Page 1

ISC

Flow Solutions Division

ISC2BB

Dual Rotating Bellows Seal

Repair Instructions

Page 2

These instructions are written for trained, experienced technicians familiar with the basic

principles and tools involved in the installation, care and service of mechanical seals and seal

support systems. A complete reading of these instructions by personnel in contact with the

equipment is essential to safety. Incorrect installation, operation or maintenance can result in

personal injury or death to personnel and damage to the equipment.

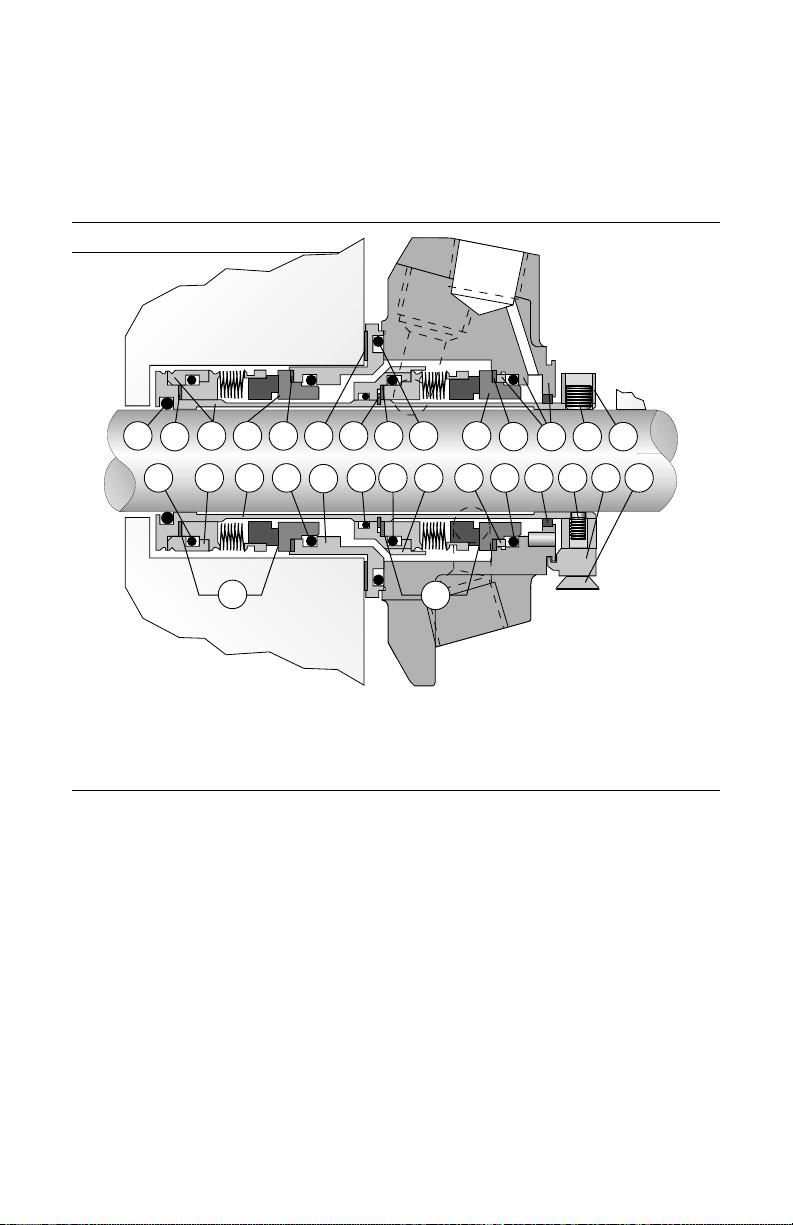

1 Nomenclature

Figure 1

11

M1

6A

Table 1

34 Outboard Bellows Assembly

34A Inboard Bellows Assembly

3B Outboard Mating Ring

3C Inboard Mating Ring

P Outboard Mating Ring O-ring

P1 Inboard Mating Ring O-ring

6 Outboard Bellows O-ring

6A Inboard Bellows O-ring

G Gasket

G1 Inner Gland O-ring

1 Gland Assembly

B Carbon Bushing

1B Gland Drive Ring

1C Inner Gland

RR Retaining Ring

RR

GM33CSL

10A 10 P1 1C 11A 6

34A

Notes: - Inboard bellows assembly (34A) is interchangeable with outboard bellows assembly (34).

- Inboard mating ring (3C) is interchangeable with outboard mating ring (3B).

- Primary seal O-rings (P, P1, 6, 6A) are all the same size and cross section.

3BG1M

M2

1B

14

P

B

13A CT K

13 91

34

14 Rotor Carrier

CT Centering Tab

K Centering Tab Cap Screw

SL Sleeve Assembly

10A Drive Ring

M Outboard Vibration Dampener

M1 Inboard Vibration Dampener

M2 Outboard Bellows Vibration Dampener

M3 Inboard Bellows Vibration Dampener

9 Sleeve Collar

13 Cup Point Set Screw

13A Quarter Dog Set Screw

11 Sleeve O-ring

11A Rotor Carrier O-ring

2

© Copyright 2000 Flowserve Corporation

Page 3

2 Disassembly

When disassembling seal, inspect for conditions which may have caused the

need for the seal to be removed from service. If seal was removed due to

premature failure, determine what conditions caused that failure and correct any

problems prior to returning the repaired seal to service. For assistance with seal

failure analysis, please contact your Flowserve representative.

Seal Parts that are always replaced

• Inboard and outboard bellows assemblies 34A and 34

• Inboard and outboard mating rings 3B

and 3C

• All O-rings P , P1 , 6 , 6A , G1 , 11 , 11A

• Gland gasket G

• Vibration dampeners M and M1

• Bellows vibration dampeners M2 and M3

• Retaining ring RR

• Centering tabs CT and cap screws K

• Cup point and quarter dog

set screws 13 and 13A

Reconditionable Seal Parts

• Gland assembly 1

• Sleeve assembly SL

• Inner gland 1B

• Rotor carrier 14

• Sleeve collar 9

3 Inspection and Reconditioning

3.1 There are certain critical areas of each part where special attention should be

paid to the condition. If any of the areas listed in 3.2, 3.3 or 3.4 show signs of

wear, corrosion, or other defects that cannot be removed without affecting

the dimensional size of the surfaces by more than 0.001 to 0.002", then the

respective part should be replaced. If grit blasting is performed, it may be

necessary to polish the O-ring surfaces to achieve the required surface finish

(see 3.2A and 3.3A for the required surface finish). If any parts require

machining to correct damage, please contact your Flowserve representative

for dimensional requirements, or for any other questions regarding repair.

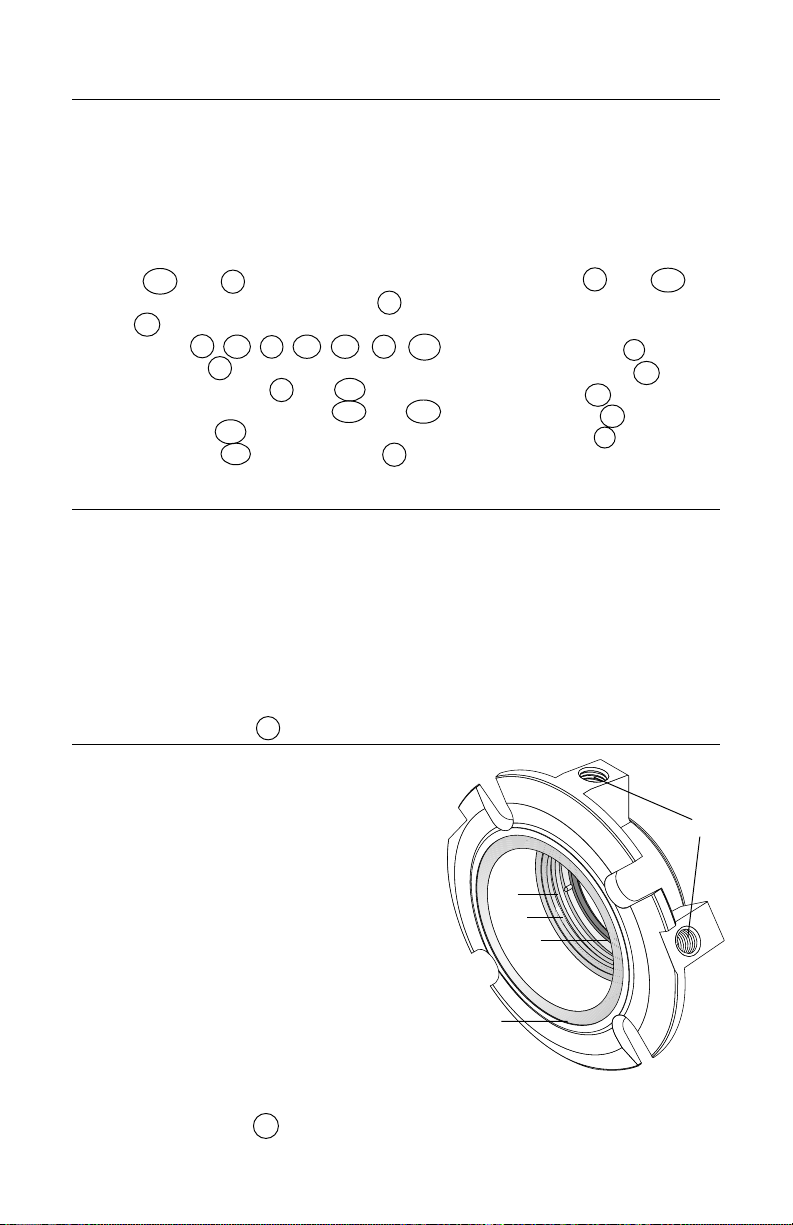

3.2 Gland Assembly 1 (Figure 2)

A Mating ring O-ring surface - Inspect for wear,

fretting, nicks, scratches, or corrosion.

Required surface finish

B Gasket surface - Remove the old gasket

and clean the gasket surface. Inspect for

nicks, scratches, or corrosion.

C Pipe taps and other threaded holes -

Inspect for damaged threads or corrosion.

Taps must be clean and free of debris and

corrosion. Re-tap as necessary.

D Bushing - Inspect for wear, breakage, or

loosened bond with gland. Replace using

Loctite®1 7471 Primer T and Loctite RCTM/640

or equivalent to adhere the bushing if any of

these conditions exist. A ten minute cure at 400°F

(204°C) is required to achieve full bond strength.

If worn or corroded, contact your Flowserve representative.

E Gland drive ring 1B - Inspect for wear or corrosion.

If worn or corroded, contact your Flowserve representative.

1 Registered Trademark of Loctite Corporation

: 63 RMS

A

E

B

D

Figure 2

C

3

Page 4

3.3 Sleeve Assembly SL (Figure 3)

A O-ring surfaces - Inspect for wear,

nicks, scratches, or corrosion.

Required surface finish

B Drive Ring 10A - Inspect for

wear or corrosion, especially

at drive flat surfaces on

ID of drive ring.

C Drive flats for rotor

carrier - Inspect for

wear, rounding of

edges of flats, or

corrosion.

D Drive end roundness

: 63 RMS.

No greater than

0.001" TIR

3.4 Inner Gland 1B (Figure 4)

A Dynamic O-ring surface - Inspect

for wear, fretting, nicks, scratches,

or corrosion.

finish:

B Gland O-ring surface - Inspect

for wear, nicks, scratches,

or corrosion.

finish:

63 RMS.

C Gasket surface - Remove

old gasket and clean surface.

Inspect for nicks, scratches,

or corrosion.

D Drive flats - Inspect for

wear or corrosion. If worn or

corroded, contact your Flowserve

representative.

Required surface

32 RMS

Required surface

Figure 3

B

C

A

D

Figure 4

C

D

A

B

3.5 Rotor Carrier 14 (Figure 5)

A O-ring surfaces - Inspect for

wear, nicks, scratches,

or corrosion.

surface finish

B Pumping vanes - Inspect for

wear, damage, or corrosion.

C Drive flats - Inspect for wear

or corrosion.

4

Required

: 63 RMS.

Figure 5

A

B

C

Page 5

3.6 Sleeve Collar 9 (Figure 6)

A Threaded holes - Inspect for thread

damage and re-tap as necessary.

B ID bore roundness -

No greater than

A

0.002" TIR

Figure 6

C Set screws - Replace cup point and dog point set

screws with those included with the repair kit.

B

Make sure the same threaded holes are used with

the same type set screws.

4 Seal Assembly Instructions

4.1 Tools Required

•3/32", 1/8" hex key wrenches (Sizes < 2.625"); 1/8", 3/16" hex key

wrenches (Sizes 2.625" and larger)

• Silicone grease (included in repair kit)

• Ethyl alcohol or acetone and clean, lint free towel for cleaning seal faces

4.2 As part of the assembly of the seal, there are several blind fits of pins and

drive flats. It may be helpful to mark the locations of the pins or drive flats

with a felt tip marker, or to align the feature with another visible feature on

the seal to assist with assembly. All seal faces should be cleaned with

alcohol or acetone prior to placing the faces together at each respective step

in the assembly process.

4.3 Arrange O-rings by diametrical size. There are four sizes

total: quantity 1 of the largest

size O-ring G1 , quantity four

of the 2

nd

largest size O-ring

P P1 6 and 6A , quantity

one of the 2nd smallest size

O-ring 11A and quantity 1 of

the smallest size O-ring 11 .

Prior to installing each O-ring

at its respective step, lightly

lubricate with silicone grease

and stretch slightly.

Figure 7

4.4 Place the sleeve assembly

SL on a flat surface with the

collar end facing up. Install

the inboard vibration dampener

M1 into the sleeve end housing.

Place the inboard bellows O-ring

6A in the sleeve O-ring groove

behind the surface with drive flats

in the sleeve. (Figure 7)

O-ring

6

Vibration

Dampner

M

5

Page 6

Inboard

Bellows

Assembly

34A

Drive Flats

Figure 8

Drive

Ring

10A

4.5 Align the two flats on the

inboard bellows assembly

34A with the two flats on the

inside of the drive ring 10A

in the sleeve end housing,

and press the bellows

assembly into place using

finger pressure only.

(Figure 8)

4.6 Place the inboard mating ring

O-ring P1 into the inner

gland 1C . Place the inboard

bellows vibration dampener

M3 into the inner gland.

(Figure 9)

4.7 Align the two flats on the

inboard mating ring 3C

with the two flats on the

inside of the inner gland, and

press the mating ring in place

using finger pressure only.

(Figure 10)

Figure 9

Vibration

Dampener

M3

O-ring

P1

Figure 10

Mating

Ring

3C

Drive

Flats

6

Page 7

4.8 Place the inner gland/mating

ring assembly face down

onto the sleeve/bellows

assembly. (Figure 11)

4.9 Install the inner gland O-ring

G1 into the face groove in

the inner gland. (Figure 11)

4.10 Place the rotor carrier O-ring

11A in the smallest diameter

groove of the rotor carrier

14 .(Figure 12)

4.11 Align the three drive flats on

the rotor carrier with the drive

flats on the sleeve and press

the rotor carrier on the sleeve

with the pumping vanes face

up. (Figure 13)

Figure 11

O-Ring

G1

Inner

Gland

&

Mating

Ring

Assembly

Figure 12

Sleeve

Rotor Carrier

Drive Flats

Retaining

Ring

Groove

Figure 13

Drive Flats

7

Page 8

4.12 Insert the retaining ring RR

into the groove in the sleeve

assembly while pressing

down on the rotor carrier.

Make sure that the retaining

ring snaps completely into

the groove in the sleeve

assembly. (Figure 14)

Figure 14

Retaining Ring RR

4.13 Insert the outboard vibration

dampener M into the rotor

carrier. Make sure that the

vibration dampener is fully

seated at the bottom of the

rotor carrier. Place the

outboard bellows O-ring 6

in the O-ring groove of the

rotor carrier, which is behind

the surface with two drive

flats. (Figure 15)

4.14 Repeat steps 4.7 through 4.9

to assemble the outboard

bellows assembly 34 into

the sleeve/rotor carrier

assembly.

Assemble the outboard

mating ring O-ring P and

the outboard bellows

vibration dampener M2

into the gland assembly 1 .

(Figure 16)

O-ring

6

Vibration

Dampener

M2

O-ring

P

Figure 15

Vibration

Dampner

M

Figure 16

Gland

Drive Ring

1B

8

Page 9

Figure 17

4.15 Align the two flats on the

mating ring 3B with the two

flats on the inside of the

gland drive ring in the gland

assembly, and press the

mating ring in place using

finger pressure only.

(Figure 17)

Figure 18

4.16 Place the gland/mating ring

assembly face down onto the

sleeve/outboard bellows

assembly. (Figure 18)

9

Page 10

4.17 Place the sleeve collar 9

onto the end of the sleeve

with the Flowserve logo

facing up. Align the quarter

dog set screws with the

smaller holes in the end of

the sleeve. On smaller seal

sizes, one of the quarter dog

set screws will be offset by

15 degrees. Align this

quarter dog set screw with

the corresponding offset

hole in the end of the sleeve.

Do not tighten any set screws

at this time. Install the

centering tabs CT and flat

head cap screws into the

collar while engaging with the

gland. Be sure to keep the

collar aligned. (Figure 19)

Figure 19

Centering

Tabs

CT

4.18 Using firm hand pressure

press down on the collar to

be even with the end of the

sleeve assembly. This will in

turn press down the gland

and inner gland, compressing the bellows. While

holding the collar even with

the end of the sleeve

assembly, tighten the

quarter dog set screws into

the holes in the sleeve until

snug. Be careful not to

distort the sleeve by over

tightening the quarter dog

set screws. (Figure 20)

10

Figure 20

Page 11

O-ring

11

Figure 21

4.1 9Install the shaft O-ring 11

into the inside diameter

groove of the sleeve

assembly. (Figure 21)

4.20Adhere the gland gasket G

to the inner gland gasket

surface with a spray

adhesive such as 3M

Super 77®2.

Gland Gasket

G

5 Static Testing

5.1 Flowserve manufacturing typically tests the ISC at 25 psig. A pressure drop

of less than one psi over a one minute time period at 25 psig using a test

set-up with a maximum fluid volume of one cubic foot is acceptable. To static

test the seal, bolt or clamp the seal to a pump seal chamber or other device

which will hold the inner gland up against the gland. WARNING: Failure to

do this will result in the inner gland unseating from the gland under pressure,

possibly resulting in damage to the inner gland O-ring and also causing a

personal safety risk. Secure the cup point set screws to the stub shaft or

equipment shaft to help prevent deformation of the centering tabs due to

axial loads. Apply pressure at either of the tangential barrier fluid ports, while

plugging the opposite port. If the seal does not pass the static pressure test,

disassemble the seal and inspect for O-ring damage, as this is the most

common cause of static test failure.

6 Installation

6.1 Refer to the ISC Installation Instructions, FIS120, for proper seal installation.

2 Trademark of Minnesota Mining and Manufacturing Company

11

Page 12

TO REORDER REFER TO

B/M #

.

F.O

The information and specifications presented in these repair instructions are believed to be accurate, but are not guaranteed by Flowserve as to

completeness or accuracy. Although Flowserve Corporation can provide general application guidelines, it cannot provide specific information

for all possible applications. The purchaser/user must therefore assume the ultimate responsibility for the proper selection, installation, operation

and maintenance of Flowserve products. Because Flowserve Corporation is continually improving and upgrading its product design, the

specifications, dimensions and information contained herein are subject to change without notice.

Flowserve Corporation Flow Solutions Division

Primary Worldwide Flow Solutions Division Locations Licensees, authorized agents, and affiliated companies located worldwide

United States

Kalamazoo, MI

Phone 616-381-2650

Fax 616-381-8368

Edmonton, Alberta

Phone 780-463-7958

Fax 780-450-1241

Canada

Scarborough, Ontario

Phone 416-292-2877

Fax 416-292-5190

Singapore Japan

Phone 65-746-4318

Fax 65-747-1963

Printed in U.S.A.

Tlaxcala

Phone 52-2-461-6791

Fax 52-2-461-6847

Sao Paulo

Phone 55-11-4066-8600

Fax 55-11-4066-70144

Netherlands

Roosendaal

Phone 31-165-581400

Fax 31-165-552622

Osaka

Phone 81-720-85-5571

Fax 81-720-85-5575

www.flowserve.com

ISO 9000

Certified

Argentina

Villa Martelli

Phone 54-11-4709-6800

Fax 54-11-4709-7072

GermanyBrazilMexico

Dortmund

Phone 49-231-6964-0

Fax 49-231-6964-248

Australia

Marayong NSW

Phone 61-2-8822-7100

Fax 61-2-9679-7511

FIS139

ORG 06/00 USA

Loading...

Loading...