Page 1

© Fast & Fluid Management, TMHC manual

FAST & FLUID MANAGEMENT

TMHC

ENGLISH

p1

Page 2

© Fast & Fluid Management, TMHC manual

TMHC Manual (PC model)

3

EU Declaration of conformity

3

Introduction & warranty

4

Explanation of drawing

6

Safety instructions

7

Installation

8

Use

9

Maintenance

11

Service

13

Technical specifications

15

Wiring diagram

16

Contributing to the Protection of the Environment

17

Table of Contents

p2

Page 3

© Fast & Fluid Management, TMHC manual

Product:

Personal care dispensers

Model:

Tintmaster

Types:

Hair Care

TMHC Manual (PC model)

EU Declaration of conformity

We,

Fast & Fluid Management, the Netherlands

A Unit of IDEX Corporation

Hub van Doorneweg 31

2171 KZ Sassenheim, the Netherlands

declare that:

are in compliance with the following directives:

Machinery Directive 98/37/EC

Low Voltage Directive 73/23/EEC

Electromagnetic Compatibility Directive 89/336/EEC

according to the following harm onized standards:

EN 292-1, EN 292-2, EN 418 & EN 1050

EN 60204-1

EN 61000-6-2, EN 61000-6-3, EN 61000-3-2 & EN 61000-3-3

Sassenheim, 04-08-2003

ir. K. Meeusen

Vice President Manufac turing

Fast & Fluid Management, Nederland

A Unit of IDEX Corporation

p3

Page 4

© Fast & Fluid Management, TMHC manual

Introduction & warranty

Introduction

By selecting a Fast & Fluid Management Dispenser you have opted for a product which is the result of

intensive research. Top-quality components, craftsmanship and a modern ergonomic design all serve to

guarantee a long service life and a high degree of user friendliness.

The machine complies with Council Directives 89/392/EEC on machines, 89/336/EEC on electromagnetic

compatibility, and 73/32/EEC on elec trical equipment intended for use within given voltage limits, as

enacted by the Council of Ministers of the European Community. The mac hine is furnished with a CE mark.

Warranty conditions

In these warranty conditions, 'F&FM' is understood to mean Fast & Fluid Management. The warranty

conditions incorporated into F&FM's general conditions of sale are summarized as follows (for free general

conditions you can contact F&FM):

F&FM guarantees the proper operation of any goods which it supplies, for a period of one year, except

where a breakdown is the result of normal wear and tear. The cost of any inspection activities carried out by

F&FM, with the aim of establishing whether or not a breakdown is covered by the warranty will be

reimbursed by the other party if it transpires that the breakdown is not covered by the warranty. If it

transpires that a breakdown is covered by the warranty then F&FM will supply identical or equivalent goods

under the conditions referred to in point 6 of the general conditions of sale. The warranty obligation

described in this article only applies if the goods supplied by F&FM have been used in accordance with the

manual. Time spent on warranty-related activities, including travel time, travel costs and accomm odation

costs, are charged at current rates.

In contrast to the above, F&FM will not be held to any warranty obligation if:

Repairs have been carried out, or attempted, by the other party or a third party, unless F&FM had

1.

previously declined to repair the goods for a fair price;

F&FM demonstrates that the defect did not emerge during testing;

2.

The other party fails to inform F&FM of the defect immediately, if possible either by letter and/or by fax,

3.

providing full, accurate details and/or has failed to comply fully with F&FM's instructions;

The other party has failed to use or treat the goods properly or in accordance with F&FM's instructions;

4.

The damage has been caused by incidents, beyond F&FM's supervision, which have oc curred either

5.

during transport or installation.

In the following text, the expression "Software" will be understood to mean the standard computer software

supplied by F&FM to the other party, recorded on a computer-readable storage medium, plus the

accompanying doc umentation (Software Manual) and including any improved and/or new versions supplied.

The expression "processing unit" (PU) is understood to mean the mac hine for which and with which the

Software is supplied, and which is the sole machine on which the Software may be used.

The other party is authorized to copy the Software either in its entirety, or in part, (up to a m aximum of 2

copies) for purposes of internal security. These copies will be furnished with the sam e marks, designations

relating to copyright and other registration numbers as the original version of the Software.

The other party will neither amend, translate, decompile nor adapt the Software, nor convert it into sourc e

code, without specific written permission from F&FM. If the other party so requests, F&FM will provide that

party with the information required to render the Software interoperable with other software.

p4

Page 5

© Fast & Fluid Management, TMHC manual

In the event that the PU experiences a breakdown, the other party may use the software on another

processing unit until the PU is again operational. The other party will inform F&FM of this within 5 days.

If it is a requirement that the Software be definitively transferred from the PU to another processing unit

then the other party shall request permission from F&FM, which will not withhold such permission on

unreasonable grounds.

p5

Page 6

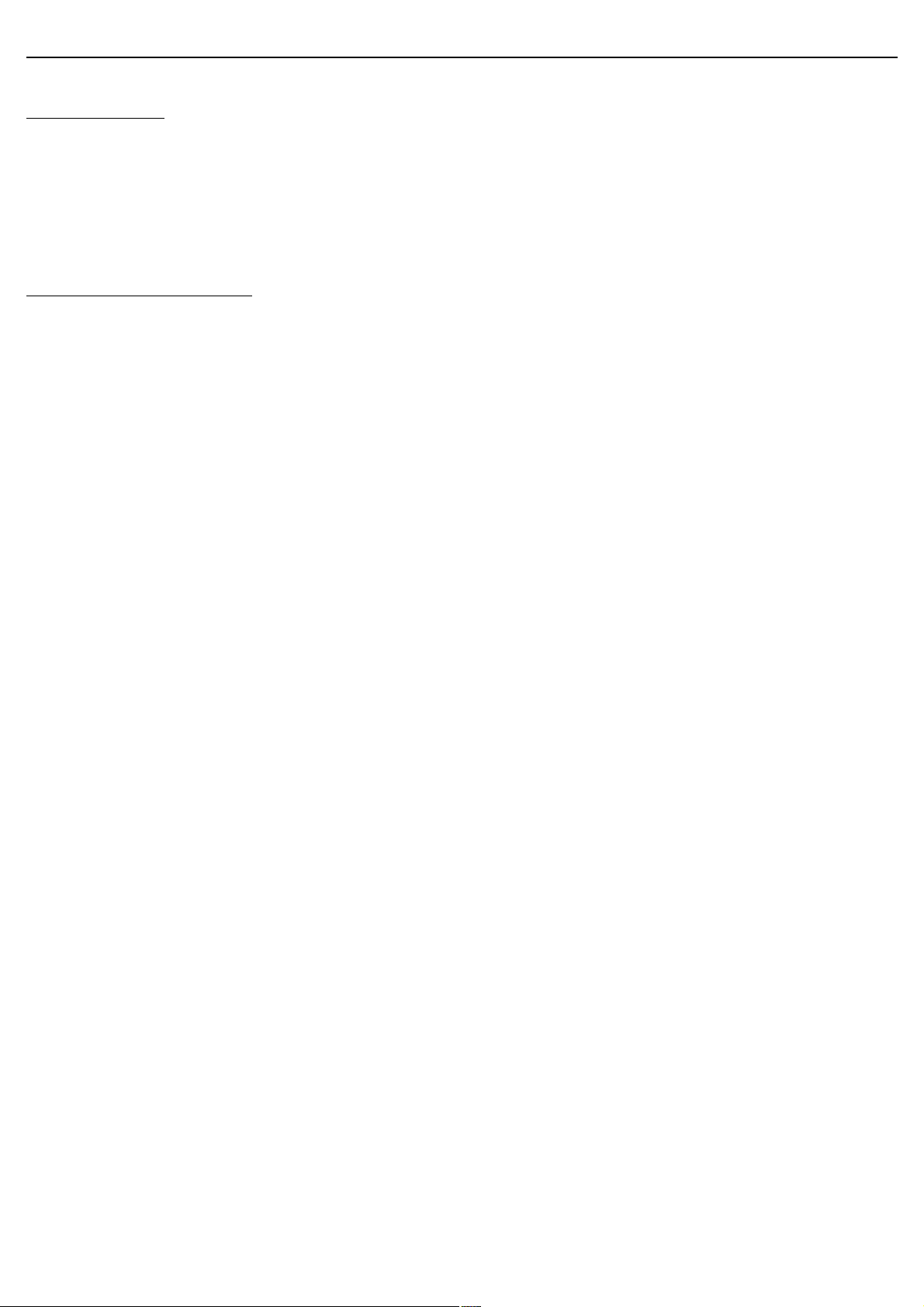

Explanation of drawing

1.

Top panel

2.

Pump & Canister

3.

Flatscreen

4.

Powerboard

5.

Gripper assy

6.

On/Off switch

7.

Side panel

8.

Disc grip

9.

Pump cap

10.

Piston rod

11.

Pump tube

12.

Piston

13.

Pin sensor

14.

Valve body

15.

Ball valve arm

16.

Ball valve housing

17.

Ball valve

© Fast & Fluid Management, TMHC manual

p6

Page 7

© Fast & Fluid Management, TMHC manual

Attention! Before installing the equipment and setting it in operation,

please read this manual carefully. This is safer both for yourself and the

machine.

Attention! When encountering a malfunction or error, always try

resetting the machine first before opening the front door. This can be

done by switching the machine off and back on.

Safety instructions

General safety instructions

The manufacturer accepts no liability if the instructions below are not followed:

If the TMHC has been damaged (e.g. during transport), do not attempt to set it in operation. When in

1.

doubt, contact either your supplier or the F&FM service department.

The equipment should be positioned and connected in strict accordance with the installation instruc tions.

2.

All local safety regulations and ordinances should be observed.

3.

The machine may be connected only to a 230V/16A/50Hz or 110V/25A/60HZ earthed wall socket

4.

installed in accordance with the regulations.

Users should see to it that the m achine is kept in good condition. Defective com ponents should be

5.

replaced by qualified personnel only.

In order to prevent physical injury, the doors should be closed and the paneling fitted during normal

6.

use.

All service activities (other than routine maintenance and adjustments) may only be carried out by

7.

qualified technicians. See to it that the mains lead is always kept unplugged while repairs are being

carried out.

p7

Page 8

Installation

Step 1 - Unpack the machine

>

>

Place the skid near the place

of installation.

Remove the cardboard box.

Remove the plastic foil

around the machine.

Remove skid brackets. There

are 4 of them (1 on each

corner).

>

Remove the brackets

between the dispenser and

the cabinet. There are 4 of

them ( 1 one each corner).

Remove the foam that is

located in the dispense bay

and on top of the turntable.

Access this by opening the

door and top panel.

Be careful not to damage the body and surfaces of your TMHC with any

tools while unpacking it.

A -Installing the dispenser

© Fast & Fluid Management, TMHC manual

p8

Page 9

Use

Step 1 - Switching ON the dispenser & computer

>

The dispenser can be turned on by the switch located on the side

of the door (the computer starts up automaticly when you turn

on the dispenser).

Now turn on the touchscreen.

Step 2 - Switching OFF the dispenser & computer

>

Please note that with normal operation there should be no reason

to take the power off the dispenser. In case the dispenser must

be switched off, do the following:

1.

Shut down the computer(start>shut down) and switch of the

dispenser.

Step 3 - Software and use

>

For further operating the dispenser use, follow the instructions on

screen.

A - First time operation

© Fast & Fluid Management, TMHC manual

p9

Page 10

Replacing pouch

Follow instructions on screen.

© Fast & Fluid Management, TMHC manual

p10

Page 11

Maintenance

Cleaning the brush tray.

>

>

Open the TMHC door and

remove the steel drip tray.

Clean with water if soiled.

Pull out the brush tray and

rinse with water. Clean the

brush with water and dry it.

For further information on

what should be used in the

brush container as c leaning

fluid, ask your supplier.

If severely soiled, the brush

can be removed from the tray

for cleaning.

Use only cleaning fluids recommended by your supplier.

Wrong materials can result in nozzle blockage and reduced accuracy.

Purge activity

Follow instructions on screen.

Weekly maintenance

© Fast & Fluid Management, TMHC manual

p11

Page 12

© Fast & Fluid Management, TMHC manual

Cleaning the leak tray.

Pull out the leak trayand clean it

with water if soiled.

Be carefull when removing the leak tray, there can be fluids in there.

p12

Page 13

© Fast & Fluid Management, TMHC manual

Attention! MOVING PARTS CAN CAUSE INJURY. Always turn off power

(e.g. by pressing emergency stop) before accessing moving parts.

Symptom

Cause

Action

No accurate dispensing

Air bubble in pump

Prime the pump (in software)

There is a blockage in the pump

Pouch is twisted

Replace pouch

Pouch is empty with no software

notification

Replace pouch

No comm unication with

machine

Reset the machine before starting

the PC

Service

A - Introduction

Before calling your machine supplier or Service Department, please chec k whether you can solve the

problem yourself. If you cannot, then call the Service Department for advice. Have the model number and

serial number at hand (these can be found on the silver CE sticker at back of the machine, next to the net

entry or behind the front door of the mac hine).

Use the Problem Solving chart below to judge whether you can solve a problem yourself or not. The tool

symbol ( ) means you cannot solve the problem yourself and the Service Department must be called. On

no occasion remove side panels yourself, this may only be done by trained service personnel. This chart

does not include any of the malfunctions which are reported in an error message by the software. In the

event of a malfunction, these messages and possible solutions are displayed on the monitor.

B - Problem solving

C - Service Department

If necessary, you can get in touch with your supplier or the local service department, or contact the

manufacturer directly. If you contact the manufacturer, make sure that you have the model number and

serial number at hand. These can be found on the silver CE sticker at back of the machine, next to the net

entry or behind the front door of the mac hine.

Fast & Fluid Management

P.O. Box 220

2170 AE Sassenheim, the Netherlands

Hub van Doorneweg 31

2171 KZ Sassenheim, the Netherlands

Tel: + 31 (0)252 240 800

Fax: +31 (0)252 240 842 (service)

+31 (0)252 240 880 (general)

p13

Page 14

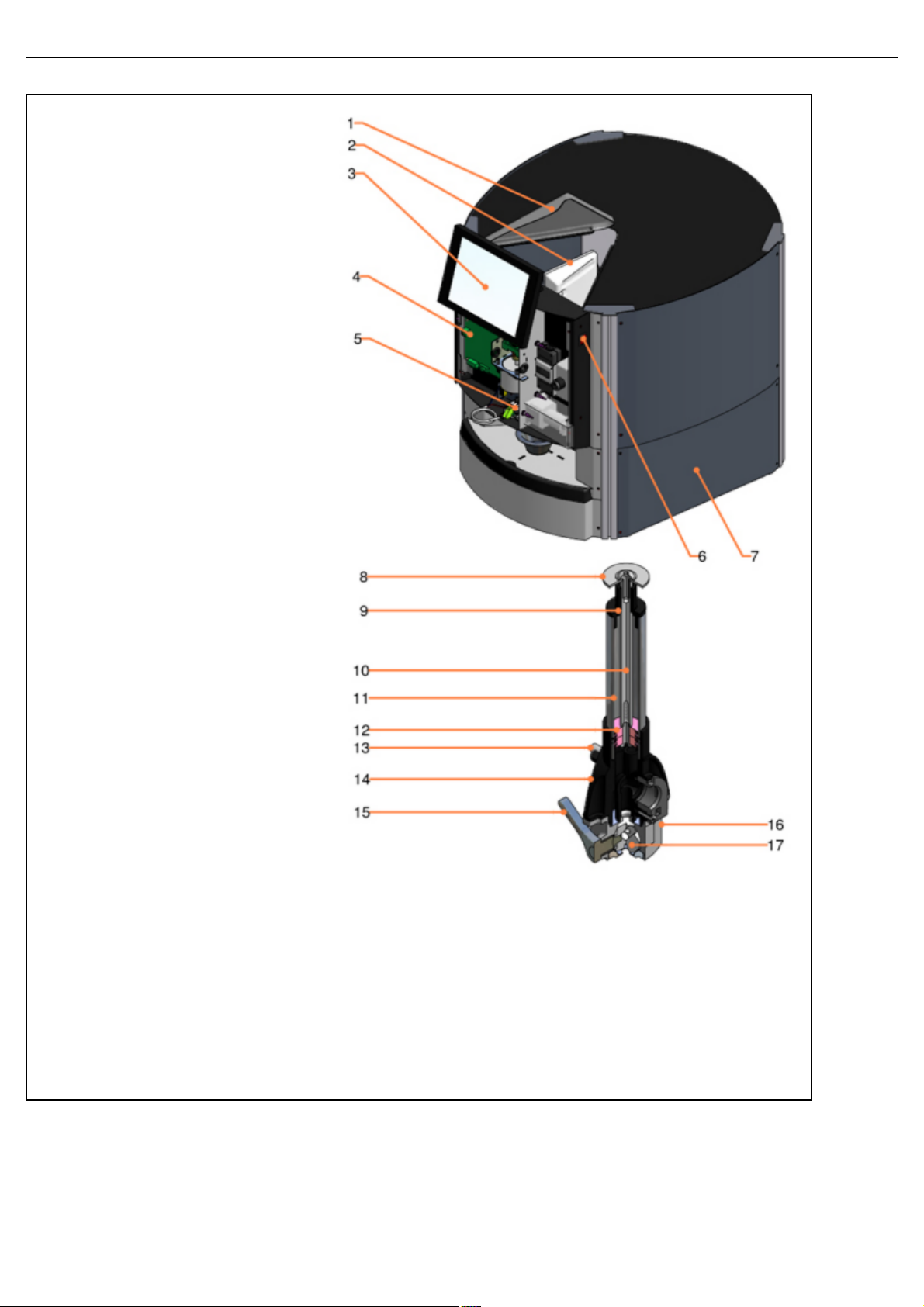

D - Fuse

Replacing fuse in net entry.

>

Spare fuse Damaged fuse

© Fast & Fluid Management, TMHC manual

p14

Page 15

Technical specifications

Number of pouch positions

32

Pouch sizes

1 liter

Valves

32x Stainless steel (mold)

Variations only upon specific request

Pump type

piston pump

Pump sizes

1 ounce

Min. dispensing

1/384 fl.oz *

Accuracy

0.004 ml/step *

Nozzle closures

integrated

Cleaning system

standard

Nozzle diameter

2 and 4,5 mm

Maximum load height

12 cm

Can detector

standard

Dimensions (H x W x D) Dispenser

86 x 74.2 x 82.5 c m

Dimensions (H x W x D) Cabinet

76 x 74.2 x 82.5 c m

Power supply

110V +/- 10%, 50Hz/60Hz

230V +/- 10%, 50Hz/60Hz

CE approved & Patent applied.

Specifications subject to change without prior notice.

* = Depending on fluid characteristics

© Fast & Fluid Management, TMHC manual

p15

Page 16

of

1 1

Sheet

1.00

1862354

1

1602782

FUSE 10AT

50-60Hz, 10Amax

SUPPLY 110/230VAC

NETENTRY DESKTOPMODEL

Ground

machineframe

CABLE (1863745)

Version

1

-

tmhc-fuent-wiringdiagram.DSN

Date Drawn Remarks

TintmasterHairCare Fuente

Filename

Revnr.

Title

1.0 8-5-2006 NvB

POWERSUPPLY 24VDC

CABLE (1862979)

2

M1

3

4

2

2

1

1

4

4P-STEPPERMOTOR

7

8

MAINSWITCH

YEL/GRN

5

3

6

YEL/GRN

BROWN BROWN

BLUE BLUE

CABLE (1863746)

I O

FLUID

MANAGEMENT

P.O.Box 220

Hub van Doorneweg 31

© 2001 Fluid Management

Monday, May 08, 2006

2170AE SASSENHEIM, The Netherlands

2

POWERSUPPLY ASSY (1862980)

MOTOR 1 (1861988)

3

CABLE 24 (1862977)

CABLE 22 (1862974)

CABLE 23 (1862976)

SWITCH 3 (1862975)

SWITCH 3 (1862975)

S3

DOORSWITCH

S3

DOORSWITCH

SENSOR 6 (1862967)

SENSOR 8 (1861982)

S8

VALVE HALF

SENSOR 5 (1863205)

SENSOR 4 (1863206)

SENSOR 2 (1862973)

SENSOR 1 (1862972)

S1

CAN-PRESENT

S2

STEPPER-HOME

S4

VALVE-CLOSED

S5

TABLE-HOME

S6

TABLE POSITION

3

VALVE MOTOR

BRUSHMOTOR

M24

-+

M22

TURNTABLEMOTOR

M23

POWER

+ -

+ -

BLUE

BLUE

BROWN

BROWNBROWN

4

BLUE

BROWN

BLUE

MGND3

HHB14

HHB13

MGND3

HHB12

HHB11

HHB10

HHB9

HHB8

BROWN42=

BLUE0

5

- +

POWERSUPPLY

LK1

BLUE

BROWN

PC

or RED

or YELLOW

or ORANGE

or BLUE

RED & WHITE/YELLOW

YELLOW & WHITE/RED

BLACK & WHITE/ORANGE

BLUE

HHB7

MGND2

MGND2

ORANGE & WHITE/BLACK

BROWN

BROWN

BLACK

HHB6

MGND2

MGND1

HHB5

J19

HHB4

HHB3

HHB2

HHB1

8

3

3

POWER BOARD 2001

465

- S + S +-

1

2

COMMUNICATION

PORT #1 PORT #2

BLUE

BROWN

BLACK

BLUE

SLP

COM 1/USB

COM 2

4

5

D D

C C

B B

A A

Page 17

© Fast & Fluid Management, TMHC manual

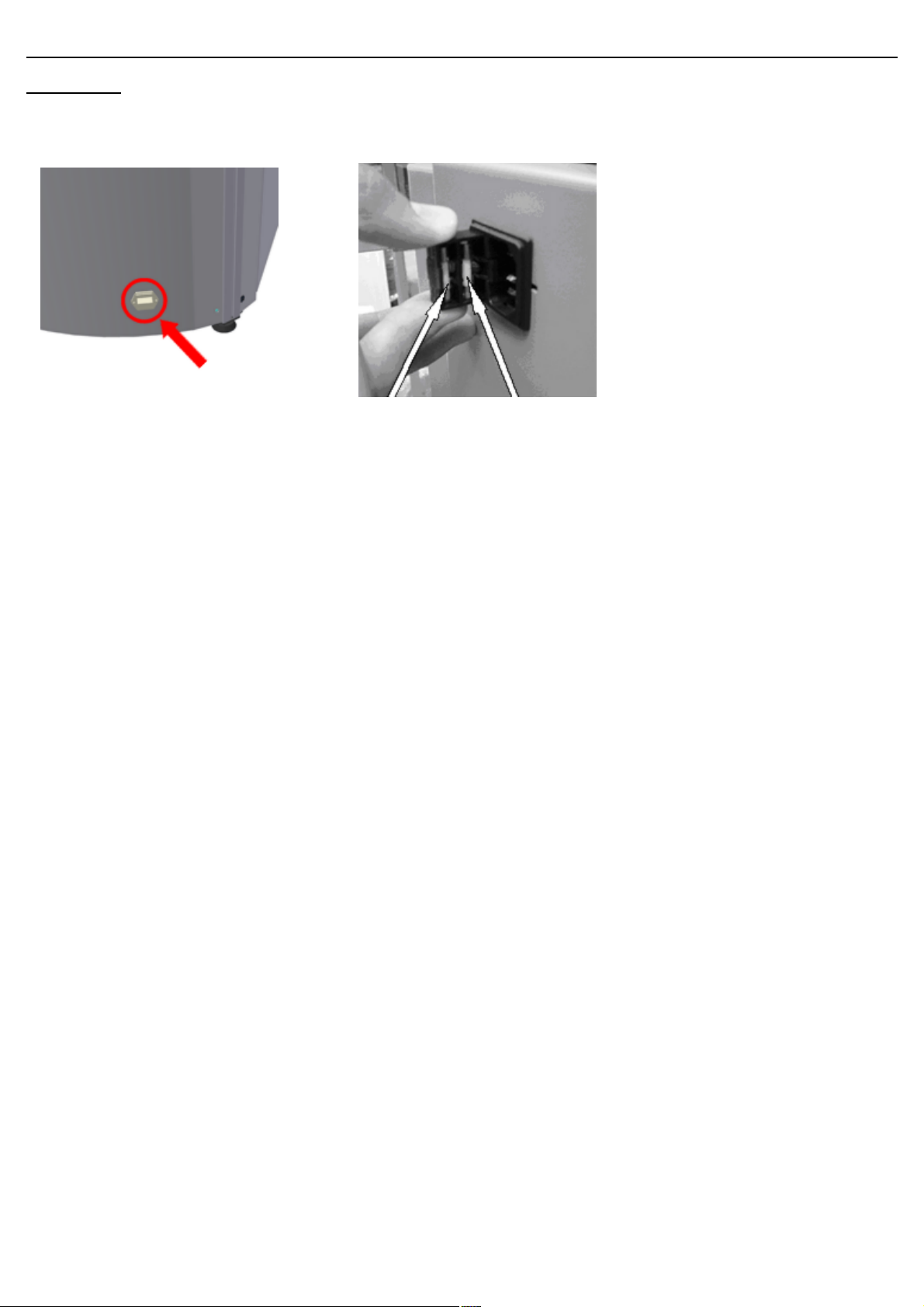

>

All red-coloured components

are made of ABS. These

components can be recycled.

Inside the red square

pictured above (on the front

of the dispenser) are

electrical components that

can be recycled.

Contributing to the Protection of the Environment

Packaging Material

The packaging protects the machine against damage during transport. The packaging material was chosen

based on its limited impact on the environment and its inherent possibilities for waste disposal.

The re use of packaging material saves raw materials and produces less waste material. Generally speaking,

your supplier will take the packaging of your hands.

Discarding the Machine

Discarded equipment usually still consists of valuable materials. For this reason, do not simply throw your

machine out with the oversized refuse, but ask your supplier whether he will take the machine back.

If he will not, then enquire at your local government offices or ask a trader of raw materials what options

there are for recycling the material (e.g. scrap processing, electrical components and plastic (see below for

additional information).

p17

Page 18

© Fast & Fluid Management, TMHC manual

© Fast & Fluid Management, 2007

ww w .Fast-Fluid.com

p18

Loading...

Loading...