Page 1

®

®

HARBIL

NSC80

Compact

Dispenser

Operating

Instruction

Manual

Part # - 4700230

Rev. F

10/01/12

Colorant

and

Page 2

CONFIDENTIAL

PROPERTY OF

(C) COPYRIGHT 2001

FLUID

FLUID

MANAGEMENT

MANAGEMENT

AS AN UNPUBLISHED WORK ALL RIGHTS RESERVED

This material cannot be copied or disclosed to others without

the prior written permission of

FLUID

MANA

Fluid Management

GE

MENT

®

.

A Unit of IDEX,

Corp.

1023 Wheeling Road

Wheeling, Illinois 60090-5776

Voice (847) 537-0880

US (800) 462-2466

Fax (847) 537-5530

www.fluidman.com

Page 3

TABLE OF

CON

TENTS

NSC80 Ope

rating & Instruction Manual 3

Table Of Contents

ASSEMBLY & INSTALLATION - - - - - - - - - - - - - - - - - - - - - - - 5

ASSEMBLY & INSTALLATION - - - - - - - - - - - - - - - - - - - - - - - 6

BASIC OPERATION - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 12

MAINTENANCE PROCEDURES - - - - - - - - - - - - - - - - - - - - - 13

PARTS: - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 14

Page 4

4

NOTES

Fluid na nt

Page 5

NSC80 Ope

rating & Instruction Manual 5

ASSEMBLY & IN

STALLAT

ION

ASSEMBLY &

INSTALLATION

INTRODUCTION

The Harbil NSC80 is a compact manual colorant dispenser that was

designed for exceptional reliability and ease of use. It is a nearly

maintenance free device that should deliver many years of reliable service.

Its features include:

• Heavy-duty components and a durable finish for long wear.

• Bottom agitation linked with rotation of the canisters.

• Special adjustable shelving to accommodate all can sizes.

SPECIFICATIONS

Height 60" (152.4 cm.) Max

Width 24" (609.6 cm.)

Depth 30" (762.6 cm.)

Weight 195 lbs" (88.5 kg.)

Motor 1/6 HP (Draws 3.0 Amps @ 115 VAC)

TYPICAL ELECTRICAL SUPPLY

See name plate for specific

120 V 10%, 60 Hz 15 Amp

information.

IMPORTANT:

If any damage is found, notify the carrier at

and arrange for inspection in order to

recovery. Claims for damage must be made

the consignee (YOU).The carrier assumes

responsibility upon acceptance of shipment

will not entertain any claims by the

(Fluid

Management).

consignor

once

claim

by

full

and

CAUTION:

To reduce the risk of Electric Shock or Injury, Use

Indoors Only.

Page 6

6

ASSEMBLY & IN

STALLAT

ION

ASSEMBLY &

INSTALLATION

ALL

BUSHINGS

VISIBLE

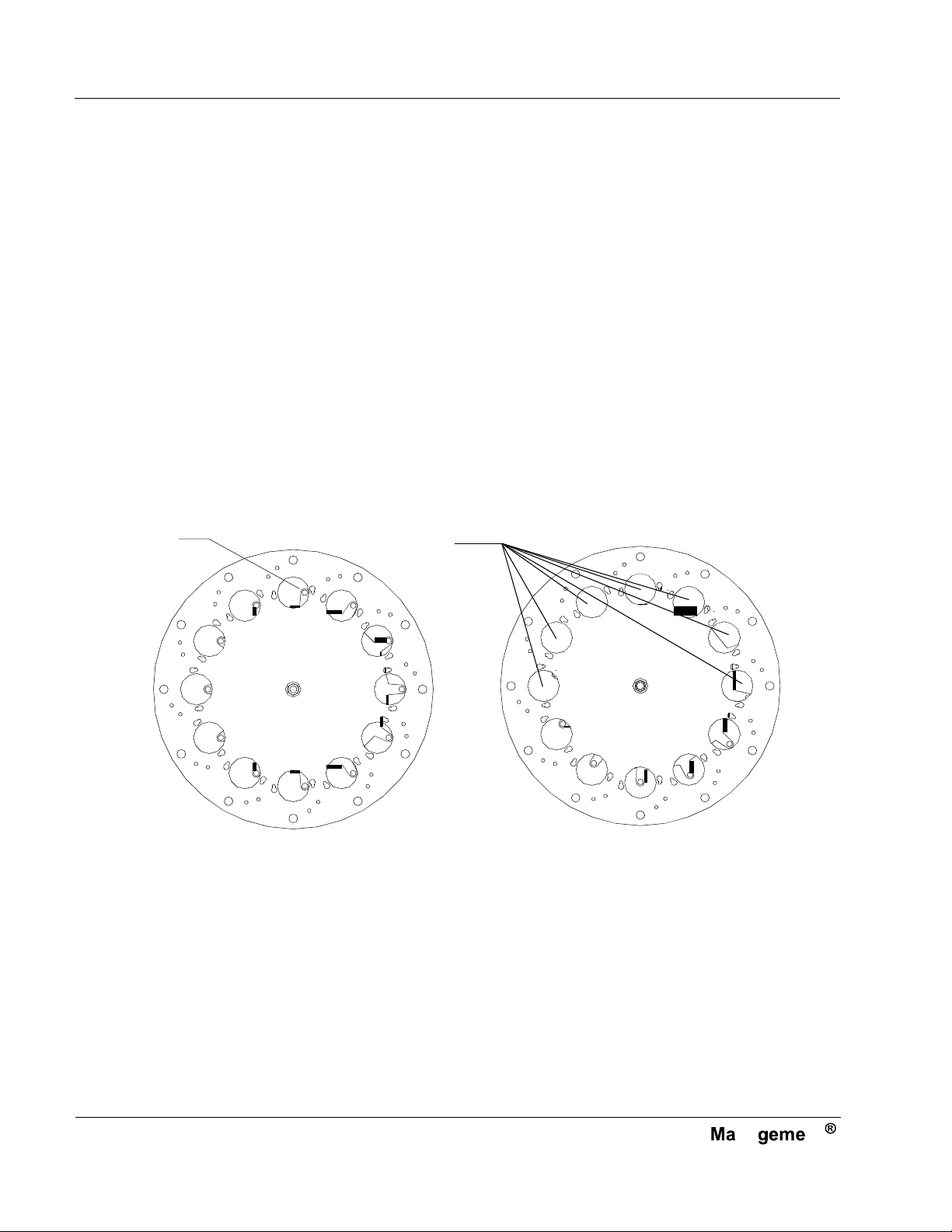

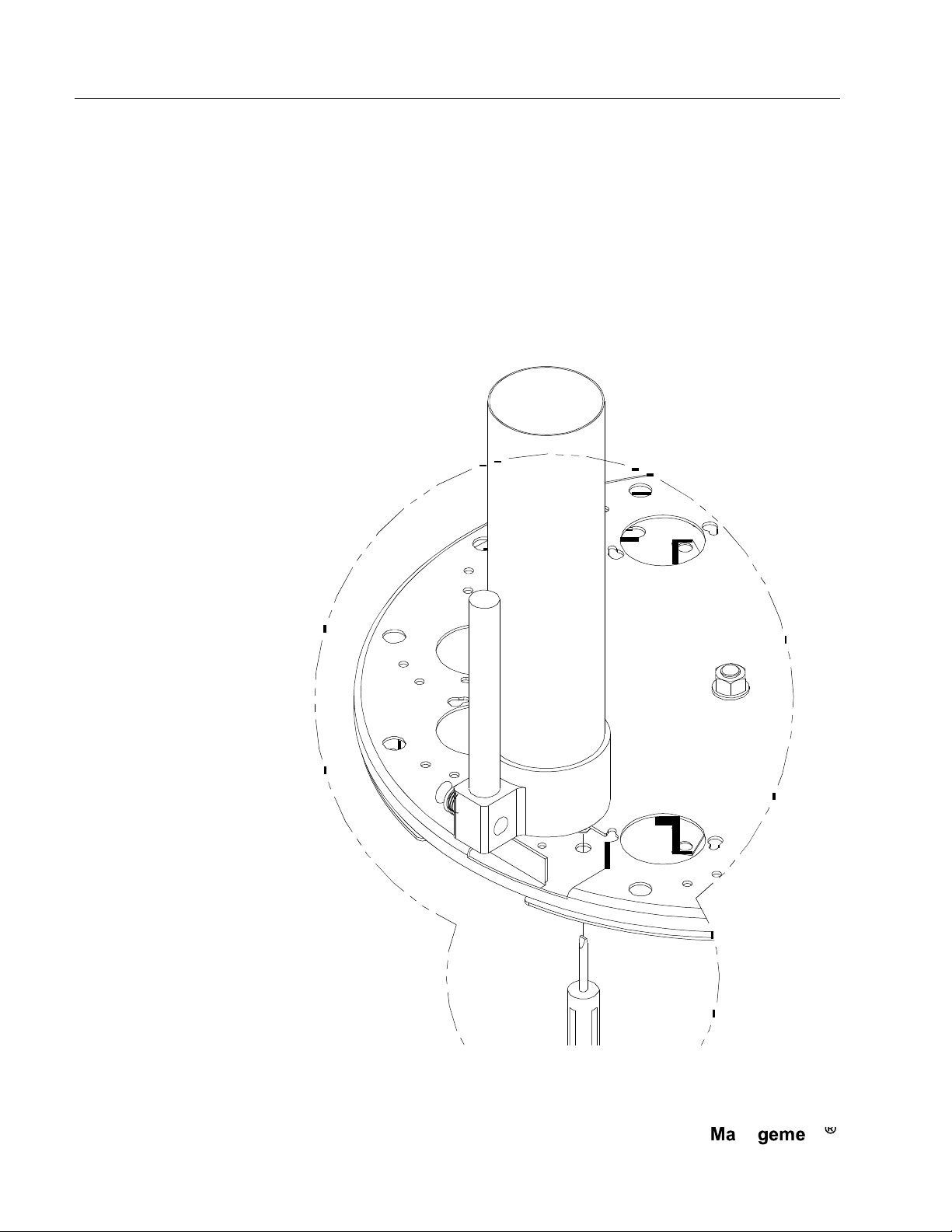

MOUNTING THE CANISTERS

The Harbil NSC80 requires only the simple fastening of the individual

canisters to the turntable. The canisters must be mounted in the proper order.

Do not fill the canisters before that are mounted.

It is critical that the crank be captured by the bushings that are part of the

star wheel assembly. For machine configurations containing less than 12

canisters, hole plugs are provided (FM P/N 25956) to cover the unused

canister positions.

1. Unplug the machine before installing canisters.

2. The drive star rotates freely around the drive cam mechanism under the

turntable. Rotate drive star with fingers (or other object) inserted through

the large holes. Rotate until all of the nylon drive star bushings are

visible through all of the large holes. (See Figure 1)

BUSHING

NOT

SHOWING

CORRECT

Figure 1 BUSHING

NOT

CORRECT

ALIGNMENT

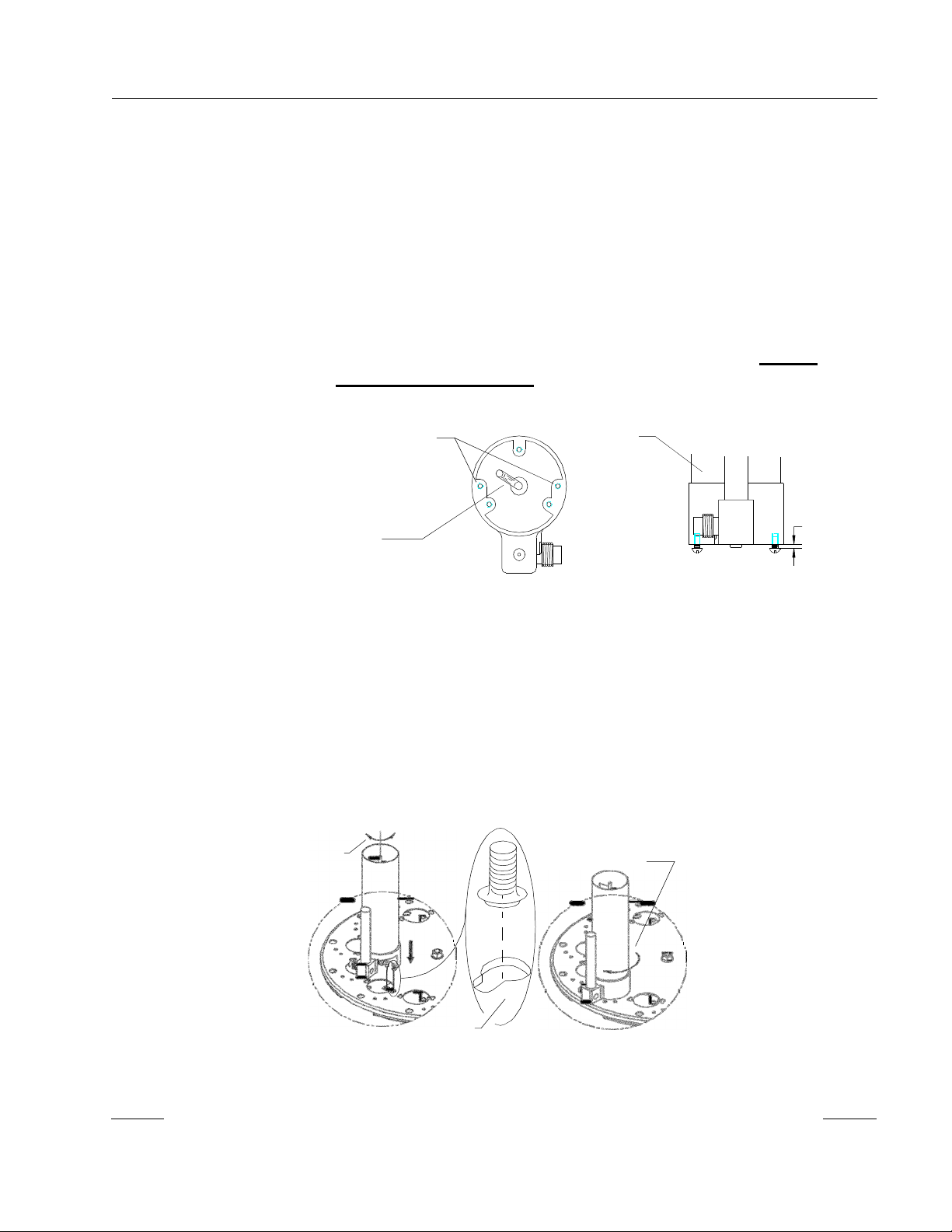

3. Insert two screws into the threaded holes on bottom of the canister.

Allow about 1/8”-1/4” of thread (3-5 threads) to be exposed, as shown in

Figure 2 on page 7.

4. Align the screw heads with the button holes on the turntable for the front

canister position and rotate the agitation blade until the agitation crank is

aligned with the nylon bushing. (Figure 3 on page 7)

Fluid na nt

Page 7

NSC80 Ope

rating & Instruction Manual 7

ASSEMBLY & IN

STALLAT

ION

5. Lower the canister into position, assuring that the agitation crank is

captured by the nylon bushing and that the screw heads pass through the

button holes, as shown in figure 3-A. Rotate canister clockwise locking

it into place as shown in Figure 3-B.

NOTE: The dispense port will fall through its hole, and the canister will sit flat on

the turntable.

6. While holding canister in position, secure the canister to the turntable

using a screwdriver. Access holes are provided at the bottom of the

turntable to tighten the two screws. (Figure 4 on page 8) Do not

overtighten these screws.

1/4”- 20

CANISTER

MOUNTING

HOLES

CANISTER

AGITATION

CRANK

BOTTOM

VIEW

Figure 2

CANISTER

1/8 to 1/4

1/8”-

1/4”

7. Verify that the agitation crank is engaged by the nylon drive star

bushing. This is done by turning the agitation blade inside the canister.

Resistance to turning indicates that the agitation rod is engaged. If the

agitation blade turns freely, the agitation rod is not engaged and the

canister must be re-mounted.

IF

AGITATION

BLADE

BY HAND,

CRANK IS

CAPTURED

BUSHING.

MOVES

THE

NOT

BY

ROTATE

TO LOCK

INTO

CLOCK-WISE

CANISTER

PLACE.

(A

)

BU T TO

N

HO LE

Figure 3 BUTTON HOLE

(B

)

MOUNTING

Page 8

8

ASSEMBLY & IN

STALLAT

ION

8. After installing the first canister, lower the index lever and rotate the

turntable to the next position.

9. Repeat steps 3-6 for each of the remaining canisters until all are

installed.

10. After completing canister assembly, connect machine to power, and turn

on the agitation switch. Verify that all the agitation blades are turning

properly.

Figure 4 SECURING

CANISTER

Fluid na nt

Page 9

NSC80 Ope

rating & Instruction Manual 9

ASSEMBLY & IN

STALLAT

ION

CONNECTING TO THE POWER SOURCE

GROUNDING

In the event of an electrical short circuit, grounding reduces the risk of

electrical shock by providing an escape wire for the electric current. The 3prong plug, equipped with grounding wire, must be plugged into a 3-slot

receptacle that is properly installed and grounded in accordance with all

local codes and ordinances.

DANGER:

GROUNDING

PIN

Figure 5 Grounding

Improper use of the grounding plug

result in a risk of electric

GROUNDED

OUTLET

Methods

shock.

can

DO NOT connect the grounding wire to a flat-blade terminal. The wire with

the insulation having an outer surface that is green (with or without yellow

stripes) is the grounding wire.

Check with a qualified electrician or serviceman if you are not sure how to

ground this machine. Under no circumstances should you modify the

plug if it does not fit the outlet.

WARNING:

After you have plugged the unit into

dedicated power line and leveled it,

to be sure that you have removed

shipping

materials.

a

inspect

the

Page 10

10

ASSEMBLY & IN

STALLAT

ION

Connect the 115 volt models only to a 115 volt outlet rated at at least 15

ampere. Connect the 220 volt models only to a 220 volt outlet rated at at

least 15 ampere. The equipment requires a single, grounded outlet.

EXTENSION CORDS

Extension cords for 220 VAC models are not recommended. If an extension

cord is to be used, it should not be combined with others. Use only a 3-wire

extension cord that has a 3-pole grounding plug. Power should be provided

by a 3-pole receptacle that will accept the plug on the product. Make sure

that your extension cord is in good condition. It must have # 16 AWG

conductors up to 25 feet long. An extension cord 25 feet long, but no longer

than 50 feet is permissible provided it has conductors of at least # 12 AWG.

It must be heavy enough to carry the current your product will draw. An

undersized cord can cause a drop in line voltage resulting in loss of power,

overheating and damage to the motor.

Under no circumstances should you modify the plug if it does not fit the

outlet.

Check with a qualified electrician or serviceman if you are not sure how to

ground this machine.

25

50

DISTANCE

ft

100

ft

150

ft

200

ft

250

ft

300

ft

400

ft

500

ft

ft

GAUGE

SIZE

220V

GAUGE

SIZE

115V

14 14

14 12

12

10

10

8

8

6

6

8

6

6

4

4

2

2

Fluid na nt

Page 11

NSC80 Ope

rating & Instruction Manual 11

ASSEMBLY & IN

STALLAT

ION

FILLING CANISTERS

After all of the canisters have been installed on the turntable, they can be

filled. Each canister has a maximum capacity of 2-1/2 quarts. It is

recommended that each canister be filled with two (2) quarts of colorant.

The maximum capacity of the pump is two (2) ounces.

The following steps represent the process by which the canisters should be

filled:

1. Locate the first canister and determine which colorant is to be placed

into that canister.

3. Shake of stir the colorant following manufacturer’s recommendations.

2. Place the appropriate decal on the canister.

4. Slowly, pour the colorant into the canister to the level of approximately

two (2) quarts.

5. Place the top on the canister.

6. Repeat these steps for each of the remaining canisters.

7. After all of the canisters have been filled, agitate by turning on the

agitation motor. This will release any air trapped in the colorant.

PRIMING OF PUMPS

Once the canisters have been both filled and agitated, the pumps attached to

each of the canisters must be properly primed. Follow these steps to prime

the pumps.

1. Locate the first canister.

2. Slowly pull the pump handle all of the way to the top of its stroke and

wait in this position for a count of approximately three (3) seconds.

3. Slowly press the pump handle all of the way down to the bottom of its

stroke.

4. Repeat these steps five (5) times.

5. Repeat steps 1 through 4 for each of the remaining canisters.

Page 12

12

BASIC O

PERATION

BASIC

OPERATION

This dispensing equipment is designed for ease of use. The following steps

represent the method by which a formula is to be dispensed:

1. Determine the formula of the color selected by the customer.

2. Refer to the formula book and select the proper base paint.

3. Remove the lid on the base paint.

4. Pull out the appropriate shelf and place the can of base paint on the shelf.

5. Press the indexing lever down and rotate the turntable to the position

indicated by the formula book.

6. Turn the pump gauge to center the indicator pointer.

7. Lift the pump handle up until the indicator is opposite the notch on the

gauge.

8. Turn the gauge into the notch that represents the desired amount of colorant per the formula book.

9. After the pump handle has been in this position for about three (3) seconds, slowly pull the valve lever down and hold in that position with the

left hand.

10. While holding the valve down with the left hand, turn the gauge to the

center of the indicator and slowly push the pump handle down all of the

way to the bottom of the stroke. This will dispense a metered amount of

colorant into the base paint. (Repeat this step as may be required by the

formula book.)

11. Referring to the formula book, Pull down the indexing lever and rotate

the turntable to the next position indicated and repeat these steps for

each of the colorants in the formula.

12. At this point in the process, the can of base paint has been tinted.

Remove the can, press the lid back on and mix appropriately.

Fluid na nt

Page 13

NSC80 Ope

rating & Instruction Manual 13

M

AIN

TENANCE

P

ROCEDUR

ES

MAINTENANCE

PROCEDURES

To ensure safe, dependable operation of the equipment, follow the

maintenance schedule detailed below:

DAILY

Cleaning & Filling:

• Agitate colorants every morning for five (5) to ten (10) minutes.

• Clean nozzles & outside cabinet surfaces with soap and water.

• Check canisters and fill as required.

WEEKLY

Cleaning & Nozzle Maintenance:

• Dispense a full measure of any colorant that has not been used

during the previous week. Dispense into a clean container and

return to the appropriate canister.

• Clean all accessible inside surfaces with soap and water.

GENERAL MAINTENANCE

If a nozzle becomes clogged, the obstruction can generally be cleared by

inserting a paper clip or similar object in the valve opening. Before inserting

such a device, open the valve by pulling the valve lever down and holding

while clearing the opening. BE SURE THAT THE VALVE IS OPENED,

AND STAYS OPEN WHILE CLEANING IN THIS WAY. IF THE

VALVE CLOSES AT ANY TIME DURING THIS OPERATION, THE

VALVE COULD BE DAMAGED. If colorant leaks develop at the top of

the pump, or if colorant can be observed on the pump piston rod, the pump

assembly must be repaired. The Pump Repair Kit (P/N 4223212) can be

purchased from the Fluid Management Customer Service Department. A

colorant leak at the bottom of the pump assembly generally indicates that the

pump assembly has been damaged. In this case, the valve assembly must be

replaced with either the Viton Valve Repair Kit (P/N 4231002) or the

Thiokol Repair Kit (P/N 4231011).

Page 14

14

PARTS:

PARTS:

EQUIPMENT MAINTENANCE LOG

SERVICE

DATE

RECORD MODEL NUMBER HERE: _________________________

RECORD SERIAL NUMBER HERE: _________________________

DESCRIPTION & PARTS REPLACED

(STATE IF UNDER WARRANTY)

SERVICED

BY

Fluid na nt

Page 15

NSC80 Ope

rating & Instruction Manual 15

1023 Wheeling Road |

Fax: 1

(

847

) 537

-

5530

Wheeli

ng, IL 60

090

|

|

SPARE PARTS ORDER

Fluid Management Parts Order Form

Fluid Management

A unit of

Photocopy and use this form to

Mail or fax orders to:

IDEX

| Phone: 1(800) 462-2466

☐☐☐☐Collect ☐☐☐☐Prepaid ☐☐☐☐Taxable

☐☐☐☐Tax Exempt

QUANTITY

Sold To: Ship To:

Purchase Order Number:

Ship Via: __________ _____

(Fax copy of exemption

PART

NUMBER

certificate.)

DESCRIPTION

UNIT

PRICE

Comments:

_________________________________________________

Signature

______________

Date

Page 16

16

PARTS:

TURNTABLE

25318

(16

CANISTER)

25033

(12

BUSHING

24039

CANISTER)

(12 CANISTER SHOWN)

CAM

25219

SPACERS

25224

NUT

07046

CAP

F0060T13XR

WASHER

25249

DRIVE

PLATE

25317

(16

25032

(12

CANISTER)

CANISTER)

WHEEL

25222

CIRCLE

25316

(16

25030

(12

SHEAR

CANISTER)

CANISTER)

MOTOR

8100001

LEVER

SPRING

4110906

MOUNTING

PLATE

25225

SWITCH

4000033

SHELF

4110909

COUNTER TOP MODELS

Fluid na nt

Page 17

NSC80 Ope

rating & Instruction Manual 17

PART

NO

4000033

4110906

4110909

8100001

F0030T13XR

5/8”-11

25219

CAM

25222

25224

25225

MOTOR MOUNTING

25249

5/8” FLAT

25318

CIRCLE SHEAR (12 CANISTER UNITS

DRIVE PLATE (12 CANISTER UNITS

TURNTABLE (12 CANISTER UNITS

ASSY

WHEEL

SPACER

TURNTABLE

POWER

LEVER

SHELF

DRIVE

CAP

WASHER

SWITCH

SPRING

MOTOR

PLATE

1 PER

1

5

10

1

1

1

1

1

1

1

1

Page 18

18

PARTS:

CAP

TURNTABLE

25318

(16

CANISTER)

25033

(12

CANISTER)

(12 CANISTER SHOWN)

NUT

07046

WASHER

25249

F0060T13XR

BUSHING

24039

CAM

25219

CIRCLE

25316

(16

25030

(12

SHEAR

CANISTER)

CANISTER)

WHEEL

25222

DRIVE

PLATE

25317

(16

CANISTER)

25032

(12

CANISTER)

SPACER

25224

MOUNTING

PLATE

25225

MOTOR

8100001

LEVER

SPRING

4110906

SWITCH

4000033

KNOB

4000008

FLOOR MODELS

Fluid na nt

Page 19

NSC80 Ope

rating & Instruction Manual 19

PART

NO

4000008

4000033

8100001

F0060T13XR

25219

25222

25224

25225

MOTOR MOUNTING

25249

5/8” FLAT

25316

TURNTABLE (16 CANISTER UNITS

25318

TURNTABLE (12 CANISTER UNITS

POWER

4110906

LEVER

DRIVE

5/8”-11

CIRCLE SHEAR (12 CANISTER UNITS

DRIVE PLATE (12 CANISTER UNITS

TURNTABLE (12 CANISTER UNITS

CAM

WHEEL

SPACER

WASHER

BLACK

SWITCH

SPRING

MOTOR

CAP

PLATE

ONLY)

ONLY)

1 PER

1

5

10

1

1

1

1

1

1

1

1

1

Page 20

20

PARTS:

PIN

8101106

CRANK

SHAFT

24382

AGITATION

BLADE

23242

CANISTER

4218000

Fluid na nt

Page 21

NSC80 Ope

rating & Instruction Manual 21

PART

NO

AGITATION

CRANK

TUBE (NOT

CANISTER (80

4220209 PUMP TUBE AND PISTON (NOT SHOWN)

4228206 PUMP CAP INDICATOR (NOT SHOW N)

4220220 PUMP TUBE AND PISTON (NOT

(METRIC UNITS ONLY)

4231000 VITON VALVE ASSY (NOT

(VITON OR THIOKOL. NEEDED ONLY, NOT BOTH.)

4231070 THIOKOL VALVE ASSY (NOT

(VITON OR THIOKOL. NEEDED ONLY, NOT BOTH.)

SHOWN)

SHOWN)

SHOWN)

8101106 PIN

8100311 TUBE BUSHING (NOT SHOWN)

1 PER

1 PER

1 PER

1 PER

1 PER CANISTER

1 PER CANISTER

1 PER CANISTER

1 PER CANISTER

1 PER CANISTER

1 PER CANISTER

1 PER CANISTER

Page 22

22

PARTS:

COVER

23245

(STANDARD)

24585

(FOR

SOLVENTS)

DRIVE

PLATE

25032

BOLT

02494

DRIVE

PLATE

25317

BOLT

02494

CANISTER

ASSEMBLY

25390

(1-OZ. PUMP W / VITON

4308001

(10-OZ. W / THIOKOL

TURNTABLE

25033

12 CANISTER SYSTEM

CANISTER

ASSEMBLY

25390

(1-OZ. PUMP W / VITON

4308001

(10-OZ. W / THIOKOL

COVER

23245

(STANDARD)

24585

(FOR

SOLVENTS)

TURNTABLE

25318

16 CANISTER SYSTEM

SEAL)

SEAL

SEAL)

SEAL

Fluid na nt

Page 23

NSC80 Ope

rating & Instruction Manual 23

PART

NO

25032 DRIVE PLATE (12 CANISTER UNITS)

MOUNTING BOLT, 14 X 20 X

CANISTER COVER

CANISTER COVER (FOR

2 PER

1 PER

1 PER

25033 TURNTABLE (12 CANISTER UNITS)

25316 TURNTABLE (16 CANISTER UNITS)

25317 DRIVE PLATE (16 CANISTER UNITS)

25390 CANISTER ASSEMBLY (INCLUDES PUMP & VITON

(1-OZ. PUMP

ONLY)

VALVE)

4000108 CANISTER ASSEMBLY (INCLUDES PUMP & THIOKOL VALVE )

(1-OZ. PUMP

4308002 CANISTER ASSY (INCLUDING PUMP & VITON

(METRIC UNITS

ONLY)

ONLY)

VALVE)

1 PER STATION

1 PER STATION

1 PER STATION

1

1

1

1

Page 24

Part No.

4700230

Rev. F

10/01/12

Fluid

Management

1023 Wheeling Road

Wheeling, Illinois 60090-5773

Telephone: (847) 537-0880

1-800-462-2466

Fax (847) 537-5530

www.fluidman.com

Part No.

4700230

Rev. F

10/01/12

Loading...

Loading...