Page 1

FAST & FLUID MANAGEMENT

Blendorama series II

ENGLISH

Page 2

© Fast & Fluid Management, Blendorama series II

p1

Page 3

© Fast & Fluid Management, Blendorama series II

Table of Contents

Blendorama series II manual (EN) 3

Introduction, Conditions of Sale & Warranty 3

Safety instructions 6

Installation 7

Operation 10

Preventitive maintenance 17

General maintenance 21

Troubleshooting 38

Service Agents 39

Specificaties 40

Wiring diagram 41

p2

Page 4

© Fast & Fluid Management, Blendorama series II

Blendorama series II manual (EN)

Introduction, Conditions of Sale & Warranty

A - Introduction

By selecting a Fast & Fluid Management Color Dispenser you have opted for a product which is the result of

intensive research. Top-quality components, craftsmanship and a modern ergonomic design all serve to

guarantee a long service life and a high degree of user friendliness.

Blendorama Colorant Dispensers have been designed for long life and will withstand the normal wear expected

during use in plant or in store. However, each is a precision machined metering device and should be treated

accordingly

The basic unit of your dispensing system is represented as “Y” (except for metric and hybrid systems), and the

volume of this unit (approx. one fluid ounce) has been determined by the paint manufacturer.

The “Y” unit is further divided into (usually) 32, 48 or 64 sub-units. The basic unit of the metric dispenser is

one millilitre.

With the exception of Models 22/23XC, all feature a small bore inner pump to dispense small amounts of

colorant very accurately. The 1/64, 1/48 or millilitre units are divided further for this inner pump.

B - Standard Terms & Conditions of Sale

1. Application of Terms

These terms and conditions apply to every sale of a Blendorama Colorant Dispenser and Blendormix mixers

and each and every component part thereof ("the Product") by Fast & Fluid Management Australia ("the

Sellers) or any of its related companies to a Buyer and in the event that such Buyer purchases the Product

for resale, such resale shall be effected on the terms and conditions set out herein, except for price, and

such resale shall be deemed to be effected on such terms and conditions in the name and on behalf of the

parties to such resale transaction only, save for the Warranty contained in paragraph 6 which is given in the

name and on behalf of the Seller only.

2. Passing of Risk - transfer of title in the product

Prices are quoted ex-works. The risk of loss or damage to the Product shall pass to the Buyer in the case of a

contract for supply of the Product immediately upon delivery either to the Buyer or a nominated carrier for

transportation to the Buyer or to a place or site nominated by the Buyer or at the direction of the Buyer.

Such delivery shall be deemed to be delivery to the Buyer and acceptance by the Buyer of the Product

whether or not the Buyer is present at the time of delivery to sign a receipt for the Product. Notwithstanding

the foregoing property in and title to the Product shall not pass to the Buyer until payment in full for the

Product has been received by the Seller.

3. Delivery Time frame

Any date(s) given to the Buyer by the Seller for delivery shall be regarded as estimates only and while the

Seller shall use its best endeavours to meet such dates the Buyer agrees that no liability shall attach to the

Seller for any loss or damage, direct or consequential arising out of any delay in delivery or for non-delivery

from any cause whatsoever. If for any cause beyond the Seller's control, the Seller is unable to deliver

either within a reasonable time or at all, the contract shall be voidable at the Seller's option with no right of

either party to claim any damages against the other.

4. Sole Terms

These terms and conditions constitute the entire agreement for sale of the Product between the Seller and

the Buyer and shall prevail over any differing terms and conditions incorporated or purported to be

incorporated into the sale of the Product by the Buyer or by the Seller or otherwise alleged to have been

agreed and shall only be varied modified or rescinded by written agreement of the Seller.

p3

Page 5

© Fast & Fluid Management, Blendorama series II

5. Limitation of Liability

Subject to Paragraph 6 of these terms and conditions and in particular sub-paragraph 6.7 hereof the seller

shall neither be subject to nor incur, and the Buyer releases the Seller from any claim or liability (including

consequential loss or damage, loss or use or profit) by reason of delay, defective or faulty components or

materials or workmanship, negligence, or any act, matter or thing done admitted or omitted by the Seller or

by reason of the unsuitability of the Product for the Buyer's , purpose and the Buyer acknowledges that it did

not rely on the skill or judgement of the Seller in selecting and ordering the Product for the purpose for

which the same was required by the Buyers.

5.1 Product return

Subject to paragraph 6 hereof or as otherwise agreed by the Seller the Buyer may not return the Product or

any part or parts thereof after delivery has been effected. Any claim or claims for return of the Product or

any Parts thereof must be made within 30 days of delivery of the Product to the Buyer.

6.6.8 improper observance of the Daily Routine care instructions in the Booklet;

6.6.9 improper use in discharging the pump without observing the instructions in the Booklet;\

6.6.10 improper observance of the instructions in the Booklet;

6.6.11 improper observance of the Canister Drive maintenance instructions in the Booklet;

6.6.12 improper observance of the servicing of replacement parts instructions in the Booklet.

6. Warranty

The Seller hereby warrants to the Buyer that the Product will be free from defects in materials and

workmanship in normal use, service and operation for a period of twelve (12) months from the date of

delivery effected by the Seller or one of its authorised Distributors to the Buyer.

6.1 Warranty Limitations (1)

The Product is supplied subject to this Warranty only and liability arising out of or in respect of the supply,

resupply, use or re-use whether singularly or otherwise of the Product howsoever arising and whether in

respect of consequential loss or otherwise and including any other liability the Seller may otherwise have

had by virtue of any representation warranty condition or term (whether express or implied by law) is

hereby excluded.

6.2 Warranty Limitations (2)

Any liability incurred by the Seller to the Buyer is limited to the replacement of the Product or (at the

Sel1er's option) refund of the price paid by the Buyer, in particular does not extend to consequential loss

and is conditional upon the Buyer within 30 days of delivery making a written claim to the Seller setting out

the full particulars of any such claim. The transportation costs both ways are to be paid in full by the Buyer.

6.3 Claims Procedure

In the event of any defect arising the Buyer must notify the Seller or one of its authorised distributors in

writing and must establish to the reasonable satisfaction of the Seller or an authorised Distributor the date

of delivery of the Product by way of invoice or receipt and particulars delineated in the relevant part of this

Warranty

6.4 Future Modifications.

The Seller may make such modifications to any existing or future models of the Product as it may deem

necessary without incurring any obligation to incorporate such modifications in any Product(s) previously

sold or to which this Warranty may relate.

6.5 Sole Warranty

Subject to sub-paragraph 6.6 hereof, the obligations of the Seller or any authorised Distributor under this

Warranty are limited to those contained above ant this Warranty is the only Warranty made by the Seller

and is exclusively and expressly in lieu of all other warranties permitted to be excluded by law, whether

these warranties are express or implied, under the common law or by statute and the terms of the Warranty

may not be modified by any person, firm or corporation other than the Seller.

p4

Page 6

© Fast & Fluid Management, Blendorama series II

6.6 Warranty Exclusions

Subject to sub-paragraph 6.7 hereof this Warranty does not extend and the Seller or an authorised

Distributor will be relieved of all and any obligations, responsibilities and liabilities (direct or consequential)

in the event that defects in or malfunctions of the Product are directly or indirectly due to or result from:

6.6.1 lack of proper maintenance or care;

6.6.2 unreasonable or incorrect use, for a purpose other than that for which it was designed;

6.6.3 faulty setting up which is not carried out in accordance with the directions in the Blendorama

Booklet (''the Booklet");

6.6.4 failure to observe any other instruction or directions provided with the Product or given to the

Buyer by the Seller;

6.6.5 modifications or repairs made or attempted to be made by any unauthorised person;

6.6.6 improper use in operating the Product without observing the instructions in the Booklet

6.6.7 improper use in discharging the pump without observing the instructions in the Booklet;

6.6.8 improper observance of the Daily Routine care instructions in the Booklet;

6.6.9 improper use in discharging the pump without observing the instructions in the Booklet;

6.6.10 improper observance of the instructions in the Booklet;

6.6.11 improper observance of the Canister Drive maintenance instructions in the Booklet;

6.6.12 improper observance of the servicing of replacement parts instructions in the Booklet.

6.7 Statutory Warranties - The Product

It is expressly provided that this Warranty or any terms or conditions contained in it or other statement(s)

contained in these terms and conditions and Warranty, the Booklet or other literature given to the Buyer

shall not be read or applied so as to purport to exclude restrict or modify or have the effect of excluding,

restricting or modifying the application in relation to the supply of the Product of all or any of the provisions

of Division 2 and 2A of Part V of the Trade Practices Act 1974 ("The Act”) as amended or the exercise of a

right conferred by such a provision or any liability of the Seller or its Authorised Distributors for breach of a

condition or warranty implied by such provisions or any other conditions or warranties implied by any

relevant State Act or Territorial Ordinance or by the general law and which by law cannot be excluded,

restricted or modified PROVIDED THAT to the extent that The Act permits the Seller to limit its liability for

a breach of a condition or warranty implied by The Act, the liability of the Seller for such breach shall be

limited to the payment of the cost of replacing the Product or acquiring equivalent Product, or of repairing

the Product.

7. Product - In Store - Set Up

The Seller shall not be liable for any loss or damage caused directly or indirectly by:

Any damage to or deterioration in the conditions of the Product occurring after delivery to the Buyer and

prior to the setting up of the product;

any damage to the Product due to incorrect support or obstruction in setting up the Product;

any damage caused by the Product due to incorrect support or obstruction in setting up the Product.

p5

Page 7

© Fast & Fluid Management, Blendorama series II

Safety instructions

A - General safety instructions

Attention! Before installing the equipment, please read this instruction

manual carefully. This will increase your personal safety and prevent

unnecessary damage to the machine.

The manufacturer accepts no liability if the instructions below are not followed:

If a machine has been damaged (during transport, for example), do not attempt to set it in operation.

1.

When in doubt, first contact either your supplier or the F&FM service department.

The equipment should be positioned and connected up in strict accordance with the installation instructions.

2.

All local safety regulations and ordinances should be observed.

3.

The machine may be connected only to a 230/240V/50/60Hz or 110V/50/60HZ earthed wall socket

4.

installed in accordance with the regulations.

Users should ensure that the machine is kept in good condition. Defective components should be replaced.

5.

In order to prevent physical injury, the doors should be closed and the paneling fitted during normal use.

6.

All service activities (other than routine maintenance and adjustments) may only be carried out by

7.

qualified technicians. Ensure that the mains lead is always kept unplugged while repairs are being carried

out.

B - Specific warnings in this manual

Attention! MOVING PARTS CAN CAUSE INJURY. Always turn off power at

the wall socket before accessing moving parts.

p6

Page 8

© Fast & Fluid Management, Blendorama series II

Installation

A - Unpacking the dispenser

The box(es) you have received contain:

1 x Machine Base Assembly (for floorstand models)

1 x Turntable Assembly (This may be already assembled onto the base)

x Colorant Canisters, each with a lid, attached pump and fixing screws

1 x Operation Manual

A plastic bag or box containing:

1 x Allen Key for Pump Calibration (Note: Pumps preset in factory)

1 x No. 2 Phillips head screwdriver (for attaching canisters)

1 x ¼” spanner (for remote canister bracket attachement)

2 x Valve Inserts with "O" Rings

1 x Valve Insert Wrench (to enable pump to be removed from canister)

1 x Outer Piston Seal Kit complete with reusable Assembly Tool

2 x Nozzle Wiper Arms (with pads)

3 x Nozzles (larger bore)

3 x Nozzles (smaller bore)

1 x Inner Piston complete with reusable Assembly Tool

If any of these parts are missing, contact your supplier of F&FM immediately.

Step 1 - Detach the dispenser from its transport

skid

>

Unscrew the 2 transport

screws connecting the

machine to the skid

Carefully maneuver the

machine off the skid

p7

Page 9

© Fast & Fluid Management, Blendorama series II

B - Installing the canisters

Please note that this procedure is used for all canister sizes, although only

1.75L (22P) canisters are shown here. Other canister assemblies will vary

in size and appearance, however the procedure remains the same.

Connecting tubes are sized specifically for each canister and turntable size

– please do not mix between different models.

Step 1 - Prepare and install the inner ring of canisters.

>

(1) Select the parts used in an inner canister

assembly:

(A) canister with bush (B) at base

(C) connecting tube

(D) remote bracket and pump assembly

(E) washer collar self-tapping screw

(2) Firmly push the

connecting tube into the

bush.

p8

Page 10

© Fast & Fluid Management, Blendorama series II

> >

(3) Firmly push the canister

and connecting tube into the

remote bracket and pump

assembly.

(4) Fit this assembly to the

turntable. Canister screws

(already fitted to the

canister) fit into the inner

ring location keyholes and

the remote bracket fits into

the 4 slots simultaneously.

Push firmly into position.

Step 2 - Prepare and install the outer ring of canisters.

> >

(5) Secure the inner ring

canister assembly in position

with the washer collar

self-tapping screw

(provided) using either a

standard screwdriver or a

socket head (1/4” or 7mm).

(6) Repeat (2) to (5) for all

other inner ring canister

assemblies.

(1) Select the outer ring

canister assembly.

(2) Fit the canister screws

into the outer ring of keyhole

slots on the turntable. Push

firmly into position.

p9

(3) Locate the 2 guide holes

directly below each canister

and fasten the screws

(already located in canister)

with a Philips (No. 2)

screwdriver.

(4) Repeat steps (2) to (3)

for all other outer ring

canister assemblies.

Page 11

© Fast & Fluid Management, Blendorama series II

Operation

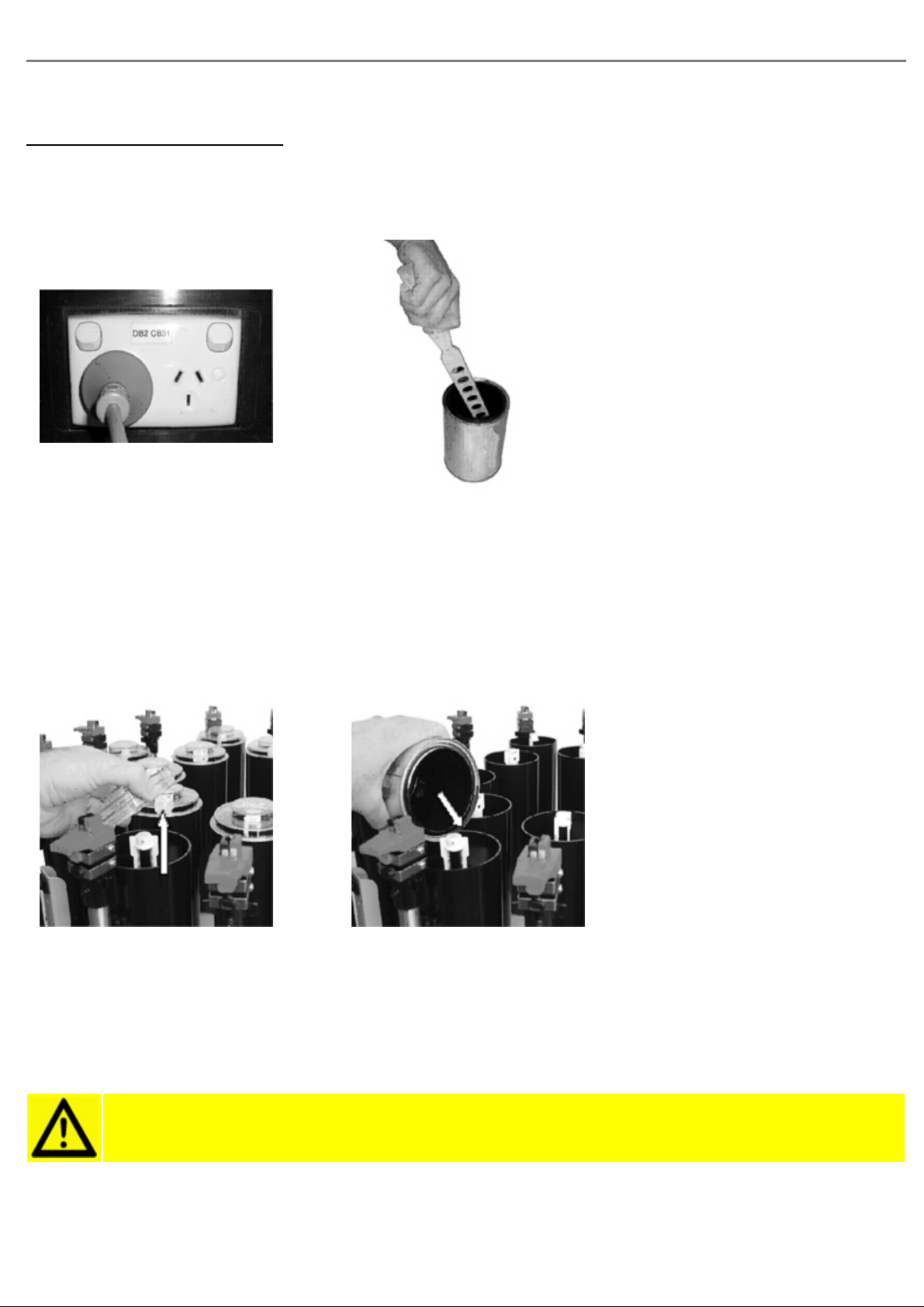

A - First time operation

Step 4 - Preparing the dispenser

> >

Ensure that the machine is

switched off at the wall

socket

Remove the lids from all

canisters

>

Stir each can of colorant

thoroughly with a flat

bottomed paddle or palette

knife to reincorporate any

settled pigment

Pour the contents of each

colorant can into the correct

canister. Discard the

colorant can and replace the

canister lid

Ensure that the machine is

adequately supported and

clear of obstructions

Attention! Always wear eye protection when handling colorants

p10

Page 12

© Fast & Fluid Management, Blendorama series II

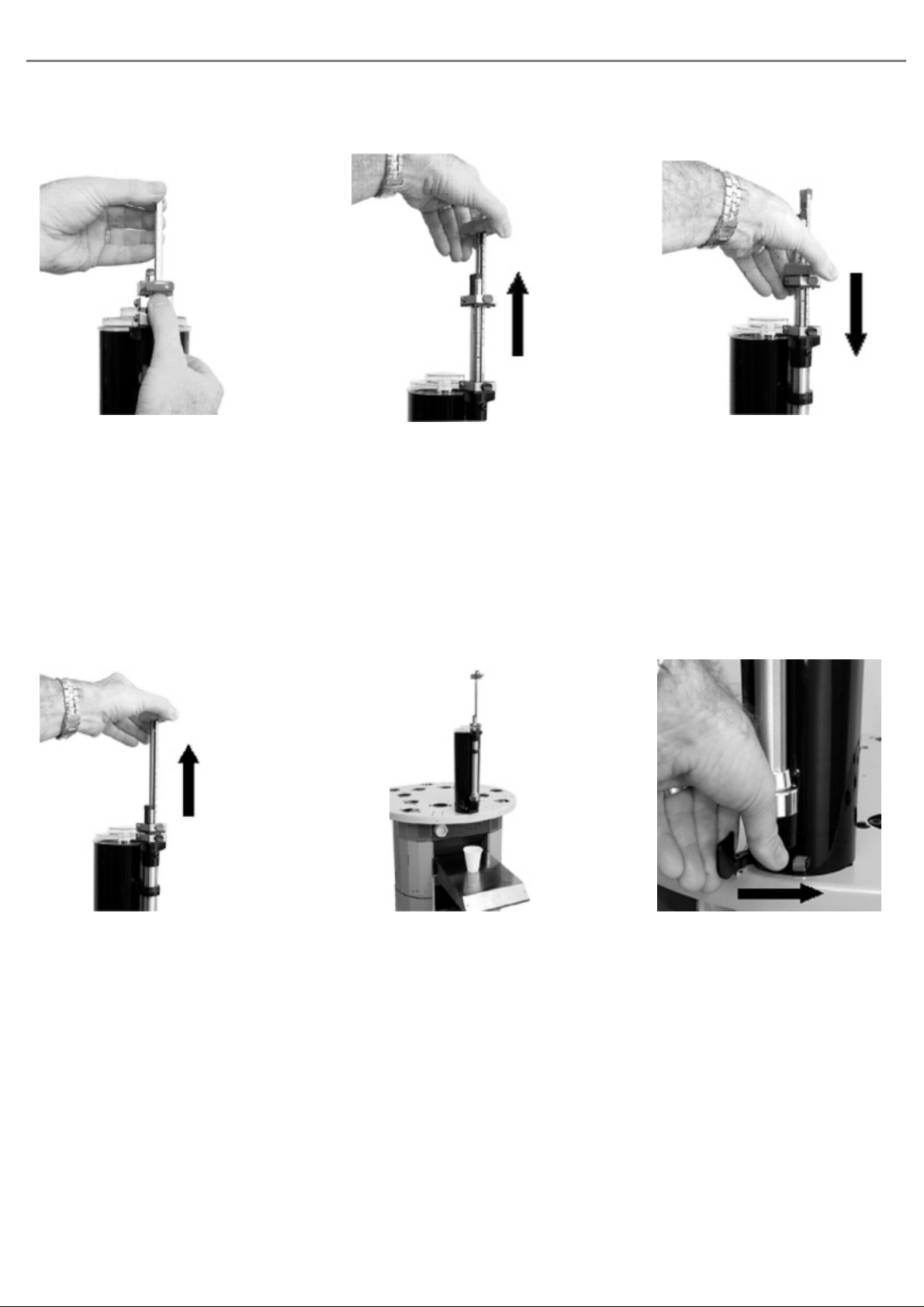

Step 2 - Purging the pumps

> >

Set the gauge or gauges of

each pump to its halfway

point by operating the spring

loaded button then lifting the

gauge by its handle

Step 3 - Purging the valve

> >

Without operating the valve

lever lift the red pump

handle to its maximum

travel (this draws the

colorant into the canister)

Discharge the colorant back

into the canister by

depressing the red pump

handle fully. Repeat this

process 30 times.

Lift the red pump handle to

its maximum travel

Place a clean can or paper

cup under the dispensing

nozzle

p11

Hold the valve lever open by

pulling the spring loaded

lever forward its full travel

Page 13

© Fast & Fluid Management, Blendorama series II

> >

Push the red pump handle

down fully to dispense

colorant into the cup

Release the valve lever Repeat this process until the

Step 4 - Check the effectiveness of the purge

> >

Open the valve lever

without operating the

pump. A small drop of

colorant will appear at the

nozzle

Release the valve lever

slowly and the drop will

withdraw into the nozzle

colorant emerges as an

unbroken stream

Repeat this process 10

times. If the drop of

colorant at the nozzle grows

appreciably with each

opening of the valve lever

and/or it drops from the

nozzle into the cup, then air

is still in the system and

steps 2 & 3 should be

repeated

Repeat this process for all

canisters.

Attention! For dispensers fitted with electronic timers, it is important that

the machine be switch on at all times unless topping up canisters.

Attention! For manual agitation type dispensers, it is good practice to

agitate the colorant twice daily for four (4) minutes.

p12

Page 14

© Fast & Fluid Management, Blendorama series II

B - General use of the dispenser

Step 1 - Select the color, base and can size

> >

Identify the color you wish

to supply either by name or

number

Step 2 - Position the

can

Look up the tint formula and

note the Tint Base required

Identify the quantity

required (can size)

Place the can on the

appropriate can shelf. Adjust

the height of the upper can

shelf (floorstand models )if

necessary

p13

Page 15

© Fast & Fluid Management, Blendorama series II

Step 3 - Bring canister to the correct position

>

Depress and hold the detent

lever to release the

turntable. You can lock the

detent lever in the release

position by pushing it

sideways.

When rotating the turntable, DO NOT use the canisters or pumps as

handles. Use the edge of the turntable.

Rotate the turntable so that

the pump of the appropriate

canister is directly over the

can. If the detent lever it

released it will lock the

canister into the correct

position. You may need to

move the turntable slightly

from side to side to allow

the locking pin to locate the

locking hole.

p14

Page 16

Step 4 - Set the Gauges

© Fast & Fluid Management, Blendorama series II

> >

According to the setting

required, operate the spring

loaded button to release the

gauge. The red knob is for

the red gauge and the black

knob is for the black gauge

Step 5 - Charge the pump

>

With the appropriate button

operated, lift the gauge to

the reading required.

The correct gauge setting is

shown when the figure

selected is fully exposed

above the RED handle and

the gauge release button

clicks firmly into place.

With the gauges correctly

set, slowly and gently lift the

red pump handle until both

red and black handles are

against the appropriate

gauge knobs

If the colorant level is too low, air can be sucked into the pump. If this

occurs, return the handle to the zero position, add sufficient colorant, and

purge the pumps and valve (see chapter IV, step 2 & 3)

Continue to hold this for a

few seconds to ensure the

pump is correctly filled with

colorant.

p15

Page 17

© Fast & Fluid Management, Blendorama series II

Step 6 - Discharge the pump

> >

While still holding the pump

handle in the raised

position, pull the

spring-loaded valve lever (at

the base of the pump)

forward its full travel

Holding the valve lever fully

forward, press the red

handle down with a smooth

and steady stroke until the

red handle is fully depressed.

Ensure that both the red and

black handles are fully

depressed against the end

cap. All the colorant has

now be discharged and the

valve lever can be released

Repeat the charging and

discharging process for each

colorant specified in the

formula

If you have to tint more than one container of the same color, leave the

gauges set at the required reading and simply recharge and discharge each

pump in turn in the order nominated by the tint formula.

p16

Page 18

Preventitive maintenance

A - Do’s & Don’ts

© Fast & Fluid Management, Blendorama series II

DO

DO

Keep the machine clean and display advertising promoting good housekeeping.

Keep this operation manual, Allen key, valve sleeve wrench and spare parts in a

convenient place to assist in regular maintenance

DON’T

DON’T

DON’T

Use the piston or valve assembly of each pump as a handle to rotate the

turntable. Instead, use the canister or edge of the turntable.

Attempt to replace the valve plate – if this is faulty, the whole valve assembly

must be replaced

Make any adjustments to the stirring timer. This unit has been factory set

and should only be adjusted by authorized personnel.

B - Daily maintenance

Clean the brush tray, refill canisters and run morning program

> >

Wipe down stand, canisters

and pumps with a moistened

cloth

Check nozzle outlets for dried

colorants.

If dried colorant is found to

be blocking the nozzle,

remove the nozzle by

pushing down on the top of

the nozzle.

p17

Page 19

© Fast & Fluid Management, Blendorama series II

>

Clean the nozzle using warm

soapy water

Refit the nozzle and dispense a

small amount of colorant

If the dispenser is not used on a regular daily basis, the following procedure

should be carried out.

> >

Check the level of colorant

and top up if required

Ensure that power is

connected to the dispenser

and turned on so that

automatic stirring occurs

Open and close each pump

valve 5 times

Purge the pumps (see chapter

IV, step 2 & 3) however only

operate the pump 5 times

>

Check the valve levers and nozzle

wiper arms for possible damage.

p18

Page 20

© Fast & Fluid Management, Blendorama series II

C - Weekly maintenance

If the dispenser is not used on a regular daily basis, the following procedure

should be carried out.

> >

Examine the machine for

loose canisters and loose

cylinder caps. Tighten if

necessary

Examine gauges for

damaged graduated scales

or worn holes and replace if

necessary

Raise the pump handle to its

maximum extension and

examine the pump shafts for

signs of colorant. This

indicates that the piston seal

will need replacement (see

Chapter VI - C,D,E)

p19

Page 21

© Fast & Fluid Management, Blendorama series II

D - Periodic maintenance

This maintenance should be carried out every 3 to 6 months depending

upon use.

> >

Inspect the function of the

valve and the canister for leaks

Remove stirrer paddle from

canister and wash the canister,

lid and stirrer paddle clean

Ensure that the machine is

disconnected from the power

source

> >

If required, tighten or replace

valve sleeve (with the wrench

supplied)

>

Remove canister from turntable

and drain colorant into a clean

container

Replace “O” ring seal

Reassemble and refit canister to

turntable

Attention! MOVING PARTS CAN CAUSE INJURY. Always turn off power

before accessing moving parts.

Return colorant to dispenser

and prepare the pump for

operation (see chapter IV-A)

p20

Page 22

© Fast & Fluid Management, Blendorama series II

General maintenance

A - Metalcal replacement (Models 22/23 XC)

Before replacing the metalcals, calibrate the plungers as per the calibration instructions. Also make sure that

the replacement metalcal is the correct one - check the part numbers.

> >

(1) Remove the red gauge

from the plunger.

(2) Peel the metalcal off the

gauge, and remove all traces

of adhesive (use a solvent if

necessary). Wipe dry.

> >

(3) Replace the gauge and

set to the zero (fully down)

position. The locking pin at

the rear of the pump should

be engaged in the first of the

small holes.

(4) Mark a line on the

gauge, level with the top of

the red handle. Use a fine

felt tip pen or pencil (or

scratch with a sharp object).

(5) Remove the gauge from

the pump and peel off the

adhesive backing.

p21

(6) Carefully place the “0”

line (the line below the

numeral) of the metalcal on

the marked line of the gauge.

Page 23

© Fast & Fluid Management, Blendorama series II

> >

(7) Once in position, press

the metalcal firmly onto the

gauge, ensuring it adheres

to the gauge along its full

length with no creases or

bubbles (use a clean cloth to

apply if necessary).

(8) Using a sharp knife or

blade cut any excess

metalcal off the end of the

gauge that may overlap the

red plastic handle.

(9) Refit the gauge to the

plunger.

B - Metalcal replacement (Models 22/23 XD/XE)

Before replacing the metalcals, calibrate the plungers as per the calibration instructions. Also make sure that

the replacement metalcal is the correct one - check the part numbers.

> >

(1) Remove both black and

red gauges.

(2) Peel the metalcals off

both the red and black

gauges, and remove all

traces of adhesive (use a

solvent if necessary). Wipe

dry.

p22

(3) Replace both gauges and

set to the zero (fully down)

position. The locking pin at

the rear of the pump should

be engaged in the first of the

small holes.

Page 24

© Fast & Fluid Management, Blendorama series II

> >

(4) Mark a line on the black

gauge, level with the top of

the red handle. Use a fine

felt tip pen or pencil (or

scratch with a sharp object).

(7) Once in position, press

the metalcal firmly onto the

gauge, ensuring it adheres

to the gauge along its full

length with no creases or

bubbles (use a clean cloth to

apply if necessary).

(5) Remove the gauge from

the pump and peel off the

adhesive backing.

> >

(8) Using a sharp knife or

blade cut any excess

metalcal off the end of the

gauge that may overlap the

black plastic handle.

(6) Carefully place the “0”

line (the line below the

numeral) of the metalcal on

the marked line of the gauge.

(9) Refit the gauge to the

plunger. Repeat steps (4)

through (9) for the inner

(red) gauge metalcal.

p23

Page 25

© Fast & Fluid Management, Blendorama series II

C - Metalcal replacement (Models 53 XB)

Before replacing the metalcals, calibrate the plungers as per the calibration instructions. Also make sure that

the replacement metalcal is the correct one - check the part numbers.

> >

(1) Remove both black and

red gauges.

(2) Peel the metalcals off

both the red and black

gauges, and remove all

traces of adhesive (use a

solvent if necessary). Wipe

dry.

> >

(3) Replace both gauges and

set to the fully down

position. Lift the black

(outer) gauge and engage

the locking pin in the 2nd

hole from the top.

(4) Mark a line on the black

gauge, level with the top of

the red handle. Use a fine

felt tip pen or pencil (or

scratch with a sharp object),

then remove the black gauge

from the pump.

(5) Peel the adhesive

backing off the black

metalcal.

p24

(6) Align the end of the

metalcal up against the

bottom edge of the gauge

knob, checking that the first

line of the metalcal (the line

below the first numeral)

lines up with the marked line

of the gauge (the metalcal is

cut to size before leaving the

factory).

Page 26

© Fast & Fluid Management, Blendorama series II

> >

(7) Once in position, press

the metalcal firmly onto the

gauge, ensuring it adheres

to the gauge along its full

length with no creases or

bubbles (use a clean cloth to

apply if necessary).

(8) Refit the black (outer)

gauge to the plunger and

remove the red (inner)

gauge from the pump.

> >

(9) Peel the adhesive

backing off the remaining

red metalcal.

(10) Align the end of the

metalcal up against the

bottom edge of the gauge

knob (the metalcal is cut to

size before leaving the

factory).

(11) Once in position, press

the metalcal firmly onto the

gauge, ensuring it adheres

to the gauge along its full

length with no creases or

bubbles (use a clean cloth to

apply if necessary).

p25

(12) Refit the red gauge to

the plunger.

Page 27

© Fast & Fluid Management, Blendorama series II

D - Metalcal replacement (Models 53 XD/XE)

Before replacing the metalcals, calibrate the plungers as per the calibration instructions. Also make sure that

the replacement metalcal is the correct one - check the part numbers.

> >

(1) Remove both black and

red gauges.

(2) Peel the metalcals off

both the red and black

gauges, and remove all

traces of adhesive (use a

solvent if necessary). Wipe

dry.

> >

(3) Replace both gauges and

set to the fully down

position. Lift the black

(outer) gauge and engage

the locking pin in the 2nd

hole from the top.

(4) Mark a line on the black

gauge, level with the top of

the red handle. Use a fine

felt tip pen or pencil (or

scratch with a sharp object),

then remove the black gauge

from the pump.

(5) Peel the adhesive

backing off the black

metalcal.

p26

(6) Align the end of the

metalcal up against the

bottom edge of the gauge

knob, checking that the first

line of the metalcal (the line

below the first numeral)

lines up with the marked line

of the gauge (the metalcal is

cut to size before leaving the

factory).

Page 28

© Fast & Fluid Management, Blendorama series II

> >

(7) Once in position, press

the metalcal firmly onto the

gauge, ensuring it adheres

to the gauge along its full

length with no creases or

bubbles (use a clean cloth to

apply if necessary).

(8) Refit the black (outer)

gauge to the plunger and

remove the red (inner)

gauge from the pump.

> >

(9) Peel the adhesive

backing off the remaining

red metalcal.

(10) Align the end of the

metalcal up against the

bottom edge of the gauge

knob (the metalcal is cut to

size before leaving the

factory).

(11) Once in position, press

the metalcal firmly onto the

gauge, ensuring it adheres

to the gauge along its full

length with no creases or

bubbles (use a clean cloth to

apply if necessary).

p27

(12) Refit the red gauge to

the plunger.

Page 29

© Fast & Fluid Management, Blendorama series II

E - Replacement of Piston Seals (Models 22/23 XC)

> >

(1) Loosen both grubscrews

in the cylinder of the end cap

(use Allen key provided) and

remove the plunger

assembly from the cylinder.

Remove the gauge and clean

all colourant from the

plunger assembly.

(2) Remove the old piston

retaining screw and discard

the screw, piston and

washer. Remove the new

piston from retainer.

> >

(3) Smear a trace of Loctite

262 on the screw thread and

secure the new piston with

the washer behind. Tighten

the screw only until the

piston can no longer be

rotated by hand.

(4) Holding the end cap (A)

in one hand, pull the red

handle (B) until the piston is

fully withdrawn inside the

end cap.

(5) After lightly oiling the

top inside edge of the

cylinder, position the plunger

assembly on the cylinder

with one hand. With the

palm of the other hand,

firmly push the red handle

down fully.

p28

(6) Lightly tighten the end

cap grubscrews, and refit the

gauge.

Page 30

© Fast & Fluid Management, Blendorama series II

F - Replacement of Piston Seals (Models 22/23 XD/XE)

Step 1 - Replacement of the inner piston

>

(1) Loosen both grubscrews

in the cylinder of the end cap

(use Allen key provided) and

remove the plunger

assembly from the cylinder.

Remove the gauges from the

plunger assembly, then

withdraw the inner plunger

assembly from the hollow

outer plunger shaft. Clean all

colourant from both plunger

assemblies.

(2) Using two pairs of pliers, grip

the inner end of the piston (A) with

one and the piston shaft with the

other. Unscrew the piston (using a

little heat if difficult) and discard.

(3) Apply Loctite 262 to the

internal thread of the piston shaft,

then screw the new piston

assembly in fully. Slide sleeve up

onto the shaft, tighten the piston

with pliers and replace the sleeve

over the piston.

p29

Page 31

© Fast & Fluid Management, Blendorama series II

Step 2 - Replacement of the outer piston

> >

(1) Using two spanners,

carefully undo the lower

piston nut. Discard the

piston but retain the nut.

(2) Remove the new piston

from retainer and fit to the

shaft curved end face up

(see picture). Replace the

front nut using a small drop

of Loctite 262 on thread.

Tighten the nut only until

the piston can no longer be

rotated by hand.

Step 3 - Returning plungers into cylinders

> >

(3) Holding the end cap (A)

in one hand, pull the outer

pump handle (B) until the

piston is fully withdrawn

inside the end cap.

(1) After lightly oiling the

top inside edge of the

cylinder, position the plunger

assembly on the cylinder

with one hand. With the

palm of the other hand,

firmly push the plunger

down fully.

(2) Remove the new piston

from retainer and fit to the

shaft curved end first.

Replace the front nut using a

small drop of Loctite 262 on

thread. Tighten the nut only

until the piston can no

longer be rotated by hand.

p30

(3) Remove the sleeve from

the inner piston and discard.

Lightly oil the inside edge of

the hollow outer piston shaft

and then gently ease the

piston inside. Refit the

gauges.

Page 32

© Fast & Fluid Management, Blendorama series II

G - Replacement of Piston Seals (Models 53 XB/XD/XE)

Step 1 - Replacement of the inner piston

>

(1) Undo the knurled nut

(A) holding the cylinder end

cap and remove the plunger

assembly (B) from the

cylinder. Remove both

gauges from the plunger

assembly, withdraw the

inner plunger assembly from

the hollow outer plunger

shaft and clean all colourant

from both plunger

assemblies.

(2) Using two pairs of pliers, grip

the inner end of the piston (A) with

one and the piston shaft with the

other. Unscrew the piston (using a

little heat if difficult) and discard.

(3) Apply Loctite 262 to the

internal thread of the piston shaft,

then screw the new piston

assembly in fully. Slide sleeve up

onto the shaft, tighten the piston

with pliers and replace the sleeve

over the piston.

p31

Page 33

© Fast & Fluid Management, Blendorama series II

Step 2 - Replacement of the outer piston

> >

(4) Fit the outer piston

assembly tool over the outer

piston shaft. Screw both

halves together then slide

the tool down over the

piston.

(5) Lightly oil the top inside

edge of cylinder and position

the tool containing the

plunger assembly on its rim.

Remove the screw from the

tool and force the piston

shaft through the split to

remove the tool.

(6) Refit the end cap onto

the top of the cylinder and

tighten the knurled nut.

Remove the sleeve from the

inner piston and discard.

Lightly oil the top inside

edge of hollow outer piston

shaft, gently ease the piston

inside. Refit all gauges.

p32

Page 34

© Fast & Fluid Management, Blendorama series II

H - Pump Calibration (Models 22/23 XC)

Recalibration of the pump is necessary if the original gauge has been replaced by another (for any reason) or if

the gauge scale detail (metalcal) is to be replaced. When recalibrating the pump, please leave the

pump/canister fixed in place on the machine.

Tools required:

1 x Allen (hex) key 3/32” A/F

1 x set of Feeler Gauges

>

(1) Using the Allen key provided, wind the

calibration screw up until it is entirely

within the red handle of the pump. Set the

gauge to the first non-zero position (see

the calibration chart or refer to your agent

for details).

(2) Wind the calibration screw down until

the desired clearance is achieved between

the small raised stop pad on the gauge

handle and the pump handle. The correct

clearance can be found on the calibration

chart (refer to your agent for details if

necessary). Measure the distance using

feeler gauges to confirm the clearance

accurately.

p33

Page 35

© Fast & Fluid Management, Blendorama series II

I - Pump Calibration (Models 22/23 XD/XE)

Recalibration of the pump is necessary if the original gauge has been replaced by another (for any reason) or if

the gauge scale detail (metalcal) is to be replaced. When recalibrating the pump, please leave the

pump/canister fixed in place on the machine.

Tools required:

1 x Allen (hex) key 3/32” A/F (originally supplied with the machine)

>

(1) To calibrate the outer

plunger, remove the inner

(red) gauge and inner (red)

plunger and set the outer

(black) gauge to the zero

position.

(2) Using the Allen key, undo both

calibration grubscrews until free movement

can be felt between the outer (black)

plunger handle and the outer (black)

gauge knob.

>

(3) Carefully wind one grubscrew down

until only slight movement is felt between

the outer pump handle and the gauge

knob. Then wind the other grubscrew

down until no free movement can be felt,

being careful not to over-adjust.

(4) To calibrate the inner (red)

plunger, refit the inner (red) gauge

and plunger removed in step (1).

Set the inner (red) gauge to zero.

p34

Page 36

© Fast & Fluid Management, Blendorama series II

>

(5) Using the Allen key, undo the

calibration grubscrew in the red pump

handle until free movement can be felt in the

handle. Carefully wind the grubscrew back

down until no free movement can be felt

between the red pump handle and the red

gauge knob. Be careful not to over-adjust.

(6) The pump is now calibrated.

p35

Page 37

© Fast & Fluid Management, Blendorama series II

J - Pump Calibration (Models 53 XB/XD/XE)

Recalibration of the pump is necessary if either of the original gauges have been replaced by another (for any

reason). It is not required if only a gauge scale detail (metalcal) has been replaced. When recalibrating the

pump, please leave the pump/canister fixed in place on the machine.

Tools required:

1 x Allen (hex) key 3/32” A/F

Step 1 - Outer pump calibration

>

(1) Calibrate the outer pump first

by removing the inner pump (red)

gauge and lifting the red pump

handle approximately 4” or

100mm. Lock the black outer pump

gauge into the top hole (zero

position). Using the Allen key,

undo the calibration grubscrew

until free movement can be felt

between the outer pump (black)

handle and the outer gauge knob.

(2) Carefully wind the grubscrew

down until no free movement is felt

between the outer pump handle and

the gauge knob, being careful not to

over-adjust. When correctly adjusted

there should be a slight binding felt

on the black gauge locking pin (as

the locking pin shaft enters the hole

in the gauge).

p36

Page 38

© Fast & Fluid Management, Blendorama series II

Step 2 - Inner pump calibration

>

(1) Calibrate the inner pump by lowering

red pump handle fully, then refitting the

inner (red) gauge and setting it to zero.

Undo the calibration grubscrew in the red

pump handle until the handle has

movement.

(2) Carefully wind the grubscrew

down until no free movement is felt

between the red pump handle and the

red gauge knob, being careful not to

over-adjust. When correctly adjusted

there should be a slight binding felt on

the red gauge locking pin (as the

locking pin shaft enters the hole in the

gauge).

p37

Page 39

© Fast & Fluid Management, Blendorama series II

Troubleshooting

A - Introduction

Before calling your machine supplier or Service Department, please check whether you can solve the problem

yourself. If you cannot, then call the Service Department for advice. Have the model number and serial

number at hand (these can be found on the sticker attached to service door at the side of the machine).

Attention! MOVING PARTS CAN CAUSE INJURY. Always turn off power

before accessing moving parts.

B - Problem solving

Symptom Cause Action

Colorant intermittently spurts

from the nozzle during

discharge

A drop of colorant falls from

the nozzle when the valve is

opened even when the pump is

not operated

The end cap twists or lifts

during operation

Canister is loose on turntable Loose fixing screws Tighten fixing screws with a philipps

Colorant appears on the piston

shaft, piston and/or gauges

Air bubbles in the colorant Operate the pump several times

without opening the valve to drive

the air back into the canister. Then

allow the colorant to sit for several

minutes to allow the bubbles to

escape.

Air is trapped in the cylinder

assembly

End-cap grub-screws are loose Lightly tighten the 2 grub-screws in

Worn seals Replace seals – refer to pages 32 to

Operate the pump several times

without opening the valve to drive

the air back into the canister. Then

allow the colorant to sit for several

minutes to allow the bubbles to

escape.

the end-cap (for 53 XB/XD/XE

tighten the end-cap sleeve) until the

end cap can no longer be twisted by

hand.

head screwdriver

35

Colorant does not dispense

easily

Colorant still does not dispense

easily

Colorant has hardened in the

canister and piston assembly

Agitation is not occurring No power to the dispenser Check that the unit is connected and

Nozzle blocked Remove nozzle and clean in warm

soapy water

High viscosity of colorant Increase the size of the nozzle

Canister and pump should be

removed, emptied, stripped and

cleaned thoroughly. Replenish only

with new colorant

that there is power to the outlet

p38

Page 40

© Fast & Fluid Management, Blendorama series II

Service Agents

A - Service Agents

For all service and repairs on Fast & Fluid Management products (including all warranty repairs), call the Fast

& Fluid Management Agent or Supplier. Within Australia, contact the service agent in your state or call the

Fast & Fluid management Service Hotline 1800 648584 or fax 02 42717306

Please make sure that you have the model number and serial number to hand. They can be found on the

nameplate on the machine.

NSW RW Palmer Electrical

Unit 17, 398 Marion Street, Bankstown, NSW, 2200

Phone : 02 97910337

Fax : 02 97910140

VIC Downer Electrical Pty Ltd

Factory 4, 33 Chambers Road, Altona North, VIC, 3025

Phone : 03 96449196

Fax : 03 96451644

QLD Downer Electrical Pty Ltd

35 Evans Road, Salisbury North, QLD, 4107

Phone : 07 32751244

Fax : 07 32752236

ACT Service On Site

140 Longmore Cr, Wanniassa, ACT

Phone : 02 62313196

WA Bridgemont Enterprises

PO Box 554, Joondalup, WA, 6919

Phone : 08 93008495

Fax : 08 93008495

SA Bob Winter

18 Metcalfe Ave, Modbury Heights, SA, 5092

Phone : 0418 426545

Fax : 08 83952255

TAS B.S.H Electrical Pty Ltd

213 Harrington Street, Hobart, TAS, 7000

Phone : 03 62310255

Fax : 03 62312691

New Zealand Kwikmix Engineering

4/12 Neil Park Drive, East Tamaki, NZ

Phone : 09 2732020

Fax : 09 2732024

p39

Page 41

© Fast & Fluid Management, Blendorama series II

Specificaties

Number of canisters Up to 24

Canister sizes 22/23 XC/XD/XE 1.75L Single canisters & 3.5L double

canisters

53 XB/XD/XE 2.5L single canisters & 5.0L double

canisters

Canister/stirrer (material) molded 100% acetal

Valves molded 100% acetal

Pump type piston pump

Pump sizes Inner ¼ ounce (22/23/53 - XD/XE) & 2 ounce (53XB)

Pump sizes Outer 2 ounce (22/23 - XC/XD/XE) & 5 ounce (53 –

XB/XD/XE)

Min. dispensing 1/384 fl.oz

Stirring timer Adjustable twin timer

Moveable upper can shelf Standard on floor model

Foldout lower canshelf Standard on floor model

Power supply 110V 50Hz/60Hz

230/240V 50Hz/60Hz

Specifications subject to change without prior notice.

p40

Page 42

© Fast & Fluid Management, Blendorama series II

Wiring diagram

A - Electrical wiring diagram – Twin Timer Version

B - Electrical wiring diagram – Clockwork Timer version

p41

Page 43

© Fast & Fluid Management, Blendorama series II

p42

Page 44

© Fast & Fluid Management, 2005

www.Fast-Fluid.com

Loading...

Loading...