Page 1

© Fast & FLuid Management, TmHC manual

FAST & FLUID MANAGEMENT

TMHC

ENGLISH

p1

Page 2

© Fast & FLuid Management, TmHC manual

TmHC Manual

3

Safety instructions

3

Installation

4

Maintenance

9

Service

10

Contributing to the Protection of the Environment

11

Table of Contents

p2

Page 3

© Fast & FLuid Management, TmHC manual

Attention! Before installing the equipment and setting it in operation,

please read this manual carefully.

This is safer both for yourself and the machine.

Attention! When encountering a malfunction or error, always try

resetting the machine first before opening the front door. This can be

done by switching the machine off and back on.

TmHC Manual

Safety instructions

General safety instructions

The manufacturer accepts no liability if the instructions below are not followed:

If the TMHC has been damaged (e.g. during transport), do not attempt to set it in operation. When in

1.

doubt, contact either your supplier or the (F&)FM service department.

The equipment should be positioned and connected up in strict accordance with the installation

2.

instructions.

All local safety regulations and ordinances should be observed.

3.

The machine may be connected only to a 230V/16A/50Hz or 110V/25A/60HZ earthed wall socket

4.

installed in accordance with the regulations.

Users should see to it that the m achine is kept in good condition. Defective components should be

5.

replaced by qualified personnel only.

In order to prevent physical injury, the doors should be closed and the paneling fitted during normal

6.

use.

All service activities (other than routine maintenance and adjustments) may only be carried out by

7.

qualified technicians. See to it that the mains lead is always kept unplugged while repairs are being

carried out.

p3

Page 4

Installation

Attention! Please do not switch on the machine before removing the

transport protection (roll of packing foam) as explained in step 2

Step 1 - Detach the TMHC from its transport skid

>

>

Place the skid close to the end

destination and remove its plastic

wrapping. Unscrew all four

transport brackets.

The brackets can be removed at

the top of the aluminum corner

beams.

Bring the TMHC to operation

location, lift at the lower side

panels (two people can lift the

TMHC).

Attention! Please take care not to damage the TMHC surfaces while

removing packaging (e.g. with knife).

© Fast & FLuid Management, TmHC manual

p4

Page 5

© Fast & FLuid Management, TmHC manual

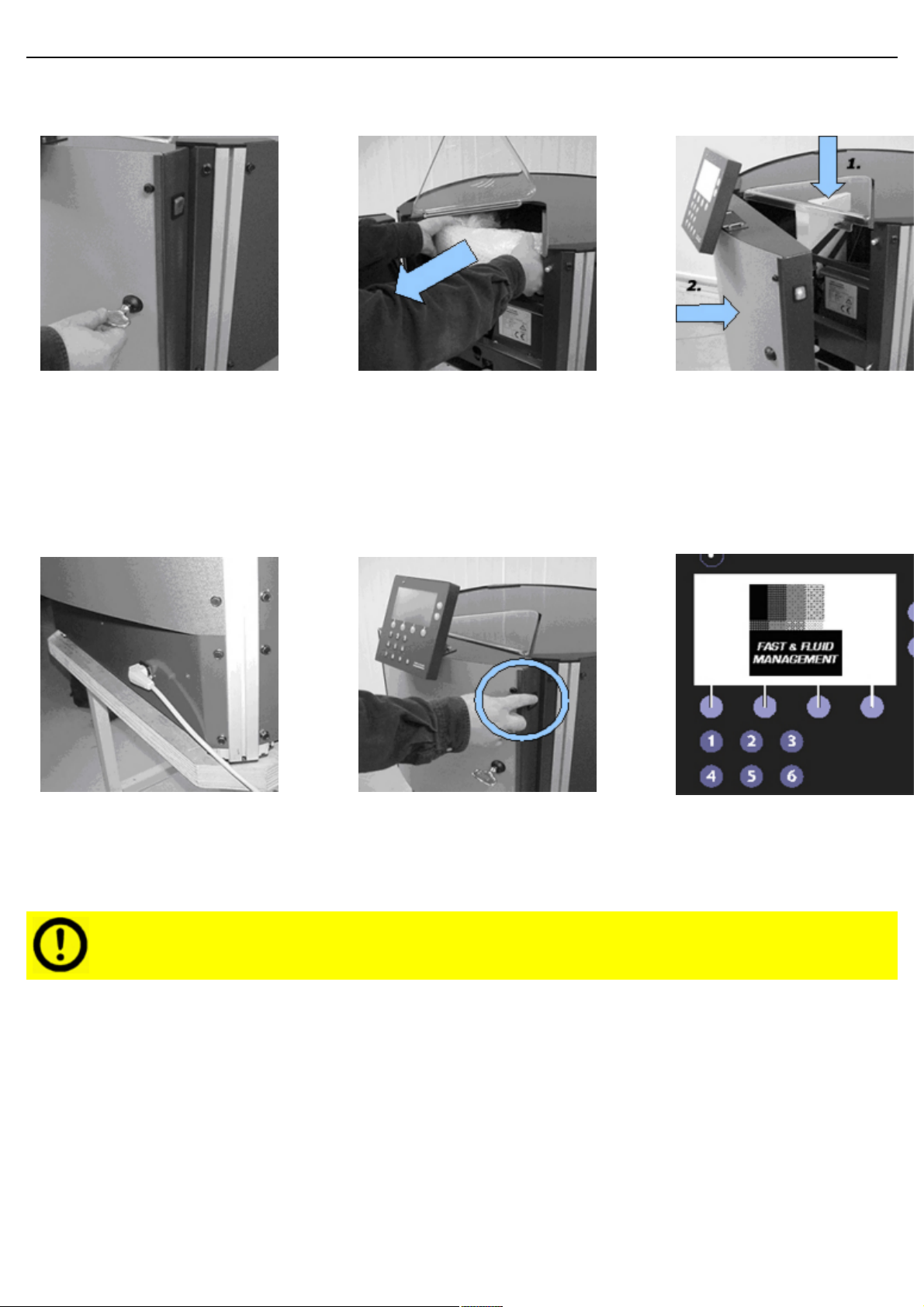

Step 2 - Remove transport protection

>

>

Unlock the front door, a

triangular key is supplied

with the machine.

Pull out the roll of foam.

Close the top lid first, then

close (and lock) the door.

Step 3 - Hook up TMHC to power outlet

>

>

Connect the power cable to a

wall socket.

Switch on the TMHC.

After the board initialisation

(appr 10 seconds), the screen

will show your logo.

Attention! Please do not switch on the machine before removing the

transport protection (roll of packing foam) as explained in step 2

p5

Page 6

© Fast & FLuid Management, TmHC manual

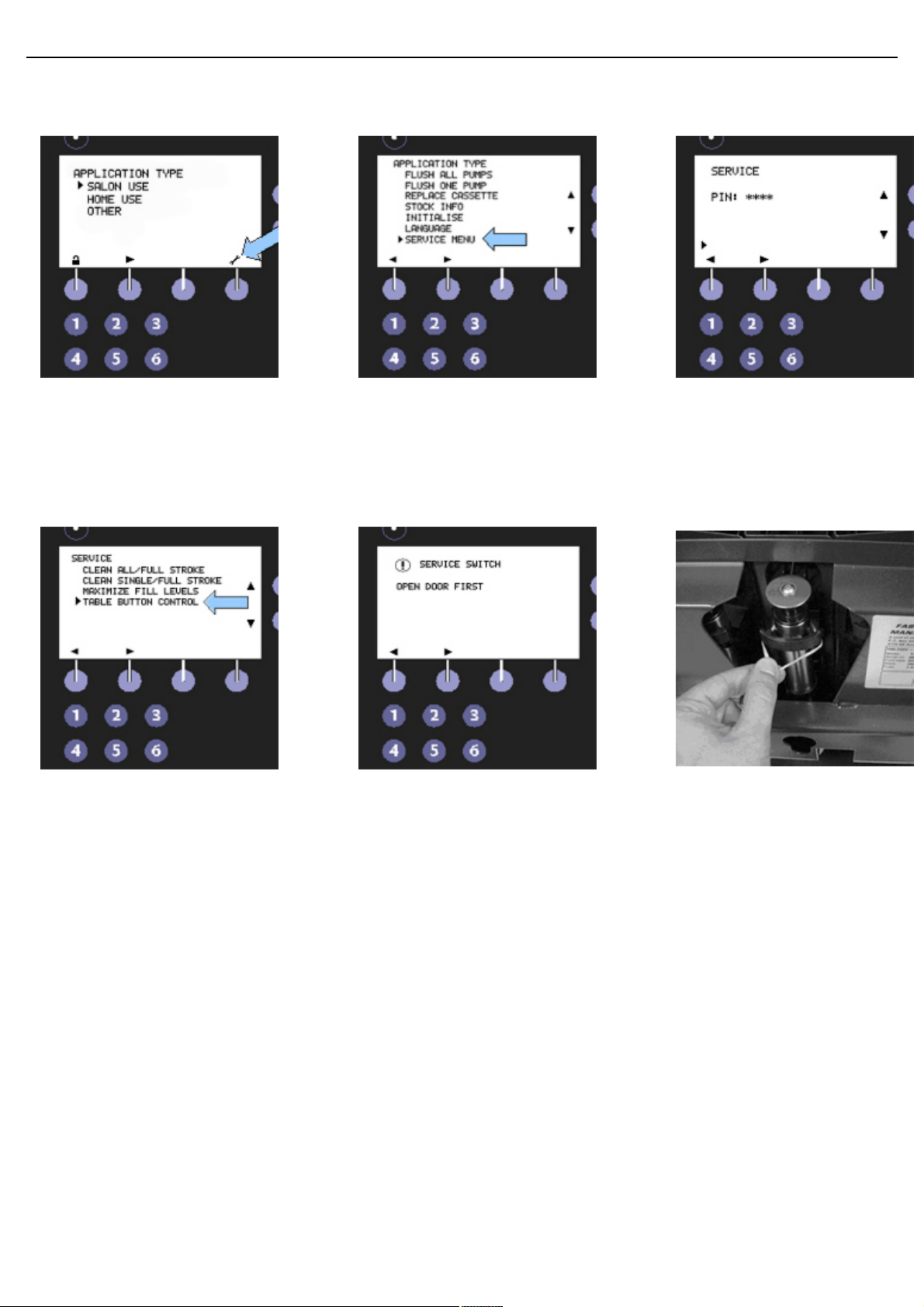

Step 4 - Place cassettes for first use

>

>

Press any key to enter the

main menu (the mac hine will

intialise once more), enter

the maintenance menu.

Enter the service menu and

press the ‘>’-key.

Enter your Personal

Identification Number

(pilot machines: 0252) and

press the ‘>’-key.

>

>

Choose the ‘button control’

function to allow m anual

positioning of the table.

Unlock and open door and

press the ‘>’-key.

In the pilot version of the

TMHC, pump handles have

been secured for

trans-portation. Remove the

one visible in the front

position.

p6

Page 7

© Fast & FLuid Management, TmHC manual

>

>

Lower the handle to its

bottom position.

Press the cassette down to

the snap. The handle will

automatically rise bac k up

Ensure the connection by

pressing the handle firmly

against the pump.

>

>

Hold key in front of sensors

on inside of the door to move

table to next position.

Repeat cassette placement

procedure for all positions.

Close the top lid first, then

close (and lock) the door.

p7

Page 8

© Fast & FLuid Management, TmHC manual

Step 5 - Prime (=flush) for first use

>

>

Return to the Service Menu

and choose the ‘m aximize fill

levels’ to reset the pouch

level parameters.

Place an empty container and

choose the ‘clean all’ function

flush air from the system.

This will take a few minutes.

Viscose materials

(yoghurt-like) may need upto

5 strokes to fully purge.

For highly viscose products

requiring many prime

strokes, it may be practical to

flush these seperately.

Choose ‘clean single’.

p8

Page 9

Maintenance

Daily maintenance

>

>

Open the TMHC door and remove

the steel drip tray. Clean with

water if soiled.

Pull out the brush tray and rinse

with water. Refill with water,

approximately 30ml.

If severely soiled, the brush can

be removed from the tray for

cleaning.

© Fast & FLuid Management, TmHC manual

p9

Page 10

Service

When (re)placing the front panel on the door’s framework, make sure

the door is closed and locked. This guarantees the door’s relatively

flexible framework is ‘stiffened’ in the correct shape and position.

Pump & box holder module replacement

>

>

Choose: Maintenance >

Go To > Position and enter

desired value +6 to have the

defect module position to the

left-hand side of the TMHC.

Remove the left-hand side

panel by unscrewing its four

fasteners.

Remove screws on either side

of the pump.

>

>

The complete module can

now be shifted outward and

removed.

When placing the new

module, place ensure its rear

‘hook’ is correctly inserted in

its slot on the table. If not,

the back of the m odule will

not align.

Press the disc fully down and

the valve handle up.

In the unlikely event of a box holder or pump being damaged, we

suggest to replace the whole module.

© Fast & FLuid Management, TmHC manual

p10

Page 11

© Fast & FLuid Management, TmHC manual

>

All red-coloured components

are made of ABS. These

components can be recycled.

Inside the red square

pictured above (on the front

of the dispenser) are

electrical components that

can be recycled.

Contributing to the Protection of the Environment

Packaging Material

The packaging protects the machine against damage during transport. The packaging material was chosen

based on its limited impact on the environment and its inherent possibilities for waste-disposal.

The reuse of packaging material saves raw materials and produces less waste material. Generally speaking,

your supplier will take the packaging off your hands.

Discarding the Machine

Discarded equipment usually still consists of valuable materials. For this reason, do not simply throw your

machine out with the oversized refuse, but ask your supplier whether he will take the mac hine back.

If he will not, then enquire at your local government offices or ask a trader of raw materials what options

there are for recycling the material (e.g. scrap processing, electrical components and plastic (see below for

additional information).

p11

Page 12

© Fast & FLuid Management, TmHC manual

© Fast & FLuid Management, 2005

ww w.Fast-Fluid.com

p12

Loading...

Loading...