Page 1

a

M

5

anu

H

rb

il H

al

A1

0

v. 05-2014

Page 2

b

e

e

bUseCE Spe

m

a

r

–B –

n

B –C –

b

rPro

c

t

C

o

.

.

t

o

.

b

.

t

t

.

.

n

m

n

r

n

s

n

t

s

s

t

o

e

e

a

f

b

Manu

a

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

1

l HA150

v. 05-20

4

Ta

Saf

Int

Lia

Dis

Expl

Dis

Pu

Inst

A B C -

Ope

A

Mai

A -

Tou

Se

Spe

Elec

le of

ty & Intr

nded use

ility .......

r qualifica

certificatio

cific warni

posal of th

anation

penser ....

p assem

llation ..

Installing

Installing

Installatio

ation ...

First time

Dispensin

tenance

Daily mai

Weekly m

Monthly

leshooti

vice Depa

blem solvi

ification

rical wiri

onte

duction

..............

..............

ion for ins

n ............

ngs in this

e machine

f image

..............

ly ...........

............

he dispen

he compu

n of the m

............

operation

g .............

............

tenance ...

aintenanc

aintenanc

.........

tment ......

g ...........

...........

ng diagr

ts

............

...............

...............

allation ....

...............

manual ....

...............

............

...............

...............

............

er ...........

er and so

nitor key

............

...............

...............

............

...............

..............

.............

............

...............

...............

............

m ........

............

..............

..............

..............

..............

..............

..............

............

..............

..............

............

..............

ware ......

oard arm .

............

..............

..............

............

..............

..............

..............

............

..............

..............

............

............

............

..............

..............

..............

..............

..............

..............

............

..............

..............

............

..............

..............

..............

............

..............

..............

............

..............

..............

..............

............

..............

..............

............

............

............

...............

...............

...............

...............

...............

...............

............

...............

...............

............

...............

...............

...............

............

...............

...............

............

...............

...............

...............

............

...............

...............

............

............

............

..............

..............

..............

..............

..............

..............

............

..............

..............

............

..............

..............

..............

............

..............

..............

............

..............

..............

..............

............

..............

..............

............

............

............

..............

..............

..............

..............

..............

..............

............

..............

..............

............

..............

..............

..............

............

..............

..............

............

..............

..............

..............

............

..............

..............

............

............

............

...............

...............

...............

...............

...............

...............

............

...............

...............

............

...............

...............

...............

............

...............

...............

............

...............

...............

...............

............

...............

...............

............

............

.... 3

...... 3

...... 3

...... 3

...... 3

...... 3

...... 3

.... 4

...... 4

...... 4

.... 5

...... 5

...... 5

...... 7

.... 8

...... 8

.... 10

.. 11

.... 11

.... 11

.... 12

.. 13

.... 13

.... 13

.. 14

.. 15

2

Page 3

Sa

f

e

m

d

b

m

u

&

&

c

m

e

e

p

s

r

n

a

r

n

c

e

c

r

e

n

c

o

o

d

o

o

i

B

g

e

n

o

o

w

h

B

o

d

e

n

w

c

t

h

s

o

n

l

n

o

n

e

w

u

n

a

n

e

s

a

a

l

w

a

t

m

O

w

o

o

e

e

a

n

t

u

y

t

c

n

k

m

a

a

c

e

n

t

r

h

e

s

g

a

o

0

n

c

a

t

e

e

o

r

C

c

n

t

d

m

m

.

t

p

w

a

t

o

S

m

r

o

o

d

e

m

s

u

f

n

i

t

i

e

Y

y

h

t

i

m

l

s

e

e

p

e

a

1

w

Int

The

forbi

Lia

Our

not f

not a

Fast

All m

Fast

ety &

nded u

achine is

den.

ility

achines a

lfilling the

ccept any

Fluid Ma

Do not u

The mac

Place m

Minimal

Install a

Observe

Always

Do not u

Keep th

This ma

Make su

Replace

aintenanc

Fluid Ma

Intro

Attenti

e

designed t

nd access

CE safety

esponsibil

agement

se a dama

hine is for

chine in w

requireme

d connect

all local sa

onnect the

se extensi

machine i

hine may

e that the

parts only

beyond t

agement

uctio

n! Befor

please

dispense

ries are fu

requireme

ty in case

.V. is not

ed machi

indoors us

ll-lit and

t of the b

the machi

fety regul

machine t

n cords.

n good co

nly be us

machine i

ith origin

e scope of

.V. has tr

Manu

installin

read the

colorants i

ly complia

ts and is

f modifica

liable if yo

e. When

only.

ell ventila

ilding stru

e accordi

tions.

o a ground

dition. Ma

d for com

installed

l Fast & Fl

this manu

ined and

l HA150

the equi

instructio

nto a can.

t with the

herefore n

tions to m

do not fo

ou have d

ed room.

ture, 120

g to the i

ed wall so

e sure th

ercial set

s prescrib

uid Manag

l must be

ertified.

pment an

ns for us

Any other

CE regula

ot allowed.

chines an

llow the ru

ubts, cont

[kg] load

structions

ket.

t defective

ings. The

d in this

ment B.V

carried ou

setting

carefully

use of the

ions. Any

Fast & Flu

/or acces

es below:

ct your s

capacity o

in this ma

parts are

achine is

anual

spare par

by a qual

t in oper

.

machine is

odificatio

id Manage

ories.

pplier.

f the floor.

ual.

mmediate

not a hou

s.

ified servic

v. 05-20

tion,

strictly

n can resul

ent B.V.

y replaced

ehold appl

technicia

4

t in

ill

.

iance.

n that

Use

Only

CE

The

conc

www

Sp

Dis

r qualifi

install the

ertifica

achine is

rning safe

.fast-fluid.

cific wa

osal of

Sort the

Do not d

regulati

Dispose

cation f

machine if

tion

CE certifie

ty. The dir

om.

rnings i

Attenti

Al

the ma

machine,

ispose of t

ns.

of the cani

r insta

you have

. This me

ctives tha

this

on! Do N

This

Attenti

ays turn

hine

he access

e machin

ters as ch

lation

ritten per

ns that th

have bee

anual

T switch

ill also s

n! MOVIN

off powe

ries and t

into dom

mical wa

mission fr

machine

taken int

dispense

op colora

G PARTS

before a

e packagi

stic waste

te, accordi

m the sup

complies

o consider

of with

nt agitati

AN CAU

cessing

g for envi

. Dispose

ng to the l

lier of the

ith the ess

tion in th

he emerg

n

E INJUR

oving pa

onmentall

f the mac

cal regula

machine.

ential requ

design ar

ency sto

.

rts

.

friendly r

ine accord

tions.

irements

available

!

cycling.

ing to local

on

3

Page 4

p

p

.4.

m

0

2

3141516

7

8

.

m

c

b

i

n

m

p

a

u

w

v

s

v

v

b

d

a

t

s

e

Manu

a

l HA150

v. 05-2014

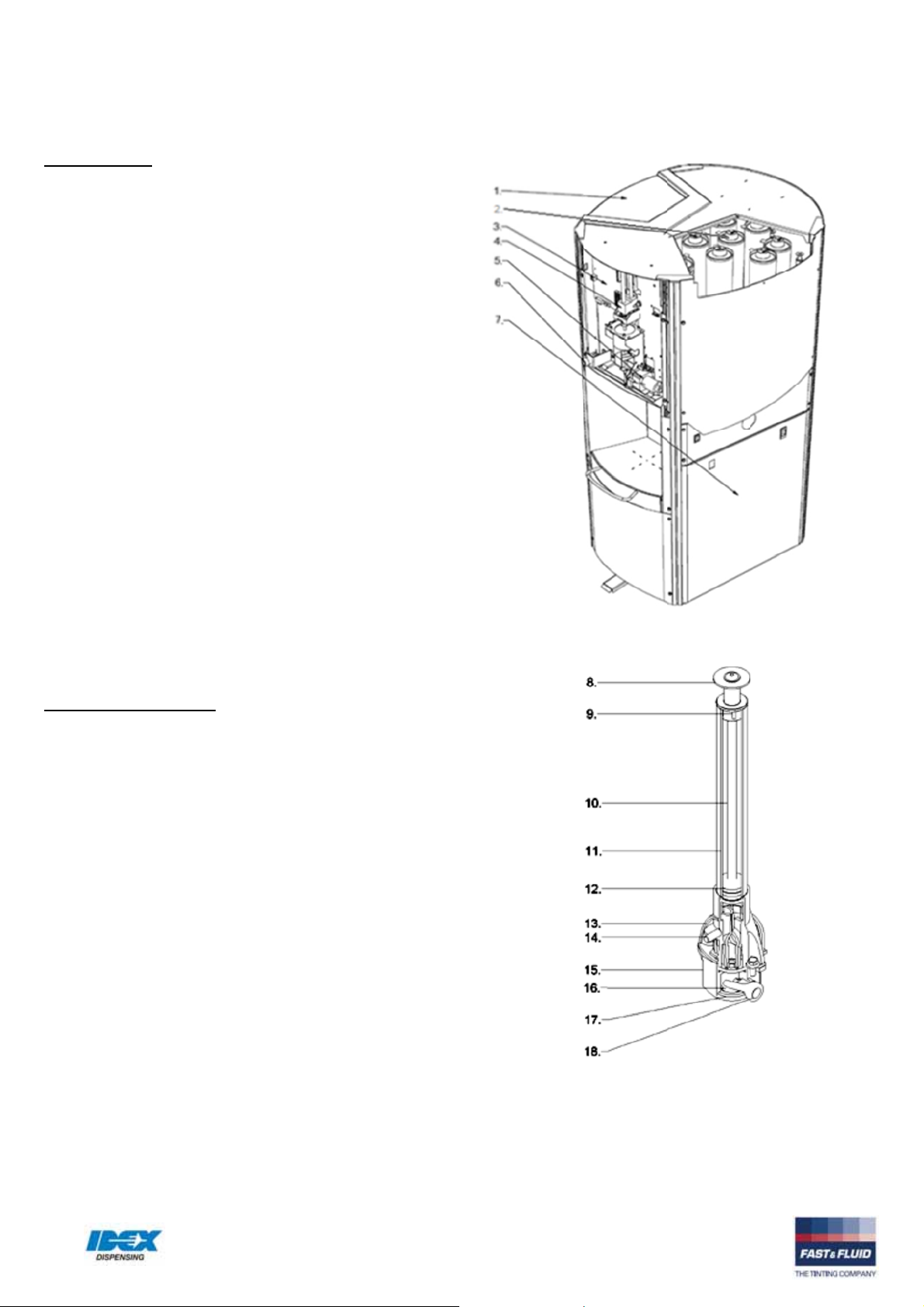

Ex

Dis

1

. Electroni

2

. Top Lids

3

5

. Valve gr

. Emerge

6

. Side pan

7

lanat

enser

Pump gr

stepper

Pump &

(details

ion of

cs power

ipper spin

otor.

canister as

elow).

pper actu

cy stop

el, compu

imag

oard.

le & spindl

sembly

tor.

er cavity

s

e

Pu

8

9

1

1

1

1

1

1

p asse

. Disc gri

. Pump c

. Pump t

1. Nozzle

. Nozzle

. Top val

. Pin sen

. Bottom

. Ball val

. Ball val

. Closer

bly

p

be

iper

e house

or

valve hou

e lid

e arm

e

4

Page 5

In

s

r

e

p

o

y

i

n

1

m

t

a

n

1

e

c

e

o

o

l

o

e

r

r

d

h

r

n

a

h

s

l

o

o

a

a

p

n

w

r

m

a

p

t

p

v

d

m

c

s

1

e

s

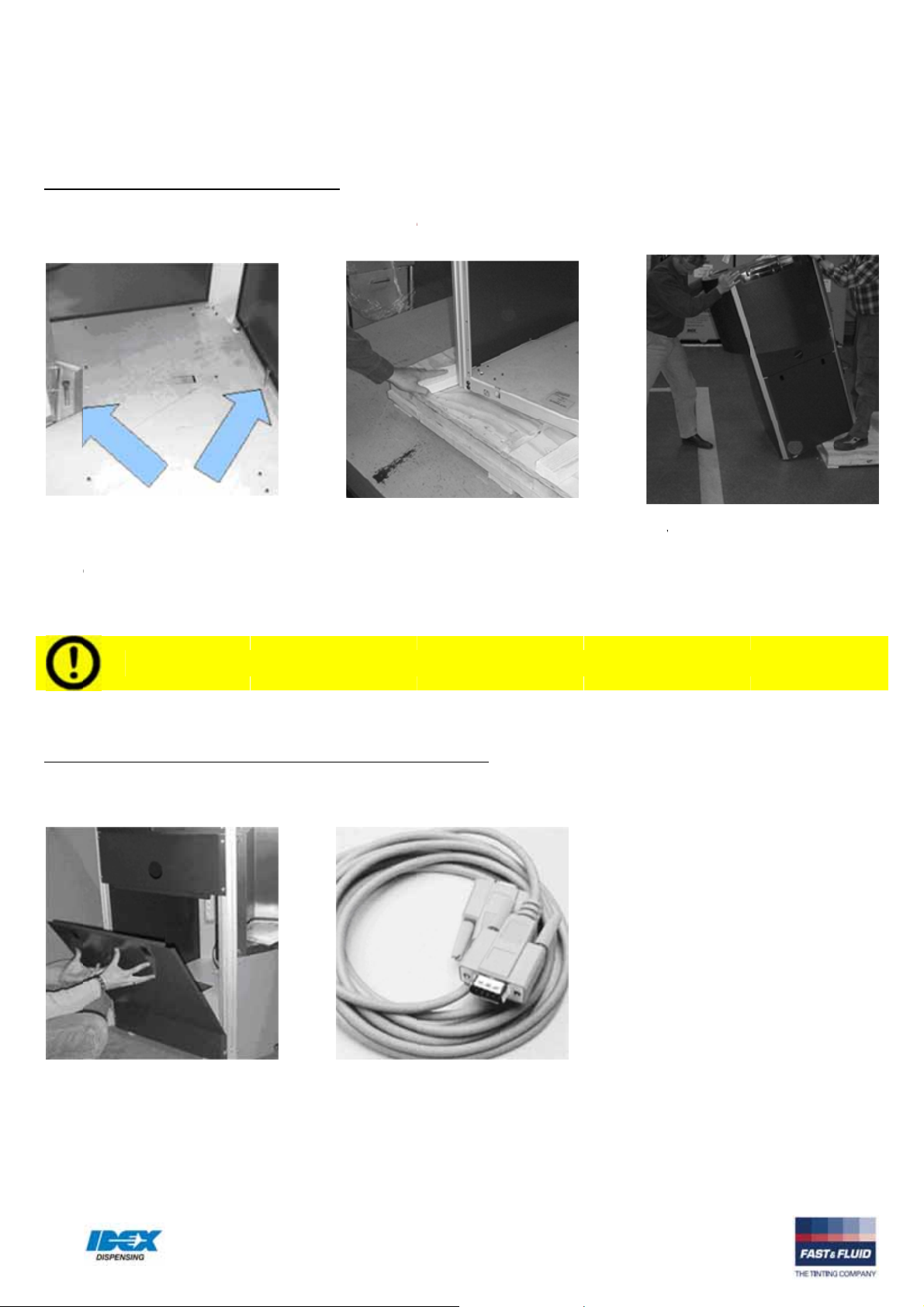

A -

tallat

Installi

on

the d

ispense

Manu

l HA150

v. 05-20

4

Unsc

conn

the

the c

Step

ew the tra

cting the

allet from

omputer c

- Deta

nsport scr

achine t

he inside

vity

P

h the

>

ws

f

ace mac

ispense

Detach t

wooden

pallet.

ine in we

r from i

e supporti

trips from

l-lit and

ts

alle

g

the

ell ventil

>

Mo

pal

an

ated roo

ve the ma

let onto it

roll it to i

.

hine from

rear whe

s final po

the

ls

ition

B -

Rem

pane

cavit

Installi

Step

ve one of

ls and plac

.

the c

- Plac

either side

compute

mpute

and co

>

in

and s

nect c

Connect di

COM1(def

keyboard

appliances

computer

ftware

mpute

spenser to

ult) and

nd other

to design

orts.

to dis

ouse,

ted

enser

5

Page 6

l

u

2

s

t

a

a

n

Manu

a

ft

a

o

r

n

b

e

o

u

l HA150

v. 05-2014

Insta

provi

supp

man

Step

ll all neces

ded by sof

ier. Check

al for det

- Insta

ary softw

ware

software

ils.

ll dispe

>

re

ser so

Use softw

functions

filling. Che

manual fo

ware o

re to test

f dispense

ck softwar

testing pr

comp

asic

r before

cedure.

ter

6

Page 7

o

e

e

)

t

1

n

2

n

t

n

s

r

t

s

n

n

Manu

a

s

y

a

a

e

k

N

d

-

o

t

h

d

t

o

g

l HA150

v. 05-2014

C -

Rem

of th

Installa

Step

ve the pa

machine

ion of

Atte

- Take

el on the

he mon

tion! Thi

the mo

>

ide

itor key

is a sale

itor ke

Carefully t

keyboard

machine

board a

option.

yboar

ke the m

rm out of

rm

ot a stan

arm ou

nitor

he

ard opti

of the

n.

HA150

Plac

Alum

right

Step

the arm i

inium profi

Wa

- Insta

to the

le slot (lef

ning! Do

ll the m

>

or

't damag

onitor

the mac

eyboar

ine with

-arm

unpackin

.

7

Page 8

Op

p

n

m

1

2

g

a

c

c

o

t

N

F

O

a

s

n

k

a

s

s

y

i

t

e

o

uthe

usocma

d

s

g

T

a

f

v

y

m

T

t

a

u

c

r

h

f

h

d

a

T

e

t

0

p

t

w

p

0

r

d

k

f

p

p

n

w

r

r

m

h

a

o

c

o

o

f

w

o

s

a

o

m

e

e

s

h

u

p

e

e

s

a

e

p

r

t

t

s

e

f

e

o

1

b

p

n

n

o

t

o

h

e

A –

eratio

First ti

n

e oper

tion

Manu

l HA150

v. 05-20

4

Step

- Swit

hing O

>

the di

Unlock the

turning clo

The machi

at the bac

socket.

Please be

timers as

the dispen

units (e.g.

affected b

modus, pe

penser

emergenc

ckwise.

e is auto

of the dis

ware that

tandard.

er will en

sensors)

this mod

rform any

& com

stop but

atically s

penser is

the HA15

his means

er a powe

re switche

s. To awa

ommand

uter

on on the

itched on

lugged int

dispenser

that after

saving m

off auto

e the disp

rom the di

ront of th

hen the

a 230V o

are fitted

pproxima

dus in whi

atically. S

nser from

spensing s

machine

ower conn

110V wal

with slee

ely 30 mi

ch all seco

irring is n

its sleepin

ftware.

y

ector

l

ing

utes

dary

t

g

Step

- Swit

hing O

>

F the d

Please no

to take th

switched

1. Sh

2. Sh

spense

e that wit

power of

ff, there a

ut down th

back of t

ut down th

ket behin

chine.

& com

normal o

the dispe

re several

e compute

e machine

e compute

the botto

uter

eration th

ser. In ca

ays of ac

and unpl

.

and switc

service

re should

e the disp

ieving thi

g the pow

h the inter

anel at th

be no reas

enser mus

:

r connect

nal power

front of t

on

be

r at

e

Ste

3 - A

Attenti

itation

n! Do N

This

imer

>

T switch

will also

The stirrin

settings*.

your softw

Please ask

your speci

* Default

ispenser

top color

time and

his can b

are manua

your pain

ic colorant

alue is 18

8

of with t

nt agitat

interval c

done thr

l for instru

supplier f

products.

seconds

e emerg

on

n be alter

ugh the di

tions.

r optimal

f agitation

ncy stop!

d from its

penser so

gitation s

every 3 h

default

tware, ch

ttings for

urs.

ck

Page 9

o

i

d

s

o

e

Step

4

u

d

w

a

5

s

a

o

h

r

b

e

g

h

g

h

h

C

D

a

s

e

t

a

n

l

e

u

s

d

f

d

h

t

u

l

b

c

e

m

l

r

d

r

e

s

h

y

g

u

c

u

gthe

n

a

e

s

i

s

y

e

u

o

a

o

1

t

h

r

r

m

- Fill t

e brus

Manu

tray (

l HA150

ozzle c

eaning

ystem)

v. 05-20

4

Rem

left s

push

falls

ve the br

ide of the

ng it back

own.

Wa

sh tray at

ispenser,

ards until

ning!!

the

y

it

o NOT us

>

leaning f

Take out

and fill th

brush liq

colorant

uid must

flamma

the brush

e containe

id propos

upplier.

be refres

le liquids

ontainer,

r with the

d by your

ed daily!

in the br

>

Pla

ori

sh conta

ce the bru

inal positi

brush tra

ner.

h tray in i

n by pus

up.

s

ing

Acce

one

turnt

conc

unde

W

Step

s the cani

f the top li

ble so th

rned, is p

r opening.

Us

Wron

rning !!

- Fill t

ters throu

ds. Turn t

t the canis

sitioned

only cle

material

Check th

e canis

>

h

e

ter

ning flui

can resu

MSDS o

require

ers wit

Remove

check yo

for filling

s recom

lt in nozz

the colo

d for han

colora

he caniste

r softwar

sequence.

ended b

e blocka

ants abo

ling the

nt

lids and

manual

your pai

e and red

t person

olorant.

>

Aft

twi

sy

t suppli

uced acc

l protecti

er filling c

ce to rem

tem.

r.

racy.

n measu

nister, pu

ve air fro

es

ge

the

9

Page 10

B –

e

r

p

s

1

t

2

n

o

h

e

e

e

a

e

t

o

n

s

a

n

a

e

d

e

a

m

i

c

o

m

m

f

o

s

f

Thethe

s

Tak

m

w

s

t

e

o

1

e

s

n

Dispen

ing

Manu

l HA150

v. 05-20

4

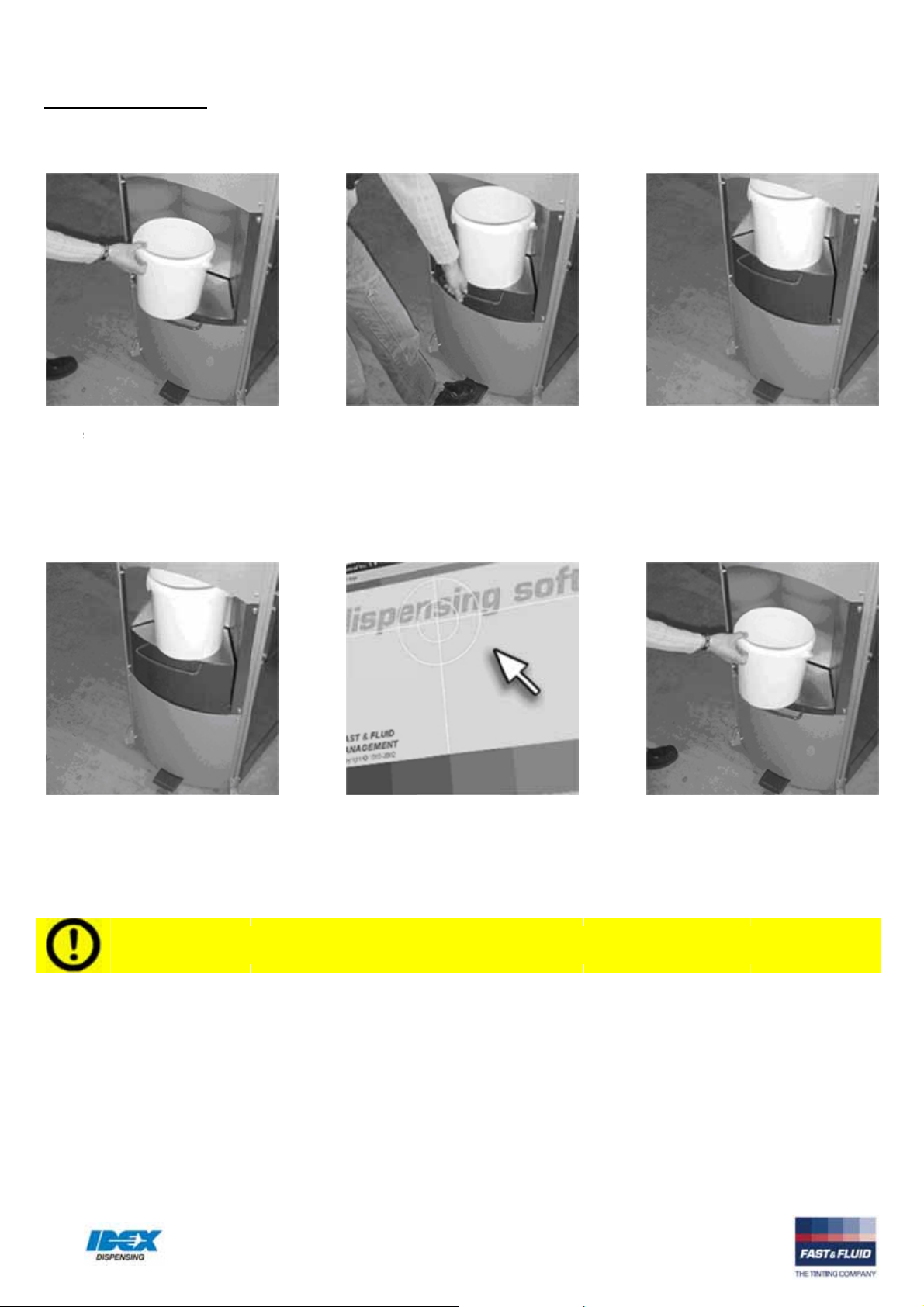

Plac

the c

Step

the can a

an table.

Step

– Plac

the centr

- Disp

can in

>

of

nse col

o dispe

Lift the c

correct h

pressing

rant

se pos

n table to

ight (unlo

own the f

tion

the

k by

ot pedal)

>

can mus

dispenser

po

sible.

be as clos

opening a

to

Ensu

the d

its o

e can ope

ispenser n

timal heig

ing is und

zzle and

t.

Please r

>

er

t

Dispe

ad your

Choose d

shown in

sing is m

oftware

esired for

software

inly a so

anual th

ula as

anual.

tware is

roughly

>

Re

no

ue.

or all po

e the can

ove can,

complet

sible opti

table dow

dispensing

.

ns.

.

is

10

Page 11

Ma

o

t

h

c

n

a

u

a

a

W

v

e

s

d

n

n

y

p

n

n

>

a

n

r

e

r

c

n

t

k

f

s

a

f

e

e

l

y

m

r

n

s

i

apro

asof

p

d

e

a

e

u

.

y

1

s

u

a

A -

inten

Daily m

nce

aintena

nce

Manu

l HA150

v. 05-20

4

Rem

emp

brus

with

Clean

ve the br

y the cont

and refill

orrect cle

the bru

sh tray an

iner. Clea

the contai

ning fluid.

Use onl

rong ma

h tray,

>

the

er

cleaning

terials ca

refill ca

Refill ca

necessa

Update l

Stir colo

fluids re

result i

nisters

isters whe

y.

vels in so

ant befor

ommend

nozzle b

nd run

n

tware.

hand.

d by you

ockage a

mornin

>

St

cle

paint su

d reduce

progr

rt softwar

gram to p

an nozzles

tware man

plier.

accurac

m

morning

rge valve

Check yo

ual for det

.

and

r

ils.

B –

Clea

parts

Weekly

Remo

can table

with dilut

mainte

e spilt

and outsid

d deterge

nance

aint &

e

t.

coloran

Chec

refill i

and re

canister c

necessar

fill cani

ontent and

.

ters

Always c

lose cani

ters and

achine l

ds after r

efilling

.

11

Page 12

o

e

y

a

e

h

t

A

a

o

o

Manu

a

u

P

b

c

I

o

t

l HA150

v. 05-2014

C –

Rem

valv

Monthl

Check

ve back p

for possib

maint

and cle

nel and c

le malfunc

Alw

nance

an imp

eck pump

ions.

ttention!

ys turn

rtant f

MOVING

ff power

nctiona

ARTS CA

efore ac

l parts

N CAUSE

essing m

NJURY.

ving par

s

.

12

Page 13

u

v

r

u

b

p

e

s

t

o

o

u

e

t

h

p

o

o

y

o

c

t

p

c

t

o

g

n

n

o

m

u

a

e

r

o

w

n

m

u

C

A

V

W

ACPCSNF

MQs

O

t

T

L MLPML

WiCKTLC

K

P

L

C

Manu

a

o

a

S

f

g

e

n

t

s

t

r

n

n

s

e

t

e

e

c

g

e

c

p

e

o

e

n

a

p

y

n

e

a

f

g

t

e

c

r

e

m

h

t

e

e

t

a

e

a

p

m

t

e

M

e

c

c

w

c

c

d

n

e

e

p

n

r

o

y

w

s

1

e

e

n

l HA150

v. 05-20

4

To

Ser

Befo

probl

If yo

1

2

3

Pro

Sym

Valv

open

Cani

the s

Air is

with

No p

No p

Colo

Poor

pictu

Keyb

Stirr

Turn

bles

F

ice

De

e calling y

em yourse

cannot s

. Find the

. Take a n

. Contact

lem so

tom

leaks thr

ing

ter conne

uction par

being dis

he paste

wer from

wer

rs are diffi

monitor pi

e

oard is not

r is not ro

able is not

ootin

r all soft

artme

ur machi

lf. The tool

lve the pr

type plate

ote of the

our suppli

lving

ugh the o

tion leaks

ensed tog

power unit

cult to rep

ture, or n

working

ating

turning

are erro

t

e supplier

symbol

blem, the

on the rea

odel nu

er or man

tlet

round

ther

oduce

r messag

or Service

means y

call the S

r of the m

ber and th

facturer.

ause

ir bubble i

alve is de

orn O-rin

ir bubble i

anister is

iston is de

omputer

oftware in

ot connec

use blown

echanism

uality fluc

upplied

ne or mo

hickened

urntable i

eaks arou

onitor is

oose cabl

icture set

onitor ma

oose cabl

indows r

correct

able defe

eyboard d

ime settin

oose cabl

able defe

eyboard d

iston rod

oose cabl

able or m

s: see th

Departme

u cannot s

ervice Dep

chine.

e serial nu

ee www.f

n pump

ect

(s)

n the pum

mpty

fect

ot correctl

correctly i

ed to pow

are dirty

tuations in

e pastes h

wrong po

d piston(s

witched of

s

oo dark

lfunctionin

(s)

gional sett

t

efect

incorrect

(s)

t

efect

ositioned

(s)

tor defect

help top

t, please

olve the p

artment fo

mber of th

st-fluid.co

booted

stalled

r grid

paste

ve

sition

)

ings

oo high

ic in the

heck whet

oblem.

r advice.

machine.

.

Action

Prime

Replac

Replac

Prime

Refill c

Replac

Reboot

Reinst

Check

Clean

Contac

Replac

Reset

Replac

Switch

Check

Adjust

Check

Check

Set tim

Check

Push pi

Check

ispense

her you ca

he pump

pump

O-ring(s)

he pump

nister

pump

computer

ll softwar

ower cabl

echanism

paste su

paste(s)

achine

piston(s)

monitor o

ables

picture co

ables

indows s

er correctl

ables

ston to lo

ables

oftware.

solve the

& softwar

s

plier

rectly

ftware ma

(softwar

er positio

nual

)

13

Page 14

e

e

b

s

p

e

l

l

p

r

t

n

d

a

e

M

s

u

u

t

m

n

v

e

a

e

u

o

i

s

r

t

m

x

t

s

s

t

t

a

t

t

c

o

u

r

s

m

m

s

h

a

a

t

c

Manu

a

n

o

1

d

b

e

n

o

8

0

[

[

o

n

nMan

t

%

5

s

o

/

[

n

2

m

p

C

m

[

l HA150

v. 05-2014

Sp

Disp

Num

Cani

Easy

Pum

Valv

Nozz

Nozz

Pum

Min.

Accu

Flow

Can

Max.

Clea

Can

Stirri

Mov

Dim

Net

Ambi

Tran

Altit

Altit

Rela

Maxi

IP (I

EMC

Over

Pow

Leak

Coun

Pow

Freq

Fuse

Opti

Spec

cifica

nsing

er of cani

ter sizes

Click canis

Type

s

e closures

e diamete

Capacity

Dispense

acy

rate

able depth

Can heigh

ing syste

etector

ng timer

bility can t

nsions (H

ass

ent Tempe

portation

de above

de above

ive humidi

um noise

gress Pro

(Electro M

oltage ca

r consump

ge curren

try specifi

r Supply

ency

specificati

n

fications s

tions

ters

ter /stirrer

able

W x D))

rature

emperatu

ea level, o

ea level, o

y, without

level

ection) cla

gnetic Co

egory

tion, maxi

net cable

n

bject to c

(material)

e empty c

perational

ut of oper

condensa

sification

pliancy)

um

ange with

nisters

tion

ion

lassificatio

out prior n

Seq

12/

2.3

Mol

Har

Stai

Int

2 a

2 [

1/3

0,0

0,4

27

46

Aut

Sta

Sta

157

180

+5

-25

-10

-10

90

< 6

32

n Cla

II

500

3.5

Eur

110

50

10

Hea

Ma

tice

uential

4/16/18/

[Ltr]

ed polime

il Piston p

nless steel

grated

d 4,5 [m

unce]

4 [fl.oz]

4 [ml/ste

[L/min]

сm]

сm]

matic

dard

dard

ual

x 80 x 94

[kg]

o +40° [C

to +55° [

to 2000 [

to 12000

RH

[dB(A)]

s B

[W]

[mA]

pean

/ 230 [V]

60 [Hz]

AT]

ting set

ual Punch

0/24

ic

ump

/ Teflon

]

]

[сm]

]

]

]

m]

+/- 10%

6 [mm]

14

Page 15

El

e

g

a

ctrical wiring dia

Manu

ram

l HA150

v. 05-2014

15

Loading...

Loading...