Page 1

FAST & FLUID MANAGEMENT

SK450

ENGLISH

Page 2

Fast & Fluid Management - SK450

p2

Page 3

Fast & Fluid Management - SK450

SK450 Manual (EN)

5

EU Declaration of Conformity

5

Introduction & warranty

6

Main SK450 components

7

Safety instructions

8

Installation

9

Operation

12

Maintenance

16

Problem solving

17

Error codes

19

Fuses

20

Specifications

21

Electrical wiring diagram

22

Contributing to the Protection of the Environment

23

Table of Contents

p3

Page 4

Fast & Fluid Management - SK450

p4

Page 5

Fast & Fluid Management - SK450

product:

Automatic Shaker

model:

Skandex

type:

SK450

SK450 Manual (EN)

EU Declaration of Conformity

We,

Fast & Fluid Management, the Netherlands

A Unit of IDEX Corporation

Hub van Doorneweg 31

2171 KZ Sassenheim, the Netherlands

Declare that:

are in compliance with the following directives:

Machinery Directive 2006/42/EC

Low Voltage Directive 2006/95/EEC

Electromagnetic Compatibility Directive 2004/108/EEC

according to the following harmonized standards:

EN-ISO 12100-1, EN-ISO 12100-2, EN-ISO 13850 & EN-ISO 14121-1

EN 60204-1 Schaltplan

EN 61000-6-2, EN 61000-6-3, EN 61000-3-2 & EN 61000-3-3

Sassenheim, 01-06-2005

ir. F. Puijman

Vice President Manufacturing

Fast & Fluid Management, the Netherlands

A Unit of IDEX Corporation

p5

Page 6

Fast & Fluid Management - SK450

Introduction & warranty

Introduction

By selecting a Fast & Fluid Management shaker you have opted for a product which is the result of intensive

research. Top-quality components, craftsmanship and a modern ergonomic design all serve to guarantee a

long service life and a high degree of user friendliness.

The machine complies with Council Directives 89/392/EEC on machines, 89/336/EEC on electromagnetic

compatibility, and 73/32/EEC on electrical equipment intended for use within given voltage limits, as

enacted by the Council of Ministers of the European Community. The machine is furnished with a CE mark.

Warranty

In these warranty conditions, 'F&FM' is understood to mean Fast & Fluid Management. The warranty

conditions incorporated into F&FM's general conditions of sale are summarized as follows (for free general

conditions you can contact F&FM).

F&FM guarantees the proper operation of any goods which it supplies, for a period of one year, except where

a breakdown is the result of normal wear and tear. The cost of any inspection activities carried out by F&FM,

with the aim of establishing whether or not a breakdown is covered by the warranty will be reimbursed by

the other party if it transpires that the breakdown is not covered by the warranty. If it transpires that a

breakdown is covered by the warranty then F&FM will supply identical or equivalent goods under the

conditions referred to in point 6 of the general conditions of sale. The warranty obligation described in this

article only applies if the goods supplied by F&FM have been used in accordance with the manual. Time

spent on warranty-related activities, including travel time, travel costs and accommodation costs, are

charged at current rates.

In contrast to the above, F&FM will not be held to any warranty obligation if:

Repairs have been carried out, or attempted, by the other party or a third party, unless F&FM had

1.

previously declined to repair the goods for a fair price;

F&FM demonstrates that the defect did not emerge during testing;

2.

The other party fails to inform F&FM of the defect immediately, if possible either by letter and/or by fax,

3.

providing full, accurate details and/or has failed to comply fully with F&FM's instructions;

The other party has failed to use or treat the goods properly or in accordance with F&FM's instructions;

4.

The damage has been caused by incidents, beyond F&FM's supervision, which have occurred either

5.

during transport or installation.

p6

Page 7

Fast & Fluid Management - SK450

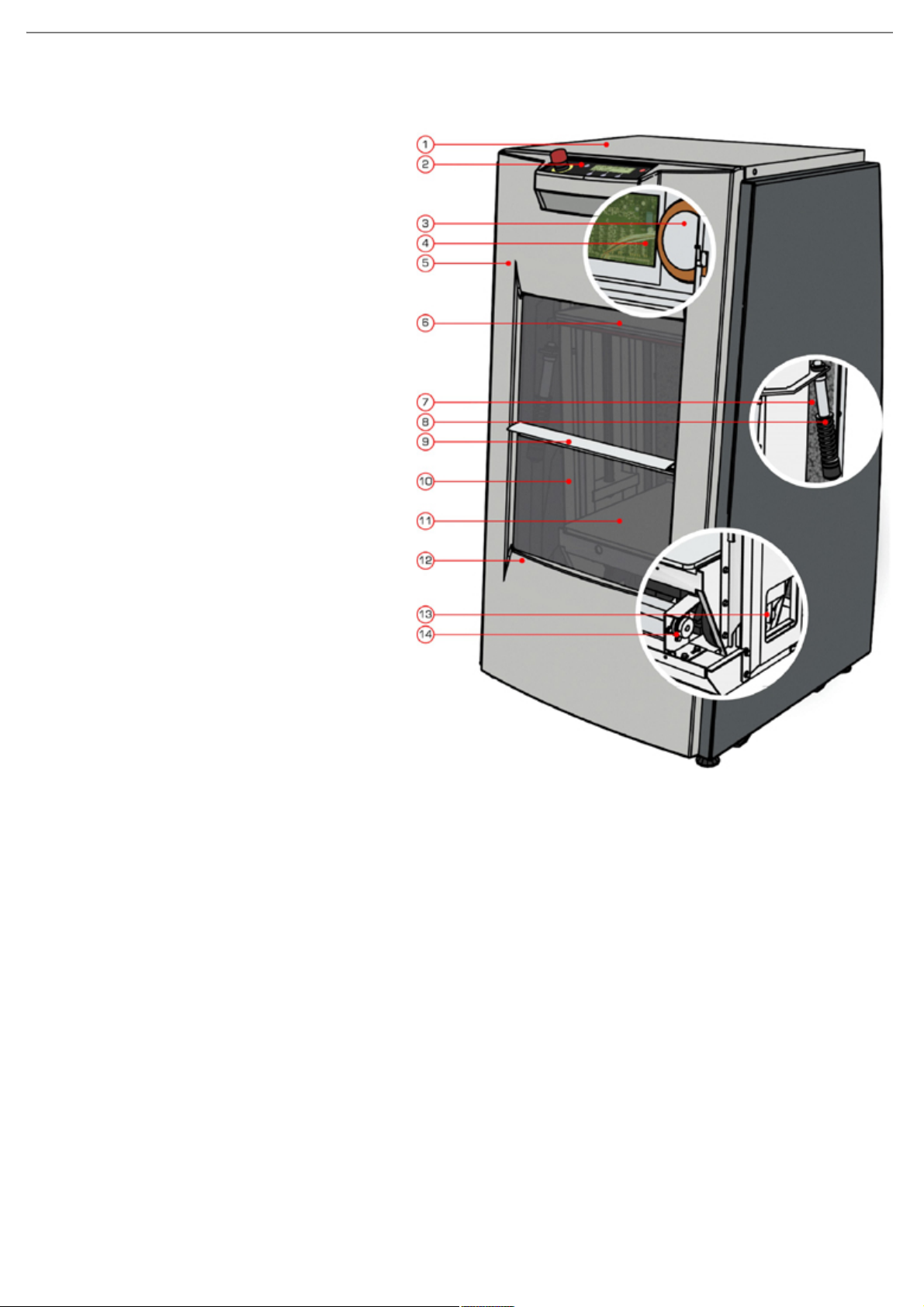

1.

Top lid

2.

Interface & Emergency stop button

3.

Transformer

4.

Power Board

5.

Removable front panel

6.

Clamping plate

7.

Sound reduction kit

8.

Super strut – suspension

9.

Door handle

10.

Shaker frame

11.

Can table

12.

Can mounting rim

13.

Excenter axle

14.

Shaker motor & driving belt

Main SK450 components

p7

Page 8

Fast & Fluid Management - SK450

Attention! Before installing the equipment and setting it in operation,

please read the instructions carefully. This is safer both for youself and

prevents unnecessary damage to the machine.

Attention! Failure to remove the frame lock correctly can result in

severe damage to your SK450 when in operation. Please take care!

Attention! To prevent damage, the SK450 may only be connected to

either 220V/16A/50Hz or 110V/25A/60Hz/50Hz power grids.

Attention! Only use the emergency stop button in case of a true

emergency. After pressing the emergency stop, wait at least 15 seconds

before unlocking it (turn clockwise). The SK450 will then reset and

unclamp the container.

Attention! MOVING PARTS CAN CAUSE INJURY. Always turn off power

(e.g. by pressing emergency stop) before accessing moving parts.

Safety instructions

General safety instructions

The manufacturer accepts no liability if the instructions below are not followed:

If a machine has been damaged (during transport, for example), do not attempt to set it in operation.

1.

When in doubt, first contact either your supplier or the F&FM service department.

The equipment should be positioned and connected up in strict accordance with the installation

2.

instructions.

All local safety regulations and ordinances should be observed.

3.

The machine may be connected only to a 230V/16A/50Hz or 110V/25A/60HZ earthed wall socket

4.

installed in accordance with the regulations.

Users should see to it that the machine is kept in good condition. Defective components should be

5.

replaced.

In order to prevent physical injury, the doors should be closed and the paneling fitted during normal use.

6.

All service activities (other than routine maintenance and adjustments) may only be carried out by

7.

qualified technicians. See to it that the mains lead is always kept unplugged while repairs are being

carried out.

Specific safety instructions in this manual

p8

Page 9

Installation

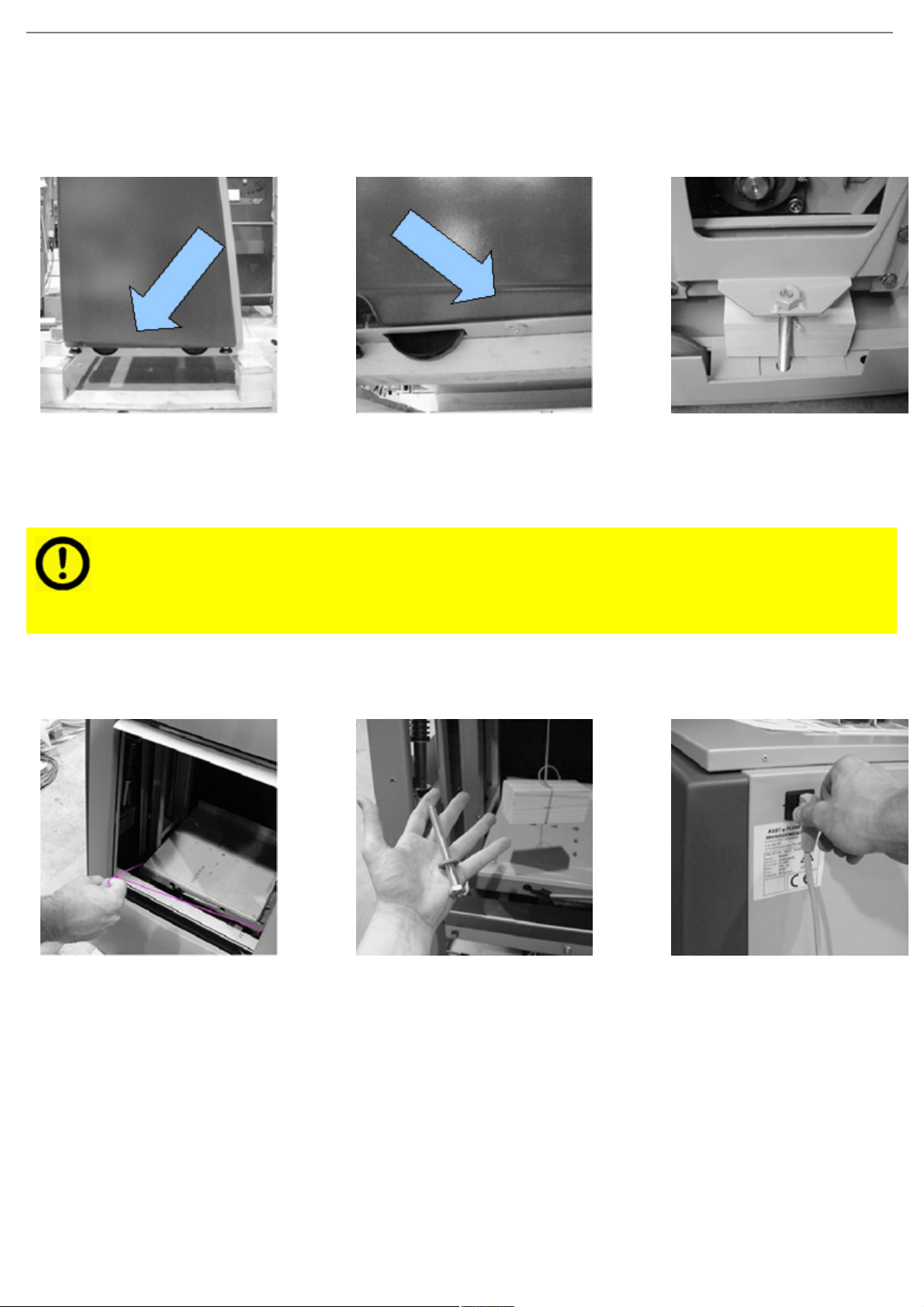

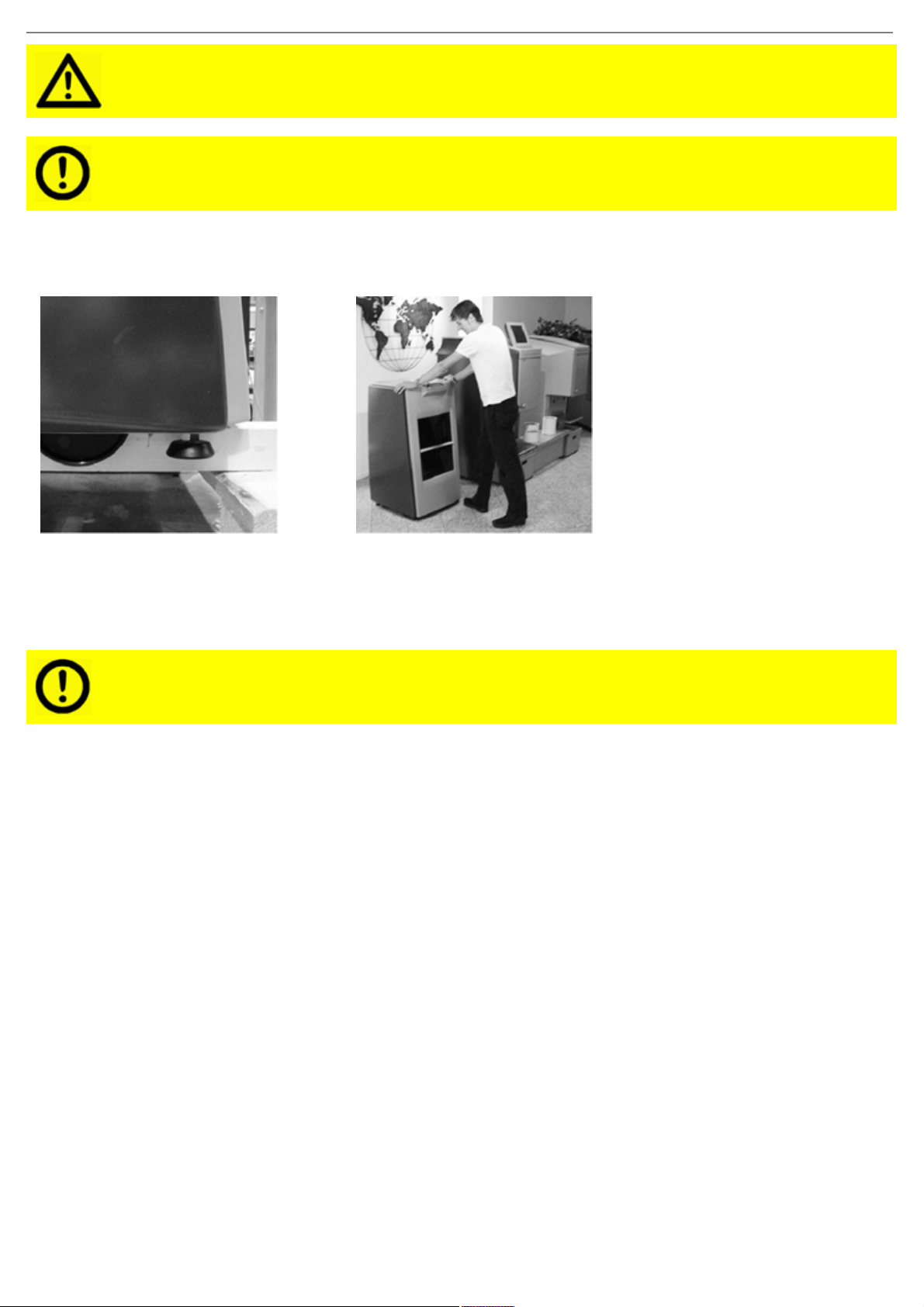

Step 1 - Unpack the machine and unlock the frame lock

>

>

Remove box and plastic foil. Note

the frame lock bolts on either side

of the machine.

Remove both bolts with a size 17

fork wrench.

By removing the bolts, the frame

lock’s wooden block is released.

Be careful not to damage the body and surfaces of your SK450 with any

tools while unpacking it. Take care not to accidentally close the door

before finishing installation, as it can then only be unlocked from User

Menu U2.

Step 2 - Remove the frame lock

>

>

Pull out cord to remove frame

lock’s loose parts.

Ensure all loose parts have

been removed – two bolts

and two wooden blocks.

Connect the SK450 to the

power mains before closing

the door.

Fast & Fluid Management - SK450

p9

Page 10

Fast & Fluid Management - SK450

Attention! Failure to remove the frame lock correctly can result in

severe damage to your SK450 when in operation. Please take care!

Please take care to store the frame lock for later use, it is essential for

correct transportation.

Step 3 - Detach shaker from its transport skid

>

Pull out cord to remove frame

lock’s loose parts.

Ensure all loose parts have

been removed – two bolts

and two wooden blocks.

For optimal mixing results and silent operation it is essential to correctly

level the machine and lock the adjustable feet.

p10

Page 11

Fast & Fluid Management - SK450

Step 4 - Place the machine in its final operational position

>

>

Lower the adjustable feet far

enough to lift the machine off

its wheels.

Take care to correctly level

the machine (by turning the

adjustable feet).

Lock all adjustable feet by

tightening the their separate

bolts.

Tip: before locking the adjustable feet, start a mixing cycle with a small

load (<5kg). While the SK450 runs, check if all four feet are firmly in

contact with the floor and then lock them.

Step 5 - Electrical connection

>

Connect the power cable to

the socket at the rear of the

machine.

Ensure the emergency stop is

unlocked (turn clockwise).

Attention! To prevent damage, the SK450 may only be connected to

either 220V/16A/50Hz or 110V/25A/60Hz/50Hz power grids.

p11

Page 12

Operation

Attention! Before operating your SK450 for the first time, please ensure

the frame lock was correctly removed (Click here to see)

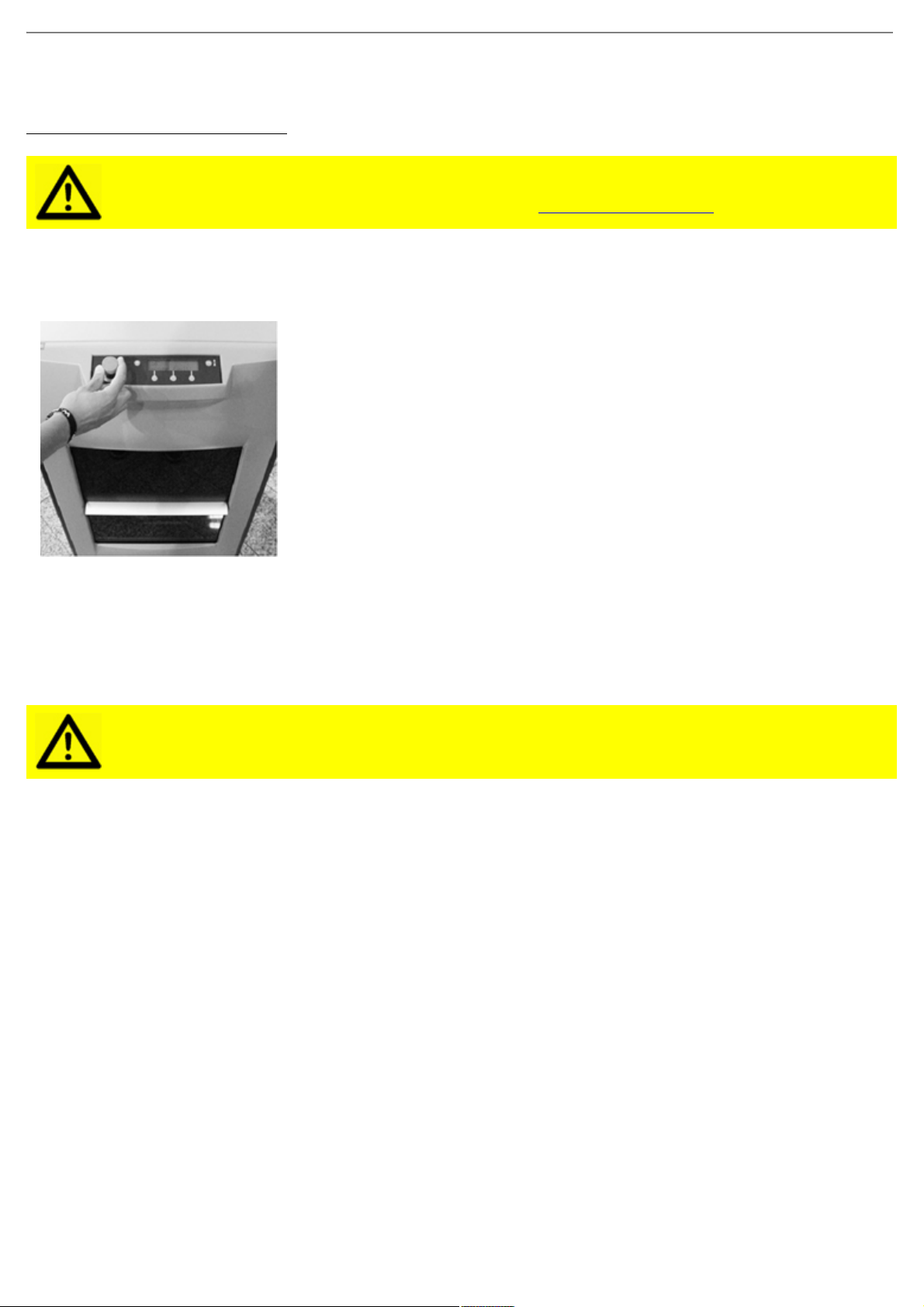

Step 1 - SK450 power management

Unlock the emergency stop button on the front

of the machine by turning clockwise. The

machine is automatically switched on when the

power connector at the rear of the shaker is

plugged into a 220V or 110V wall socket.

Please be aware that the SK450 is fitted with a

sleeping timer as standard. This means that

after approximately 15 minutes the machine will

enter a stand-by modus automatically. The

display will then show the Fast & Fluid

Management logo. To awake the machine from

its sleeping modus, press any of the interface

buttons, the normal interface will then reappear.

Please note that during normal operation there

should be no reason ever to take the power off

the machine. In case the shaker must be

switched off (e.g. for maintenance) there is only

one way of achieving this: unplug the power

connector at the back of the machine.

Turn the emergency stop

clockwise to unlock: the

screen displays the startup

actions and 'ready' message.

Attention! To prevent damage, the SK450 may only be connected to

either 220V/16A/50Hz or 110V/25A/60Hz power grids.

A - First time operation

Fast & Fluid Management - SK450

p12

Page 13

Fast & Fluid Management - SK450

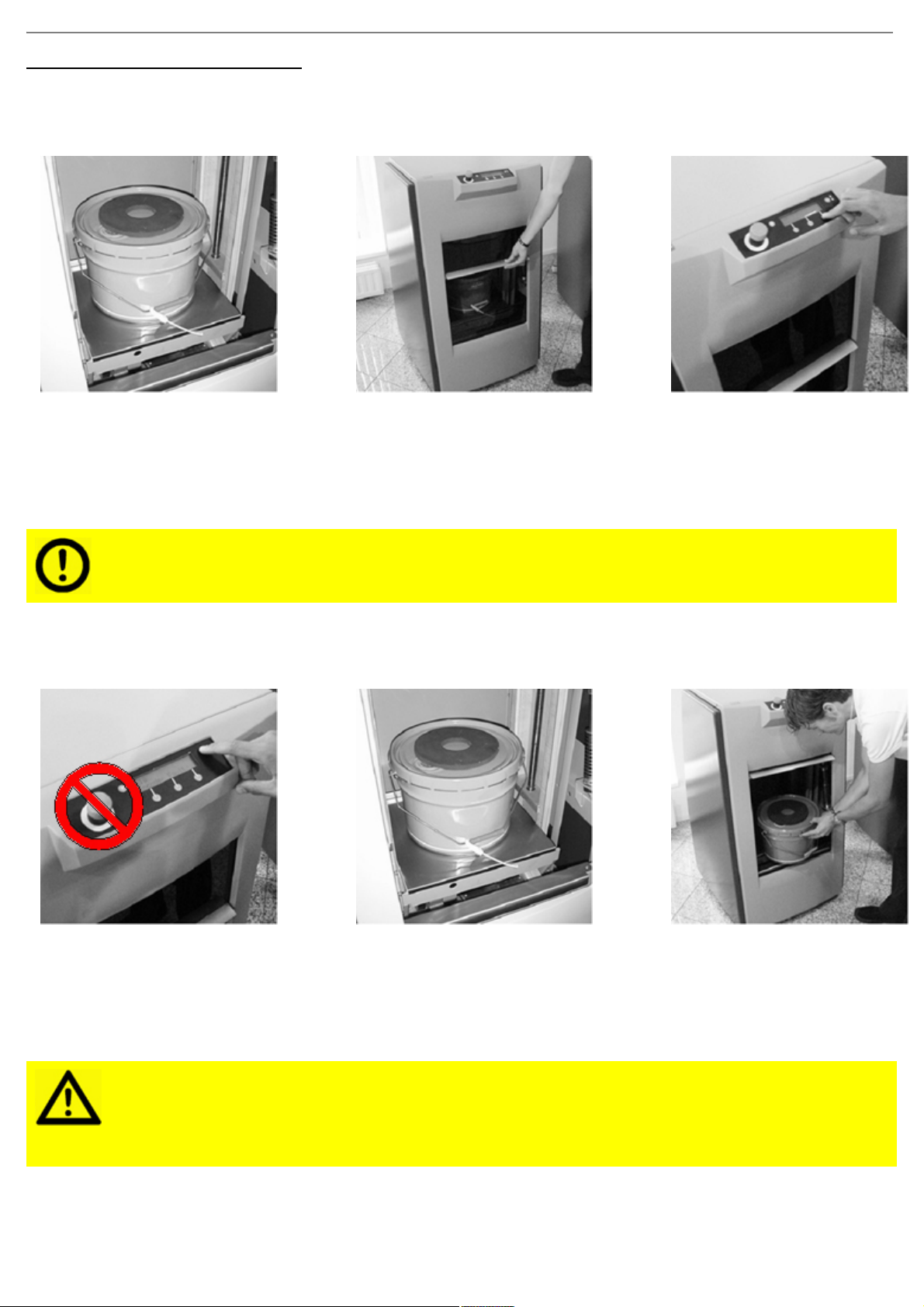

Step 2 - Correct placement of cans and other containers

>

>

Place one or more containers

at gravitational center of the

can table, between the

spindles.

Place filler disc on lid to

prevent displacement during

operation.

Use the hook to fixate the can

handle. When mixing more

than one can, use adhesive

tape.

Step 3 - SK450 Control interface

Emergency stop

for shutting off

power completely

Program key

sequential series

of mixing programs

Timer keys

program start

& can clamping

Stop & Up

program stop

& unclamping

Various user settings are available in the User Mode menu.

p13

Page 14

B - Operating the SK450

Step 1 - Place can, choose program and start program

>

>

Place the container in the can

table center, place filler disc

and attach hook to container

handle.

Close door. If your SK450 is

fitted with an electric door,

skip this step as it will close

automatically later.

Choose correct program and

press desired timing button.

Clamping and mixing will now

start.

Attention! The mixing program will not start unless the door is closed.

Step 2 - Program ends or is interrupted, remove can

>

>

To interrupt the mixing

program, press the stop

button. Use the emergency

stop only in case of calamity.

When the program finishes or

is interrupted with the stop

button, the SK450 will

unclamp automatically.

Open door and remove

container. If your SK450 is

fitted with an electric door, it

will open automatically.

Attention! Only use the emergency stop button in case of a true

emergency. After pressing the emergency stop, wait at least 15 seconds

before unlocking it (turn clockwise). The SK450 will then reset and

unclamp the container.

Fast & Fluid Management - SK450

p14

Page 15

Fast & Fluid Management - SK450

Upon entering the User

Mode menu, a screen will

appear showing your

SK450 ’s life in mixing

cycles and total hours.

Press the program button

to run through the different

user menu’s.

U2 - Lock or unlock door

The U2 option is used to

either lock or unlock the

door manually. This may be

necessary after a power

failure or accidentally

closing the door while the

power is down.

U3 - Move clamp plate

The U3 option is used to

force the clamp plate to

move either up or

downwards. This may be

necessary in case of the

clamp plate jamming in its

upper or lower position.

U4 - Standby interval

The U4 option is used to define

the amount of time before

entering standby modus.

C - User presets for the SK450

Certain SK450 software presets can be adjusted using the interface screen and buttons. To enter the User

Mode menu, press the emergency stop button and then unlock it while simultaneously keeping the program

button (P) pressed.

p15

Page 16

Maintenance

Keep your SK450 clean and free of paint residue

>

Remove all spilt paint from

accessible parts (especially

clamping plate spindles).

Use diluted detergent only

and Teflon spray only.

Though the SK450 is

designed to be completely

maintenance free, periodic

greasing of moving parts will

ensure it remains in top

shape.

Attention! MOVING PARTS CAN CAUSE INJURY. Always turn off power

(e.g. by pressing emergency stop) before accessing moving parts.

Fast & Fluid Management - SK450

p16

Page 17

Fast & Fluid Management - SK450

Attention! MOVING PARTS CAN CAUSE INJURY. Always turn off power

(e.g. by pressing emergency stop) before accessing moving parts.

Symptom

Cause

Action

The display is blank, no reaction

from machine after pressing

buttons

No supply voltage present.

Check main power supply

Emergency stop is active

Turn emergency stop clockwise

Main power supply is present

but the machine does not work

Door of the machine is open

Close the door

Emergency stop is active

Turn emergency stop clockwise

Machine is overloaded

Unload (max 40 kg)

Fuse blown

Shut power off and replace fuse

Door switch is defective

Call service

Key panel is defective

Call service

Circuit-board is defective

Call service

Extreme vibration when mixing

Machine incorrectly loaded

Place load in can table center

Machine is not level

Level the machine

Adjustable feet set incorrectly

Adjust all feet so they support the

machine properly and lock them into

position.

Suspension struts are defective

Call service

Clamping plate goes down,

then nothing happens

Excenter driver motor is defective or

a wire is broken

Call service

Clamping plate will not go

down

Clamping plate jammed

Use interface user setting U4

Fuse blown

Shut power off and replace fuse

Machine starts shaking before

the container has been

clamped

Too much spindle resistance

Clean the spindles and lubricate

Clamping plate incorrectly set

Call service

Clamping plate goes down and

back up again without mixing

Container is too low

Use taller container

Container is too weak (crushed)

Use stronger container or adjust

clamping force Call service

Problem solving

Introduction

Before calling your machine supplier or Service Department, please check whether you can solve the problem yourself. If

you cannot, then call the Service Department for advice. Have the model number and serial number at hand (these can be

found on the silver CE sticker at the back of the machine). Use the Problem Solving chart below to judge whether you can

solve a problem yourself or whether you need to call in the Service Department. Use the Error chart for error messages from

the software interface. The tool button

be called.

On no occasion remove side panels yourself, this may only be done by trained service personnel.

Problem Solving

means you cannot solve the problem yourself and the Service Department must

( )

p17

Page 18

Fast & Fluid Management - SK450

Too much mechanical resistance

Clean the spindle and lubricate

Clamping plate will not go up

after mixing

Clamping plate is jammed

Use interface user setting U4

If persistent, call service

Container unclamps while

mixing

Container(s) not centered

Replace container(s) in gravitational

centre.

p18

Page 19

Error codes

Error

Cause

Action

E01

Clamping motor power too low or bad electric

wiring

Call service

E02

Preset minimal clamping pressure not reached

Call service

E03

Door opened during mixing or door switch

defective

Keep door closed during mixing. If persistent,

call service

E04 - E06

SK450 Mainboard 5V or 12V circuitry overload

Call service

E07

Clamping plate reached minimal position

Place (taller) can

E08

Can shrunk during mixing

Use less fragile can

E09

Component overload

Call service

E10

No pulses received from encoder

Call service

E12

T5 (turbo FET) of 100V power supply

defective

Call service

E18

Clamping plate risen or loosened during

mixing

Check can position

E20 - E33

SK450 Mainboard component overheat (> 90°

Celsius)

Pause for cooling, check machine ventilation.

If persistent, call service

E41

EEPROM read error

Allow reset to default settings. If persistent,

call service

E71

SK450 Mainboard defective (T7 of T10)

Call service

E89

SK450 Mainboard defective (T8 of T9)

Call service

E99

Shake motor or wiring short circuit

Call service

E100

SK450 Mainboard defective (main motor

power feed)

Call service

E101

Power supply from wall socket too high

Check mains. If persistent, call service

E102

Power supply from wall socket too low

Check mains. If persistent, call service

Fast & Fluid Management - SK450

p19

Page 20

Fuses

Replace fuse at rear of SK450.

>

Remove mains connector and pull

fuse tray outwards.

The inner fuse is the (damaged)

one to replace, the outer is the

spare to replace it with.

Dispose of the burnt fuse and in

time, remember to get a new

spare, type 5x20/T10A (slow).

If problem persists, check mains

for power surges.

Fast & Fluid Management - SK450

p20

Page 21

Specifications

Maximum product weight

40 kg

Timer

electronic/programmable

Maximum product size (H x W x D)

45 x 35 x 35 cm

Minimum product height

7 cm

Clamping

automatic

Clamping pressure

variable

Product access

internal sliding door

Shaking speed

variable up to 720 rpm

Sliding table

option

Large can table

standard

Machine size (H x W x D)

116 x 72 x 61 cm

Machine weight (empty)

180 kg

Available colors available

side panels available in all (RAL) colors (middle

section RAL7042)

Power input

750W

Power supply

230V/16A/50Hz or 110V/25A/60Hz/50Hz

CE approved & Patent applied.

Specifications subject to change without prior notice.

Fast & Fluid Management - SK450

p21

Page 22

Fast & Fluid Management - SK450

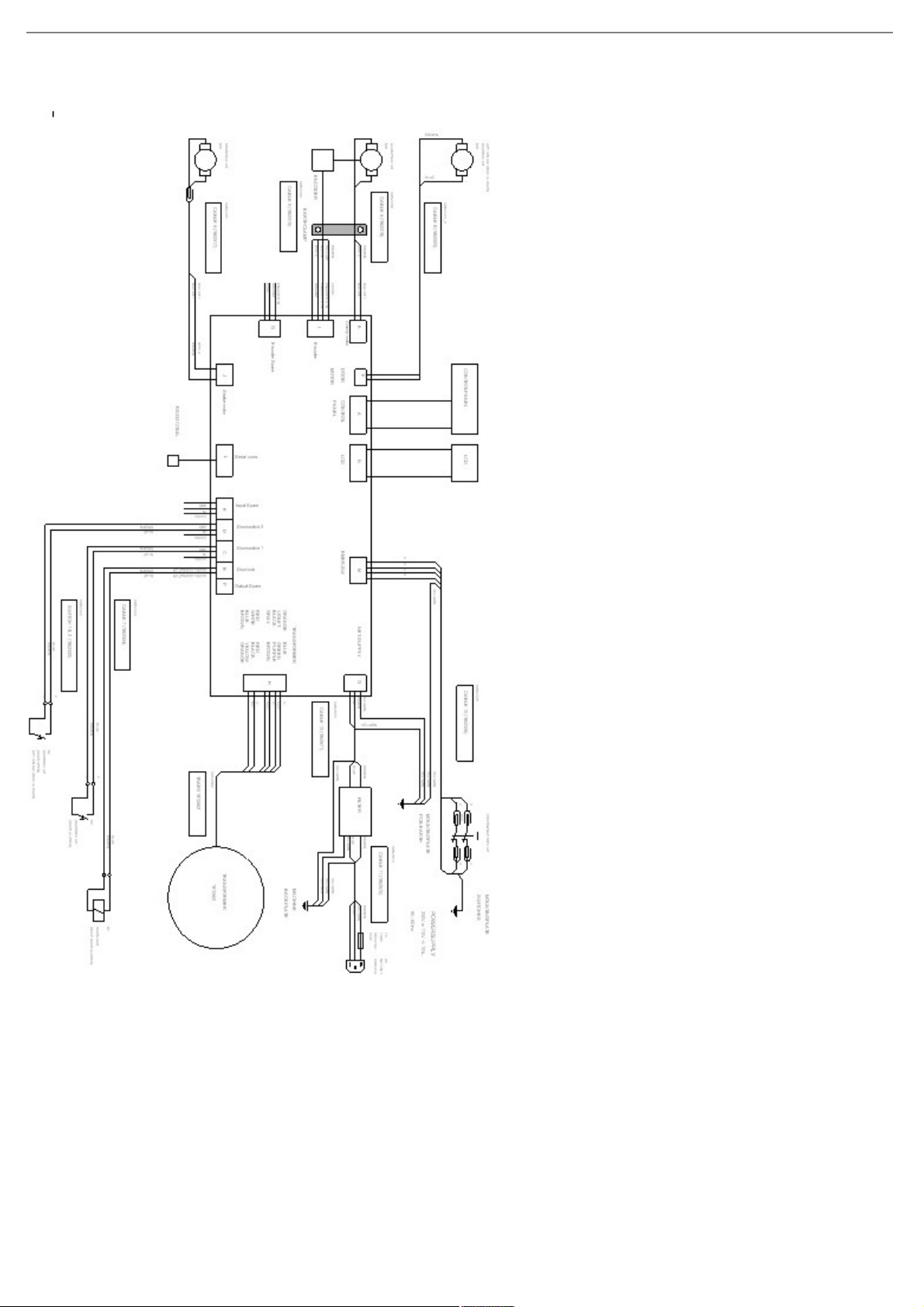

Electrical wiring diagram

SicherheitsanweisungenBetrieb

p22

Page 23

Fast & Fluid Management - SK450

>

All red-coloured components

are made of ABS. These

components can be recycled.

Inside the red square

pictured above (on the front

of the dispenser) are

electrical components that

can be recycled.

Contributing to the Protection of the Environment

Packaging Material

The packaging protects the machine against damage during transport. The packaging material was chosen

based on its limited impact on the environment and its inherent possibilities for waste-disposal.

The reuse of packaging material saves raw materials and produces less waste material. Generally speaking,

your supplier will take the packaging off your hands.

Discarding the Machine

Discarded equipment usually still consists of valuable materials. For this reason, do not simply throw your

machine out with the oversized refuse, but ask your supplier whether he will take the machine back.

If he will not, then enquire at your local government offices or ask a trader of raw materials what options

there are for recycling the material (e.g. scrap processing, electrical components and plastic (see below for

additional information).

p23

Page 24

© Fast & Fluid, 2007

ww w.Fast-Fluid.com

Loading...

Loading...