Page 1

ISC2

Single pusher seal

Repair

Instructions

Experience In Motion

Page 2

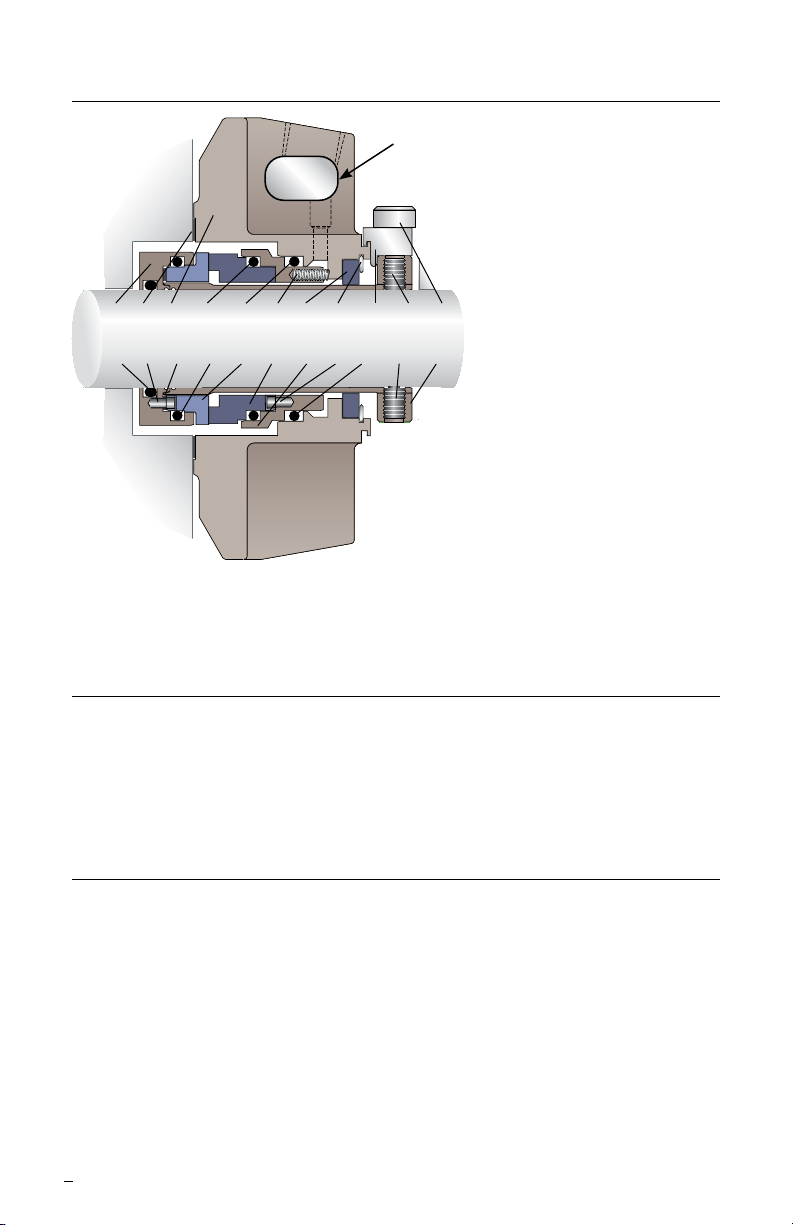

1 Nomenclature

Part

Sizes

≤ 2.750 inch

(70 mm)

ISC2-PX

1.875

316 SS

marking

sample

1 18 11 13.1 13 16 24 111 103 57 40

19 5 183 76 15 14 100 5 13 57.1 58

Sizes

> 2.750 inch

(70 mm)

Figure 1

Part references in this document are denoted in square parenthesis, e.g. [15]

Primary seal O-rings [13], [13.1] and [76] are the same size and cross-section.

Part Description

Ref.

1 Sleeve Assembly

5 Square-headed Pin

11 Gland

13 Seat Gasket O-ring

13.1 Seat Gasket O-ring

14 Stationary Face

15 Rotating Face

16 Springs

18 Gland Gasket

19 Sleeve Gasket O-ring

24 Gland Bushing

40 Cap Screw

57 Cup-point Set Screw

57.1 Quarter-dog Set Screw

58 Drive Collar

76 Rotating Face Gasket O-ring

100 Stationary Face Support

103 Setting Device

111 Snap Ring

183 Vibration Dampener

2 Disassembly

When disassembling the seal, inspect for conditions which may have caused the

seal to be removed from service. If seal was removed due to premature failure,

determine what conditions caused that failure and correct any problems prior to

returning the repaired seal to service. For assistance with seal failure analysis,

please contact your Flowserve representative.

3 Repair or Replace Guide

Seal parts that are always replaced

• Stationary face [14]

• Rotating face [15]

• Springs [16]

• Square-headed pin [5]

• Stationary face support [100]

• All gaskets (O-rings) [13], [13.1], [19] and [76]

• Gland gasket [18]

• Vibration dampener [183]

• Setting devices [103] and cap screws [40]

• Cup-point [57] and quarter-dog set screws [57.1]

• Gland bushing [24] and snap ring [111]

2

Page 3

Seal parts that are reconditionable

• Gland assembly [11]

• Sleeve assembly [1]

• Sleeve collar [58]

4 Inspection and Reconditioning

There are certain critical areas of each part where special attention should be

paid to the condition. If any of the listed areas show signs of wear, corrosion,

or other defects that cannot be removed without affecting the dimensional size

of the surfaces by more than 0.001 - 0.002 inch (0.025 - 0.05 mm), then the

respective part should be replaced. If grit blasting is performed, polish the O-ring

surfaces to achieve the required surface nish (see critical area listings for nish

requirements). If any parts require machining to correct damage, please contact

your Flowserve representative for dimensional requirements, or for any other

questions regarding repair.

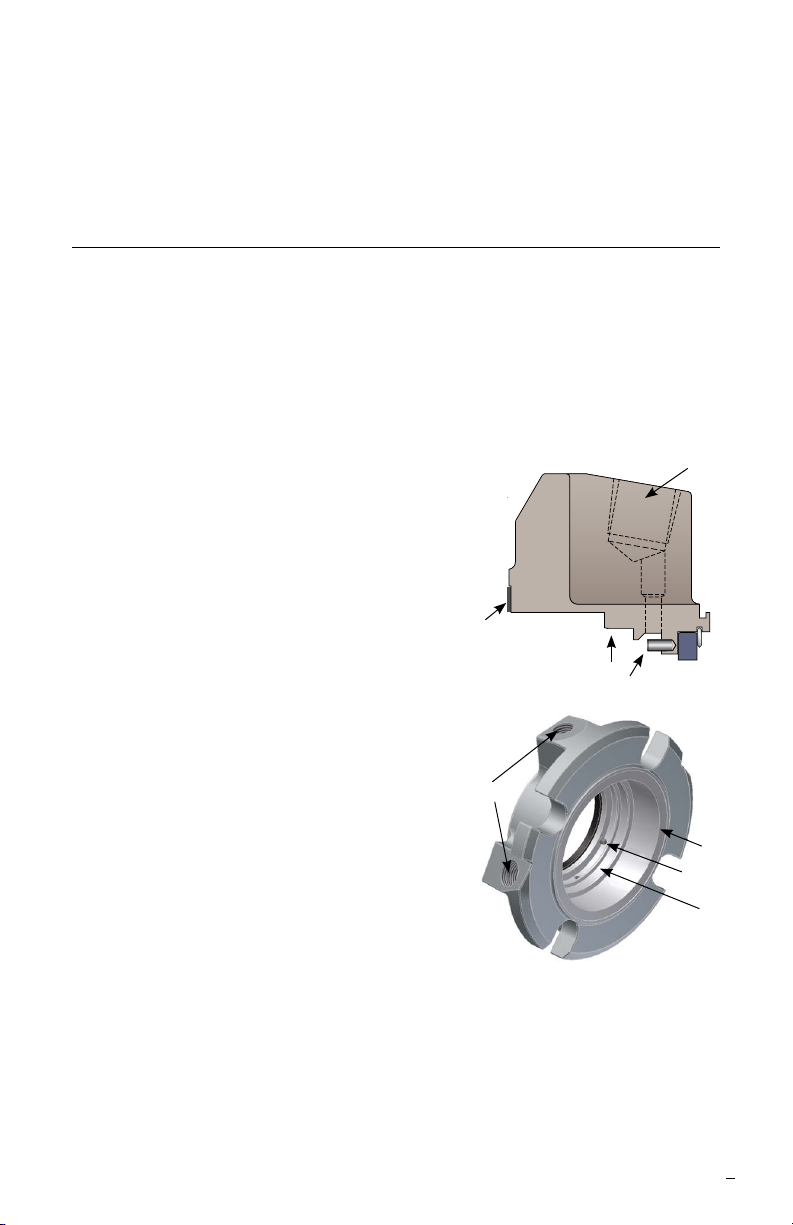

4.1 Gland assembly [11] see Figures 2 and 3.

A Dynamic O-ring surface - Inspect for wear,

fretting, nicks, scratches or corrosion.

Required surface nish: 32 RMS

B Gasket surface - Remove the old gasket and

clean the gasket surface. Inspect for nicks,

scratches or corrosion.

C Pipe taps and lifting holes - Inspect for

damaged threads or corrosion. Re-tap as

necessary.

B

Figure 2

A

D

C

D Anti-rotation pins - Inspect for wear or

corrosion. Replace as necessary.

4.2 Sleeve assembly [1] see Figures 4 and 5.

A O-ring surfaces - Inspect for wear, nicks,

scratches, or corrosion. Required surface

nish: 63 RMS.

B Drive ats or drive pin - Inspect for wear or

corrosion. Replace pin as necessary.

C Drive end roundness - No greater than

0.001 inch (0.025 mm) TIR (Total Indicated

Reading) under the bushing.

D Inspect ID of sleeve at weld point for

corrosion.

C

B

D

A

Figure 3

3

Page 4

A

A

B

D

Figure 4a, sizes ≤ 2.750 inch (70 mm)

A

B

Figure 4b, sizes > 2.750 inch (70 mm)

4.3 Drive Collar [58] see Figure 6.

A Threaded holes - Inspect for thread damage

and re-tap as necessary.

C

C

C

B

A

A

Figure 5

B ID bore roundness - No greater than 0.002 inch

(0.05 mm) TIR.

C Set screws - Replace cup-point and quarter-dog point

set screws with those included with the repair kit.

Make sure the same threaded holes are used.

B

A

Figure 6

5 Seal Assembly Preparation

Tools Needed:

• Sizes ≤ 2.750": 3/16", 1/8" hex key wrenches

• Sizes > 2.750": 1/8", 3/16" and/or 7/32" hex key wrenches

• Sizes ≤ 65 mm: 3 mm hex key wrench

• Sizes > 65 mm: 5 mm hex key wrench for standard bore

• Sizes > 65 mm: 6 mm hex key wrench for enlarged bore

• Silicone grease (included in repair kit)

• Ethyl alcohol and clean, lint-free towel for cleaning seal faces

• Needle nose pliers or tweezers

6 Seal Assembly Instructions

Some assembly steps include blind ts of pins and drive ats. Mark the locations

of the pins or drive ats with a felt tip marker, or align the feature with another

visible feature on the seal to assist with assembly. All seal faces should be

cleaned with ethyl alcohol prior to placing the faces together at each respective

step in the assembly process.

6.1 Arrange O-rings by diametrical size. There are two sizes: quantity 3 of the

largest size [13], [13.1] and [76], and quantity 1 of the smallest size [19].

Prior to installing each O-ring at its respective step, lightly lubricate with

silicone grease, unless an alternative lubricant is specied, and stretch

slightly.

6.2 Place the sleeve assembly [1] on the work surface with the drive end (set

screw holes) positioned upward.

4

Page 5

For sizes ≤ 2.750 inch (70 mm) install the vibration damper [183] into the

back counterbore of the sleeve assembly.

For sizes > 2.750 inch (70 mm) install the square-headed pin [5] in the hole

on the counterbore of the sleeve assembly. Cut a 0.25 inch (6 mm) slot in

the vibration dampener [183] and install onto the sleeve assembly where

the rotating face will be installed with the slot positioned where the drive pin

is located. See Figure 7.

6.3 Select O-ring [19] and stretch slightly. Lightly lubricate the O-ring using

silicone grease.

For sizes ≤ 2.750 inch (70 mm) install the O-ring

into the sleeve assembly, on the inner diameter

groove of the sleeve. See Figure 8.

For sizes > 2.750 inch (70 mm) install the O-ring

into the inner diameter groove of the bellows

assembly.

6.4 Select rotating face [15] and lightly lubricate

O-ring surface using silicone grease unless

otherwise specied. Install the rotating face [15]

into the sleeve/O-ring assembly. See Figure 9.

Use hand pressure only.

For sizes ≤ 2.750 inch (70 mm) ensure that the

ats on the rotating face and the ats on the

sleeve are aligned.

Figure 7

Figure 8

For sizes > 2.750 inch (70 mm) ensure that the

drive slot on the rotating face and the squareheaded drive pin in the sleeve are aligned.

6.5 Check for the proper seating of the rotating

face by measuring from the back of the sleeve

assembly to the face of the rotating face with

a caliper or micrometer. Measure in 3 equally

spaced locations, measurement variations

should not exceed 0.005 inch (0.127 mm).

6.6 Clean the sealing face of the rotating face [15]

to remove dirt, dust, ngerprints or any other

residue using alcohol on a clean cloth or tissue.

6.7 Select gland assembly [11] and using a parallelplate press, press bushing [24] into the outboard

side of the gland. Once the bushing is fully

pressed in the gland assembly [11] (no gap

behind bushing), insert the snap ring [111] into

the groove on the inner diameter of the gland to

retain the bushing as shown in Figure 10.

Figure 9

[24]

Figure 10

[111]

5

Page 6

6.8 Select O-ring [13]. Lightly lubricate the O-ring using silicone grease. Install

the O-ring onto the stationary face [14]. See Figure 11.

6.9 Select the square-headed pins [5] and dab

silicone grease on the tip of each pin before

inserting to assist keeping pins in place. Install

the long end of the pins into the stationary face

support [100]. Tweezers or needle nose pliers

may assist installation of the pins. See Figure 12.

6.10 Select the stationary face [14] and install it onto

stationary face support [100], the square-headed

pins must line up with the slots in the stationary

face [14]. Silicone grease may be applied to the

O-ring bore in the stationary face support [100].

6.11 Clean the sealing face of the stationary face [14]

to remove dirt, dust, ngerprints or any other

residue using alcohol on a clean cloth or tissue.

6.12 Install springs [16] into the holes in the stationary

face support [100]. Silicone grease should be

used to hold the springs in the spring holes. See

Figure 13.

6.13 Install the stationary face assembly down onto

the sleeve assembly as shown in Figure 14.

6.14 Lightly lubricate the area where the O-ring [13]

will ride on the stationary face support [100] with

silicone grease. See Figures 14, area A.

Lightly lubricate the area where the O-ring [13]

will ride in the gland [11] with silicone grease.

See Figure 15, area B. Install the dynamic

O-ring [13.1] into the gland [11].

A

Figure 11

Figure 12

Figure 13

6.15 Install the gland assembly [11] onto the sleeve

assembly. See Figure 16. During the installation,

ensure that the drive pins in the gland line up

with the slots in the stationary face support [100].

Caution: Do not rotate the gland assembly

during installation.This may cause the springs

[16] to buckle. Verify the pins are aligned with the

slots by exercising the gland.

6.16 Thread set screws and quarter-dog set screws

in proper, equally spaced locations in drive collar

[58].

Note: Some sizes > 2.750 inch (70 mm)

do not utilize quarter-dog set screws.

6

Figure 14

B

Figure 15

Page 7

6.17 Perform a dry t of the collar on the sleeve.

6.18 Install the drive collar [58] onto the sleeve

assembly [1]. The drive collar may need to be

rotated so that the set screws [57] line up with the

large holes and quarter-dog set screws [57.1] line

up with the two smaller holes.

Note: Some sizes > 2.750" do not utilize quarter-

dog set screws.

6.19 Install the setting devices and cap screws [103]

and [40] into the drive collar, engaging with the

gland [11]. See Figure 17.

Caution: Do not rotate the gland assembly

during installation. This may cause the springs

[16] installed in step 6.12 to buckle if the gland

assembly [11] is rotated with respect to the

stationary face support [100].

6.20 While compressing seal by pushing down on

gland assembly [11], tighten the quarter-dog set

screws [57.1] to engage into the two smaller holes

of the sleeve assembly [1]. If the seal does not

contain quarter-dog set screws then install the set

screws [57] into the sleeve [1]. See Figure 18.

Caution: Over tightening will cause distortion

of the sleeve assembly [1]. Check integrity of

the sleeve with a plug of the appropriate size to

ensure no distortion has occurred.

6.21 Install sleeve O-ring [19] into the inner diameter

groove of the sleeve assembly.

6.22 The cartridge seal assembly is now ready for

testing.

Figure 16

Figure 17

Figure 18

6.23 Adhere the gland gasket [18] to the gland gasket

surface with a spray adhesive such as 3M Super

®

. See Figure 19.

77

6.24 Permanently mark the seal type ISC2-PX or

ISC2-XP, seal size and gland ring

material clearly on the gland surface.

See Figure 1 for placement location.

ISC2-PX

1.875

316 SS

Example

inch

marking

Figure 19

ISC2-PX

M060

316 SS

Example

metric

marking

7

Page 8

TO REORDER REFER TO

flowserve.com

B/M #

F.O

.

7 Static Testing

The ISC2 single pusher seal may be static tested at pressures up to 300 psi

(20.6 bar) prior to installation on the equipment. Flowserve manufacturing

typically tests the ISC2 at 25 psig (1.7 bar). To static test the seal, bolt it to a

single seal test barrel or to the equipment. Secure the cup-point set screws to the

stub shaft or equipment shaft to prevent deformation of the centering tabs due to

axial loads. The seal can be pressurized through the tangential ush port. If the

seal does not pass, according to QP-B.28, the static pressure test, disassemble

the seal and inspect for O-ring damage, as this is the most common cause of

static test failure.

8 Installation

For installation instructions, reference FIS190eng ISC2 Series.

FIS191eng REV 09/14 Printed in USA

To find your local Flowserve representative

and find out more about Flowserve Corporation,

visit www.flowserve.com

Flowserve Corporation has established industry leadership in the design and manufacture of its products. When

properly selected, this Flowserve product is designed to perform its intended function safely during its useful life.

However, the purchaser or user of Flowserve products should be aware that Flowserve products might be used

in numerous applications under a wide variety of industrial service conditions. Although Flowserve can provide

general guidelines, it cannot provide specific data and warnings for all possible applications. The purchaser/user

must therefore assume the ultimate responsibility for the proper sizing and selection, installation, operation, and

maintenance of Flowserve products. The purchaser/user should read and understand the Installation Instructions

included with the product, and train its employees and contractors in the safe use of Flowserve products in connection

with the specific application.

While the information and specifications contained in this literature are believed to be accurate, they are supplied for

informative purposes only and should not be considered certified or as a guarantee of satisfactory results by reliance

thereon. Nothing contained herein is to be construed as a warranty or guarantee, express or implied, regarding any

matter with respect to this product. Because Flowserve is continually improving and upgrading its product design,

the specifications, dimensions and information contained herein are subject to change without notice. Should any

question arise concerning these provisions, the purchaser/user should contact Flowserve Corporation at any one of

its worldwide operations or offices.

© Copyright 2014 Flowserve Corporation

USA and Canada

Kalamazoo, Michigan USA

Telephone: 1 269 381 2650

Telefax: 1 269 382 8726

Europe, Middle East, Africa

Roosendaal, the Netherlands

Telephone: 31 165 581400

Telefax: 31 165 554590

Asia Pacific

Singapore

Telephone: 65 6544 6800

Telefax: 65 6214 0541

Latin America

Mexico City

Telephone: 52 55 5567 7170

Telefax: 52 55 5567 4224

Loading...

Loading...