Page 1

Part No: 37611

Re

07-15

®

Harbil

NSC80

Compact Colorant

Dispenser

Operating and

Instruction Manual

A

v.

Page 2

2011 Fluid Management as published work all rights reserved.

Under the copyright laws, this material may not be copied, in whole or in part, without the

written consent of Fluid Management.

Your rights to the software are governed by the accompanying software license agreement.

Use of Fluid Management trademarks, service marks, or logos for commercial purposes

without the prior written consent of Fluid Management may constitute trademark infringement

and unfair competition in violation of federal and state laws. Fluid Management, FMDirect,

ColorPro, DVX, Harbil, Blendorama, Accutinter, Duraflow, Fast & Fluid Management,

GyroFlex, GyroMixer, MicroTint, TintMaster, V1, and VR1 are trademarks of Fluid

Management, registered in the U.S. and/or other countries.

Every effort has been made to ensure that the information in this guide is accurate. Fluid

Management is not responsi bl e for pr int ing or clerical errors.

Fluid Management

1023 Wheeling Road

Wheeling, Illinois 60090-5776 USA

800-462-2466

http://www.fluidman.com

Published in the United States.

Mention of third-party products is for informational purposes only and constitutes neither an

endorsement nor a recommendation. Fluid Management assumes no responsibility with regard

to the performance or use of these products.

2 | Harbil NSC80 Series

Fluid Management Customer Service 1.800.462.2466

Page 3

LIMITED WARRANTY ON EQUIPMENT

If within one year from the date of shipment or one year from the proven date of installation, any

equipment covered by this manual shall prove to be defective in materials or workmanship upon

examination by FLUID MANAGEMENT LP. ("SELLER"), SELLER will supply identical or

substantially similar replacement equipment or parts, or at SELLER's option, will repair or allow

credit for such equipment. In addition, within the United States and Canada, labor costs are

covered for the first six months following shipment or proven installation date for repairs to the

following components: crankshafts, motors, speed reducers, circuit boards, relays, relay panels,

power supplies, transformers, frames, gear pumps, solenoid valves, can holders, bearings and

clutch springs. All labor must be approved in advance by SELLER and performed by a Fluid

Management Authorized Service Center.

PURCHASER MUST NOTIFY SELLER OF A WARRANTY CLAIM WITHIN THIS PERIOD. NO

RETURNS ARE AUTHORIZED WITHOUT A RETURN GOODS AUTHORIZATION FORM. Any

repair or replacement provided hereunder shall be warranted against detects in material or

workmanship for the unexpired portion of the equipment warranty. This warranty does not cover

software, which is covered by separate warranty.

DISCLAIMER

THIS WARRANTY SHALL BE APPLICABLE ONLY IF THE EQUIPMENT SHALL BE THE

PROPERTY OF THE ORIGINAL PURCHASER OR USER, AND SHALL HAVE BEEN

PROPERLY USED, OPERATED AND MA INTA INED IN ACCO RDANCE WITH THE MANUAL OR

INSTRUCTIONS PROVIDED W ITH THE EQUIPMENT AND FOR T HE PURPOSE FOR WHICH

SOLD. NORMAL WEAR AND TEAR IS NOT COVERED BY THIS WARRANTY. THIS

WARRANTY SHALL NOT BE APPLICABLE IF THE EQUIPMENT OR ANY PART THEREOF

HAS BEEN REPAIRED OR REPLACED BY THE BUYER WITHOUT THE SELLER'S PRIOR

PERMISSION OR HAS BEEN SUBJECTED TO ANY ACCIDENT, CASUALTY,

MISAPPLICATION, ALTERATION, ABUSE OR MISUSE.

NO OTHER W ARRANTY, EITHER EXPRESS OR IMPLIED, AND INCLUDING A WARRANTY

OR MERCHANTABILITY AND FIT NESS FOR A PARTICULAR PURPOSE, HAS BEEN OR WILL

BE MADE BY OR ON BEHALF OF SELLER OR BY OPERATION OF LAW WITH RESPECT TO

THE EQUIPMENT AND ACCESSORIES OR THEIR INSTALLATION, USE, OPERATION,

REPLACEMENT OR REPAIR.

SELLER SHALL NOT BE LIABLE BY VIRTUE OF THIS WARRANTY, OR OTHERWISE, FOR

ANY INCIDENTAL, SPECIAL OR CONSEQUENTIAL DAMAGE RESULTING FROM THE USE

OR OPERATION OF THE EQUIPMENT, WHETHER OR NOT SELLER WAS INFORMED OF

THE POSSIBILITY OF SUCH DAMAGES.

IRRESPECTIVE OF ANY STATUTE, THE BUYER RECOGNIZES THAT THE EXPRESS

WARRANTY SET FORTH ABOVE IS THE EXCLUSIVE REMEDY TO WHICH IT IS ENTITLED

AND WAIVES ALL OTHER REMEDIES, STATUTORY OR OTHERWISE. REPAIR OR

REPLACEMENT SHALL BE BUYER'S SOLE REMEDY UNDER THIS WARRANTY.

Fluid Management Customer Service 1.800.462.2466

Harbil NSC80 Series | 3

Page 4

O

nce your NSC80 Dispenser is installed,

what’s next? In this guide, you’ll find

more information to help you get the

most from your new Fluid Management

NSC80 Dispenser.

NSC80 12 Canister Dispenser

Safety Precautions

About This Guide

5 How to Use this Guide

5 For Your Safety

Important Safet y Information

6 Information and Instruction Labels

6 Safety Notice Information

6 General Safety Information

7 Grounding

7 Danger

7 Safety and Regulatory Compliance Information

7 FCC Compliance Statement

Getting to Know Your NSC80 Dispenser

7 Technical Specifications

7 Environmental Conditions

7 Highlights

7 Features

Getting Started

9 Unpacking & Installation

11 Filling the Canisters

11 Priming the Pumps

Basic Operations

12 Dispensing from the Machine

13 Remote Dispensing

14 Repeatability Gauge

Maintenance Procedures

15 Daily and Weekly Maintenance

16 Clogged Nozzle

16 Cleaning the Canister Pump Assembly

Service

17 Upgrades and Replacement Parts

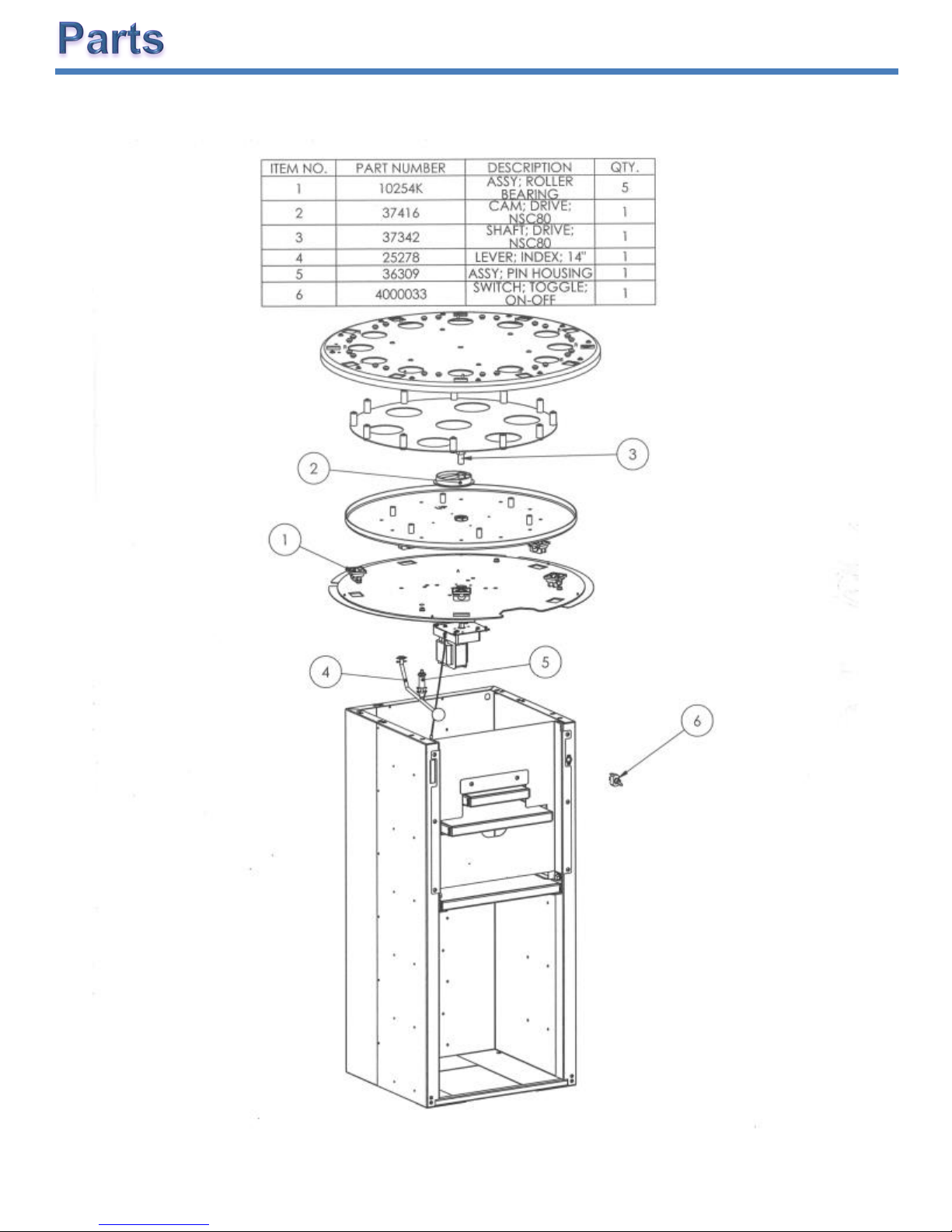

Parts

18 Parts

Warranty

23 Fluid Management Statement of Limited

Warranty

• Read this guide and all warning labels before using the ma c hine .

• Keep this guide in a safe place.

Index

25 A-W

4 | Harbil NSC80 Series

Fluid Management Customer Service 1.800.462.2466

Page 5

Important S

NOTE:

• Read and adhere to all

Warning and Caution

labels on the machine.

• Prepare, level, and clear

the area where the

machine will be

installed.

• To avoid risk of fire or

injury, unplug the

power before servicing

electrical components.

• DO NOT use the

dispenser with or near

flammable or

combustible materials.

• DO NOT dispense

flammable materials.

• After installing,

complete a purge for

each position.

• Check that canisters are

in place and secure.

• DO NOT install

equipment in an area

that water jet equipment

is used.

• Ensure that nothing

rests on your

equipment’s cables an d

that the cables are not

located where they can

be stepped on or tripped

over.

• Plug into an approved

grounded outlet only.

Make sure the outlet

meets all national and

local codes.

• To reduce the risk of

electric shock or injury,

use indoors only.

How to Use this

Guide

This guide is organized

into eleven sections.

Each section provides

detailed information on NSC80 Dispenser topics and provides a basic reference

that can be used to help you with specific issues.

Important:

Carefully read all the installation instructions and the safety

information before you first use your NSC80 Dispenser.

This guide provides instructions for safely and easily installing your NSC80

Dispenser when it arrives. This publication also includes operational instructions,

daily and preventative maintenance procedures, basic troubleshooting

suggestions, customer service, and warranty information.

If you are an experienced user, you may already know enough to get started. Make

sure you look over the information in Getting to Know Your NSC80 Dispenser to

find out about the features of this NSC80 Dispenser.

If you have internet access, the most current information for your NSC80

Dispenser is available from the worldwide web at

http://www.fluidman.com

For Your Safety

Customer safety is important. Our products are designed to be safe and effective.

However, dispensers are electrical equipment. The NSC80 Dispenser is safe and

reliable—designed to bring many years of operation. There are precautions you

can take to avoid damage to the equipment or bodily injury before operating. By

carefully following the instructions in this document and the warning and

maintenance labels on the machine, you can help protect yourself from hazards

and create a safer work environment.

Equipment can become damaged due to misuse or neglect. Some product damage

is serious enough that the product should not be used again until it has been

inspected and, if necessary, repaired by a Fluid Management authorized service

technician.

As with any electronic device, pay close attention to the mixer when it is turned on.

On very rare occasions, you might notice an odor or see a puff of smoke or sparks

vent from your machine, or you might hear sounds like popping, cracking or

hissing. These conditions might merely mean that an internal electronic component

has failed in a safe and controlled manner. However, it may indicate a potential

safety issue. DO NOT t ake risks or attempt to diagnose the situation yourself.

Contact Fluid Management at 1-800-462-2466 for assistance.

This appliance can be used by children aged from 8 years and above, and persons

with reduced physical, sensory, or mental capabilities or lack of experience and

knowledge, if they have been given supervision or instruction concerning use of

the appliance in a safe way and understand the hazards involved. Children shall

not play with the appliance. Cleaning and user maintenance shall not be made

by children without supervision.

Fluid Management Customer Service 1.800.462.2466

Harbil NSC80 Series | 5

Page 6

About this Guide

Information and Instruction Labels

You should become familiar with the information labels affixed to the machine, as

well as the warnings, cautions, and notes which appear throughout this guide.

Read all the warning labels on the exterior and interior of the mixer. If the labels

become damaged or unreadable, you may purchase replacements from Fluid

Management Customer Service.

Safety Notice Information

The two main notices used in this guide and on the NSC80 Dispenser are

Warning and Caution

WARNING

HAZARDOUS

ELECTRICAL

COMPONENTS

CAUTION

POTENTIAL

SAFETY

HAZARD

.

A Warning notice tells you about a hazard that

could cause serious injury to you or extensive

damage to the equipment. This information is

featured in the beginning of the guide to

emphasize safety. When you see a Warning

notice in this guide, read it carefully before

continuing with the operation of the machine. Take

all necessary precautions to avoid potential injury.

A Caution notice tells you about a danger that

could cause injury to you or minor damage to the

mixer. When you see a Caution notice in this

guide, read it carefully and be sure you understand

it before continuing.

WARNING

Unplug before

servicing

Use a dedicated

15 amp circuit (US &

Latin America only)

WARNING

DO NOT use with or

near flammables

General Safety Information

ALWAYS make sure that the power is turned off and the machine is unplugged

before you attempt to replace any components on your dispenser. If you have

any questions or concerns, contact Fluid Management Customer Service

6 | Harbil NSC80 Series

Fluid Management Customer Service 1.800.462.2466

Page 7

Important Safety Information

(A)

GROUNDED PIN

Warnings

• This machine draws

1.5 Amps at 120 ± 10% VAC

0.8 Amps at 220 ± 10% VAC

• DO NOT modify the

provided plug

• Improper use of grounding

plug can result in risk of

electric shock.

Cautions

• Check with a qualified

electrician or service

person if grounding

instructions are not

completely understood or

if in doubt as to whether

product is properly

grounded.

• DO NOT use an adapter or

extension cord with this

product.

• To reduce the risk of

electric shock or injury, use

indoors only.

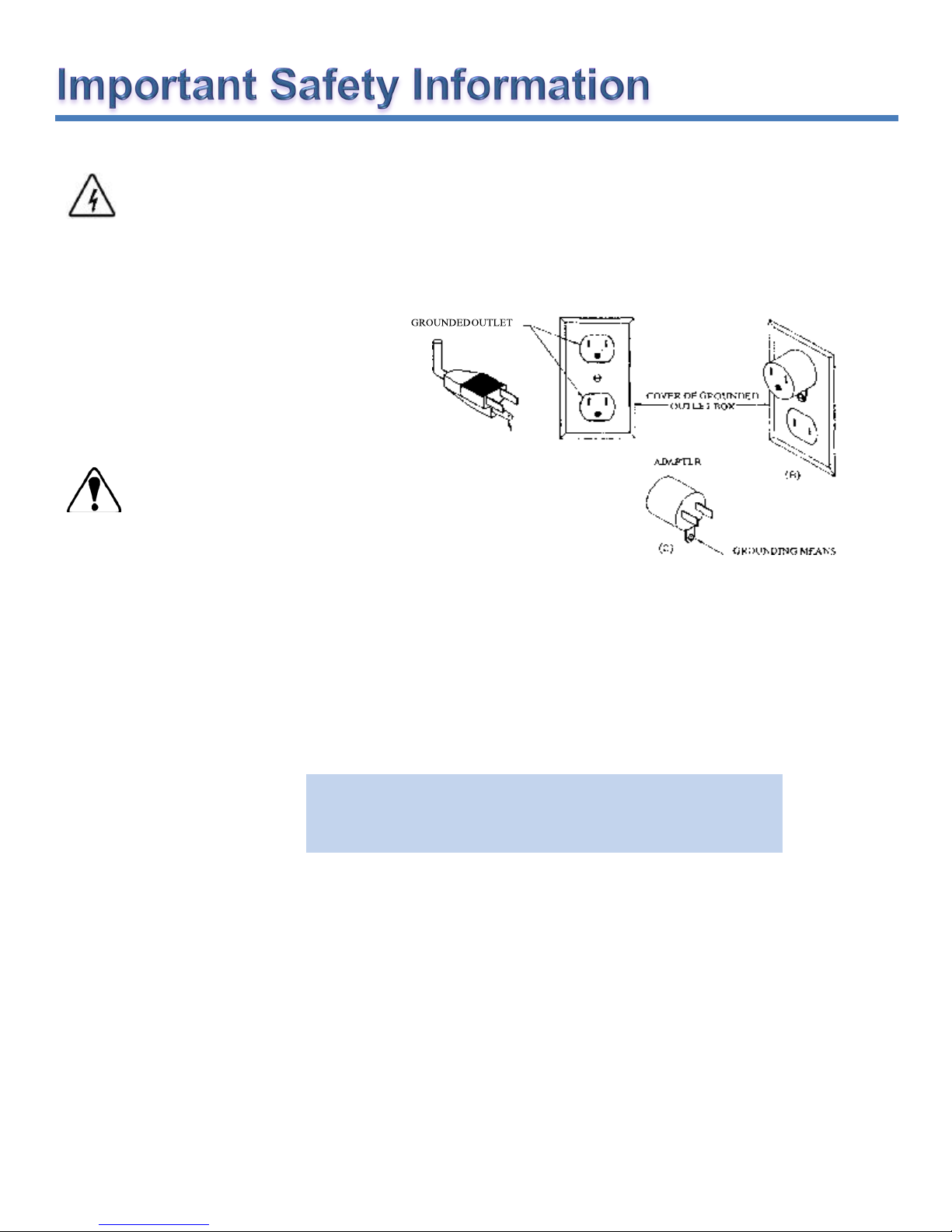

Grounding

This product must be grounded. In the event of an electrical short circuit,

grounding reduces the risk of electrical shock by providing an escape for

the electric current. This product is equipped with a cord that has a

grounding wire and an appropriate grounding plug. The plug must be

inserted into an outlet that is properly installed and grounded in

accordance with all local codes and ordinances.

Danger

Improper installation of the grounding plug can result in a risk of electric

shock. If repair or replacement of the cord or plug is necessary, DO NOT

connect the grounding wire to either flat blade terminal. The insulation wire

with green or green and yellow stripes on the outer surface is the grounding

wire. Check with a qualified electrician if the grounding instructions are not

completely understood or if in doubt about whether the product is properly

grounded. DO NOT modify the plug provided. If it will not fit into the outlet,

have the proper outlet installed by a qualified electrician.

Note: This product is for use on a dedicated nominal 120

Volt (US only) or nominal 220 Volt circuit where

applicable and has a grounding plug.

Safety and Regulatory Compliance Information

See the affixed labeling on the machine. ETL Listed, conforms to UL

STD 1450. Certified to CAN/CSA STD C22.2 NO. 68.

FCC Compliance Statement

This device complies with part 15 of the FCC Rules. Operation is subject

to the following two conditions: (1) This device may not cause harmful

interference, and (2) this device must accept any interference received,

including interference that may cause undesired operation.

Fluid Management Customer Service 1.800.462.2466

Harbil NSC80 Series | 7

Page 8

NSC80 Front View NSC80 Side View

NSC80 12 Canister

Model Shown

Highlights

• Accurate dispensing through saw-toothed, selfzeroing gauges

• 2.5 qt stainless steel canisters

• 2-oz piston pumps with 1/128

accuracy (colorant dependent)

• Industrial grade seals and lid compatible with solvent

and LVOC/ZVOC colorant.

• Agitation timer provided with all floor model

dispensers.

8 | Harbil NSC80 Series

th

minimum dispense

Technical Specificati ons

NSC80 Dispensers

12 Canister Model

Height: 56.3” (143 cm)

Width: 27.7” (70cm)

Depth: 27.7” (70 cm)

1-Gal. Shelf Height: 28.5” (72 cm)

5-Gal. Shelf Height: 21” (53

cm)

Weight: 117 pounds (53 kg)

Maximum power:

120V, 1.5 Amps +/- 10%, 60 Hz

220V, 0.75 Amps +/- 10%, 50Hz

16 Canister Model

Height: 56.3” (143 cm)

Width: 34.2” (87 cm)

Depth: 34.2” (87 cm)

1-Gal. Shelf Height: 28.5” (72 cm)

5-Gal. Shelf Height: 21” (53

cm)

Weight: 117 pounds (53 kg)

Maximum power:

120V, 1.5 Amps +/- 10%, 60 Hz

Environment al Conditions

• Operating Temperature:

Between 50°F (10°C) and

104°F (40°C)

• Relative Humidity: Between 5%

and 85% without condensation

Features

• Nozzle closers provided on every canister to

help minimize tip drying for water-based

colorants.

• Larger and greater number of agitation blades

for better colorant agitation in each canister.

• Repeatability gauges provided on every canis ter

making it easier for your operators to repeat the

last dispense with multiple gallon orders.

• Removable canisters from the dispenser with a

press of a button

• Bottom electric driven agitation making it easier

to fill colorant and reduce the risk of canisters

being left open when removed from the

dispenser.

Fluid Management Customer Service 1.800.462.2466

Page 9

Important Safety Information

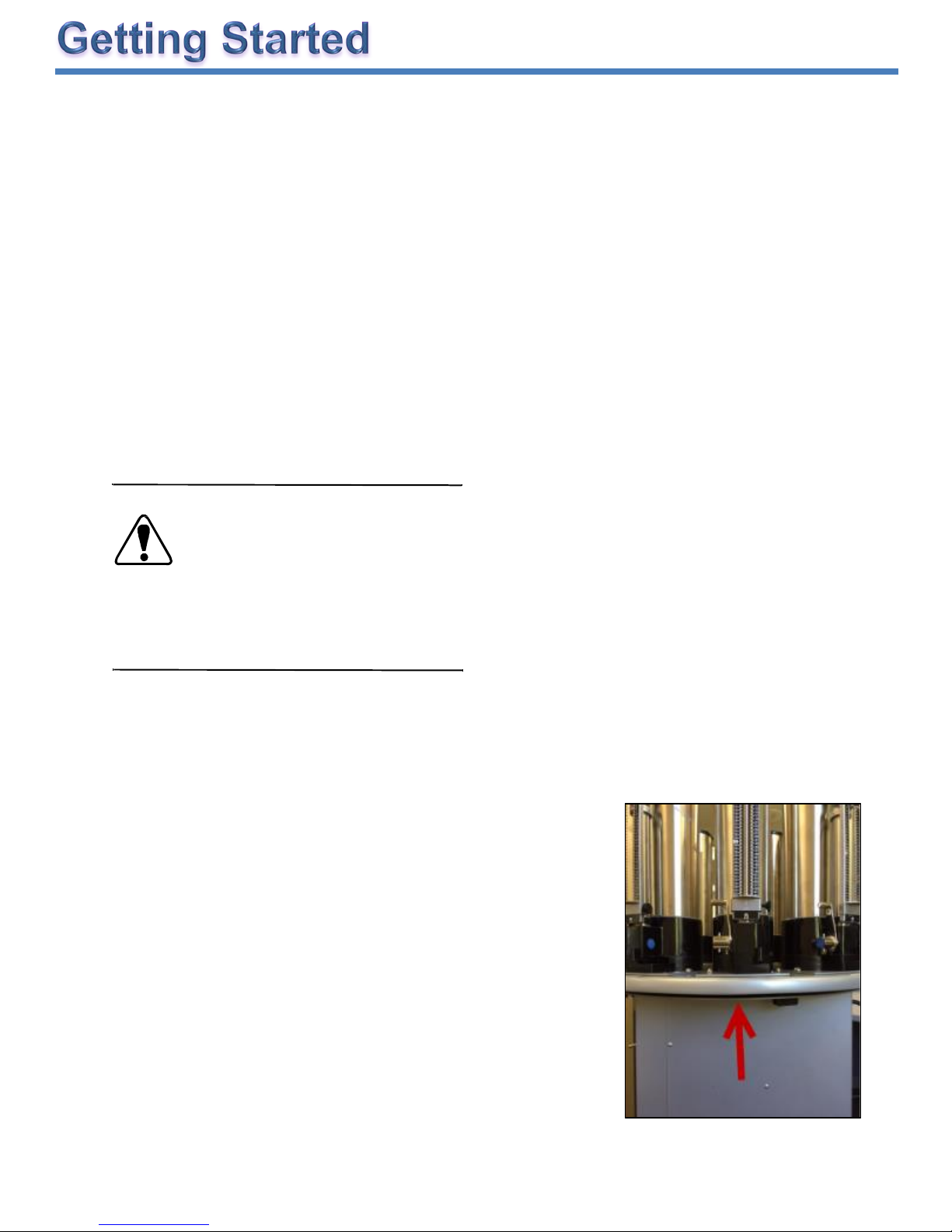

Figure #1

Your Harbil NSC80 is a compact manual colorant dispenser that was designed for exceptional reliability and

ease of use. It is a nearly maintenance free device that should deliver many years of reliable service. Its

features include:

• Heavy-duty components and a durable finish for long wear.

• Bottom agitation linked with rotation of the canisters.

• Special adjustable shelving to accommodate all can sizes.

Your Harbil NSC80 Compact Color Dispenser has been designed with every consideration possible to provide

for simplicity of operation, complete accuracy and no maintenance of any mechanical parts. It can be set up

and put into service within a matter of minutes and anyone can learn to operate it on the first attempt by

following the simple instructions contained in this manual.

While function was a primary factor in the design, the NSC80 Dispenser is an attractive unit and will always

look like new with proper housekeeping. Cleanliness of the dispenser and proper maint enance of the colorant

in the machine are the only requirements necessary for a long and satisfactory use of this dispenser.

IMPORTANT:

Unpack all of the shipping cartons and carefully inspect the contents for any

concealed damage, which may have occurred in transit. If any damage is

found, notify the carrier at once and arrange for inspection in order to claim

recovery. Claims for damage must be made by the consignee (YOU).The

carrier assumes full responsibility upon acceptance of shipment and will not

entertain any claims by the consignor (Fluid Management).

CAUTION:

To reduce the risk of Electric Shock or Injury, Use Indoors Only.

READ CAREFULLY BEFORE REMOVING BASE FROM PACKAGING

When removing the base of the dispenser from the packaging, be

sure to use the lower plate shown in the figure #1 when lifting into

location. This lower plate is mounted directly to the bottom cabinet

and will provide the support needed to move the dispenser into its

final location.

Fluid Management Customer Service 1.800.462.2466

Harbil NSC80 Series | 9

Page 10

Assembling the Machines

Your Harbil NSC80 Compact Color Dispenser requires only the simple attaching of the individual canister s to

the turntable or f astening to t he in-line base. Do not fill the canisters with colorant before they are mounted on

the base.

For In-Line NSC80 Dispensers

1. Place the first canister in position on the in-line base or at the front of the turntable.

2. Screw three 1/4-20 hex-head bolts with rubber washers into the bottom of the canister and after all

three bolts are in place snug them up with a wrench (these bolts and washers are packaged in a

separate bag with the red nozzle caps). DO NOT overtighten the bolts.

3. The canister covers can now be installed on the canisters. (See IMPORTANT note in turntable section,

#3.)

For Turntable NSC80 Dispensers

1. Place the first canister in position at the front of the turntable.

2. Depress the index lever and move the turntable to the next position and repeat the above

procedure until all of the canisters are mounted.

3. The canister covers can now be installed on the canisters.

IMPORTANT:

• The canister covers should be kept on the canisters at all times to minimize the

evaporation and drying of the colorant.

• Nozzle closers are provided with every canister to help prevent drying of the colorant

and they closed after every use.

10 | Harbil NSC80 Series

Fluid Management Customer Service 1.800.462.2466

Page 11

Important Safety Information

Filling the Canisters

After all of the canisters have been installed on the turntable, they can be filled. Each canister has a

maximum capacity of 2-1/2 quarts. It is recommended that each canister be filled with two (2) quarts of

colorant. The maximum capacity of the pump is two (2) ounces.

The following steps represent the process by which the canisters should be filled:

1. Locate the first canister and determine which colorant is to be placed into that canister.

2. Place the appropriate decal on the canister.

3. IMPORTANT – After setting up machine, let machine and colorants warm to room

temperature before pouring colorants into canisters

4. Shake of stir the colorant following manufacturer’s recommendations.

5. Slowly, pour the colorant into the canister to the level of approximately two (2) quarts.

6. Place the top on the canister.

7. Repeat these steps for each of the remaining canisters.

8. After all of the canisters have been filled, agitate by turning on the agitation motor. This will release

any air trapped in the colorant.

Priming the Pumps

Once the canisters have been both filled and agitated, the pumps attached to each of the canisters must be

properly primed. Follow these steps to prime the pumps.

1. Locate the first canister.

2. Slowly pull the pump handle all of the way to the top of its stroke and wait in this position for a count of

approximately three (3) seconds.

3. Slowly press the pump handle all of the way down to the bottom of its stroke.

4. Repeat these steps five (5) times.

5. Repeat steps 1 through 4 for each of the remaining canisters.

Fluid Management Customer Service 1.800.462.2466

Harbil NSC80 Series | 11

Page 12

Dispensing from the Machine

This dispensing equipment is designed for ease of use. The following steps represent the method by which a

formula is to be dispensed:

1. Determine the formula of the color selected by the customer.

2. Refer to the formula book and select the proper base paint.

3. Remove the lid on the base paint.

4. Pull out the appropriate shelf and place the can of base paint on the shelf.

5. Press the turntable indexing lever down and rotate the turntable to the position indicated by the formula

book.

6. Turn the pump gauge to the left or right to center the indicator pointer.

7. Raise the pump gauge so that the indicator is opposite the notch on the gauge corresponding to the

amount of colorant to be dispensed.

8. Turn the handle to the left or right and move the indicator into the desired notch that represents the desired

amount of colorant per the formula book.

9. After the pump handle has been in this position for about three (3) seconds, open the dispensing valve by

pulling the valve lever forward until a positive stop is felt.

10. Open the nozzle closer by pressing the black lever to the right.

11. Turn the gauge to the center of the indicator and slowly push the pump handle down all of the way to the

bottom of the stroke. This will dispense a metered amount of colorant into the base paint.

12. Lift the dispense valve lever and repeat from step 6 as may be required by the formula book.

13. When finished dispensing, close the nozzle closer on the canister by pressing the black lever to the left.

14. Referring to the formula book, Pull down the turntable indexing lever and rotate the turntable to the next

position indicated and repeat these steps for each of the colorants i n the formula.

15. At this point in the process, the can of base paint has been tinted. Remove the can, press the lid back on

and mix appropriately.

CAUTION:

Do not open (pull forward) the dispensing valve lever when measuring colorant. If the valve lever is opened

before the pump gauge has been located in the proper notch, it can be corrected by releasing (closing)

the valve lever and fully depressing the pump gauge returning the colorant to the canister. The pump

must then be re-primed (see Priming the Pumps) before starting the measuring procedure again.

12 | Harbil NSC80 Series

Fluid Management Customer Service 1.800.462.2466

Page 13

Important Safety Information

Press Button to Release

Canister

After the pump gauge indicator is located in the notch and the valve lever is opened, any further

movement of the pump gauge either in an upward or downward direction will have no effect on the

accuracy of the amount of colorant to be dispensed, as the color ant source from the canister is shut off

once the valve lever is opened. However, if the pump gauge is raised after the valve lever is opened air

will be drawn into the pump through the dispense nozzle. Therefor e, care should be taken in SLOWLY

depressing the pump gauge to avoid spattering of the colorant as the air leaves the dispense nozzle.

IMPORTANT:

If at any time after raising the pump gauge and with the valve lever open the pump gauge cannot be

depressed, DO NOT FORCE the pump gauge. Release (close) the valve lever and then depress the

pump gauge, returning the colorant to the canister. The failure to depress the pump gauge will be due to

dried colorant clogging the dispense nozzle of the canister. To correct this OPEN the valve lever and

while holding it in the open position, insert a paper clip or other similar object into the dispense nozzle. BE

SURE TO REMOVE the paper clip before allowing the valve lever to close (any movement of the valve

lever while the paper clip is in place may cause damage to the Teflon Valve Assembly).

Remote Dispensing

The canisters on the turntable version of the NSC80 can be easily removed from the machine with the press of a

button allowing for remote dispensin g. For large paint orders, it can be easier to remotely tint paint directly into

the 5-gallon cans instead of lifting them onto the dispenser. The canisters can be removed from the turntable

with the following steps.

Fluid Management Customer Service 1.800.462.2466

Harbil NSC80 Series | 13

Page 14

Repeatability Gauge

For large orders of the same colorant formula with multiple gallons, a

repeatability gauge has been provided w ith each c anister prov idin g the operator

a way to set the gauge once as speci fied in a formula and re peat the same

dispense without havin g to adjust the dis pen se stroke each time .

1. Loosen black dial and slide repeatability gau ge to desired location as

specified in the formula.

2. Dispense as directed on page 12 using the rep ea t abi lity gauge as a stop

when filling the tube with colorant before di spensin g.

3. Repeat for each colorant as specified by the formul ation for tha t custome r

color.

4. The same stops can be used w hen custom ers re quest multiple quarts , 1gallons or 5-gallon of the same color.

5. When finished, loosen each black dial on the repea tabili ty gauge and lower

to their original locatio n.

14 | Harbil NSC80 Series

Fluid Management Customer Service 1.800.462.2466

Page 15

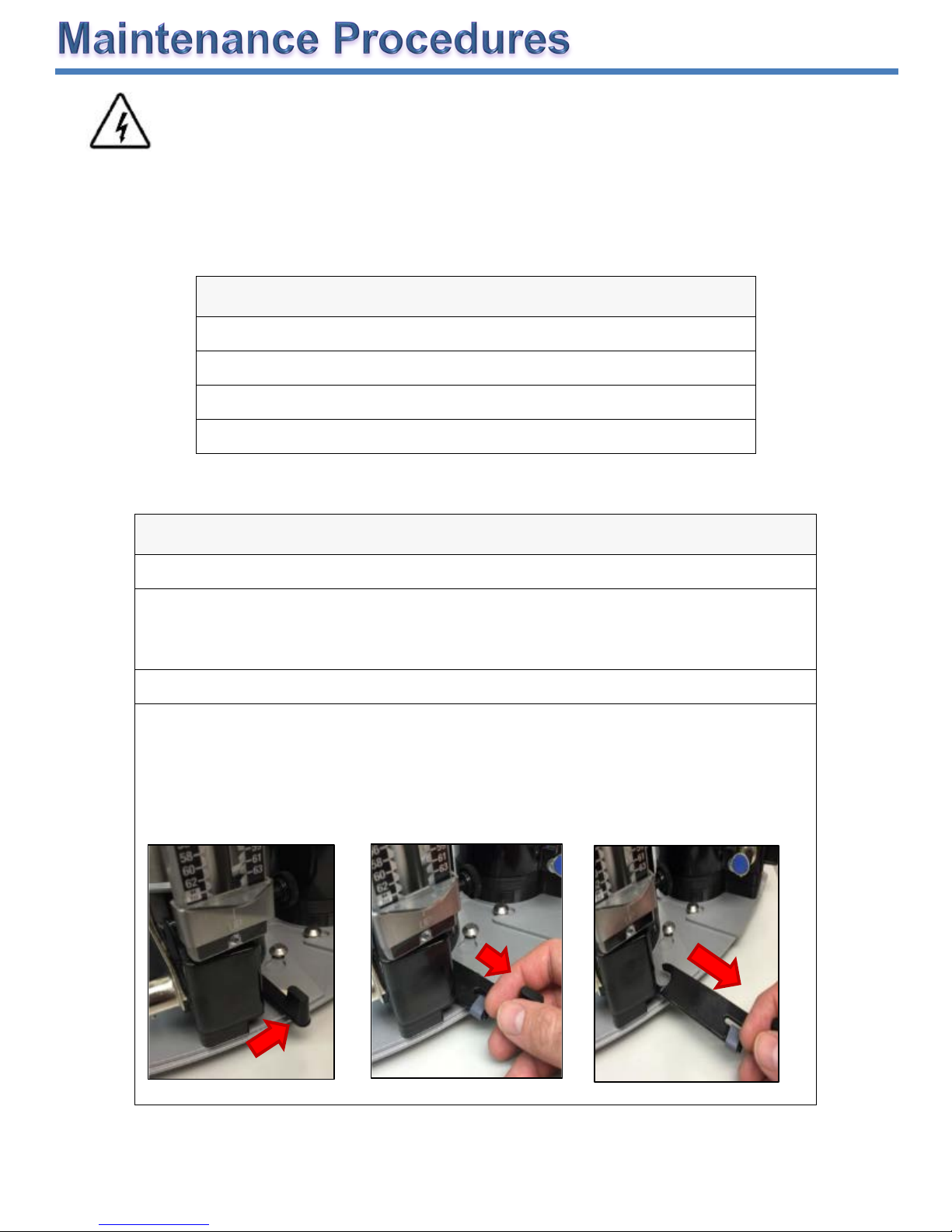

Important Safety Information

Unplug from outlet before servicing and cleaning

To ensure safe, dependable operation of the equipment, follow the maintenance schedule detailed

below:

DAILY

Cleaning & Filling:

• Agitate colorants every morning for five (5) to ten (10) minutes.

• Clean nozzles & outside cabinet surfaces with soap and water.

• Check canisters and fill as required.

.

WEEKLY

Cleaning & Nozzle Maintenance:

• Dispense a full measure of any colorant that has not been used during the

previous week. Dispense into a clean container and return t o the appropriate

canister.

• Clean all accessible inside surfaces with soap and water.

• Clean nozzle closers and inspect sealing pads.

o Open nozzle closer, pull towards you and clean using soap and water.

o Return nozzle closer into canister, which will click into place.

o Close nozzle closer.

Fluid Management Customer Service 1.800.462.2466

Harbil NSC80 Series | 15

Page 16

Clogged Nozzle

If a nozzle becomes clogged, the obstruction can generally be cleared by inserting a paper clip or similar

object in the valve opening. Before inserting such a device, open the valve by pulling the valve lever down

and holding while clearing the opening. BE SURE THAT THE VALVE IS OPENED, AND STAYS OPEN

WHILE CLEANING IN THIS WAY. IF THE VALVE CLOSES AT ANY TIME DURING THIS OPERATION, THE

VALVE COULD BE DAMAGED. If colorant leaks develop at the top of the pump, or if colorant can be

observed on the pump piston rod, the pump assembly must be repaired. The Pump Repair Kit (P/N 4223212)

can be purchased from the Fluid Management Customer Service Department. A colorant leak at the bottom of

the pump assembly generally indicates that the pump assembly has been damaged. In this case, the valve

assembly must be replaced with the Thiokol Repair Kit (P/N 4231011).

Cleaning the Canister Pump Assembly

When it becomes necessary to clean a canister pump assembly, remove the canister from the base and

pour out as much of the colorant as possible.

If the colorants are water soluble, wash the canister t horoughly with warm water and a liquid detergent

and rinse with clean warm water. Next fill the canister with a small amount of water, and with the valve

lever closed, raise and lower the handle on the pump and gauge assembly several times. Then make

several dispenses of the water through the dispense nozzle, the same as you would for colorant. Pour out

any remaining water and wipe dry before replacing the canister on the dispenser. Dispense any water left

in the pump assembly before refilling the colorant.

If the colorants are not water soluble, the procedure is the same as above, except in place of water

mineral spirits or a similar solvent is recommended.

IMPORTANT:

When cleaning the canister, DO NOT submerge the pump gauge assembly portion of the canister or

let water or mineral spirits get into the top of the pump assembly.

16 | Harbil NSC80 Series

Fluid Management Customer Service 1.800.462.2466

Page 17

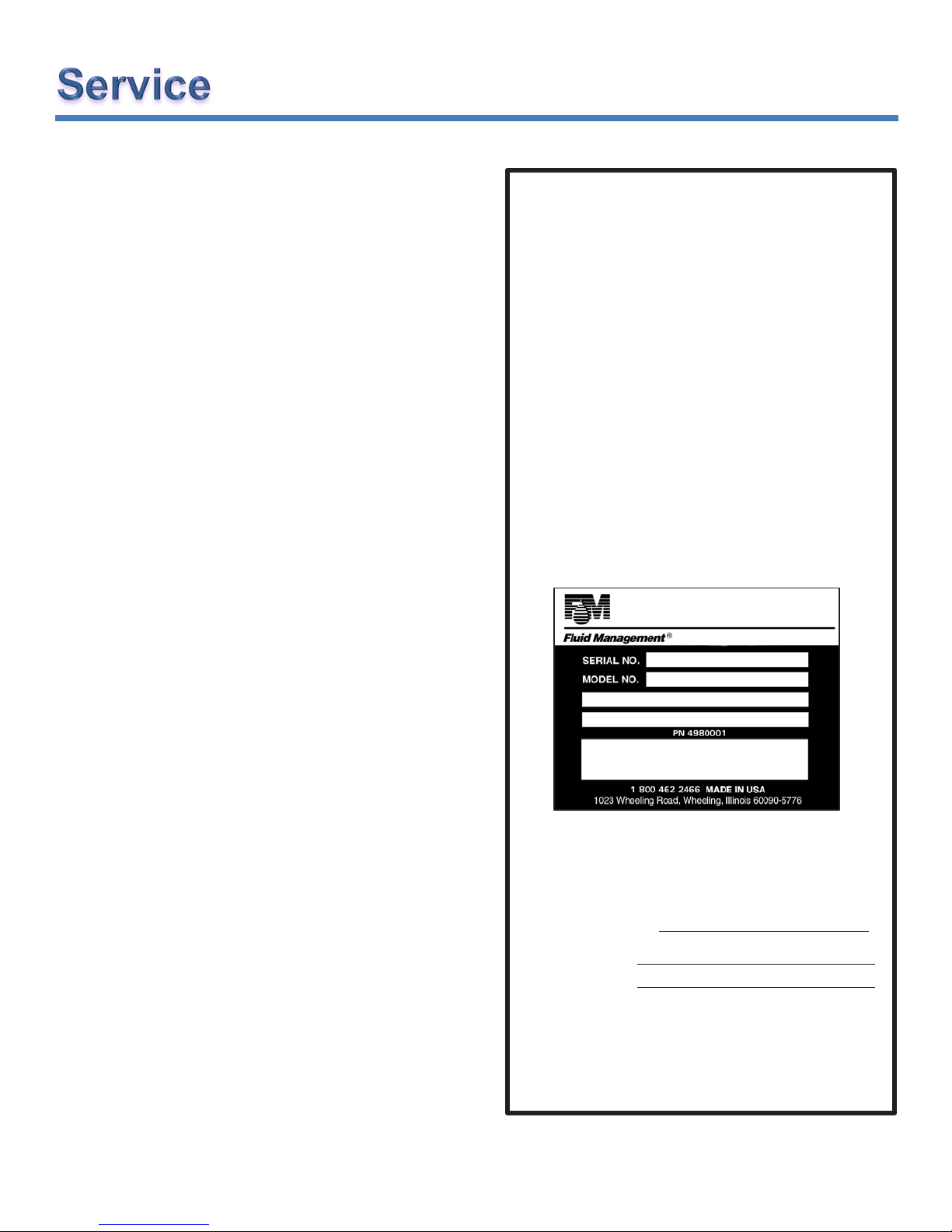

Upgrades and Replacement Parts

Some parts can be upgraded or replaced by the

customer. Fluid Management expressly identifies

parts as such, and provides documentation with

instructions when it is appropriate for customers to

replace those parts. You must closely follow all

instructions when performing such replacements.

ALWAYS make sure that the power is turned off and

that the product is unplugged from any power source

before you attempt the replacement.

Fluid Management Customer Service

1.800.462.2466

Save time and money.

If something should go wrong, we suggest

consulting the Maintenance, and Service sections

of this guide. They are designed to solve basic

problems before consulting a service technician.

However, should you need assistance,

please have your model and serial number

ready. Be near your machine when you call

and have a purchase order number if

ordering parts.

The serial plate is located on the side panel of

the machine. It includes the serial and model

numbers for your machine. Please make a

note of these numbers below:

Date of purchase:

Fluid Management Customer Service 1.800.462.2466

Model Number:

Serial Number:

Harbil NSC80 Series | 17

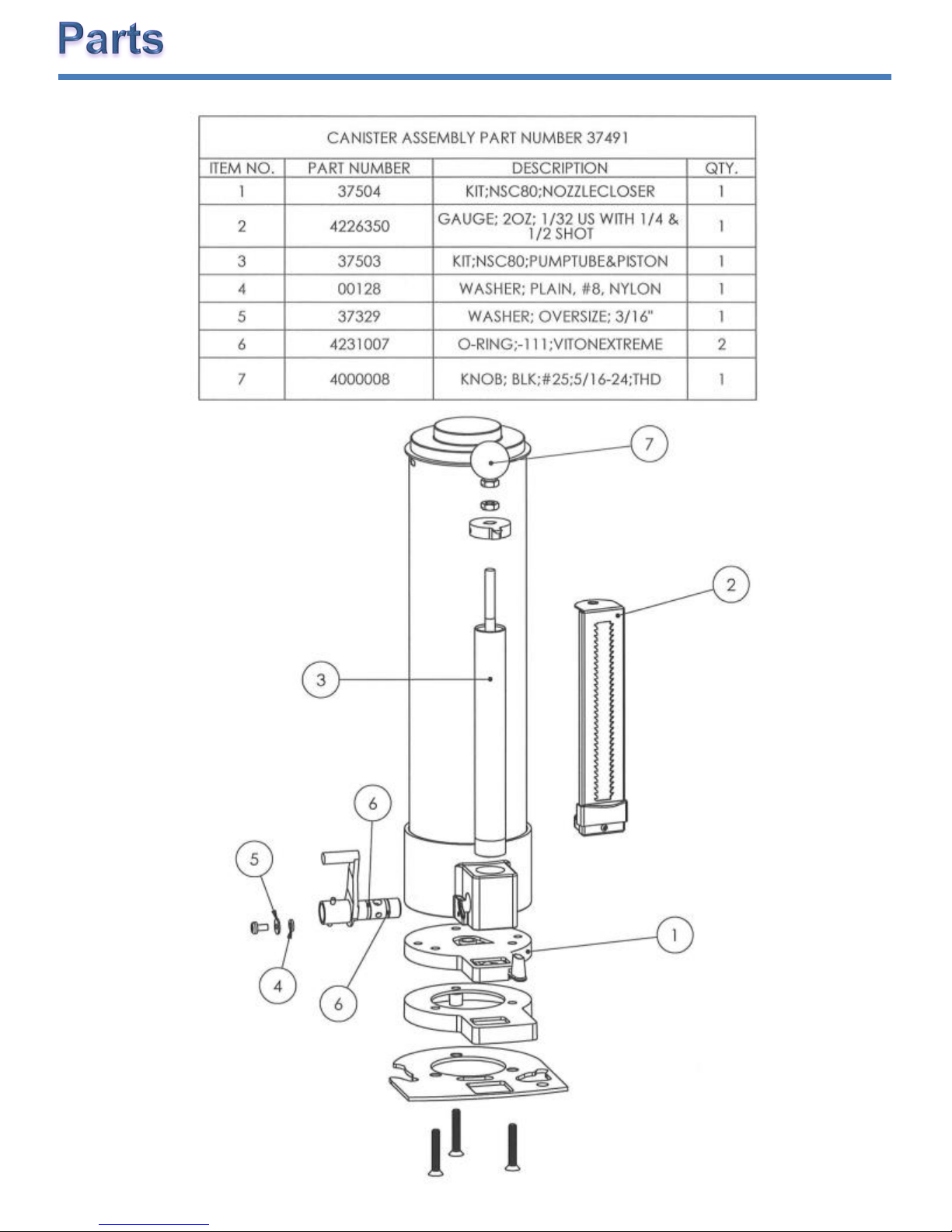

Page 18

12 | Harbil NSC80 Series

Fluid Management Customer Service 1.800.462.2466

Page 19

Page 20

NSC80 Compact

Colorant Dispenser

Fluid Management, Inc.

1023 Wheeling Road • Wheeling IL 60090\

p: 847.462.246 6

f: 847.537.3221

www.fluidman.com

Loading...

Loading...