Diagnostic Manual

DishDrawer™

MODELS:

DD605 DS605

Fisher & Paykel Appliances © 2007 - All Rights Reserved

599464

599464 - September 2007

CONTENTS

1 DIMENSIONS & SPECIFICATIONS....................................3

1.1 Product Size (mm)........................................................3

1.2 Specifications...............................................................3

2 OPTION ADJUSTMENT......................................................5

2.1 Changing Setup Options..............................................5

2.1.1 Rinse Aid Setup (rA) ...........................................................5

2.1.2 Water Supply Hardness Setup (hd) (Where Fitted).............6

2.1.3 Auto Power Option (AP)......................................................6

2.1.4 End of Cycle Beeps (EC)....................................................6

2.1.5 Closed Drawer Option (Ld) .................................................7

2.1.6 Clean/Dirty Dish Symbol (dS) .............................................7

3 DIAGNOSTICS ....................................................................8

3.1 DishDrawer™ Diagnostics ...........................................8

3.2 Display/Download Mode...............................................8

3.3 Optical LED Download/Fault Display ...........................8

3.4 Clearing Fault Logs......................................................8

3.5 Hardware Output Diagnostic Test Mode......................9

3.6 Fast Test Cycle ..........................................................11

3.7 Continuous Cycle Test Mode.....................................11

3.8 Temperature & Voltage Display Mode .......................13

3.9 Show Off/Showroom Wash Mode..............................13

3.10 Playing Tunes.............................................................14

4 DIAGNOSTICS QUICK REFERENCE CHARTS ..............14

4.1 Fault Display/Download Mode....................................14

4.2 Hardware Output Test Mode......................................15

4.3 Fast Test Cycle ..........................................................16

4.4 Continuous Cycle.......................................................16

4.5 Temperature & Voltage Display Mode .......................16

4.6 Fault Codes................................................................17

4.7 Fault Code Description Chart.....................................18

4.8 Fault Code Problem Solving Charts...........................22

4.8.1 Poor Dry Performance ......................................................32

4.8.2 Poor Wash Performance...................................................33

5 WIRING DIAGRAM............................................................38

5.1 Power Distribution Concept........................................38

5.2 Wiring Diagram...........................................................39

1 DIMENSIONS & SPECIFICATIONS

1.1 Product Size (mm)

Height (double) 819.5 – 879.5mm

Height (single) 409mm

Width 595mm

Depth 570mm

Drawer Open

(including cabinet) 1090mm

599464

1.2

Specifications

Electrical

NZ/AUS/UK/UE 230-240Volt AC 50Hz 10 amp/5 amp max.

USA 110-120Volt AC 60Hz 10.6 amp/5.3 amp max.

JAP 90-110Volt AC 50/60Hz 11.6 amp/5.3 amp max.

Water Inlet Valves 24Volt DC

65 ± 10 Ohms

2.5 Lt/min (0.65 US gal/min)

Japan only 4 Lt/min

Chassis P.C.B.

NZ/AUS/UK/UE 230 Volt AC

USA/JAP 120 Volt AC

Temperature Sensor 12000 Ohms @ 20

o

C (68oF)

(On Heater Plate) 8300 Ohms @ 30

3000 Ohms @ 60

o

C (86oF)

o

C (140oF)

Drying Fan 2 to 3 Meg Ohms

Motor 80 Volt DC 3 Phase Brushless

Drain 4200 RPM

Wash 2300 – 2850 RPM

Stator 8 ± .5 Ohms per winding

Inlet Hose 1.56m (61 inches)

1000Kpa (145 PSI)

3

599464

Drain Hose 2.01m (78 inches) from rear of cabinet

2.5m (98 inches) bottom tub

2.9m (114 inches) top tub

Detergent Dispenser 24 Volt DC

65 ± 10 Ohms

Rinse Aid Dispenser 24 Volt DC

65± 10 Ohms

Heater Plate (NZ/AUS/UK/UE) 230 Volt AC

Heater Track 50 ± 4 Ohms

Power Supply Resistor 98 +

7 Ohms

Heater Plate (USA) 120 Volt AC

Heater Track 24 ± 3 Ohms

Power Supply Resistor 24 +

3 Ohms

Heater Plate (JAP) 100 Volt AC

Heater Track 20 ± 2 Ohms

Power Supply Resistor 19 +

3 Ohms

Diverter Valve Softener Assy 24 Volt DC

65 +

10 Ohms

Brine Pump 24 Volt DC

65 +

10 Ohms

4

599464

2 OPTION ADJUSTMENT

2.1 Changing Setup Options

To enter the option adjustment mode, press POWER to turn the LCD on, then

hold the ECO button and KEYLOCK button simultaneously for 5 seconds,

ensuring that ECO is pressed first. Once the option adjustment mode is

entered, a beep is emitted and the LCD displays the letters rA. Pressing the

START/PAUSE button scrolls through the options and allows changes as

follows:Rinse Aid Setup (rA).

Water Supply Hardness Setup (hd). (Water softener models only)

Auto Power Option (AP).

End of Cycle Beeps (EC).

Closed Drawer Option (Ld).

Clean/Dirty Dish Symbol (dS).

Integrated and flat door models:- On an integrated or flat door

DishDrawer™ where there is no display, the option chosen is indicated by the

lights showing on the integrated badge as follows:Rinse Aid Setup (red light above START/PAUSE button).

Water Supply Hardness (green light above START/PAUSE button).

Auto Power Option (orange light above START/PAUSE button).

End of Cycle Beeps (green light above START/PAUSE button and ECO light

is red).

Closed Drawer Option (red light above START/PAUSE and ECO light is red).

Clean/Dirty Dish Symbol (not available on Integrated or flat door models).

Dry Enhancement Option (no light above buttons, ECO light is red).

Press POWER at any time to exit this setup mode.

2.1.1 Rinse Aid Setup (rA)

The current rinse aid setting is shown using the red LED’s on the touch switch

panel.

The amount of rinse aid dispensed into a rinse cycle can be varied to suit the

level of hardness of the local water supply. It is adjusted for 1 - 5 dispensing

levels.

(1 = approx 0.5mls (1/10) teaspoon of rinse aid, 5 = approx. 2.5mls (1½)

teaspoon of rinse aid).

5

599464

Press KEYLOCK to advance the rinse aid setting. Once the desired setting is

achieved, press POWER to exit. The rinse aid index is stored in EE memory,

so even with the power removed, the rinse aid level is retained.

2.1.2 Water Supply Hardness Setup (hd) (Where Fitted)

The current supply hardness setting is shown using the red LED’s on the

touch switch panel. One of 5 settings should be selected according to the

known hardness of the supply water. Each setting is appropriate for the

following water supply hardness:

No LED Water Softener turned off, continuous bypass of softener.

1 LED 150-250 ppm water supply hardness.

2 LEDs 250-350 ppm water supply hardness.

3 LEDs 350-450 ppm water supply hardness.

4 LEDs 450-550 ppm water supply hardness.

5 LEDs 550-625 ppm water supply hardness.

Press KEYLOCK to advance the Water Softener setting. Once the desired

setting has been achieved, press POWER to exit.

Selection of a setting affects how the Electronic Controller diverts supply

water, how much water is treated, and how much salt is used in regeneration,

in a manner that optimises the performance of the Water Softener.

2.1.3 Auto Power Option (AP)

The automatic power up sequence that occurs when the tub is opened can be

turned on or off using the KEYLOCK button. If the scrubbing brush symbol is

showing on the LCD, then the auto power up sequence will occur when the

tub is opened. If the scrubbing brush symbol is not showing, then the

DishDrawer™ will not automatically power up when the tub is opened (the

customer will need to press the power button each time they wish to use the

DishDrawer™). Press POWER to exit when the desired setting has been

selected.

2.1.4 End of Cycle Beeps (EC)

The six beeps that occur at the end of the cycle can be turned on or off using

the KEYLOCK button. If the scrubbing brush symbol is showing on the LCD,

then the end of cycle beeps are activated. If the scrubbing brush symbol is

not showing, then the end of cycle beeps are deactivated. Press POWER to

exit when the desired setting has been selected.

6

599464

2.1.5 Closed Drawer Option (Ld)

The closed drawer option can be turned on or off using the KEYLOCK button.

If the scrubbing brush symbol is showing on the LCD, then the closed drawer

option is selected and it will keep the DishDrawer™ locked at all times by

bringing the lid down. When this mode is selected, the customer needs to

press the POWER button to lift the lid whenever they want to open the

drawer. When they close the drawer again, the lid comes down automatically

after 30 seconds and locks the tub. If the scrubbing brush symbol is not

showing, then the closed drawer option is deactivated. Press POWER to exit

when the desired setting has been selected.

2.1.6 Clean/Dirty Dish Symbol (dS)

(Not available on integrated or flat door models)

The clean/dirty dish symbol can be turned on or off using the KEYLOCK

button. If the scrubbing brush symbol is showing on the LCD, then the

clean/dirty dish option is selected. This means that the end of cycle clean

dishes symbol will remain in the LCD display until the power button is pressed

to clear it. If the scrubbing brush symbol is not showing, then the clean/dirty

dish symbol will disappear when the drawer is first opened at the end of a

cycle (factory setting). Press POWER to exit when the desired setting has

been selected.

7

599464

3 DIAGNOSTICS

3.1 DishDrawer™ Diagnostics

Dishwasher Diagnostics can only be entered in Power Off mode, i.e. when

there is no display on the LCD or the badge LED’s are off. Diagnostics is

entered by holding the KEYLOCK and START/PAUSE buttons

simultaneously for 5 seconds. Ensure that KEYLOCK is pressed first.

There are currently four levels of diagnostics. To move to the next level,

press POWER. To enter a level, press START/PAUSE. Once a level has

been entered, pressing POWER will exit diagnostics completely. If no level is

entered, then the display will cycle through the four levels and exit after the

last. On entering diagnostic mode, the first level is the Display/Download

Mode.

3.2

In this mode, all LED’s and LCD segments (except keylock) are illuminated.

3.3

An optical data download is available here to download all EE data to a PC or

Palm PC via the lower tub-home sensor light pipe. Hold the reader pen over

the lower tub-home sensor light pipe and press START/PAUSE to initiate the

download. A short beep indicates the start and finish of download.

The last two faults are displayed on the LCD (secondary control panel LEDs

for integrated and flat door models) during the optical download. The Current

Fault code is displayed first followed by the Previous Fault Code. To read the

Fault Code on the secondary display, refer to Section

3.4

To clear the current fault code, press the KEYLOCK button until a beep is

sounded. This action moves the current fault into the previous fault while

Display/Download Mode

Optical LED Download/Fault Display

4.7 on Fault Codes.

Clearing Fault Logs

clearing the current fault. To clear the previous fault code, press KEYLOCK

once more until the beep is sounded.

Warning: Once a fault code has been cleared, it is permanently removed

from memory and cannot be recovered.

Press POWER to advance to the next level.

8

599464

3.5

This level tests all the hardware outputs and inputs. The LCD display shows

“HO”.

Press POWER to skip hardware diagnostics and advance to the next level.

Press START/PAUSE to enter hardware diagnostics.

Once hardware diagnostics has been entered, the current hardware output

being tested is indicated by letters in the LCD display, and for integrated and

flat door models the LEDs on the touch switch panel using binary encoding,

as shown in the table on the next page.

Different combinations of outputs can be switched on or off together, but the

controller will prevent higher current drawing components such as the wash

pump and the lid motors being turned on together.

Hardware Output Diagnostic Test Mode

Press START/PAUSE to advance to the next hardware output.

Press KEYLOCK to turn the currently displayed output on or off. If the

scrubbing brush symbol (green LED above start/pause button on integrated

and flat door models) is displayed, then that output has been switched on,

and if it is not displayed then that output is off.

Press POWER to exit at any time (all outputs will be switched off on exit).

9

599464

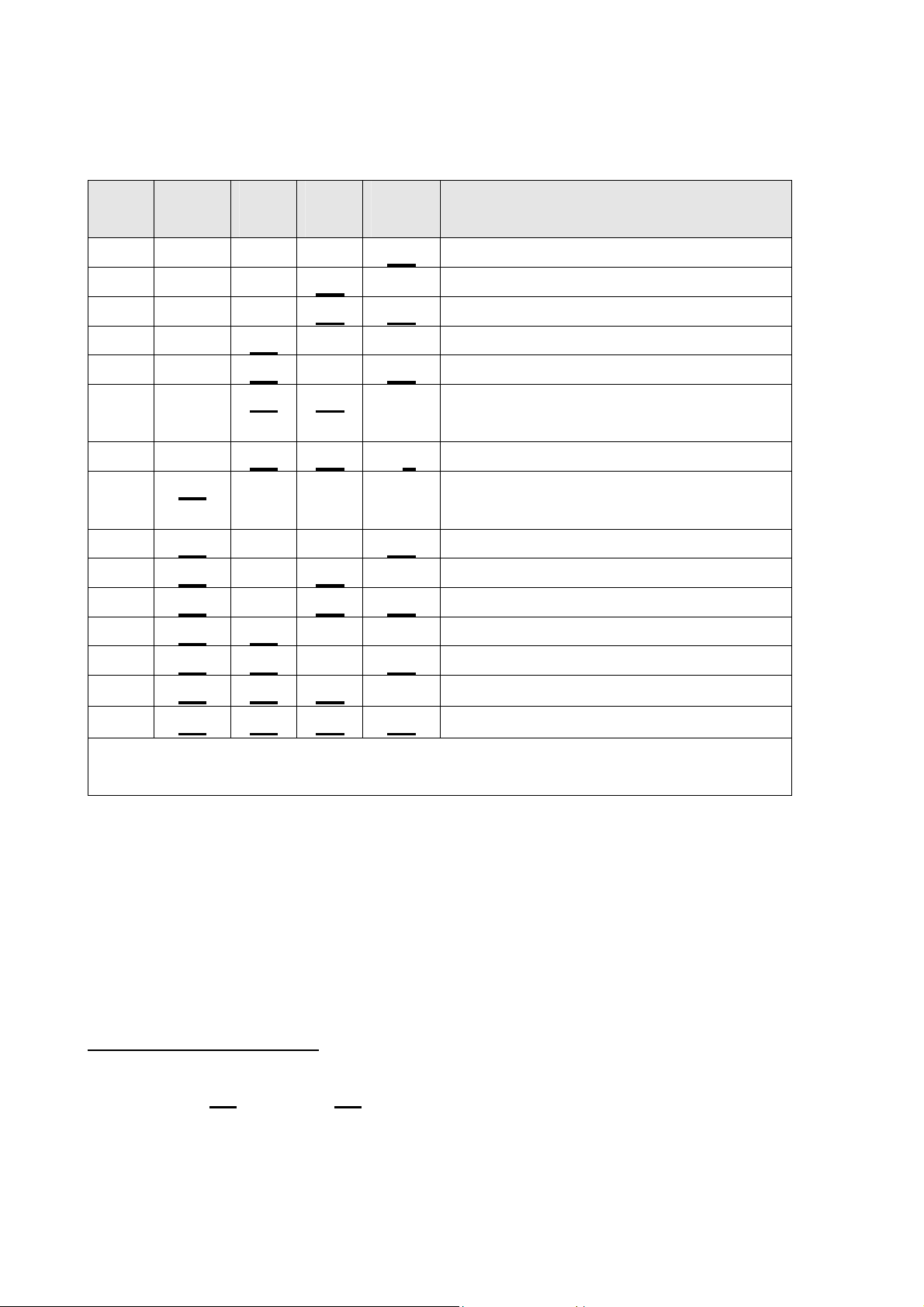

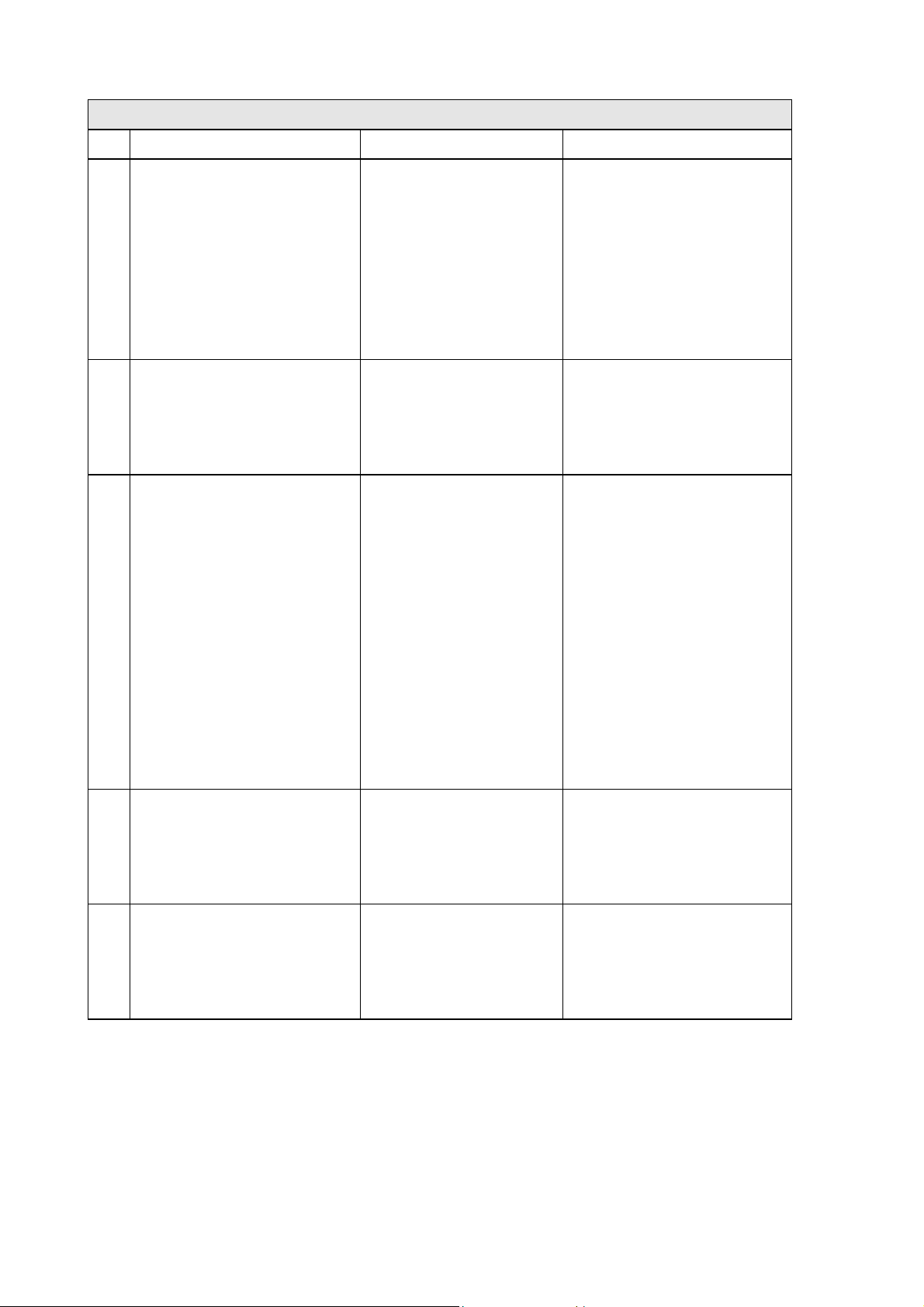

As mentioned on the previous page, the LCD display and touch switch panel

LEDs are illuminated to correspond to a particular hardware device. The

following table details the display order of the test.

Norm

Fast

Deli

Rinse

Hardware Output

LCD

LED

LED

LED

bL Off Off Off

On

Er Off Off

Ld Off Off

On

dd Off

FU Off

P1 Off

P2 Off

On

rd

dF

LE

C1

C2

C3

On

On

On

On

On

On

On

On

On

On

On

On On

Off Off Off Rinse Aid Dispenser (dispenses

Off Off

Off

Off

On

On

Off Off Detergent Diverter Valve

Off

On

On On

Off Off Water Softener Brine Pump

Off

LED

On

Backlight

Off Element Relay

Lid Motors (will run for 10 seconds)

On

Fill Water Valve

Off Motor Wash direction (2300-2850

rpm)

Motor Drain direction (4200 rpm)

current setting)

On

Drying fan

Off Rinse Aid LED

Water Softener Diverter Valve

On

Water Softener Brine Valve

°C

°E

On

On On On

On

Off Displays current water temperature.

Displays controller rail voltage

On On

(C3 is used in the Factory to empty the Water Softener before the Product is

packed.)

WARNING: In diagnostic mode there is no component protection. Therefore

take care when running individual components not to overload them. It is

advisable to avoid turning the element on without placing some water in the

tub first.

NB : No fault codes will come up while in diagnostics mode.

Tub Home Sensor Test:

At any time during HO test mode, the Keylock

symbol on the LCD display (Keylock LED on integrated badge) indicates the

tub position. On

= Closed, Off = Open.

10

599464

3.6

WARNING: Only run this cycle if the DishDrawer™ is connected to the water

supply.

This level runs an 8 minute fast test cycle.

Press POWER to skip Fast Test Cycle and advance to the next level.

Press START/PAUSE to enter Fast Test cycle.

Once Fast Test Cycle is selected the DishDrawer™ goes into standby mode

and 8 minutes will be showing on the display. The test cycle is started by

pressing START/PAUSE, and the following components are run during the 8

minute cycle that follows:- Lid motors, fill valve, wash motor, element, drain

motor, drying fan.

Press POWER to exit at any time.

3.7

Fast Test Cycle

Continuous Cycle Test Mode

In this level the DishDrawer™ can be run continuously in any wash cycle.

Once the cycle has finished, the DishDrawer™ automatically restarts the

same wash cycle.

Press POWER to skip Continuous Cycle. As this is the last level, doing this

will exit diagnostics.

Press START/PAUSE to enter Continuous Cycle.

Once selected, the LCD backlight flashes on and off to indicate the

DishDrawer™ is in continuous cycle and the cycle starts straight away (for

integrated and flat door models the LED above the start/pause button will be

orange instead of green to indicate the DishDrawer™ is running in continuous

cycle). It will run the last cycle that had been selected prior to going into

diagnostics mode.

If it is desired to run a different cycle, exit diagnostics, turn the DishDrawer™

on as normal and select the cycle required. Then turn the DishDrawer™ off

again, re-enter diagnostics and restart the Continuous Cycle as above.

Press POWER to Exit at any time.

11

599464

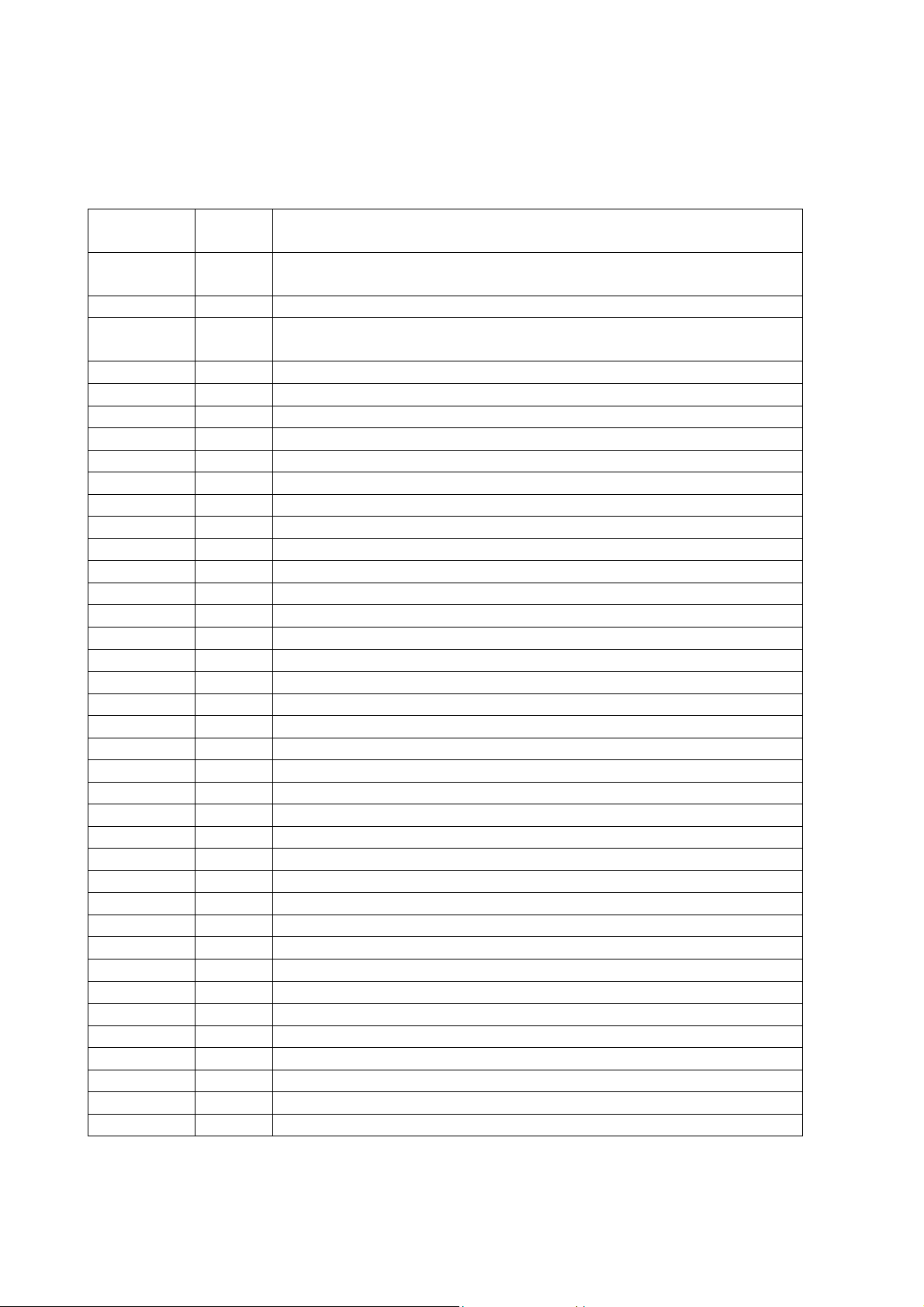

The test sequence in fast cycle mode performs 33 tests. The number of any

failed test is displayed on the touch switch panel LEDs. The test sequence

continues even if a test fails. If there are multiple failures the LEDs will

change during the test.

0 = LED off, X = LED on.

LED Display

H N F D R E

0 0 0 0 0 X 1 Uncontrolled load on PSU (PSU volts < 30 with PSU on and no devices

0 0 0 0 X 0 2 Unrealistic zero crossing time, mains frequency non standard

0 0 0 0 X X 3 Uncontrolled load on PSU (volts dropped when PSU turned off and no

4 Unused

0 0 0 X 0 X 5 Detergent diverter not connected

0 0 0 X X 0 Fill valve not connected

0 0 0 X X X Water softener bypass valve not connected

0 0 X 0 0 0 Rinse Aid pump not connected

0 0 X 0 0 X Water softener brine pump not connected

0 0 X 0 X 0 Fan not connected

0 0 X 0 X X 11 Detergent diverter solenoid low resistance (shorted?)

0 0 X X 0 0 Fill valve solenoid low resistance (shorted?)

0 0 X X 0 X Water softener bypass valve solenoid low resistance (shorted?)

0 0 X X X 0 Rinse Aid pump solenoid low resistance (shorted?)

0 0 X X X X Water softener brine pump solenoid low resistance (shorted?)

0 X 0 0 0 0 16 Fan low resistance (shorted?)

0 X 0 0 0 X 17 Lid motor 1 no current (not connected?) in down direction

0 X 0 0 X 0 Lid motor 1 no current (not connected?) in up direction

0 X 0 0 X X Lid motor 2 no current (not connected?) in down direction

0 X 0 X 0 0 Lid motor 2 no current (not connected?) in up direction

0 X 0 X 0 X 21 Lid motor 1 excessive current in down direction

0 X 0 X X 0 Lid motor 1 excessive current in up direction

0 X 0 X X X Lid motor 2 excessive current in down direction

0 X X 0 0 0 24 Lid motor 2 excessive current in up direction

25-29 Unused

0 X X X X 0 30 Motor FET A phase high side “shorted”

0 X X X X X Motor FET B phase high side “shorted”

X 0 0 0 0 0 Motor FET C phase high side “shorted”

X 0 0 0 0 X Motor FET A phase low side “shorted”

X 0 0 0 X 0 Motor FET B phase low side “shorted”

X 0 0 0 X X 35 Motor FET C phase low side “shorted”

X 0 0 X 0 0 36 Motor phases AB no current (not connected?)

X 0 0 X 0 X Motor phases BC no current (not connected?)

X 0 0 X X 0 38 Motor phases CA no current (not connected?)

X 0 0 X X X 39 Motor phases AB current excessive (shorted winding?)

X 0 X 0 0 0 Motor phases BC current excessive (shorted winding?)

X 0 X 0 0 X 41 Motor phases CA current excessive (shorted winding?)

Test ID Test Description / Probable Cause

turned on)

devices on)

12

599464

3.8

(Not available on integrated or flat door models)

During a wash cycle, the current water temperature or the power supply rail

voltage of the controller can be displayed on the LCD instead of the time

remaining. To enter temperature/voltage display mode, start a wash cycle as

normal. Initiate a keylock by pressing and holding the KEYLOCK button for 4

seconds.

Once in keylock mode, press and hold START/PAUSE for 8 seconds to enter

temperature display mode. The display now alternates between a °C symbol

and the water temperature. Pressing the START/PAUSE again changes the

display to alternate between an °E symbol and the power supply rail voltage

of the controller.

To cancel temperature/voltage display mode, press the POWER button.

3.9

Temperature & Voltage Display Mode

Show Off/Showroom Wash Mode

This mode initiates a shop show off display and wash operation

demonstration.

With the DishDrawer™ powered up and turned on, the show off mode is

entered by pressing and holding the ECO and POWER buttons

simultaneously for 5 seconds. Ensure that ECO is pressed first.

The DishDrawer™ is now in the show off mode and cycles through all of the

LED & LCD segments.

Pressing the POWER button now puts the DishDrawer™ into the showroom

wash mode. Before running this, mode the tub should be filled with water

until it is just touching the underside of the spray arm. The showroom wash is

started by pressing the START/PAUSE button whereby the following cycle is

run:The lid is pulled down.

The wash motor starts and runs for 4 minutes.

The wash motor stops.

The lid is lifted.

The display counts down to zero throughout this cycle.

The DishDrawer™ turns off at the end of this cycle.

13

599464

The DishDrawer™ is still in the Showroom wash mode however, and it can be

re-run by pressing POWER and then START/PAUSE. Once show

off/showroom wash mode has been initiated, the mains power must be

removed to exit out.

3.10

Once in showroom mode, pressing the START/PAUSE button for 3 seconds

will start a tune playing. Pressing the START/PAUSE button again will toggle

the tune between Bach and the Star Spangled Banner. This feature is not

widely known about, may not be present in all models and may be removed in

future products.

Playing Tunes

4 DIAGNOSTICS QUICK REFERENCE CHARTS

4.1 Fault Display/Download Mode

Press and hold KEYLOCK, then START/PAUSE for 5 seconds.

All LEDs & LCD segments except Keylock are illuminated.

Press START/PAUSE.

This initiates pen data download via the lower tub-home light pipe. At the

same time the current and then the previous fault code will be displayed in

the LCD screen and on the secondary control panel LEDs. To read the

fault code on the secondary display, refer to Section 4.7 on fault codes.

Press KEYLOCK.

This will clear current fault code. Note: If Keylock is pressed again, the

previous fault code will be cleared. Pressing Keylock also toggles the wash

icons on the LCD on and off.

Press POWER to exit.

14

599464

4.2

Press and hold KEYLOCK, then START/PAUSE for 5 seconds.

All LEDs & LCD segments except Keylock are illuminated.

Press POWER once.

“HO” will show in the display (integrated and flat door models: Heavy,

Normal, Fast, Delicate, Rinse LEDs showing).

Press START/PAUSE.

Scroll through the following outputs using Start/Pause. Turn the outputs on

& off using Keylock button.

Press POWER to exit.

Note: Scrubbing brush symbol = output on, no scrubbing brush = output off

(on integrated and flat door models a green LED above the start/pause

button is used in place of the scrubbing brush).

LCD Norm Fast Deli Rinse Hardware Output

Display LED LED LED LED

bL Off Off Off

Hardware Output Test Mode

On

Backlight

Er Off Off

Ld Off Off

On

dd Off

FU Off

P1 Off

P2 Off

On

rd

dF

LE

C1

C2

C3

°C

°E

On

On

On

On

On

On

On

On On

On

On On On

On

On

On

On

On

On On

Off Off Off

Off Off

Off

Off

On

On

Off Off Detergent Diverter Valve

Off

On

On On

Off Off Water Softener Brine Pump

Off

On

Off Element Relay

On

Off

On

Off Rinse Aid LED

On

Off

Lid Motors (will run for 10

seconds)

Fill Water Valve

Motor Wash direction (23002850 rpm)

Motor Drain direction (4200

rpm)

Rinse Aid Dispenser

(dispenses current setting)

Drying fan

Water Softener Diverter

Valve

Water Softener Brine Valve

Displays current water

temperature.

Displays controller rail

voltage

Tub Home Sensor test:- Keylock symbol on = tub closed, off = tub open

15

599464

4.3

Fast Test Cycle

Press and hold KEYLOCK, then START/PAUSE for 5 seconds.

All LEDs & LCD segments except Keylock are illuminated.

Press POWER twice.

“FC” will show in the display (integrated and flat door models: Heavy,

Normal, Delicate, Rinse LEDs showing).

Press START/PAUSE twice.

The 8 minute fast test cycle will start.

Press POWER to exit.

4.4 Continuous Cycle

Press and hold KEYLOCK, then START/PAUSE for 5 seconds.

All LEDs & LCD segments except Keylock are illuminated.

Press POWER three times.

“CC” will show in the display (integrated and flat door models: Heavy,

Normal, Rinse LEDs showing).

Press START/PAUSE.

The last cycle that had been selected prior to going into diagnostics mode

will be run continuously.

Press POWER to exit.

4.5 Temperature & Voltage Display Mode

(Not available on integrated or flat door models.)

Start a wash cycle running.

Press & hold KEYLOCK for 4 seconds.

Keylock will be activated.

Press & hold START/PAUSE for 8 seconds.

LCD will now alternate between °C symbol and the water temperature.

Press START/PAUSE.

LCD will now alternate between °E symbol and the controller’s rail voltage.

Press & hold KEYLOCK for 4 seconds.

Keylock is deactivated.

Press POWER to exit.

16

599464

4.6

There are 10 F (fatal) faults, which are displayed in the LCD along with the

symbol of a spanner (not on integrated or flat door models). A fatal fault will

usually require the assistance of a qualified service person.

In addition, there are 4 U (user) faults.

U1 indicates the machine had failed to prime within a certain length of time

usually because the tap has not been turned on. For this reason, at the same

time a U1 comes up in the display we also show the symbol of a tap.

U2 indicates restricted lid travel. The customer can usually rectify a U1 or U2

fault.

A U3 fault is not displayed to the customer, but is recorded in the fault history

and displayed in Smart Tool. It is logged if the motor senses prime in less

than 20 seconds because water was left in the tub from a previous fill, or

Fault Codes

because it has filled too quickly. The product will drain and refill up to 5 times

before logging the fault and continuing on with the cycle.

On a double drawer model, a U4 fault indicates an F fault with the other tub

that has disabled the power supply.

In the Integrated and flat door models, an LCD is not available, and the

presence of a fault is indicated by a red centre (start/pause) LED, with the

fault number indicated by the red LEDs on the touch switch panel.

Once a fault is repaired, it can be cleared by pressing the POWER button. If

the fault is still present, then it will not clear.

A fatal or user fault is accompanied by a continuous pulsating beep, which

can be turned off by pressing either the POWER, START/PAUSE, or KEY

LOCK button. This also stops the drain pump running for an F1 fault.

The last two faults are logged into EE memory.

If a tub is forced open, the product simply pauses as if someone had pressed

the start/pause button.

Except for U4, F1, F3, F8 and F9 faults, the other tub can still be used on a

double drawer model.

17

599464

Once the fault has been cleared for an F3, F8 or F9 fault, the power needs to

be disconnected and reconnected to reset the isolation relay before the

product can be used again.

4.7

Fault Code Description Chart

The following chart is a quick reference guide on fault codes. To read a fault

code off an integrated or flat door model, refer to the LED Display column on

the chart below. The LED that has activated on the secondary display

indicates which fault code has occurred.

To make diagnostics easier, a test handle can be made for use on integrated

or flat door models using a cut down handle and a DD605 PCB LCD. This will

not be able to be used on DD603 products, nor can a DD603 test handle be

used on DD605 products.

Fault

Code

F1 Rinse LED. The bottom

LED

Display

Fault Possible Causes

• Lid not closing.

controller flood

sensor

detector has

been activated

for more than

six seconds.

• Overfilling.

• Foaming.

• Not draining.

• Lid seal damaged.

• Dispenser or water softener or

their seals leaking.

• Damaged water inlet or drain

hoses.

• Leaking heater plate or motor

seals, or drain o-ring seals.

• Yoke jammed or broken.

• Inlet hose to inlet valve

connection loose.

• Inlet valve body leak.

• Heater plate damage (chipped

enamel).

• Dry F1 – PCB mains filter,

harness or connectors,

electronic controller.

18

599464

Fault

Code

F2 Delicate

LED

Display

LED.

The controller

has not

sensed the

motor rotating.

F3 Delicate

and Rinse

The water

temperature

Fault Possible Causes

• Foreign object has jammed the

rotor.

• The rotor has failed.

• Hall sensor connector or wiring

fault at hall sensor or

controller.

• The hall sensor has failed.

• Motor stator winding or

connection open circuit.

• The electronic controller has

failed.

• PCB mains filter has failed.

• The incoming water is greater

°

than 85

C (185°F).

LEDs.

has been

sensed as

greater than

°

85

C (185°F).

F4 Fast LED. No

temperature

increase has

been sensed

for about 4

hours while

the element is

on.

F5 Fast and

Rinse

LEDs.

Lid motor

current too

high during

• The element has failed closed

circuit.

• The temperature sensor on the

heater plate has failed.

• The electronic controller has

failed.

• The element is not connected.

• The element has failed open

circuit.

• The temperature sensor has

failed.

• The electronic controller has

failed.

• Lid jammed up or down.

• The electronic controller has

failed.

F6

Fast and

Delicate

LEDs.

start.

Lid motors ran

but did not

reach stall

current.

19

• Lid actuator off yoke or slide.

• Yoke off lid.

• Faulty lid actuator.

599464

Fault

Code

F7 Fast,

LED

Display

Delicate

and Rinse

Fault Possible Causes

No lid motor

current

detected.

LEDs.

F8

F9 Normal and

Normal

LED.

Rinse LED.

Earth leakage

fault.

Power supply /

controller fault.

• Lid actuator not connected.

• PCB mains filter and controller

connectors.

• Faulty PCB mains filter.

• Faulty electronic controller.

• Test for earth leakage.

• Connectors and earth

connections fitted correctly.

• Damaged harnesses.

• Water damaged harness,

connector, or controller.

• Caused by F3, F8 or F9 faults.

• Check coils and motor

windings.

FF

Normal,

Fast,

Delicate

and Rinse

LEDs.

Top tub not

responding.

• Check lid actuators.

• Check controller for signs of

damage.

• Check PCB mains filter and

controller connectors.

• Check heater plate harness

and connectors.

• Replace electronic controller.

• Replace PCB mains filter.

• Chassis harness or

connectors.

• Faulty top controller.

• Faulty PCB mains filter.

20

599464

Fault

Code

U1 Heavy and

LED

Display

Rinse LED.

Machine has

failed to prime

with water

within approx.

3 minutes.

Fault Possible Causes

• The water supply is not turned

on.

• Low water pressure.

• Blocked water softener if fitted.

• The inlet valve has failed.

• The machine is siphoning.

• The spray arm is not in place,

or the flapper is jammed.

• Excessive foaming - using

tablets (not EU/GB), liquid

detergent or spilled rinse aid.

• The motor has failed.

• Rotor not fitted correctly or

faulty.

U2

U3

U4

Heavy and

Dry LEDs.

Not

displayed to

customer.

Heavy and

Fast LEDs.

Restricted lid

travel, the lid

has reached

stall current

too soon.

Water filled too

quickly, or tub

failed to drain.

Advisory only

– the other tub

has a fault and

has disabled

the power

• The electronic controller has

failed.

• Dishes or cups / glasses

prevent the lid from closing.

• Lid, lid actuators or yokes

jammed.

• Not draining completely from

previous fill.

• Excess water pressure.

• Faulty fill valve.

• Diagnose and repair the fault

in the other tub.

supply.

21

599464

4.8

Fault Code Problem Solving Charts

The following charts can be used as a guide to help locate faults in a

DishDrawer™.

F1 Flood Detected

The bottom controller flood detector circuit has been activated.

The product will abort the wash program, log the fault, start the drain pump,

and report to the user.

Neither tub can be used until the fault is cleared.

PRIMARY ACTION

- Determine if a flood actually occurred? Is there water in the base of the

machine?

SECONDARY ACTION

If water in base.

- Determine where the water has come from, check the following:

Check for the lid not closing (lid actuators), overfilling (spray arm correctly

fitted and flapper shutting off, rotor correctly fitted) or foaming (rinse aid spill

or wrong detergent (liquid or tablets) used, not draining (rotor or motor

housing damaged, drain hose blocked / crushed), lid seal damaged,

dispenser or water softener seals leaking, damaged fill or drain hoses, tub

leaking around heater plate or motor seals, drain hose o-ring at connection

to motor, yoke pegs broken or yoke jammed at front or rear, oversize

dishes, inlet hose connection to water inlet valve leak (washer not fitted,

connection not tight) water inlet valve not shutting off.

- Mop up water in the chassis base before attempting to restart.

TERTIARY ACTION

If no water in base

- Check the chassis harness connection to the PCB mains filter.

- Check for corrosion/dirt around the flood sensor on the side of the mains

filter housing.

- Replace the PCB mains filter.

22

599464

F2 Motor Not Rotating

The controller has not sensed the motor rotating.

The product will pause the wash program, log the fault, and report to the

user.

PRIMARY ACTION

- Check the rotor is free to turn.

- Check that power is available at controller (e.g. do the lid actuators run in

diagnostics).

SECONDARY ACTION

- Check whether the rotor is not moving or is vibrating in diagnostics.

- If vibrating, check the hall sensor is properly fitted, check that the motor

stator connections are OK.

- If not moving, check the connections at the controller and the motor.

- Check the resistance of the motor windings.

TERTIARY ACTION

- Check if a replacement hall sensor solves problem.

- Check if a replacement controller solves problem.

- Check if a replacement PCB mains filter solves problem.

23

599464

F3 Water Temperature Measurement Exceeds 85 Degrees Celsius

The water temperature is sensed at greater than 85 degrees C / 185 degrees

F.

The product will abort the wash program, log the fault, report to the user, and

disable the power supply.

Note: The isolation relay will be disabled. Power to the product will need to

be disconnected then reconnected for it to become fully functional again.

PRIMARY ACTION

- Check the incoming water temperature is not too hot.

- Check the temperature reading in diagnostics, and if 199, ensure the

power connector is properly fitted to the controller and the connector on

the heater plate is correctly fitted.

SECONDARY ACTION

- Check the resistance between pins 1 and 2 of the controller power

connector is about 10K at approx. 25

o

C / 77oF ambient room temperature.

- If not (provided the harnesses are ok and the connectors are correctly

fitted), replace the heater plate (bad temperature sensor).

TERTIARY ACTION

- Check that the temperature reading in diagnostics is the same as the

temperature of the water in the tub. If the tub water temperature is

obviously below 85

o

C / 185oF, replace the controller.

24

599464

F4 Element Has Been On Too Long (About 4 Hours) And Water Has Not

Reached Required Temperature

The element has been on too long (about 3 hours) and the water has not

reached the required temperature.

The product will abort the wash program, log the fault and report to the user.

PRIMARY ACTION

- Check that the controller power connector and the heater plate connectors

are properly fitted and the harness is not damaged.

- Check the resistance between pins 1 and 3 of heater plate PCB, and if

open circuit, replace the heater plate.

SECONDARY ACTION

- Check the resistance between pins 1 and 2 of the controller power

connector is about 10K at approx. 25

o

C / 77oC ambient room temperature.

- If not (provided the harnesses are OK and the connectors are correctly

fitted), replace the heater plate (bad temperature sensor).

TERTIARY ACTION

- Replace the controller.

F5 Lid Motor Current(s) Too High During Start

Lid actuator is jammed up or down.

The product will abort the wash program, log the fault and report to the user.

PRIMARY ACTION

- Check for dishes, cutlery or cups and glasses preventing lid from closing.

- Check the lid actuators in diagnostics.

- Check the yokes are moving freely and are not jammed at the front or the

rear (physical inspection).

SECONDARY ACTION

- Replace the lid actuators.

TERTIARY ACTION

- Replace the controller.

25

599464

F6 Lid Motors Ran But Did Not Reach Stall Current

Lid actuators ran but did not reach stall current.

The product will pause the wash program, log the fault and report to the user.

PRIMARY ACTION

- Check that the lid actuators are properly connected to the yokes and the

slide mounting bracket.

- Check that the yokes are clipped into the lid.

- Run the lid actuators in diagnostics.

SECONDARY ACTION

- Replace the lid actuators.

- Replace the controller.

F7 No Lid Motor Current Detected

No lid actuator current detected.

The product will abort the wash program, log the fault and report to the user.

PRIMARY ACTION

- Check that the lid actuator connectors are properly fitted.

SECONDARY ACTION

- Check that the controller is receiving power (use diagnostics to run the wash

or drain pump).

- If not, check the harnesses.

TERTIARY ACTION

- Replace the PCB mains filter.

- Replace the controller.

26

599464

F8 Earth Leakage Fault

Earth leakage fault.

The product will disable the power supply, log the fault, lock out the user and

report to the user.

Note: The isolation relay will be disabled. Power to the product will need to be

disconnected then reconnected for it to become fully functional again.

PRIMARY ACTION

- Test for earth leakage (using a Megger).

SECONDARY ACTION

- Check that the connectors are properly fitted and earthing connectors are

fitted.

TERTIARY ACTION

- Check for physically damaged harnesses.

- Check for water damage to the harnesses, connectors, PCB mains filter

and controllers.

- Check the heater plate tracks for water, damage.

27

599464

F9 Power Supply/Controller Fault

Power supply/controller fault.

The product will disable power supply, log the fault, lock out the user and report

to the user.

Note: The isolation relay will be disabled. Power to the product will need to be

disconnected then reconnected for it to become fully functional again.

PRIMARY ACTION

- Check the previous fault, and if it was F3, F8 or F9, then this F9 is a

consequential fault - fix the previous fault.

- If the fault occurred immediately after power on, check the solenoid coils and

motor stator windings for damage, overheating and correct resistances.

- Check the lid actuators are properly connected.

- Check the controller for damage, signs of overheating or fluid leaking.

IMPORTANT

Check the solenoid coils and motor winding resistances are OK before replacing

a controller.

SECONDARY ACTION

- If the fault is on the top controller and the bottom controller works, check the

top controller chassis and power harnesses are properly connected, are not

damaged and no wires are loose (controller may not be receiving power from

bottom tub).

- If OK, replace the top controller.

- If the fault is on the top controller and the bottom controller does not work,

check the chassis connector on the bottom controller is properly fitted and the

harness is not damaged. Check the connectors on PCB mains filter is

properly fitted.

- Check the heater plate harnesses are properly connected/undamaged.

- If still not OK, replace the bottom controller.

TERTIARY ACTION

- If a single product, and harnesses and resistances are OK, replace the

controller. If replacing the controller does not fix the fault, replace the PCB

mains filter.

28

599464

FF Top Tub Not Responding

Top tub not responding.

PRIMARY ACTION

- Check the top controller works when swapped with the bottom controller

and vice versa. Replace the top controller if it does not work in the bottom

tub.

SECONDARY ACTION

- Check the chassis harnesses and connec tors if the top controller works in

the bottom tub and the bottom controller does not work in the top tub.

TERTIARY ACTION

- Replace PCB mains filter.

U1 (“No Tap” Symbol) Wash Pump Has Not Primed.

The fill valve has been open for more than 180 seconds and the wash pump

has not primed.

The product will pause the wash program, log the fault, report to the user, and

restart when the start/pause button is pressed.

PRIMARY ACTION

No water in the tub:

- Check that the tap is turned on.

- Check for kinked inlet hose, blocked inlet hose filter.

- Check harness connections to water inlet valve.

- Check for a blocked pipe interrupter in the water softener (if fitted).

Not enough water in the tub:

- Is the water pressure sufficient (above 30kPa or 4.3psi)?

Too much water in the tub:

- Is the spray arm correctly fitted? Is the spray arm flapper shutting off?

- Is the rotor correctly fitted?

- Check for foaming - spilled rinse aid or wrong detergent (liquid detergent, or

tablets).

SECONDARY ACTION

- Check the rotor wash (top) impellor is not loose on the shaft.

- Check the fill valve operation (using diagnostics).

- Check the motor operation (using diagnostics).

29

599464

U2 Restricted Lid Travel

Restricted lid travel. The lid has reached its stall current too soon.

The product will retry the lid 3 times, log the fault if the retries fail, then report

to the user.

PRIMARY ACTION

- Check dishes, cutlery or cups are not projecting above the top of the tub.

SECONDARY ACTION

- Check the lid actuator connections and operation in diagnostics.

- Check the yokes for jamming at the front and rear.

U3 Filled Too Quickly Or Failed To Drain

This fault is not displayed to the customer, but it is recorded in the fault history

and can be seen by Smart Tool.

If the motor senses prime too soon (in less than 20 seconds), it will drain and

refill up to 5 times, then continue the wash program regardless, and log the

fault.

PRIMARY ACTION

Not draining completely from previous fill, test in diagnostics.

Check for:

- A blocked drain or kinked drain hoses.

- Blocked drain sump inlet / outlet pipes.

- Blocked drain filter.

- Faulty rotor.

- Faulty connection to the motor.

- Faulty hall sensor.

SECONDARY ACTION

Filling too quickly. Check for:

- Excess water pressure.

- Faulty water inlet valve.

30

599464

U4 This Fault is Advisory Only. The Other Tub has a Fault and has

Disabled the Power Supply.

This fault is advisory only. The other tub has disabled the power supply.

PRIMARY ACTION

- Diagnose and repair the fault displayed on the other tub.

31

599464

4.8.1 Poor Dry Performance

Poor Dry Performance

Question Yes No

1 Is the customer

complaining of plastic

items not drying?

2 Is the customer using

rinse aid?

3 Is the customer using

Fast or Eco cycles.

Advise customer

Go to Question 2.

that due to plastics

having a low

thermal mass these

items give inherently

bad drying

performance.

Go to Question 3. Advise customer that

the use of rinse aid will

improve dry

performance.

Advise customer

Go to Question 4.

that due to lower

final rinse

temperatures dry

performance is

4 Is the rinse aid setting

high enough for the

water hardness in the

area?

5 Using diagnostics, test

the dispenser. Is it

dispensing the correct

amount of rinse aid?

comprised when

using Fast and Eco

cycles (there is less

residual heat for

drying at the end of

cycle).

Go to Question 5. Turn the rinse aid up to

a higher setting.

Replace dispenser.

32

4.8.2 Poor Wash Performance

Customers Complaint Food Particles left on Dishes

599464

Cause of

Spray arm has stopped rotating.

problem (1)

How to resolve the

problem.

a) One of the dishes / cutlery / utensils has fallen

through the basket and jammed the spray arm.

Remove the obstruction.

b) The filter plate, drain filter, or drain filter access

panel is not installed correctly and is causing the

spray arm to jam.

Cause of

problem (2).

How to resolve the

The product is being over loaded or incorrectly loaded

with dishes.

Advise customer of correct loading.

problem.

Cause of

problem (3).

Customer is selecting the wrong wash cycle for the soil

level on the dishes.

How to resolve the

problem.

Customers Complaint Coffee/Tea Stains left in Cups

Cause of

problem (1).

How to resolve the

problem.

Advise customer about reduced water temperatures

(up to 20ºC / 70°F lower) and wash times when using

Fast and Eco cycles.

Not enough detergent being used. To remove these

stains requires a stronger concentration of detergent in

the water.

More detergent is also required in hard water areas as

minerals in the hard water reduce the effectiveness of

the detergent.

Fill the main-wash detergent cup to the top & for best

results also fill the pre-wash detergent cup. Run on

normal or heavy cycles not Eco.

Cause of

problem (2).

How to resolve the

problem.

The product is being over loaded, which is preventing

water reaching the cups on the upper cup racks.

Advise customer of correct loading.

33

599464

Customers Complaint Dishes have blotchy marks on them that look

like water stain marks not food

Cause of

problem.

Not enough rinse aid being used. The water is not soft

enough during the final rinse and therefore hard water

droplets containing impurities are drying on the dishes

instead of running off during the dry cycle.

How to resolve the

problem.

Confirm that the customer is using rinse aid.

The rinse aid may need to be turned up to a higher

setting (4 or 5 lights) and for optimum dry performance

run the DishDrawer™ on normal or heavy cycles, not

Eco.

Check that the rinse aid dispenser is dispensing

correctly in diagnostics.

Customers Complaint Glasses & Cutlery have a Cloudy White film on

them and/or Plates have a White Chalky film on them

Cause of

problem.

How to resolve the

problem.

Hard water and not enough detergent being used.

Minerals from the water are building up on the dishes

or the water softener is not set to the correct water

hardness level, or is faulty.

Once this film forms on the dishes it cannot be

removed by normal running in the dishwasher. The

dishes will need to be cleaned by soaking them in an

acidic solution (such as white vinegar and water).

Where a water softener is not fitted;

To prevent the build up re-occurring the customer will

need to fill both the main-wash & pre-wash detergent

cups to the top with a power detergent and we would

recommend running on normal cycles.

In problem areas with very hard water, the customer

may need to use a detergent additive designed for use

in hard water areas, or fit a water softener to the

incoming water supply.

34

Where a water softener is fitted;

Set the water softener for the correct local water supply

hardness. Check that the water softener is functioning

correctly in diagnostics.

C1 Water Softener Diverter Valve

In hardware output diagnostics test mode:

FU – turn the fill water valve on.

P2 – turn the motor drain on.

C1 – water softener diverter valve.

On – water bypasses the resin tank.

Off – water flows through the resin tank.

C2 Water Softener Brine Pump

Turn the Brine Pump on in diagnostics mode. Observe

a small quantity of water (approx. 30 ml per min.)

599464

flowing out the bottom of the dispenser. (Drop the

dispenser door down to observe this.) Observe a

change in the water level (approximately 120ml per 4

min.) in the salt reservoir. The reservoir should pump

dry of water in this time.

Note:- Fill the salt reservoir with salt (and then water if

not already) before performing this test.

Pipe Interrupter (Air Break) Function

A critical component in the performance of the water

softener is the pipe Interrupter (PI). There is a certain

amount of spray leakage from the PI, which is used to

provide water to the salt reservoir.

If the spray is inadequate, there will be insufficient

water in the salt reservoir to make brine.

If there is too much spray, then the excess bypasses

the water softener and defeats the softening process

by pouring untreated water straight into the tub.

35

599464

To check that the amount spray leakage is

appropriate:-

Fill the salt reservoir with water.

• In diagnostics mode, turn on the fill water valve and

the motor drain. Water will flow out of the dispenser

into the tub, as well as out of the water softener

overflow into the tub.

• Observe the flow from the water softener overflow

(beside the Dispenser). There should be a trickle

(25-100 ml per minute). With experience you can

guess what is appropriate. If the trickle is outside

these rates, replace the softener, as the PI is faulty.

To check that there is water in the salt reservoir,

remove the drawer front and observe the level of water

in the tank. (A quick way to check that there is water in

the salt reservoir is to remove the salt bung and test

the water level by placing your finger down through the

opening.)

Detergent or Rinse Aid in the Water Softener

If detergent or rinse aid is poured in to the salt

reservoir it will destroy the water softener. This could

also happen if the salt bung is left off or falls out.

Evidence of this could be white streaks through the

resin.

36

599464

37

599464

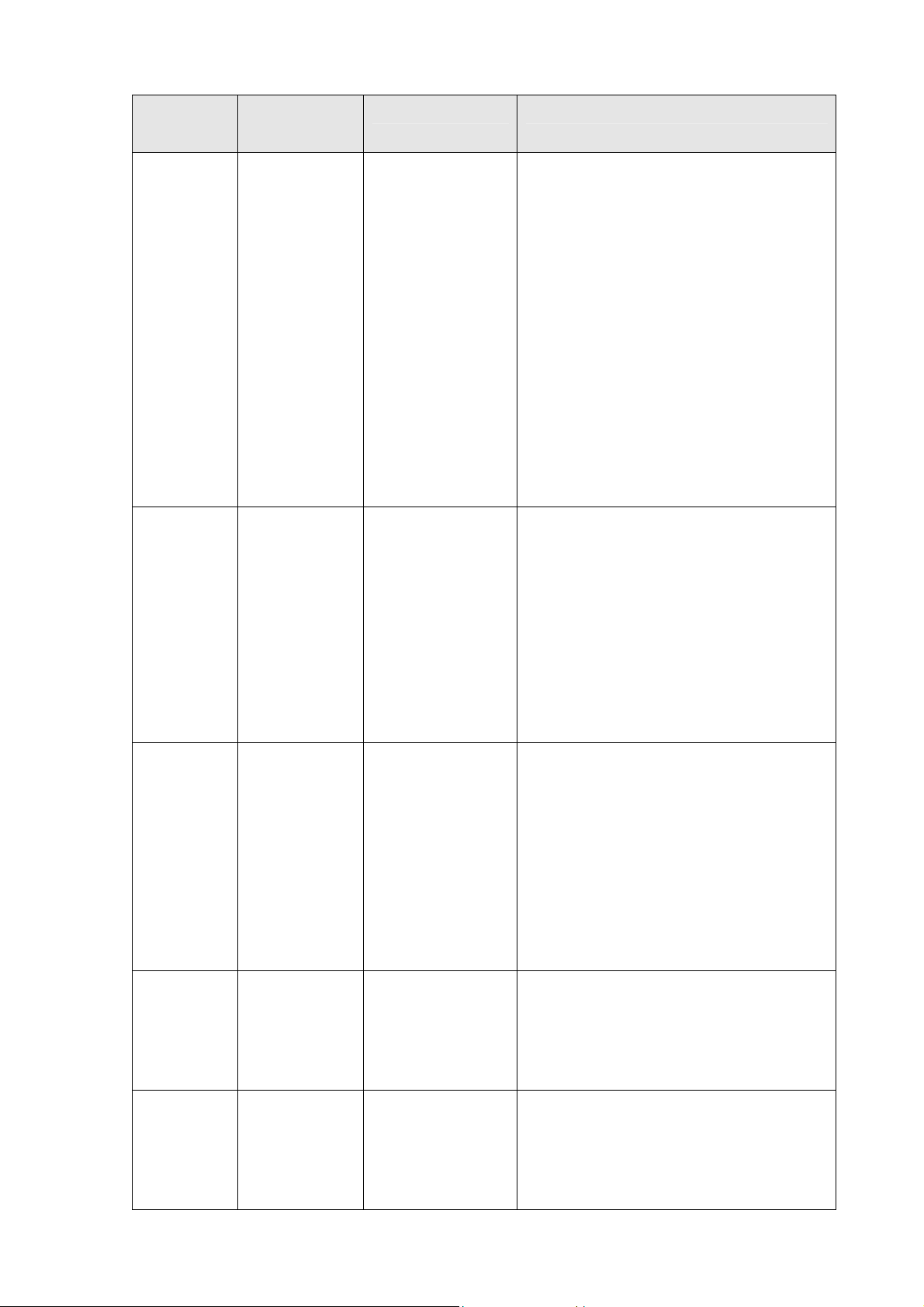

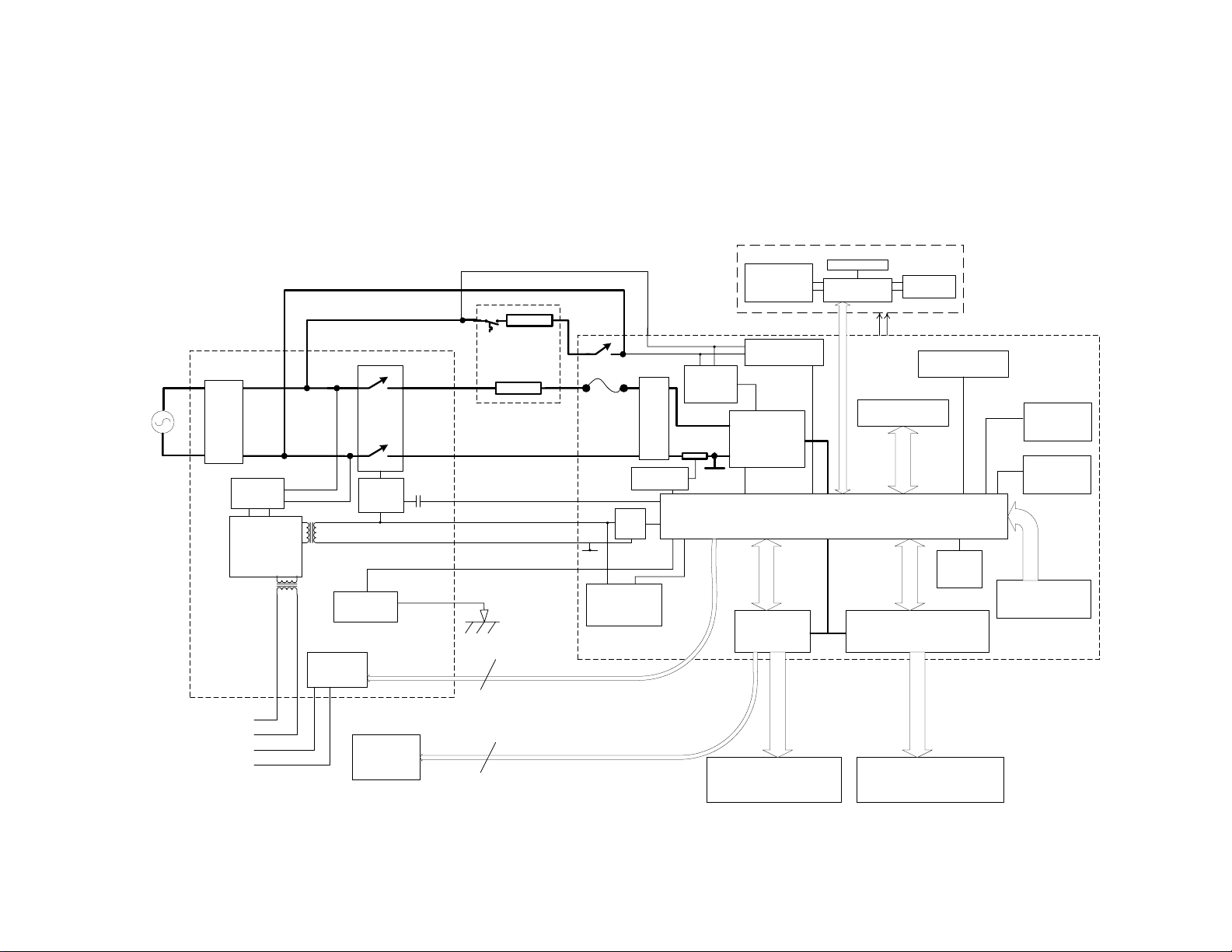

5 WIRING DIAGRAM

5.1 Power Distribution Concept

DD605 Power Distribution concept

Mains

RFI

filter

Rectifier

Auxillary PSU

Chassis PCB

N

P

24V 0V

24V

0V

Comms

Isolation

Isolation

Flood

sensor

relay

Relay

control

2

Heater

Heater

Plate

100

Relay

Fuse

Detector

5 v

reg

0V

24V loads

(Touch switches,

relays, backlights)

Lower (or single)

Controller

Bridge Rectifier

Current

supply

I sens

Gate

0V

LCD

Zero crossing

detector

main PSU

Output Drivers

Buttons

interface

device

Microcomputer

LCD Module

Backlight

Power

Touch switches

Wash Cycle LEDs

Beeper

Wash/drain motor bridge

Salt detector

Tub Home

sensor

sensors

(temperature,current,voltage)

Connections to upper

controller

24V supply

Comms

Fill valve +

Lid Motors

6

dispenser, water softener,

drying fan, LEDs

Wash/drain motor

38

5.2 Wiring Diagram

599464

39

Loading...

Loading...