Page 1

Part No: 30590

06.13

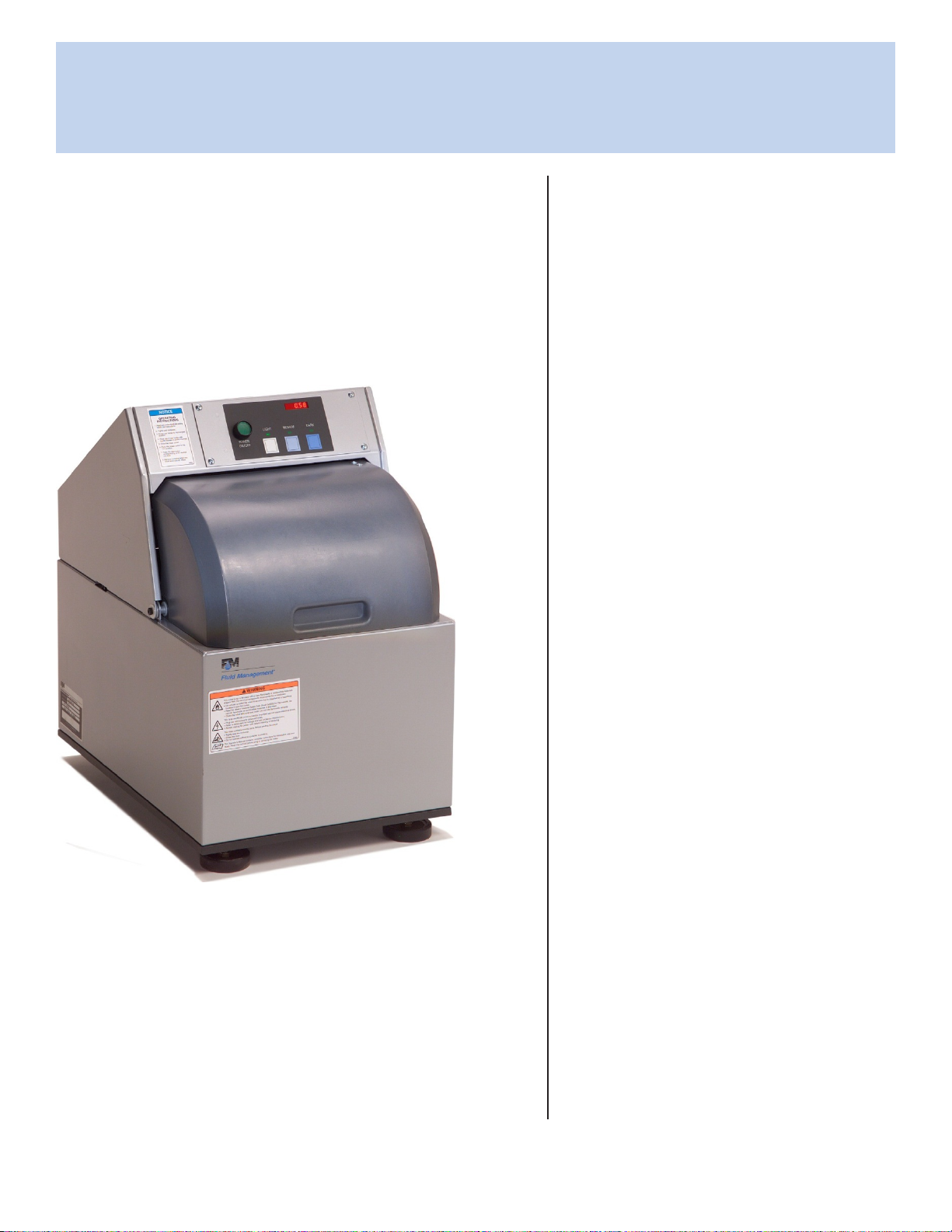

V-Series Mixer

| End

User

Guide

Getting

Maintenance

Trouble

Service

Started

and Care

sh

ooting

Parts

Warranty

Rev. D

Page 2

Yo u r

customers have a

vision, you want to make it

happen, and Fluid M anagement can give

you the answer. Fluid M anagement is a global

leader in dispensing and mixing equipment used i n

the paint industr y, as well as, specialized equipment for

the food and beverage, chemical, health and beaut y, and home

improvement industr ies. Located in the subur bs of Chicago, I llinois,

Fluid M anagement is a United States owned and operated company

with histor ical roots to the paint industr y dating back to 1927. I n 1996,

IDEX Cor poration purchased Fluid M anagement giving the organization the

financial wherewithal and global footpr int of a large organization while still

maintaining its deep values and histor y.

As industr y leaders, Fluid M anagement provides trend-setting creativit y in the design,

produc ts, and ser vices it offers. United with FMDirec t, our nationwide ser vice team,

we provide af ter-sales suppor t around the clock—when you need them. B eing fac to r y-

direc t employees, FMDirec t technicians are exper ts on Fluid M anagement equipment and

understand customer needs from star t to finish.

The combination of leading edge technology, excellent ser vice and suppor t, and a

company prepared for the future’s ever- changing business environment makes Fluid

M anagement an ideal par tner to assist in providing solutions to your business needs.

Thank you for putting your trust in Fluid M anagement produc ts and mak ing us par t of

your customer ’s vision.

Page 3

2 | V-Series

©2011 Fluid Management as published work all rights reserved.

Under the copyright laws, this material may not be copied, in whole or in part,

without the written consent of Fluid Management.

Your rights to the software are governed by the accompanying software license

agreement.

Use of Fluid Management trademarks, service marks, or logos for commercial

purposes without the prior written consent of Fluid Management may constitute

trademark infringement and unfair competition in violation of federal and state

laws. Fluid Management, FMDirect, ColorPro, DVX, Harbil, Blendorama, Accutinter,

Duraflow, Fast & Fluid Management, GyroFlex, GyroMixer, Infina, MicroTint, TintMaster,

V1, and VR1 are trademarks of Fluid Management, registered in the U.S. and/or other

countries.

Every effort has been made to ensure that the information in this guide is accurate.

Fluid Management is not responsible for printing or clerical errors.

Fluid Management

1023 Wheeling Road

Wheeling, Illinois 60090-5776 USA

800-462-2466

http://www.fluidman.com

Published in the United States.

Mention of third-party products is for informational purposes only and constitutes

neither an endorsement nor a recommendation. Fluid Management assumes no

responsibility with regard to the performance or use of these products.

Fluid Management Customer Service 1.800.462.2466

Page 4

Contents

V-Series | 3

O

nce your V-Series Mixer is installed,

what’s next? In this guide, you’ll find

more information to help you get

the most from your new Fluid Management

V-Series Mixer.

About This Guide

4 How to Use this Guide

4 For Your Safety

Important Safety Information

5 Information and Instruction Labels

5 Safety Notice Information

5 General Safety Information

6 Grounding

6 Danger

6 Safety and Regulatory Compliance Information

6 FCC Compliance Statement

Getting to Know Your V-Series Mixer

7 Technical Specifications

7 Environmental Conditions

7 Highlights

7 Features

8 Tips to Improve Operation

Getting Started

9 Installation

Basic Operations

11 Mixing

12 Using the Adapter

Accessories

13 V-Series Mixer Adapters

13 V-Series Mixer Stands

Maintenance, Care, and Use

14 Daily, Weekly, Monthly Maintenance

Frequently Asked Questions

15 Equipment Troubleshooting

Service

V-Series Mixer

16 FM Direct

16 Upgrades and Replacement Parts

16 Obtain Warranty Service

Parts

17 Parts

Warranty

21 Fluid Management Statement of Limited

Warranty

Index

24 A-W

Fluid Management Customer Service 1.800.462.2466

Page 5

4 | V-Series

About this Guide

Safety Precautions

• Read this guide and all

warning labels before using

the machine.

• Keep this guide in a safe

place.

• Read and adhere to all

Warning and Caution labels

on the machine.

• Prepare, level, and clear the

area where the machine will

be installed.

• To avoid risk of fire or

injury, unplug the power

before servicing electrical

components.

• DO NOT use mixer on or near

flammable or combustible

materials

fl

• DO NOT mix

materials.

• Plug into an approved

grounded outlet only. Make

sure the outlet meets all

national and local codes.

• To reduce the risk of electric

shock or injury, use indoors

only.

• This mixer contains moving

parts. Tightly seal the

container before operating.

ammable

How to Use this Guide

This guide is organized into eleven sections. Each section provides detailed

information on V-Series Mixer topics and provides a basic reference that can be used

to help you with specific issues.

Important:

information before you first use your V-Series Mixer.

This guide provides instructions for safely and easily installing your V-Series Mixer

when it arrives. This publication also includes operational instructions, daily and

preventative maintenance procedures, basic troubleshooting suggestions, adapters to

use for various can types, customer service, and warranty information.

If you are an experienced user, you may already know enough to get started. Make

sure you look over the information in Getting to Know Your V-Series Mixer to find

out about the features of this V-Series Mixer.

If you have internet access, the most current information for your V-Series Mixer is

available from the worldwide web at

Carefully read all the installation instructions and the safety

http://www.fluidman.com

For Your Safety

Customer safety is important. Our products are designed to be safe and effective.

However, mixers are electrical equipment. The V-Series Mixer is safe, fast, and

reliable—designed to bring many years of operation. There are precautions you can

take to avoid damage to the equipment or bodily injury before operating. By carefully

following the instructions in this document and the warning and maintenance labels

on the machine, you can help protect yourself from hazards and create a safer work

environment.

Equipment can become damaged due to misuse or neglect. Some product damage is

serious enough that the product should not be used again until it has been inspected

and, if necessary, repaired by a Fluid Management authorized service technician.

As with any electronic device, pay close attention to the mixer when it is turned on.

On very rare occasions, you might notice an odor or see a puff of smoke or sparks

vent from your machine, or you might hear sounds like popping, cracking or hissing.

These conditions might merely mean that an internal electronic component has

failed in a safe and controlled manner. However, it may indicate a potential safety

issue. DO NOT take risks or attempt to diagnose the situation yourself. Contact Fluid

Management at 1-800-462-2466 for assistance.

Fluid Management Customer Service 1.800.462.2466

Page 6

V-Series | 5

Important Safety Information

Information and Instruction Labels

You should become familiar with the information labels affixed to the machine, as

well as the warnings, cautions, and notes which appear throughout this guide. Read

all the warning labels on the exterior and interior of the mixer. If the labels become

damaged or unreadable, you may purchase replacements from Fluid Management

Customer Service.

Safety Notice Information

The two main notices used in this guide and on the V-Series Mixer are Warning and

Caution.

W

ARNIN

HAZARDOUS

ELECTRICAL

COMPONENTS

CAUT

POTENTIAL

SAFETY

HAZARD

IO

G

N

A Warning notice tells you about a hazard that could

cause serious injury to you or extensive damage to the

equipment. This information is featured in the beginning

of the guide to emphasize safety. When you see a

Warning notice in this guide, read it carefully before

continuing with the operation of the machine. Take all

necessary precautions to avoid potential injury.

A Caution notice tells you about a danger that could

cause injury to you or minor damage to the mixer. When

you see a Caution notice in this guide, read it carefully

and be sure you understand it before continuing.

General Safety Information

DO NOT attempt to service a product yourself unless instructed to do so by Fluid

Management Customer Service. Use only a Fluid Management Authorized Service

Technician to repair your equipment. Please note that some parts can be upgraded

or replaced by the customer. Fluid Management identifies those parts as such and

provides documentation with instructions when it is appropriate for customers to

replace those parts. You must closely follow all instructions when performing such

replacements. ALWAYS make sure that the power is turned off and the machine is

unplugged before you attempt the replacement. If

contact Fluid Management Customer Service.

you have any questions or concerns,

WARNING:

Unplug before

servicing

Use a dedicated

15 amp circuit

(US & Latin

America only)

WARNING:

DO NOT use with or

fl

near

ammables

Fluid Management Customer Service 1.800.462.2466

Page 7

6 | V-Series

Important Safety Information

Warnings

• This machine draws

6.0 Amps at 120 ± 10% VAC

3.6 Amps at 220 ± 10% VAC

• DO NOT modify the

provided plug

• Improper use of grounding

plug can result in risk of

electric shock.

Cautions

• Check with a qualified

• DO NOT use an adapter or

• This unit must be plugged

• To reduce the risk of

electrician or service

person if grounding

instructions are not

completely understood or

if in doubt as to whether

product is properly

grounded.

extension cord with this

product.

into a dedicated electrical

line.

electric shock or injury, use

indoors only.

Grounding

This product must be grounded. In the event of an electrical short circuit, grounding

reduces the risk of electrical shock by providing an escape for the electric current.

This product is equipped with a cord that has a grounding wire and an appropriate

grounding plug. The plug must be inserted into an outlet that is properly installed and

grounded in accordance with all local codes and ordi na nc es .

Danger

Improper installation of the grounding plug can result in a risk of electric shock. If

repair or replacement of the cord or plug is necessary, DO NOT connect the

grounding wire to either flat blade terminal. The insulation wire with green or green

and yellow stripes on the outer surface is the grounding wire. Check with a qualified

electrician if the grounding instructions are not completely understood or if in doubt

about whether the product is properly grounded. DO NOT modify the plug provided. If

it will not fit into the outlet, have the proper outlet installed by a qualified electrician.

Note: This product is for use on a dedicated nominal 120 Volt

(US only) or nominal 220 Volt circuit where applicable and has a

grounding plug.

Safety and Regulatory Compliance Information

See the affixed labeling on the machine. ETL Listed, conforms to UL STD 1450.

Certified to CAN/CSA STD C22.2 NO. 68.

FCC Compliance Statement

This device complies with part 15 of the FCC Rules. Operation is subject to the

following two conditions: (1) This device may not cause harmful interference, and (2)

this device must accept any interference received, including interference that may

cause undesired operation.

Fluid Management Customer Service 1.800.462.2466

Page 8

V-Series | 7

Getting to Know Your V-Series Mixer

Power On/Off Button

Serial

Plate

Mix Time Buttons

LED Display

Control Panel

Lid Retainer

Feet

* VR-1 Digital Model Shown

Features

• One-gallon mixer for round and square containers (V-1 model; VR-1 model mixes round only)

• Durable steel frame

• Three mixing settings- Light, Medium, and Dark (or 1-4 minutes with Mechanical Knob Timer

Model)

• Pint and quart mixing possible with adapter

• Partially enclosed motor for clean, quiet and safe operations

• Easy access for maintenance

• Compact design fits on counter or stacking unit

Technical Specifications

V1 Series

Height: 26” (66 cm)

Width: 17” (43 cm)

Depth: 24” (61 cm)

Weight: 165 pounds (75 kg)

Maximum power:

120 volts, 6.0 Amps +/- 10%, 60 Hz

VR1 Series

Height: 27.9” (71 cm)

Width: 17” (43 cm)

Depth: 24” (61 cm)

Weight: 117 pounds (53 kg)

Maximum power:

120 volts, 6.0 Amps +/- 10%, 60 Hz

220 volts, 3.6 Amps +/- 10%, 50Hz

Environmental Conditions

• Operating temperature: between

50°F (10°C) and 104°F (40°C)

• Relative humidity: between 5%

and 85% without condensation

Highlights

• Mixes round and square cans (V-1

model only; VR-1 model mixes

round only)

• Fast and thorough mixing action

• Fully rotational, dual-axis vortex

motion

• Adapter allows for pint and quart

mixing

• Programmable mix timer up to 5

minutes

• LED display shows mix time

countdown and life cycle counter

• Automatic shut off

• Small and compact to fit on

counter or stacking unit

Fluid Management Customer Service 1.800.462.2466

Page 9

8 | V-Series

Getting to Know Your V-Series Mixer

Tips to improve operations

These tips will help improve the operation of your V-Series Mixer:

• DO NOT mix dented or damaged cans

• DO NOT mix flammable materials or solvent based colorants

• DO NOT run the mix without a container in place

• For optimal performance, DO NOT run mixer on carpet, countertops, or tables

• Seal the paint container tightly before mixing to prevent any spills

• Press the red Emergency Button to stop the machine in an emergency

• When the red LED is lit on the display, the machine has power

• Position the containers correctly to ensure best mixing results

• Make sure the mixer is level and the position where it will be operating

• The mixer will stop running if the door is opened during operation

• Follow the preventative maintenance procedures in this guide.

Your V-Series Mixer has been designed so that you can set it up quickly and

begin using it right away. If you have never used a mixer, read this section for

instructions on getting started and installing your machine.

Warnings

ALWAYS shut off the power

and unplug your machine

from the AC power outlet

before servicing.

This unit must be plugged

into a dedicated electrical

line. This includes: 15 Amp

line for 120 Volt equipment

The surface the mixer sits on

must be strong enough to

support its weight.

Fluid Management Customer Service 1.800.462.2466

Page 10

V-Series | 9

Getting Started

Installation

Unpacking and Set up

Follow the steps on the next two pages to set up your V-Series Mixer

Important: Before you plug the V-Series Mixer into a power

outlet, carefully read all of the following

and the safety information. It is recommen d ed that at least one

other person assist in taking the machine off the pallet.

Make sure these items are available before installing.

1

V-Series Mixer

Surge protector (recommended, not included)

Tools needed for installation:

2

9/16“ socket wrench and extension

Scissors or diagonal cutters

Straight screw driver

installation instructions

3 Unpack the machine while still on the shipping skid.

a. Remove the interior packaging materials

b. While unpacking, inspect the machine for any damage that may have

occurred during shipping.

If any damage is found, notify the carrier immediately. Arrange for

inspection in order to claim recovery. Claims for damage must be

made by the consignee (YOU). The carrier assumes full responsibility

upon acceptance of the shipment and will not entertain any claims by

Verify the contents against the packing slip. Note if any items are missing

or damaged. Call Fluid Management Customer Service at 1-800-462-2466 if

any items are missing.

the consignor.

Warnings

Verify that your mixer is

firmly positioned on the

surface it will sit on.

This machine is not

explosion proof and must

not be used in a flammable

atmosphere or with

flammable materials.

Protect the cords and any

surge protectors from

liquids. Liquids can cause

gradual corrosion of the

power cord which can

result in overheating

To reduce the risk of

electric shock or injury, use

indoors only.

Cautions

DO NOT operate the mixer

until it is in a permanent

location.

ALWAYS route power cords

so they will not be walked

on, tripped over, or pinched

by objects

Avoid using extension

cords with unit.

4 Remove from skid (see unpacking instructions attached to machine).

a. Open upper cabinet by removing the back screw that secures the top

cabinet to the lower cabinet. Do not discard this screw. (See Figure 1.)

b. Carefully flip the top cabinet forward.

c. Remove shipping bolts located through the holes in the inner base. Using

9/16” socket wrench and extension, unbolt the two bolts that secure the

machine to the skid.

d. Using at least two people, remove mixer from skid and lower to floor.

Fluid Management Customer Service 1.800.462.2466

Page 11

10 | V-Series

Getting Started

Installation

5a Remove the packing blocks from inside the mixer

(for V1 models only)

a. Carefully lift up the top cover until it rests on the front of the mixer.

b. Unscrew the wooden block on the interior of the mixer between the

gears and the motor (see Figure 2).

c. Remove the wooden block.

d. Close the top cover and reattach the latch (see Figure 1).

5b Remove the packing blocks from inside the mixer

(for VR1 models only)

a. Close the upper cabinet and secure it to the lower cabinet by

reattaching the back screw (see Figure 1).

b. Carefully lift up the mixer at an angle providing access to the bottom.

c. Remove the three (3) central bolts holding the shipping blocks

(see Figure 3).

d. Carefully set the mixer down and open the top cover.

e. Use the cord that joined together the shipping blocks to pull the

blocks out of the mixer.

Position mixer in permanent location.

6

a. Choose a location for your mixer capable of supporting its weight.

(V-1 = 165 pounds, 75 kilograms, VR-1 = 117 pounds, 53 kilograms).

b. Make sure there is enough room to access the rear of the machine to

perform routine maintenance.

c. Adjust the feet to level the mixer and prevent it from rocking.

Final preparations.

7

Plug in the power cord. Follow Basic Operations for operating

instructions.

Figure

Figure

Figure

1

2

3

Fluid Management Customer Service 1.800.462.2466

Page 12

V-Series | 11

Basic Operations

Mixing

There are three mix cycles to choose from – Light, Medium, and Dark depending on the paint you are mixing. Follow these steps

to begin the mix cycle for your V-Series Mixer:

1 Press the Power On/Off button.

2 Place container.

a. Open the mixer door.

b. Turn the can holder towards you and pl

Note: Make sure the paint container is tightly sealed to prevent

spills. For plastic square paint containers, align the container’s

handle with the metal lever on the side of th e can holder.

(See Figure 4.)

c. Turn both lid retainer levers on the can holder until they firmly snap into place.

Note: If you are mixing a metal paint container, make sure the

handles fit firmly into the slots on the side of the can holder.

(See Figure 5.)

d. Close the mixer door.

3 Select the mix cycle.

a. Press the Light, Medium, or Dark button to start the mixing cycle.

(See Figure 6.) The mix times are factory set at 1.5, 2, and 3 minutes, respectively.

b. To program your timer for alternate mix settings, contact Fluid Management

Customer Service.

Note: For mechanical timer models, turn the timer knob to the

desired mixing time (1 to 4 minutes). (See Figure 7.)

ace the paint container inside the holder.

Figure

Figure

Figure

4

5

6

4 Remove the container from the mixer.

a. Open the door when the mixing cycle is complete.

b. Turn the lid retainer levers to the open position.

c. Remove the paint container.

Fluid Management Customer Service 1.800.462.2466

Figure

7

Page 13

12 | V-Series

Basic Operations

Using the adapter

The adapter is used to mix quarts and pints. Each can shape is molded into the adapter.

1 Open the adapter.

Select the appropriate adapter to match the paint container size.

2 Place the paint container in adapter.

(See Figures 8 and 9.)

Close the adapter and insert into the mixer can holder.

3

Make sure the adapter handles fit against the reinforced side of can holder.

(See Figure 10.)

Clamp both lid retainers over the adapter.

4

(See Figure 11.)

Figure

Figure

8

9

Follow Basic Operation-Mixing steps to begin mixing.

5

Figure

10

Figure

11

Fluid Management Customer Service 1.800.462.2466

Page 14

V-Series | 13

Accessories

V-Series Mixer Adapters

PAR T N UM B E R D E SCR I P T I O N I M AG E

25090

30598

Round Quart Adapter for use with VR-1 Mixer

Square Quart Adapter for use with V-1 Mixer

Contact Fluid Management Customer Service for custom adapters that are available.

V-Series Mixer Stands

PAR T N UM B E R D E SCR I P T I O N I M AG E

30740 Holds two V-Series Mixers

32340 Lifts mixer to conveyor height

Fluid Management Customer Service 1.800.462.2466

Page 15

14 | V-Series

Maintenance, Care, and Use

To ensure safe, dependable operation of your V-Series Mixer follow the maintenance

schedule detailed below:

Clean every day:

• Clean all accessible inside and outside surfaces with a mild cleaning solution.

• Clean control panel surfaces with a mild cleaning solution.

Every six months:

• Level the machine.

• Adjust belt tension as needed.

• Check for dirt accumulations on motor. Remove dirt by vacuuming.

Every year:

• Lubricate the sleeve bearings on the motor with 30-35 drops of SAE 20 oil.

• Change the drive belt.

Unplug from outlet before servicing and cleaning.

Fluid Management Customer Service 1.800.462.2466

Page 16

V-Series | 15

Frequently Asked Questions

Equipment troubleshooting

Most problems with the V-Series Mixer can be easily solved with a quick and easy solution. For instance, follow the

daily cleaning suggestions in the Maintenance, Care, and Use and the Getting to Know Your V-Series Mixer

section. Think about the conditions that led up to the problem. Making a note of things you did before the problem

occurred will help you narrow down possible causes and find the answers you need.

First, make sure:

• The power cords are securely connected to a working dedicated power source.

• The power button is on.

• You have followed the suggestions in the Maintenance, Care, and Use section.

• The machine is situated on a flat, level, and stable surface capable of supporting the weight of the machine.

Use the chart below to locate the problem, check the possible cause, and then take the action recommended.

Contact Fluid Management Customer Service if you are unable to find a resolution.

PR O B LE M FI R S T CH ECK AC T I O N

The mixer does not start.

The mixer will not shut off.

The motor has voltage and hums,

but it will not run.

An excessive amount of vibration

occurs.

The motor starts slowly.

• Is mixer plugged in?

• Does “0” appear on led?

• Is voltage present?

• Is front door closed?

• Is motor overheated?

• Is time shown on led display

showing and counting down?

• Is the line voltage low?

• Is the belt too loose or too tight?

• Is can holder empty?

• Is mixer level?

• Is one of adjustable legs

broken, low, or damaged?

• Is paint can positioned in

the can holder correctly?

• Is the belt tension too tight?

• Connect mixer to power source.

• Connect mixer to power source.

• Contact an electrician.

• Close front door.

• Allow motor to cool for at least

five minutes. Check for an

excessive accumulation of

dirt. Vacuum if necessary.

• Call customer service.

• Let mixer finish mixing cycle.

• Unplug mixer.

• Call customer service.

• Make sure the mixer is

on a dedicated line.

• Check the tension of the belt.

• Call customer service.

• Place container in can holder.

• Adjust legs until balanced.

• Replace or adjust damaged leg.

• Position container in the can holder.

• Adjust the tension of the belt.

Fluid Management Customer Service 1.800.462.2466

Page 17

16 | V-Series

Service

FMDirect

Fluid Management products are backed by FMDirect,

our nationwide team of phone and field service

engineers. Providing you with local, hands-on support,

over 30 factory-direct service technicians deliver

expertise when and where you need it.

•

24/7 multilingual tech support

•

Professional installation and on-site operator training

•

Fully-stocked parts inventory on FMDirect vans

•

Extended warranty and preventive maintenance

programs

Upgrades and Replacement Parts

Some parts can be upgraded or replaced by the

customer. Fluid Management expressly identifies parts

as such, and provides documentation with instructions

when it is appropriate for customers to replace those

parts. You must closely follow all in s tructions when

performing such replacements. ALWAYS make sure

that the power is turned off and that the product is

unplugged from any power source before you attempt

the replacement.

DO NOT attempt to service a product yourself

unless instructed to do so by a Customer Service

Representative. Use only a service provider who is

approved to repair your particular product.

Obtain Warranty Service

First, follow the advice in this guide. If the unit still

does not function, call Customer Service for

information about how to obtain warranty service.

Fluid Management Customer Service

1.800.462.2466

Save time and money. If something should go

wrong, we suggest consulting the Maintenance,

Troubleshooting and Service sections of this

guide. They are designed to solve basic problems

before consulting a service technician.

However, should you need assistance, please

have your model and serial number ready. Be

near your machine when you call and have a

purchase order number if ordering parts.

The serial plate is located on the side pan el of

the machine. It includes the serial and model

numbers for your machine. Please make a note

of these numbers below:

Date of purchase:

Model Number:

Serial Number:

Your Service Technician’s

Name:

Fluid Management Customer Service 1.800.462.2466

Page 18

V-Series | 17

Parts

1

5

7

6

2

4

3

Fluid Management Customer Service 1.800.462.2466

Page 19

18 | V-Series

Parts

ITEM N O. PAR T NUM BE R D ESCR IP TI O N QUANTIT Y

1

1

1

1

2

3

4

5

6

7

27970

35831

30990

35886

35146

35049

32782

26065

F015308025

F0098P06

CONTROL PANEL - DIGITAL TIMER 120V

CONTROL PANEL - MECHANICAL KNOB TIMER 120V

CONTROL PANEL - MECHANICAL KNOB TIMER WITH INTERLOCK

120V

CONTROL PANEL - MECHANICAL KNOB TIMER 220V

PLASTIC DOOR ASSEMBLY

ADJUSTMENT FOOT

SOLENOID ASSEMBLY - INTERLOCK MODEL

CONTROL PANEL SWITCH

SHOULDER SCREW 8X25MM, M6 THREAD

HEX NUT, M6 WITH NYLON PATCH

1

1

1

1

1

1

1

1

2

2

Fluid Management Customer Service 1.800.462.2466

Page 20

V-Series | 19

Fluid Management Statement

of Limted Warranty 2011

15 16 10 14

11

12

17

4 2 1 3 5 6

7

8

9

13

Fluid Management Customer Service 1.800.462.2466

Page 21

20 | V-Series

Parts

ITEM N O. PAR T NUM BE R D ESCR IP TI O N QUANTIT Y

1

2

3

4

5

6

7

7

8

8

9

10

11

12

13

14

15

16

17

35014

24188

3005002

35015

3005014

35019

16429

00630

26004

32449

35021

35026

3005011

3005103

23430

35545

35123

F0145A05B14

F0141P0616

SHAFT, MAIN TRANSARMS

GEAR, BEVEL

BEARING

TRANSARM

PULLEY

BEARING SHAFT

MOTOR, 48 FRAME - MODEL 120V

MOTOR, 1/3 HP ODP 1425 RPM - 220V MODEL

SHEAVE - 120V MODELS

SHEAVE - 220V MODELS

V-BELT

HUB AND SHAFT ASSEMBLY

SQUARE KEY, 3/16 X 7/16 LONG

COUNTERWEIGHT

SHOCK MOUNT

BUCKET ASSEMBLY

LID RETAINER LEVERS

SCREWS, FHCS M5 X 15

HEX NUT, M6 X 15MM

1

2

4

1

1

2

1

1

1

1

1

1

2

2

3

1

2

4

1

Fluid Management Customer Service 1.800.462.2466

Page 22

Fluid Management Statement

24 | V-Series

Index

of Limted Warranty 2011

A

adapters 12, 13

accessories 13

C

cleaning 14

connecting to power source 6

container placement 11, 12

E

environmental conditions 4, 6, 7

F

FCC compliance 6

features 7

feet 7, 10, 15

flammable materials 4, 5, 8, 9

FMDirect 1, 16

G

grounding 6

I

installation 9-10

L

labels 5, 6, 7, 16

leveling the machine 10, 14, 15

M

maintenance 14, 15

mix cycles 7, 11

O

operation 11, 12

P

parts 17-20

power button 7, 11

power cord 4, 5, 6, 8, 10, 15

preventive maintenance 14

R

regulatory compliance information 6

S

safety 4, 5, 6, 8, 9, 14, 15, 16

serial number 7, 16

service 16

specifications 7

stands 13

T

timer 7, 8, 11, 18

troubleshooting 15, 18

U

unpacking 9-10

V

voltage 6-8

W

warnings 5, 6, 8, 9, 14

warranty 21 -23

warranty service 16

Fluid Management Customer Service 1.800.462.2466

Page 23

V-Series | 25

V-Series Mixer

Fluid Management, Inc.

1023 Wheeling

p:

847.462.2466

f: 847.537.3221

www.fluidman.c

Fluid Management Customer Service 1.800.462.2466

Road • Wheeling

om

IL

60090

Loading...

Loading...