Page 1

MODELS

DD603

DD603I

DS603

DS603 I

DD603M

DS603M

DD603H

DD603IH

DS603H

DS603IH

DD603HM

DD603HM

599082

Page 2

Page 3

Manual 599082 March 2004

Changes:

Aug 03: Addition of info on Dry Enhancement Mode – refer section 4.1.8, page 20, plus many minor alterations

throughout manual.

Mar 04: Dimensions and Specifications updated p 9, 10.

Fisher & Paykel Appliances Inc

27 Hubble, Irvine, California,

CA92618,

USA

Ph: 949 790 8900

Fax: 949 790 8911

Fisher & Paykel Customer Services

PO Box 798

19 Enterprise St

Cleveland, Queensland 4163

AUSTRALIA

Tel: (07) 3826 9122

Fax: (07) 3826 9164

Email: parts@fp.com.au

A.C.N 003 335 171

Fisher & Paykel Appliances

150 Ubi Avenue 4

Sunlight Building #02-00

SINGAPORE 408825

Tel: 6547 0100

Fax: 6547 0123

COPYRIGHT Ó FISHER & PAYKEL LTD 2004

Fisher & Paykel Appliances Ltd

Whiteware Spare Parts

PO Box 58-732, Greenmount

80 Springs Rd, East Tamaki

NEW ZEALAND

Tel: (09) 272 0261

Fax: (09) 272 0219

Email: parts@fp.co.nz

Fisher & Paykel Appliances

Helpline

209 Purley Way, Croydon

Surrey, CT9 4RY

GREAT BRITAIN

Tel: 0845 600 1934

Fisher & Paykel Appliances Ltd

International Division

PO Box 58-732, Greenmount

80 Springs Rd, East Tamaki

NEW ZEALAND

Tel: (09) 2730660

Fax: (09) 2730580

Email: parts.international@fp.co.nz

Fisher & Paykel Helpline

C/o C&F Quadrant

Unit L

40 Cherry Orchard Industrial Estate,

Dublin 10

IRELAND

Tel: 01 630 5757

Fax: 01 630 5706

Page 4

C O N T E N T S

1.0 SERVICE REQUIREMENTS ........................................................................................................... 7

1.1 HEALTH & SAFETY ........................................................................................................................7

1.1.1 E

1.1.2 E

1.1.3 G

1.1.4 I

1.1.5 W

1.1.6 I

1.1.7 S

1.1.8 S

1.1.9 D

1.2 S

1.2.1 S

1.2.2 F

2.0 DIMENSIONS & SPECIFICATIONS ................................................................................................ 9

LECTRICAL SAFETY...............................................................................................................7

LECTROSTATIC DISCHARGE................................................................................................... 7

OOD WORKING PRACTICES................................................................................................... 7

SOLATE WATER SUPPLY.........................................................................................................7

ATER LEAK CHECK...............................................................................................................7

NSULATION TEST ................................................................................................................... 7

OLVENT AND EXCESSIVE HEAT DAMAGE ................................................................................8

HEET METAL EDGES .............................................................................................................8

IAGNOSTICS .........................................................................................................................8

PECIALISED TOOLS...................................................................................................................... 8

TATIC STRAP:.......................................................................................................................8

ISHER & PAYKEL SMART TOOL ..............................................................................................8

2.1 DIMENSIONS..................................................................................................................................9

2.2 S

2.2.1 E

2.2.2 C

PECIFICATIONS ............................................................................................................................ 9

LECTRICAL ........................................................................................................................... 9

OMPONENTS ........................................................................................................................ 9

3.0 TECHNICAL OVERVIEW ............................................................................................................. 11

3.1 CHASSIS ..................................................................................................................................... 11

3.2 D

3.3 E

3.3.1 T

3.3.2 T

3.4 M

3.4.1 R

3.4.2 S

3.5 W

3.6 L

3.6.1 L

3.6.2 W

3.6.3 D

3.7 T

3.8 F

3.8.1 W

3.8.2 D

3.8.3 A

3.9 H

3.9.1 T

3.9.2 H

3.9.3 M

3.9.4 O

RAWER FRONTS ........................................................................................................................11

LECTRONICS..............................................................................................................................11

UB HOME SENSOR ..............................................................................................................11

OUCH SWITCHES ................................................................................................................ 12

OTOR .......................................................................................................................................12

OTOR.................................................................................................................................12

PRAY ARM..........................................................................................................................12

IRING COVER............................................................................................................................ 12

ID SYSTEM.................................................................................................................................12

ID OPERATION ....................................................................................................................12

HEN ACTIVATED................................................................................................................. 12

URING A POWER FAILURE ...................................................................................................12

UB.............................................................................................................................................12

ILLING ....................................................................................................................................... 13

ATER INLET ....................................................................................................................... 13

ISPENSING DETERGENT AND RINSE-AID...............................................................................13

MOUNT OF WATER ..............................................................................................................13

EATING .....................................................................................................................................13

HE ELEMENT.......................................................................................................................13

EATING THE WATER............................................................................................................ 13

AINTAINING THE TEMPERATURE ..........................................................................................13

VERHEAT PROTECTION .......................................................................................................14

- 4 -

Page 5

3.10 LOCKRING NUT.......................................................................................................................... 14

3.11 D

3.12 F

3.12.1 T

3.12.2 R

3.13 D

3.14 W

RAIN CYCLE ............................................................................................................................14

ILTER PLATE ...........................................................................................................................14

HE FILTER SYSTEM ...........................................................................................................14

EMOVING AND CLEANING THE FILTER PLATE......................................................................14

RYING CYCLE..........................................................................................................................14

ATER SOFTENER (WHERE FITTED) ...........................................................................................15

4.0 OPTION ADJUSTMENT MODE .................................................................................................... 16

4.1 HOW TO CHANGE SETUP OPTIONS ...............................................................................................16

4.1.1 R

INSE AID / WATER SUPPLY HARDNESS / AUTO POWER / END OF CYCLE BEEPS / CLOSED

DRAWER OPTION / CLEAN/DIRTY DISH SYMBOL /DRY ENHANCEMENT OPTION ............................................16

4.1.2 R

4.1.3 W

4.1.4 A

4.1.5 E

4.1.6 C

4.1.7 C

4.1.8 D

4.1.9 O

INSE AID SETUP (RA).......................................................................................................... 16

ATER SUPPLY HARDNESS SETUP (HD) ................................................................................ 16

UTO POWER OPTION (AP)...................................................................................................17

ND OF CYCLE BEEPS (EC) ..................................................................................................17

LOSED DRAWER OPTION (LD) .............................................................................................17

LEAN/DIRTY DISH SYMBOL (DS)...........................................................................................17

RY ENHANCEMENT OPTION (LH) ........................................................................................17

PTION ADJUSTMENT QUICK REFERENCE CHARTS ...............................................................18

5.0 DIAGNOSTICS .............................................................................................................................. 20

5.1 DISHDRAWER DIAGNOSTICS ........................................................................................................20

5.1.1 D

5.1.2 O

5.1.3 C

5.1.4 H

5.1.5 F

5.1.6 C

5.1.7 T

5.1.8 S

ISPLAY / DOWNLOAD MODE ................................................................................................20

PTICAL LED DOWNLOAD / FAULT DISPLAY ..........................................................................20

LEARING FAULT LOGS......................................................................................................... 20

ARDWARE OUTPUT DIAGNOSTIC TEST MODE....................................................................... 20

AST TEST CYCLE ................................................................................................................21

ONTINUOUS CYCLE TEST MODE .......................................................................................... 21

EMPERATURE & VOLTAGE DISPLAY MODE ...........................................................................22

HOW OFF / SHOWROOM WASH MODE .................................................................................22

6.0 DIAGNOSTICS QUICK REFERENCE CHARTS ........................................................................... 24

6.1 FAULT DISPLAY/DOWNLOAD MODE:- ...........................................................................................24

6.2 H

6.3 F

6.4 C

6.5 T

ARDWARE OUTPUT TEST MODE:-...............................................................................................24

AST TEST CYCLE:-.....................................................................................................................25

ONTINUOUS CYCLE:- .................................................................................................................25

EMPERATURE & VOLTAGE DISPLAY MODE:-............................................................................... 25

7.0 FAULT CODES ............................................................................................................................. 26

7.1 FAULT CODE DESCRIPTION CHART ..............................................................................................27

7.2 F

7.3 P

7.4 P

AULT CODE PROBLEM SOLVING CHARTS ...................................................................................28

OOR DRY PERFORMANCE ..........................................................................................................32

OOR WASH PERFORMANCE .......................................................................................................32

8.0 WIRING DIAGRAM ....................................................................................................................... 35

- 5 -

Page 6

9.0 SERVICE PROCEDURES ............................................................................................................. 36

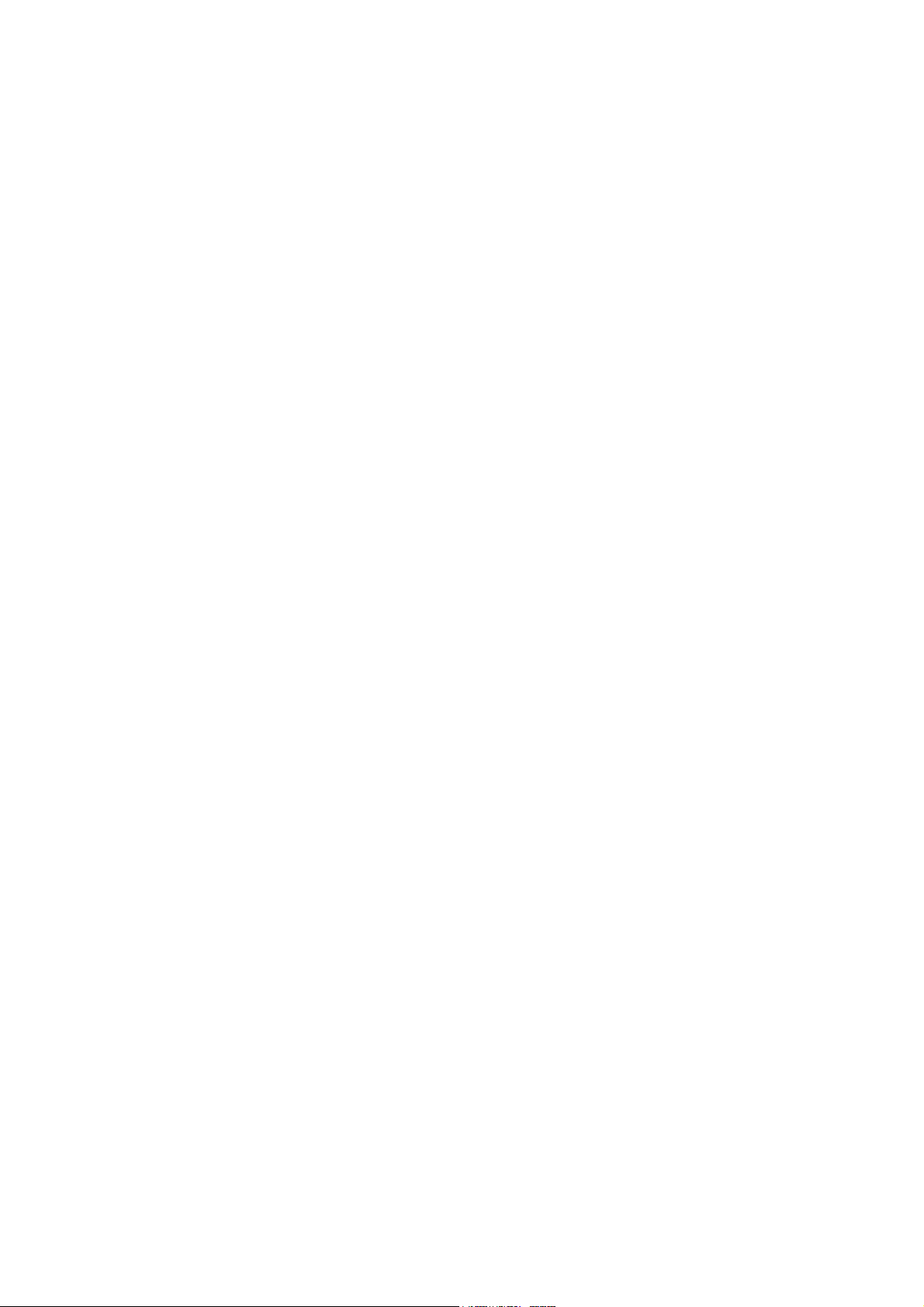

9.1 DRAWER FRONT REMOVAL ..........................................................................................................36

9.2 T

9.3 D

9.4 D

9.5 D

9.6 E

9.7 F

9.8 R

9.9 W

9.10 T

9.11 R

9.12 L

9.13 L

9.14 Y

9.15 L

9.16 S

9.17 C

9.18 W

9.19 F

9.21 T

9.22 L

9.23 F

9.24 W

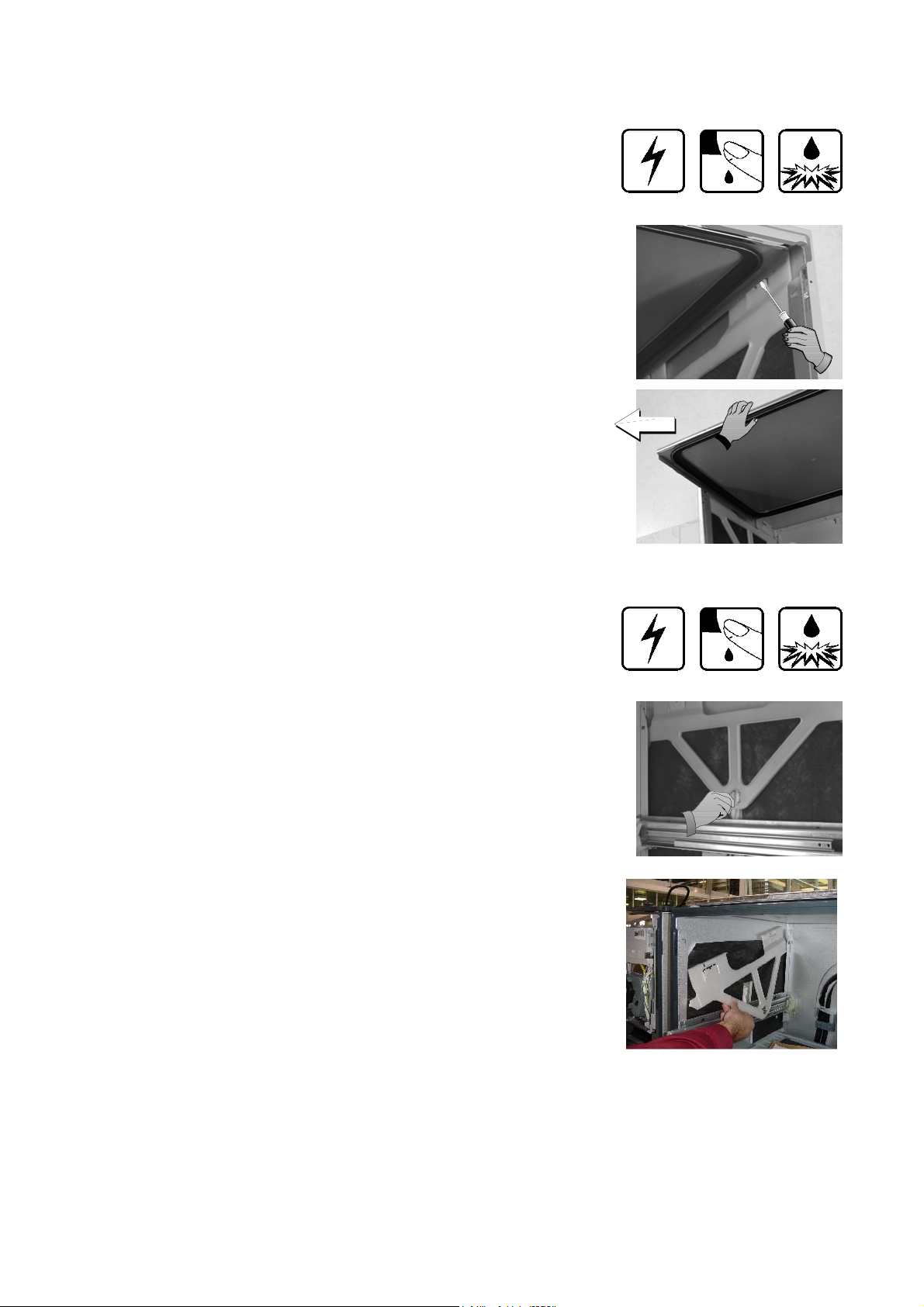

UB REMOVAL.............................................................................................................................36

RAWER AND LCD DISPLAY REMOVAL ........................................................................................37

RYING FAN REMOVAL ................................................................................................................ 37

ETERGENT DISPENSER ..............................................................................................................38

LECTRONIC CONTROLLER..........................................................................................................38

ILTER PLATE REMOVAL .............................................................................................................39

OTOR ASSEMBLY REMOVAL ......................................................................................................39

IRING COVER REMOVAL............................................................................................................39

UB DISCONNECTION.................................................................................................................40

OTOR SENSOR REMOVAL ........................................................................................................40

OCKING RING, ELEMENT PLATE AND MOTOR ASSEMBLY REMOVAL ..........................................41

ID REMOVAL............................................................................................................................42

OKE REMOVAL ........................................................................................................................42

ID ACTUATOR REMOVAL ..........................................................................................................43

LIDE RAIL REPLACEMENT ........................................................................................................44

HASSIS CIRCUIT BOARD / FLOOD SENSOR REMOVAL ............................................................... 44

ATER VALVE REMOVAL........................................................................................................... 45

ILL HOSE, DRAIN HOSE, WIRING HARNESS REPLACEMENT.......................................................45

OE KICK REMOVAL ..................................................................................................................46

OWER TUB COWLING...............................................................................................................46

RONT TRIM REPLACEMENT....................................................................................................... 47

ATER SOFTENER ....................................................................................................................47

- 6 -

Page 7

March 2004 Manual 599082

1.0 SERVICE REQUIREMENTS

1.1 Health & Safety

Note: When servicing the DishDrawer, Health and Safety issues must be considered at all

times. Specific safety issues are listed below with their appropriate icon. These are illustrated

throughout the service information to remind service people of the Health and Safety issues.

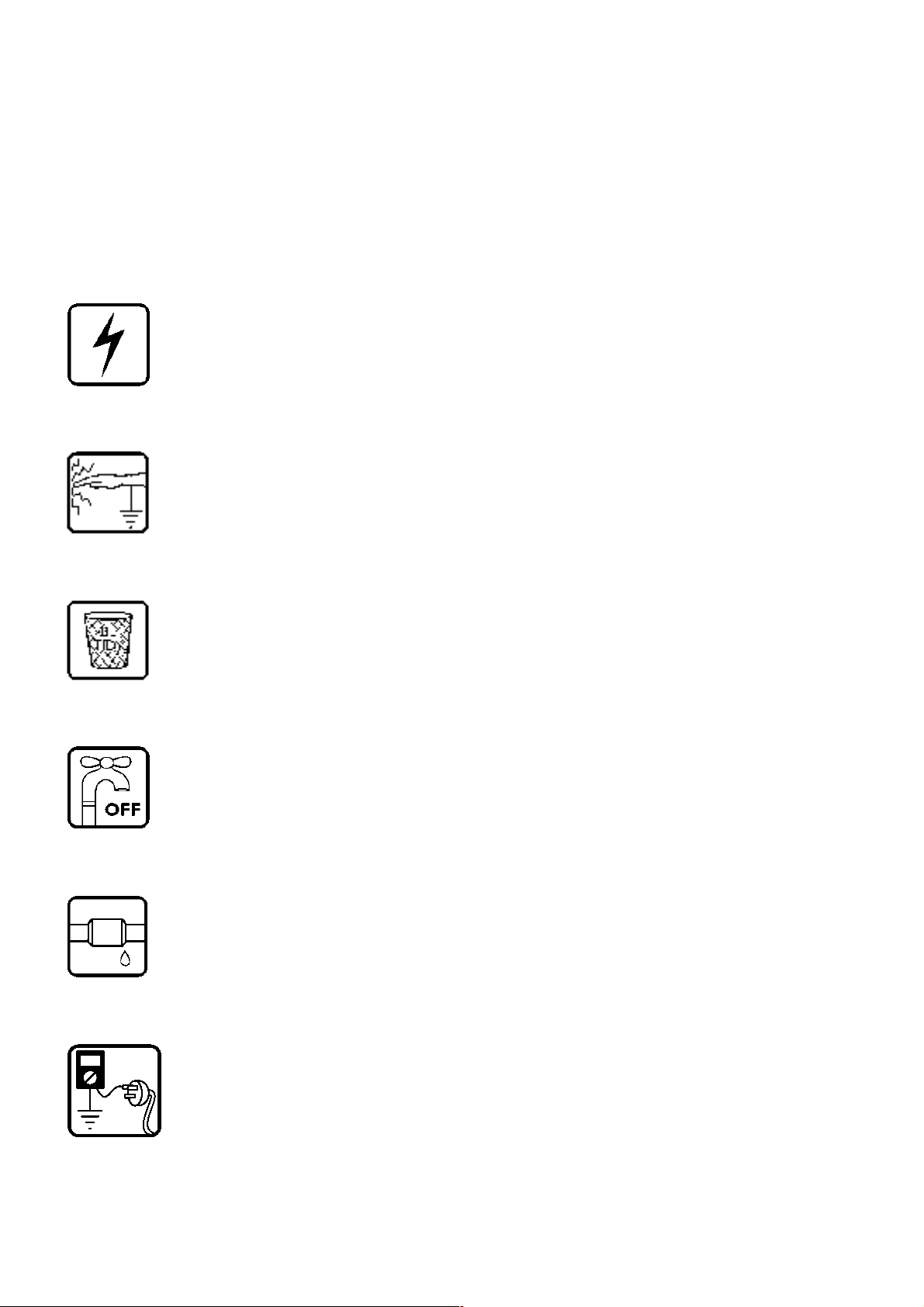

1.1.1 Electrical Safety

Ensure the mains power has been disconnected before servicing the DishDrawer. If the mains

supply is required to be on to service the DishDrawer, make sure it is turned off when removing

any electrical component or connection to avoid electrical shock.

1.1.2 Electrostatic Discharge

An anti-static strap is to be used as electrical static discharge (ESD) protection when servicing

electronic components.

1.1.3 Good Working Practices

Ensure the work area is in a tidy and orderly condition at all times so as not to cause a hazard

while service work is being completed. Always clean and tidy the DishDrawer and work area after

service is completed.

1.1.4 Isolate Water Supply

Turn off the water connection tap before servicing.

1.1.5 Water Leak Check

Check for water leaks as part of the testing after the service has been completed.

1.1.6 Insulation Test

Megger test to check insulation.

Warning: Short together the phase and neutral pins on the plug so as not to damage any

electronic circuitry.

- 7 -

Page 8

March 2004 Manual 599082

1.1.7 Solvent and Excessive Heat Damage

Plastic surfaces can be damaged by solvents and excessive heat.

1.1.8 Sheet Metal Edges

When working around cut sheet metal edges use appropriate gloves or protection to eliminate

the chance of receiving a laceration.

1.1.9 Diagnostics

While in diagnostics some safety devices are bypassed.

Ensure you do not run components unattended. They may overheat, flood, burnout or cause

water damage.

1.2 Specialised Tools

For servicing this product Specialised tools are required.

1.2.1 Static Strap:

To be used as ESD protection when replacing or handling electronic components.

1.2.2 Fisher & Paykel Smart Tool

Handheld palm computer supplied in protective case with F&P diagnostics software and service information

loaded:

P/N 813141 (includes light pen P/N 425930).

- 8 -

Page 9

March 2004 Manual 599082

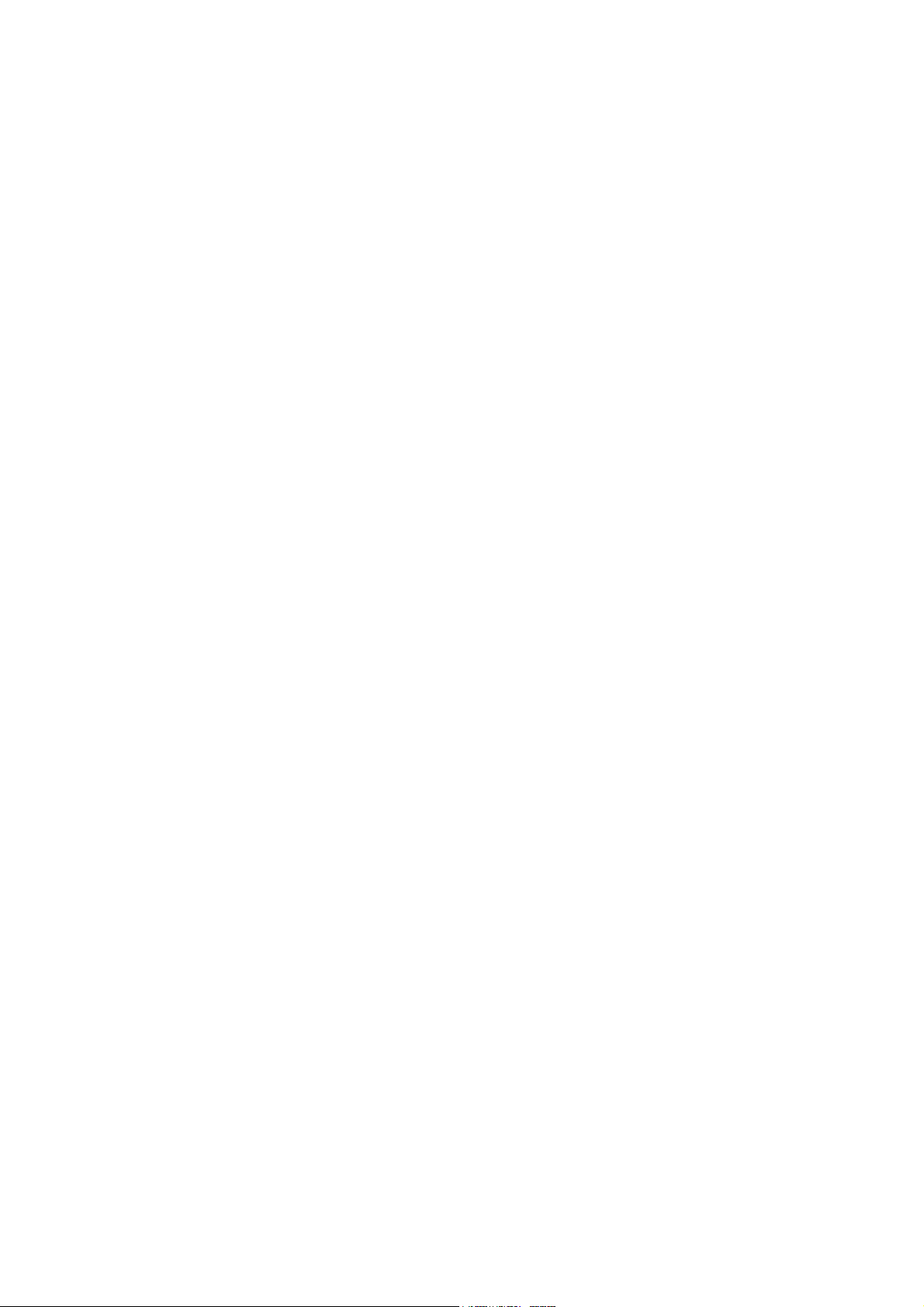

2.0 DIMENSIONS & SPECIFICATIONS

2.1 Dimensions

Product Size

(mm)

Height (double) 819.5-879.5 32

Height (single) 409mm 16

Width 595mm 23

Depth 570mm 22

Drawer Open (inc cab) 1080mm 42

2.2 Specifications

2.2.1 Electrical

Market Voltage Frequency Current double/single

NZ/AUS/UK/EU 230-240 V AC 50 Hz 10 A / 5 A max

USA 110-120 V AC 60 Hz 12.5 A / 6.5 A max

JAP 90-110 V AC 50/60 Hz 11.6 A / 5.8 A max

KOREA 220 - 240 60 HZ - / 4.5 A max.

Product Size

(inches)

1/4

inch – 34

3/32

inch 412mm 16

7/16

inch 600mm 23

7/16

inch 580mm 22

1/2

inch

5/8

inch 822.5-882.5mm 32

Minimum Cavity

Size

Minimum

Cavity Size

3/8

inch

7/32

inch

5/8

inch

7/8

inch

2.2.2 Components

Component Part Number Specifications

Water Inlet Valve Ph3.5

Ph3.5

Ph3

Ph3

Dispenser

P/N 526850 Double 2.5litre

P/N 526851 Single 2.5 litre

P/N 525113 Double 5 litre

P/N 525842 Single 5 litre

24V DC

70+/- 5 Ohms per coil

2.5Lt/min (0.65 USgal/min)

5 litre/min (1.3 US gal/min)

P/N 526860 24V DC per coil

70+/- 5 Ohms per coil

Rinse Aid capacity

Mains Filter Board

P/N 525958P

50mls (approx. 25 washes)

240V AC

(NZ/AUS/UK/EU/KR)

Mains Filter Board (USA/JAP)

Motor

Drain Direction

Wash Direction

P/N 525959P

5 litres / min.

120V AC

80V DC 3 Phase

4200 RPM

2600 RPM

Stator P/N 526530 8.0 +/- 5 Ohms (per winding), 16

ohms phase to phase from controller

connector

- 9 -

Page 10

March 2004 Manual 599082

Component Part Number Specifications

Heater Plate (NZ/AUS/UK/EU/KR)

Heater Track

Power Supply Resistor

Heater Plate (USA)

Heater Track

Power Supply Resistor

Heater Plate (JAP)

Heater Track

Power Supply Resistor

Temperature Sensor On Heater Plate 962 Ohms @ 200C (680F)

Fuseable Link On Heater plate 268 – 302oC (514 – 576oF)

Inlet Hose (NZ/AU/ /KR)

Inlet Hose (WP/EU/DK/GB)

Inlet Hose (USA)

Inlet Hose (JAP)

Drain Hose

Drain Hose (Lower)

Drain Hose (Upper)

Drying Fan P/N 526752 3.4K Ohms

Diverter Valve Softener Assy P/N 526416 24V DC Coil

Brine Pump Assy P/N 526418 24V DC Coil

Water Softener 500 grams Salt Capacity

Lid Actuator

Top left

Top right

Bottom left

Bottom right

Hall Sensor P/N 526340 4.13, and 3.43 M ohms

P/N 527701 240V AC

60 Ohms +/- 3 Ohms

125 Ohms +/- 5 Ohms

P/N 527702 120V AC

26 Ohms +/- 2.5 Ohms

30 Ohms +/- 5 Ohms

P/N 527703 110V AC

20 Ohms +/- 1.5 Ohms

20 Ohms +/- 2 Ohms

1000 Ohms @ 300C (860F)

1202Ohms @ 600C (1400F)

P/N 521349

P/N 527021

P/N 525970

P/N 526809

P/N 525966

P/N 525967

P/N 526275

P/N 526371

P/N 526469

P/N 526470

1.7m (66 inches)

1000Kpa / 145 P.S.I.

2.0m (78 inches) from rear of

cabinet

2.5m (98 inches) bottom tub

2.9m (114 inches) top tub

70 +/- 5 Ohms Coil

70 +/- 5 Ohms Coil

approx 14 regenerations

290+/- 10ml Resin

24 V DC

measured +ve in centre, -ve to

outside

- 10 -

Page 11

March 2004 Manual 599082

3.0 TECHNICAL OVERVIEW

3.1 Chassis

The DishDrawer chassis is one complete assembly composed of 5 steel metal components locked together by a

proprietry riveting process. The chassis exterior is made of a lacquered electrogalvanised material called

Galvoclean.

Unlike most other dishwashers, the chassis assembly is a load carrying structure designed to impart stiffness to the

product and to ensure deflection is minimised.

The feet of the Double cabinet are assembled into the chassis by means of four steel inserts which are clinched in

place to form a permanent threaded connection.

The tub extends 520mm (2015/32”) out of the cabinet by travelling along two rigidly attached slides on either side of

the tub.

3.2 Drawer Fronts

Prefinished drawer fronts are formed from a painted, brushed or Iridium finish stainless steel blank. The drawer

fronts are attached to the tub by means of formed hooks and two pins which are inserted through either side of the

tub.

On the integrated model, the front panel supplied on each drawer is the mounting panel for the joinery finished

drawer front. The joinery finished drawer front is supplied by the customer.

3.3 Electronics

In the DD603/ DS603 (Phase 3) electronic controller the functions of controlling the motor as well as controlling the

user interface console have been combined into a single 16-bit Micro Controller on the main printed circuit board.

This Micro controller also controls a transformerless 85w switchmode power supply. This power supply utilises a

large dropping resistor on the heater plate in conjunction with phase control of the mains voltage in order to produce

a variable voltage rail. From this the controller can supply voltages from 5V to 85V to the various components in the

DishDrawer.

NOTE:- With power supplies of this nature all components regardless of supply voltage should be treated as live to

earth. i.e = supply voltage.

The user interface comprises a printed circuit board for front controls and a touch switch panel for internal controls.

The electronics can connect to a computer service tool via an optical light pen for fault finding and product

information.

The element is switched by one single pole relay. Overheat protection is effected by a short length of solder in series

with the dropper resistor track on the heater plate. In an overheat situation this solder melts causing the power

supply to go open circuit.

3.3.1 Tub Home Sensor

A tub home sensor is used to determine when the tub is closed and it is safe to start a cycle. The tub home sensor

consists of an inferred LED (sender) and an inferred transistor (receiver) mounted on the circuit board in the

controller. Inferred light is transmitted from the LED through an optical light pipe to the right hand side of the tub. The

inferred receiving transistor also has an optical light pipe leading from it out to the side of the tub. When the tub is

closed the two light pipes are optically connected via a prism mounted in the trim on the side of the chassis.

- 11 -

Page 12

March 2004 Manual 599082

3.3.2 Touch Switches

Two touch switches are used on the secondary control panel one to select the required wash cycle and one to turn

the Eco option on or off. They are capacitive touch switches and are supplied with an analogue signal from the

controller that will change in the presence of an earthed mass (i.e. customer’s finger).

3.4 Motor

The motor is a fully electronically controlled 80V, 60w, 3 phase, 6 pole brushless DC motor, running on wash at

between 2300-2850rpm depending on the cycle selected and at approximately 4200 rpm on Drain.

3.4.1 Rotor

The rotor is a four pole permanent magnet rotor with a graphite bearing at each end of the vertical shaft. At the

lower end of the rotor shaft is the drain impellor and at the upper end is the wash impellor.

3.4.2 Spray Arm

The spray arm is shaped for most efficient waterflow. The holes are positioned for best penetration into the wash

load, with the water jets angled to ensure the spray arm rotates at the most efficient speed. There is a flap valve

moulded into the top of the spray arm. This part lets air through the spray arm when the DishDrawer is filling with

water. The DishDrawer fill levels are more consistent with the flap valve system.

3.5 Wiring Cover

The wiring cover protects the customer from all electrical components in the motor area underneath the tub. All

electrical components regardless of voltage should be treated as live with respect to earth. It also serves to protect

the motor assembly, drain and fill hoses from damage when opening and closing drawers. The wiring cover acts as

a cosmetic part of the product.

3.6 Lid System

3.6.1 Lid Operation

The lid is a single piece of polymer plastic with a static seal co-injection moulded into it. Each side of the lid is clipped

into a yoke which is in turn connected to a worm drive lid actuator assembly containing a small brushed DC 24V

motor.

3.6.2 When Activated

At the beginning of each wash cycle, both motors are powered for approximately 10 seconds, which pulls the lid

down onto the tub in approx 5 seconds. The lid remains down for the duration of the cycle and is only lifted when the

DishDrawer beeps to signal the end of the cycle or if the customer pauses it to gain access to the tub.

3.6.3 During a Power Failure

If power to the DishDrawer fails with the lid down you can still force the tub open manually if access is required. It is

very difficult however to close the tub again without lifting the lid. The lid can be wound up manually with the tub fully

removed. Failure to raise the lid before closing the Drawer could result in the lid seal being damaged.

3.7 Tub

The tub is the main cavity where all the wash activity occurs. The tub is a polymer plastic receptacle which has a

wash pump and spray arm at the base. The tub also has guide vanes around its walls which direct falling water from

the wash cycle in a clockwise direction around the filter plate. This clears the filter plate of food particles into the

sump where they can be trapped or pumped out during the drain cycle.

- 12 -

Page 13

March 2004 Manual 599082

3.8 Filling

3.8.1 Water Inlet

The tub of the DishDrawer fills by a single water inlet hose, hot water connection for USA and Japanese products

and cold water connection recommended for the Australasian/UK/ Europe products. From the connection to the

water supply in the kitchen, the inlet hose enters the cabinet of the dishwasher at the base, onto a dual water valve.

Each tub is supplied water independently via one of the dual valve coils and a fill hose that runs through a

customised link assembly at the back of each tub and travels along the base of the tub under the wiring cover to the

front. At the front of the tub, the fill hose connects to the detergent dispenser which allows water to enter the tub,

firstly through the pre rinse section of the dispenser for the pre rinse cycle and secondly through the main wash

section for all other cycles.

In a product fitted with a water softener, water is directed through the softener before entering the dispenser.

3.8.2 Dispensing Detergent and Rinse-aid

The dispenser is mounted in the front wall of the wash tub.

The detergent dispenser consists of two detergent chambers, one for pre wash and the other for the main wash.

The detergent dispenser door is opened manually for detergent loading and then manually closed ready for the

detergent to be transported to the wash tub by the inlet water. To enable each detergent chamber to be dispensed

separately, an inlet water diverter valve controlled by the electronics is required.

Additionally a positive displacement pump unit and storage tank are incorporated within the dispenser to supply rinse

aid. The rinse aid dispensed volume can be adjusted by the customer in option adjustment mode. A glowing red

light on the tank filler cap indicates an empty rinse aid tank.

3.8.3 Amount of Water

The tub fills with approximately 2.5 litres / 0.8 US gallons of water, approximately level with the base of the spray

arm. Once this level is reached, the wash pump (which has sensed the fill via the electronics) becomes primed and

pumps the water through the spray arm which will then rotate. The load on the wash pump is constantly monitored

throughout the wash cycle and the water level adjusted if necessary.

3.9 Heating

3.9.1 The Element

The heater plate is an element consisting of a porcelain enamelled steel plate with a thick film resistive circuit printed

onto the dry side. As well as the heating circuit a large dropping resistor is also printed onto the heater plate which

forms part of the controllers power supply. The element is clamped in place by a lockring nut and supports the motor

at the base of the tub.

3.9.2 Heating the Water

The heater plate lies beneath the filter plate. A flow through water heating system is created during the wash cycle

by allowing water to flow through the filter plate, over the surface of the element and into the wash pump.

3.9.3 Maintaining the Temperature

Attached to the element is a sub printed circuit board with a temperature sensitive thermistor. This connects by

means of a RAST 2.5 connector system to the wiring harness of the element. Sensor components are

unserviceable and if they fail a new heater plate is required.

- 13 -

Page 14

March 2004 Manual 599082

3.9.4 Overheat Protection

The heater plate is only activated during the wash cycles. It is not used for drying. The temperature is maintained

by the thermistor. If a failure occurs with the electronic control of the heater plate, overheat protection is effected by

a thermal fuse on the heater plate itself.

The thermal fuse consists of a short length of solder in series with the dropper resistor track which will melt at a

relatively low temperature, 268 – 302oC (514 – 576oF) causing the controllers power supply to go open circuit

disconnecting power to the element.

3.10 Lockring Nut

The lockring nut holds the heater plate into the base of the tub and motor housing assembly to form a watertight

seal. It does this by compressing two large ‘O’ rings between the heater plate and tub and between the heater plate

and the motor assembly.

It has clips which hold the drain hose, fill hoses and the wiring loom in place.

Another function of the lockring nut is to support the wiring cover with three clips.

3.11 Drain Cycle

The drain pump is a self priming centrifugal pump which only pumps when the motor is rotating in the drain direction

(anti-clockwise). It has a five bladed impellor pushed into a spline on the end of the rotor shaft.

The drain pump housing, which incorporates an inlet and outlet pipe, is welded to the motor housing, hence

captivating the motor.

The inlet pipe plugs straight into the sump and is sealed there by a small ‘O’ ring.

The outlet pipe has a non return flap valve to prevent soiled water returning to the tub.

The drain hose is an extruded blow mould hose which is routed over the link assembly and exits out of the base of

the product and is connected to a domestic drain.

The drain speed during the wash program is approx. 4200 rpm. In hardware output diagnostics test mode it is

approx. 5000 rpm. This can account for draining OK in diagnostics but not during normal operation.

3.12 Filter Plate

The filter plate is a stainless steel disk which lies below the dish rack and spray arm and completely encompasses

the base of the tub.

3.12.1 The Filter System

The tub is designed with vanes which swirl the water around and over the filter plate. At the front of the tub, located

as part of the filter plate, is the drain filter. Large soils collect in the drain filter and only smaller soils flow through its

micro mesh filter, eliminating re-depositing of soil during the wash. The drain filter should be regularly checked and

cleaned.

3.12.2 Removing and Cleaning the Filter Plate

The drain filter can be emptied with the dish rack in place by removing the cutlery basket and opening the plastic

section of the dish rack. The filter plate is removable for cleaning by removing the dish rack and spray arm and

unlocking the lockring nut anti-clockwise.

3.13 Drying Cycle

Immediately after water from the final hot rinse has been drained from the tub, the drying system begins operation.

The drying fan draws air through from the vent in the rear of the tub, where it absorbs water from the dish load. The

moisture laden air is then mixed with a larger quantity of ambient air (from the kitchen), to minimise the amount of

vapour visible when exiting from bottom of the drawer front.

- 14 -

Page 15

March 2004 Manual 599082

The fan runs continuously during the drying cycle and will restart if the tub is opened and closed again. After the

wash program is complete, the lid drives up, and the fan continues to run for 30 minutes, but will not restart if the tub

is opened.

3.14 Water Softener (where fitted)

The Water Softener uses a softening material (resin) to prevent most of the elements that cause hard water from

being present in the wash water. The resin can only treat a limited amount of water before it needs to be

regenerated. Regeneration is achieved by pumping salty water (brine) through the resin, and flushing away the hard

elements to the drain. The process of delivering softened water, and regeneration is controlled by the Electronic

Controller.

Delivering Softened Water:- Supply water arrives from the inlet valve. In the water softener it passes through a

piper interrupter (air break) and a diverter valve. It is then either directed through the resin to the dispenser, or

directly to the dispenser, then into the tub. The electronic controller measures the volume of water treated, and adds

an appropriate amount of non-treated water, to deliver a mix which is at the required hardness according to a predetermined schedule. Water is treated according to its supply hardness. The customer is able to select one of 5

settings in option adjustment mode.

Regeneration:- Regeneration is triggered when the amount of water that has been treated since the last

regeneration nears the capacity of the Water Softener. The quantities treatable for each of the 5 settings of supply

hardness have been predetermined, and are stored in the electronic controller. When triggered, immediately after

filling for the main wash, the brine pump is activated and delivers a volume of salty water into the resin, at an amount

appropriate to the hardness setting. When the wash cycle finishes, the resin is flushed with supply water, and the

by-products of regeneration are delivered into the wash water, and drained with it away to waste. Normal treatment

of incoming water then resumes.

Salt:- the customer is required to fill the salt tank with dishwashing salt from time to time. Salt is used in the water

softener by mixing it with water to produce the salty water (brine) used in regeneration. When the salt level is low, a

salt level detector causes a glowing red light to appear in the salt bung, and a “Salt” symbol appears in the LCD.

When this happens, the customer should remove the salt bung, and using the salt container provided, pour salt into

the salt reservoir until salt can be seen at the opening. The “Salt” symbol on the LCD will disappear and the red light

will not be visible when the salt tank bung is replaced. In areas where the supply water is moderately hard (21 dH –

degrees of hardness, 375ppm – parts per million, Water Softener Setting 3) the salt reservoir will need to be filled

about once a month, and in harder areas more frequently. Delivery of treated water from one fill of the salt reservoir:

240 litres at 30 – 100 ppm from 375 ppm supply water

144 litres at 30 – 100 ppm from 625 ppm supply water

- 15 -

Page 16

March 2004 Manual 599082

4.0 OPTION ADJUSTMENT MODE

4.1 How to Change Setup Options

4.1.1 Rinse Aid / Water Supply Hardness / Auto Power / End of Cycle Beeps / Closed Drawer Option /

Clean/Dirty Dish Symbol /Dry Enhancement Option

To enter this setup mode, press Power, then hold the Eco touch switch and KeyLock button simultaneously for 5

seconds ensuring that Eco is pushed first. Once the setup mode is entered a beep is emitted and the LCD displays

the letters rA. By pushing the Start/Pause button you can scroll through and change the following options:Rinse Aid Setup (rA)

Water Supply Hardness Setup (hd)

Auto Power Option (AP)

End of Cycle Beeps (EC)

Closed Drawer Option (Ld).

Clean/Dirty Dish Symbol (dS)

Dry Enhancement Option (LH)

Integrated:- On an Integrated DishDrawer, where there is no display, you can still tell which option you have chosen

by using the lights showing on the integrated badge as follows:Rinse Aid Setup (red light above Start/Pause button)

Water Supply Hardness (green light above Start/Pause button)

Auto Power Option (orange light above Start/Pause button)

End of Cycle Beeps (green light above Start/Pause and red light above Keylock) button)

Closed Drawer Option (red light above Start/Pause and Keylock buttons)

Clean/Dirty Dish Symbol (not available on Integrated models)

Dry Enhancement Option (orange light above Start/Pause button, Eco light is red)

Push Power at any time to exit this setup mode.

4.1.2 Rinse Aid Setup (rA)

The current rinse aid setting is shown using the red LED’s on the touch switch panel.

The amount of rinse aid dispensed into a rinse cycle can be varied to suit the level of hardness of the local water

supply. It is adjusted for 1 - 5 dispenser levels

(1 = approx 0.5mls (1/10) teaspoon of rinse aid, 5 = approx. 2.5mls (½) teaspoon of rinse aid).

Push Keylock to advance the rinse aid setting. Once the desired setting is achieved, push Power to exit. The rinse

aid index is stored in EE memory, so even with the power removed, the rinse aid level is retained.

Integrated:- On an Integrated DishDrawer when you turn on or turn off one of the following options it is indicated by

the red wash cycle LEDs on the secondary control panel. If an option is turned on then all the LEDs turn on and if an

option is turned off all the LEDs turn off.

4.1.3 Water Supply Hardness Setup (hd)

The current supply hardness setting is shown using the red LED’s on the touch switch panel. One of 5 settings

should be selected according to the known hardness of the supply water. Each setting is appropriate for the

following water supply hardness:

No. LED Water Softener turned off, continuous bypass of softener

1 150-250 ppm water supply hardness

2 250-350 ppm water supply hardness

3 350-450 ppm water supply hardness

4 450-550 ppm water supply hardness

5 550-625 ppm water supply hardness

- 16 -

Page 17

March 2004 Manual 599082

Push Keylock to advance the Water Softener setting. Once the desired setting has been achieved push Power to

exit.

Selection of a setting affects how the Electronic Controller diverts supply water, how much water is treated, and how

much salt is used in regeneration, in a manner that optimises the performance of the Water Softener.

4.1.4 Auto Power Option (AP)

The automatic power up sequence that occurs when the tub is opened can be turned on or off using the Keylock

button. If the Scrubbing Brush is showing on the LCD then the auto power up sequence will occur when the tub is

Opened. If the Scrubbing Brush is not showing then the DishDrawer will not automatically power up when the tub is

Opened (the customer will need to push the power button each time they wish to use the DishDrawer). Push Power

to exit when the desired setting has been selected.

4.1.5 End of Cycle Beeps (EC)

The six beeps that occur at the end of every cycle can be turned on or off using the Keylock button. If the

Scrubbing Brush is showing on the LCD then the end of cycle beeps are activated. If the Scrubbing Brush is not

showing then the end of cycle beeps are deactivated. Push Power to exit when the desired setting has been

selected.

4.1.6 Closed Drawer Option (Ld)

The Closed Drawer Option can be turned on or off using the Keylock button. If the Scrubbing Brush is showing on

the LCD then the Closed Drawer Option is selected and it will keep the DishDrawer locked at all times by bringing

the lid down. When this mode is selected the customer needs to push the power button to lift the lid whenever they

want to open the drawer. When they close the drawer again the lid comes down automatically after 30 seconds and

locks the tub. If the Scrubbing Brush is not showing then the Closed Drawer Option is deactivated.

4.1.7 Clean/dirty Dish Symbol (dS)

(not available on integrated models)

The Clean/dirty dish symbol can be turned on or off using the keylock button. If the Scrubbing Brush is showing on

the LCD then the Clean/dirty dish option is selected. This means that the end of cycle clean dishes symbol will

remain in the LCD display until the power button is pressed to clear it. If the Scrubbing Brush is not showing then the

Clean/dirty dish symbol will disappear when the drawer is first opened at the end of a cycle (factory setting).

4.1.8 Dry Enhancement Option (LH)

(available in prefinished products from MEM741743, manufactured after 21/5/03,

software vesion 3.2.06

available in integrated models from MKM704522, software version 3.2.07)

Dry Enhancement Option can be turned on or off using the keylock button. If the Scrubbing Brush is showing on the

LCD then the Dry Enhancement Option is selected.

This means the lid will stay down and the drying fan will continue running for 4 hrs after the wash program

completes.

If the customer wishes to open or stop the DishDrawer during this 4 hr period, they can do so by pushing the

POWER or START / PAUSE button. This will reset the feature until the end of the next wash program

- 17 -

Page 18

March 2004 Manual 599082

4.1.9 Option Adjustment Quick Reference Charts

Rinse Aid Setting (rA):-

(alter the amount of rinse aid dispensed)

Press and hold Eco, then Keylock for 5 seconds

rA will be displayed (integrated: Red LED above start/pause button showing)

Press keylock

The rinse aid setting will advance on the secondary control panel LEDs with each press

Press Power

Will exit & save selected setting

Water Softener Supply Hardness Setup(hd) (where fitted):-

(alters the Water Softener setting depending on Water Supply hardness)

Press and hold Eco, then Keylock for 5 seconds

RA will be displayed

Press Start / Pause once

Hd will be displayed (integrate: Green LED above Start / Pause Button showing)

Press Keylock

The Water Softener setting will advance on the Secondary Control Panel LED’s with each press.

Press Power.

Will exit and save selected settings.

Auto Power Option (AP):-

(powers up automatically when the drawer is opened)

Press and hold Eco, then Keylock for 5 seconds

rA will be displayed

Press Start/Pause Twice

AP will be displayed (integrated: Orange LED above start/pause button showing)

Press Keylock

Turns Auto Power on & off. Scrubbing brush or secondary control panel LEDs showing = AP on, Scrubbing brush or

secondary control panel LEDs not showing = AP off

Press Power

Will exit & save selected setting

End of Cycle Beeps (EC):-

(six beeps at the end of every cycle)

Press and hold Eco, then Keylock for 5 seconds

rA will be displayed

Press Start/Pause Three Times

EC will be displayed (integrated: Green LED above start/pause button showing)

Press Keylock

Turns end of cycle beeps on & off. Scrubbing brush or secondary control panel LEDs showing = EC on, Scrubbing

brush or secondary control panel LEDs not showing = EC off

Press Power

Will exit & save selected setting

- 18 -

Page 19

March 2004 Manual 599082

Closed Drawer Option (Ld):-

(lid closes automatically every time the drawer is closed)

Press and hold Eco, then Keylock for 5 seconds

rA will be displayed

Press Start/Pause Four times

Ld will be displayed (integrated: Red LEDs above start/pause & keylock buttons showing)

Press Keylock

Turns closed drawer option on & off. Scrubbing brush or secondary control panel LEDs showing = Ld on, Scrubbing

brush or secondary control panel LEDs not showing = Ld off

Press Power

Will exit & save selected setting

Clean/Dirty Dish Option (dS):-

(clean dishes symbol stays on at end of cycle until cleared by pressing power)

Press and hold Eco, then Keylock for 5 seconds

rA will be displayed

Press Start / Pause Five times

dS will be displayed (not available on integrated models)

Press Keylock

Turns clean/dirty dish option on & off. Scrubbing brush showing = dS on, Scrubbing brush not showing = dS off

Press Power

Will exit & save selected setting

Dry Enhancement Option (LH):-

(lid down and fan run-on for 4 hrs at the end of the cycle)

Press and hold Eco, then Keylock for 5 seconds

rA will be displayed)

Press Start / Pause Six times

LH will be displayed (orange light above start/pause, ECO light is red)

Press keylock

Turns the Dry Enhancement Option on / off. Scrubbing brush symbol on = LH on.

Press Power

Will exit & save selected setting

- 19 -

Page 20

March 2004 Manual 599082

5.0 DIAGNOSTICS

5.1 DishDrawer Diagnostics

DishDrawer Diagnostics can only be entered in Power Off mode, ie. When there is no display on the LCD or the

badge LED’s are off. Diagnostics is entered by holding the Keylock and Start/Pause buttons simultaneously for 5

seconds. Ensure that Keylock is pushed first.

There are currently four levels of diagnostics. To move to the next level push Power. To enter a level push

Start/Pause. Once a level has been entered, pushing Power will exit diagnostics completely. If no level is entered

then the display will cycle through the four levels and exit after the last. On entering diagnostic mode the first level is

the Display/Download Mode.

5.1.1 Display / Download Mode

In this mode all LED’s and LCD segments (except keylock) are illuminated.

5.1.2 Optical LED Download / Fault Display

An optical data download is available here to download all EE data to a PC or Palm PC via the lower tub-home

sensor light pipe. Hold the reader pen over the lower tub-home sensor light pipe and press Start/Pause to initiate

the download. A short beep indicates the start and finish of download.

In products manufactured before MEM741743, 21/5/03, the last two faults are displayed on the LCD (secondary

control panel LEDs for integrated models) during the optical download, the Current Fault code is displayed first

followed by the Previous Fault Code. To read the Fault Code on the secondary display for integrated and

prefinished products after MEM741743, refer to Section 7.1 on Fault Codes.

5.1.3 Clearing Fault Logs

To Clear the current Fault press the Keylock button until a beep is sounded. This action moves the Current Fault

into the Previous Fault while clearing the Current Fault. To Clear the Previous Fault press Keylock once more until

the beep is sounded.

Warning: Once a fault has been cleared, it is permanently removed from memory and cannot be recovered.

Press Power to advance to the next level.

5.1.4 Hardware Output Diagnostic Test Mode

This level tests all the hardware outputs and inputs. The LCD display shows ‘HO’.

Press Power to skip hardware diagnostics and advance to the next level.

Press Start/Pause to enter hardware diagnostics.

Once hardware diagnostics has been entered letters in the LCD display indicate the current hardware output being

tested and for integrated models the LEDs on the touch switch panel, using binary encoding, as shown in the table

on the next page.

Different combinations of outputs can be switched on or off together but the controller will prevent higher current

drawing components such as the wash pump and the lid motors being turned on together.

Press Start/Pause to advance to the next hardware output.

Press Keylock to turn the currently displayed output On or Off. If the scrubbing brush symbol (green LED above

start/pause button on integrated models) is displayed then that output has been switched on, and if it is not

displayed then that output is off.

- 20 -

Page 21

March 2004 Manual 599082

Press Power to Exit at any time (All outputs will be switched off on exit).

As mentioned above the LCD display and touch switch panel LED’s are illuminated to correspond to a particular

hardware device. The following table details the display order of the test.

LCD Norm Fast Deli Rinse Hardware Output

------------------------------------------------------------------------------------------bL Off Off Off On Backlight

Er Off Off On Off Element Relay

Ld Off Off On On Lid Motors (will run for 10 seconds)

dd Off On Off Off Detergent Diverter Valve

FU Off On Off On Fill Water Valve

P1 Off On On Off Motor Wash direction

(2300-2850 rpm)

P2 Off On On On Motor Drain direction

(4200 rpm)

rd On Off Off Off Rinse Aid Dispenser (dispenses

current setting)

dF On Off Off On Drying fan

LE On Off On Off Rinse Aid LED

C1 On Off On On Water Softener Diverter Valve

C2 On On Off Off Water Softener Brine Pump

°C On On Off On Displays current water

temperature.

°E On On On Off Displays controller rail voltage

(C3 is used in the Factory to empty the Water Softener before the Product is packed.)

WARNING : In diagnostic mode there is no component protection. Therefore take care when running individual

components not to overload them. It is advisable to avoid turning the element on without filling the tub with water

first.

NB : No Fault codes will come up while in diagnostics mode.

Tub Home Sensor Test: At any time during HO test mode the Keylock symbol on the LCD display (Keylock LED

on integrated badge) indicates the tub position. On = Closed, Off = Open.

5.1.5 Fast Test Cycle

WARNING : only run this cycle if connected to the water supply

This level runs a 5 minute fast test cycle.

Press Power to skip Fast Test Cycle and advance to the next level.

Press Start/Pause to enter Fast Test cycle.

Once Fast Test Cycle is selected the DishDrawer goes into standby mode and 5 minutes will be showing on the

display. The test cycle is started by pushing Start/Pause and the following components are run during the 5 minute

cycle that follows:- Lid motors, fill valve, wash motor, element, drain motor.

Press Power to Exit at any time.

5.1.6 Continuous Cycle Test Mode

In this level the DishDrawer can be run continuously in any wash cycle. Once the cycle has finished, the DishDrawer

automatically restarts the same wash cycle.

Press Power to skip Continuous Cycle. As this is the last level, doing this will exit diagnostics.

- 21 -

Page 22

March 2004 Manual 599082

Press Start/Pause to enter Continuous Cycle.

Once selected the LCD backlight flashes on and off to indicate the DishDrawer is in continuous cycle and the cycle

starts straight away (for integrated models the LED above the start/pause button will be orange instead of green to

indicate the DishDrawer is running in continuous cycle). It will run the last cycle that had been selected prior to going

into diagnostics mode.

If you wish to run a different cycle you need to exit diagnostics turn the DishDrawer on as normal and select the

cycle you want. Then turn the DishDrawer off again reenter diagnostics and restart the Continuous Cycle as above.

Press Power to Exit at any time.

Cycle Count Retrieval

(not available on integrated models)

To display the cycle count on the LCD screen, pause the DishDrawer while running a Continuous Cycle. The two

bytes of the cycle count will be displayed alternately, in syncronisation with the changing backlight.

The Low byte is displayed when the backlight is Off.

The High byte is displayed when the backlight is On.

To calculate the Total DishDrawer cycle count use the formula below.....

Cycle_Count = (200 x High_byte) + Low_byte.

Eg. Low_byte = 156

High_byte = 2

Cycle_count = (200 x 2) + 156 = 556.

5.1.7 Temperature & Voltage Display Mode

(not available on integrated models)

During a wash cycle, the current water temperature or the power supply rail voltage of the controller can be

displayed on the LCD instead of the time remaining. To enter temperature/voltage display mode, start a wash cycle

as normal. Initiate a keylock by pushing and holding the Keylock button for 4 seconds.

Once in keylock mode push and hold Start/Pause for 8 seconds to enter temperature display mode. The display

now alternates between a °C symbol and the water temperature. Pressing the Start/Pause again changes the

display to alternate between an °E symbol and the power supply rail voltage of the controller.

To cancel temperature/voltage display mode, press the Power button.

5.1.8 Show Off / Showroom Wash Mode

This mode initiates a shop show off display and wash operation demonstration.

With the DishDrawer powered up and turned on the show off mode is entered by holding the Eco and Power

buttons simultaneously for 5 seconds. Ensure that Eco is pushed first.

The DishDrawer is now in the Show Off mode and cycles through all of the LED & LCD segments while pulsing the

LCD backlight on and off.

Pressing the Power button now puts the DishDrawer into the Showroom Wash mode. Before running this mode the

tub should be filled with water until it is just touching the underside of the spray arm. The Showroom Wash is started

by pushing the Start/Pause button whereby the following cycle is run:The lid is pulled down

The wash motor starts and runs for 4 minutes

The wash motor stops.

- 22 -

Page 23

March 2004 Manual 599082

The lid is lifted

The display counts down to zero throughout this cycle

The DishDrawer turns off at the end of this cycle.

The DishDrawer is still in the Showroom wash mode however and it can be re-run by pushing Power and then

Start/Pause. Once Show Off/Showroom Wash mode has been initiated, the mains power must be removed to exit

out.

- 23 -

Page 24

March 2004 Manual 599082

6.0 DIAGNOSTICS QUICK REFERENCE CHARTS

6.1 Fault Display/Download Mode:-

Press and hold Keylock, then Start/Pause for 5 seconds

All LEDs & LCD segments except Keylock are illuminated

Press Start / Pause

This initiates Pen upload via lower tub-home light pipe. At the same time the current and then the previous fault code

will be displayed in the LCD screen & on the secondary control panel LEDs. To read the fault code on the

secondary display refer to Section 7.1 on Fault Codes.

Press Keylock

This will clear current fault code. Note if you press Keylock again you will remove the previous fault

Press Power

To exit

6.2 Hardware Output Test Mode:-

Press and hold Keylock, then Start/Pause for 5 seconds

All LEDs & LCD segments except Keylock are illuminated

Press Power Button Once

HO will show in the display (integrated: Heavy, Normal, Fast, Delicate, Rinse LEDs showing)

Press Start/Pause

Scroll through the following outputs using Start/Pause. Turn the outputs on & off using Keylock button.

Press Power

To exit

Note: Scrubbing Brush = output on, No Scrubbing Brush = output off (on integrated models a green LED above the start/pause button is

used inplace of the scrubbing brush)

LCD Norm Fast Deli Rinse Hardware Output

Display LED LED LED LED

-------------------------------------------------------------------------------------------

bL Off Off Off On Backlight

Er Off Off On Off Element Relay

Ld Off Off On On Lid Motors (will run for 10 seconds)

dd Off On Off Off Detergent Diverter Valve

FU Off On Off On Fill Water Valve

P1 Off On On Off Motor Wash direction (2300-2850 rpm)

P2 Off On On On Motor Drain direction (5000 rpm)

rd On Off Off Off Rinse Aid Dispenser (dispenses current setting)

dF On Off Off On Drying fan

LE On Off On Off Rinse Aid LED

C1 On Off On On Water Softener Diverter Valve

C2 On On Off Off Water Softener Brine Pump

°C On On Off On Displays current water temperature.

°E On On On Off Displays controller rail voltage

Tub Home Sensor test:- keylock symbol on = tub closed, off = tub open

- 24 -

Page 25

March 2004 Manual 599082

6.3 Fast Test Cycle:-

Press and hold Keylock, then Start/Pause for 5 seconds

All LEDs & LCD segments except Keylock are illuminated

Press Power Button Twice

FC will show in the display (integrated: Heavy, Normal, Delicate, Rinse LEDs showing)

Press Start/Pause Twice

The 5 minute fast test cycle will start

Press Power

To exit

6.4 Continuous Cycle:-

Press and hold Keylock, then Start/Pause for 5 seconds

All LEDs & LCD segments except Keylock are illuminated

Press Power Button Three times

CC will show in the display (integrated: Heavy, Normal, Rinse LEDs showing)

Press Start/Pause

The last cycle that had been selected prior to going into diagnostics mode will be run continuously

Press Power

To exit

6.5 Temperature & Voltage Display Mode:-

(not available on integrated models)

Start a wash cycle running

Press & hold Keylock for 4 seconds

Keylock will be activated

Press & hold Start/Pause for 8 Seconds

LCD will now alternate between °C symbol & the water temperature

Press Start/Pause

LCD will now alternate between °E symbol & the controllers rail voltage

Press & hold Keylock for 4 seconds

Keylock is deactivated

Press Power

To exit

- 25 -

Page 26

March 2004 Manual 599082

7.0 FAULT CODES

The faults are displayed in the LCD as one of 5 F (fatal) faults or 1 U (user) fault along with the symbol of a spanner.

A fatal fault will usually require the assistance of a qualified service person, while a U1 user fault indicates the

machine had failed to prime within a certain length of time usually because the tap has not been turned on. For this

reason at the same time a U1 comes up in the display we also show the symbol of a tap. In the Integrated models,

an LCD is not available, and the presence of a fault is indicated by a Red center LED, with the fault number

indicated on the touch switch panel with Red LED’s.

Once a fault is repaired it can be cleared by pressing the Power button. If the fault is still present then it will not

clear.

A fatal or user fault is accompanied by a continuous pulsating beep which can be turned off by pressing either the

power, start/pause, or key lock button.

The last two faults are logged into EE memory.

The other U (user) faults have been removed. The old U2 fault, which was the tub forced open during a cycle, has

been removed completely. Instead if the tub is forced open the product simply pauses as if someone had pressed

the start/pause button. The old U3 fault, which indicated a failure to drain i.e. water left in the tub, will not show up a

fault and the DishDrawer will continue through the cycle.

- 26 -

Page 27

March 2004 Manual 599082

7.1 Fault Code Description Chart

The following chart is a quick reference guide on fault codes. To read a fault code off an integrated model, or

prefinished products after MEM741743, refer to the LED Display column on the chart below. The LED that has

activated on the secondary display indicates which fault code has occurred.

Fault Code LED Display Fault Possible Causes

F1 Rinse LED The flood switch has

been activated for

more than six seconds

F2 Delicate LED The motor has not

been sensed rotating

F3 Delicate and

Rinse LED

F4 Fast LED No temperature

F9 Normal and

Rinse LED

U1 Heavy and

Rinse LED

The water temperature

has been sensed at

greater than 85°C

(185°F)

increase has been

sensed for 2 hours

while the element is

on

Electronics Failure

Machine has failed to

prime with water within

approx. 3 minutes

· Inlet hose to inlet valve connection loose

· Inlet valve body leak

· Damage to the fill or drain hoses

· Heater plate damage (chipped enamel)

· Seals/O Rings (pinched, contaminated or poor join)

· Dispenser (seal, diverter valve or weld leak)

· Lid area (lid motors not functioning correctly, lid off

yoke or foreign object interfering with lid seal)

· Foreign object has jammed the rotor

· The rotor has failed

· The hall sensor has failed

· The electronic controller has failed

· The incoming water is greater than 85°C (185°F)

· The element has failed closed circuit

· The temperature sensor has failed

· The electronic controller has failed

· The element is not connected

· The element has failed open circuit

· The temperature sensor has failed

· The electronic controller has failed

· The electronic controller has failed

· The water supply is not turned on

· The machine is syphoning

· The spray arm is not in place

· Excessive foaming

· The Inlet Valve has failed

· The electronic controller has failed

· Rotor not fitted correctly

- 27 -

Page 28

March 2004 Manual 599082

7.2 Fault Code Problem Solving Charts

The following charts can be used as a guide to help locate faults in a DishDrawer. Answer each question with a yes

or no and follow the instructions inside the relevant box.

F1 The flood switch has been activated for more than 6 seconds

Question Yes No

1 Is there a F1 on both displays? Go to Question 2 If power fails to the bottom tub it will cause the

top tub to go F1. Test heater plate.

2 Has a flood occurred? (N.B.

The flood may have dried up)

3 Is the lid sealing on the tub

correctly?

4 Are the lid actuators

functioning correctly?

5 Is the water level in the tub

high?

6 Is the water inlet valve leaking? Replace inlet valve Go to Question 7

7 Is the DishDrawer priming

correctly?

8 Is the spray arm split? Replace spray arm Go to Question 9

9 Is the spray arm running

freely?

10 Is water leaking from a split

inlet or drain hose?

11 Is water leaking around the

heater plate ‘O’ rings?

12 Is the drain hose blocked? Clear drain hose of

13 Is there condensation or

foreign matter around the flood

switch PCB?

14 After clearing water does the

F1 fault code still activate?

15 Refer to Bulletin DW028 DW025, 028, 031, 040

Go to Question 3 Go to Question 13

Go to Question 5 Go to Question 4

Go to Question 5 Check the lid actuators are assembled

correctly on the slides and yokes. Check the

plugs on the RFI board and the terminals on

the lid motors. If the lid actuators look slow

replace them.

Go to Question 6 Go to Question 8

Go to Question 12 Go to Question 8

Go to Question 10 Check the rotor is running freely, clear of

foreign objects and fitted correctly. Make sure

the wash impeller is not slipping off the rotor

shaft

Replace split inlet or

drain hose

Replace or refit ‘O’ rings Go to Question 12

blockage

Clear flood sensor of

condensation or foreign

matter

Replace Chassis RFI

board

Go to Question 11

Go to Question 13

Go to Question 14

Go to Question 15

- 28 -

Page 29

March 2004 Manual 599082

F2 The motor is not sensed to be rotating

Question Yes No

1 Is the rotor jammed? Free jammed rotor, check for

foreign object damage to rotor

and rotor housing.

2 Does the stator wiring from the

controller test okay?

3 Do the stator windings show the

correct resistance?

4 Is the hall sensor clipped into the

stator housing correctly? Is the

sensor plugged into the controller

with a good connection?

5 Hall sensor fault? Replace hall sensor Go to Question 1

F3 Water temperature sensed at greater than 85°C ( 185°F)

Question Yes No

1 Is the incoming water temperature

greater than 85°C (185°F)

2 Is the element on all the time? Replace the electronic

3 Are the wiring and connections

from the controller to the element

all okay?

4 Are there any signs of moisture

around the temperature sensor?

5 Is the resistance of the

temperature sensor correct?

6 Does the machine fault again if run

through a test cycle?

Go to Question 3 Replace wiring harness or repair

Go to Question 4 Repair or replace stator as required

Go to Question 5 Clip hall sensor into stator housing

Adjust the incoming water

temperature.

controller

Go to Question 4 Repair or replace wiring harness or

Locate and repair source of

leak

Go to Question 6 Replace heater plate assembly

Go to Question 1 No fault found

Go to Question 2

faulty connections.

or repair wiring connection at

electronic controller.

Go to Question 2

Go to Question 3

wiring connections

Go to Question 5

- 29 -

Page 30

March 2004 Manual 599082

F4 No temperature increase has been sensed while the element is turned on

Question Yes No

1 Does the element heat in diagnostics? Go to Question 7 Go to Question 2

2 Test the resistance of the heater

element using the connection on the

controller, is it correct?

3 Is the connection on the controller

okay?

4 Electronic controller failure? Replace electronic controller Go to Question 1

5 Are the wiring and connections from

the controller to the element all okay?

6 Is the resistance of the heater

element correct?

7 Is the resistance of the temperature

sensor correct?

8 Are the wiring and connections down

to the temperature sensor okay?

9 Heater element failure? Replace heater plate Go to Question 1

Go to Question 3 Go to Question 5

Go to Question 4 Replace or repair connection

Go to Question 6 Repair or replace wiring harness

or wiring connections

Go to Question 7 Replace heater plate

Replace electronic controller Go to Question 8

Go to Question 9 Replace or repair wiring harness

or wiring connections

F9 Electronics failure (EEPROM access error)

Question Yes No

1 If the DishDrawer is isolated from the

power supply for 10 seconds, does

the fault clear?

2 Electronic controller failure? Replace electronic controller Go to Question 1

No fault found Go to Question 2

- 30 -

Page 31

March 2004 Manual 599082

U1 DishDrawer failed to prime with water within approx. 3 minutes

Question Yes No

1 Is the tap turned on? Go to Question 2 Turn the tap on

2 Is the spray arm in place? (spray arm

may have been refitted since U1 fault

occurred)

3 Activate the water inlet valve in

diagnostics. Does any water enter

the machine?

4 Is the impeller on the rotor slipping? Replace the rotor Go to Question 5

5 Is the supply water pressure above

30Kpa (4.3p.s.i)?

6 Are the inlet water hoses and valves

free of any blockages or obstructions?

7 Is the resistance of the water inlet

valve measured at the plug on the

controller correct?

8 Is there 24V DC coming from the

controller during the water inlet valve

test?

9 Are the wiring and edge connections

down to the water inlet valve okay?

10 Water inlet valve failure? Replace water inlet valve Go to Question 11

11 Is the Rotor fitted correctly? Go to Question 1 Refit Rotor

Go to Question 3 Refit spray arm

Go to Question 4 Go to Question 7

Go to Question 6 The DishDrawer requires a minimum

water pressure installation of 30Kpa

(4.3p.s.i)

Go to Question 10 Clear the water valves or hoses of

blockage or obstruction

Go to Question 8 Go to Question 9

Go to Question 6 Replace the electronic controller

Go to Question 10 Replace or repair wiring harness or

wiring connections

- 31 -

Page 32

March 2004 Manual 599082

7.3 Poor Dry Performance

Poor Dry Performance

Question Yes No

1 Is the customer complaining of

plastic items not drying?

2 Is the customer using rinse

aid?

3 Is the customer using Fast or

Eco cycles

4 Is the rinse aid setting high

enough for the water hardness

in the area?

5 Using diagnostics test the

dispenser. Is it dispensing the

correct amount of rinse aid?

Advise customer that due to plastics

having a low thermal mass these

items give inherently bad drying

performance

Go to Question 3 Advise customer that the use of

Advise customer that due to lower

final rinse temperatures dry

performance is comprised when

using Fast and Eco cycles (there is

less residual heat for drying at the

end of cycle)

Go to Question 5 Turn the rinse aid up to a higher

Go to Question 1 Replace dispenser

Go to Question 2

rinse aid will improve dry

performance

Go to Question 4

setting

7.4 Poor Wash Performance

Customers Complaint Food Particles left on Dishes

Cause of problem (1)

How to resolve the

problem

Cause of problem (2)

How to resolve the

problem

Cause of problem

(3)

How to resolve the

problem

Spray arm has stopped rotating.

a) One of the dishes / cutlery / utensils has fallen through the basket and jammed

the spray arm, remove the obstruction.

b) Filter plate, drain filter, or drain filter access panel is not installed correctly and is

causing the spray arm to jam.

The product is being over loaded or incorrectly loaded with dishes.

Advise customer of correct loading.

Customer is selecting the wrong wash cycle for the soil level on the dishes.

Advise customer about reduced water temperatures (up to 20ºC / 70°F lower) and

wash times when using Fast and Eco cycles.

- 32 -

Page 33

March 2004 Manual 599082

Customers Complaint Coffee/Tea Stains left in Cups

Cause of problem

(1)

How to resolve the

problem

Not enough detergent being used. To remove these stains requires a stronger

concentration of detergent in the water.

More detergent is also required in hard water areas as minerals in the hard water

reduce the effectiveness of the detergent.

Fill the main-wash detergent cup to the top & for best results also fill the pre-wash

detergent cup. Run on normal or heavy cycles not Eco.

Cause of problem (2)

How to resolve the

problem

The product is being over loaded which is preventing water reaching the cups on the

upper cup racks.

Advise customer of correct loading.

Customers Complaint Dishes have blotchy marks on them that look like water stain

marks not food

Cause of problem

How to resolve the

problem

Not enough rinse aid being used. The water is not soft enough during the final rinse

and therefore hard water droplets containing impurities are drying on the dishes

instead of running off during the dry cycle.

Confirm that the customer is using rinse aid.

The rinse aid may need to be turned up to a higher setting (4 or 5 lights) and for

optimum dry performance run the DishDrawer on normal or heavy cycles not Eco.

Check that the rinse aid dispenser is dispensing correctly in diagnostics.

Customers Complaint Glasses & Cutlery have a Cloudy White film on them and/or Plates

have a White Chalky film on them

Cause of problem

How to resolve the

problem

Hard water & not enough detergent being used. Minerals from the water are building

up on the dishes or the Water Softener is not set to the correct Water Hardness

Level or is faulty.

Once this film forms on the dishes it cannot be removed by normal running in the

dishwasher. The dishes will need to be cleaned by soaking them in an acidic

solution such as white vinegar and water.

Where a Water Softener is not fitted;

To prevent the build up re-occurring the customer will need to fill both the main-wash

& pre-wash detergent cups to the top with a power detergent and we would

recommend running on normal cycles.

In problem areas with very hard water the customer may need to use a detergent