolean> .....................................................................................99

8.7.3.122 SYST:PASS:GROU:PROB <boolean> .....................................................................................99

8.7.3.123 SYST:PASS:GROU:RES <boolean> ........................................................................................99

8.7.3.124 SYST:PASS:GROU:TIME <boolean> ......................................................................................99

8.7.3.125 SYST:PASS:NEW <current password>,<new password> ......................................................99

8.7.3.126 SYST:PON:MIN? ......................................................................................................................99

8.7.3.127 SYST:TIME <hour>,<minute>,<second> ...............................................................................99

8.7.3.128 SYST:TIME:DAYL OFF|NAM|EUR ............................................................................................99

8.7.3.129 TEST:CURR:CONF <channel>,<current>,<polarity> ...........................................................100

8.7.3.130 TEST:CURR[:STAT] <boolean> .............................................................................................100

8.7.3.131 TEST:LIN:ABOR ....................................................................................................................100

8.7.3.132 TEST:LIN:PAR? ......................................................................................................................100

8.7.3.133 TEST:LIN:INIT ........................................................................................................................100

8.7.3.134 TEST:LIN:REP<n>? ...............................................................................................................101

8.7.3.135 TEST:LIN:REP:TIME?.............................................................................................................101

vii

Page 8

1594A/1595A Super-Thermometer

8.7.3.136 TEST:LIN[:STAT]? ..................................................................................................................101

8.7.3.137 TEST:LIN:TIME? ....................................................................................................................101

8.7.3.138 TEST:LIN:TOL<n>? ...............................................................................................................102

8.7.3.139 TEST:SYST:ABOR ..................................................................................................................102

8.7.3.140 TEST:SYST:INIT .....................................................................................................................102

8.7.3.141 TEST:SYST:REP[<n>]? ..........................................................................................................102

8.7.3.142 TEST:SYST:STAT? ..................................................................................................................102

8.7.3.143 UNIT:TEMP C|K|F ..................................................................................................................102

9 Calibration ......................................................................................... 103

9.1 Introduction ............................................................................................................103

9.2 SYSTEM TEST (F1) ................................................................................................103

9.3 CURRENT TEST (F2) .............................................................................................103

9.4 RATIO CALIBRATION (F3) .....................................................................................104

9.4.1 WRITE FILE (F1) ............................................................................................................ 106

9.4.2 ADJUST PARAMETERS (F2) .........................................................................................106

9.5 RESISTANCE CALIBRATION (F4) ..........................................................................106

9.5.1 WRITE FILE (F1) ............................................................................................................ 107

9.5.2 ADJUST RESISTOR (F2) ...............................................................................................108

9.6 CALIBRATION PARAMETERS (F5) ........................................................................108

9.6.1 Calibration Interval ........................................................................................................108

9.6.2 Standby Current Check .................................................................................................109

10 Maintenance .......................................................................................111

11 Troubleshooting .................................................................................113

Index ...........................................................................................................115

viii

Page 9

Figures

Figure 1 PEM (Power Entry Module) .................................................................................16

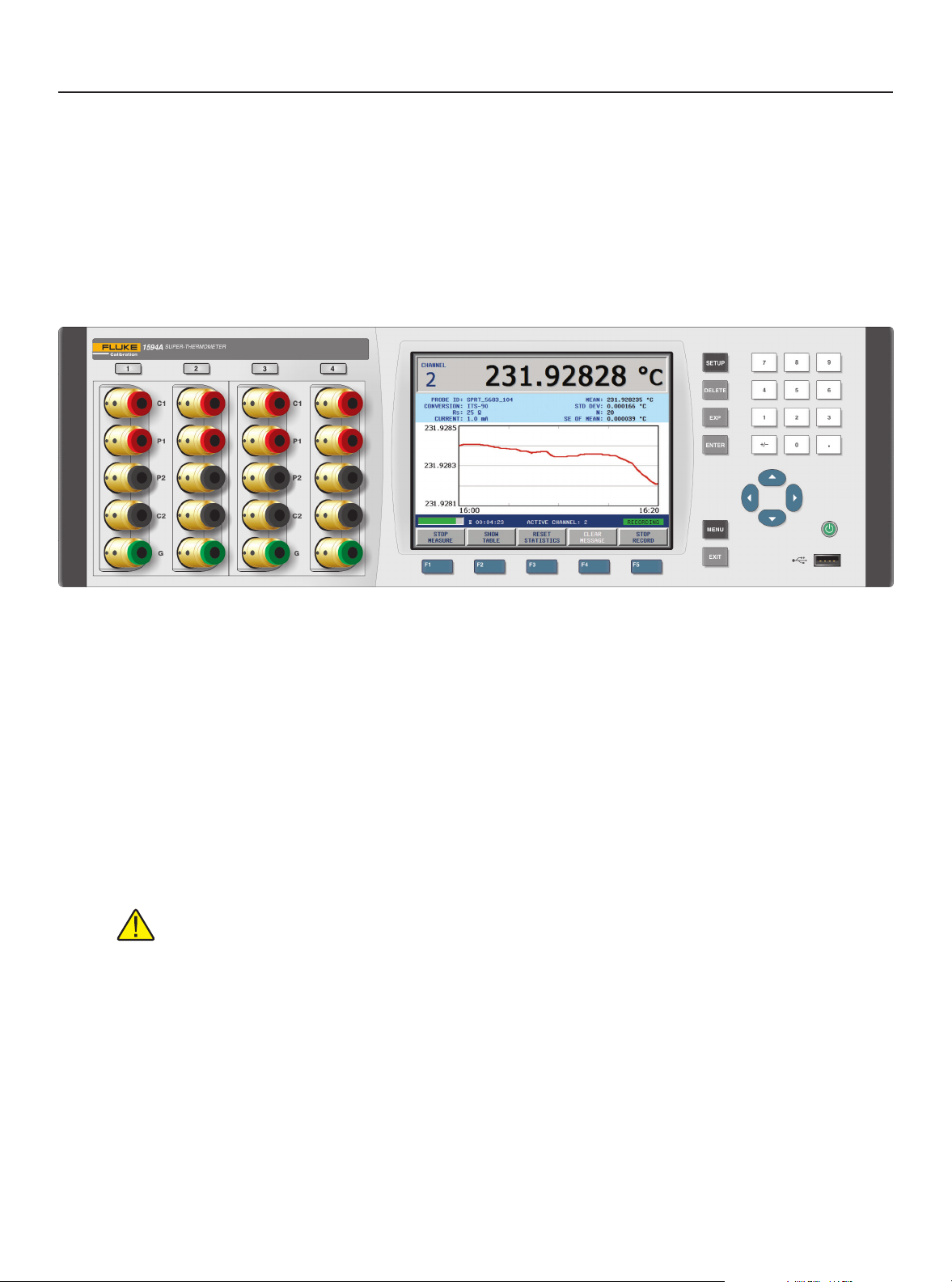

Figure 2 Front view ...........................................................................................................17

Figure 3 Front Panel Display .............................................................................................19

Figure 4 Rear view ............................................................................................................20

Figure 5 External Resistor Inputs ......................................................................................20

Figure 6 Power Entry Module ...........................................................................................22

Figure 7 Location Descriptor Example .............................................................................23

Figure 8 Alpha-Numeric Interface ....................................................................................23

Figure 9 Measurement Screen ..........................................................................................26

Figure 10 Channel Setup Screen ......................................................................................29

Figure 11 Probe Menu Screen ..........................................................................................34

Figure 12 Measure Menu Screen ......................................................................................38

Figure 13 Measurement Process Block Diagram .............................................................39

Figure 14 Display Menu Screen........................................................................................46

Figure 15 System Menu Screen ........................................................................................50

Figure 16 Input Wiring ......................................................................................................58

Figure 17 Super-Thermometer Web Interface ..................................................................68

Figure 18 Current meter connection diagram.................................................................103

ix

Page 10

1594A/1595A Super-Thermometer

Tables

Table 1 Symbols ..................................................................................................................1

Table 2 Resistance Ratio Accuracy Specifications ............................................................6

Table 3 Resistor Stability Specifications .............................................................................7

Table 4 Absolute Resistance Accuracy Specifications ......................................................7

Table 5 Measurement Current Accuracy Specifications.....................................................8

Table 6 Temperature Measurement Noise Specifications...................................................8

Table 7 Relative Measurement Current Specifications .......................................................8

Table 8 General Specifications ...........................................................................................9

Table 9 Optional Accessories ...........................................................................................15

Table 10 Front panel key descriptions ..............................................................................18

Table 11 Remote Operation Connections .........................................................................21

Table 12 Alert Messages ..................................................................................................27

Table 13 Recommended Reference Resistor for Various Probe Types ............................30

Table 14 Probe Conversion Information ............................................................................35

Table 15 Default Statistical Fields .....................................................................................48

Table 16 Statistical Field Descriptions ..............................................................................48

Table 17 Recommended Reference Resistors and Sensing Current ...............................62

Table 18 Remote Operation Ports ..................................................................................... 65

Table 19 Report Operation Commands ............................................................................ 70

Table 20 Recommended Resistors For Testing The Current ..........................................104

x

Page 11

1 Before You Start

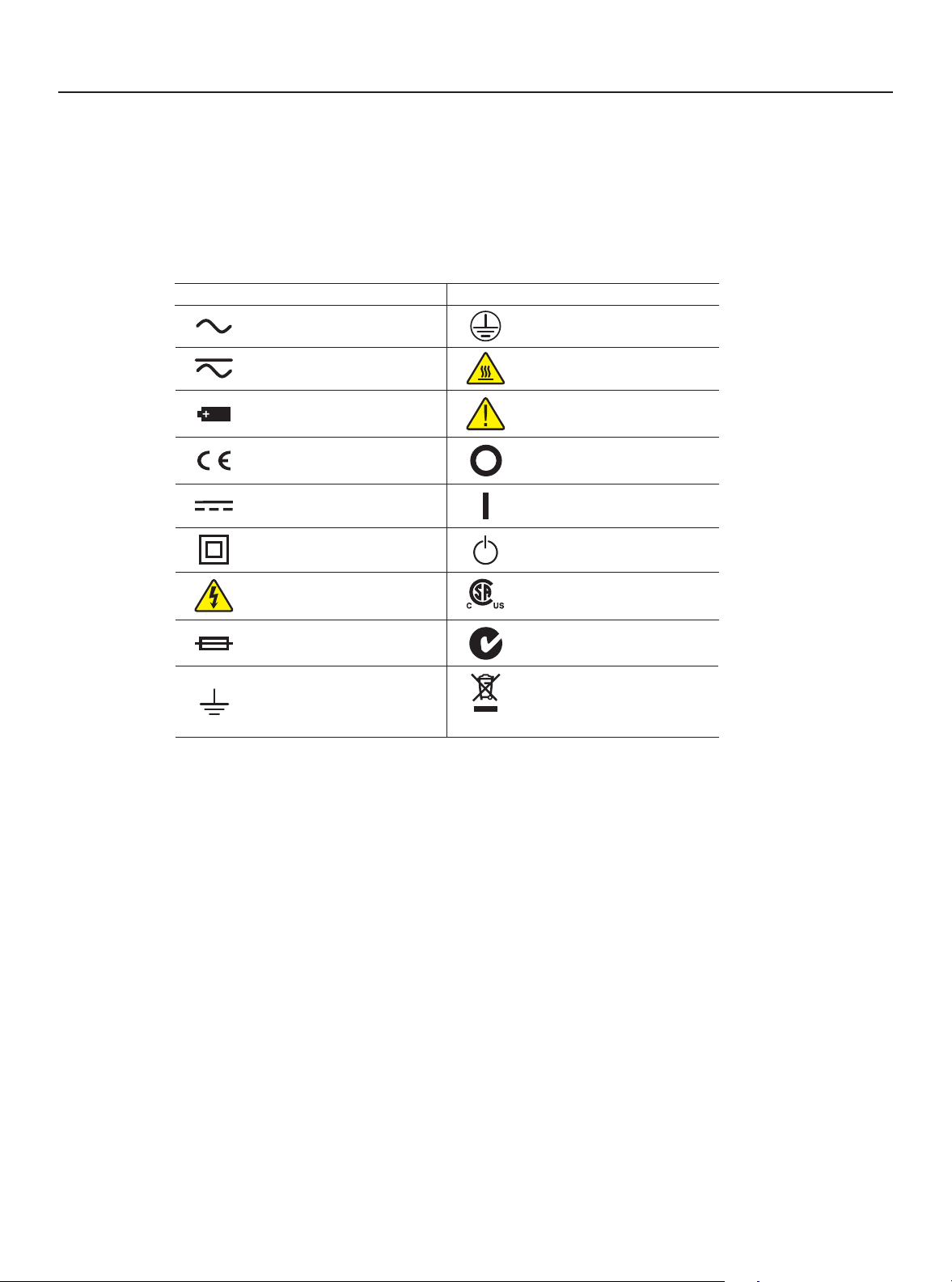

1.1 Symbols Used

Table 1 lists the symbols that may be used on the instrument or in this manual and the meaning of each

symbol.

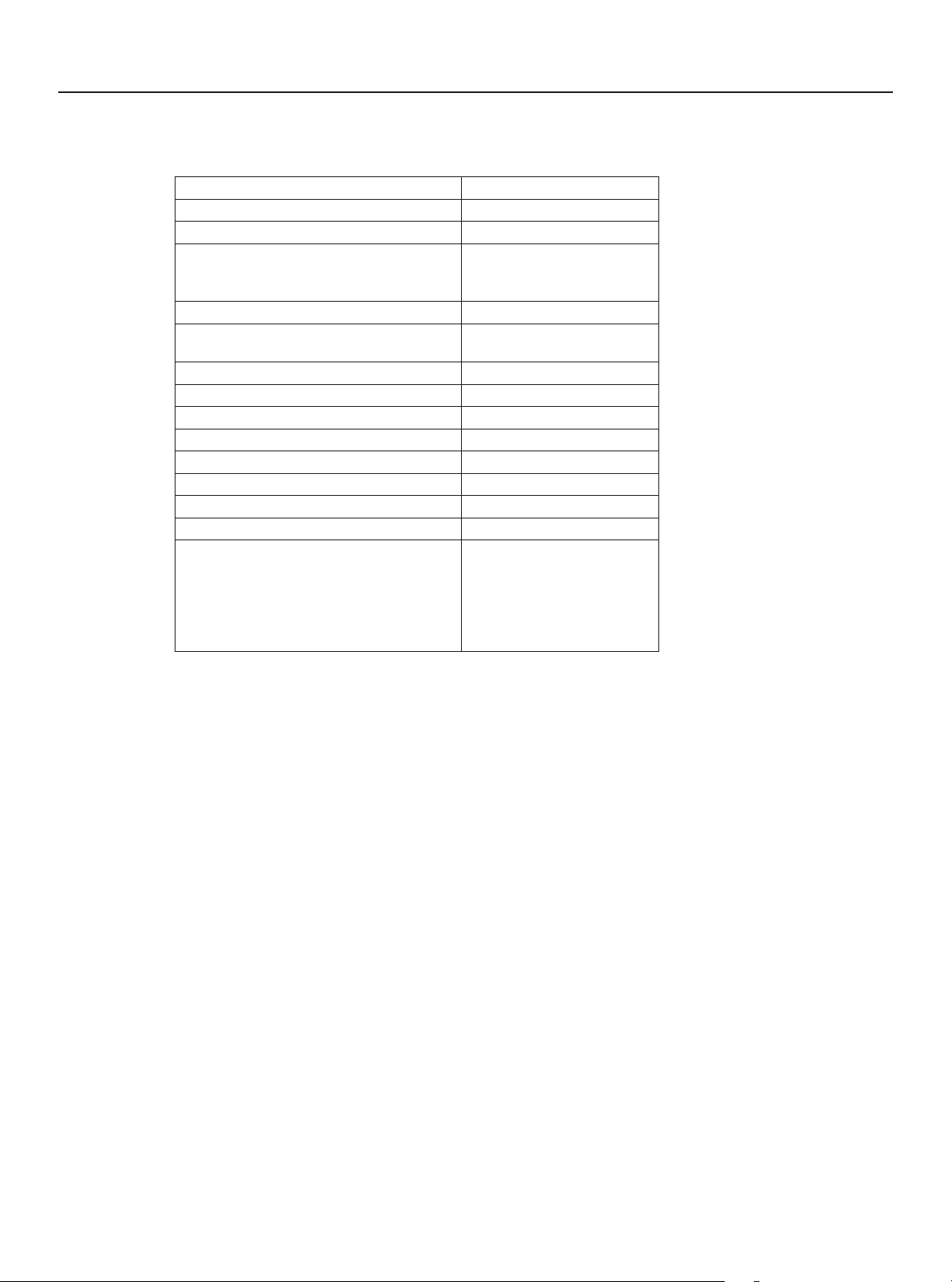

Table 1 Symbols

Symbol Description Symbol Description

AC (Alternating Current) PE Ground

AC-DC Hot Surface (Burn Hazard)

Before You Start

Safety Information

Battery

Complies with European Union

directives

DC On

Double Insulated Standby Indication

Electric Shock

Fuse C-TICK Australian EMC mark

Ground

Read the User’s Guide

(Important Information)

Off

Canadian Standards

Association

The European Waste Electrical

and Electronic Equipment

(WEEE) Directive (2002/96/EC)

mark.

1.2 Safety Information

This instrument is compliant to EN 61010-1 {2nd Edition}, and CAN/CSA 22.2 No 61010.1-04, Pollution

Degree 2. This instrument is designed for indoor use only. Use this instrument only as specified in this manual.

Otherwise, the protection provided by the instrument may be impaired.

The following denitions apply to the terms “Warning” and “Caution”.

“WARNING” identifies conditions and actions that may pose hazards to the user.

“CAUTION” identifies conditions and actions that may damage the instrument being used.

1.2.1 WARNINGS

DO NOT use this unit in environments other than those listed in the User’s Guide.

Follow all safety guidelines listed in the User’s Guide.

Calibration equipment should only be used by trained personnel.

This instrument can measure extreme temperatures. Precautions must be taken to prevent personal

injury or damage to objects. Probes may be extremely hot or cold. Cautiously handle probes to prevent

personal injury. Carefully place probes on a heat/cold resistant surface or rack until they reach room

temperature.

DO NOT operate near flammable materials.

Use only a grounded AC mains supply of the appropriate voltage to power the instrument.

1

Page 12

1594A/1595A Super-Thermometer

Authorized Service Centers

DO NOT connect an AC mains supply that does not match the voltage setting on the back of the unit.

DO NOT use this instrument in combination with any probe ( PRT or thermistor) to measure the

temperature or resistance of any device where the probe might come in contact with a conductor that is

electrically energized. Severe electric shock, personal injury, or death may occur.

DO NOT position this instrument in a manner where it is difficult to reach the power cord or power

entry module mains switch. When rack mounting the instrument, ensure the rack power cord and mains

supply switch are accessible.

1.2.2 CAUTIONS

If the instrument is dropped, struck, or handled in a way that causes internal or external physical

damage, immediately unplug the instrument, discontinue use, and contact a Fluke Authorized Service

Center for repair. Do not attempt to disassemble or repair the instrument. Refer repairs or replacement

of components to a Fluke Authorized Service Center.

DO NOT connect AC voltage to any input terminal on the instrument. Permanent damage to the

instrument will result.

1.3 Authorized Service Centers

Please contact one of the following authorized Service Centers to coordinate service on your Fluke product:

Fluke Corporation

799 E. Utah Valley Drive

American Fork, UT 84003-9775

USA

Phone: +1.801.763.1600

Telefax: +1.801.763.1010

E-mail: support@hartscientific.com

Fluke Nederland B.V.

Customer Support Services

Science Park Eindhoven 5108

5692 EC Son

NETHERLANDS

Phone: +31-402-675300

Telefax: +31-402-675321

E-mail: ServiceDesk@fluke.nl

Fluke Int’l Corporation

Service Center - Instrimpex

Room 2301 Sciteck Tower

22 Jianguomenwai Dajie

Chao Yang District

Beijing 100004, PRC

CHINA

Phone: +86-10-6-512-3436

Telefax: +86-10-6-512-3437

E-mail: xingye.han@fluke.com.cn

2

Page 13

Before You Start

Authorized Service Centers

Fluke South East Asia Pte Ltd.

Fluke ASEAN Regional Office

Service Center

60 Alexandra Terrace #03-16

The Comtech (Lobby D)

118502

SINGAPORE

Phone: +65 6799-5588

Telefax: +65 6799-5588

E-mail: antng@singa.fluke.com

When contacting these Service Centers for support, please have the following information available:

Model Number

Serial Number

Voltage

Complete description of the problem

3

Page 14

Page 15

Introduction and Specications

2 Introduction and Specications

2.1 Introduction

The Fluke family of Hart Super-Thermometers long ago established the standard for easy-to-use, precision

temperature measurement instrumentation. Laboratories worldwide have selected the Super-Thermometer

not only for the assurance of achieving high-quality results, but also for the innovative features that increase

productivity in the lab. The Fluke 1594A and 1595A Hart Super-Thermometers continue this legacy adding

new patent pending measurement technology and features that truly are best in class. Below is a summary of

key capabilities and features.

Typical 1595A accuracy 0.2 ppm (0.05 mK), 1594A accuracy 0.8 ppm (0.2 mK)

Sample rates as fast as 1 second

Measures SPRTs, HTPRTs, PRTs, and thermistors

Four input channels on the front panel accept most probe terminations with the patented DWF, gold-

plated, tellurium-copper, quick-connect terminals

Congurable standby current for each input channel minimizes self-heating transients when scanning

between channels

Two input channels on the back panel, dedicated for external standard resistors, keep the front panel

inputs free for Reference Thermometers or Standard Resistors and UUTs

Channel Select Keys above each input channel change color to indicate whether a channel is actively

measuring, in standby, or inactive—pressing a channel key activates the selected channel

Temperature-controlled internal reference resistors allow for traceable temperature and absolute

resistance measurements in ambient conditions from 15 °C to 30 °C

Patent pending, Ratio Self-Calibration performs a linearity check or calibration of the SuperThermometer ratio accuracy without the need of any external equipment

Automated Zero-Power Measurement allows for determination and/or cancellation of a thermometer’s

self-heating error

Updated computer interface with USB control, RS-232, and IEEE-488 included as standard

Ethernet connection allows for remote view of the Super-Thermometer’s display from a web browser

USB memory device on the front panel to accommodate data logging, transfer of probe parameters, and

storage and retrieval of Super-Thermometer user congurations

VGA output allows the Super-Thermometer’s screen to be displayed on a VGA monitor

Selectable operating language: English, Chinese, Japanese, Spanish, French, German, or Russian

Intuitive User Interface makes the Super-Thermometer easy to congure and use right out of the box

Specications

2.2 Specications

2.2.1 General

Current best practices in metrology require uncertainty analyses to be in compliance with the ISO Guide to the

Expression of Uncertainty in Measurement (often referred to as the “GUM”). For convenience, the specica-

tions in this section are listed in k = 2 (95%) coverage and in k = 3 (99%) coverage to allow the user to easily

apply the specications in an uncertainty analysis.

The following specications apply after the standard warm-up period of 30 minutes. The Super-Thermometer

is designed to measure with accuracy and stability without the need for internal auto-cal or zeroing routines.

To realize the full potential of measurement ability, accepted metrology practices such as the use of proper

wiring should be adhered to. In addition, it is important to ensure that the instrument is correctly set up.

The specications are divided into three categories: primary specications, ancillary specications, and general specications.

5

Page 16

1594A/1595A Super-Thermometer

Specications

Primary Specications: the core set of measurement accuracy specications of the Super-Thermometer. They

are guaranteed for performance verication at the 99% condence level.

Ancillary Specications: additional specications that help the user understand more of the uncertainties

involved in measurement. Since they may be subject to the application and setting in which the Super-Ther-

mometer is used, they are not guaranteed for performance verication but should be considered typical.

General specications: general specications such as measurement range, environmental operating range,

dimensions, etc.

2.2.2 Primary Specications

2.2.2.1 Resistance Ratio Accuracy

Resistance ratio accuracy is the ability of the Super-Thermometer to measure the ratio of two resistances, Rx/

Rs. It is determined primarily by the linearity of the measurement circuit. The following specications apply

for resistance ratios measured with a reference resistor of 25 Ω or 100 Ω using a measurement current of 0.5

mA to 2.0 mA. Other reference resistors are specied using a factor as explained in the following specication table. Performance verication is guaranteed for 99% condence level specications within the specied

operating temperature range of 15°C to 30°C. The listed uncertainties are in terms of parts-per-million (ppm)

of reading unless stated otherwise.

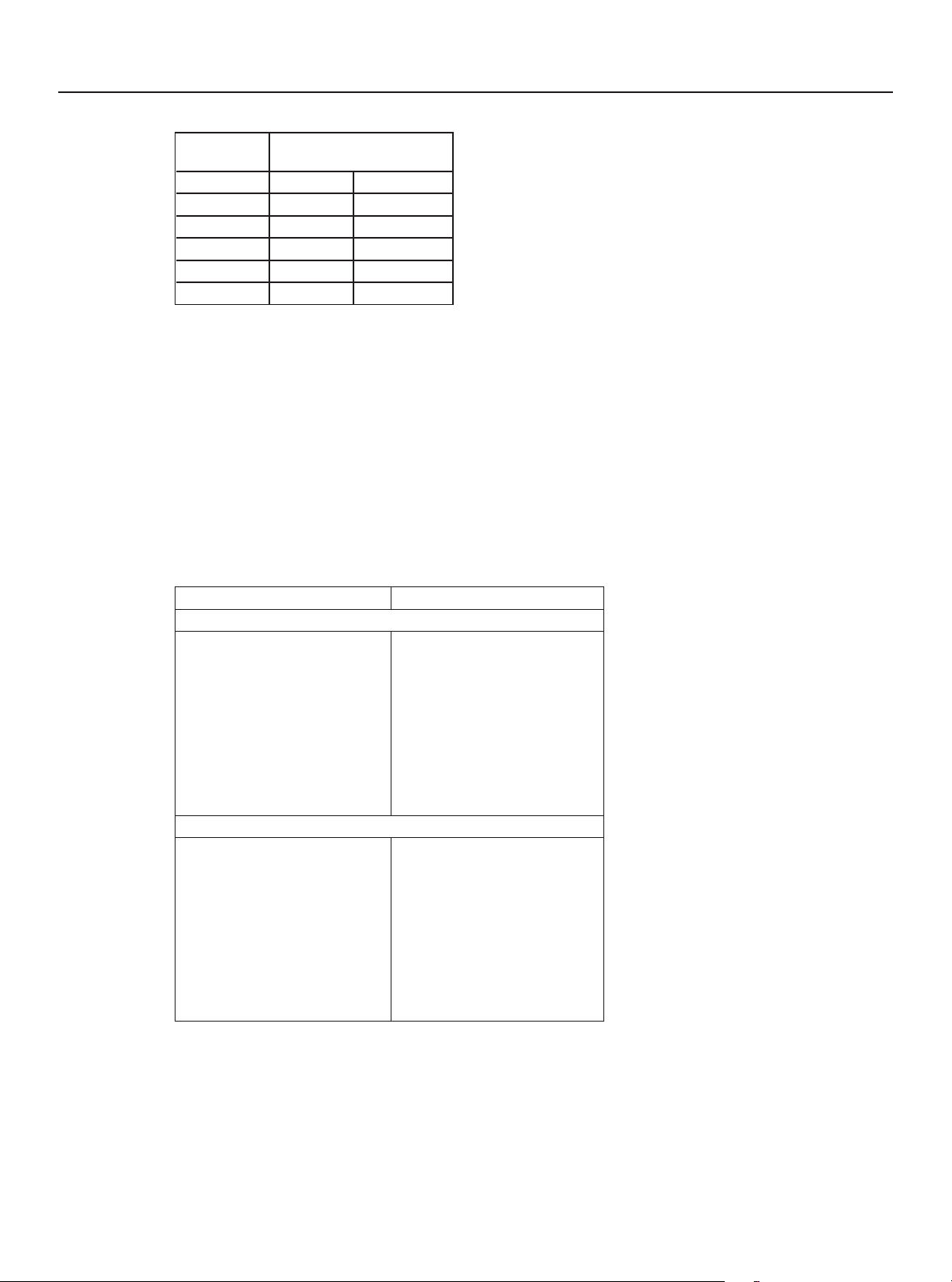

Table 2 Resistance Ratio Accuracy Specifications

Ratio Range

95% condence level, 1-year

0.95 to 1.05 0.24 ppm 0.06 ppm

0.5 to 0.95, 1.05 to 2.0 0.64 ppm 0.16 ppm

0.25 to 0.5, 2.0 to 4.0 0.8 ppm 0.2 ppm

0.0 to 0.25 2.0 x 10

4.0 to 10.0 2.0 ppm 0.5 ppm

99% condence level, 1-year

0.95 to 1.05 0.3 ppm 0.075 ppm

0.5 to 0.95, 1.05 to 2.0 0.8 ppm 0.2 ppm

0.25 to 0.5, 2.0 to 4.0 1.0 ppm 0.25 ppm

0.0 to 0.25 2.5 x 10

4.0 to 10.0 2.5 ppm 0.63 ppm

†

Specications are in terms of absolute ratio

All specications listed in this table apply when using a 25 W or 100 W

reference resistor. Multiply stated specications by a factor of 2 when using a

10 W reference resistor with sensing current between 1 and 5 mA, and a factor

of 10 when using a 1 W reference resistor with sensing current between 5 and

20mA. When using a 10 kohm reference resistor, internal or external, use the

Absolute Resistance Accuracy specication in Table 4.

1594A Accuracy

(ppm of reading)

–07 †

–7 †

1595A Accuracy

(ppm of reading)

–8 †

5.0 x 10

–8 †

6.3 x 10

2.2.2.2 Resistor Stability

Resistor stability characterizes the ability of the instrument to accurately compare two similar resistances

within some time period using the internal resistors as references. The following specications apply using the

given reference resistor over a one-minute average. The specications assume typical laboratory conditions,

which do not include transportation and large ambient temperature uctuations.

Resistance stability is determined by the short-term stability of the internal reference resistors and control

stability of the temperature stabilizing block. It does not include measurement noise.

6

Page 17

Table 3 Resistor Stability Specifications

Resistor (Rs) Accuracy (ppm of reading),

95% condence level

24 hours 30 days

1W 5 ppm 10 ppm

10W 0.5 ppm 2 ppm

25W 0.25 ppm 1 ppm

100W 0.2 ppm 1 ppm

10kW 0.25 ppm 1 ppm

2.2.2.3 Absolute Resistance Accuracy

Absolute resistance accuracy is the ability of the instrument to measure absolute resistance, Rx, using the

internal reference resistors. The following specications apply using the given reference resistor, Rs, and

excitation current.

The 1-year specications include calibration uncertainty, reference resistor drift, ambient temperature sensitivity, resistance ratio uncertainty, and measurement noise using 1-minute average and a 2-second sample period

(n = 30).

Performance verication is guaranteed for 99% condence level, 1-year specications within the specied

operating temperature range of 15°C to 30°C, maintaining a calibration interval of 6 months for the rst year

and 1 year thereafter.

Introduction and Specications

Specications

Table 4 Absolute Resistance Accuracy Specifications

Resistance range (Rs, current) Accuracy (ppm of reading)

95% condence level, 1-year

0W to 1.2W (1W,10mA) Greater of 40 ppm or 0.000012W

0W to 12W (10W,3mA) Greater of 10 ppm or 0.000024W

0W to 120W (25W, 1mA) Greater of 5 ppm or 0.000024W

0W to 400W (100W, 1mA) Greater of 4 ppm or 0.00008W

0 W to 10 kW (10 kW, 10mA) Greater of 5 ppm or 0.000012kW

10 kW to 40 kW (10 kW, 10mA)

40 kW to 100 kW (10 kW, 2mA)

100 kW to 500 kW (10 kW, 1mA)

99% condence level, 1-year

0W to 1.2W (1W, 10 mA) Greater of 50 ppm or 0.000015W

0W to 12W (10W, 3 mA) Greater of 13 ppm or 0.00003W

0W to 120W (25W, 1 mA) Greater of 6.3 ppm or 0.00003W

0W to 400W (100W, 1 mA) Greater of 5 ppm or 0.0001W

0 kW to 10 kW (10kW, 10mA) Greater of 6.3 ppm or 0.000015 kW

10 kW to 40 kW (10kW, 10mA)

40 kW to 100 kW (10kW, 2mA)

100 kW to 500 kW (10kW,1 mA)

8 ppm

20 ppm

80 ppm

10ppm

25ppm

100ppm

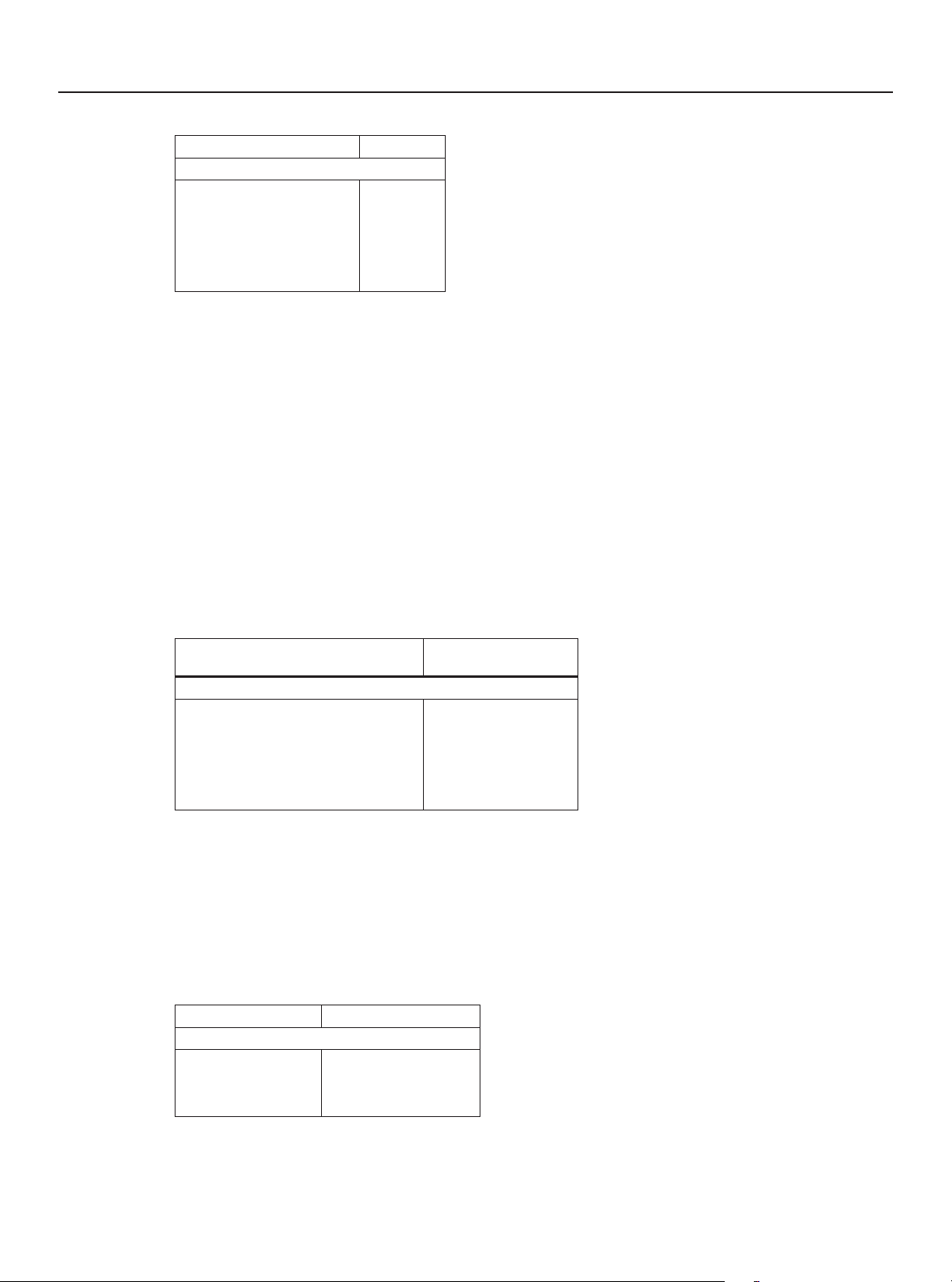

2.2.2.4 Measurement Current Accuracy

Measurement current accuracy is guaranteed to meet the following specications. The specications are stated

as percent of selected current or in absolute mA.

7

Page 18

1594A/1595A Super-Thermometer

Specications

Table 5 Measurement Current Accuracy Specifications

Current Range Accuracy

99% condence level, 1-year

0.001 mA to 0.005 mA 0.00005 mA

0.005 mA to 0.02 mA 1 %

0.02 mA to 0.2 mA 0.5 %

0.2 mA to 2 mA 0.2 %

2 mA to 20 mA 0.5 %

2.2.3 Ancillary Specications

2.2.3.1 Temperature Measurement Noise

Temperature measurement noise indicates typical measurement noise in temperature measurements. The speci-

cations below are given for averages taken over a period of 1 minute with a 2-second sample rate. The effect

of noise may be reduced for longer averages or may be greater for shorter averages.

Noise performance is dependent upon many conditions. Some of the most important things to consider are the

type of thermometer, setup, and environmental conditions such as electromagnetic interference.

Due to the subjective nature of measurement noise, it is not a guaranteed specication. The specications

listed in the table below are obtainable in a typical laboratory environment. It is important that the user make

their own evaluation of measurement noise in the application and environment where the Super-Thermometer

is used.

Table 6 Temperature Measurement Noise Specifications

Standard Error

Conditions (Rs, Current)

Typical performance

25W SPRT at 0°C (25W, 1.0 mA) 0.00002

25W SPRT at 420°C (25W, 1.0 mA) 0.00006

100W PRT at 0°C (100W, 1.0 mA) 0.00001

100W PRT at 420°C (100W, 1.0 mA) 0.00003

10 kW Thermistor at 25°C (10 kW, 10 mA) 0.000003

of the Mean, °C

2.2.3.2 Relative Measurement Current Accuracy

Zero-Power resistance values are calculated based on measurements taken at two levels of excitation current

that differ by a factor of 1.4142. Only the portions of the errors in the currents that are uncorrelated contribute

to error in the zero-power resistance value.

The following specications may be used to estimate the contribution of current error in zero-power resistance

measurements.

Table 7 Relative Measurement Current Specifications

Range Relative Accuracy, mA

99% condence level

0.001 mA to 0.1 mA 0.0008

0.1 mA to 2 mA 0.003

2 mA to 20 mA 0.03

8

Page 19

2.2.4 General Specications

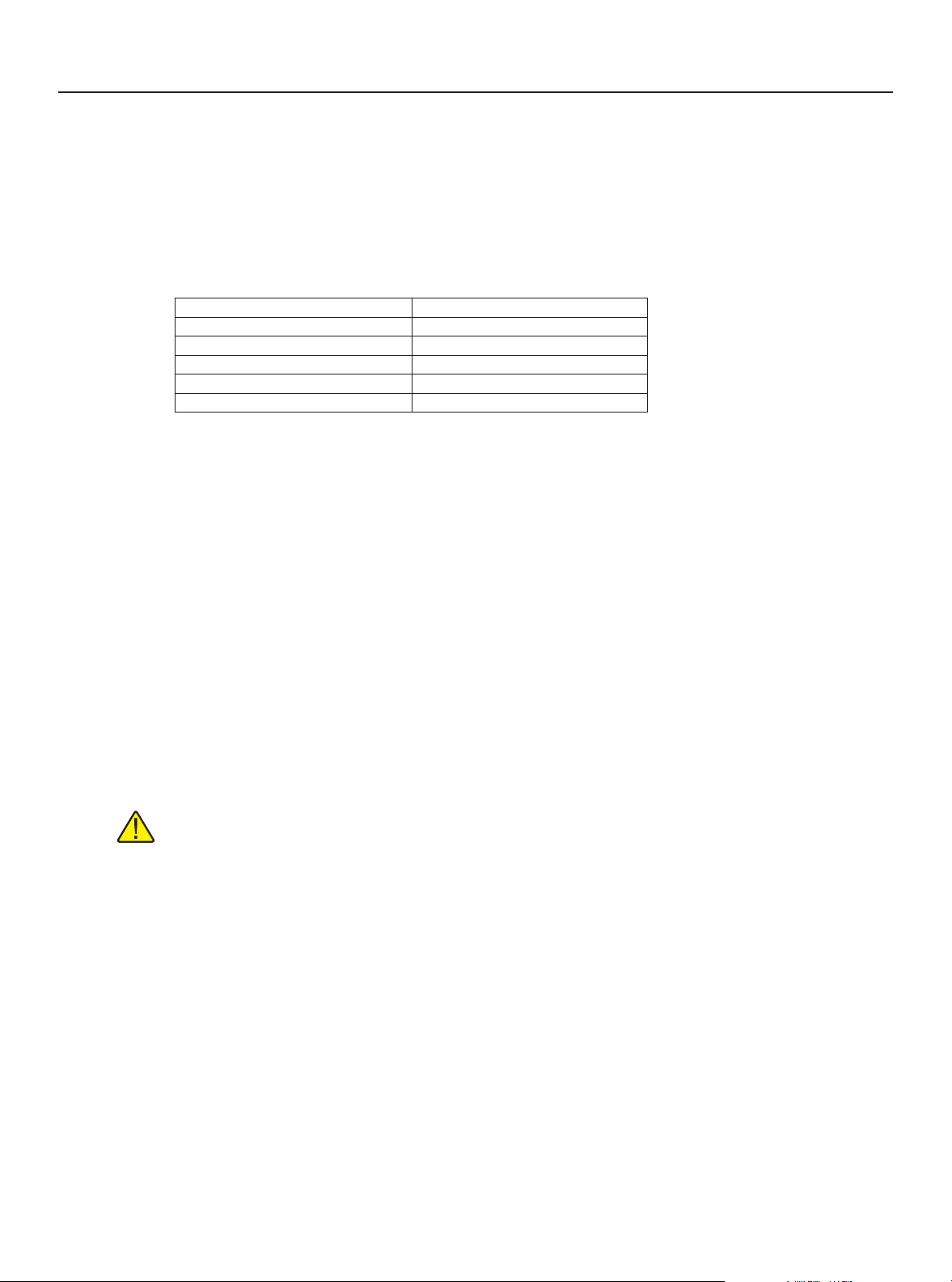

Table 8 General Specifications

Warm-up period 30 minutes

Measurement range 0W to 500 kW

Measurement current range 0.001 mA to 20 mA

Measurement current reversal interval:

Sample period of 1 second or 2 seconds

Sample period of 5 second or 10 seconds

Standby current range 0.001 mA to 2 mA

AC power 100 V to 230 V (±10%)

Fuse Rating 2 A – T – 250 V

Specied operating temperature 15°C to 30°C

Absolute operating temperature 5°C to 40°C

Storage temperature 0°C to 40°C

Operating relative humidity, 5°C to 30°C 10% to 70%

Operating relative humidity, 30°C to 40°C 10% to 50%

Storage relative humidity 0% to 95%, non-condensing

Maximum operating altitude 3000m

Dimensions:

Height

Width

Depth (with handles)

Depth (without handles)

Weight

Introduction and Specications

Specications

0.2 second

1.2 second

50 or 60 Hz

147 mm (5.8 in)

439 mm (17.3 in)

447 mm (17.6 in)

406 mm (16.0 in)

7.3 kg (16.0 lb)

2.2.5 Applying the Specications

2.2.5.1 Introduction

The purpose of this section is to help the user apply the specications in measurement scenarios for which

the Super-Thermometer was designed. The following uncertainty calculation examples may not include all

uncertainties that are present in a measurement. Be sure to follow current best practices in uncertainty analysis

to correctly calculate measurement uncertainty.

2.2.5.2 How the Super-Thermometer Measures

In order to understand how to apply the specications, it is important to know how the Super-Thermometer

measures. The fundamental measurement of the Super-Thermometer is the resistance ratio. It is the ratio

between an unknown resistance (Rx) and a reference resistor (Rs) – either internal or external. If a resistance

measurement is needed, the ratio is multiplied by the value of the reference resistor to calculate the resistance

of the Rx resistor (for more information refer to Measurement Timing in the Menus and Screens section).

If a temperature reading is required, the Rx resistance value is used to calculate the temperature using the calibration coefcients entered into the Probe Library. When ITS-90 is selected as the temperature conversion, the

Rx resistance is divided by the RTPW (resistance at the triple-point of water) value that is entered in the probe

denition. The resulting value is called W

then applied to W

Since W

is a ratio between a probe’s resistance at temperature (R

T90

to calculate the temperature reading of the probe.

T90

curacy relies primarily on ratio accuracy if both R

Also, this only applies if the RTPW was measured by the Super-Thermometer and entered into the probe

denition.

. The probe calibration coefcients and the ITS-90 equations are

T90

) and its RTPW, W

) and RTPW are measured in close proximity in time.

T90 (Rx

T90

measurement ac-

T90

9

Page 20

1594A/1595A Super-Thermometer

Specications

When calibrating an SPRT on the ITS-90, the W

This is done by measuring the resistance of the SPRT at a xed-point temperature followed immediately by

measurement of the RTPW. This is repeated for each temperature point. Once again the ratio accuracy of the

Super-Thermometer, applied to each measured resistance, determines the accuracy of the resulting W

2.2.5.3 Example 1: Measuring an SPRT

This section explains how to calculate the uncertainty of a temperature measurement when measuring a

calibrated 25.5 W SPRT at 157 °C, using the internal 25 W reference resistor in a 1595A. Since the SuperThermometer measurement accuracy is directly related to other sources of uncertainty, additional uncertainties

will be included in the calculation for completeness.

Since an SPRT can be measured with different techniques, two different calculations will be presented to represent the most common and recommended techniques.

2.2.5.3.1 Measuring With Updated RTPW

In this example, the RTPW of the SPRT is measured by a 1595A and entered into the SPRT’s probe denition

in the 1595A. Then the SPRT is measured at 157 °C, in temperature mode, using the coefcients entered in the

SPRT probe denition.

As explained above, this measurement technique primarily uses the ratio accuracy of the Super-Thermometer.

It is equivalent to measuring the ITS-90 W

The total uncertainty of this measurement is based on six uncorrelated uncertainties. These uncertainties are:

Resistance ratio accuracy of the 1595A at 157 °C

Measurement noise at 157 °C

Resistance ratio accuracy of the 1595A at 0.01 °C (triple-point of water)

Measurement noise at 0.01 °C

Reference resistor drift

Uncertainty of the triple-point of water cell

The following demonstrate how to calculate and combine the listed uncertainties.

value is measured at required xed-point temperatures.

T90

value and using it to calculate temperature.

T90

T90

value.

2.2.5.3.2 Resistance Ratio Accuracy at 157 °C

The resistance of the SPRT, when measuring at 157 °C, is 41.1 Ω. The ratio of this resistance against the 25

W reference resistor is 1.644. From the resistance ratio accuracy specications of the 1595A, the standard

uncertainty (k = 1) when measuring a resistance ratio of 1.644 is 0.08 ppm. This is converted to temperature

by dividing 0.08 ppm by 1.0 × 106 and then multiplying by 1.644. The result is then divided by W

ity (dW/dT) at 157 °C which is 0.0038 (found on the SPRT calibration report, see tip below). The nal result is

0.000035 °C.

2.2.5.3.3 Measurement Noise at 157 °C

Random error due to measurement noise must be included as an uncertainty. During measurement at 157 °C, it

is observed that the standard error of the mean is 0.000040 °C.

Note: The user must monitor measurement noise and use the actual measured measurement noise in the

uncertainty calculations.

2.2.5.3.4 Resistance Ratio Accuracy at 0.01 °C

Uncertainties related to measuring the RTPW of the SPRT must be included in the analysis. However, RTPW

uncertainties are magnied when applied to uncertainties of temperatures that are above 0 °C. At 157 °C this

magnication is estimated by multiplying RTPW uncertainties by the W

example).

The resistance of the SPRT at the triple-point of water is approximately 25.5 Ω. The resistance ratio against the

25 W reference resistor is then about 1.02. From the resistance ratio accuracy specications of the 1595A, the

standard uncertainty due to linearity while measuring a resistance ratio of 1.02 is 0.03 ppm. This specication

T90

value at 157 °C (1.612 in this

T90

sensitiv-

10

Page 21

is converted to temperature by dividing 0.03 ppm by 1.0 × 106 and then multiplying by 1.02. The result is then

divided by W

ing by W

2.2.5.3.5 Measurement Noise at 0.01 °C

sensitivity, dW/dT, at 0.01 °C, which is 0.004. The nal result is 0.000008 °C. After multiply-

T90

(1.612), the uncertainty of the RTPW resistance ratio, when applied to 157 °C, is 0.000013 °C.

T90

During measurement of the RTPW, it is observed that the standard error of the mean is 0.0000018 Ω. To

convert this value into temperature, divide by the resistance sensitivity (dR/dT) of the SPRT at 0.01 °C. dR/dT

at 0.01 °C is 0.1 W/°C (see tip below). The result is 0.000018 °C. Multiplying by W

°C.

Tip: Most SPRT calibration reports list the Temperature versus W values of the SPRT in a table.

Typically, the dT/dW value at each temperature will be included in the same table. dR/dT can be

calculated by inverting dT/dW and multiplying by the RTPW of the SPRT. Also, dW/dT can be calculated

by simply inverting dT/dW.

2.2.5.3.6 Uncertainty of the TPW Cell

Uncertainty of the temperature of the triple-point of water cell must also be included. For this example, the

standard uncertainty of the triple-point of water cell is 0.000050 °C. Multiplying by W

0.000081 °C.

Introduction and Specications

Specications

(1.612) yields 0.000029

T90

(1.612) results in

T90

2.2.5.3.7 Reference Resistor Drift

Possible drift of the 25 W reference resistor between the TPW measurement and the 157 °C measurement must

be accounted for. To reduce the possible error, both measurements should be taken in close proximity in time.

For this example, the 24-hour stability specication will be used. This requires that both measurements are

taken within the same 24-hour period. The standard uncertainty due to drift of the reference resistor is 0.125

ppm. This is converted to temperature by dividing 0.125 ppm by 1.0 × 106 and then multiplying by 1.612. The

result is then divided by W

2.2.5.3.8 Combining the Uncertainties

sensitivity (dW/dT) at 157 °C which is 0.0038. The result is 0.000053 °C.

T90

At this point, all of the uncertainties can be combined by root-sum-square (RSS) since they are uncorrelated.

Even though the 1595A resistance ratio accuracy is used twice in the calculation, both measurements are considered uncorrelated.

This RSS sum produces a combined standard uncertainty of 0.000115 °C. Multiplying by the coverage factor

(k = 2) results in a total expanded uncertainty of 0.000230 °C.

In this example, it is assumed the SPRT did not drift between the measurements at the TPW and 157 °C. It

may be necessary to add an additional uncertainty that accounts for SPRT drift.

2.2.5.3.9 Measuring With Calibration Report RTPW

In this example, the SPRT is monitored by periodically measuring its RTPW in a TPW cell but the original

RTPW from the SPRT calibration report is entered in the 1595A, not the measured RTPW. This requires a dif-

ferent set of specications to be used in the measurement uncertainty.

The uncertainty of this measurement is based on four uncorrelated uncertainties. These uncertainties are:

Resistance accuracy of the 1595A when measuring the SPRT at 157 °C

Measurement noise at 157 °C

Uncertainty of the SPRT resistance at the triple-point of water

Drift of the RTPW of the SPRT

2.2.5.3.10 Resistance Accuracy at 157 °C

The resistance of the SPRT at 157 °C is 41.1 Ω. Using the 25 Ω internal reference resistor, the 1595A oneyear resistance standard uncertainty is 2.5 ppm. This uncertainty, in terms of temperature, is calculated by rst

dividing 2.5 ppm by 1.0 × 106 then multiplying by 41.1 Ω. The result is then divided by the sensitivity (dR/dT)

11

Page 22

1594A/1595A Super-Thermometer

Specications

of the SPRT at 157 °C which is 0.1 Ω/°C (see tip above). This results in a standard temperature uncertainty of

0.001028 °C.

2.2.5.3.11 Measurement Noise at 157 °C

During measurement at 157 °C, the standard error of the mean (as reported by the 1595A) is observed to be

0.00004 °C.

Note: The user must monitor measurement noise and use the actual measured measurement noise in the uncertainty calculations.

2.2.5.3.12 Uncertainty of the Calibration Report RTPW

In this example, the RTPW is not measured and entered into the 1595A. The RTPW from the SPRT calibration

report is entered into the 1595A. The standard (k = 1) uncertainty of the RTPW value listed on the calibration

report must be included. In this example, it is 0.0001 °C. As explained in the previous example, all uncertainties related to RTPW must be multiplied by W

0.000161 °C.

2.2.5.3.13 Drift of the RTPW of the SPRT

Since an SPRT tends to drift, the long-term drift should be included as a source of uncertainty. In this example

the SPRT is allowed to drift 0.002 °C. The assumed distribution of this uncertainty is rectangular. To convert

to a standard uncertainty divide by 1.732 (square root of 3). The result, 0.001155 °C, multiplied by 1.612

yields a standard uncertainty of 0.001861 °C.

of the measured temperature. Multiplying by 1.612 yields

T90

2.2.5.3.14 Combining the Uncertainties

At this point, all of the uncertainties can be combined by root-sum-square (RSS) since they are uncorrelated.

The RSS sum produces a combined standard uncertainty of 0.002133 °C. Multiplying by the coverage factor

(k = 2), and rounding, results in a total expanded uncertainty of 0.0043 °C.

2.2.5.4 Example 2: Calibrating an SPRT

As explained in “How the Super-Thermometer Measures” at the beginning of this section, the calibration of an

SPRT is performed by measuring the resistance at some required xed-point temperature and then at the triple-

point of water. The two measurements are combined by division to get a W

based primarily on the ratio accuracy of the Super-Thermometer.

In this example, an SPRT is calibrated at 419.527 °C (FP of Zinc). The RTPW is measured directly afterward.

The uncertainties resulting from the 1595A in this example are:

Resistance ratio accuracy of the 1595A at 419.527 °C

Measurement noise at 419.527 °C

Resistance ratio accuracy of the 1595A at 0.01°C (triple-point of water)

Measurement noise at 0.01°C

Reference resistor drift

The uncertainties in this example are calculated and combined as described in Example 1. However, there is a

slight difference in the reference resistor drift component.

2.2.5.4.1 Reference Resistor Drift

In Example 1, the 24-hour stability specication of the internal 25 Ω is used. This may not be necessary when

calibrating an SPRT. When calibrating an SPRT typically both measurements of W

imity of time (< 8 hours elapsed time). It is possible for the reference resistor drift to be negligible, especially

if the Super-Thermometer is in a stable temperature environment.

value. The uncertainty of W

T90

are taken in close prox-

T90

T90

is

12

To be sure reference resistor drift is correctly estimated, the user should perform a test to determine actual

reference resistor drift over the elapsed time. One way to perform this test is to measure a very stable external reference resistor over the actual time period using the internal reference resistor. If it is not possible to

measure the reference resistor drift, it may be necessary to use the 24-hour stability specication resulting in a

slightly larger total uncertainty. Another alternative is to use an external reference resistor of very low drift.

Page 23

2.2.5.4.2 Example 3: Measuring Zero-Power Resistance

The purpose of this example is to demonstrate how the Relative Current specication applies when performing

a zero-power measurement. The zero-power uncertainty calculated in this example would be added to the rest

of the uncertainties involved in the measurement as explained in previous examples. The intention of the zeropower measurement is to remove measurement errors due to self-heating of the SPRT.

In this example a 1595A is used to measure a 25 Ω SPRT at the triple-point of water using the Zero-Power

function. The SPRT is measured at nominal current, 1.0 mA and 1.4142 mA (double-power current). In this

example, the self-heating sensitivity of the SPRT in a triple-point of water cell is 0.0024 °C/mA. This was

found by using the Zero-Power function and reading the SELF-HEATING eld in the Zero-Power results

screen. This value will vary signicantly depending on temperature, measurement medium, and probe

construction.

The uncertainties used to calculate zero-power uncertainty are:

Ratio accuracy of the 1595A

Measurement noise