Page 1

GyroMixer | End User Guide

Getting Started

Maintenance and Care

Troubleshooting

Service Parts

Warranty

Part No: 4708000

Rev. I

07.30.10

Page 2

©2010 Fluid Management as published work all rights reserved.

Fluid Management Customer Service 1.800.462.2466

Under the copyright laws, this material may not be copied, in whole or in part, without the

written consent of Fluid Management.

Your rights to the software are governed by the acc om p an yin g softwa r e licen se

agreement.

Use of Fluid Management trademarks, service marks, or logos for commercial purposes

without the prior written consent of Fluid Management may constitute trademark

infringement and unfair competition in violation of fe deral and state laws. Fluid

Management, FMDirect, ColorPro, DVX, Harbil, Blendorama, Accutinter, Duraflow, Fast &

Fluid Management, GyroFlex, GyroMixer, Infina, MicroTint, TintMaster, V1, and VR1 are

trademarks of Fluid Management, registered in the U.S. and/or other countries.

Every effort has been made to ensure that the information in this guide is accurate.

Fluid Management is not responsible for printing or clerical errors.

Fluid Management

1023 Wheeling Road

Wheeling, Illinois 60090-5776 USA

800-462-2466

http://www.fluidman.com

Published in the United States.

Mention of third-party products is for informational purposes only and constitutes neither

an endorsement nor a recommendation. Fluid Management assumes no responsibility

with regard to the performance or use of these products

Page 3

Table of Contents

SAFETY INFORMATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

MIXER WARNING LABELS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

SAFETY NOTICE INFORMATION . . . . . . . . . . . . . . . . . . . . . . . . . . 1

WARNINGS AND CAUTIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

INTRODUCTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3

PRODUCT DESCRIPTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

SPECIFICATIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

CONTAINER DIMENSIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

ELECTRICAL SUPPLY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

EQUIPMENT MAINTENANCE LOG. . . . . . . . . . . . . . . . . . . . . . . . . . 5

SPARE PARTS ORDER FORM. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

UNPACKING DIRECTIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

INSPECT FOR DAMAGE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

REMOVE MIXER FROM SKID . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

UNPACK THE MIXER . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

SETTING UP THE MIXER . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

INSTALLATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

ELECTRICAL CONNECTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

LEVELING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

OPERATIONAL TEST . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

OPERATIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13

OPERATING THE MIXER . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

MIX TIMES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

MAINTENANCE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .15

TROUBLESHOOTING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .17

SERVICE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .20

GENERAL INFORMATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

REMOVING THE SHEET METAL COVERS . . . . . . . . . . . . . . . . . . 21

REPLACING/SERVICING THE SECONDARY DRIVE V-BELT . . . 21

REPLACING/SERVICING THE PRIMARY DRIVE POLY V-BELT . 22

ADJUSTING THE CLAMPING FORCE IN THE CLAMP HANDLE . 23

ADJUSTING THE DOOR LOCK LINKAGE AND START SWITCH . 23

GyroMixer End User Guide

Page 4

Table of Contents

REPLACING THE ROLLER . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

INSTALLING THE UPPER TABLE PAD . . . . . . . . . . . . . . . . . . . . . 24

REPLACING THE SLIDING DOOR . . . . . . . . . . . . . . . . . . . . . . . . 25

REMOVING THE MOTOR . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

REASSEMBLING THE MOTOR . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

ELECTRICAL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

REPLACING THE TIMER . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

REPLACING THE POWER RELAY . . . . . . . . . . . . . . . . . . . . . . . . . 30

ELECTRICAL DRAWINGS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

PARTS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

FLUID MANAGEMENT PAINT EQUIPMENT

LIMITED WARRANTY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

Page 5

SAFETY INFORMATION

SAFETY

INFORMATION

MIXER WARNING LABELS

You should become familiar with important warning labels which are affixed to the

mixer, as well as the symbols which appear throughout this manual. These

warnings have been included to help you safely perform your job.

Please read all warning labels that are on the mixer. Keep them clean so they are

easy to read. If the warning labels become damaged or unreadable, new labels can

be purchased from Fluid Management. See the parts list in the back of the manual

for ordering information.

SAFETY NOTICE INFORMATION

The two main safety notices used in this manual are Warning and Caution.

Notices in this manual will look like the example below.

Warning Notice

WARNING ELECTRICAL HAZARD

Do not operate the mixer with the door open.

Disconnect power before servicing.

A Warning notice tells you about a hazard that could cause serious injury to you or

extensive damage to the mixer. This information is placed at the beginning of the

manual to emphasize the importance of safety to your well being.

When you see a Warning notice in this manual, read it carefully . Before continuing

with the operation of the mixer, take all necessary precautions to avoid potential

injury.

Caution Notice

CAUTION ELECTRICAL HAZARD

All electrical components must be kept dry.

Never place containers of liquid on or near the

control box.

A Caution notice tells you about a danger that could cause injury to you or minor

damage to the mixer. When you see a Caution notice in this manual, read it

carefully and be sure you understand it before continuing.

GyroMixer End User Guide 1

Page 6

SAFETY INFORMATION

Information Notice

An Information notice gives details that will assist you in efficiently using the

mixer. When you see an Information notice in this manual, know that it is there to

save you time and energy.

WARNINGS AND CAUTIONS

WARNINGS

Note: If the cabinet vibrates, loosen the locking nuts on the right

front leveling foot and slightly adjust the length.

• The paint mixer must be properly grounded to protect the operator from

possible electrical shock. Only use a 3-prong receptacle.

• Do not operate the mixer if the power cord has been cut or damaged. Keep

the cord away from open flame or heat exposure.

• Properly level the paint mixer. Improper leveling may cause severe damage

to the machine during the mixing operation.

• Always shut off the POWER lever and unplug the mixer from the AC

power outlet before servicing the paint mixer.

• Keep hands away from moving parts.

• NON-EXPLOSION MODEL

• Do not use the paint mixer near flammable liquids.

• Do not mix flammable liquids containing gasoline or toxic materials.

• Do not clean the mixer with flammable solvents.

CAUTIONS

• Always check to be sure that the containers are tightly sealed.

• Overloading can damage the paint mixer. The maximum capacity is a 125

pound solid load.

• Make sure the bail shield is properly positioned before operating the mixer .

• The mixer's sliding door must be closed to operate the mixer.

• Most containers one gallon or larger have bails. All such containers must

have the bail properly secured to prevent possible damage to the

equipment. As an option to using the bail shield, an elastic cord can be used

to achieve this purpose.

2

Page 7

INTRODUCTION

INTRODUCTION

PRODUCT DESCRIPTION

The Miller GyroMixer is a versatile, automatic paint mixer designed for safety,

reliability and ease of use. Its features are as follows:

• Improved mixing. Gyroscopic mixing at a 2:1 ratio thoroughly blends the

toughest colorants.

• Robust design. Handles up to 125 pound (56.7 kg.) solid load.

• Easy to service. Most service and repair procedures can be performed by

opening the door, removing the back panel or the top cover.

• Simple to move and operate. Casters on the bottom of the mixer allow it to

be moved into operating position.

• Safe to operate. The mixer offers improved safety features.

• Universal can sizes. Handles the requirements of paint manufacturers

around the world.

• Easy to load. A roller in the front of the table assists in loading the

container. A groove in the table keeps the container centered and in the

proper position.

SPECIFICATIONS

Height 39.5" (100.3 cm)

Width 32" (83.8 cm)

Depth 28" (71.0 cm) with removable shelf

26” (66.0 cm) without shelf

Shipping Weight 400 lb (181 kg)

CONTAINER DIMENSIONS

Accepts can heights from 3.5” (with bail shield removed) to 16”

GyroMixer End User Guide 3

Page 8

INTRODUCTION

ELECTRICAL SUPPLY

Explosion-Proof Model

28708 200-240 V 60 Hz 5.5-4.6 Amps

28709 100-120 V 60 Hz 12-10.1 Amps

Standard Models

28988, 28989 110 V 60 Hz 11.0-9.4 Amps

30099 220 V 60 Hz 5.5-4.8 Amps

28987 220 V 50 Hz 6.5-5.7 Amps

Motor

1 HP, 1425/1725 RPM, 50/60 Hz

4

Page 9

EQUIPMENT MAINTENANCE LOG

RECORD MODEL NUMBER HERE: _________________________

RECORD SERIAL NUMBER HERE: _________________________

SERVICE

DATE

DESCRIPTION & PARTS REPLACED

(STATE IF UNDER WARRANTY)

SERVICED

BY

INTRODUCTION

GyroMixer End User Guide 5

Page 10

INTRODUCTION

SPAREPARTSORDER

Fluid Management Parts Order Form

Photocopy and use this form to

Mail or fax orders to:

IDEX

Phone: 1(800) 462-2466

1023 Wheeling Road | Fax: 1(847)537-5530

Wheeling, IL 60090 |

|

Sold To:

Ship To:

________________________ ________________________

________________________ ________________________

________________________ ________________________

________________________ ________________________

PurchaseOrder Number_________________

Ship Via: ______________________

Collect Prepaid

Taxable Tax Exempt (Fax copy of exemption certificate.)

QUANTITY PART

NUMBER

DESCRIPTION UNIT

PRICE

S

S

S

S

S

S

S

S

S

S

S

Comments: ____________________________________________________

____________________________________________________

____________________________________________________

_________________________________________________

Signature

______________

Date:

6

Page 11

UNPACKING DIRECTIONS

UNPACKING

DIRECTIONS

INSPECT FOR DAMAGE

Inspect the shipping carton for damages. If any damage is found, notify the carrier

at once and arrange for an inspection in order to claim recovery.

Note: Claims for damage must be made by the consignee (you).

The carrier assumes full responsibility upon acceptance of

shipment and will not entertain any claims by the consignor

(Fluid Management).

REMOVE MIXER FROM SKID

1. Place the carton in the area where the mixer will be located.

2. Remove the strapping and the cardboard carton stapled to the skid.

3. Open the sliding door.

4. Remove the two bolts holding mixer to the skid.

5. Slide the mixer back until half of the unit is off of the skid.

6. Carefully tilt the mixer back until its lower rear edge touches the floor

and the skid is free.

Important: Keep the weight of the mixer on its lower rear edge.

7. Pull the skid out from under the front of the unit.

8. Carefully tilt the mixer forward until all four casters are on the floor.

UNPACK THE MIXER

Caution Do not operate the mixer until the shipping

inserts are removed.

1. Open the mixer’s sliding door

2. Remove the two (2) shipping inserts positioned in the base of the mixer.

Note: The inserts are wedged against the sides of the mixer.

3. Record the serial number and model number in the space provided on

page 5. (See the identification label located on the side of the mixer. It is

important data when ordering parts or servicing the mixer.)

GyroMixer End User Guide 7

Page 12

SETTING UP THE MIXER

Explosion-Proof Installation

• Installation to be completed by a registered master electrician

following local codes and regulations.

• Loosen the screws in order to remove the back cover.

• Referring to the wiring diagram in the Service Section of this manual,

connect the power supply to the explosion-proof box.

The timer, shipped with the mixer , is located within th e explosion-proof box.

It is preset for 1-1/2 minutes, but may be adjusted up to 3 minutes by

qualified service personnel.

SETTING UP

THE MIXER

INSTALLATION

The following instructions are for both the standard and explos ion-proof models.

Refer to the boxes for special information on explosion-proof installations.

1. Move the mixer to its permanent location.

2. Refer to the Electrical Supply section of this manual for power

requirements.

3. Locate the mixer as close as possible to a properly grounded outlet.

4. Leave ample room around the paint mixer to facilitate safe operation and

routine maintenance.

ELECTRICAL CONNECTION

Caution The unit must be plugged into a dedicated

electrical line with no other equipment using the

same circuit. DO NOT use an adapter or

extension cord with this product.

WARNING Improper use of the grounding plug can result in

a risk of electric shock.

8

Page 13

SETTING UP THE MIXER

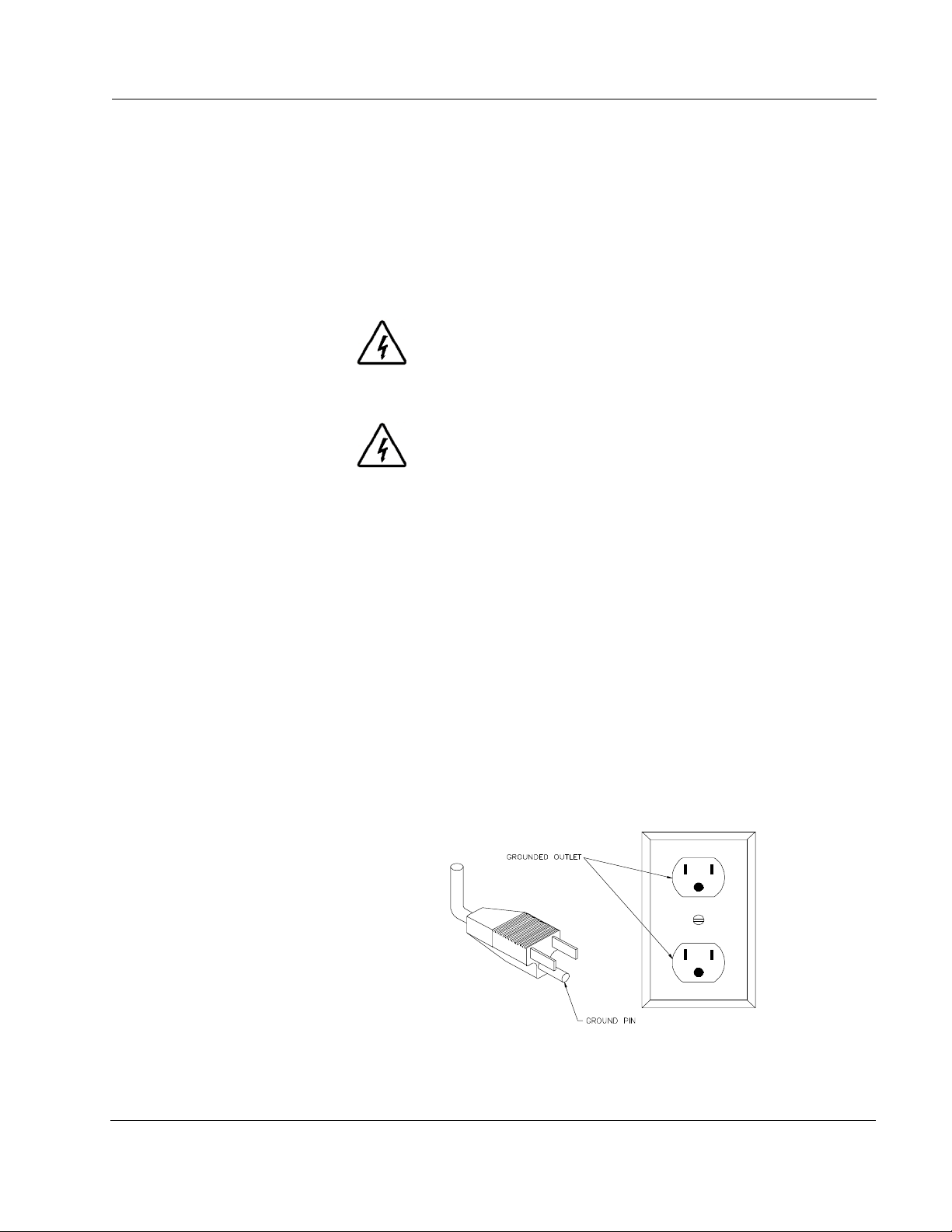

Grounding

This product must be grounded. In the event of an electrical short circuit, grounding

reduces the risk of electrical shock by providing an escape for the electric current.

This product is equipped with a cord that has a grounding wire and an appropriate

grounding plug. The plug must be inserted into an outlet that is properly installed

and grounded in accordance with all local codes and ordinances.

WARNING Check with a qualified electrician or service

person if grounding instructions are not

completely understood or if in doubt as to

whether product is properly grounded.

WARNING Improper installation of the grounding plug can

result in a risk of electric shock. If repair or

replacement of the cord or plug is necessary, do

not connect the grounding wire to either flat

blade terminal.

The insulation wire with green or green and yellow stripes on the outer surface is

the grounding wire. Check with a qualified electrician if the grounding instructions

are not completely understood, or if in doubt about whether the product is properly

grounded. DO NOT modify the plug provided. If it will not fit into the outlet, have

the proper outlet installed by a qualified electrician.

This product is designed for use in 100 to 240 Volt operation. The power

requirements of your unit will be outlined on the nameplate.

The non explosion-proof model is for use on a nominal 120-volt circuit and has a

grounding plug that looks like the plug illustrated in the figure below. Make sure

that the product is connected to an outlet having the same configuration as the p lug.

No adapter should be used with this product.

Note: If product has a nameplate for nominal 220-vo lt circuit, make

sure the proper grounded outlet is used.

Figure 1. Grounding Methods

GyroMixer End User Guide 9

Page 14

SETTING UP THE MIXER

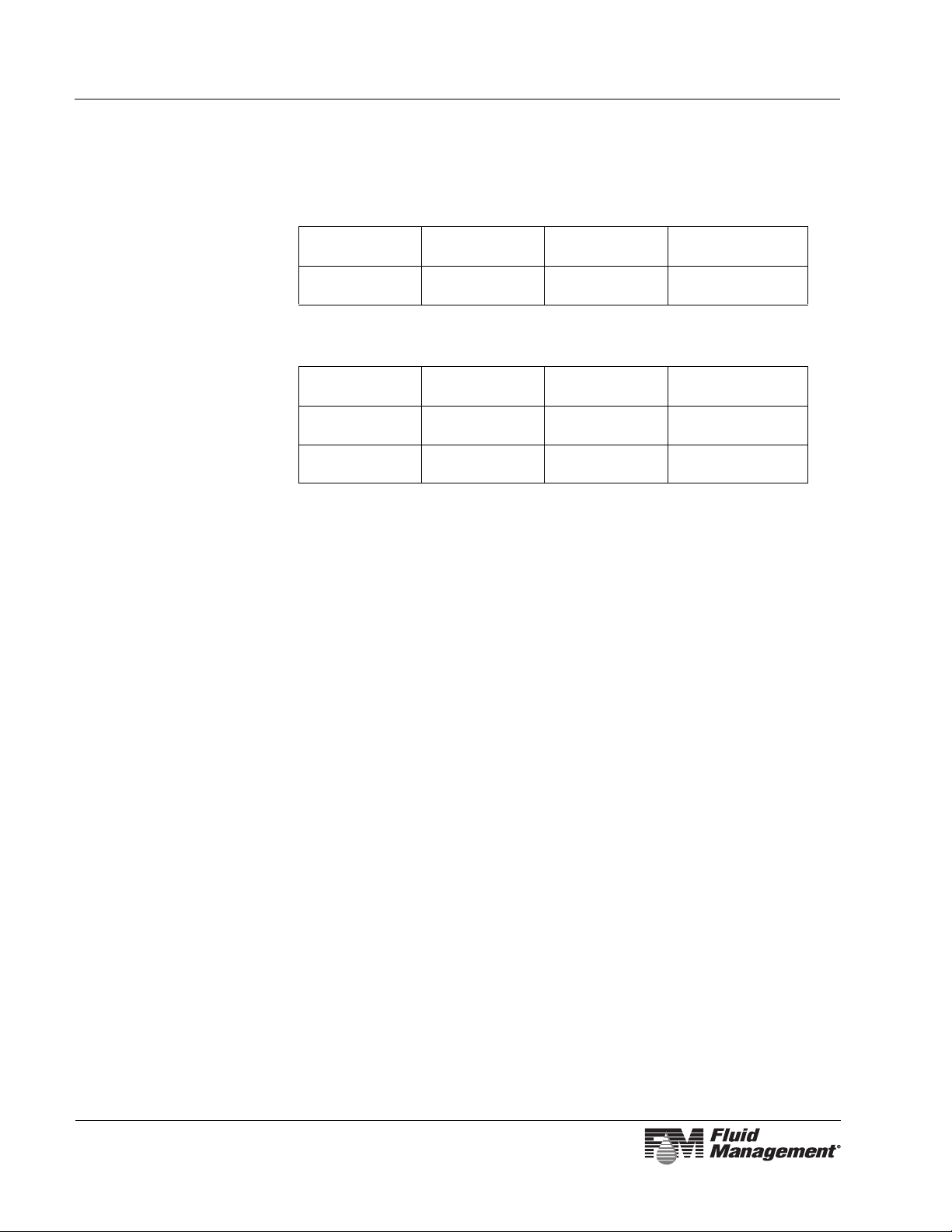

Supply Current

The table "Minimum Wire Gauge" (below) shows the recommended wire size for

home run lengths. NOTE: The smaller the gauge number, the heavier the wire.The

following chart is the wire gauge size required for the distance from the circuit box

to the grounded receptacle (for up to 15 amperes at 115V, 60 Hz). Smaller gauge

wire than shown on the table could result in a voltage drop that can effect the

operation of your unit.

Caution Under no circumstances should you modify the

plug if it does not fit the outlet. Check with a

qualified electrician or serviceman if you are not

sure how to ground this unit.

Distance (feet) 25 50 100 150 20 250 300 400 500

Gauge Size

220V

Gauge Size

115V

14 14 12 10 10 8 8 6 6

14128664422

Table 1. Minimum Wire Gauge

Extension Cords

Extension cords for 220 VAC models are not recommended. If an extension cord is

to be used, it should not be combined with others. Use only a 3-wire extension cord

that has a 3-pole grounding plug. Power should be provided by a 3-pole receptacle

that will accept the plug on the product. Make sure that your extension cord is in

good condition. It must have # 14 AWG conductors up to 25 feet long. An

extension cord no longer than 50 feet is permissible provided it has conductors of at

least # 12 AWG. It must be heavy enough to carry the current your product will

draw. An undersized cord will cause a drop in line voltage resulting in loss of

power and overheating.

10

Page 15

SETTING UP THE MIXER

LEVELING

The customer must level the mixer. Although the unit is shipped on casters for ease

of positioning the mixer, all 4 feet must be extended firmly to the floor. Variations

on the floor will necessitate adjusting the leveling feet to ensure proper operation

and to minimize vibration.

CAUTION Improper leveling may cause severe vibration

while the mixer is operating.

1. Roll the unit into its intended location.

2. Lower the four (4) leveli ng feet to the ground. Each of the four leveling

feet can be adjusted independently. Using the front of the mixer as a

position guide, turn the foot in a clockwise direction to lengthen, or in a

counter-clockwise direction to shorten.

IMPORTANT: The feet should carry the load; not the casters.

Check the stability of the mixer on the floor by making

sure that the mixer is resting on all four feet, not on its

casters. All casters must rotate freely.

3. Verify that the mixer is level by gripping its sides and gently attempting

to rock the machine. It should not move.

4. Lock the leveling feet into place by tightening the upper locknuts to the

mixer bottom with a 3/4" wrench.

Note: Should additional leveling be necessary, loosen the upper

locknuts and repeat steps 2 - 3.

GyroMixer End User Guide 11

Page 16

SETTING UP THE MIXER

OPERATIONAL TEST

1. Verify that the power is connected to the mixer.

2. Open the mixer's sliding door.

3. Slide a container into the groove on the table.

Note: Rotate the clamp handle counter clockwise first to open

the clamp arms.

4. Rotate the bail shield over the container bail. Remove the shield for

containers smaller than one gallon.

Note: Failure to properly position the bail shield on containers

larger than one gallon may damage the mixer.

5. With both hands, turn the knobs on the crank handle clockwise until

snug. Continue turning until the crank handle suddenly slips.

6. Close the sliding door.

7. Set the timer. (Not required for Explosion-Proof model)

Note: Make sure that the emergency stop switch is in the "on"

(pulled out) position. This can be done by turning the

knob counter clockwise.

8. Move the power lever to the ON position. The unit should cycle

automatically with minimum vibration. If vibration of the cabinet

occurs, immediately depress the emergency stop switch.

Note: Vibrations may occur because the unit is not properly

leveled. Try rocking the unit to make sure that all four feet

are solidly contacting the floor. Readjust the feet if

necessary. After the feet have been adjusted, reset the

emergency stop switch and continue.

9. When the test is complete, move the power lever to the OFF position.

10. Open the sliding door.

11. Rotate the mechanism to an upright locking position.

12. Use the knob marked "open" to turn the crank handle in the direction of

the arrow until the container is free. If necessary rotate the bail shield

away from the bail and remove the container.

12

Page 17

OPERATIONS

OPERATIONS

Before operating the paint mixer, carefully read the Warnings and Cautions in the

Safety section and on the mixer, then follow these steps:

OPERATING THE MIXER

1. Open the mixer's sliding door.

2. Slid e a co ntainer into the groo ve on the table. Rotate the clamp handle

counter clockwise to open the clamp arms.

3. Position the bail shield over the container bail by rotating the upper

plate. The bail shield must be removed for containers smaller than

7-1/4" high.

Note: In situations involving frequent mixing of large and small

(less then 1-gallon) containers, a special elastic cord is

supplied to fasten the bail to the can.

CAUTION Failure to properly position the bail shield on

containers larger than one gallon may damage

the mixer. It is normal for the bail to move freely

behind the shield.

4. With both hands, turn the knobs on the crank handle clockwise until

snug. Continue turning until the crank handle suddenly slips.

5. Close the sliding door.

6. Set the timer. (Not required for Explosion-Proof model)

7. Make sure that the emer gency stop switch is in the "on" position (pulled

out). This can be done by turning the knob counter clockwise.

EXPLOSION-PROOF MODEL

• The timer is set to 1-1/2 minutes at the factory before

shipment.

• See the Service Section of this manual or consult an

authorized Service Center to adjust the timer.

GyroMixer End User Guide 13

Page 18

OPERATIONS

8. Move the POWER lever to the ON position.

WARNING A safety interlock system prevents the operator

from opening the sliding door while the mixer is

running. Do not attempt to open the door while

the mixer is running.

• For an emergency stop in mid-cycle, push the EMERGENCY STOP

button.

• If vibrations occur, turn off the machine and refer to the leveling

section of this manual.

9. When the mixer has completed its cycle, move the power lever to the

OFF position.

10. Open the sliding door.

11. Rotate the mechanism to an upright locking position.

12. Use the knob marked "open" to turn the crank handle in the direction of

the arrow until the container is free. If necessary rotate the bail shield

away from the bail and remove the container.

MIX TIMES

Material Quantities Approx. Mix Times *

Latex Paint 5 gal, 15L, 20L 15 - 30 seconds

Latex Paint 1 gal, 5L or less 30 - 60 seconds

Gum-Based Paint 20L 1 - 1.5 minutes

Stucco** 5 gal, 15L, 20L 1.5 - 2 minutes

* Actual mixing times may vary depending upon material viscosity, container

size, head space, and colorant.

** When mixing stucco or other textured coatings, tip the container upside-

down, then upright again before adding colorant.

14

Page 19

MAINTENANCE

MAINTENANCE

The Miller GyroMixer is designed for simple maintenance. For example, the motor

contains sealed bearings which require no lubrication.

To ensure safe, dependable operation of the paint mixer, follow the maintenance

schedule detailed below.

WARNING Always unplug the power cord when performing

maintenance procedures

.

DAILY

Immediately clean up spills with mild soap and water. A 3/4” drain pipe is

located under the front shelf to aid in cleanup.

• Thoroughly remove soap film with clean, lukewarm water.

• DO NOT clean this mixer with flammable solvents.

WEEKLY

• Inspect electrical cord for damage or wear.

• Clean/scape debris from sliding door track to maintain smooth operation.

MONTHLY

• Clean debris from guide rods for the upper and lower moving arms.

• Lubricate the guide rods and lead screws with graphite grease or

medium weight oil. NO grease or oil should touch the belts or pulleys.

GyroMixer End User Guide 15

Page 20

MAINTENANCE

SEMI-ANNUALLY

• Test the secondary drive V-belt tension. Adjust, if necessary, to proper

tension (approximately 7 lbs to deflect the belt 1/4”).

• Check the secondary drive V-belt for wear or damage. Replace if

necessary.

• Remove the rear access panel. Test the primary drive poly V-belt

tension. Adjust, if necessary to proper tension (approximately 4-5 lbs to

deflect the belt 3/8”).

• Check the primary drive poly V-belt for wear or damage . Replace, if

necessary.

• Check clamping force.

- Load a container into the mixer

- Fully clamp the container into position.

- Attempt to move the container.

- If the container moves, adjusts the clamping force by tightenin g th e

nut on the handle. Refer to the Service section for further instructions.

• Spray silicone in the door tracks for smooth operation.

• Inspect the door lock linkage for tightness. Refer to the Service section.

16

Page 21

TROUBLESHOOTING

TROUBLESHOOTING

Using the chart below, locate the problem in the first column, then select the

probable cause to check and action to take from the next two column s. The

problems are arranged from the simplest to the most complex.

Where appropriate, refer to the Service section to correct the problem.

PROBLEM POSSIBLE CAUSE ACTION

Mixer does not start. POWER lever is in OFF position. • Move POWER level to ON position.

Power supply cord is unplugged or

damaged.

Extension cord unplugged or inoperative. • Inspect extension cord. Connect or

Door is open and the safety switch has

prevented operation.

Emergency stop button is pushed. • Turn to disengage E-stop button

Power lever not fully engaging switch. • Adjust the power level switch.

E-stop button is inoperative. • Check E-stop button. Replace, if

Door lock linkage needs adjusting. • Adjust door lock linkage.

Power relay not operating. • Press the test switch underneath the

• Plug in cord.

• Replace damaged cord.

replace if damaged.

• Close door.

Replace, if necessary.

necessary

power relay to close the points.

• Check for loose wire connections.

• Check voltage.

• Replace power relay, if defective.

Timer knob is turned on, the

power level is in ON position, the

E-stop button is disengaged, but

mixer does not operate.

Electrical supply voltage not present. • Check electrical supply voltage at

the wall breaker. Correct if

necessary.

Thermal overload protection engaged due

to excessive heat in motor.

• Turn off mixer and allow to cool

overnight. The next day test run the

mixer for 60 seconds. If the

symptom persists, replace the

motor.

GyroMixer End User Guide 17

Page 22

TROUBLESHOOTING

PROBLEM POSSIBLE CAUSE ACTION

Mixer operates, but does not

mix.

Mixer operates, but is noisy. Container not securely clamped in. • Check container. Reposition and

Mixer operates, but vibrates

excessively or “walks”.

Mixer operates and timer cycles

completely, but does not mix

thoroughly.

Belts loose or defective. • Check the poly V-belt and the V -belt.

Replace if necessary.

Improper timer setting. • Extend mixing setting. Smaller

containers and heavier viscosities

require extended mixing times.

clamp securely if necessary.

Bail is not retained. • Retail bail.

Belt has fallen off. • Check belt. Reposition if necessary.

Binding occurring when rotating clamping

assembly.

Mixer is not level. • Verify if mixer is level. Level if

Container is not centered. • Center the pail on the table and

Improper timer setting. • Extend mixing setting. Smaller

• Replace flange bearing in clamping

assembly.

necessary.

reclamp into position.

containers and heavier viscosities

require extended mixing times.

Incorrect drive belt tension. • Inspect and adjust drive belt tension

if necessary.

Secondary belt broken. • Check secondary belt and replace if

necessary.

Motor runs erratically. Frayed or loose motor wire. • Tighten loose wire or replace

damage wire.

Thermal overload relay defective. • Replace motor.

Motor bearings bad. • Replace motor.

Primary belt has fallen off. • Check primary drive belt. Reposition

or replace, if necessary.

18

Page 23

TROUBLESHOOTING

PROBLEM POSSIBLE CAUSE ACTION

Mixer will not shut off. Damaged timer relay. • Replace timer relay.

Faulty connection to the potentiometer. • Tighten connection to potentiometer.

Damaged potentiometer. • Replace potentiometer.

Mixer hums, but will not run. Insufficient current. • Verify mixer is correctly installed to a

dedicated line.

Something caught in mixer. • C heck for obstructions.

Mixer squeaks at startup, but still

runs.

Defective bearing in pulleys four arms or

main drive.

Defective motor. • Replace motor.

Belts loose. • Check V-belt and poly-V belt

• Check each bearing for roughness.

Replace if necessary.

tension. Tighten if necessary.

GyroMixer End User Guide 19

Page 24

SERVICE

SERVICE

GENERAL INFORMATION

If you do not feel confident about disassembling the paint mixer or replacing a part,

DO NOT ATTEMPT THE PROCEDURE

contact Customer Service at Fluid Management.

Carefully read all of the instructions before you begin. For component

identification and location, refer to the Parts Section of this manual.

WARNING ELECTRICAL HAZARD

Always shut off the POWER switch and unplug

the mixer before servicing.

CAUTION Wear safety glasses to prevent possible injury.

Recommended Spare Parts

. Should problems or questions arise,

Belts: Primary: 16-rub poly-V belt Part Number 18444

Bail Retainer Part Number 20810

Rubber Pad Part Number 18351

Special Tools

Belt tensioning gauge

Voltage meter

Secondary: V-belt, Part Number 18396

20

Page 25

REMOVING THE SHEET METAL COVERS

1. Unplug the mixer.

2. Loosen the six (6) screws on the rear access panel and lift the panel up

and off of the screws. Set aside the panel.

3. Remove the top cover by removing the two (2) screws which are located

under-neath the right and left back corners of th e mixer cover. Save the

screws in a cup or jar.

4. Open the sliding door.

5. Remove the two (2) screws underneath the right and left front corners of

the mixer cover.

6. Perform service.

7. Replace top cover, then rear access panel.

SERVICE

8. Restore power to the mixer.

REPLACING/SERVICING THE SECONDARY DRIVE V-BELT

1. Unplug the unit.

2. Close the sliding door approximately 4" to disengage the anti-rotation

pin.

3. Turn the rotating assembly until upside down.

4. Inspect the secondary drive V-belt for worn or frayed areas.

• If the belt is in good condition, continue to set the belt tension to

approximately 1/4" deflection, as described in steps 8-9.

• If the belt needs to be replaced continue to step 5.

5. Using a 1-1/8" open-end wrench, loosen the nuts holding the secondary

idler bracket in place.

6. Move the bracket forward until it is loose enough to remove the old belt.

Note: It is easier to remove the belt from the bottom first.

7. Beginning at the bottom, place the new V-belt into position around the

stationary pulley, up and around the two (2) idler pulleys and finally

around the secondary pulley in the front.

GyroMixer End User Guide 21

Page 26

SERVICE

8. Evenly move the secondary idler bracket to set the belt tension.

Note: Belt tension should be set so that a seven (7) pound force

will deflect the belt 1/4".

9. Tighten the nuts holding the secondary idler bracket in place.

10. Restore power to the unit.

REPLACING/SERVICING THE PRIMARY DRIVE POLY V-BELT

1. Unplug the unit.

2. Remove the rear access panel by loosening the screws and lifting the

panel off the screws.

3. Inspect the primary drive poly V-belt for worn or frayed areas.

• If the belt is in good condition, continue to set the belt tension in

step 7.

• If the belt is frayed or damaged, continue to step 4.

4. Usi ng a 9/1 6" wrench , loosen the two screws holding the idler bracket.

5. Loosen the idler adjustment screw behind the idler pulley in order to

release the tension enough to remove the old belt.

6. Place the new belt in position over the motor drive pulley, then over the

idler pulley, and finally around the driven pulley.

Note: The belt must be fully engaged in all the grooves of both

the driven pulley and the motor drive pulley. Rotate the

motor drive pulley by hand to ensure that the belt is riding

on all the grooves.

7. T ight en the screw behind the idler pu lley to set the belt tension. The poly

V-belt requires a 4-5 pound force to deflect the belt 3/8".

Note: The poly V-belt will feel looser than a standard V-belt.

8. Tighten the two screws holding the idler bracket.

9. Test run the mixer for 60 seconds. Check the belt tension and adjust if

necessary.

22

Page 27

SERVICE

10. Replace the rear access panel.

11. Restore power.

ADJUSTING THE CLAMPING FORCE IN THE CLAMP HANDLE

1. Unplug the unit.

2. Load container into mixer.

3. Clamp the container.

4. Test the clamping force by pushing the container with two hands. If the

container moves, the clamping force must be adjusted as follows:

• Remove the black plastic plug from the center of the clamp handle.

• Using a needle-nose pliers, remove the cotter pin.

• Tighten the locknut by turning it clockwise one or two revolutions.

• Recheck the clamping force. If the container still moves when

clamped, tighten the nut until the pail does not move when clamped.

5. When the clamping force is correct, place the cotter pin that was

removed in step 4 back into the mechanism.

6. Place the plastic plug back into the center of the crank handle.

7. Restore power to the mixer.

ADJUSTING THE DOOR LOCK LINKAGE AND START SWITCH

1. Disconnect the power.

2. Remove rear access panel.

3. Remove the top cover by removing the screws holding it in place.

4. Loosen the two (2) screws between the door lock linkage brackets.

5. Loosen the two (2) screws in the start switch mounting bracket. (Only

for explosion-proof models.)

6. Turn the power lever to the ON position.

7. With the door locking bracket in a fully upright position against the

rubber stop, retighten the two (2) adjustment screws between the door

lock linkage brackets.

GyroMixer End User Guide 23

Page 28

SERVICE

CAUTION: To avoid breakage, do not over actuate the power

lever.

8. After tightening the screws i n step 7 and with the power lever still in the

ON position, slide the start switch bracket toward the front of the mixer

until fully depressed by the roller . T ighten the screws while the switch is

in this position.

9. Replace the top cover and rear access panel. Tighten the screws.

10. Restore the power.

REPLACING THE ROLLER

1. Unplug the mixer.

2. Open the sliding door.

3. Remove the screw on each end of the roller bracket. Use a needle-nose

pliers to hold the plastic bushing while removing the Phillips screw.

4. Remove and discard the old roller.

5. Place the plastic bushings in the ends of the new roller.

6. Place the roller on the roller bracket.

7. Using the needle-nose pliers to keep the plastic bushing from rotating,

tighten the screws on the roller bracket.

8. Close the sliding door.

9. Restore power to the mixer.

INSTALLING THE UPPER TABLE PAD

1. Unplug the electrical cord.

2. Raise the sliding door.

3. Turn the rotating assembly upside down.

24

4. Use a scraper to loosen the pad around the edges.

5. Pull off the old pad.

Page 29

6. Using mineral spirits or similar non-flammable liquid, remove the old

TOP COVER

TRACK

adhesive residue left on the table.

7. Remove the adhesive paper on the back of the new pad.

8. Carefully aligning the new pad, attach the pad to the upper table. Apply

pressure from the center outward and over the entire surface of the pad

until it is secure.

9. Close the sliding door.

10. Restore power to the mixer.

REPLACING THE SLIDING DOOR

1. Unplug the mixer.

2. Remove the rear access panel.

3. Remove the top cover.

SERVICE

Figure 2. Door Covers

4. Rem ove the two (2) screws and door stop from th e right track. (Figure 3 ,

as viewed from back.)

GyroMixer End User Guide 25

Page 30

SERVICE

TRACK

DOOR STOP

5. Close the sliding door.

Figure 3. Door Stop

6. Working at the back of the mixer, gently slide the door out of the two

notches in the top of the right and left side door tracks (see Figure 3).

Set door aside.

7. Clean the door tracks.

8. Place the new door on a clean, flat surface.

9. Vertically apply masking tape to the slats in order to keep the slats in

line.

10. Feed the replacement sliding door into the two notches on the top right

and left side door tracks.

11. Gently glide the door all the way down.

12. Remove the masking tape.

13. Test the operation of the door by opening and closing. Make

adjustments, as necessary.

14. Mount the door stop back onto the right track with the two (2) screws.

15. Reassemble the top cover and rear access panel.

16. Restore power to the mixer.

26

Page 31

REMOVING THE MOTOR

1. Unplug the electrical cord.

2. Remove the rear access panel and top cover by removing the screws.

3. Loosen, but do not remove, the idler pulley.

4. Remove the belt from the motor pulley.

5. Loosen the screw holding the conduit box cover in place.

6. Remove the conduit box cover in order to disconnect the fol lowing three

wires:

• Brown (L1) and blue (L2) wires which are secured with wire nuts.

• Ground wire held with in place with a green screw.

7. Inside the conduit box, remove the nut securing the tubing connector to

the conduit box and separate the connector from the conduit box.

SERVICE

8. Holding the motor securely, remove the four (4) screws holding the

motor to the motor mounting bracket. Save the screws. Discard the

motor.

9. For reassembly purposes, measure the position of the motor drive pulley

before removing it from the driveshaft: measure from the face of the

motor to the edge of the pulley.

Note: The key should be flush with the shaft.

10. Loosen the motor drive pulley set screw and remove the pulley. Save the

circular push-on retaining ring for reassembly.

11. Set the pulley aside for later use.

12. Discard the old motor.

GyroMixer End User Guide 27

Page 32

SERVICE

REASSEMBLING THE MOTOR

1. Remove the key taped to the side of the new motor.

2. Slide the motor drive pulley onto the shaft and into the same position

measured during removal in Step 9, REMOVING THE MOTOR.

3. Place the key inside the keyway in the motor drive pulley and tighten the

set screw. The key should be seated in the driveshaft keyway. It should

be positioned in the same way as on the old motor (as noted in Step 9,

REMOVING THE MOTOR).

4. Push the circular retaining ring into the motor pulley.

5. Viewing the shaft end of the motor, confirm that the rotation of the

motor is CW (clockwise). Refer to the diagram on the side of the motor

for a detailed wiring diagram.

6. Lift the motor, with the wires pointing downward, into position and

fasten to the motor mounting bracket with the four (4) screws.

7. Before completely tightening the screws, manually turn the rotating

mechanism one full revolution to verify that the motor does not interfere

with the rotating mechanism.

Note: If there is interference, move the motor slightly to correct

the problem before tightening the screws.

8. Connect L1, L2, and ground wires to the motor . Refer to the diagram on

the side of the motor to verify the motor wiring for clockwise rotation as

viewed from the shaft end.

9. Reassemble the tubing connector nut onto the conduit box.

10. Close the motor cover plate with the screw.

28

Page 33

11. Perform a motor test:

• Plug in the mixer.

• Turn on the motor and confirm that the rotation of the motor is

clockwise, as viewed from the shaft end.

• If not, refer to the wiring diagram on the side of the motor and

correct the rotation setting.

Note: If the diagram does not specify, the default is as viewed

from the lead end where the power wires are located.

• Unplug the mixer.

12. Replace the belt on the motor pulley and set the belt tension.

Note: The tension on the poly V-belt will fell looser than a

standard V-belt.

13. Plug in the mixer.

SERVICE

14. Test run the mixer for 60 seconds to check the belt tension.

Note: If necessary , un plug the mixer and adjust the tension. This

is also the time to adjust the motor drive pulley, if

required.

15. Reassemble the top cover and the rear access panel.

16. Plug in the mixer.

GyroMixer End User Guide 29

Page 34

ELECTRICAL

ELECTRICAL

REPLACING THE TIMER

1. Unplug the mixer.

2. Remove the rear access panel and the electrical cover plate.

3. Locate the timer module.

4. From the back of the mixer, perform the following steps:

• Make a wiring diagram or label the wires.

• Disconnect all wire connections at the timer.

• The timer is secured to a screw on the back panel with one (1) nut.

Use a socket wrench to remove the nut.

• Place the new timer on the screw and hand tighten the nut. Do not

over tighten.

• Reattach the new timer to the connecting wires according to your

diagram or labels.

5. Verify that all connections fit tightly. Repair any loose conn ec tions by

crimping or replacing the loose ones.

6. Reinstall the electrical cover plate and rear access panel.

7. Plug in the electrical cord and verify that the mixer operates properly.

Make adjustments, if necessary.

REPLACING THE POWER RELAY

1. Unplug the mixer.

2. Remove the rear access panel and the electrical cover plate.

3. Locate the power relay.

4. From the back of the mixer, perform the following steps:

• Make a wiring diagram or label the wires.

• Disconnect all six (6) wire connections at the power relay.

• The power relay is secured to two (2) screws on the back panel with

two (2) nuts. Use a socket wrench to remove the nuts.

• Place the new power relay on the screws and hand tighten the nuts.

Do not over tighten.

• Reattach the six (6) connecting wires according to your diagram or

labels.

30

Page 35

ELECTRICAL

S1

S2

K1

T1

+

-

A

B

C

D

EMERGENCY

STOP

START

0

CYCLE

COUNTER

M

SWITCH

1

3

4

5

46 21

S1

S2

K1

T1

+

-

A

B

C

D

EMERGENCY

STOP

START

0

CYCLE

COUNTER

SWITCH

1

3

4

5

68 21

2

4

L1

L2

GND

L1

L2

GND

ELECTRICAL SCHEMATIC, 100-120V, 50/60Hz

ELECTRICAL SCHEMATIC, 200-240V, 50/60Hz

M

NOTE: THE CONNECTIONS SHOWN FOR S1 & S2

ARE LABELS ONLY. REFER TO TABLE FOR

CORRESPONDING CONNECTIONS.

5. Verify that all connections fit tightly. Repair any loose conn ec tions by

crimping or replacing the loose ones.

6. Reinstall the electrical cover plate and the rear access panel.

7. Plug in the electrical cord and verify that the mixer operates properly.

Make adjustments, if necessary.

ELECTRICAL DRAWINGS

Figure 4. Electrical Schematic

GyroMixer End User Guide 31

Page 36

ELECTRICAL

Switch Terminal Standard Intn’l

X-Proof

S1 A 21 1 N.C. ---

S1 B 22 2 N.C. ---

S2 C 13 3 N.O. ---

S2 D 14 4 N.O. ---

S1 A 21 --- --- N.C.

S1 B 22 --- --- N.C.

S2 C 13 --- --- N.O.

S2 D 14 --- --- N.O.

Table 2. Electrical Schematic

US

X-Proof

X-Proof

32

Page 37

PARTS

PARTS

This section is designed to assist you in performing service functions and

identifying parts. All repairs must be performed by qualified service personnel.

TERMS

Unless prior arrangements have been made, parts will be shipped UPS. All prices

are F.O.B. Wheeling, Illinois, and are subject to change without notice.In all

correspondence or phone orders for parts, please state model number and serial

number of the equipment.

RETURNS

No parts are to be returned without prior authorization. A Returned Goods

Authorization number is required.

WARRANTY SERVICE

Defective parts are replaced under warranty for a period of two years. Labor on

major components is covered for a period of one year. The procedure is as follows:

• Call the Customer Service department at 1(800) 462-2466. Have the serial

number and model number ready.

• If the problem can be handled over the phone, an RGA(Return Goods

Authorization) number will be assigned.You must return defective parts to

avoid billing.

NON-WARRANTY SERVICE

• Call the Customer Service department at 1(800) 462-2466. Have the model

number ready.

GyroMixer End User Guide 33

Page 38

PARTS

A

D

B

E

F

H

G

C

34

Page 39

PARTS

PART NO DESCRIPTION NO REQ

A 18307 BACK PANEL 1

B F29082-01 DIGITIAL TIMER PANEL 1

C 20811 SCREW, PAN HEAD WITH EXTERNAL LOCK WASHER

(10-24 X 1/2”, PHILLIPS) BACK PANEL MOUNTING SCREW

D 29546 STANDARD COVER ASSEMBLY 4

E 4980024 DECAL, CONTROL PANEL

STANDARD GYROMIXER

F 4980025 DECAL, WARNING/NOTICE

STANDARD GYROMIXER

G 4980029 DECAL, EMERGENCY STOP SWITCH

STANDARD GYROMIXER

H 28232 ON/OFF EMERGENCY STOP KIT 1

H 26050 EMERGENCY STOP - SWITCH ONLY 1

H 26052 EMERGENCY STOP - SWITCH MECHANISM ONLY 1

19337 TIMER KNOB (NOT SHOWN)

EXPLOSION PROOF GYROMIXER ONLY

1980026 DECAL, WARNING / NOTICE (NOT SHOWN)

EXPLOSION-PROOF GYROMIXER ONL Y

4980067 DECAL, CONTROL PANEL (NOT SHOWN)

EXPLOSION-PROOF GYROMIXER ONL Y

6

1

1

1

1

1

GyroMixer End User Guide 35

Page 40

PARTS

A

J, K

M

B

C

E

D

L

H

I

G

F

36

Page 41

PART NO DESCRIPTION NO REQ

A F0113 STAINLESS STEEL THREADED STANDARD SCREW 1

B 18334 SHAFT, HEX, SOUPLER, 11” HEXX4.66LG 1

C 18396 SECONDARY DRIVE V-BELT 1

PARTS

D 18442 POLY-V MOTOR PULLEY

STANDARD GYROMIXER

E 184 44 MAIN DRIVE POLY-V BELT, 820 J 16 1

F 18450 EMERGENCY STOP SWITCH COVER 1

G 18490 CABINET, STANDARD MACHINE 1

H 4980029 DECAL, E-STOP, STANDARD GYROMIXER 1

I 28232 ON/OFF EMERGENCY STOP KIT 1

J 5108219 BULB HOLDER AND START SWITCH MECHANISM

STANDARD GYROMIXER

K 510 8330 START PUSH BUTTON, GREEN

STANDARD GYROMIXER

L 21516 STANDARD COVER ASSEMBLY 1

M F0103408 SCREW, HEX, 1/4-20X1/2, FLANGE 1

19345 POTENTOMETER, 1.5 MEGOHM (NOT SHOWN)

EXPLOSION PROOF GYROMIXER ONLY

F0116A406 SCREW, SET, 1/4-20X3 /8 , SOC KET CAP (NOT SHOWN) 1

1

1

1

4

GyroMixer End User Guide 37

Page 42

PARTS

000000

A

B

C

D

E

F

G

H

I

J

38

Page 43

PART NO DESCRIPTION NO REQ

A 183 70 INCOMING CORD, 12 FEET; STANDARD GYROMIXER 1

B 184 44 MAIN DRIVE POLY-V BELT, 820 J 1

C 118487 IDLER ADJUSTMENT BRACKET 1

PARTS

D 26458 MOTOR (1 HP, 100-200V/200-2 40V, 50/60 HZ - 1425/1725 RPM)

STANDARD GYROMIXER

D 20824 MOTOR (1 HP, 115/230VAC, 60 HZ - 1425/1725 RPM)

EXPLOSION PROOF GYROMIXER ONLY

E 119348 CABINET WIRING HARNESS

STANDARD 100-120V GYROMIXER

F 32563 SOLID STATE INTERVAL TIMER 100-120V

STANDARD GYROMIXER

F 32564 SOLID STATE INTERVAL TIMER 220-230V

EXPLOSION PROOF GYROMIXER ONLY

G 4000096 NUT, HEX (1/4-20, WITH NYLON PATCH)

ANTI-ROTATION ASSEMBLY AND TIMER MOUNTING SCREW

AVAILABLE ONL Y IN PACKAGE OF TWELVE - PART NO. S4000438

H 5608204 LOW VOLTAGE POWER RELAY

STANDARD AND EXPLOSION PROOF GYROMIXER

NOTE: THE LOW VOLTAGE POWER RELAY IS USED ON 100-120VOLT

EXPLOSION PROOF GYROMIXERS AND MUST BE INSTALLED IN AN

EXPLOSION PROOF BOX.

I F0103616 SCREW, HEX SERRATED FLANGE (3/8-16 X 1")

TWO IDLER ADJUSTMENT BRACKET MOUNTING SCREW AND FOUR

MOTOR MOUNTING SCREWS

J F01191008 SCREW, HEX SERRATED FLANGE; NO. 10 X 1/2”, WITH NYLON PATCH

ELECTRICAL COVER MOUNTING SCREW

1

1

1

1

1

5

1

6

4

20446 ELECTRICAL COVER (NOT SHOWN) 1

GyroMixer End User Guide 39

Page 44

PARTS

P

G

D

A

J

I

H

F

E

C

B

K

M

N

O

M

L

Q

R

40

Page 45

PART NO DESCRIPTION NO REQ

A 17268 SEALED BEARING (35MM ID) 2

B 18354 SWIVEL CASTER 4

C 18387 STAINLESS STEEL FRONT SHELF 1

D 18400 ANTI-ROTATION ASSEMBLY 1

E 18441 PRIMARY AXIS SHAFT 1

F 18443 MAIN DRIVE POLY-V PULLEY (19” DIAMETER) 1

G 18452 STATIONARY PULLEY 1

PARTS

H 16077 WASHER (3/8” ID X 1" OD)

(FOR STATIONARY PULLEY MOUNTING SCREWS)

I 17279 MAIN DRIVE PULLEY WASHER 1

J 18480 FRONT PANEL 1

K 21515 LEVELING FOOT ASSEMBLY 4

L 4000096 NUT, HEX (1/4-20, WITH NYLON PA T CH)

ANTI-ROTATION ASSEMBLY AND TIMER MOUNTING SCREW

AVAILABLE ONL Y IN PACKAGE OF TWELVE - PART NO. S4000438

M 4000370 SCREW, HEX HEAD CAP (5/16-18 X 3/4”, WITH NYLON PATCH)

ONE - MAIN DRIVE POLY-V PULLEY MOUNTING SCREW AND SIXTEEN

SWIVEL CASTER MOUNTING SCREWS

N 4000126 NUT, HEX (5/16-18, WITH NYLON PATCH)

FOR STATIONARY PULLEY MOUNTING SCREWS

AVAILABLE ONL Y IN PACKAGE OF TWELVE - PART NO. S4000441

O F 0100A4P12 SCREW, BUTTON HEAD CAP (1/4-20 X 3/4”, SOCKET, WITH NYLON PATCH)

FRONT PANEL AND SHELF MOUNTING SCREWS

P F0106A5B44 SCREW, SOCKET HEAD CAP (5/16-18 X 2-3/4”)

STATIONARY PULLEY MOUNTING SCREWS

Q F0104A6B14 SCREW (3-8-16 x .875) BLACK OXIDE WITH PATCH 1

6

4

17

6

1

6

R 18305 START SWITCH SPRING MOUNTING BRACKET EXPLOSION PROOF

GYROMIXER ONLY

1

GyroMixer End User Guide 41

Page 46

PARTS

A

C

B

D

F

E

G

H

42

Page 47

PARTS

PA RT NO DESCRIPTION NO REQ

A 28533 SLATTED FRONT DOOR ASSEMBLY 1

B 18487 IDLER ADJUSTMENT BRACKET 1

C 19437 SCREW, HEX HEAD (3/8-16 X 3-1/2”)

IDLER ADJUSTMENT BRACKET MOUNTING SCREW

D 20459 MAIN DRIVE IDLER PULLEY1 1

E F0103616 SCREW, HEX SERRATED FLANGE (3/8-16 X 1")

TWO - IDLER ADJUSTMENT BRACKET MOUNTING SCREW AND FOUR MOTOR MOUNTING SCREWS

F F0103824 SCREW, HEX SERRATED FLANGE (1/2-13 X 1-1/2”)

MAIN IDLER PULLEY MOUNTING SCREW

G 29536 SOLENOID ASSEMBLY, 120VAC, 60 HZ 1

H 26065 INTERLOCK SWITCH ASSEMBLY 1

1

6

1

GyroMixer End User Guide 43

Page 48

PARTS

A

E

D

C

B

F

G

H

H

44

Page 49

PARTS

PART NO DESCRIPTION NO REQ

A 18306 START SWITCH SPRING PIN 1

B 18325 DOOR LOCKING BRACKET 1

C 21518 START SWITCH HANDLE ASSEMBLY 1

D 18365 DOOR LOCK MOUNTING BLOCK 11

E 18393 START HANDLE MOUNTING BLOCK 1

F 20445 START HANDLE SPRING 1

G 20813 DOOR LOCKING LINKAGE 1

H F0103408 SCREW HH (1/4-20X1/5 LG, LOCKING, SERRATED) 4

GyroMixer End User Guide 45

Page 50

PARTS

CABINET & ELECTRIC COMPONENTS NOT SHOWN

PART NO DESCRIPTION NO REQ

18305 START SWITCH SPRING MOUNTING BRACKET PIN 1

18365 DOOR LOCK MOUNTING BRACKET 1

18393 START HANDLE MOUNTING BLOCK 1

19333 TIMER RELAY AND CONTROL MOUNTING BRACKET, EXPLOSION-PROOF 1

19334 TIMER MOUNTING BRACKET

EXPLOSION-PROOF GYROMIXER ONLY

19340 CABINET ASSEMBLY

EXPLOSION-PROOF GYROMIXER ONLY

19347 POTENTIOMETER (2.0 MEGOHM)

EXPLOSION-PROOF GYROMIXER ONLY

19351 SOLID STATE INTERVAL TIMER (EXPLOSION-PROOF 200-240V)

NOTE: THE INTERVAL TIMER MUST BE INSTALLED IN AN EXPLOSIONPROOF BOX ON THE EXPLOSION-PROOF MIXER.

19354 DOUBLE GANG EXPLOSION-PROOF BOX

EXPLOSION-PROOF GYROMIXER ONLY

19355 EMERGENCY STOP SWITCH

EXPLOSION-PROOF GYROMIXER ONLY

19356 MOMENTARY START SWITCH

EXPLOSION-PROOF GYROMIXER ONLY

20804 CABINET WIRING HARNESS 200-240V

EXPLOSION-PROOF GYROMIXER ONLY

20806 EXPLOSION-PROOF CONDUIT BOX

EXPLOSION-PROOF GYROMIXER ONLY

1

1

1

1

1

1

1

1

1

46

20812 DOOR STOP BRACKET 1

20813 DOOR LOCKING LINKAGE 1

21515 LEVELING FOOT ASSEMBLY 1

21516 COVER ASSEMBLY

ST ANDARD GYROMIXER

1

Page 51

PARTS

21517 COVER ASSEMBLY

EXPLOSION-PROOF GYROMIXER ONLY

21518 START SWITCH HANDLE ASSEMBLY, INCLUDES DOWEL PIN AND ROLLER 1

21519 STATIONARY PULLEY ASSEMBLY, INCLUDES BEARINGS AND PRIMARY

AXIS SHAFT

21521 DOOR LOCK MOUNTING ASSEMBLY 1

4980026 DECAL, WARNING/NOTICE

EXPLOSION-PROOF GYROMIXER ONLY

26052 ON/OFF EMERGENCY STOP SWITCH MECHANISM

ST ANDARD GYROMIXER

5108219 BULB HOL DER AND START SWITCH MECHANISM

ST ANDARD GYROMIXER

5608300 HIGH VOLTAGE POWER RELAY (EXPLOSION-PROOF)

NOTE: THE HIGH VOLTAGE POWER RELAY IS USED ON 200-240 VOLT

EXPLOSION-PROOF

4000370 CREW, HEX HEAD CAP (5/16-18 X 3/4” WITH NYLNO PATCH)(1 MAIN DRIVE

POLY-V PULLEY MOUNTING & 16 CASTERS)

1

1

1

1

1

1

1

F0103408 SCREW, HEX SERRATED FLANGE (1/4-20 X 1/2”, WITH NYLON PATCH)

(FOUR - COVER ASSEMBLY MOUNTING SCREW AND TWO - DOOR STOP

BRACKET)

6

GyroMixer End User Guide 47

Page 52

PARTS

C

F

K

I

Q

O

D

E

L

M

E

H

O

I

G

M

N

J

B

F

P

A

R

Upper Stationary Arm Assembly

Lower Moving Arm Assembly

48

Page 53

PART NO DESCRIPTION NO REQ

A 17268 BEARIN G, SEALED (35MM) 2

B 18312 LOWER MOVING ARM 1

C 18313 UPPER ARM TABLE 1

D 18316 UPPER ARM LEAD SCREW BUSHING 2

E 18317 GUIDE ROD BUSHING (1.004 X 1.25 X 1.5) 2

F 18332 LOWER TABLE 1

G 18333 DRIVE SHAFT 1

H 18336 LOWER ARM LEAD SCREW ASSEMBLY 2

18339 UPPER TABLE PAD (NOT SHOWN) 2

PARTS

I 1 8438 WASHER (1/4” ID X 3/4” OD) 4

J 19317 LOWER ARM ROLLER MOUNTING BRACKET 1

K 20814 BAIL SHIELD 1

21520 UPPER TABLE KIT, INCLUDES UPPER TABLE & UPPER TABLE PAD

(NOT SHOWN)

21522 UPPER MOVING ARM, WITH BEARINGS & TABLE HUB (NOT SHOWN) 1

21523 UPPER TABLE HUB ASSEMBLY (NOT SHOWN) 1

L 21524 LOWER TABLE HUB KIT , INCLUDES DOWEL PINS, HUB AND LOWER TABLE 1

M 4000255 SCREW (5/16-18 X 1/2 SOCKET) 4

N 5103153 PLASTIC ROLLER ASSEMBLY, INCLUDES BEARINGS, TUBE, SHAFT

AND SCREWS

O F01050410 SCREW, SHOULDER (1/4” X 5/8” WITH NYLON PATCH) 4

P F001101 RETAINING RING (80MM INTERNAL) 1

Q F0100A4B12 SCREW, BUTTON HEAD CAP (10-24 X 5) 3

1

1

R F012703 RETAINING RING, INTERNAL (5/8” CRESCENT) 1

GyroMixer End User Guide 49

Page 54

PARTS

G

K

G

E

F

B

H

L

D

I

J

C

M

Lower Stationary Arm Assembly

50

Page 55

PART NO DESCRIPTION NO REQ

A 01007 ROLL PIN (3/16 X 1” SS) 2

B 03163 NUT (3/4-10 HEX) 2

C 18334 SHAFT COUPLER (1” HEX) 1

D 18392 SEALED BALL GEARING 1

E 18397 SECONDARY PULLEY 1

F 18456 SECONDARY IDLER SHAFT 2

G 20454 BALL BEARING, R8ZZ (5” ID X 1.125 OD) 2

PARTS

H 21528 PULLEY HUB ASSEMBLY, INCLUDES ROLL PINS, HUB, PULL EY AND

LOWER ARM

I F 00101 RETAINING RING, EXTERNAL (. 1”) 2

J F000904 RETAINING RING, EXTERNAL (1.5”) 1

K F001101 RETAINING RING, INTERNAL (80MM) 1

L F0100A4B12 SCREW (1/4-20) 1

M 21529 LOWER ST ATIONARY ARM ASSEMBLY, INCLUDES BEARINGS AND HUB 1

M 18391 LOWER STATIONARY ARM 1

1

GyroMixer End User Guide 51

Page 56

PARTS

I

Q

R

U

C

U

S

A

J

V

H

G

O

P

N

M

B

D

F

L

Rotary Assembly

52

Page 57

PART NO DESCRIPTION NO REQ

A 01113 SCREW (8-32 X 3/8) 4

PARTS

B 18310 UPPER MOVING ARM ASSEMBL Y, INCLUDES BUSHINGS, SCREWS,

MOVING ARM & UPPER TABLE

C 18322 YOKE 1

D 18323 ROD GUIDE 2

E 18324 LEAD SCREW 2

F 18330 LOWER MOVING ARM ASSEMBLY (INCLUDES BUSHINGS, SCREWS,

LOWER MOVING ARM & TABLE)

G 18341 PLANE BUSHING (1/2” X 5/8” OD X 5/16”) 1

H 18342 COMPRESION SPRING (0.6 OD, X 1”) 4

I 22876 PIN 1

J 22875 NUT, SLOTTED 1

K 18340 CLAMP HANDLE ASSEMBLY 1

L 18390 LOWER STATIONARY ARM ASSEMBLY 1

M 18420 UPPER STATIONARY CLAMPING GEAR ARM ASSEMBLY, INCLUDES

BEARINGS, BUSHINGS, CLAMPING PRESSURE PLATES, GEAR ARM

ASSEMBL Y & GEARS

N 18422 GEAR ARM COVER 1

18430 TORSION SPRING (NOT SHOWN) 1

1

1

1

O 25279 RATCHET, CLAMP LOCKING 1

P 18447 THRUST BUSHING (1/2” X 1” OD) 3

Q 18459 PLUG, POLYETHYLENE (2”) 1

21525 LOWER MOVING ARM ASSEMBLY, INCLUDES BEARINGS AND HUB

(NOT SHOWN)

21526 CLAMP HANDLE ASSEMBLY, INCLUDES BUSHINGS AND DOWL PIN

(NOT SHOWN)

21527 LOCKING LINKAGE KIT, INCLUDES DOWEL PIN, PAWL SCREWS AND

SPRING (NOT SHOWN)

R F0103816 SCREW (1/2-13 X 1”) 2

S F0103824 SCREW (1/2-13 X 1-1/2”) 2

F0115A0724 DOWEL PIN (1/2-13 X 1-1/2”) (NOT SHOWN) 2

T F0100A3B08 SCREW (10-24 X 1/2”) 8

U F01260812062 SPACER, 1/2” ID X 3/4” OD X 1/8” 6

1

1

1

GyroMixer End User Guide 53

Page 58

PARTS

E

A

C

B

D

F

Secondary Idler Pully Assembly

54

Page 59

PART NO DESCRIPTION NO REQ

A 03163 NUT (3/4-10 HEX) 2

B 18453 V-IDLER PULLEY WITH BEARINGS 2

PARTS

C 18454 SECONDARY IDLER MOUNTING BRACKET118457SECONDARY IDLER

BUSHING

D 18457 SECONDARY IDLER BUSHING 4

E 18460 IDLER ASSEMBLY, SECONDARY(INCLUDES BUSHINGS, MOUNTING

BRACKET, PULLEYS, AND SCREWS)

F 4000227 HEX SCREW (3/8-16 X 1.25) 2

1

1

GyroMixer End User Guide 55

Page 60

PARTS

A

18421

B

H

F

G

K

C

D

I

E

J

E

Upper Stationary Gear Arm Assembly

56

Page 61

PART NO DESCRIPTION NO REQ

A 18301 LEAD SCREW CAP 2

B 18302 KEY, 48 TOOTH GEAR (1/8” X 1/8” X 1/4”) 2

18311 FEMALE CLAMPING PRESSURE PLATE (NOT SHOWN) 1

C 18319 NYLON SPACER (3/8” X 3/4” X 1/8”) 4

D 18343 CLAMPING HANDLE PIN 1

PARTS

18398 BRASS 72 TOOTH GEAR (NOT SHOWN)

EXPLOSION PROOF GYROMIXER ONLY

E 18399 STEEL 48 TOOTH GEAR 2

F 18427 THRUST BUSHING (3/8” ID X 3/4” OD) 4

18428 FLANGE BUSHING, 3/8” ID X 1/2” OD 5/16” (NOT SHOWN)

G 18429 FLANGE BEARING (1/2” ID X 5/18” OD X 1/2”) 1

H 18447 THRUST BUSHING (1/2” ID X 1” OD) 2

18451 BRASS 48 TOOTH GEAR (NOT SHOWN)

EXPLOSION PROOF GYROMIXER ONLY

I 20454 RADIAL BALL BEARING (1/2” X 1-1/8:) (NOT SHOWN) 2

21530 GEAR ARM ASSEMBLY(INCLUDES DOWEL PINS) 1

21531 UPPER STATIONARY GEAR ARM ASSEMBLY, COMPLETE,

INCLUDES BEARINGS, BUSHINGS, CLAMPING PRESSURE PLATES,

GEAT ARM ASSEMBLY AND GEARS (NOT SHOWN)

STANDARD GYROMIXER

21532 UPPER STATIONARY GEAR ARM ASSEMBLY, COMPLETE,

INCLUDES BEARINGS, BUSHINGS, CLAMPING PRESSURE PLATES,

GEAT ARM ASSEMBLY AND GEARS (NOT SHOWN)

EXPLOSION PROOF GYROMIXER ONLY

J 21533 STEEL 72 TOOTH CENTER GEAR WITH TAPPED HOLES,

INCLUDES BUSHINGS

2

2

1

1

1

K 21534 STEEL 72 TOOTH GEAR WITH BUSHING

(TWO FOR EXPLOSION-PROOF, FOUR FOR STANDARD)

21535 MALE CLAMPING PRESSURE PLATE ASSEMBLY, INCLUDES

BUSHINGS (NOT SHOWN) STANDARD GYROMIXER

21536 MALE CLAMPING PRESSURE PLATE ASSEMBLY, INCLUDES

BUSHINGS (NOT SHOWN) EXPLOSION PROOF GYROMIXER ONLY

L F0024A3B08 SCREW, FLANGE HEAD CAP (10-32 X 1/2” SOCKET WITH NYLON

PATCH)

2 / 4

1

1

6

GyroMixer End User Guide 57

Page 62

Part No. 4708000

Rev. I

07.30.10

Fluid Management

1023 Wheeling Road

Wheeling, Illinois 60090-5776

Telephone: (847) 537-0880

1-800-462-2466

Fax: (847) 537-5530

www.fluidman.com

®

Loading...

Loading...