Page 1

Accutinter 1500 | Accutinter 1500 HS

End User Guide

Getting Started

Maintenance and Care

Troubleshooting

Warranty

Part No: 33042

Rev. D

08.2013

Page 2

Page 3

Your

customers have a vision,

you want to make it happen, and

Fluid Management can give you the answer.

Fluid Management is a global leader in dispensing and

mixing equipment used in the paint industry, as well as,

specialized equipment for the chemical, and home improvement industries.

Located in the suburbs of Chicago, Illinois, Fluid Management

is a United States owned and operated company with historical roots

to the paint industry dating back to 1927. In 1996, IDEX Corporation

purchased Fluid Management giving the organization the financial

wherewithal and global footprint of a large organization while

still maintaining its deep values and history.

As industry leaders, Fluid Management provides trend-setting creativity

in the design, products, and services it offers. United with FMDirectSM,

our nationwide service team, we provide after-sales support around

the clock—when you need them. Being factory-direct employees,

FMDirect technicians are experts on Fluid Management equipment and

understand customer needs from start to finish.

The combination of leading edge technology, excellent service and

support, and a company prepared for the future’s ever-changing

business environment makes Fluid Management an ideal partner to

assist in providing solutions to your business needs. Thank you for

putting your trust in Fluid Management products

and making us part of your customer’s vision.

Page 4

©2011 Fluid Management as published work all rights reserved.

Under the copyright laws, this material may not be copied, in whole or in part, without

the written consent of Fluid Management.

Your rights to the software are governed by the accompanying software license

agreement.

Use of Fluid Management trademarks, service marks, or logos for commercial purposes

without the prior written consent of Fluid Management may constitute trademark

infringement and unfair competition in violation of federal and state laws.

Fluid Management, FMDirect, ColorPro, DVX, Harbil, Blendorama, Accutinter, Duraflow,

Fast & Fluid Management, GyroFlex, GyroMixer, Infina, MicroTint, TintMaster, V1, and VR1 are

trademarks of Fluid Management, registered in the U.S. and/or other countries.

Every effort has been made to ensure that the information in this guide is accurate.

Fluid Management is not responsible for printing or clerical errors.

Fluid Management

1023 Wheeling Road

Wheeling, Illinois 60090-5776 USA

800-462-2466

http://www.fluidman.com

2 | Accutinter 1500

Published in the United States.

Mention of third-party products is for informational purposes only and constitutes

neither an endorsement nor a recommendation. Fluid Management assumes no

responsibility with regard to the performance or use of these products.

Fluid Management Customer Service 1 . 800 . 462 . 2466

Page 5

Fluid Management Accutinter 1500

nce you’ve installed your Accutinter 1500

O

find more information to help you get the most from

your new Fluid Management Accutinter 1500 .

Dispenser, what’s next? In this booklet, you’ll

Fluid Management Customer Service 1 . 800 . 462 . 2466

Accutinter 1500

Accutinter 1500 | 3

Page 6

Contents

About this Guide

5 How to Use this Guide

5 For Your Safety

Important Safety Information

6 Information and Instruction Labels

6 Safety Notice Information

6 General Safety Information

6 Air Circulation

7 Grounding

7 Danger

7 Caring for Your Computer

7 Communication Regulation Information

Getting to Know Your Accutinter 1500

8 Technical Specifications

8 Environmental Conditions

8 Optional accessories

9 Accutinter 1500 Features

10 Tips to Improve Operation

Getting Started

11 Installation

12 Unpacking and Set Up

14 Connecting the label printer (optional)

14 Connecting the barcode scanner (optional)

17 Preparing and refilling the canisters

19 Preparing the system

20 Using the shelves

Maintenance, Care, and Use

32 Daily, weekly, monthly maintenance

Frequently Asked Questions

34 Equipment troubleshooting

38 ColorPro troubleshooting

Service

40 FMDirect

40 Upgrades and Replacement Parts

40 Obtain Warranty Service

Warranty

41 Fluid Management Statement

of Limited Warranty

Index

42 A - W

Basic Operations

21 Welcome to ColorPro4

22 Main menu

23 Dispensing from Formula Book

25 Manual dispensing

26 Using an external data source

and dispense queuing

27 Adjusting formulas

28 Using color scaling

29 Purging the lines

30 Stirring the colorant

31 Using ColorPro Help

4 | Accutinter 1500

Fluid Management Customer Service 1 . 800 . 462 . 2466

Page 7

About this Guide

How to Use this Guide

This Guide is organized into nine sections. Each section provides detailed

information on Accutinter 1500 topics and provides a basic reference that can be

used to help you with specific issues.

This Guide provides the information for installing your Accutinter 1500,

dispensing for the first time, and using ColorPro. This publication also includes basic

troubleshooting suggestions, customer service, help information, daily and preventative

maintenance procedures, and warranty information.

Your Accutinter 1500 dispenser includes detailed illustrated labels for how to

clean the nozzles located inside the top canister cover of the machine. You can also

find daily maintenance instructions in this guide starting on page 31. Make sure to

follow these directions for the best performance of your machine.

ColorPro has basic information about using your Accutinter and ColorPro in the Help

section of the software.

If you have internet access, the most current information for your Accutinter 1500 is

available from the worldwide web at http://www.fluidman.com.

For Your Safety

Customer safety is important. Our products are designed to be safe and effective.

However, dispensers are electrical equipment. The Accutinter line is safe, fast, and

reliable—designed to bring many years of operation. There are precautions you can

take to avoid damage to the equipment or bodily injury before operating. By carefully

following the instructions in this document and the warning and maintenance labels

on the machine, you can help protect yourself from hazards and create a safer work

environment.

Equipment can become damaged due to misuse or neglect. Some product damage is

serious enough that the product should not be used again until it has been inspected

and, if necessary, repaired by a Fluid Management authorized service technician. As

with any electronic device, pay close attention to the dispenser when it is turned on.

On very rare occasions, you might notice an odor or see a puff of smoke or sparks

vent from your machine, or hear sounds like popping, cracking or hissing. These

conditions might merely mean that an internal electronic component has failed in a

safe and controlled manner. However, it may indicate a potential safety issue. DO NOT

take risks or attempt to diagnose the situation yourself. Contact Fluid Management at

1.800.462.2466 for assistance.

Safety Precautions

• Read this guide and all

warning labels before using

the machine.

• Keep this guide in a safe

place.

• Read and adhere to all

Warning and Caution labels

on the machine.

• Prepare, level, and clear the

area where the machine will

be installed.

• To avoid risk of fire or

injury, unplug the power

before servicing electrical

components.

• DO NOT dispense

flammable materials.

• After installing, complete

a purge and check the

plumbing.

• Check that canisters and

lines are secure and in

place.

• Plug into an approved

grounded outlet only. Make

sure the outlet meets all

national and local codes.

• To reduce the risk of electric

shock or injury, use indoors

only.

• DO NOT push any

objects into the air vents

or openings of your

equipment. Doing so can

cause fire or electric shock

by shorting out interior

components.

• Ensure that nothing rests

on your equipment’s cables

and that the cables are not

located where they can be

stepped on or tripped over.

Fluid Management Customer Service 1 . 800 . 462 . 2466

Accutinter 1500 | 5

Page 8

Important Safety Information

Information and Instruction Labels

You should become familiar with the information labels affixed to the machine,

as well as the warnings, cautions, and notes which appear throughout this guide.

Read all the warning labels on the exterior and interior of the dispenser. If the

WARNING:

Unplug before

servicing

Use a dedicated

15 amp circuit

labels become damaged or unreadable, you may purchase replacements from

Fluid Management Customer Service.

Safety Notice Information

The two main notices used in this Guide and on the

WARNING

•

HAZARDOUS

ELECTRICAL

COMPONENTS

When you see a Warning notice in this guide, read it carefully before continuing with the

operation of the machine. Take all necessary precautions to avoid potential injury.

Accutinter 1500 / Accutinter 1500 HS are Warning and

Caution. A Warning notice tells you about a hazard that

could cause serious injury to you or extensive damage to

the equipment. This information is featured in the beginning

of the guide to emphasize safety.

WARNING:

DO NOT use with or

near flammables

A Caution notice tells you about a danger that could cause

CAUTION:

•

POTENTIAL

SAFETY

HAZARD

injury to you or minor damage to the dispenser. When you

see a Caution notice in this guide, read it carefully and be

sure you understand it before continuing.

General Safety Information

DO NOT attempt to service a product yourself unless instructed to do so by Fluid

Management Customer Service. Use only a Fluid Management Authorized Service

Technician to repair your equipment. Please note that some parts can be upgraded or

replaced by the customer. Fluid Management identifies those parts as such and provides

documentation with instructions when it is appropriate for customers to replace those

parts. You must closely follow all instructions when performing such replacements.

ALWAYS make sure that the power is turned off and that the machine is unplugged

before you attempt the replacement. If you have any questions or concerns, contact

Fluid Management Customer Service.

Air Circulation

Your computer and monitor for your dispenser produce heat. The computer has a fan

that pulls in fresh air and forces out hot air. The monitor lets hot air escape through

vents. Blocking the air vents can cause overheating, which might result in a malfunction

or damage. Place the computer and monitor so that nothing blocks the air vents. Allow 4

inches (101.6 mm) clearance around air vents.

6 | Accutinter 1500

Fluid Management Customer Service 1 . 800 . 462 . 2466

Page 9

Important Safety Information

Grounding

This product must be grounded. In the event of an electrical short circuit, grounding

reduces the risk of electrical shock by providing an escape for the electric current.

This product is equipped with a cord that has a grounding wire and an appropriate

grounding plug. The plug must be inserted into an outlet that is properly installed and

grounded in accordance with all local codes and ordinances.

Danger

Improper installation of the grounding plug can result in a risk of electric shock. If

repair or replacement of the cord or plug is necessary, DO NOT connect the

grounding wire to either flat blade terminal. The insulation wire with green or green

and yellow stripes on the outer surface is the grounding wire.

Check with a qualified electrician if the grounding instructions are not completely

understood, or if in doubt about whether the product is properly grounded. DO NOT

modify the plug provided. If it will not fit into the outlet, have the proper outlet installed

by a qualified electrician.

NOTE: This product is for use on a dedicated nominal 120 Volt or nominal 220 Volt

circuit where applicable and has a grounding plug.

Caring for Your Computer

Disconnect the power plug on the computer (by pulling the plug, not the cord) if

any of the following conditions exists:

• You want to remove any parts.

• The power cord or plug becomes frayed or otherwise damaged.

• You spill something into the case.

• Your computer is exposed to rain, flooding, or any other excess moisture.

Keep the flat panel monitor in room temperature conditions. Excessive cold or hot

conditions can have an adverse effect on the liquid crystal display of the monitor.

NOTE: Review the weight limits referenced in your computer documentation before

placing monitor or other devices on top of your computer.

Warnings

• The AT1500 and AT1500

HS machines draw 5 amps

at 120 or 2.5 amps at

220/230 ± 10% VAC.

• DO NOT modify the

provided plug.

• Improper use of grounding

plug can result in risk of

electric shock.

• Hazardous moving parts.

Keep fingers and other

body parts away.

Cautions

• Check with a qualified

electrician or service person

if grounding instructions

are not completely

understood or if in doubt

as to whether product is

properly grounded.

• DO NOT use an adapter

or extension cord with

this product.

• This unit must be plugged

into a dedicated

electrical line.

• To reduce risk of electric

shock or injury, use

indoors only.

Communication Regulation Information

Safety and regulatory compliance Information

See the affixed labeling on the machine. ETL Listed, conforms to UL STD 1450.

Certified to CAN/CSA STD C22.2 NO. 68.

FCC Compliance Statement

This device complies with part 15 of the FCC Rules. Operation is subject to the

following two conditions: (1) This device may not cause harmful interference, and

(2) this device must accept any interference received, including interference that

may cause undesired operation.

Fluid Management Customer Service 1 . 800 . 462 . 2466

• Never force a connector

into a port. If the connector

and port do not join

with reasonable ease,

they probably do not

match. Make sure that

the connector matches

the port and that you have

positioned the connector

correctly in relation to the

port.

Accutinter 1500 | 7

Page 10

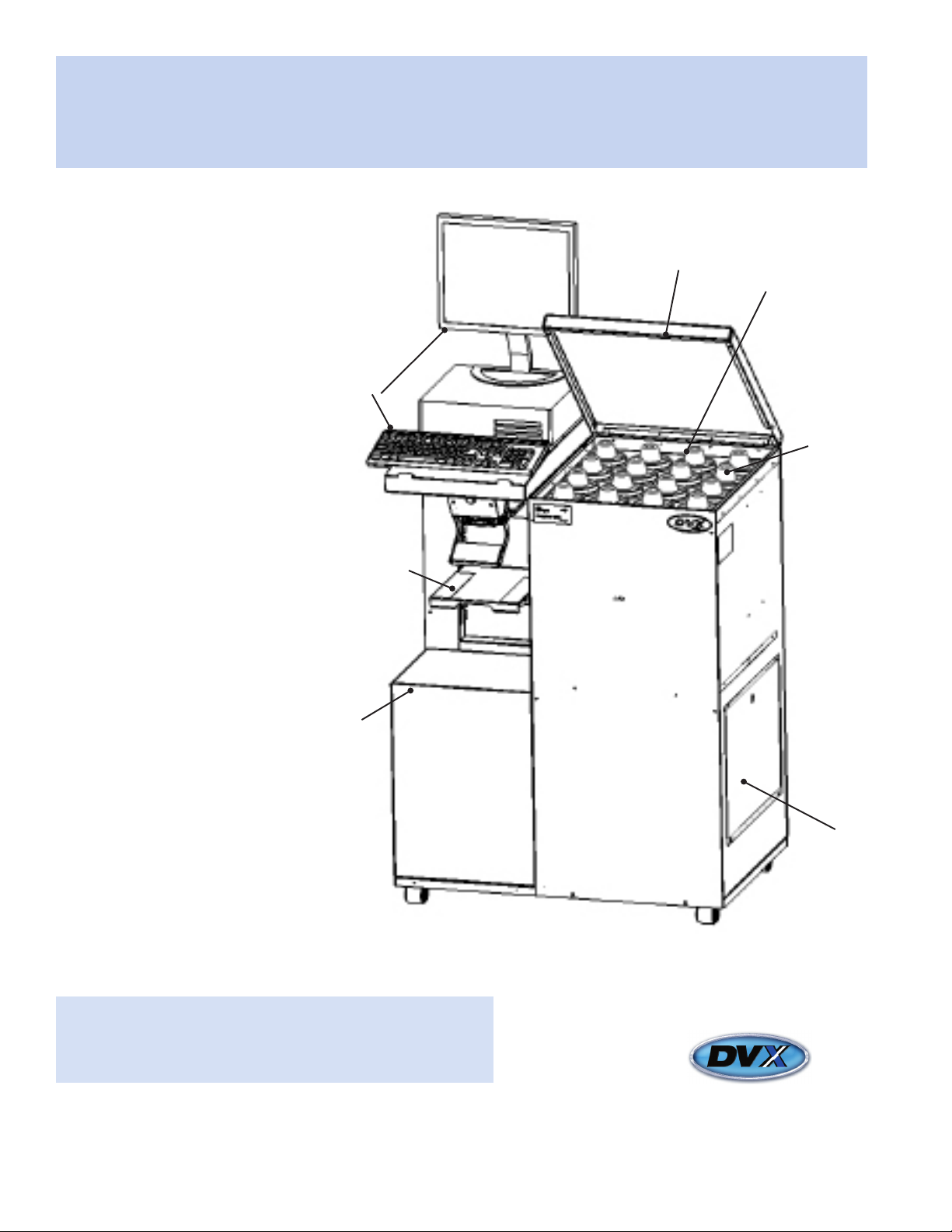

Getting to Know Your Accutinter 1500

Technical Specifications

16 Canisters:

35” W x 24” D x 48” H –

370 lbs. (empty canisters)

Maximum power:

• 120 volts +/- 10%,

60 Hz, 5 amp

• 220/230 volts +/- 10%,

50/60 Hz, 2.5 amp

Environmental

Conditions*

• Operating temperature:

between 50

104o F (40o C)

• Relative humidity:

between 5% and 85%

without condensation

o

F(10

o

C) and

Optional Accessories

Top Cover

Canisters

Monitor/

Keyboard

Stand

Spill Tray

Quart/Pint/

Gallon

Container Shelf

• Computer with Flat Screen

Monitor, Keyboard &

Mouse

• Label Printer

• Barcode Scanner

• Surge Protector

5-gallon

Container

Shelf

*NOTE: Environmental conditions are strictly based on the types

of colorants used (information provided by paint manufacturer).

The specifications shown are for the machine only.

Service

Panel

8 | Accutinter 1500

Fluid Management Customer Service 1 . 800 . 462 . 2466

Page 11

Getting to Know Your Accutinter 1500 HS

Technical Specifications

16 Canisters:

35” W x 24” D x 48” H –

370 lbs. (empty canisters)

Maximum power:

• 120 volts +/- 10%,

60 Hz, 5 amp

• 220/230 volts +/- 10%,

50/60 Hz, 2.5 amp

Environmental

Conditions*

• Operating temperature:

between 50

104o F (40o C)

• Relative humidity:

between 5% and 85%

without condensation

o

F(10

o

C) and

Optional Accessories

Top Cover

Canisters

Monitor/

Keyboard

Stand

Spill Tray

Quart/Pint/

Gallon

Container Shelf

• Computer with Flat Screen

Monitor, Keyboard &

Mouse

• Label Printer

• Barcode Scanner

• Surge Protector

5-gallon

Container

Shelf

*NOTE: Environmental conditions are strictly based on the types

of colorants used (information provided by paint manufacturer).

The specifications shown are for the machine only.

Service

Panel

Fluid Management Customer Service 1 . 800 . 462 . 2466

Accutinter 1500 | 9

Page 12

Getting to Know Your Accutinter 1500

Accutinter 1500 / Accutinter 1500 HS Features

DVX technology drives accurate, consistent and repeatable dispenses

Mechanical spring-loaded nozzle closer (Accutinter 1500) and automatic nozzle closer (Accutinter 1500 HS) keep

low-VOC colorants from drying and causing mis-tints

Small footprint delivers accurate performance

Low profile design makes filling and tinting easy

Intuitive software allows operators to learn tinting fast

Tips to Improve Operation

Clean nozzles daily for consistent and accurate dispense

Purge each colorant once a day

Follow the preventative maintenance schedule for your Accutinter 1500 / Accutinter 1500 HS

DO NOT use solvents in your Accutinter 1500 / Accutinter 1500 HS

Keep ColorPro software current

DO NOT load screen savers onto your Accutinter 1500 / Accutinter 1500 HS computer/monitor. Adding this and

other software may conflict with ColorPro and effect dispense operation

Use the Welcome to ColorPro section of this manual for answers to questions about ColorPro

Use the correct sized labels for your label printer (optional).

10 | Accutinter 1500

Fluid Management Customer Service 1 . 800 . 462 . 2466

Page 13

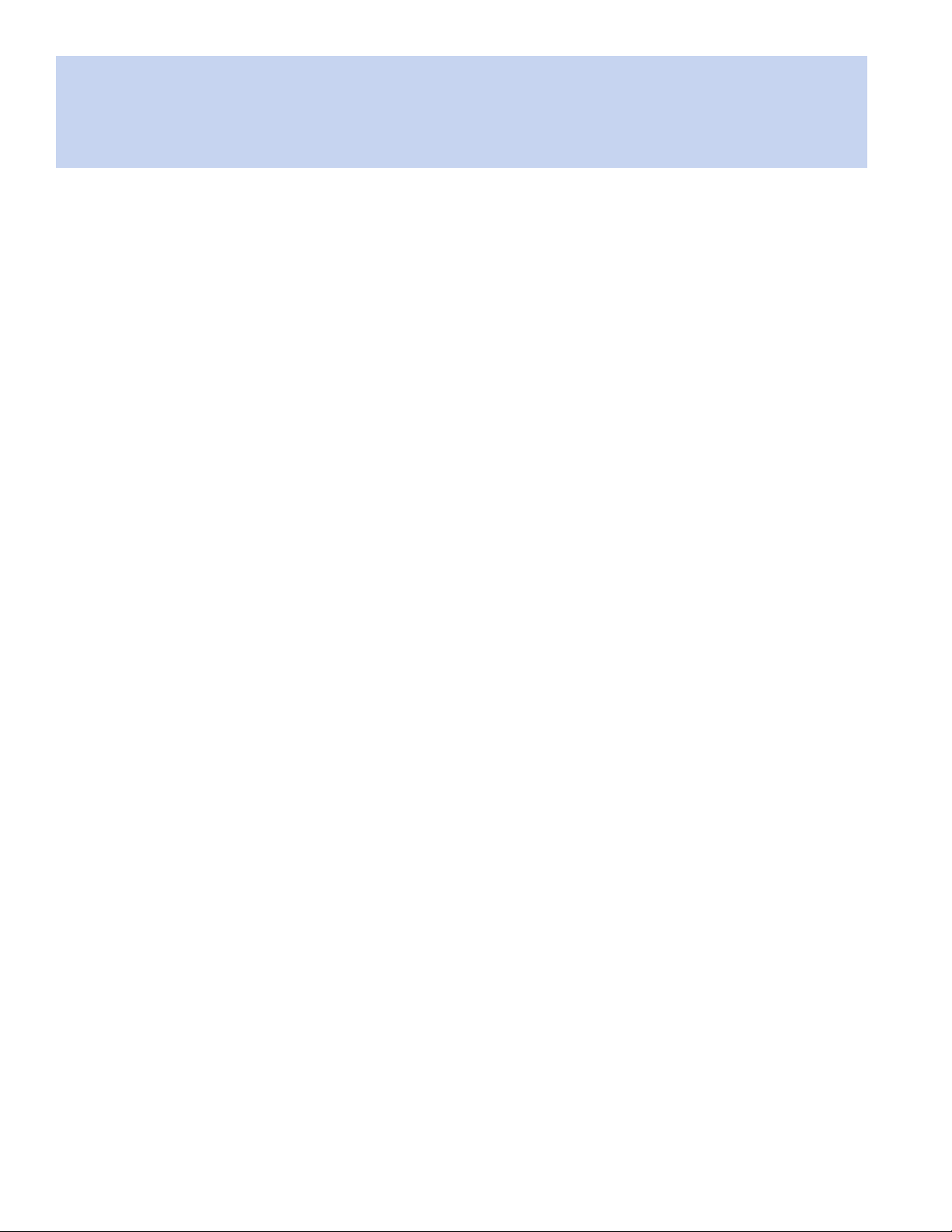

Getting Started

Installation

Your Accutinter 1500 and Accutinter 1500 HS have been designed for quick set up. If you have never

used an Accutinter dispenser or are new to paint dispensers, read this section for instructions on getting

started and installing your machine.

If you are an experienced user, you may already know enough to get started. Be sure to look over the

information in the “Welcome to ColorPro” section of this guide to find out more about the new features and

capabilities in ColorPro.

Monitor

Computer

Keyboard

Power cable

Fluid Management Customer Service 1 . 800 . 462 . 2466

Mouse

USB cable

Accutinter 1500 | 11

Page 14

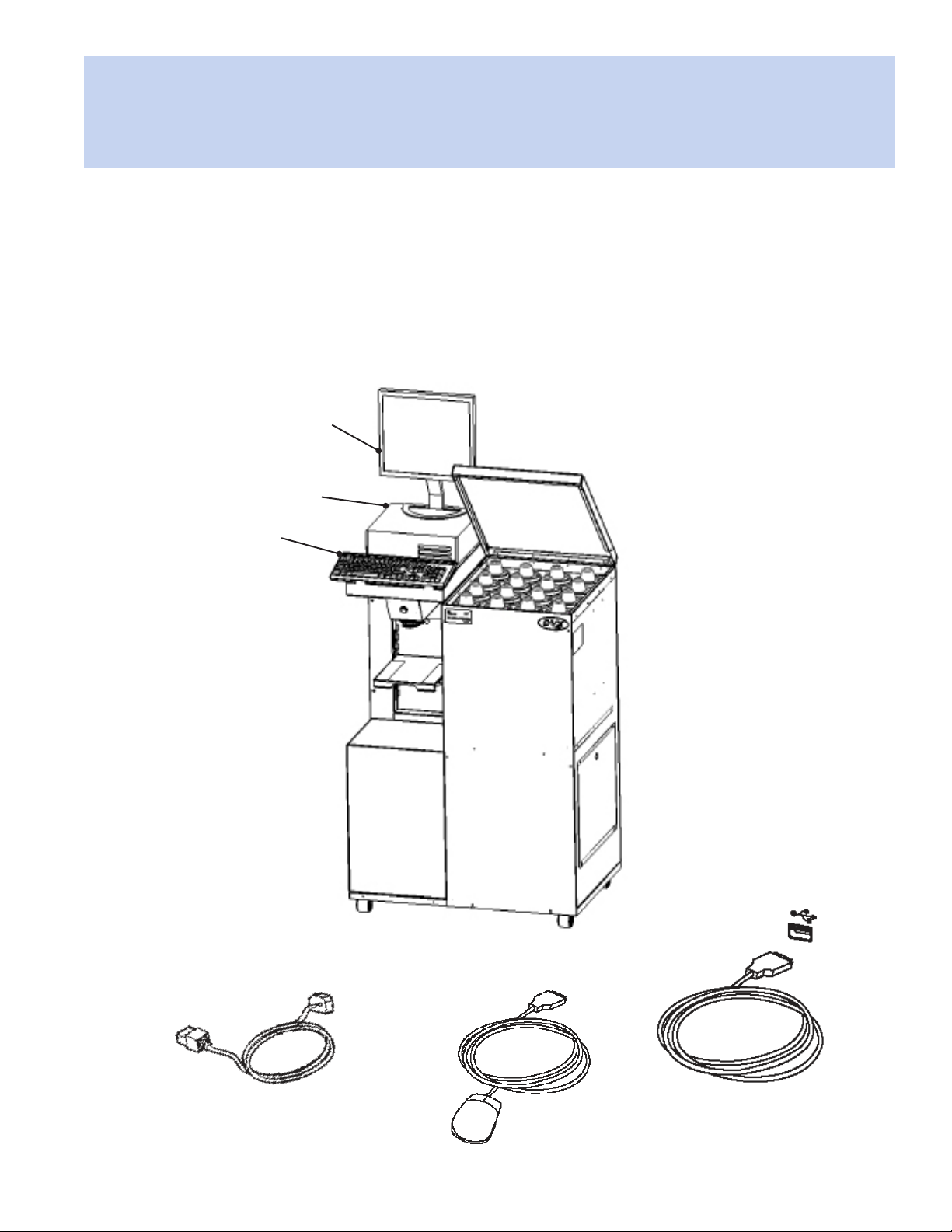

Getting Started

Installation

Unpacking and Set up

Follow the steps on the next nine pages to set up your Accutinter 1500 or Accutinter

1500 HS.

Warnings

1 Make sure these items are available before installing.

Accutinter 1500 or Accutinter 1500 HS unit

Computer, mouse, and keyboard

Label printer and labels (optional accessory)

Barcode scanner (optional accessory)

Surge protector (not included)

2 Tools needed for installation.

Phillips screwdriver

Scissors or diagonal cutters

3 Unpack the machine.

a. Remove the interior contents of the packaging.

b. While unpacking the machine, inspect the machine for any damage that

may have occurred during shipping.

If any damage is found, notify the carrier immediately. Arrange for

inspection in order to claim recovery. Claims for damage must be made by the

consignee (YOU). The carrier assumes full responsibility upon acceptance

of the shipment and will not entertain any claims by the consignor.

Verify the contents against the packing slip. Note if any items are missing

or damaged. Call Fluid Management Customer Service at 1-800-462-2466

if any items are missing.

ALWAYS shut off the power

and unplug your machine

from the AC power outlet

before servicing.

This unit must be plugged

into a dedicated electrical

line. This includes:

• 15 amp line for 120 Volt

equipment

• 15 amp line for 220 Volt

equipment

The surface the dispenser sits

on must be strong enough to

support its weight of up to

700 pounds (317 kg).

Replace all fuses with the

exact sized replacements.

This machine is not explosion

proof and must not be used

in a flammable atmosphere or

with flammable materials.

To reduce the risk of electric

shock or injury, use indoors only.

4 Position dispenser in permanent location.

Choose a location for your dispenser that is capable of supporting the weight

(700 pounds [317 kg]). Make sure there is enough room for service personnel

to have access to the rear of the machine. If there is not enough room, routine

maintenance may be difficult to perform.

5 Position the monitor, keyboard,

and computer.

Place the monitor and keyboard on the

keyboard support on the left of the

machine. See Figure 1.

12 | Accutinter 1500

Fluid Management Customer Service 1 . 800 . 462 . 2466

FIGURE 1

Page 15

Getting Started

Installation

6 Plug in the power cord and connect all cables.

a. Route the keyboard, monitor, and mouse cables to the rear of the machine where the computer has been

placed. Plug them into the appropriate ports on the back of the computer.

b. If you purchased the optional barcode scanner, label printer or are using a spectrophotometer, route the

cables to the rear of the machine where the computer has been placed. Plug these cables into the

appropriate ports on the back of the computer.

c. Connect the USB cable coming out of the hole of machine where the

computer has been placed. Attach the USB cable to the port labeled

“DISPENSER” on the back of the computer. See Figure 2

d. Plug the power cords from the monitor, computer and Accutinter into

the recommended surge protector.

e. Plug the surge protector into a 15 amp dedicated electrical outlet.

7 Turn on machine.

a. Locate the front panel below the nozzle closer in the center of the

machine.

b. Locate and unscrew the two Phillips head machine screws provided.

c. Open the front panel and locate on the red toggle switch near the

bottom of the compartment.

d. The red toggle switch needs to be in the ‘ON’ position on or ‘RESET’

position for the Accutinter to work properly.

e. Close the front panel and screw in the two Phillips head machine

screws provided.

FIGURE 2

8 Turn on computer and monitor.

Locate the on/off button on your computer and turn it on. Reference the computer’s user manual if you have

difficulty locating.

9 Locate the ColorPro icon on your desktop.

ColorPro and your manufacturer’s database were loaded at Fluid Management’s factory. If you cannot locate

the ColorPro icon, load software using the backup CD provided. Open ColorPro by double clicking on the icon.

10 After the machine is installed, fill the canisters and update ColorPro

Complete an initial manual dispense for each colorant.

(See “Getting Started: Preparing and refilling the canisters” on page 16).

Fluid Management Customer Service 1 . 800 . 462 . 2466

Accutinter 1500 | 13

Page 16

Getting Started

Connecting the label printer (optional)

The label printer software for the label printer is installed on the computer by Fluid Management. All you

need to do is connect the printer cables to the computer and to a dedicated power outlet. The original

packaging from the printer vendor includes the software, a quick start guide with detailed instructions,

and the necessary cables.

Follow these steps to connect the printer:

1

3

a. Unpack the printer.

b. Make sure you have

these items:

-CD - ROM

-Quick Start Guide

-Roll of labels

-USB cable

-Label writer printer

-Power cable

-Power adapter

c. Plug the power cord

into the power adapter.

2

a. Plug the power adapter into the power

connector on the bottom of the printer.

b. Plug the other end of the power cord

into a power outlet.

c. Plug the USB cable into the bottom of

the printer.

4

The blue light on the front of the printer

should be on if the printer is ready.

Plug the USB cable into the available USB

port on the back of the computer.

14 | Accutinter 1500

- Click the Print Label (F5) button to print

labels when dispensing a formula.

Fluid Management Customer Service 1 . 800 . 462 . 2466

Page 17

Getting Started

Connecting the barcode scanner (optional)

The barcode scanner must be connected to the computer and keyboard. The barcode scanner is

pre-programmed by Fluid Management. After the barcode scanner is connected, the scanner must be

enabled to be compatible with ColorPro. The original packaging from the vendor includes the barcode

scanner, the cable, and a quick start guide.

Follow these steps to install the barcode scanner:

1

a. Unpack the barcode scanner.

b. Make sure the barcode scanner and the

cable are included.

c. Turn on the computer.

3

2

Plug the interface cable modular cord into the

port in the bottom of the scanner’s handle.

4

Connect the scanner cable to the keyboard

cable from the Accutinter1500.

NOTE! If the keyboard cable is a USB, add

an adapter and connect the two cables.

Fluid Management Customer Service 1 . 800 . 462 . 2466

Connect the scanner cable to

the purple keyboard connector

on the back of the computer

where the keyboard symbol

is marked.

Accutinter 1500 | 15

Page 18

Getting Started

Connecting the barcode scanner (optional)

After the barcode scanner is connected to the computer and keyboard, it must be enabled in ColorPro.

Follow these steps to enable the barcode scanner:

Locate FM_Customizer from Fluid

Management folder and launch.

5

a. Type in “service” when you are prompted

for the password.

b. Click Check.

a. Check Print Override Base to allow

7

operators to manually override using

scanner.

b. Check Barcode Chip Scanning Enabled

if you are using barcodes to identify

formulas from other color chips.

a. Check the Barcode Scanning Enabled box

6

8

on the Barcoding and Extra Options tab.

b. Click Apply Changes, then click Yes and

OK.

c. Close.

After enabling the barcode scanner, you can

test the scanner by dispensing.

a. Open the Dispense menu.

b. Select a formula.

c. Click the Dispense button. If you receive

a prompt that says, “Please Scan the Base

Barcode”, you have successfully enabled

the bar code scanner.

16 | Accutinter 1500

Fluid Management Customer Service 1 . 800 . 462 . 2466

Page 19

Getting Started

Preparing and refilling the canisters

After your machine is installed in the proper location, you need to fill the canisters with colorant so you

can dispense for the first time. Your machine may be shipped with a small amount of glycol or colorant in

the canisters already, but you need to fill them to capacity with colorant. When re-filling canisters, you will

follow the same process using steps 3-8. Canisters come in varying capacities. Check the label inside

the top cover for capacity and colorant locations. DO NOT overfill the canisters. After the canisters are

filled, ColorPro (or your manufacturer’s software) must be updated (See page 18).

2

1

Raise the top cover of the

Accutinter so you can see

the canisters inside.

Remove the caps from

each canister one at a

time and prepare to fill

them with colorant.

Cautions

• DO NOT operate the

dispenser until it is in a

permanent location.

• DO NOT dispense if

canisters are empty

• Before dispensing colorant

for the first time, you

must complete a manual

dispense.

• DO NOT dispense without a

container in place.

• DO NOT use shelf surface to

seal open cans.

Fluid Management Customer Service 1 . 800 . 462 . 2466

Accutinter 1500 | 17

Page 20

Getting Started

Preparing and refilling the canisters

Fill Menu

Use the Fill Menu to

update the software

after you have filled

all of the canisters for

the first time. When

refilling, select All

(F2) or the correct

individual colorant.

Main Menu

3

4

Update ColorPro with the canister level information

after you have filled all of the canisters.

From the Main Menu, select Maintenance (F3). In the

Fill tab, select All (F2).

18 | Accutinter 1500

5

Select Fill To Top (F2)

button.

*NOTE: When refilling, update the

canisters by entering the amount of colorant

you added in the text box. Press Enter.

6

Fluid Management Customer Service 1 . 800 . 462 . 2466

When prompted, “...are

you sure?”, click Yes.

7

*NOTE: Repeat entire process for each

empty canister.

Select Done (Esc) to

return to the Main Menu.

Page 21

Getting Started

Preparing the system

After you have filled the canisters and updated the software, you must do an initial dispense to make sure

the Accutinter is working properly.

Smart Purge

Use “Smart Purge” for daily Purging.

This will only purge colorants that

have not been recently used.

1

From any screen choose Maintenance (F3 or F11).

3

4

2

Purge (F3) button.

underneath the nozzle

Click on the

Purge tab.

Purge colorants.

Click on the

colorant to be

purged or select

ALL button to

purge entire

system. Click the

Place a container

with nozzle closer

open.

NOTE:

Accutinter 1500

HS, the nozzle will

open automatically

after step 5. At this

point, just place the

container aligned

with the nozzle tip.

In the

5

Click Dispense (F2).

Colorant(s) will dispense.

Prompt will appear

confirming dispense.

6

Click Done (Esc).

Fluid Management Customer Service 1 . 800 . 462 . 2466

Accutinter 1500 | 19

Page 22

Getting Started

Using the shelves

For 5-gallon containers, keep shelf flipped

upright into the Accutinter.

For all other container sizes, flip down the

shelf.

Place the quart/pint can directly onto the

shelf beneath the red LED can locator light.

Lift shelf to the pint, quart, or one-gallon

position labeled. Push shelf in to lock it in place.

Make sure the shelf is sturdy before using.

To move shelf from locked position, lift

shelf upward and outward slightly and slide

shelf to desired container height.

With shelf stored in upright position,

center the five-gallon can directly

beneath the red LED can locator light

before dispensing.

20 | Accutinter 1500

Fluid Management Customer Service 1 . 800 . 462 . 2466

Page 23

Basic Operations

Welcome to ColorPro4

ColorPro and ColorPro Professional puts usability at your fingertips with features that allow you to operate

your Accutinter 1500 dispenser—instantly dispense any formula in your database, perform maintenance,

run usage reports, estimate paint coverage for any room, adjust formulas, and calculate the formulas for

lightening and darkening paint.

ColorPro4 Features:

• Dispense all your database

formulations or manually

create your own colors

• Store customer information

and color requirements so

you can provide consistent

service time and time again

• Integrates with

spectrophotometer

hardware and software

• Customize settings to meet

your business volume needs.

• Easy to use screens will assist

you in routine maintenance

• Run diagnostics on

the machine for quick

troubleshooting

• Track and report colorant,

machine, and formula usage

to assist you in inventory,

maintenance and trend

management

• All functions can be

conducted with mouse or

keyboard

• ColorPro translated into

a variety of operator

languages

Fluid Management Customer Service 1 . 800 . 462 . 2466

Accutinter 1500 | 21

Page 24

Basic Operations

Main menu

The main screen of ColorPro features five selections.

Dispense

Click here to go to the Formula Book, Manual

Dispense, and Dispense Queue menus.

Maintenance

Click here to add

colorant, purge lines,

agitate colorants.

Reports

Click here to run

reports for a selected

date range in csv.file

format.

Help Menu

Click here for training

videos to get answers

to your ColorPro and

Accutinter questions.

About

Click here to see ColorPro

and Accutinter information.

22 | Accutinter 1500

Fluid Management Customer Service 1 . 800 . 462 . 2466

Page 25

Basic Operations

Dispensing from Formula Book

From the Main Menu, choose Dispense (F2) button. The Formula Book tab allows you to select, dispense,

and adjust the formula. You can also estimate paint quantities and enter new formulas.

Clear Formula

To select a new formula or to start

over, choose Clear Formula (F9).

Formula Information

Select the Brand of

formula you are

searching for by using the

drop down menus.

Enter the Formula Name

or use the drop down

menus to search for

the Formula Number

in your database.

Select the desired

Product, Finish, and

Container Size using the

drop down menus.

Dispense

Choose Dispense (F2) to dispense

the formula now. When dispensing,

place container under nozzle. Prompt

will appear confirming dispense.

To dispense another container of the

same formula, choose Dispense (F2).

Fluid Management Customer Service 1 . 800 . 462 . 2466

Accutinter 1500 | 23

Page 26

Basic Operations

Dispensing from Formula Book

Ingredients

The colorant ingredients needed to

dispense your formula will show here.

Print Label

Click here to print labels.

2

Order Queue

This number indicates the

number of jobs queuing.

Adjust

Click here (F6) to adjust

individual formulas

(See page 28).

Save As Custom

Click here (F7) to save as a

custom color or customer

information.

Price

Click here (F3) to estimate

the cost of a job or price for a

specific formula (optional).

Send To Queue

Choose Send to Queue

(F10) to dispense the

formula later.

Coverage Estimator

Click Coverage Estimator (F8)

to estimate how much paint is

needed for a job.

24 | Accutinter 1500

Fluid Management Customer Service 1 . 800 . 462 . 2466

Page 27

Basic Operations

Manual dispensing

From the Main Menu, choose Dispense (F2) button. The Manual Dispense tab allows you to select,

dispense, and adjust the formula. You can also estimate paint quantities, and enter new formulas.

Enter Amounts

The colorants will be displayed under Selected Ingredients. Type in the shot size

of the colorant that you require. Repeat the steps for each colorant in that formula.

Brand

Select the Brand of

paint you are creating a

formula for by using the

drop down menu.

Ingredients

From the ingredient

list, select the first

colorant by double

clicking on the button.

Get Base

After selecting brand

and colorants, click

here to select Base and

size to dispense new

formula info.

Save As Custom

Click here (F7) to save

custom formula information.

Dispense Now

Dispense now by selecting Dispense (F2).

Fluid Management Customer Service 1 . 800 . 462 . 2466

Or

Send to Queue

Choose to dispense the formula later by selecting

Send to Queue (F10).

Accutinter 1500 | 25

Page 28

Basic Operations

Using external data source and dispense queuing

From the Main Menu, choose Dispense (F2). The Dispense Queue tab allows you to enter and dispense

a formula scanned by a spectrophotometer (optional) or from a previous order not yet dispensed.

Order Queue

This number indicates the

number of jobs queuing.

Input List

The Input List (F4)

displays all the formulas

waiting to be dispensed

from an external source

or previously requested.

The number of jobs

queuing is located

in top right corner.

Search for a job by

clicking on any of

the input tabs.

Remove Job

Click here to remove

the highlighted dispense

from the input list.

Dispense

Choose Dispense (F2) after selecting the

formula from the Input List.

26 | Accutinter 1500

Fluid Management Customer Service 1 . 800 . 462 . 2466

Page 29

Basic Operations

Adjusting formulas

Color formulas can be modified to adjust lightness, darkness, and modify existing formulas. From any tab in

the Dispense Menu, click Adjust (F6) after a formula is selected.

Adjust Ingredients

On the Adjust

Ingredients tab, the

original formula colorant

amounts are displayed.

Selected Ingredients

In the Change +/- fields,

type the amount to add

or subtract from the

original formula for

each colorant. The totals

will change based upon

amounts you enter.

Fluid Management Customer Service 1 . 800 . 462 . 2466

Dispense Total

Click Dispense Total

(F3) to dispense the

original formula plus

adjusted amounts.

Dispense Change

Click Dispense

Change (F2) to

dispense the

incremental added

colorant amounts.

Accutinter 1500 | 27

Page 30

Basic Operations

Using color scaling

On the Adjust Scaling tab, the original formula colorant amounts are displayed.

Create a deeper or

lighter formula by

selecting Percent

Change and selecting

a value from drop down

box, or select Container

Size and select a

different paint container

size from drop down box.

28 | Accutinter 1500

Reset

Click here (F9) to

return to original

formula settings.

Dispense Total

Click Dispense Total

(F3) to dispense the

original formula plus

adjusted amounts.

Dispense Change

Click Dispense

Change (F2) to

dispense the

incremental added

colorant amounts.

Fluid Management Customer Service 1 . 800 . 462 . 2466

Page 31

Basic Operations

Purging the lines

It is recommended that you complete a purge daily to ensure optimal Accutinter performance and avoid

possible mis-tints.

Smart Purge

Use “Smart Purge” for daily Purging.

This will only purge colorants that

have not been recently used.

1

From any screen choose Maintenance (F3 or F11).

3

4

2

All button to purge

open automatically

after step 5. At this

point just place the

Click on the

Purge tab.

Purge colorants.

Click on the

colorant to be

purged or select

entire system.

Click the Purge

(F3) button.

Place a container

underneath the

nozzle with nozzle

closer open.

NOTE:

Accutinter 1500

HS the nozzle will

container aligned

with the nozzle tip.

In the

5

Click Dispense (F2).

Colorant(s) will dispense.

Prompt will appear

confirming dispense.

6

Click Done (Esc).

Fluid Management Customer Service 1 . 800 . 462 . 2466

Accutinter 1500 | 29

Page 32

Basic Operations

Stirring the colorants

When adding new colorants or if the colorant has not been used for several days, you may want to

manually stir colors. From any screen, choose Maintenance (F3 or F11). The Agitate tab allows you to

stir colorants in the canister.

1

2

Click on Agitate

tab. In the Duration

in Minutes (F4)

field, type in

the amount of

time colorants

should stir.

Click Agitate (F2)

to begin agitation

cycle. Progress bar

will appear confirming

agitation cycle. Click

Done (Esc).

30 | Accutinter 1500

NOTE: The default cycle is 30 seconds per

hour. Fluid Management recommends 4 minutes

for manual agitation.

Fluid Management Customer Service 1 . 800 . 462 . 2466

Page 33

Basic Operations

Using ColorPro Help

For additional information on how to operate your Accutinter or ColorPro, click Help (F1). The main screen

of ColorPro features six selections.

Accutinter Models

Contains information

regarding shelves,

container sizes, and

dispensing.

ColorPro

Find information

about dispensing

with ColorPro,

maintaining the

machine, and

customization.

Quick Start Guide

Overviews regarding

dispensing, maintaining,

and customizing

your Accutinter.

Maintenance

Includes information

about canister, nozzle, and

preventative maintenance,

and line purging.

Troubleshooting

Contains information

regarding dispensing,

color tinting and other

operational issues.

Safety

Important safety

instructions to note when

operating equipment.

Fluid Management Customer Service 1 . 800 . 462 . 2466

Accutinter 1500 | 31

Page 34

Maintenance, Care and Use - Accutinter 1500

Your Accutinter 1500 depends on clean and well maintained parts. To ensure dispensing accuracy and

increase the operation of your Accutinter 1500, follow the maintenance schedule detailed below:

PERFORM EVERY DAY:

• Clean each of the nozzles with the recommended nozzle cleaning tool and purge (see below).

• Remove all excess colorant and debris from the nozzle and nozzle area.

• Clean all accessible surfaces and cabinet with a mild cleaning solution.

• Empty and clean the drip tray. Replace if necessary.

• Moist sponge daily to keep colorant from drying.

PERFORM EVERY WEEK:

• Clean the spill trays around canisters.

PERFORM EVERY SIX MONTHS:

• Check the calibration and re-calibrate as required.*

*This should be performed by a Fluid Management authorized service technician.

32 | Accutinter 1500

*This should be performed by a Fluid Management authorized service technician.

Fluid Management Customer Service 1 . 800 . 462 . 2466

Page 35

Maintenance, Care and Use - Accutinter 1500 HS

Your Accutinter 1500 HS depends on clean and well maintained parts. To ensure dispensing accuracy and

increase the operation of your Accutinter 1500 HS, follow the maintenance schedule detailed below:

PERFORM EVERY DAY:

• Clean each of the nozzles with the recommended nozzle cleaning tool and purge (see below).

• Remove all excess colorant and debris from the nozzle and nozzle area.

• Clean all accessible surfaces and cabinet with a mild cleaning solution.

• Empty and clean the drip tray. Replace if necessary.

• Moist sponge daily to keep colorant from drying.

PERFORM EVERY WEEK:

• Clean the spill trays around canisters.

PERFORM EVERY SIX MONTHS:

• Check the calibration and re-calibrate as required.*

*This should be performed by a Fluid Management authorized service technician.

Your Accutinter 1500 HS will perform best if the nozzle and colorant lines are purged and cleaned every day. If

you use your machine frequently, Fluid Management recommends cleaning and purging the nozzle at least once

a day. The instructions for daily nozzle cleaning are below. For filling the colorant canisters, go to page 17.

Do not clean the equipment with a water jet.

Open nozzle closer

. Click Maintenance (F11)

. Choose Purge tab

. Click Open/Close (F7)

Replace sponge

. Replace sponge insert

. Moisten sponge with water

. Replace cup holder to closer

bracket

Remove cup holder from

nozzle closer

. Slide black cup holder left

. Remove cup from bracket

and place to the side

Replace cup holder to

nozzlecloser

NOTE: Environmental Conditions: Operating temperature between 50

The A-weighted sound pressure is below 70 dB.

Fluid Management Customer Service 1 . 800 . 462 . 2466

Clean nozzle

. Clean each opening with

included nozzle cleaning pick

. Use a circular motion to make

sure opening is clear

Purge colorants

. Click Maintenance (F11)

. Choose Purge tab

. Click All

. Click Purge (F3)

. Click Dispense (F2)

0

F (100 C) and 1040 F (400 C)

Clean cup

. Remove sponge insert

. Clean inside of cup liner with

water and paper towel

Close nozzle closer

. Click Maintenance (F11)

. Choose Purge tab

. Click Open/Close

Accutinter 1500 | 33

Page 36

Frequently Asked Questions

Equipment troubleshooting

Most of the problems listed in this section can be prevented by daily cleaning and by purging the nozzle.

See the Maintenance, Care and Use section in this manual for instructions.

Use the chart below to locate the problem and perform the recommended actions in the last column.

Contact Fluid Management Customer Service if you are unable to find a resolution.

PROBLEM FIRST CHECK: ACTION

The machine is

dispensing mis-tints.

…Do the fill settings in

ColorPro match what is

inside the canister?

…Have the nozzle openings

been cleaned recently?

…Is the Accutinter dispensing

accurately?

Compare the canister

contents with the fill

settings. Adjust if necessary:

1- Look inside the canister

and compare the contents

with what the fill settings in

ColorPro show.

2- If they do not match, fill

the canister and adjust the

colorant level in ColorPro

(see page 17).

Clean the nozzles:

1- Clean each nozzle opening

with a nozzle cleaning tool.

2- Remove all excess colorant

from around the nozzles

(see page 33/34).

3- Purge the lines with

ColorPro (see page 28).

4- Repeat cleaning and

purging if necessary.

Dispense one ounce of

each colorant into a marked

measuring container. If you

notice any colorants are not

dispensing, call Customer

Service for assistance.

The colorant shoots to the

side during a dispense.

34 | Accutinter 1500

…Have the nozzles been

cleaned recently?

Fluid Management Customer Service 1 . 800 . 462 . 2466

1- Clean the nozzle. Remove

all excess colorant and

dried debris.

2- Purge the colorant line.

3- Repeat if necessary.

Page 37

Frequently Asked Questions

Equipment troubleshooting

PROBLEM FIRST CHECK: ACTION

The nozzle closer is not

opening or closing.

Colorant drips or runs

after dispensing.

…Is the nozzle closer

covered with dried colorant

and debris?

…Is ColorPro prompting you

to fill the canister?

...Do the nozzle openings

need to be cleaned?

…Does the colorant have air

in it?

Clean all dried colorant

and debris from the

nozzle closer area. Make

sure the nozzle arm is clean

so it moves freely.

If the nozzle closer still does

not close, call Customer

Service.

1- If yes, fill the canister with

colorant (see page 16).

2- Agitate for up to three

minutes.

3- Purge the line.

If the canister is full, clean the

nozzle and complete a purge

using ColorPro (see page 28).

Repeat if necessary.

Complete a purge using

ColorPro (see page 28).

Repeat if necessary.

A colorant canister needs

to be filled.

The canister cover and

lids need to be cleaned.

The colorant coming out

of the nozzle is drippy or

clumpy.

Fluid Management Customer Service 1 . 800 . 462 . 2466

...Do the nozzle openings

need to be cleaned?

Follow the “Preparing

and refilling canisters”

instructions on page 16.

Soak the canister covers in

hot water and mild detergent.

Wipe off the excess debris

and dried colorant when the

colorant has loosened.

Scrape the excess colorant

off with a putty knife.

Clean the nozzle openings

and purge the lines (see pages

33/34). The colorant should

come out of the nozzle in a

steady stream.

Accutinter 1500 | 35

Page 38

PROBLEM

FIRST CHECK:

ACTION

Frequently Asked Questions

Equipment troubleshooting

The machine is not

dispensing.

There is no power. …Is the machine turned on

The printer is not printing. …Is the power cord firmly

…Is the machine turned on

and plugged in?

and plugged in?

…Is there power at the

receptacle?

…Is the surge protector

turned on?

connected to the computer

and functioning properly?

…Is the USB cable

connected at both ends?

Make sure the power cord is

plugged in.

Restart the machine:

1- Exit ColorPro.

2- Shut down the computer.

3- Press the reset switch on the

front of the keyboard tray.

4- Wait 30 seconds.

5- Turn the computer back on.

If the problem still persists, call

Customer Service.

Make sure the power cord is

plugged in. Replace the power

cord is damaged.

Check the circuit breaker

Turn on the surge protector;

replace if necessary.

Make sure the printing device

is properly connected.

Unplug the power to the printer

for 30 seconds and then

replug. Try to print again.

The motor is running

erratically or not at all.

36 | Accutinter 1500

…Is the dispenser on a

dedicated line?

Fluid Management Customer Service 1 . 800 . 462 . 2466

Restart the computer. After

restarting, print again.

If you still have problems, after

following these suggestions,

contact the printer manufacturer

at 1.800.426.7827

If no, plug the dispenser into a

dedicated 115 or 220 Volt line.

Page 39

Frequently Asked Questions

Equipment troubleshooting

PROBLEM FIRST CHECK: ACTION

One or two colorants are

not dispensing.

How do I clean the nozzle

openings?

The computer doesn’t

start when you press the

power button.

The monitor screen is

blank.

…Are the nozzles clogged? Follow the daily nozzle

cleaning instructions

(see pages 33/34) for your model.

Follow the daily nozzle

cleaning instructions (see page

33/34).

OR

Follow the “Daily Nozzle

Cleaning Instructions” on

the inside of the top cover of

your machine.

…Is the power cord

plugged in?

…Is the power turned on and

are the cables attached?

Make sure the power cord is

plugged into the rear of the

computer and to a working

electrical outlet.

Make sure the USB cable is

plugged into the back of the

monitor and to the back of

the computer.

Make sure the power cord

is plugged to the back of the

computer and to a working

electrical outlet.

The keyboard isn’t

responding.

Fluid Management Customer Service 1 . 800 . 462 . 2466

…Are all the cables securely

attached between the

computer and the keyboard?

…Are all the cables securely

attached between the

computer and the keyboard?

…Does the keyboard need

replacing?

Make sure the recommended

surge protector is turned on.

If not, firmly attach all cables.

Replace the keyboard.

Accutinter 1500 | 37

Page 40

Frequently Asked Questions

ColorPro Troubleshooting

PROBLEM FIRST CHECK: ACTION

General ColorPro related …Make sure ColorPro is

installed.

…Try re-starting the machine

to see if that solves the

problem.

…Can you find the answer

in the Help section of

ColorPro?

…Make sure your computer

is properly connected.

Turn on the computer.

Does the ColorPro main

screen open up? If yes, then

ColorPro is installed.

Press the restart switch on

the front of the keyboard tray.

Look in Help for

instructions and

troubleshooting information.

Make sure the communication

cable connects the computer

to the dispenser.

If screen savers have been

installed recently, they may

conflict with ColorPro.

Uninstall the screen savers.

Restart the computer.

Press the on/off button of

the computer. Wait thirty

seconds and turn the

computer back on.

A message in ColorPro

says, “Communication

to dispenser has been

severed. Recheck

connections and try

again.”

…Make sure the

communication cable is

connected between the

computer and the machine.

If none of these suggestions

work, call Customer Service.

Exit ColorPro.

Shut down the computer.

Restart the computer. Press

the red button on the right

side of the computer.

30 seconds and turn the

computer back on.

If you still receive the

message, call Customer

Service.

Wait

38 | Accutinter 1500

Fluid Management Customer Service 1 . 800 . 462 . 2466

Page 41

Frequently Asked Questions

ColorPro

Troubleshooting

PROBLEM FIRST CHECK:

A message in ColorPro

says, “Encoder pulse

failure. Motor failed on

canister containing...”

The optional barcode

scanner does not work...

If you suspect a problem

with the label printer...

If you suspect a problem

with the colorants...

Call Customer Service.

You must have ColorPro Professional for barcoding capability;

Make sure the Barcode Scanning Enabled box is checked in

FM_Customizer (see pages 14-15).

Contact the printer manufacturer at 1.800.426.7827

Contact your department manager or store manager.

Fluid Management Customer Service 1 . 800 . 462 . 2466

Accutinter 1500 | 39

Page 42

Service

FMDirect

Fluid Management products are backed by FMDirect,

our nationwide team of phone and field service

engineers. Providing you with local, hands-on support,

over 30 factory-direct service technicians deliver

expertise when and where you need it.

• 24/7 multilingual technical support

• Professional installation and on-site operator training

• Fully-stocked parts inventory on FMDirect vans

• Extended warranty and preventive maintenance

programs

Upgrades and Replacement Parts

Some parts can be upgraded or replaced by the

customer. Fluid Management expressly identifies parts

as such, and provides documentation with instructions

when it is appropriate for customers to replace those

parts. You must closely follow all instructions when

performing such replacements. ALWAYS make sure

that the power is turned off and that the product is

unplugged from any power source before you attempt

the replacement.

Fluid Management Customer Service

1.800.462.2466

Save time and money. If something should go

wrong, we suggest consulting the Maintenance,

Troubleshooting and Service sections of this

guide. They are designed to solve basic problems

before consulting a ser vice technician.

However, should you need assistance, please

have your model and serial number ready. Be

near your machine when you call and have a

purchase order number ready if ordering parts.

DO NOT attempt to service a product yourself

unless instructed to do so by a Customer Service

Representative. Use only a service provider who is

approved to repair your particular product.

Obtain Warranty Service

First, follow the advice in this guide. If the unit still does

not function, call Customer Service for information

about how to obtain warranty service.

The serial plate is located underneath the lid of

the machine. It includes the serial and model

numbers for your machine. Please make a note

of these numbers below:

Date of purchase:

Model Number:

Serial Number:

Your Service Technician’s

Name:

40

40 | Accutinter 1500

Fluid Management Customer Service 1 . 800 . 462 . 2466

Page 43

Index

A

accessories 8

adding colorant 16-17

adjusting formulas 26

B

barcode scanner 8, 11-12, 14-15, 37

C

cabinet, about the 8, 32

canisters 5, 8, 11-12, 16-18, 33

cautions 5-7

cleaning your Accutinter 33

colorant 8-9, 11-12, 16-18, 22-29, 32-33, 35, 37

ColorPro 5, 9, 12, 16, 21-24, 29-31

ColorPro help 30

computer 6, 8, 9, 11, 12

connecting

to a Spectrophotometer 12

to the computer 11, 12

to a monitor 11, 12

coverage estimator 23

custom formula 24, 27

D

database 9, 20, 22, 24

diagnostics 9, 20

dispense 5, 8, 9, 11-12, 16, 20-26, 29

DVX 8

M

maintenance 5, 8-9, 11, 17, 21, 30-31

mis-tints 28, 32

monitor 6, 8-12,

N

nozzle 5, 8, 9, 11, 28, 30-33, 35

nozzle cleaning tool 38

P

preventative maintenance 5, 9

printer 8-9, 11, 13, 34, 36

pumps 9

purge 5, 9, 21, 28, 31

R

replacement parts 6

reports 20-21

reset 27

S

safety 5-7

scaling percentages 27

screen savers 9

service 1, 5-9, 30-31, 38,

shaking colorant 9, 11

spectrophotometer 9, 12, 25

T

F

filling canisters 9, 11, 16-17, 29

formulas 20, 22-26

formula book 21, 22

fuses 11

G

grounding 7

I

installation 7, 10-12

K

keyboard 8, 10-12, 14-15, 35

L

labels 5, 6, 11-13, 23, 37

44 | Accutinter 1500

troubleshooting 5, 9, 32-36

U

upgrading software 17, 21

USB cable 10, 12

usage reports 20

utilities 21, 30

W

WARNINGS 6, 7, 11

warning labels 5, 6

warranty 39

Fluid Management Customer Service 1 . 800 . 462 . 2466

Page 44

Accutinter 1500

Fluid Management, Inc.

1023 Wheeling Road • Wheeling IL 60090

p: 800.462.2466

f: 847.537.3221

www.fluidman.com

Loading...

Loading...