Fluid Management SK350 User Manual

Fast & Fluid Management – SK350

FAST & FLUID MANAGEMENT

SK350

ENGLISH

V 2.0 page 1

Fast & Fluid Management – SK350

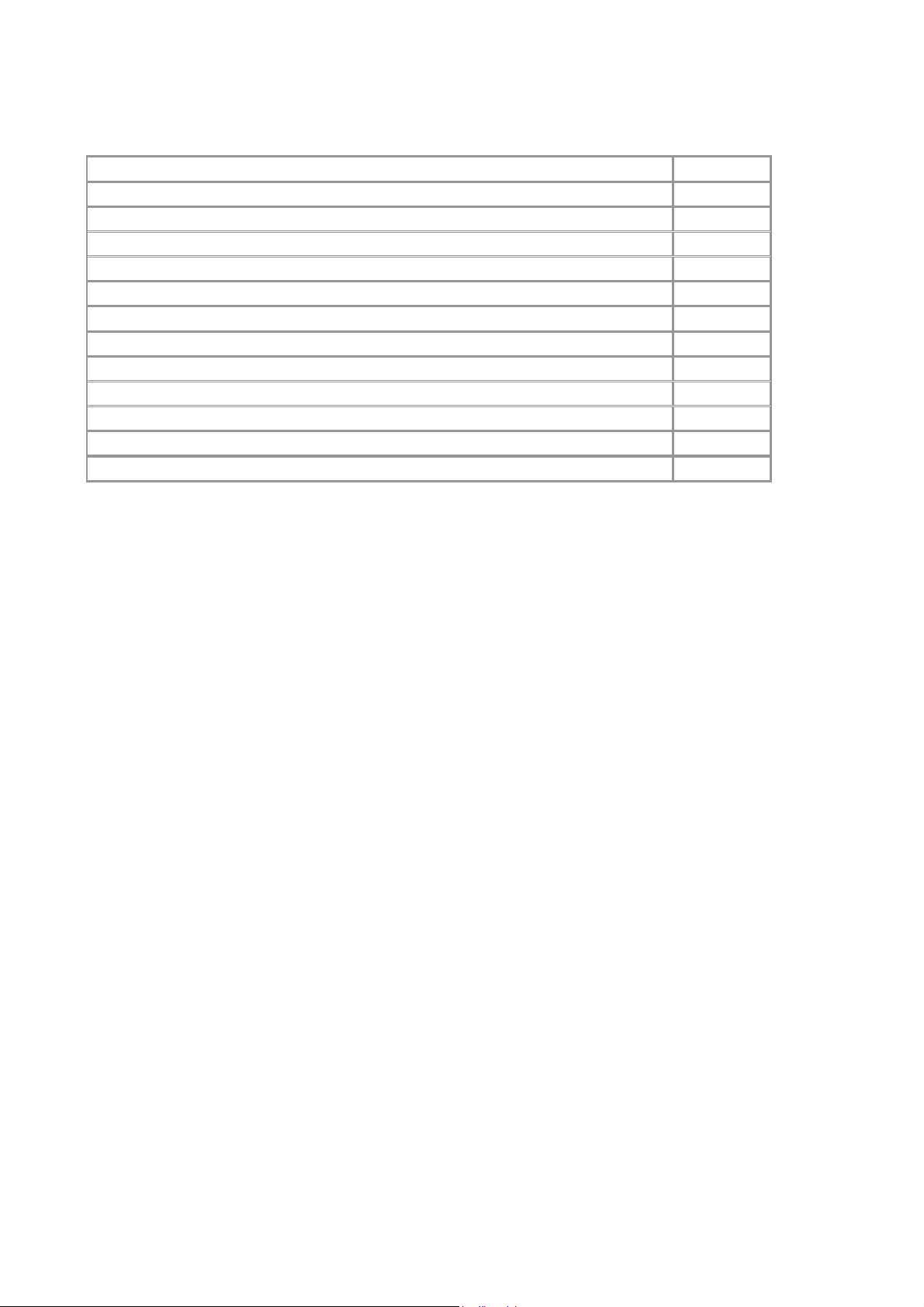

Table of Contents

SK350 Manual

Introduction, warranty & CE certification

Main SK350 components

Safety instructions

Installation

Operation

Maintenance

Problem solving

Service and Support, Fuses

Specifications

Electrical wiring diagram

Contributing to the Protection of the Environment

Pag. 3

Pag. 4

Pag. 5

Pag. 6 – 8

Pag. 9 – 12

Pag. 13

Pag. 14 – 15

Pag. 15

Pag. 16

Pag. 17

Pag. 18

V 2.0 page 2

Fast & Fluid Management – SK350

Introduction & warranty

Introduction

By selecting a Fast & Fluid Management shaker you have opted for a product which is the

result of intensive research. Top-quality components, craftsmanship and a modern ergonomic

design all serve to guarantee a long service life and a high degree of user friendliness.

Warranty

In these warranty conditions, 'F&FM' is understood to mean Fast & Fluid Management. The

warranty conditions incorporated into F&FM's general cond itions of sale are summarized as

follows (for free general conditions you can contact F&FM).

F&FM guarantees the proper operation of any goods which it supplies, for a period of one year,

except where a breakdown is the result of normal wear and tear. The cost of any inspection

activities carried out by F&FM, with the aim of establishing whether or not a breakdown is

covered by the warranty will be reimbursed by the other party if it t r anspires that the

breakdown is not covered by the warranty. If it transpires that a breakdown is covered by the

warranty then F&FM will supply identical or equivalent goods under the cond itions referred to

in point 6 of the general conditions of sale. The warranty obligation described in this article

only applies if the goods supplied by F&FM have been used in accordance with the manual.

Time spent on warranty-related activities, including travel time, travel costs and

accommodation costs, are charged at current rates.

In contrast to the above, F&FM will not be held to any warranty obligation if:

1. Repairs have been carried out, or attempted, by the other party or a third party, unless

F&FM had previously declined to repair the goods for a fair price;

2. F&FM demonstrates that the defect did not emerge during testing;

3. The other party fails to inform F&FM of the defect immediately, if possible either by letter

and/or by fax, providing full, accurate details and/or has failed to comply fully with F&FM's

instructions;

4. The other party has failed to use or treat the goods properly or in accordance with F&FM's

instructions;

5. The damage has been caused by incidents, beyond F&FM's supervision, which have

occurred either during transport or installation.

CE certification

The machine is CE certified. It means that the machine complies with the essential

requirements concerning safety and hygiene. The directives that have been taken into

consideration in the design are available on www.fast-f lu id. com.

V 2.0 page 3

Fast & Fluid Management – SK350

Main SK350 components

1. Top lid

2. Keyboard & Emergency stop button

3. Transformer

4. Power Board

5. Removable front panel

6. Clamping plate

7. Super strut – suspension

8. Door handle

9. Shaker frame

10. Can table

11. Can mounting rim

12. E xcenter axle

13. Shaker motor & driving belt

1.

2.

5.

6.

8.

11

4.

3.

7.

9.

10.

12.

13.

V 2.0 page 4

Fast & Fluid Management – SK350

Safety instructions

General safety instructions

Attention! Before installing the equipment and setting it in operation,

please read the instructions carefully. This is safer both for yourself

and prevents unnecessary damage to the machine.

The manufacturer accepts no liability if the instructions below are not followed:

1. If a machine has been damaged (during transport, for example), do not attempt to set it in

operation. When in doubt, first contact either your supplier or the F&FM service

department.

2. The equipment should be positioned and connected up in strict accordance with the

installation instructions.

3. All local safety regulations and ordinances should be observed.

4. The machine may be connected only to a 220-240V/16A/50Hz earthed wall socket installed

in accordance with the regulations.

5. Users should see to it that the machine is kept in good condition. Defective components

should be replaced.

6. In order to prevent physical injury, the doors should be closed and the paneling fitted

during normal use.

7. All service activities (other than routine maintenance and adjustments) may only be carried

out by qualified technicians. See to it that the mains lead is always kept unplugged while

repairs are being carried out.

Specific safety instructions in this manual

Attention! Failure to remove the frame lock correctly can result in

severe damage to your SK350 when in operation. Please take care!

Attention! To prevent damage, the SK350 may only be connected to

either 220-240V/16A/50Hz power grids.

Attention! Only use the emergency stop button in case of a true

emergency. After pressing the emergency stop, wait at least 15

seconds before unlocking it (turn clockwise). The SK350 will then

reset and unclamp the container.

Attention! MOVING PARTS CAN CAUSE INJURY. Always turn off power

(e.g. by pressing emergency stop) before accessing moving parts.

V 2.0 page 5

Fast & Fluid Management – SK350

Installation

Step 1 - Unpack the machine and unlock the frame lock

> >

Remove box and plastic

foil. Note the frame lock

bolts on either side of the

machine.

Remove both bolts with a size

17 fork wrench.

Be careful not to damage the body and surfaces of your SK350 with

any tools while unpacking it. Take care not to accidentally close the

door before finishing installation, as it can then only be unlocked

power on the machine.

Step 2 - Remove the frame lock

> >

By removing the bolts, the

frame lock’s wooden block is

released.

Pull out cord to

remove frame lock’s

loose parts.

Attention! Failure to remove the frame lock correctly can result in

severe damage to your SK350 when in operation. Please take care!

Please take care to store the frame lock for later use, it is essential for

correct transportation.

Ensure all loose parts

have been removed – two

bolts and two wooden

blocks.

V 2.0 page 6

Connect the SK350 to the

power mains before

closing the door.

Loading...

Loading...