Page 1

Original

Manual X-Smart

®

www.fluidman.com

V 1.2

www.fast-fluid.com

Page 2

© Fast & Fluid Management B.V.

This manual or parts thereof may not be reproduced, stored in a retrieval system, or transmitted, in any form or by any means,

electronic, mechanical, photocopying, recording, nor otherwise, without the prior written permission of Fast & Fluid

Management B.V.

This manual could contain technical inaccuracies or typographical errors.

Fast & Fluid Management B.V. reserves the right to revise this manual from time to time in the contents thereof without the

obligation of Fast & Fluid Management B.V. to notify any person of such revision or change.

Details and values given in this manual are average values and have been compiled with care. They are not binding, however,

and Fast & Fluid Management B.V. disclaims any liability for damage or detriments suffered as a result of reliance on the

information given herein or the use of products, processes or equipment to which this manual refers. No warranty is made that

the use of the information or of the products, processes or equipment to which this manual refers will not infringe any third

party’s patents or rights. The information given does not release the user from making their own experiments and tests.

2

Page 3

Table of Contents

Table of Contents

1 About this manual.........................................................................................................5

1.1 How to work with the manual............................................................................................5

1.2 Record of changes............................................................................................................5

2 Safety .............................................................................................................................7

2.1 Intended use .....................................................................................................................7

2.2 Liability..............................................................................................................................7

2.3 User qualification for installation .......................................................................................7

2.4 Certifications .....................................................................................................................8

2.5 Safety symbols on the machine........................................................................................8

2.6 Safety symbols in the manual...........................................................................................9

2.7 Disposal of the machine ...................................................................................................9

3 Operator manual .........................................................................................................11

3.1 Description......................................................................................................................11

3.1.1 Overview of the machine ....................................................................................11

3.1.2 Overview of the available optional parts.............................................................12

3.1.3 Type plate: details...............................................................................................13

3.2 Operation ........................................................................................................................13

3.2.1 General dispensing procedure............................................................................13

3.2.2 Placing a can ......................................................................................................14

3.2.3 Using the emergency stop switch.......................................................................14

3.3 Maintenance ...................................................................................................................15

3.3.1 X-Smart Maintenance Kit....................................................................................15

3.3.2 General cleaning: daily .......................................................................................15

3.3.3 Cleaning the brush unit: daily .............................................................................16

3.3.4 Cleaning the nozzles: daily.................................................................................17

3.3.5 Refilling a canister ..............................................................................................18

4 Installation ...................................................................................................................19

4.1 Turning on the machine ..................................................................................................19

4.2 First use ..........................................................................................................................19

4.3 Flushing the air out of the pump .....................................................................................19

5 Troubleshooting..........................................................................................................21

5.1 Contact service ...............................................................................................................21

5.2 Troubleshooting guide ....................................................................................................21

3

Page 4

Table of Contents

6 Technical data .............................................................................................................23

6.1 General specifications ....................................................................................................23

6.2 Dimensions and mass ....................................................................................................23

6.3 Ambient conditions .........................................................................................................24

6.4 Noise level ......................................................................................................................24

6.5 Safety classifications ......................................................................................................24

6.6 Electrical specifications...................................................................................................24

6.6.1 Power supply ......................................................................................................24

6.6.2 Dispenser............................................................................................................24

6.7 Electrical diagram ...........................................................................................................25

4

Page 5

About this manual X-Smart V 1.2

1 About this manual

The manual shows the information necessary to:

-install the machine

- operate the machine

- perform basic maintenance

- correct small problems.

The X-Smart and all its versions are referred to in the manual as the ’machine’.

This manual contains the original instructions. The original language of the manual is English.

Note

For the unpacking and installation procedures, refer to the separate installation

instruction sheets.

1.1 How to work with the manual

1. Familiarize yourself with the structure and content.

2. Read the safety chapter in detail and make sure you understand all the instructions. See § 2.

3. Carry out the actions completely and in the given sequence.

1.2 Record of changes

/i

Edition Editor Check Date Description

1.0 ET TB 02/2013 First edition

1.1 ET TB 06/2013 X-Smart Maintenance Kit added

1.2 ET TB 06/2014 Certification and other changes

5

Page 6

About this manual X-Smart V 1.2

6

Page 7

Safety X-Smart V 1.2

2 Safety

WARNING

Read the manual before you install or use the machine. Failure to do so can result in personal

injury, death or property damage.

2.1 Intended use

The machine is designed to dispense colorants into a can. Any other use of the machine is strictly forbidden.

2.2 Liability

Our machines and accessories are fully compliant with the CE regulations. Any modification can result in not

fulfilling the CE safety requirements and is therefore not allowed. Fast & Fluid Management B.V. will not accept

any responsibility in case of modifications to machines and/or accessories.

Fast & Fluid Management B.V. is not liable if you do not follow the rules below:

- The machine is for indoors use only.

- This machine may only be used for commercial settings. The machine is not a household appliance.

- Do not use a damaged machine. When you have doubts, contact your supplier. See § 5.1.

- Install and connect the machine according to the instructions on the installation instructions sheets.

- Observe all local safety regulations.

- Place the machine in a well-lit and well-ventilated room.

- Make sure that the load capacity of the floor meets the minimal requirements. Refer to § 6.2.

- Connect the machine to a grounded wall socket.

- Do not use extension cords.

- Make sure that the machine is installed as prescribed in the installation instruction sheets.

- Keep the machine in good condition. Make sure that defective parts are immediately replaced.

- Replace parts only with original Fast & Fluid Management B.V. spare parts.

WARNING

Do not place objects on top of the machine.

All maintenance beyond the scope of this manual must be carried out by a qualified service technician that Fast

& Fluid Management B.V. has trained and certified.

2.3 User qualification for installation

Only install the machine if you have written permission from the supplier of the machine.

7

Page 8

Safety X-Smart V 1.2

2.4 Certifications

For some markets machines need a certification to proove the machine complies with the essential requirements

concerning safety. The directives that have been taken into consideration in the design are available on the

website.

If applicable to your market, the machine contains the logo of the certification either as a seperate sticker or on

the type plate.

/i

Logo Certification Website

CE www.fast-fluid.com

ETL (includes specific UL and CSA directives) www.fluidman.com

2.5 Safety symbols on the machine

/i

Moving parts hazard Pinch hazard

Warning Read the manual

Safety instructions

8

Page 9

Safety X-Smart V 1.2

2.6 Safety symbols in the manual

/i

WARNIN G

Can cause personal injury.

CAUTION

Can cause damage to the machine.

2.7 Disposal of the machine

1. Sort the machine, the accessories and the packaging for

environmentally friendly recycling.

2. Do not dispose of the machine into domestic waste. Dispose

of the machine according to local regulations.

3. Dispose of the canisters as chemical waste, according to the

local regulations.

Note

Shows further information.

9

Page 10

Safety X-Smart V 1.2

10

Page 11

Operator manual X-Smart V 1.2

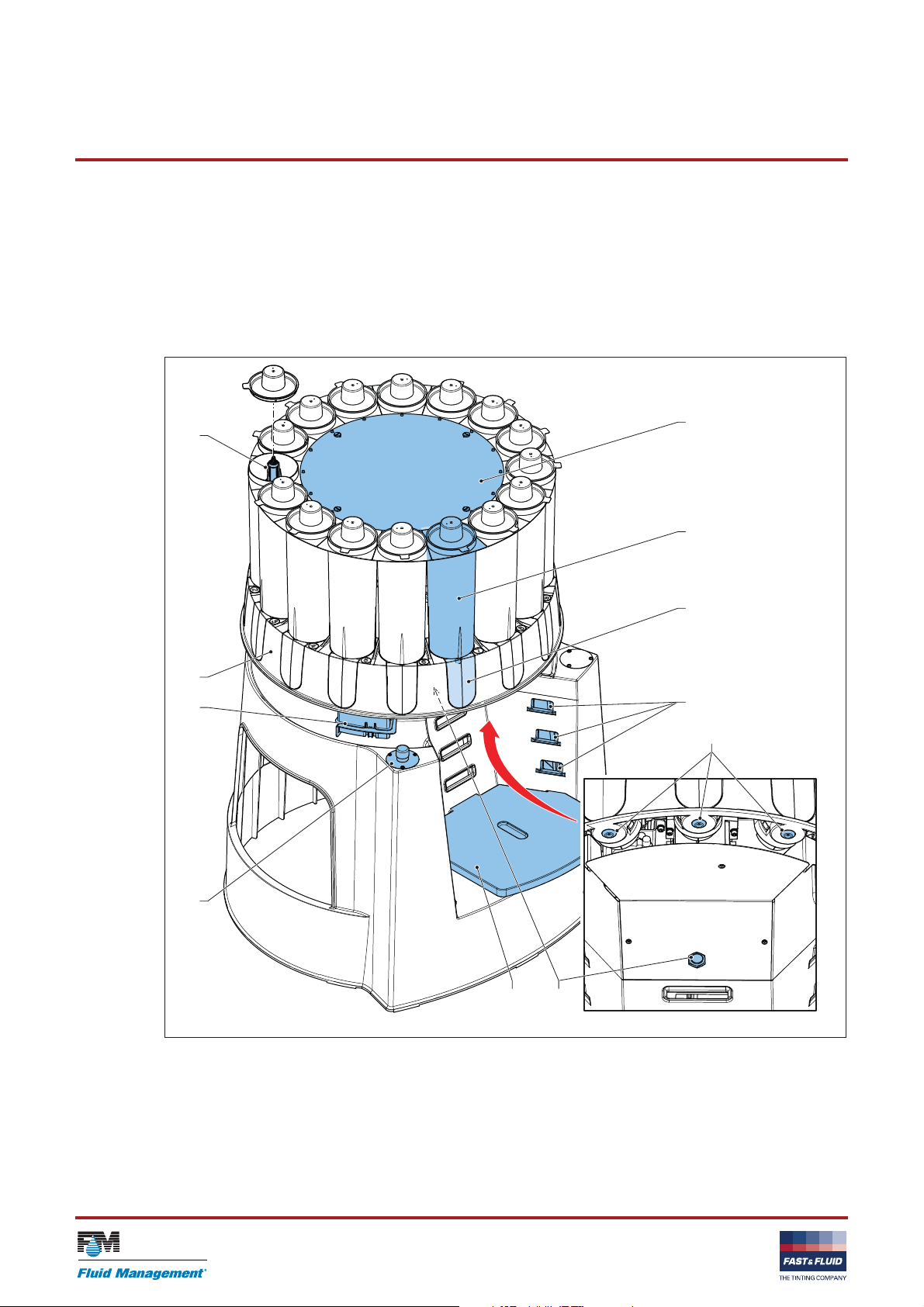

FG

B

C

D

I

H

J

E

K

A

3 Operator manual

3.1 Description

3.1.1 Overview of the machine

A: Top cover

B: Canister

C: Pump

D: Slot (for the can table)

E: Nozzle

F: Can sensor

G: Can table

H: Emergency stop switch

I: Brush unit

J: Turntable

K: Agitator (part of the stirring mechanism)

11

Page 12

Operator manual X-Smart V 1.2

3.1.2 Overview of the available optional parts

A: Monitor Keyboard arm

B: Wrap

A

B

12

Page 13

Operator manual X-Smart V 1.2

www.xxxxxx.com

24VDC 75W

Model X-Smart

Serial no.

Prod.week

Mass xx kg

Made in xxxxx

XXXX

Patented f amilies Des ign ©

xxxxx-xx-xxxxxxxx

xx-xxxx

3.1.3 Type plate: details

3.2 Operation

WARNING

Do not place objects on top of the machine.

CAUTION

Do not remove the power from the machine. See § 4.1. The machine must stir the colorants

periodically.

3.2.1 General dispensing procedure

For all the dispense software instructions: see the dispense

software documentation.

1. Place the can table in the correct slots for the correct height.

See § 3.2.2.

2. Place the can. See § 3.2.2.

3. Choose the recipe and dispense. See the dispense software

documentation.

4. Remove the can.

13

Page 14

Operator manual X-Smart V 1.2

D

E

C

B

A

3.2.2 Placing a can

1. Check the height of the can.

Note

The correct height of the can table depends

on the height of the can.

2. Place the can table (A) in the correct slots for the correct

height.

CAUTION

Make sure that the can table is secure.

3. Place the can (B) at the center of the mark (C) on the can

table.

CAUTION

Make sure that the can does not touch the

turntable (E). Keep enough free space.

Note

Make sure that the can sensor (D) is able to

detect the can.

3.2.3 Using the emergency stop switch

1. Push the emergency stop switch (A). The machine stops

immediately.

CAUTION

Only push the emergency stop switch in the

case of a safety emergency. Do not use the

emergency stop switch as an on/off function!

2. Solve the problem as quickly as possible.

CAUTION

When the machine is shut down, the stirring

mechanism, which is necessary to keep the

colorant in optimal condition, is also shut

down.

3. Reset the emergency stop switch by turning the emergency

stop switch. The machine restarts automatically.

1

A

2

Note

After the reset, the machine is operational

when you hear two 'beeps'.

14

Page 15

Operator manual X-Smart V 1.2

EDCBA

3.3 Maintenance

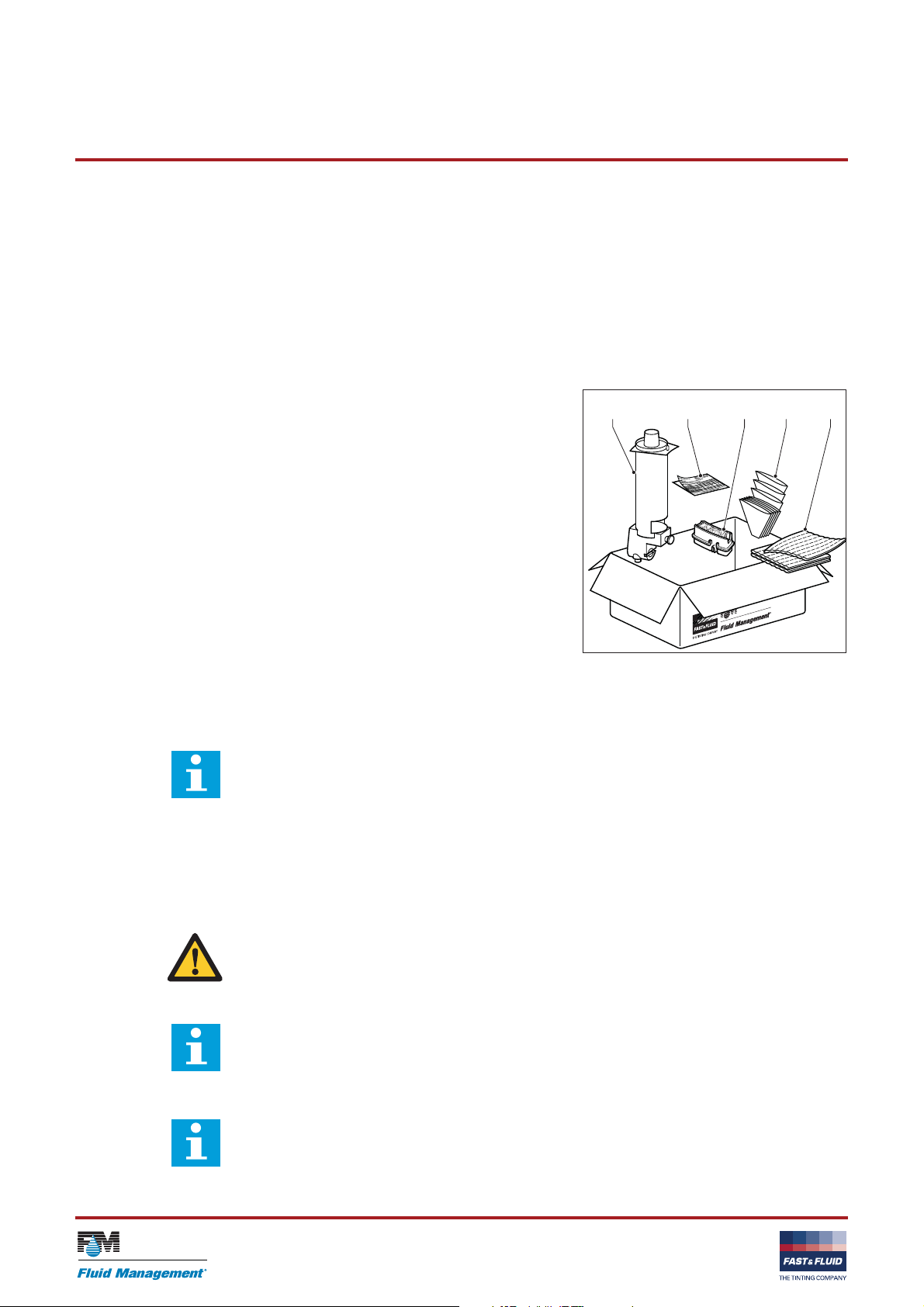

3.3.1 X-Smart Maintenance Kit

To keep your X-Smart in optimal condition, we highly recommend you to use the X-Smart Maintenance Kit. The

X-Smart Maintenance Kit contains everything you need to keep your machine in optimal condition for the period

of 1 year.

A: Replacement canister with pump (1x)

B: X-Smart schedule sticker (1x)

C: Replacement brush unit (3x)

D: Paper funnel (200x)

E: X-Smart cleaning cloth (3x)

- The replacement canister with pump (A) should be used as a

spare part and can be used whenever one of the canisters

needs to be replaced.

- The X-Smart schedule sticker (B) gives you a clear overview of

the maintenance tasks and a reminder to keep your machine in

optimal condition.

- Replace the brush unit (C) every 4 months for optimal

performance.

- Use the X-Smart paper funnels (D) for the clean filling and

refilling of the canisters.

- Use the X-Smart cleaning cloth (E) with a non-organic cleaning liquid to clean the machine and the nozzles.

Note

The X-Smart Maintenance Kit is available through

your machine supplier.

3.3.2 General cleaning: daily

1. Clean the machine with a damp X-Smart cleaning cloth and

remove all spilled colorant or other fluids.

CAUTION

Do not use cleaning agents based on organic

solvents to clean plastic parts of the machine.

Note

Remove spilled colorant and other fluids as

soon as possible.

Note

Do not drain spilled colorant or other fluids in

the sink. Observe the local regulations.

15

Page 16

Operator manual X-Smart V 1.2

A

B

C

D

E

E

2. When the brush is too dirty and does not clean the nozzle of

the canister, rinse and clean the brush. See § 3.3.3.

3. When the nozzles are too dirty, clean the nozzles individually

with a damp cloth. See § 3.3.4.

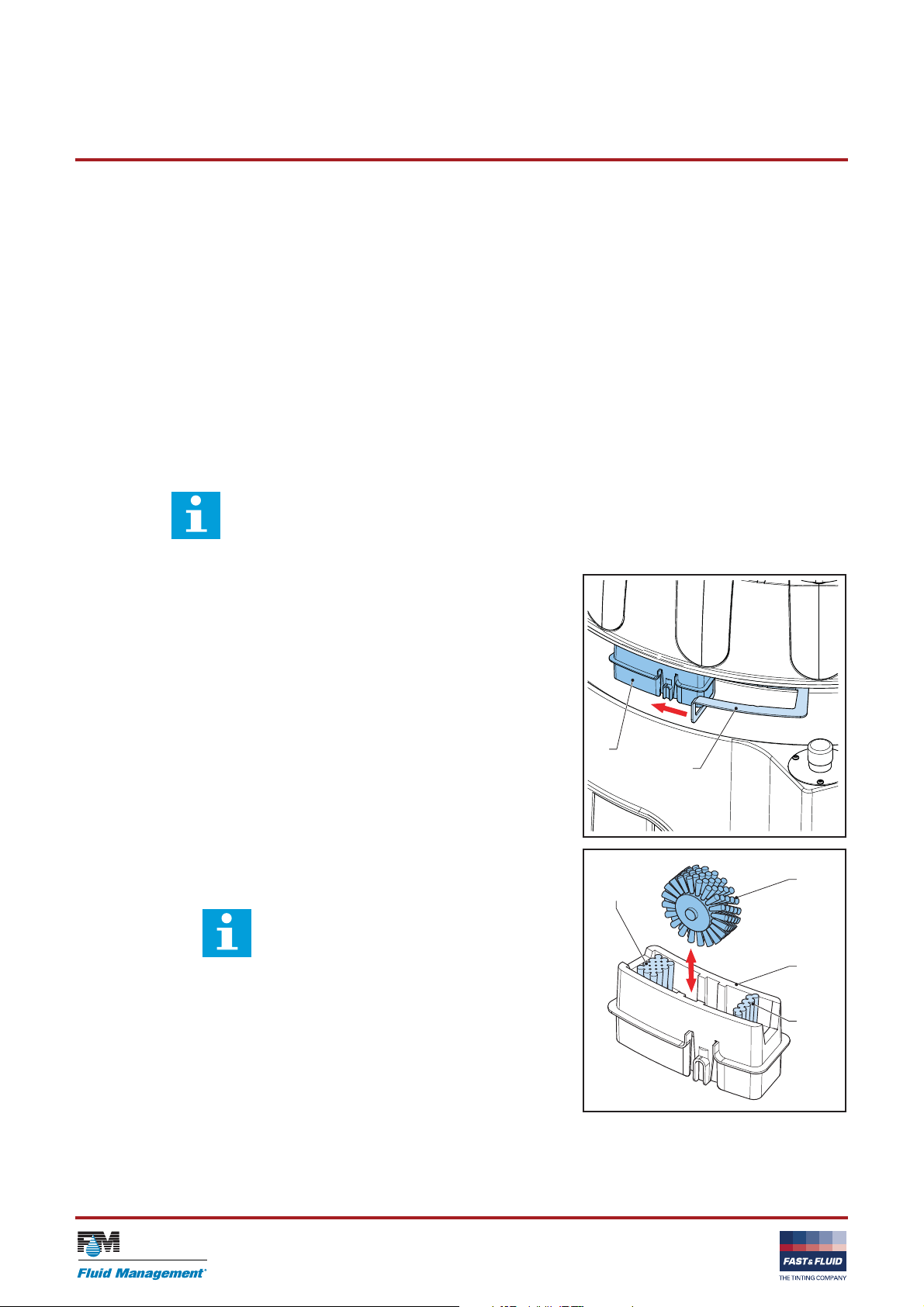

3.3.3 Cleaning the brush unit: daily

The brush unit removes the excess colorant from the nozzles.

The brush unit consists of a brush container and a removable

brush that rotates. The brush unit is installed in a bracket with a

click connection.

It is advised to replace the brush unit every 4 months to ensure

optimal performance. Replacement brush units are provided in

the X-Smart Maintenance Kit.

Note

If you do not clean these items daily, mistinting

might occur.

1. Slide the brush unit (A) out of the bracket (B).

2. Remove the rotary brush (C) from the brush container (D).

3. Remove the fluids from the brush container.

Note

For the disposal of the fluids, follow the local

regulations.

4. Rinse and clean the static brushes (E).

5. Rinse and clean the rotary brush.

6. Place the rotary brush back in the brush container.

16

Page 17

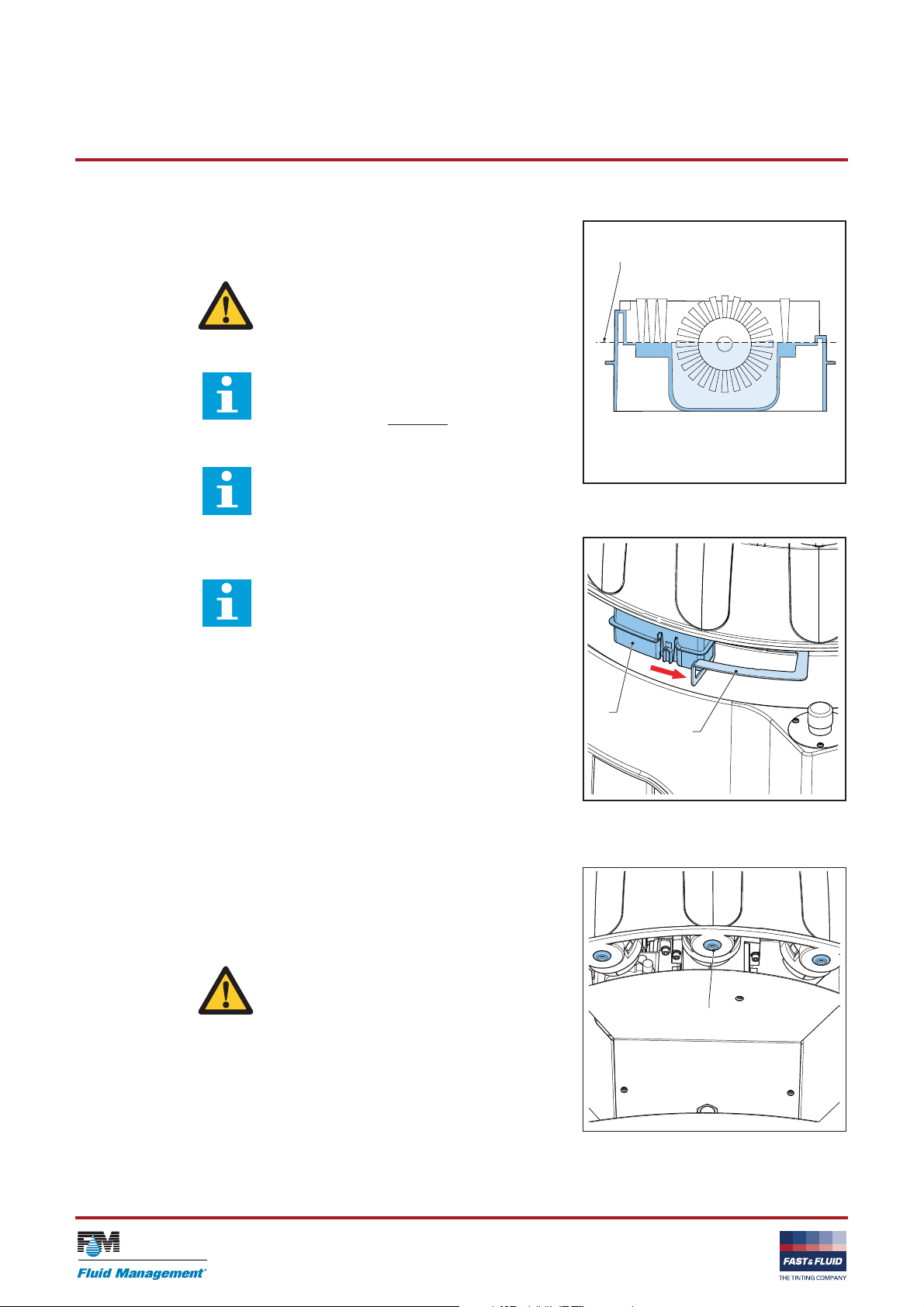

Operator manual X-Smart V 1.2

A

B

A

7. Fill the brush container with fluid. This fluid must be a waterbased cleaning agent.

F

WARNING

Do not put flammable liquids in the brush

container.

Note

Do not exceed the maximum

Note

The optimum fluid level depends on the type

of colorant that is used.

8. Slide the brush unit (A) back in the bracket (B).

filling height (F).

Note

The brush unit is properly connected to the

bracket when you feel a snap-fit. Make sure

you hear the click sound.

3.3.4 Cleaning the nozzles: daily

1. Examine the nozzle (A) for contamination.

2. If necessary, clean the nozzle. Use the X-Smart cleaning

cloth, as provided in the X-Smart Maintenance Kit, with a nonorganic cleaning liquid.

WARNING

Do not clean the nozzles when the turntable

moves.

17

Page 18

Operator manual X-Smart V 1.2

A

C

B

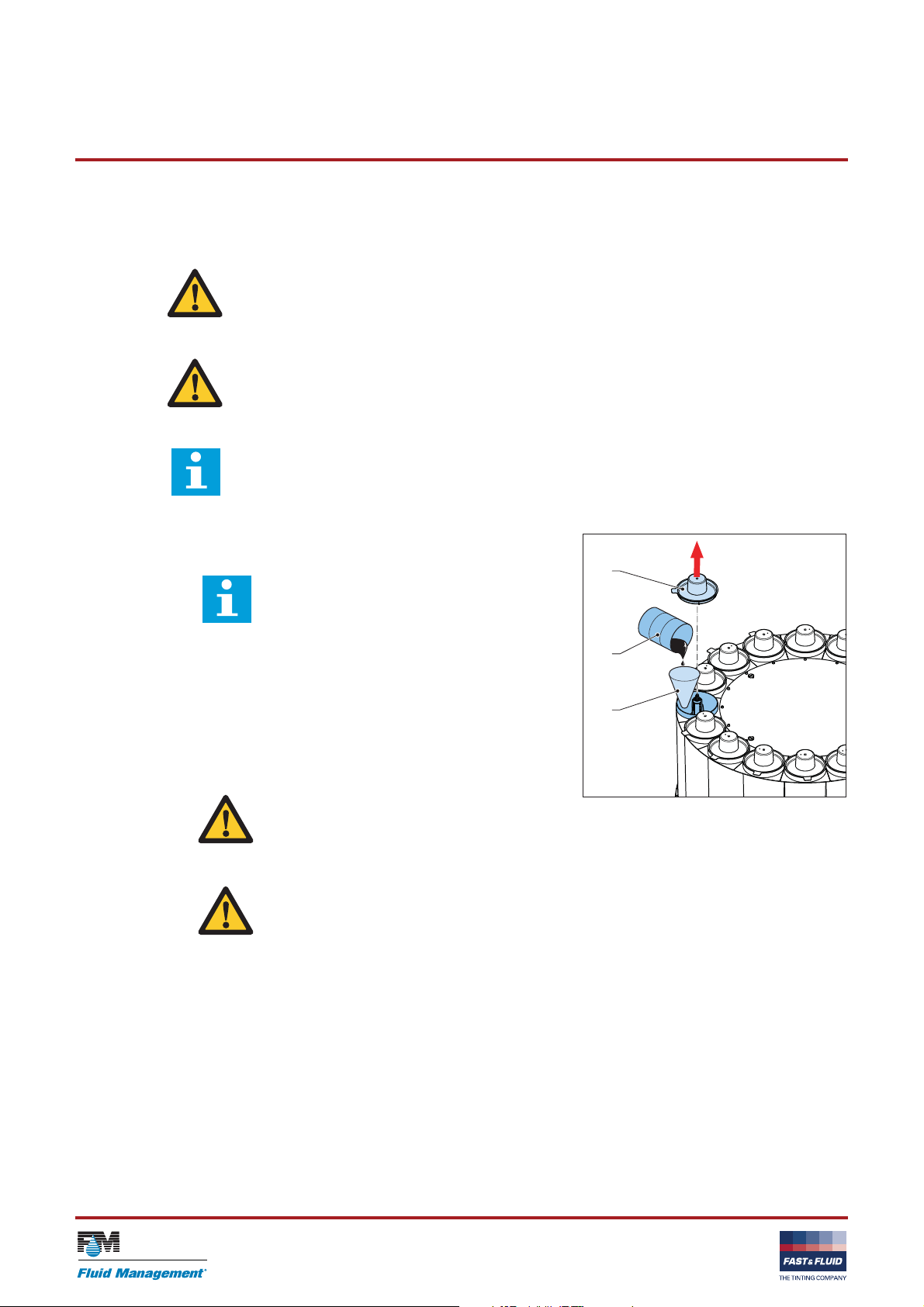

3.3.5 Refilling a canister

WARNING

Check the material safety data sheet (MSDS) of the colorants for the personal protection measures

that are required for handling the colorant.

CAUTION

Make sure that the colorant level in the canister is correct. If a canister is empty, it can cause an

inaccurate dispensing and/or a recipe fault.

Note

The dispense software checks the level of colorant in each canister. The dispense software shows

when you need to refill a canister.

1. In the dispense software, start the fill canister command.

Note

The fill canister command of the dispense

software controls the motor of the turntable.

The turntable turns the empty canister to the

front.

2. Remove the lid (A) from the canister.

3. Follow the instructions on the display.

4. Add the correct colorant (B). Do not spill. Use an X-Smart

paper funnel (C), which is provided in the X-Smart

Maintenance Kit.

CAUTION

Do not fill the canister to the brim. Leave at

least 2.5 cm (1 inch) unfilled.

CAUTION

Do not pour the colorant on the agitator.

5. Place the lid back on the canister.

18

Page 19

Installation X-Smart V 1.2

4 Installation

Note

For the unpacking and installation procedures,

refer to the separate installation instruction sheets.

4.1 Turning on the machine

1. Connect the power cable to the wall socket. When the

machine is operational, you hear two ’beeps’.

2. Make sure that the emergency stop switch is released.

3. Set the computer switch to ‘ON’.

4. Run the dispense software.

4.2 First use

1. Fill and place the brush unit. See § 3.3.3.

2. Fill the canisters correctly. See § 3.3.5.

3. Flush all air out of the pumps. See § 4.3.

4.3 Flushing the air out of the pump

Note

Before the first use it is important that all air is

removed from all individual pumps.

1. Flush the air out of the pump:

- Use the air flushing command in the dispense software.

- If the dispense software does have an air flushing

command option or is not able to flush the air out of the

pump automatically, dispense 120 ml / 3 oz. Repeat the

action until all air is out of the pump.

19

Page 20

Installation X-Smart V 1.2

20

Page 21

Troubleshooting X-Smart V 1.2

5 Troubleshooting

Note

For all error messages on the computer: see the

help topic in the dispense software.

5.1 Contact service

1. Find the type plate on the plate next to the emergency stop

switch. See § 3.1.3.

2. Take a note of the model number and the serial number of the

machine.

3. Contact your supplier or manufacturer.

See www.fast-fluid.com

Asia) or www.fluidman.com

(Fast & Fluid Management Europe and

(Fluid management, U.S.A.).

5.2 Troubleshooting guide

Problem Possible cause Possible solution

Main power supply is

present but the machine

does not work.

The machine has a failure

and does not respond

correctly to the request from

the dispense software.

The emergency stop switch is

active.

The failure could be mechanically

or electronically.

Reset the emergency stop switch.

See § 3.2.3.

Push the emergency stop switch to reset

the machine. Reset the emergency stop

switch. See § 3.2.3.

If the machine still has a failure, contact

service. See § 5.1.

21

Page 22

Troubleshooting X-Smart V 1.2

22

Page 23

Technical data X-Smart V 1.2

6 Technical data

6.1 General specifications

/i

Parameter Specification

Metric standard Imperial standard

Model X-Smart

Number of canisters 16

Dispensing Sequential

Pump type Piston pump

Cleaning system Rotary brush

Suitable for Water and universal colorants

Canister size 2.25 L 0.594 USgal

Resolution ± 0.005 mL/step ± 0.000169 fl oz/step

Maximum flow rate 0.25 L/min. 0.066 USgal/min.

Minimum dispensing 0.077 mL 0.0026 fl oz

Nozzle diameter 4 mm 0.517 in

6.2 Dimensions and mass

/i

Parameter Specification

Dimensions [height x width x depth] 125x83x95 cm 49.2x32.7x37.4 in

Packed dimensions [height x width x depth] 113x88x88 cm 44.5x34.6x34.6 in

Mass incl. packaging 65 kg 143.3 lbs

Mass filled machine (max.) 140 kg 308.6 lbs

Minimum requirement of load capacity of the floor

according to EN 61010-1:2010

Metric standard Imperial standard

560 kg 1234.6 lbs

Filling height of the canister 120 cm 47.2 in

Maximum can height 48 cm 18.9 in

Minimum can height 7 cm 2.8 in

Can table dimensions [width x depth] 38x27 cm 15.0x10.6 in

23

Page 24

Technical data X-Smart V 1.2

6.3 Ambient conditions

/i

Parameter Specification

Metric standard Imperial standard

Temperature +15 to +40 °C +59 to +104 °F

Altitude above sea level, operational -10 to 2000 m -33 to 6562 ft

Altitude above sea level, out of operation -10 to 12000 m -33 to 39370 ft

Maximum Relative Humidity, without condensation 90% RH

6.4 Noise level

/i

Parameter Specification

Maximum noise level < 65 db(A)

6.5 Safety classifications

/i

Parameter Specification

IP (Ingress Protection) classification 32

EMC (ElectroMagnetic Compatibility) classification Class B

6.6 Electrical specifications

6.6.1 Power supply

/i

Parameter Specification

Maximum power consumption 85 W

Voltage 90~264 V AC

Maximum leakage current 3.5 mA

AC inlet IEC320/C14

50/60 Hz

6.6.2 Dispenser

/i

Parameter Specification

Maximum power consumption 75 W

Voltage 24 V DC

24

Page 25

Technical data X-Smart V 1.2

5

5

4

4

3

3

2

2

1

1

D D

C C

6.7 Electrical diagram

0

Sheet

2.02

Version

First production version

Emergency in powerline

Corrected emergency, is now double pole.

M12

VALVE MOTOR

Removed e-switch jumper, is dipsw.setting now.

NvB

NvB

NvB

Cable, Valve

Cable, Valve

RESETDIPSW.

24VDC

Powersu pply

BLUE

ORANGE

YELLOW

S1

MACHINE STOP

RED

BLUE

BROWN

1234

BROWN

BLACK

BLUE

Cansensor

BLUE

BROWN

(OPTION)

S3

CANSENSOR

Cansensor

XSmart

Title

FAST & FLUID

<Filename>

Date Drawn Remarks

21-1-2013

3-4-20132.01

17-4-20142.02

Filename

Revnr.

2.0

1.0 <revdate0> <drawn0>

The Netherlands

2170 AE Sassenheim

PO Box 220

Hub v. Doorneweg 31

© Fast & FLuid

Thursday, April 17, 2014

USB to PC

Cable, Agiation

Cable, Agiation

Cable, Turntable

Cable, Turntable

2

1

3

4

M1

4P-STEPPERMOTOR

M5

AGITATION MOTOR

M6

TURNTABLE MOTOR

B B

A A

25

Page 26

Manufactured by:

IDEX Fluid & Metering Pvt. Ltd.,

Survey no: 256, GIDC Manjusar, Savli,

Dist.: Vadodara 391 770, India

Loading...

Loading...