Page 1

Fast & Fluid Management

Manual TM300

English

version 11-2014

Page 2

Table of contents

Record of Changes 3

Introduction 4

Warrenty Regulations 4

Explanation of images 5

Safety Instructions 6

Installation 7

Installing the computer and the software 8

Operation 9

Agitation timer 9

Fill the brush tray (nozzle cleaning system) 10

Fill the canisters with colourant 10

Dispensing 11

Punch hole in Lid - Manual (optional) 11

Daily Maintenance 12

Weekly Maintenance 13

Monthly Maintenance 13

Troubleshooting 14

Service and Support 15

Replace fuse behind back panel 15

Specifi cations 16

Electrical wiring diagram 17

WEEE 18

2

Page 3

Record of changes

Rev Editor Date Change description

11-2011 TB 17-11 First release

11-2014 TB 11-11 Add Power consumption and IP value

3

Page 4

Introduction

By selecting a Fast & Fluid Management Color Dispenser you have opted for a product which is the result

of intensive research. Top-quality components, craftsmanship and a modern ergonomic design all serve to

guarantee a long service life and a high degree of user friendliness.

The machine complies with Council Directives on machines, on electromagnetic

compatibility, and on electrical equipment intended for use within given voltage limits, as enacted

by the Council of Ministers of the European Community. The machine is furnished with a CE mark.

Warranty regulations

In these warranty conditions, ‘F&FM’ is understood to mean Fast & Fluid Management. The warranty

conditions incorporated into F&FM’s general conditions of sale are summarized as follows (for free general

conditions you can contact F&FM):

F&FM guarantees the proper operation of any goods which it supplies, for a period of one year, except

where a breakdown is the result of normal wear and tear. The cost of any inspection activities carried

out by F&FM, with the aim of establishing whether or not a breakdown is covered by the warranty will

be reimbursed by the other party if it transpires that the breakdown is not covered by the warranty. If

it transpires that a breakdown is covered by the warranty then F&FM will supply identical or equivalent

goods under the conditions referred to in point 6 of the general conditions of sale. The warranty obligation

described in this article only applies if the goods supplied by F&FM have been used in accordance with the

manual. Time spent on warranty-related activities, including travel time, travel costs and accommodation

costs, are charged at current rates.

In contrast to the above, F&FM will not be held to any warranty obligation if:

1. Repairs have been carried out, or attempted, by the other party or a third party, unless F&FM had

previously declined to repair the goods for a fair price;

2. F&FM demonstrates that the defect did not emerge during testing;

3. The other party fails to inform F&FM of the defect immediately, if possible either by letter and/or by

fax, providing full, accurate details and/or has failed to comply fully with F&FM’s instructions;

4. The other party has failed to use or treat the goods properly or in accordance with F&FM’s instructions;

5. The damage has been caused by incidents, beyond F&FM’s supervision, which have occurred either

during transport or installation.

In the following text, the expression “Software” will be understood to mean the standard computer software supplied by F&FM to the other party, recorded on a computer-readable storage medium, plus the accompanying documentation (Software Manual) and including any improved and/or new versions supplied.

The expression “processing unit” (PU) is understood to mean the machine for which and with which the

Software is supplied, and which is the sole machine on which the Software may be used.

The other party is authorized to copy the Software either in its entirety, or in part, (up to a maximum of 2

copies) for purposes of internal security. These copies will be furnished with the same marks, designations

relating to copyright and other registration numbers as the original version of the Software.

The other party will neither amend, translate, decompile nor adapt the Software, nor convert it into source code, without express written permission from F&FM. If the other party so requests, F&FM will provide

that party with the information required to render the Software interoperable with other software.

In the event that the PU experiences a breakdown, the other party may use the software on another

processing unit until the PU is again operational. The other party will inform F&FM of this within 5 days.

If it is a requirement that the Software be defi nitively transferred from the PU to another processing unit

then the other party shall request permission from F&FM, which will not withhold such permission on unreasonable grounds.

4

Page 5

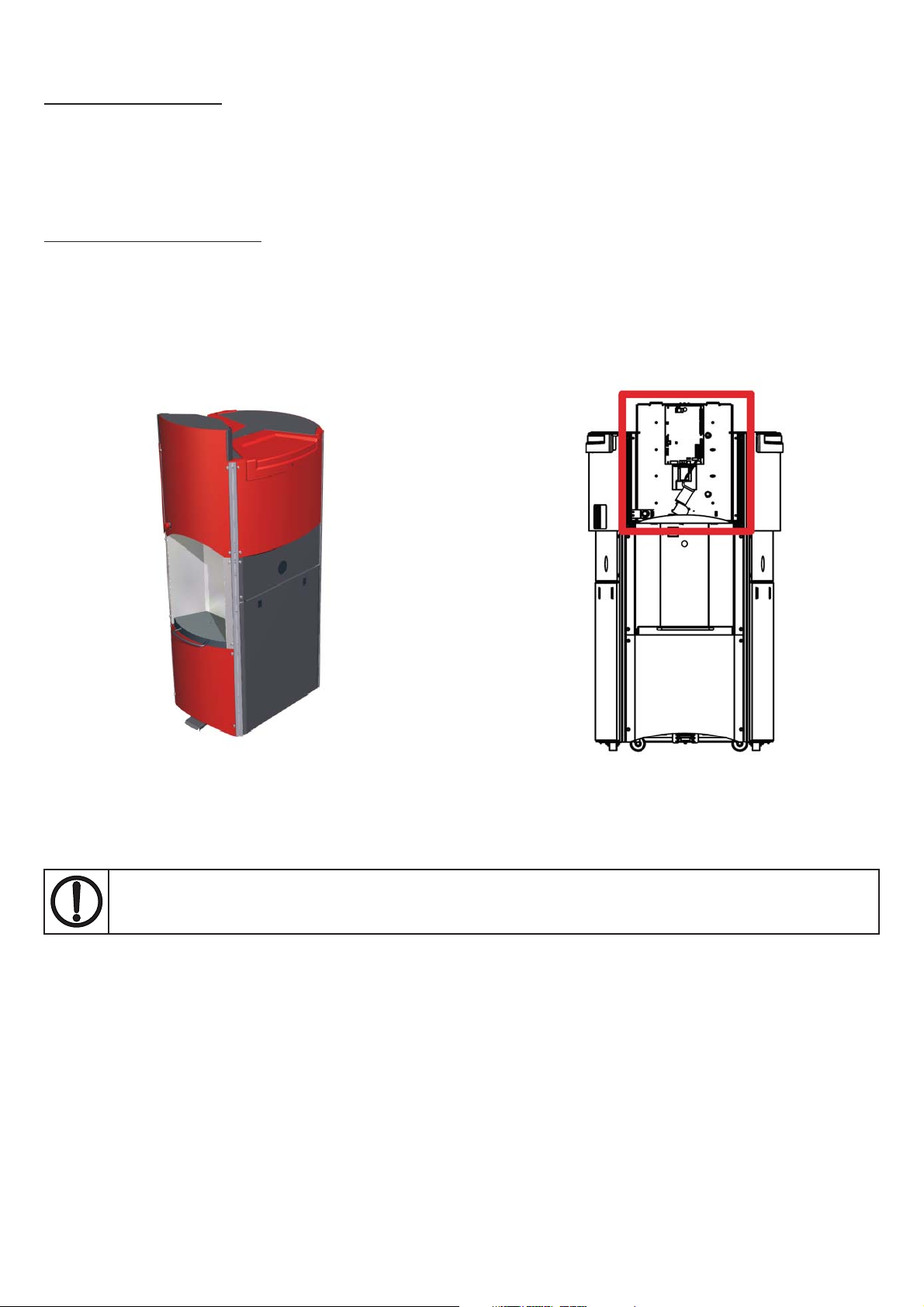

Explanation of images

1. Top lids

2. PowerBoard

3. Pump/canister assembly

4. Pump gripper spindle & spindle

stepper motor

5. Emergency stop

6. Valve gripper actuator

7. Computer cavity

8. Disc grip

9. Pump tube

10. Nozzle wiper

11. Nozzle

5

Page 6

Safety Instructions

Attention! Before installing the equipment and setting it in operation, please read the

instructions for use carefully. This is safer for yourself and prevents unnecessary

damage to the machine.

The manufacturer accepts no liability if the instructions below are not followed:

1. If a machine has been damaged (during transport, for example), do not attempt to set it in operation.

When in doubt, fi rst contact either your supplier or the F&FM service department.

2. The equipment should be positioned and connected up in strict accordance with the installation

instructions.

3. All local safety regulations and ordinances should be observed.

4. The machine may be connected only to a 230V/16A/50Hz or 110V/25A/60HZ earthed wall socket installed in accordance with the regulations.

5. Users should see to it that the machine is kept in good condition. Defective components should be

replaced.

6. In order to prevent physical injury, the doors should be closed and the paneling fi tted during normal

use.

7. All service activities (other than routine maintenance and adjustments) may only be carried out byqualifi ed technicians. See to it that the mains lead is always kept unplugged while repairs are being

carried out.

8. Because of the design of the valve, a nozzle drill may never be used. Cleaning is done by running thecleaning program.

Specifi c warnings and tips

Attention! Switching off the dispenser with the emergency stop will also

stop colorant agitation.

Attention! MOVING PARTS CAN CAUSE INJURY. Always turn off power

(e.g. by pressing emergency stop) before accessing moving parts.

6

Page 7

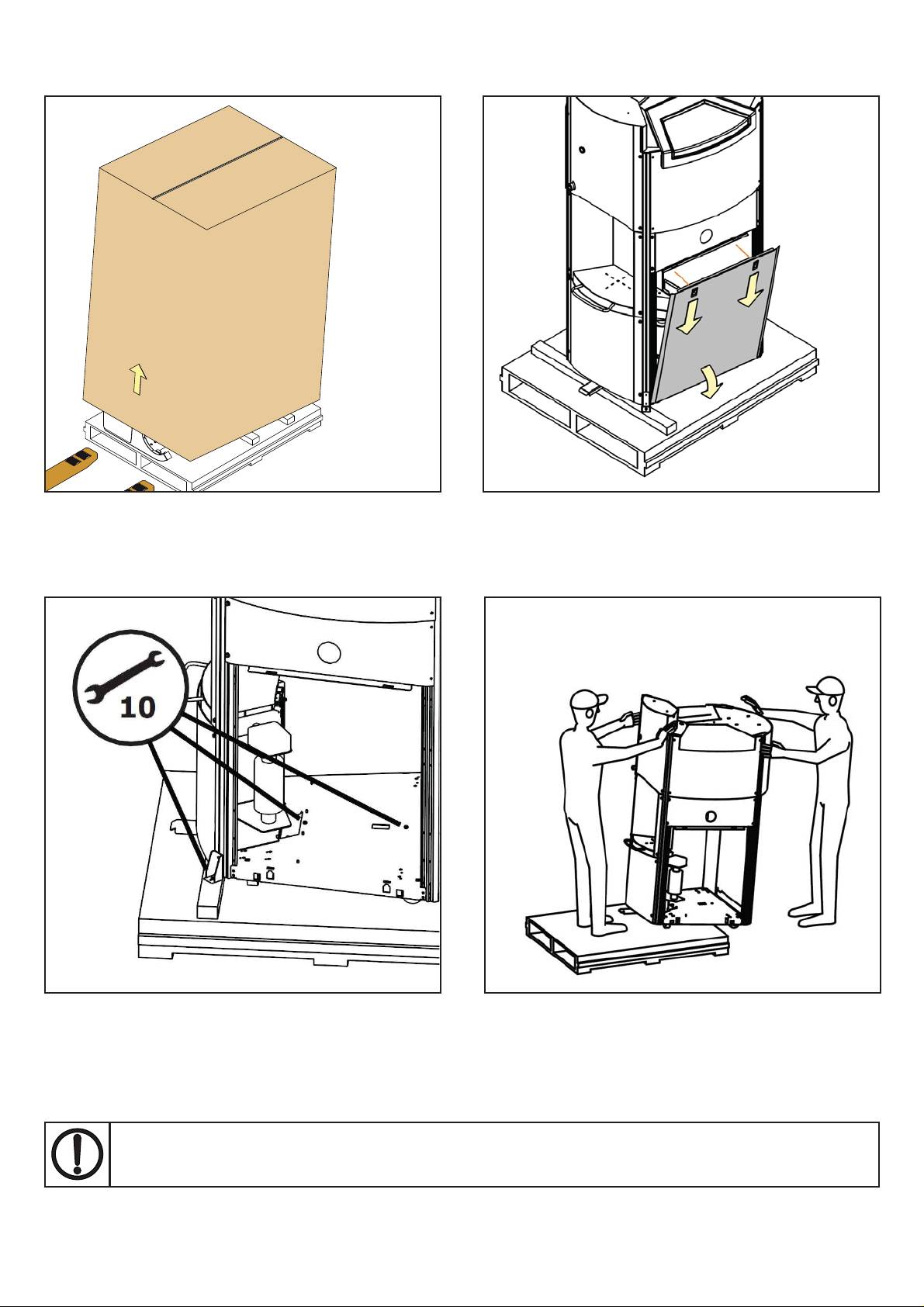

Installation

Step 1 - Detach the dispenser from its transport skid

>

Place the transport pallet near the defi nitive

location of the machine. Remove cardboard box,

plastic wrapping and accessory parts.

Remove one of either side panels.

>

Unscrew transport the transport screws

connecting the machine to the skid from the

inside of the computer cavity.

Detach the supporting wooden blocks.

Keep the fastening bows of the pallet, the two wooden beams and the two foam parts

for possible future transportation.

Move the machine off the pallet.

7

Page 8

Installing the computer and the software

Step 1 - Place the computer

>

Place the computer in cavity.

Connect the dispenser as indicated in the image

above.

Step 2 - Install the dispensing software

Install all necessary software provided by software supplier.

Use software to test basic functions of dispenser before fi lling.

Check software manual for testing procedure.

Consult the software manual for installation instructions.

8

Page 9

Operation

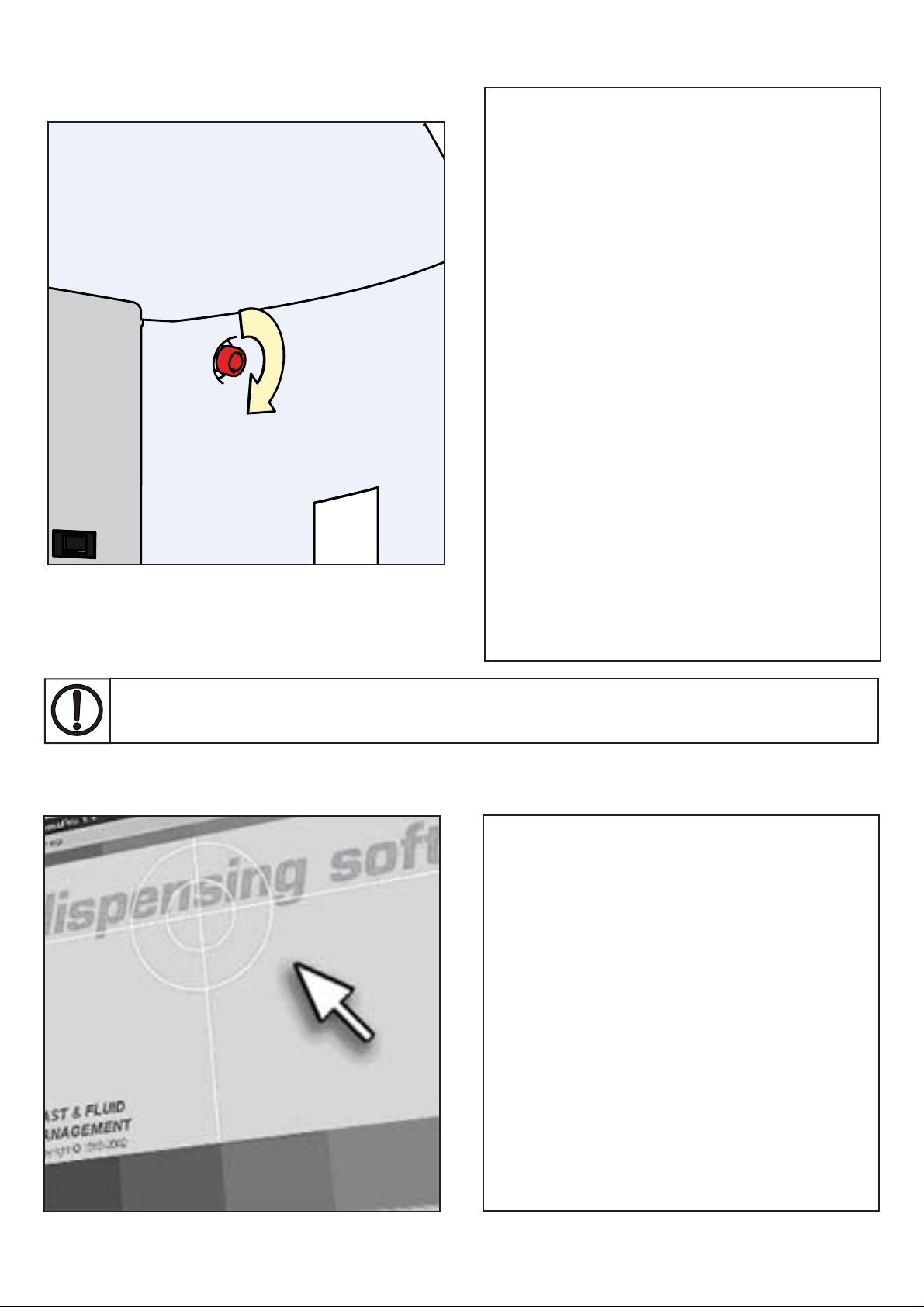

Switching ON:

Unlock the emergency stop button on the front of

the machine by turning clockwise. The machine is

automatically switched on when the power connector at the back of the dispenser is plugged into

a 220V or 110V wall socket.

Please be aware that the TintMaster series

dispensers are fi tted with sleeping timers as

standard. This means that after approximately 30

minutes the dispenser will enter a power saving

modus in which all secondary units (e.g. sensors)

are switched off automatically.

>

Stirring is not affected by this modus. To awake

the dispenser from its sleeping modus, perform

any command from the dispensing software or

press either of the can table buttons.

Switching OFF

Please note that with normal operation there

should be no reason to take the power off the

dispenser. In case the dispenser must be

switched off, there are several ways of achieving

this:

1. Shut down the computer and unplug the power

connector at the back of the machine.

2. Shut down the computer and switch the

internal power socket behind the bottom service

panel at the front of the machine.

3. Shut down the computer and press the

emergency stop button.

Caution! Switching off the dispenser with the emergency stop switch will also cause

the stirring mechanism to be turned off.

Agitation timer

The stirring time and interval can be altered from

its default settings*. This can be done through

the dispenser software, check your software

manual for instructions.

Please ask your paint supplier for optimal

agitation settings for your specifi c colorant

products.

>

* Default value is 180 seconds of agitation every

3 hours.

9

Page 10

Fill the brush tray (nozzle cleaning system)

>

Remove the brush tray at the left side of the

dispenser.

Use only cleaning fl uids recommended by your paint supplier.

Wrong materials can result in nozzle blockage and reduced accuracy.

Fill the canisters with colourant

Fill the container with water or an alternative

liquid proposed by your paint supplier.

Replace the brush tray in its original position.

Cleaning fl uid must be refreshed daily!

Access the canisters from either side top lid and

remove the canister lids.

>

Check your software manual for fi lling sequence.

Run software purge program twice to remove air

from system.

10

Page 11

Dispensing

Place the can at the center of the can table cross

hair. Lift the can table upward (unlock by pressing

down the foot pedal) *dispensers with optional

can lift only. Bring upward as far as possible. This

is the optimal dispensing position.

Ensure can opening is under the dispenser nozzle

and at its optimal height.

>

Choose desired formula as shown in software

manual. The turntable will subsequently rotate to

correct positions.

Remove can, dispensing is now complete.

Dispensing is mainly a software issue. Please read your software manual

thoroughly for all possible options.

Punch hole in Lid - Manual (optional)

Attention! Punch knife is very sharp. Do not hold while punching

11

Page 12

Daily Maintenance

Clean the brush tray, refi ll canisters and run morning program

>

Remove the brush tray and empty the container.

Clean the brush with water and refi ll the container

with correct fl uid (e.g. water).

Fill canisters if level is low and update levels in

software. Stir colorant beforehand.

Start software morning program to purge valves

and clean nozzles. Check your software manual

>

for details.

Use only cleaning fl uids recommended by your paint supplier.

Wrong materials can result in nozzle blockage and reduced accuracy.

12

Page 13

Weekly Maintenance

Remove spilt paint & colorant and refi ll canisters

>

Clean can table and outside parts with diluted

detergent.

Always close canisters and machine lids after refi lling.

Check canister content and refi ll if necessary.

Monthly Maintenance

Check and clean important functional parts

Remove back panel and check pump valve for

>

possible malfunctions (e.g. leakage or blockage).

Attention! MOVING PARTS CAN CAUSE INJURY. Always turn off power (e.g.

by pressing emergency stop) before accessing moving parts.

13

Page 14

Troubleshooting

Before calling your supplier or the service department, please check if you can solve the problem yourself.

If that does not work, you can call the service department for advice. Have the serial number and

dispenser type ready (these can be found on the silver CE sticker at the behind the service panel at the

front of the machine).

Use the table below to determine whether you can solve a problem yourself or if you need to call the

service department. You should never remove side panels from the dispenser, only certifi ed personnel are

allowed to do this. This table does not contain any error codes from the dispense software; please consult

the software manual for these.

Caution! MOVING PARTS CAN CAUSE INJURY. Always switch off the power (e.g. with

the emergency stop) before approaching moving parts.

Symptom Cause Action

Valve leaks through the outlet

opening

Canister connection leaks around

the suction point

Air is being fed together with

the paste

(New) software is not working Program not correctly booted Reboot computer & software

No power from power unit Not connected to power grid Check power cables

Colours are diffi cult to

reproduce

Poor monitor picture, or no

picture

Keyboard is not working Loose cable(s) Check cables

Air bubble in pump Prime the pump

Valve is defective Replace pump “Service”

Worn O-ring(s) Replace O-ring(s) “Service”

Air bubble in the pump Prime the pump

Canister is empty Refi ll canister

Piston is defective Replace pump “Service”

Software incorrectly installed Reinstall software

Fuse blown Remove plug from socket,

replace fuse

Mechanisms are dirty Clean and oil

Quality fl uctuations in paste

supplied

One or more pastes have

thickened

Turntable in wrong position Reset (press and unlock

Leaks around piston(s) Replace piston(s) “Service”

Monitor is switched off Switch monitor on

Loose cable(s) Check cables

Picture set too dark Adjust picture correctly

Monitor malfunctioning “Service”

Windows Regional setting is

incorrect

Defective cable(s) “Service”

Keyboard is defective “Service”

Contact paste supplier

Replace paste(s)

emergency stop button)

Check Windows software manual

Stirrer is not rotating Timer setting incorrect Set the timer correctly (software)

Loose cable Check cable

Defective cable “Service”

Defective motor “Service”

Turntable is not turning Piston rod positioned too high Set piston in lower position

Cable(s) loose Check cables

Cable or motor defective “Service”

14

Page 15

Service and Support

If necessary, you can get in touch with your supplier or the local service department, or contact the

manufacturer directly. If you contact the manufacturer, make sure that you have the model number and

serial number to hand. They can be found on the nameplate on the machine.

Fast & Fluid Management

P.O. Box 220

2170 AE Sassenheim, the Netherlands

Hub van Doorneweg 31

2171 KZ Sassenheim, the Netherlands

Tel: +31 (0)252 240 800

Fax: +31 (0)252 240 882 (service)

+31 (0)252 240 880 (general)

For more information please visit our website www.fast-fl uid.com

Replace fuse behind back panel

Spare fuse Damaged fuse

15

Page 16

Specifi cations

Number of canisters 12/14/16/18/20/24

Canister content 1.75, 3.5 [L]

EasyClick canister/stirrer (material) molded polymeric

Valves molded polymeric

Pump type piston pump

Pump sizes 1.64 [ounce]

Min. dispense 1/384 [fl .oz]

Accuracy 0.005 [ml/step]

Flow rate 0.4 [L/min]

Nozzle closures integrated

Maximal can height 45 [cm]

Can table depth 25 [cm] on benchtop model

25 [cm]

Cleaning system standard

Can detector standard on fl oor model

Stirring timer standard

Moveable can table option (only for fl oor model)

Heating set option (only for fl oor model with can table)

Manual punch 46 [mm] option (only for fl oor model)

Dimensions (H x W x D) 156 x 80 x 99 [cm]

Width with keyboard 120 [cm]

Power supplies 110 [V] +/- 10%, 50/60 [Hz]

230 [V] +/- 10%, 50/60 [Hz]

Power consumption, maximum 500 [W]

IP (Ingress Protection) classifi cation 32

CE approved & Patent applied.

Specifi cations subject to change without prior notice.

16

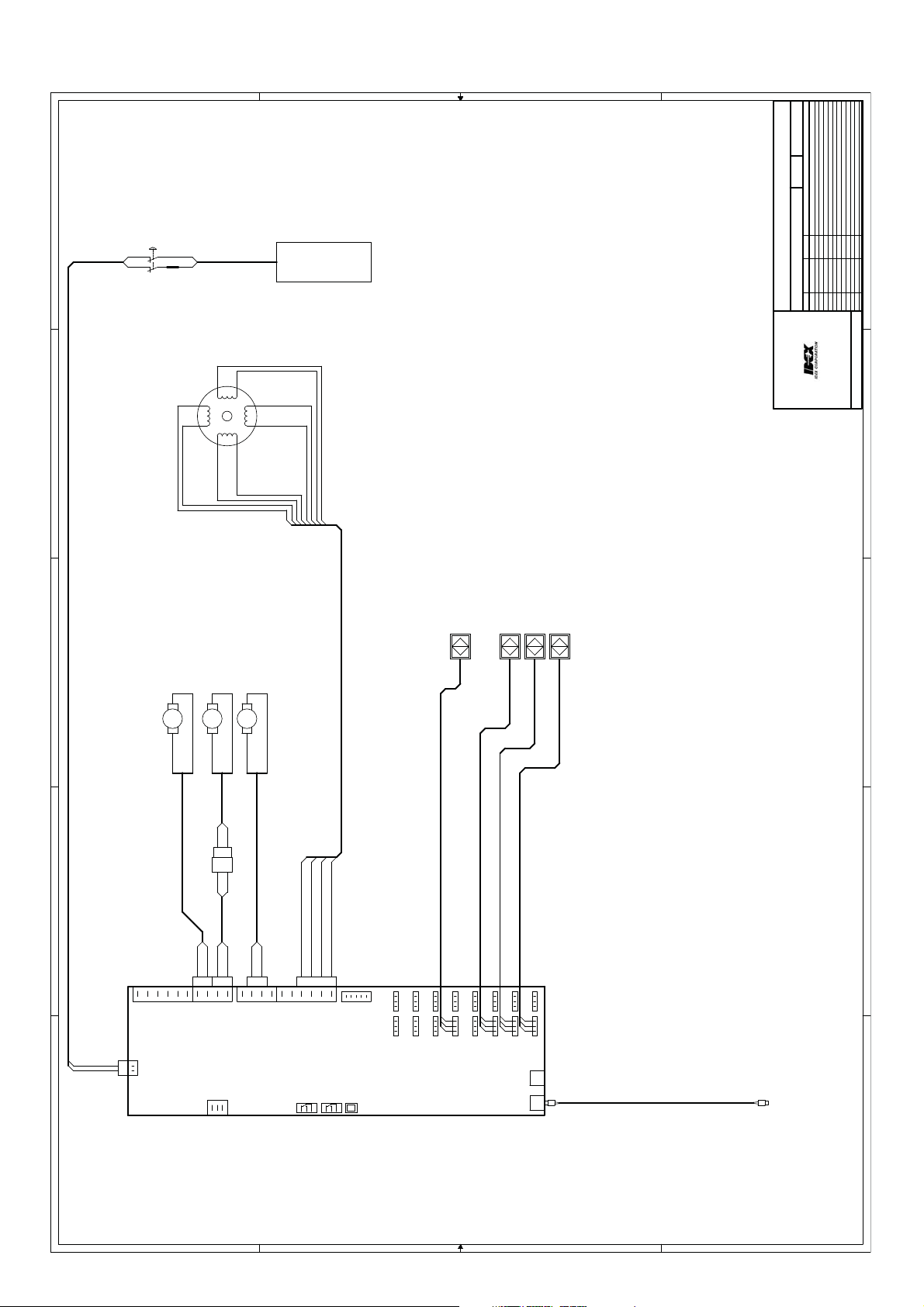

Page 17

Electrical scheme

of

11

Sheet

1.1

Version

1

3

2

4

8

MO TOR ASSY

11300 71

4

7

POWERSUP PLY ASSY 1862749

5

3

6

MO TOR ASSY

18145 41

WHITE

BROWN

BLUE

CABLE 31 1862742

2

M1

SHIELD

4P-STEPPE RMOTOR

MO TOR ASSY

18145 42

2

1

1

SU PPLY 110/230VAC

POWER SUPPLY 24VDC

MOTOR 1 ( 18 61988)

NEW 1 814540

50-60Hz, 1Am ax

First version

Added agit & ttmotorcable

NvB

1862618.DSN

Date Drawn Remarks

27-6-2008

TM300V1.1

Filename

Title

Revnr.

0.1 10-3-2008 NvB

0.2

FLUID

MANAGEMENT

SENSOR 6 (1 861980)

NEW: 181 4567

S6

TABLE POSITION

SENSOR 4 (1 861978)

NEW: 181 4563

SENSOR 2 (1 861976)

NEW: 181 4568

S1

SENSO R 1 1861975

CAN-PRESEN TS2STEPPER-H OMES4VALVE-CLOS ED

Removed agitmotor ext. cable

Changed name to 1.1, change partnmbrs. turntablemotor.

NvB

NvB

28-11-20081.0

18-11-20131.1

© 2001 Fluid Management

P.O.Box 220

Hub van Doorneweg 31

2170AE SASSENHEIM, The Netherlands

1

Friday, November 28, 2008

2

3

VALVE M OTOR

M32

-+

BLUE

BROWN

4

AGITATIONMOTOR

M35

TURNTABLEMOTOR

M33

-

+-

+

BLUE

BLUE

BROWN

BROWN

GREEN

RED

BLUE

BROWN

3

4

CABLE 33 1862744

BROWN

BROWN

BLUE

MGND3

HHB14

HHB13

MGND3

HHB12

HHB11

HHB10

HHB9

BROWN42=

BLUE0

5

- +

POWERSUPPLY

LK1

BROWN

BLUE

BLUE

HHB7

HHB8

MGND2

MGND2

HHB6

MGND2

MGND1

BLACK & WHITE/ORANGE or ORANGE

ORANGE & WHITE/BLACK or BLUE

YELLOW & WHITE/RED or YELLOW

RED & WHITE/YELLOW or RED

BROWN

BLACK

HHB5

J19

HHB4

HHB3

HHB2

HHB1

1

2

4

6

POWERBOARD 2001

COMMUNICATION

PORT #1 PORT #2

BLUE

BROWN

BLACK

BLUE

-S+ S+-

12722 30

TO RS232 PC

5

D D

C C

B B

A A

17

Page 18

WEEE

Packaging material

The packaging protects the machine against damage during transport. The packaging material was chosen

based on its limited impact on the environment and its inherent possibilities for waste-disposal.

The reuse of packaging material saves raw materials and produces less waste material. Generally

speaking,your supplier will take the packaging off your hands.

Discarding the Machine

Discarded equipment usually still consists of valuable materials. For this reason, do not simply throw your

machine out with the oversized refuse, but ask your supplier whether he will take the machine back.

If he will not, then enquire at your local government offi ces or ask a trader of raw materials what options

thereare for recycling the material (e.g. scrap processing, electrical components and plastic (see below for

additional information).

All red-coloured components are made of ABS.

These components can be recycled.

Caution! The canisters may contain chemical waste; bring this to your chemical depot.

>

Inside the red square pictured above (on the front

of the dispenser) are electrical components that

can be recycled.

18

Loading...

Loading...