Fluid Management Miller GyroMixer User Manual

GyroMixer | End User Guide

Getting Started

Maintenance and Care

Troubleshooting

Service Parts

Warranty

Part No: 4708000

Rev. I

07.30.10

©2010 Fluid Management as published work all rights reserved.

Under the copyright laws, this material may not be copied, in whole or in part, without the

written consent of Fluid Management.

Your rights to the software are governed by the acc om p an yin g softwa r e licen se

agreement.

Use of Fluid Management trademarks, service marks, or logos for commercial purposes

without the prior written consent of Fluid Management may constitute trademark

infringement and unfair competition in violation of fe deral and state laws. Fluid

Management, FMDirect, ColorPro, DVX, Harbil, Blendorama, Accutinter, Duraflow, Fast &

Fluid Management, GyroFlex, GyroMixer, Infina, MicroTint, TintMaster, V1, and VR1 are

trademarks of Fluid Management, registered in the U.S. and/or other countries.

Every effort has been made to ensure that the information in this guide is accurate.

Fluid Management is not responsible for printing or clerical errors.

Fluid Management

1023 Wheeling Road

Wheeling, Illinois 60090-5776 USA

800-462-2466

http://www.fluidman.com

Published in the United States.

Mention of third-party products is for informational purposes only and constitutes neither

an endorsement nor a recommendation. Fluid Management assumes no responsibility

with regard to the performance or use of these products

Fluid Management Customer Service 1.800.462.2466

Table of Contents

GyroMixer End User Guide

SAFETY INFORMATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

MIXER WARNING LABELS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

SAFETY NOTICE INFORMATION . . . . . . . . . . . . . . . . . . . . . . . . . . 1

WARNINGS AND CAUTIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

INTRODUCTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3

PRODUCT DESCRIPTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

SPECIFICATIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

CONTAINER DIMENSIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

ELECTRICAL SUPPLY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

EQUIPMENT MAINTENANCE LOG. . . . . . . . . . . . . . . . . . . . . . . . . . 5

SPARE PARTS ORDER FORM. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

UNPACKING DIRECTIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

INSPECT FOR DAMAGE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

REMOVE MIXER FROM SKID . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

UNPACK THE MIXER . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

SETTING UP THE MIXER . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

INSTALLATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

ELECTRICAL CONNECTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

LEVELING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

OPERATIONAL TEST . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

OPERATIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13

OPERATING THE MIXER . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

MIX TIMES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

MAINTENANCE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .15

TROUBLESHOOTING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .17

SERVICE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .20

GENERAL INFORMATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

REMOVING THE SHEET METAL COVERS . . . . . . . . . . . . . . . . . . 21

REPLACING/SERVICING THE SECONDARY DRIVE V-BELT . . . 21

REPLACING/SERVICING THE PRIMARY DRIVE POLY V-BELT . 22

ADJUSTING THE CLAMPING FORCE IN THE CLAMP HANDLE . 23

ADJUSTING THE DOOR LOCK LINKAGE AND START SWITCH . 23

Table of Contents

REPLACING THE ROLLER . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

INSTALLING THE UPPER TABLE PAD . . . . . . . . . . . . . . . . . . . . . 24

REPLACING THE SLIDING DOOR . . . . . . . . . . . . . . . . . . . . . . . . 25

REMOVING THE MOTOR . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

REASSEMBLING THE MOTOR . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

ELECTRICAL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

REPLACING THE TIMER . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

REPLACING THE POWER RELAY . . . . . . . . . . . . . . . . . . . . . . . . . 30

ELECTRICAL DRAWINGS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

PARTS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

FLUID MANAGEMENT PAINT EQUIPMENT

LIMITED WARRANTY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

SAFETY INFORMATION

GyroMixer End User Guide 1

SAFETY

INFORMATION

MIXER WARNING LABELS

You should become familiar with important warning labels which are affixed to the

mixer, as well as the symbols which appear throughout this manual. These

warnings have been included to help you safely perform your job.

Please read all warning labels that are on the mixer. Keep them clean so they are

easy to read. If the warning labels become damaged or unreadable, new labels can

be purchased from Fluid Management. See the parts list in the back of the manual

for ordering information.

SAFETY NOTICE INFORMATION

The two main safety notices used in this manual are Warning and Caution.

Notices in this manual will look like the example below.

Warning Notice

WARNING ELECTRICAL HAZARD

Do not operate the mixer with the door open.

Disconnect power before servicing.

A Warning notice tells you about a hazard that could cause serious injury to you or

extensive damage to the mixer. This information is placed at the beginning of the

manual to emphasize the importance of safety to your well being.

When you see a Warning notice in this manual, read it carefully . Before continuing

with the operation of the mixer, take all necessary precautions to avoid potential

injury.

Caution Notice

CAUTION ELECTRICAL HAZARD

All electrical components must be kept dry.

Never place containers of liquid on or near the

control box.

A Caution notice tells you about a danger that could cause injury to you or minor

damage to the mixer. When you see a Caution notice in this manual, read it

carefully and be sure you understand it before continuing.

SAFETY INFORMATION

2

Information Notice

Note: If the cabinet vibrates, loosen the locking nuts on the right

front leveling foot and slightly adjust the length.

An Information notice gives details that will assist you in efficiently using the

mixer. When you see an Information notice in this manual, know that it is there to

save you time and energy.

WARNINGS AND CAUTIONS

WARNINGS

• The paint mixer must be properly grounded to protect the operator from

possible electrical shock. Only use a 3-prong receptacle.

• Do not operate the mixer if the power cord has been cut or damaged. Keep

the cord away from open flame or heat exposure.

• Properly level the paint mixer. Improper leveling may cause severe damage

to the machine during the mixing operation.

• Always shut off the POWER lever and unplug the mixer from the AC

power outlet before servicing the paint mixer.

• Keep hands away from moving parts.

• NON-EXPLOSION MODEL

• Do not use the paint mixer near flammable liquids.

• Do not mix flammable liquids containing gasoline or toxic materials.

• Do not clean the mixer with flammable solvents.

CAUTIONS

• Always check to be sure that the containers are tightly sealed.

• Overloading can damage the paint mixer. The maximum capacity is a 125

pound solid load.

• Make sure the bail shield is properly positioned before operating the mixer .

• The mixer's sliding door must be closed to operate the mixer.

• Most containers one gallon or larger have bails. All such containers must

have the bail properly secured to prevent possible damage to the

equipment. As an option to using the bail shield, an elastic cord can be used

to achieve this purpose.

INTRODUCTION

GyroMixer End User Guide 3

INTRODUCTION

PRODUCT DESCRIPTION

The Miller GyroMixer is a versatile, automatic paint mixer designed for safety,

reliability and ease of use. Its features are as follows:

• Improved mixing. Gyroscopic mixing at a 2:1 ratio thoroughly blends the

toughest colorants.

• Robust design. Handles up to 125 pound (56.7 kg.) solid load.

• Easy to service. Most service and repair procedures can be performed by

opening the door, removing the back panel or the top cover.

• Simple to move and operate. Casters on the bottom of the mixer allow it to

be moved into operating position.

• Safe to operate. The mixer offers improved safety features.

• Universal can sizes. Handles the requirements of paint manufacturers

around the world.

• Easy to load. A roller in the front of the table assists in loading the

container. A groove in the table keeps the container centered and in the

proper position.

SPECIFICATIONS

Height 39.5" (100.3 cm)

Width 32" (83.8 cm)

Depth 28" (71.0 cm) with removable shelf

26” (66.0 cm) without shelf

Shipping Weight 400 lb (181 kg)

CONTAINER DIMENSIONS

Accepts can heights from 3.5” (with bail shield removed) to 16”

INTRODUCTION

4

ELECTRICAL SUPPLY

Explosion-Proof Model

Standard Models

Motor

1 HP, 1425/1725 RPM, 50/60 Hz

28708 200-240 V 60 Hz 5.5-4.6 Amps

28709 100-120 V 60 Hz 12-10.1 Amps

28988, 28989 110 V 60 Hz 11.0-9.4 Amps

30099 220 V 60 Hz 5.5-4.8 Amps

28987 220 V 50 Hz 6.5-5.7 Amps

INTRODUCTION

GyroMixer End User Guide 5

EQUIPMENT MAINTENANCE LOG

RECORD MODEL NUMBER HERE: _________________________

RECORD SERIAL NUMBER HERE: _________________________

SERVICE

DATE

DESCRIPTION & PARTS REPLACED

(STATE IF UNDER WARRANTY)

SERVICED

BY

INTRODUCTION

6

SPAREPARTSORDER

Fluid Management Parts Order Form

Photocopy and use this form to

Mail or fax orders to:

IDEX

Phone: 1(800) 462-2466

1023 Wheeling Road | Fax: 1(847)537-5530

Wheeling, IL 60090 |

|

Sold To:

Ship To:

________________________ ________________________

________________________ ________________________

________________________ ________________________

________________________ ________________________

PurchaseOrder Number_________________

Ship Via: ______________________

Collect Prepaid

Taxable Tax Exempt (Fax copy of exemption certificate.)

QUANTITY PART

NUMBER

DESCRIPTION UNIT

PRICE

S

S

S

S

S

S

S

S

S

S

S

Comments: ____________________________________________________

____________________________________________________

____________________________________________________

_________________________________________________

Signature

______________

Date:

UNPACKING DIRECTIONS

GyroMixer End User Guide 7

UNPACKING

DIRECTIONS

INSPECT FOR DAMAGE

Inspect the shipping carton for damages. If any damage is found, notify the carrier

at once and arrange for an inspection in order to claim recovery.

Note: Claims for damage must be made by the consignee (you).

The carrier assumes full responsibility upon acceptance of

shipment and will not entertain any claims by the consignor

(Fluid Management).

REMOVE MIXER FROM SKID

1. Place the carton in the area where the mixer will be located.

2. Remove the strapping and the cardboard carton stapled to the skid.

3. Open the sliding door.

4. Remove the two bolts holding mixer to the skid.

5. Slide the mixer back until half of the unit is off of the skid.

6. Carefully tilt the mixer back until its lower rear edge touches the floor

and the skid is free.

Important: Keep the weight of the mixer on its lower rear edge.

7. Pull the skid out from under the front of the unit.

8. Carefully tilt the mixer forward until all four casters are on the floor.

UNPACK THE MIXER

Caution Do not operate the mixer until the shipping

inserts are removed.

1. Open the mixer’s sliding door

2. Remove the two (2) shipping inserts positioned in the base of the mixer.

Note: The inserts are wedged against the sides of the mixer.

3. Record the serial number and model number in the space provided on

page 5. (See the identification label located on the side of the mixer. It is

important data when ordering parts or servicing the mixer.)

SETTING UP THE MIXER

8

SETTING UP

THE MIXER

INSTALLATION

The following instructions are for both the standard and explos ion-proof models.

Refer to the boxes for special information on explosion-proof installations.

1. Move the mixer to its permanent location.

2. Refer to the Electrical Supply section of this manual for power

requirements.

3. Locate the mixer as close as possible to a properly grounded outlet.

4. Leave ample room around the paint mixer to facilitate safe operation and

routine maintenance.

ELECTRICAL CONNECTION

Caution The unit must be plugged into a dedicated

electrical line with no other equipment using the

same circuit. DO NOT use an adapter or

extension cord with this product.

WARNING Improper use of the grounding plug can result in

a risk of electric shock.

Explosion-Proof Installation

• Installation to be completed by a registered master electrician

following local codes and regulations.

• Loosen the screws in order to remove the back cover.

• Referring to the wiring diagram in the Service Section of this manual,

connect the power supply to the explosion-proof box.

The timer, shipped with the mixer , is located within th e explosion-proof box.

It is preset for 1-1/2 minutes, but may be adjusted up to 3 minutes by

qualified service personnel.

SETTING UP THE MIXER

GyroMixer End User Guide 9

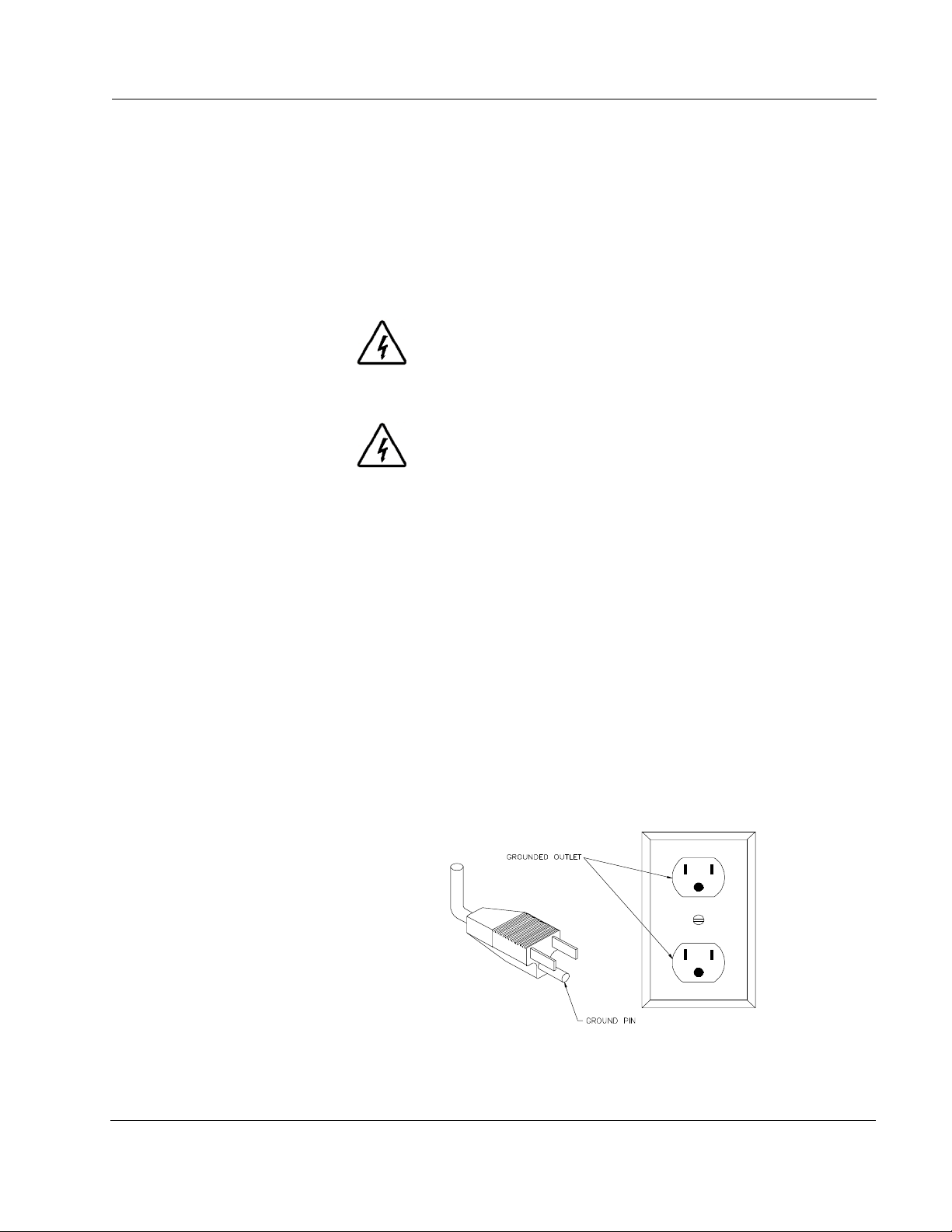

Grounding

This product must be grounded. In the event of an electrical short circuit, grounding

reduces the risk of electrical shock by providing an escape for the electric current.

This product is equipped with a cord that has a grounding wire and an appropriate

grounding plug. The plug must be inserted into an outlet that is properly installed

and grounded in accordance with all local codes and ordinances.

WARNING Check with a qualified electrician or service

person if grounding instructions are not

completely understood or if in doubt as to

whether product is properly grounded.

WARNING Improper installation of the grounding plug can

result in a risk of electric shock. If repair or

replacement of the cord or plug is necessary, do

not connect the grounding wire to either flat

blade terminal.

The insulation wire with green or green and yellow stripes on the outer surface is

the grounding wire. Check with a qualified electrician if the grounding instructions

are not completely understood, or if in doubt about whether the product is properly

grounded. DO NOT modify the plug provided. If it will not fit into the outlet, have

the proper outlet installed by a qualified electrician.

This product is designed for use in 100 to 240 Volt operation. The power

requirements of your unit will be outlined on the nameplate.

The non explosion-proof model is for use on a nominal 120-volt circuit and has a

grounding plug that looks like the plug illustrated in the figure below. Make sure

that the product is connected to an outlet having the same configuration as the p lug.

No adapter should be used with this product.

Note: If product has a nameplate for nominal 220-vo lt circuit, make

sure the proper grounded outlet is used.

Figure 1. Grounding Methods

SETTING UP THE MIXER

10

Caution Under no circumstances should you modify the

plug if it does not fit the outlet. Check with a

qualified electrician or serviceman if you are not

sure how to ground this unit.

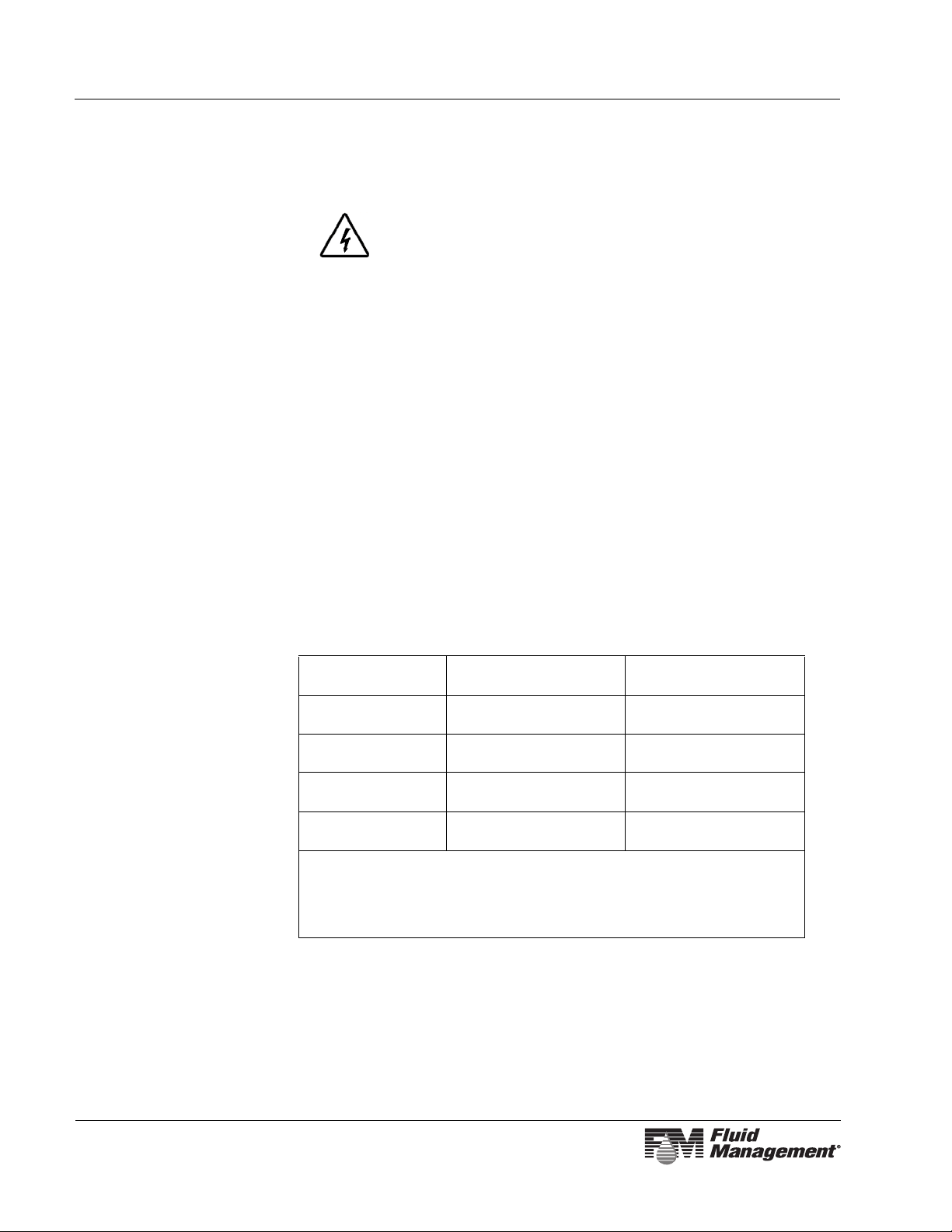

Supply Current

The table "Minimum Wire Gauge" (below) shows the recommended wire size for

home run lengths. NOTE: The smaller the gauge number, the heavier the wire.The

following chart is the wire gauge size required for the distance from the circuit box

to the grounded receptacle (for up to 15 amperes at 115V, 60 Hz). Smaller gauge

wire than shown on the table could result in a voltage drop that can effect the

operation of your unit.

Extension Cords

Extension cords for 220 VAC models are not recommended. If an extension cord is

to be used, it should not be combined with others. Use only a 3-wire extension cord

that has a 3-pole grounding plug. Power should be provided by a 3-pole receptacle

that will accept the plug on the product. Make sure that your extension cord is in

good condition. It must have # 14 AWG conductors up to 25 feet long. An

extension cord no longer than 50 feet is permissible provided it has conductors of at

least # 12 AWG. It must be heavy enough to carry the current your product will

draw. An undersized cord will cause a drop in line voltage resulting in loss of

power and overheating.

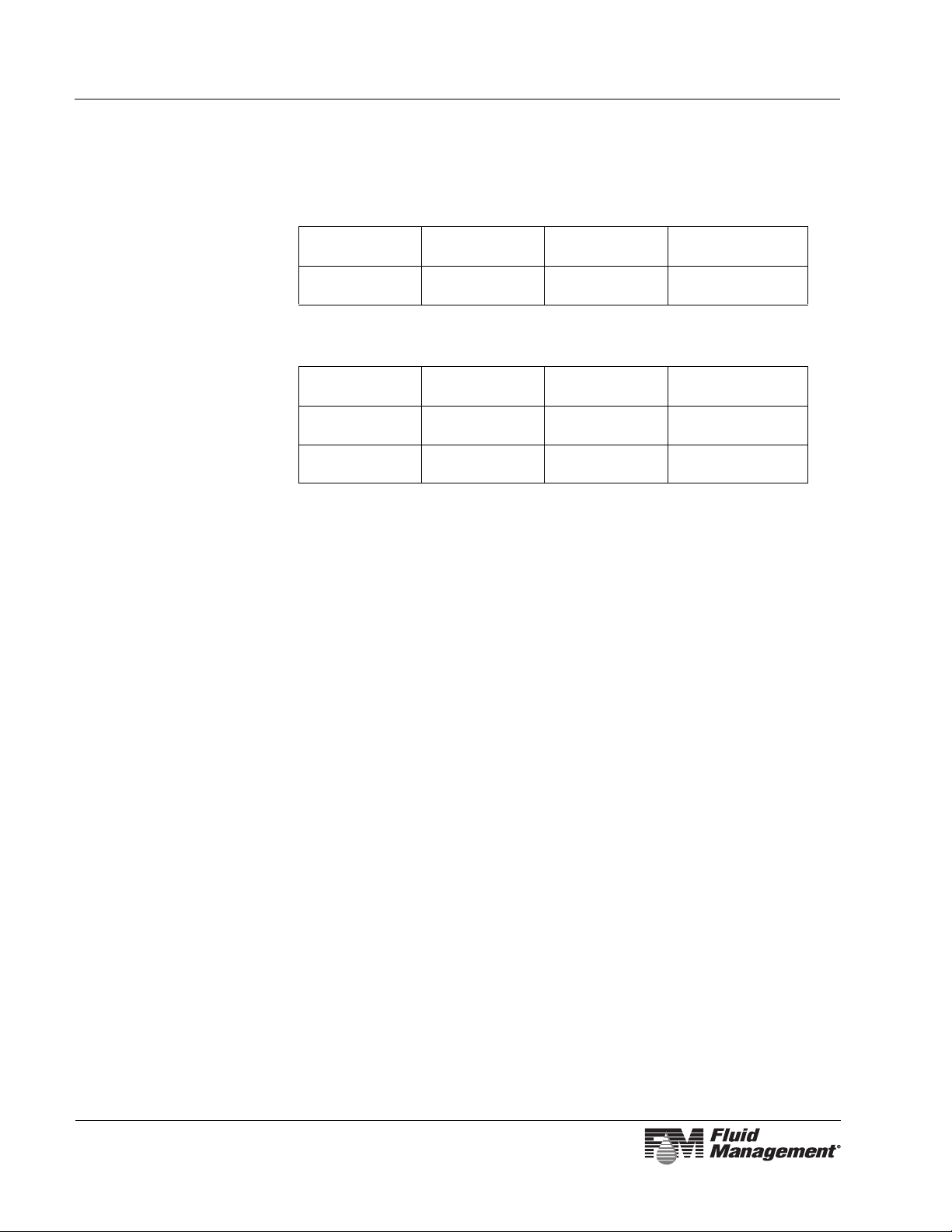

Distance (feet) 25 50 100 150 20 250 300 400 500

Gauge Size

220V

14 14 12 10 10 8 8 6 6

Gauge Size

115V

14128664422

Table 1. Minimum Wire Gauge

SETTING UP THE MIXER

GyroMixer End User Guide 11

LEVELING

The customer must level the mixer. Although the unit is shipped on casters for ease

of positioning the mixer, all 4 feet must be extended firmly to the floor. Variations

on the floor will necessitate adjusting the leveling feet to ensure proper operation

and to minimize vibration.

CAUTION Improper leveling may cause severe vibration

while the mixer is operating.

1. Roll the unit into its intended location.

2. Lower the four (4) leveli ng feet to the ground. Each of the four leveling

feet can be adjusted independently. Using the front of the mixer as a

position guide, turn the foot in a clockwise direction to lengthen, or in a

counter-clockwise direction to shorten.

IMPORTANT: The feet should carry the load; not the casters.

Check the stability of the mixer on the floor by making

sure that the mixer is resting on all four feet, not on its

casters. All casters must rotate freely.

3. Verify that the mixer is level by gripping its sides and gently attempting

to rock the machine. It should not move.

4. Lock the leveling feet into place by tightening the upper locknuts to the

mixer bottom with a 3/4" wrench.

Note: Should additional leveling be necessary, loosen the upper

locknuts and repeat steps 2 - 3.

SETTING UP THE MIXER

12

OPERATIONAL TEST

1. Verify that the power is connected to the mixer.

2. Open the mixer's sliding door.

3. Slide a container into the groove on the table.

Note: Rotate the clamp handle counter clockwise first to open

the clamp arms.

4. Rotate the bail shield over the container bail. Remove the shield for

containers smaller than one gallon.

Note: Failure to properly position the bail shield on containers

larger than one gallon may damage the mixer.

5. With both hands, turn the knobs on the crank handle clockwise until

snug. Continue turning until the crank handle suddenly slips.

6. Close the sliding door.

7. Set the timer. (Not required for Explosion-Proof model)

Note: Make sure that the emergency stop switch is in the "on"

(pulled out) position. This can be done by turning the

knob counter clockwise.

8. Move the power lever to the ON position. The unit should cycle

automatically with minimum vibration. If vibration of the cabinet

occurs, immediately depress the emergency stop switch.

Note: Vibrations may occur because the unit is not properly

leveled. Try rocking the unit to make sure that all four feet

are solidly contacting the floor. Readjust the feet if

necessary. After the feet have been adjusted, reset the

emergency stop switch and continue.

9. When the test is complete, move the power lever to the OFF position.

10. Open the sliding door.

11. Rotate the mechanism to an upright locking position.

12. Use the knob marked "open" to turn the crank handle in the direction of

the arrow until the container is free. If necessary rotate the bail shield

away from the bail and remove the container.

OPERATIONS

GyroMixer End User Guide 13

OPERATIONS

Before operating the paint mixer, carefully read the Warnings and Cautions in the

Safety section and on the mixer, then follow these steps:

OPERATING THE MIXER

1. Open the mixer's sliding door.

2. Slid e a co ntainer into the groo ve on the table. Rotate the clamp handle

counter clockwise to open the clamp arms.

3. Position the bail shield over the container bail by rotating the upper

plate. The bail shield must be removed for containers smaller than

7-1/4" high.

Note: In situations involving frequent mixing of large and small

(less then 1-gallon) containers, a special elastic cord is

supplied to fasten the bail to the can.

CAUTION Failure to properly position the bail shield on

containers larger than one gallon may damage

the mixer. It is normal for the bail to move freely

behind the shield.

4. With both hands, turn the knobs on the crank handle clockwise until

snug. Continue turning until the crank handle suddenly slips.

5. Close the sliding door.

6. Set the timer. (Not required for Explosion-Proof model)

7. Make sure that the emer gency stop switch is in the "on" position (pulled

out). This can be done by turning the knob counter clockwise.

EXPLOSION-PROOF MODEL

• The timer is set to 1-1/2 minutes at the factory before

shipment.

• See the Service Section of this manual or consult an

authorized Service Center to adjust the timer.

OPERATIONS

14

8. Move the POWER lever to the ON position.

WARNING A safety interlock system prevents the operator

from opening the sliding door while the mixer is

running. Do not attempt to open the door while

the mixer is running.

• For an emergency stop in mid-cycle, push the EMERGENCY STOP

button.

• If vibrations occur, turn off the machine and refer to the leveling

section of this manual.

9. When the mixer has completed its cycle, move the power lever to the

OFF position.

10. Open the sliding door.

11. Rotate the mechanism to an upright locking position.

12. Use the knob marked "open" to turn the crank handle in the direction of

the arrow until the container is free. If necessary rotate the bail shield

away from the bail and remove the container.

MIX TIMES

Material Quantities Approx. Mix Times *

Latex Paint 5 gal, 15L, 20L 15 - 30 seconds

Latex Paint 1 gal, 5L or less 30 - 60 seconds

Gum-Based Paint 20L 1 - 1.5 minutes

Stucco** 5 gal, 15L, 20L 1.5 - 2 minutes

* Actual mixing times may vary depending upon material viscosity, container

size, head space, and colorant.

** When mixing stucco or other textured coatings, tip the container upside-

down, then upright again before adding colorant.

MAINTENANCE

GyroMixer End User Guide 15

MAINTENANCE

The Miller GyroMixer is designed for simple maintenance. For example, the motor

contains sealed bearings which require no lubrication.

To ensure safe, dependable operation of the paint mixer, follow the maintenance

schedule detailed below.

WARNING Always unplug the power cord when performing

maintenance procedures

.

DAILY

Immediately clean up spills with mild soap and water. A 3/4” drain pipe is

located under the front shelf to aid in cleanup.

• Thoroughly remove soap film with clean, lukewarm water.

• DO NOT clean this mixer with flammable solvents.

WEEKLY

• Inspect electrical cord for damage or wear.

• Clean/scape debris from sliding door track to maintain smooth operation.

MONTHLY

• Clean debris from guide rods for the upper and lower moving arms.

• Lubricate the guide rods and lead screws with graphite grease or

medium weight oil. NO grease or oil should touch the belts or pulleys.

Loading...

Loading...