Page 1

CBR Series

Experience In Motion

Single Inside Bellows Seal

Installation

Instructions

Page 2

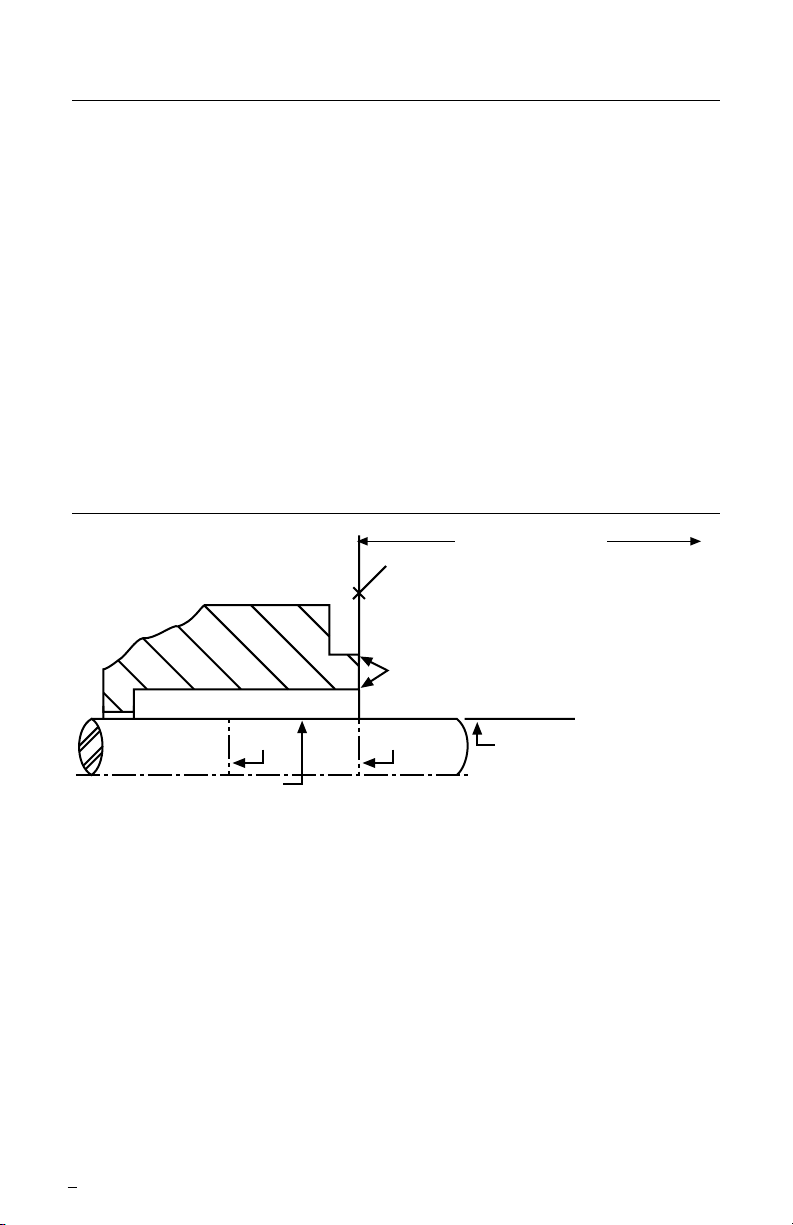

1 Equipment Check

To first obstruction

Face of seal housing to be square to the axis

of the shaft to within 0.0005 inches per inch of

seal chamber bore (0.013 mm) FIM and ha

ve a

√63 µinch (1.6 µm) R finish or better

a

Gland pilot can be at either of these

register locations. concentric to within

0.005 inch (0.13 mm) FIM of shaft or sleeve OD

Sleeve or shaft finish to be

32 µinch (0.8 µm) R or better

a

a

Scribe

Mark A

Shaft or sleeve OD

+0.000 inch (+0.000 mm)

-0.002 inch (-0.050 mm) ANSI

+0.000 inch (+0.000 mm) API 610

-0.001 inch (-0.025 mm) DIN/ISO

• Bearings must be in good condition

• Maximum lateral or axial movement of shaft (end play) = 0.010 inch (0.25 mm) FIM

• Maximum shaft runout at face of seal housing = 0.002 inch (0.05 mm) FIM

• Maximum dynamic shaft deflection at seal housing = 0.002 inch (0.05 mm) FIM

Scribe

Mark B

Seal housing bore to have √125 µinch

(3.2 µm) R finish or better

1.1 Follow plant safety regulations prior to equipment disassembly:

• lock out motor and valves.

• wear designated personal safety equipment.

• relieve any pressure in system.

• consult plant MSDS les for hazardous material regulations.

1.2 Disassemble equipment to allow access to seal installation area.

1.3 Remove all burrs and sharp edges from the shaft or sleeve including sharp edges of keyways and threads. Replace worn shaft or

sleeve. Make sure the seal housing bore and face are clean and

free of burrs.

1.4 Check requirements for shaft, sleeve and seal housing.

See Figure 1.

Seal Chamber Requirements Figure 1

1.5 Check assembly drawing included with the seal for specic

seal design, materials of construction, dimensions, and piping

connections.

1.6 Check shaft or sleeve OD, box bore, box depth, and distance

to rst obstruction to ensure that they are dimensionally the same

as shown on the seal assembly drawing.

2

Page 3

1.7 Check gland pilot and bolt holes to ensure they are adaptable

to the equipment and are the same as shown on the assembly

drawing.

1.8 Handle all seal parts with care, they are manufactured to precise

tolerances. The seal faces; Seal Ring and Insert, are of special

importance. These two sealing faces are lapped at to within

three light bands (34.8 millionths of an inch). Keep the seal faces

perfectly clean at all times.

2 Installation

The basic CBR design is shown in Figure 2. Variations may include

rotating face gasket, seat gasket, and environmental control features.

See the Flowserve assembly drawing included with each complete seal

for details. Additional recommendations for vetical pumps are shown in

section 3.

2.1 Scribe mark A, Figure 1, on the shaft or sleeve to line up with the

face of the seal housing. The shaft or sleeve must be in its nal

axial operating position with regard to the seal housing face before

mark A is scribed.

Basic CBR Figure 2

1.19

0.06

Gland

Set

Screw

Bellows

Adapter

Gasket

Bellows

Assembly

Gasket

Stationary

Face

Seat

Gasket

3

Page 4

Determining the Correct Installed

Operating Length Dimension Figure 3

Inch Units

(Metric Units)

R

Seal

Size

(I1)

Seal Size

inch

.750" thru 1.250" 1.38"

1.375" thru 2.375" 1.56"

2.500" thru 3.375" 1.75"

3.500" thru 4.750" 1.88"

5.000" 2.00"

5.500" .25"

Seal Size

mm

18 thru 22 27.5 mm

24 thru 25 30.0 mm

28 thru 35 32.5 mm

38 thru 48 34.0 mm

50 thru 55 34.5 mm

58 thru 65 39.5 mm

68 37.2 mm

70 thru 75 44.7 mm

80 thru 85 44.3 mm

90 thru 100 49.3 mm

CBR Bellows Assembly

Installed Length (R)

CBR Bellows Assembly

Installed Length (l1)

4

Page 5

2.2 Scribe mark B, Figure 1, at the seal setting point shown on the

assembly drawing included with the seal. (This is the seal setting

dimension as measured from the face of the seal housing to the

back of the bellows drive collar. The back of the bellows drive collar

will be located at this point. See Figure 3 for the correct installed

operating length dimension R (l1). This dimension can be used

to calculate the seal setting point B if no assembly drawing is

available.

2.3 Lightly lubricate the stationary face mounting O-ring with the silicone

lubricant provided with the seal and install the O-ring in the gland.

2.4 Lightly lubricate the stationary face gasket shoulder and carefully

press the face into the seat gasket O-ring in the gland. Use hand

pressure only. All standard CBR stationary faces are supplied with

holding pins. Locate the pin to engage the pin slot in the gland to

avoid over compressing the bellows assembly.

2.5 Install the gland with the stationary face over the shaft. Place the

gland as close to the bearing bracket as possible. Do not bump the

stationary face against the shaft as it may chip, crack, or break.

2.6 Lightly lubricate the shaft or sleeve lightly with silicone lubricant.

2.7 Lightly lubricate the Bellows adapter gasket O-ring with silicone

lubricant and install the O-ring in the bellows drive collar end

groove.

2.8 Install the CBR bellows assembly with the bellows rotating face

gasket O-ring in place onto the shaft or sleeve. Do not compress

the CBR bellows assembly more than the indicated working length

R (l1) shown on the assembly drawing. Excessive compression may

destroy the capability of the seal to operate properly.

2.9 Set the back of the CBR bellows assembly at reference mark B,

Figure 1, and tighten set screws rmly and evenly. The rotating

bellows assembly is now in the proper position to provide the

correct setting and spring compression for nal assembly.

2.10 Wipe the seal faces clean with alcohol before completing equipment

assembly. Seal faces should not be lubricated, but should be left

clean and dry.

2.11 Assemble the pump.

5

Page 6

2.12 Position the gland to the face of the seal housing. Be sure the gland

pilot is properly engaged. Tighten the gland stud nuts evenly, cross

stagger the adjustment of the nuts. Excessive gland bolt tightening

can result in distortion of the stationary face.

2.13 See section 4, Operational Recommendations, before starting

pump.

3 Vertical Pumps

3.1 Follow the above installation instructions except that (a) the

reference mark A must be established with the shaft, impeller(s),

and coupling in their nal running position and (b) the gland

assembly, Step 2.5, is installed after the bellows assembly is

installed, Step 2.10.

3.2 Any change in position of the shaft requires resetting of the seal.

3.3 Special attention must be taken to avoid trapping air in the seal

chamber. When the seal chamber pressure is below pump

discharge pressure, use Piping Plan 11, bypass line from pump

discharge to the gland ush tap to ensure sealing liquid at the seal

faces. When the seal chamber pressure is at pump discharge

pressure, use Piping Plan 13, bypass line from seal chamber to

pump suction.

3.4 See section 4, Operational Recommendations, before starting

pump.

4 Operational Recommendations

4.1 Do not start up the equipment dry. Vent air from the casing of the

pump and the seal chamber before startup. Circulate clean product

or a clean uid from an external source through the seal chamber

whenever the equipment is in operation, Piping Plan 11.

4.2 If the seal runs hot, check for proper seal setting, seal housing

dimensions, and check the bypass or ush line for obstructions.

Shut down the equipment immediately if the seal gets hot.

For special problems encountered during installation, contact your

nearest Flowserve Sales and Service Representative.

6

Page 7

5 Repair

This product is a precision sealing device. The design and dimension

tolerances are critical to seal performance. Only parts supplied by

Flowserve should be used to repair a seal. These are available from

numerous Flowserve stocking locations. To order replacement parts,

refer to the part code number and B/M number. A spare backup seal

should be stocked to reduce repair time.

When repairs are not conducted at the customer’s location,

decontaminate the seal assembly and return it to Flowserve, with

an order marked “Repair or Replace”. A signed certicate of

decontamination must be attached. A Material Safety Data Sheet

(MSDS) must be enclosed for any product that came in contact with

the seal. The seal assembly will be inspected and, if repairable, it will be

rebuilt, tested, and returned in its original condition.

7

Page 8

flowserve.com

TO REORDER REFER TO

USA and Canada

Kalamazoo, Michigan USA

Telephone: 1 269 381 2650

Telefax: 1 269 382 8726

Europe, Middle East, Africa

Essen, Germany

Telephone: 49 201 3937-0

Telefax: 49 201 2200-561

Asia Pacific

Singapore

Telephone: 65 6544 6800

Telefax: 65 6214 0541

Latin America

Mexico City

Telephone: 52 55 5567 7170

Telefax: 52 55 5567 4224

B/M #

F.O.

FIS117eng REV 01/08 Printed in USA

To nd your local Flowserve representative

and nd out more about Flowserve Corporation,

visit www.owserve.com

Flowserve Corporation has established industry leadership in the design and manufacture of its products. When

properly selected, this Flowserve product is designed to perform its intended function safely during its useful life.

However, the purchaser or user of Flowserve products should be aware that Flowserve products might be used

in numerous applications under a wide variety of industrial service conditions. Although Flowserve can provide

general guidelines, it cannot provide specic data and warnings for all possible applications. The purchaser/user

must therefore assume the ultimate responsibility for the proper sizing and selection, installation, operation, and

maintenance of Flowserve products. The purchaser/user should read and understand the Installation Instructions

included with the product, and train its employees and contractors in the safe use of Flowserve products in connection

with the specic application.

While the information and specications contained in this literature are believed to be accurate, they are supplied for

informative purposes only and should not be considered certied or as a guarantee of satisfactory results by reliance

thereon. Nothing contained herein is to be construed as a warranty or guarantee, express or implied, regarding any

matter with respect to this product. Because Flowserve is continually improving and upgrading its product design,

the specications, dimensions and information contained herein are subject to change without notice. Should any

question arise concerning these provisions, the purchaser/user should contact Flowserve Corporation at any one of

its worldwide operations or ofces.

© Copyright 2008 Flowserve Corporation

Loading...

Loading...