Fisher & Paykel DD603-88269, DD603-88270, DD603-88445-B, DD603FC-88449, DD603FC-88449-B Installation Guide

...

part number526607 N

Drawer

INSTALLATION INSTRUCTIONS

(NOTE:FOR INTEGRATEDPANELPREPARATIONINSTRUCTIONSREFERTOSUPPLIEDSHEET)

05/2005

(page1 ot 12)

DOUBLEDDC03 MODELS

DD603 PREFINISHED(shown left)

DD603 FLATDOOR(not shown)

DD6031 INTEGRATED(shown right)

NOTE TOTHEINSTALLER

1. Readthese instructions completely and carefully.

2. Installation of this DishDrawer® requires basic

mechanical and electrical skills.

3. Be sure to leave these Instructions with the Customer.

4. At the completion of the DishDrawer® installation, the

Installer must perform Final Check List as per Section 12

of these Installation Instructions.

5. Remove all packaging materials supplied with the

DishDrawer®.

6. This dishwasher is manufactured for indoor use only.

NOTE TOTHECUSTOMER

Keep these Installation Instructions with your User Guide

for future reference, TheDishDrawer® must be securely

anchored before it is operated,

S_NGLE#$603 MO#ELS

I}S(O;_ PI_tttINI',<Ut[}(',_h>v/l_k.#t)

DS603 FLAFDOOROsotshown)

DS6031 INIEGRAIED (sh>wl_light)

i_XWARNING!

Before installingthe DishDrawer® , remove thehouse fuseor open

the circuit breaker.Ensure all water connectionsare turnedOFF. It is

the responsibilityof theplumber and electricianto ensurethat each

installationcomplieswith all CodesandRegulations.

Important!

Theseinstructionsmustbe followed precisely toensure correct

venting andoperation ofthe DishDrawer@. In the event ofa fault

related tothe incorrectinstallation, theinstaller will be liable for any

repairs.

Important!

TheDishDrawer® MUST be installed toallow for futureremoval

fromthe enclosure if serviceis required.

Important!

Improperinstallationis not covered underthe Warranty.

Important!

If the DishDrawer® is to be relocated fromone installationto

anotherit mustbe keptuprightto avoid damagefrom water spillage.

,,- BEFOREYOUSTART- DOUBLE& S/NG£E MODELS

|_ft_k"]!,_lP.,P.,ill.'ll]

r

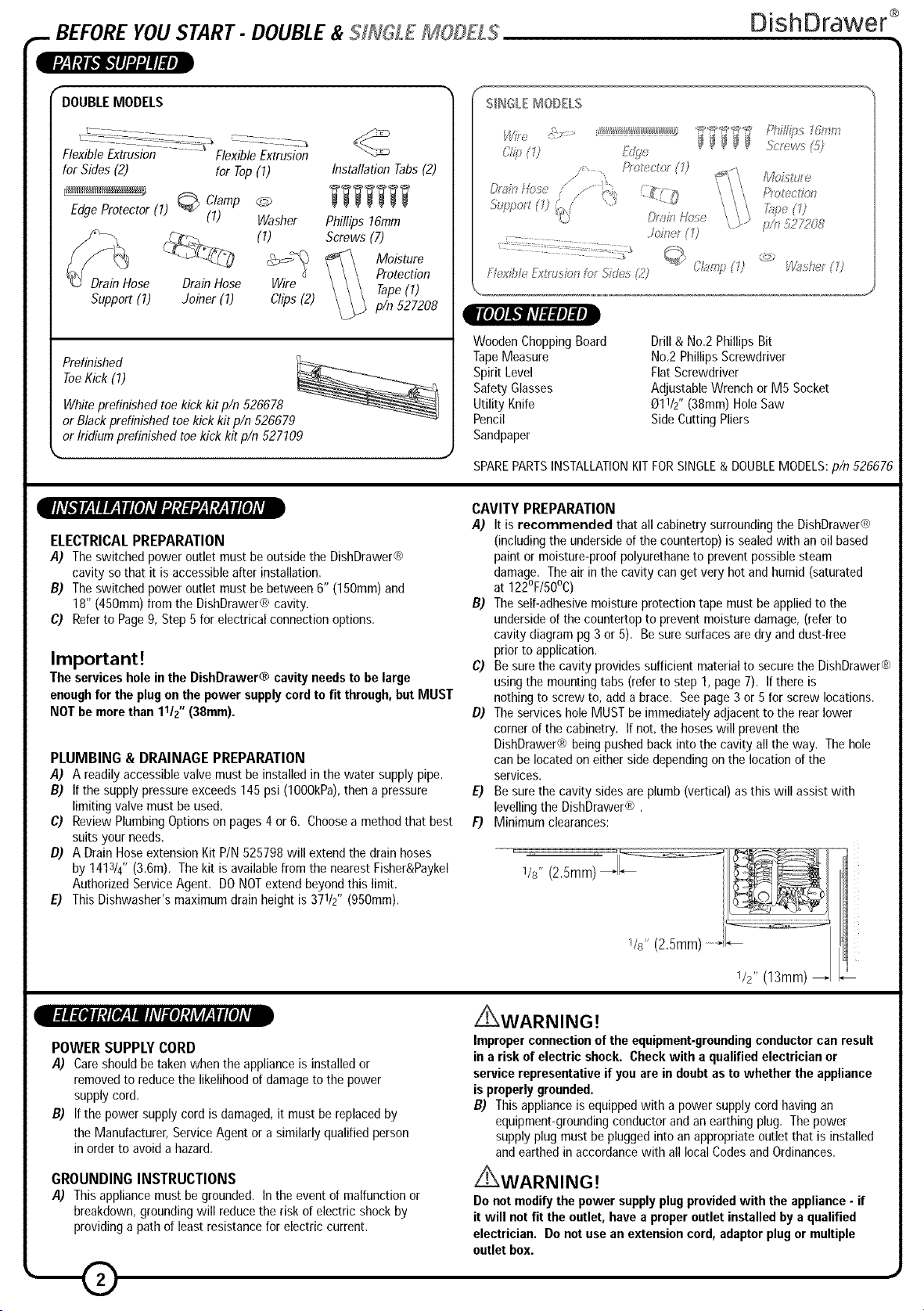

DOUBLEMODELS

F

%NGLEMODELS

DishDrawer ®

E_.... : ......... __ _ ...........

FlexibleExtrusion FlexibleExtrusion

forSides (2) for Top(7)

EdgeProtector (7)

Clamp

(7) Washer

@)

Installation Tabs(2)

Phillips 76mm

Screws (7)

Moisture

Drain Hose DrainHose Wire

Support (7) Joiner (7) Clips(2)

Protection

Tape(1)

p/n 527208

ToeKick (I)

Prefinished

Whiteprefinishedtoe kick kit pin 526678

or Blackprefinished toe kickkitpin 526679

or Iridiumprefinished toekick kit pin 527109

• J

lllVk_lP.fl l,.lll [llArl ,.Itlll ,.i,.It!,.lll[lllv|

ELECTRICALPREPARATION

,4) Theswitched power outlet mustbe outsidethe DishDrawer®

cavity so that it is accessibleafter installation,

B) Theswitched power outlet must be between 6" (150mm)and

18" (450mm)from the DishDrawer® cavity.

¢) Referto Page9, Step5for electricalconnectionoptions,

Important!

The services hole in the DishDrawer® cavityneedsto be large

enoughfor the plugon the power supply cordto fit through,but MUST

NOTbe morethan 11/{' (38ram).

PLUMBING & DRAINAGE PREPARATION

,4) A readilyaccessiblevalve must be installed in the water supply pipe.

B) If the supplypressureexceeds145psi (lO00kPa),then apressure

limiting valvemust be used,

C) Review PlumbingOptionson pages4 or6. Chooseamethodthat best

suitsyour needs,

D) A DrainHoseextension KitP/N525798 will extendthe drainhoses

by 1413/4"(3,6m), Thekit is availablefrom the nearestFisher&Paykel

AuthorizedServiceAgent, DONOTextend beyondthis limit,

E) This Dishwasher'smaximumdrain heightis 37//2" (950mm).

iMm <::' !!!!!!!!!!!!!!!!I_=_'_=_'"_'"_"_";'Phillips 1ram

[tolllo_ (1)

L}_aklllos_

Pm ction

Iq_x%I Exuz s_o,_Ic>_Skl s (?)

I[eIe]!._r#lIlln]llnJ

Wooden Chopping Board

Tape Measure

Spirit Level

Safety Glasses

Utility Knife

Pencil

Sandpaper

SPAREPARTS INSTALLATION KIT FORSINGLE& DOUBLE MODELS: pin 526676

CAVITY PREPARATION

,4) It is recommended that all cabinetry surroundingthe DishDrawer®

(includingthe undersideof the countertop)is sealedwith anoil based

paintor moisture-proofpolyurethaneto prevent possiblesteam

damage, Theair in the cavity can get very hot andhumid(saturated

at 122°F/50°C)

B) Theself-adhesivemoisture protection tape must beappliedto the

undersideof the countertopto preventmoisture damage,(referto

cavity diagram pg 3or 5), Besure surfacesaredry and dust-free

prior to application.

C) Be surethe cavity providessufficient materialto securetheDishDrawer®

using the mountingtabs (referto step 1, page7). Ifthere is

nothing to screw to, add a brace. Seepage3 or 5 for screw locations,

D) The servicesholeMUST be immediatelyadjacent to the rearlower

cornerof the cabinetry, If not, the hoseswill preventthe

DishDrawer® being pushedback into the cavityallthe way, Thehole

can belocated oneither side dependingon the location of the

services.

E) Be surethe cavity sidesare plumb (vertical)as this will assistwith

levellingthe DishDrawer®,

F) Minimum clearances:

Vs" (2,5mm)LIL

Drill& No.2Phillips Bit

No,2Phillips Screwdriver

FlatScrewdriver

AdjustableWrenchor M5 Socket

011/2" (38mm)HoleSaw

SideCutting Pliers

e___lV.,'[_Jltl[_f|llVl,fl]tlA_V.,ll[IAw

POWER SUPPLY CORD

,4) Care should be taken when the appliance is installed or

removed to reduce the likelihood of damage to the power

supply cord,

B) If the power supply cord is damaged, it must be replaced by

the Manufacturer, Service Agent or a similarly qualified person

in order to avoid a hazard,

GROUNDING INSTRUCTIONS

,4) Thisappliancemust begrounded. Inthe event of malfunctionor

breakdown,groundingwill reducethe risk of electric shock by

providinga pathof leastresistancefor electriccurrent.

1/s" (2,5mm)

V2" (13mm)

Z_WARNING!

Improperconnectionof the equipment-groundingconductorcan result

in a risk of electric shock. Check with a qualifiedelectricianor

servicerepresentativeif youare indoubtas towhether the appliance

is properlygrounded.

B) Thisapplianceis equippedwith a power supplycord having an

equipment-groundingconductorand an earthingplug, Thepower

supply plug mustbe pluggedinto an appropriateoutlet that is installed

andearthedin accordancewith all local CodesandOrdinances,

Z_WARNING!

Donot modifythe power supplyplugprovidedwith the appliance- if

it will not fit the outlet, havea properoutlet installedby a qualified

electrician. Do notusean extensioncord,adaptorplugor multiple

outletbox.

,._ DOUBLEMODELS

DishDrawer ®

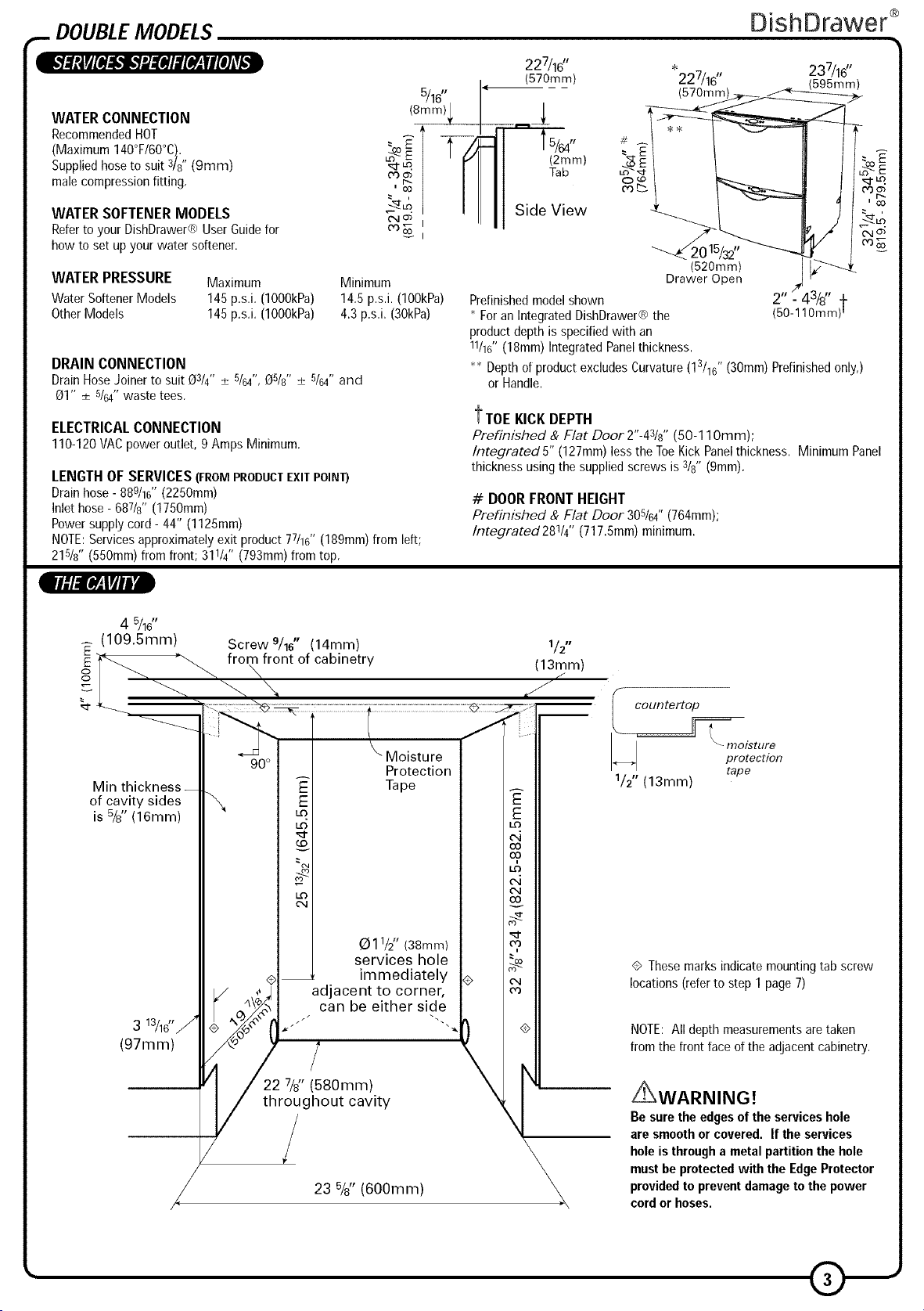

WATER CONNECTION

RecommendedHOT

(Maximum140°F/60°C).

Suppliedhoseto suit 3/8"(9ram)

malecompressionfitting,

WATER SOFTENER MODELS

Referto your DishDrawer®UserGuidefor

how to set upyour water softener.

WATER PRESSURE

WaterSoftenerModels

OtherModels

DRAIN CONNECTION

DrainHoseJoiner to suit 03/4" _+ 5/64", 05/8" + 5/64" and

_31"_+5/64"waste tees,

ELECTRICALCONNECTION

110-120VACpower outlet, 9 Amps Minimum,

LENGTH OF SERVICES(FROMPRODUCTEXITPOINT}

Drainhose- 889/16" (2250mm)

Inlet hose- 687/8"(I 750ram)

Powersupplycord- 44" (l125mm)

NOTE: Services approximately exit product 77/16" (189mm) from left;

215/8" (550ram) from front; 311/4'' (793mm) from top,

Maximum

145p,s.i, (1000kPa)

145p,s,i, (1000kPa)

Minimum

14,5 p,s,i. (lOOkPa) Refinished modelshown

4,3 p.s.i, (30kPa)

Vl#ll _lrJll'd

5/16- I_-

mm/ I,

* Foran IntegratedDishDrawer® the (50-1lOmm)

productdepth is specifiedwith an

11/16" (18mm)IntegratedPanelthickness.

*_ Depthof productexcludes Curvature(13/16,, (30mm)Prefinishedonly,)

t TOE KICK DEPTH

Prefinished & Flat Door 2"-43/8"(50-110mm);

Integrated 5" (127mm) lessthe ToeKick Panelthickness. Minimum Panel

thicknessusingthe suppliedscrews is 3/8"(gmm).

# DOOR FRONT HEIGHT

Prefinished & Flat Door 305/64" (764mm);

Integrated 281/4'' (717.Smm)minimum.

227/16"

(570mm)

Side View ° __2015/_,,_ _ :

or Handle.

"227/16" 237/16"

(570turn) _

(520rnm) k-"'----_

Drawer Open

2" _ _3/8" _

_Lo

4 5/16"

(109.5mm)

Min thickness

of cavity sides

is 5/8" (16ram)

3 13/16_'/

(97mm)

Screw 9/16" (14mm)

from front of cabinetry

\

. can be either side

i adjacent to corner,

Moisture

Protection

Tape

011/2" (38mm)

services hole

immediately

1/2"

(13mm)

countertop

1/2" (13mm)

Thesemarksindicate mountingtab screw

locations(referto step 1 page 7)

NOTE: All depth measurements are taken

from the front face of the adjacent cabinetry.

22 7/8" (580mm)

throughout cavity

/

23 %" (600mm)

Z_WARNING!

Be sure the edgesof the services hole

are smooth or covered. If the services

holeis througha metal partitionthe hole

must be protectedwith the EdgeProtector

providedto preventdamageto the power

cord or hoses.

._ DOUBLEMODELS

1_'21Oh_lXfld[efe]Ml[e]=vi,1

DishDrawer ®

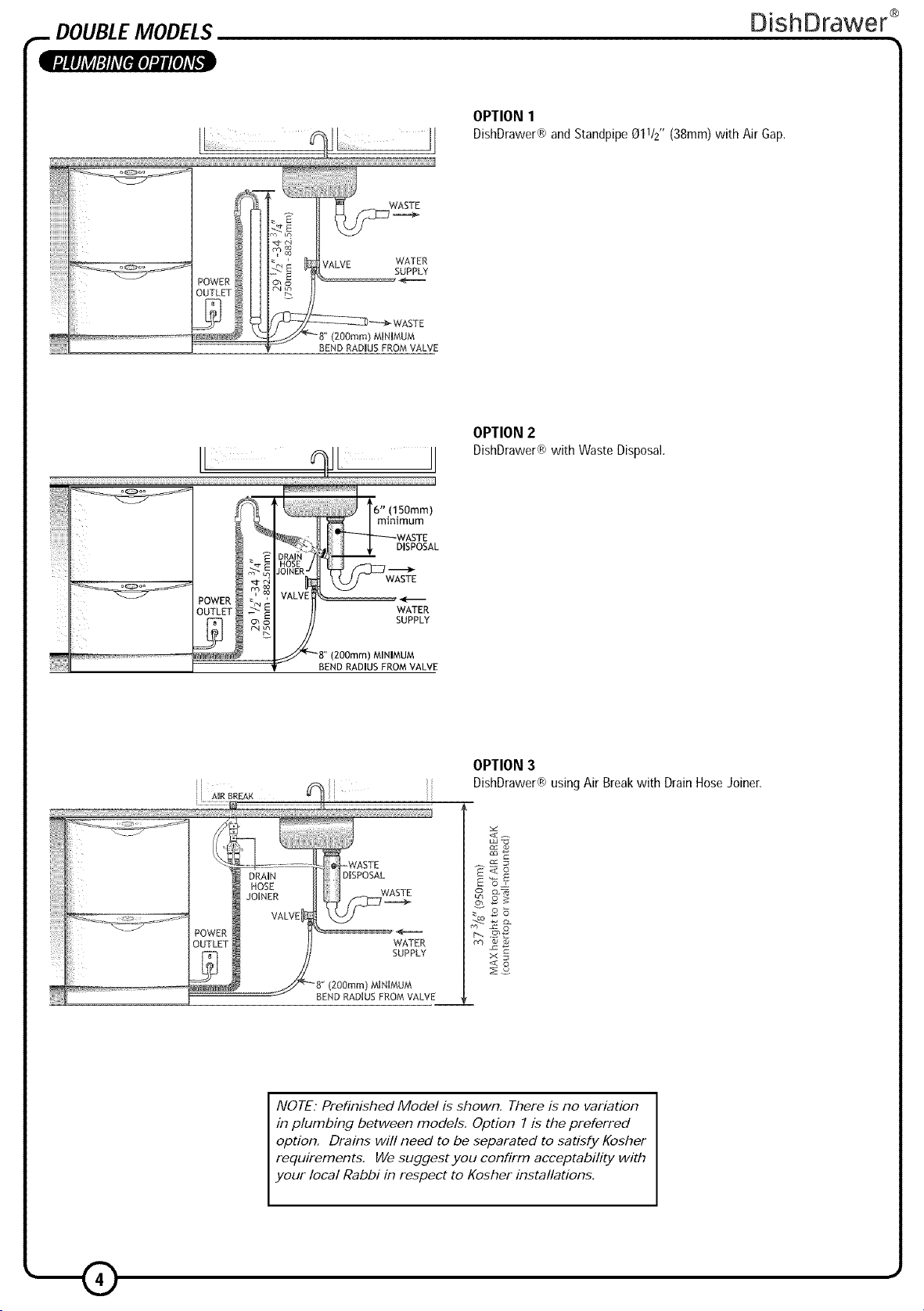

OPTION1

DishDrawer®andStandpipe011/2"(38mm)with AirGap,

VALVE WATER

BEND RADIUS FROM VALVE

SUPPLY

MINIMUM

II qll JI

]

minimum

DISPOSAL

WASTE

WATER

SUPPLY

BEND RADIUS FROM VALVE

MINIMUM

OPTION 2

DishDrawer®with Waste Disposal.

ii _uRBREAK _i ii

OUTLET _ H WATER

NOTE." Prefinished Model is shown, There is no variation

in plumbing between models, Option 1 is the preferred

option, Drains will need to be separated to satisfy Kosher

requirements, We suggest you confirm acceptability with

your local Rabbi in respect to Kosher installations,

OPTION 3

DishDrawer® usingAir Breakwith DrainHose Joiner,

_J _o

x

< o

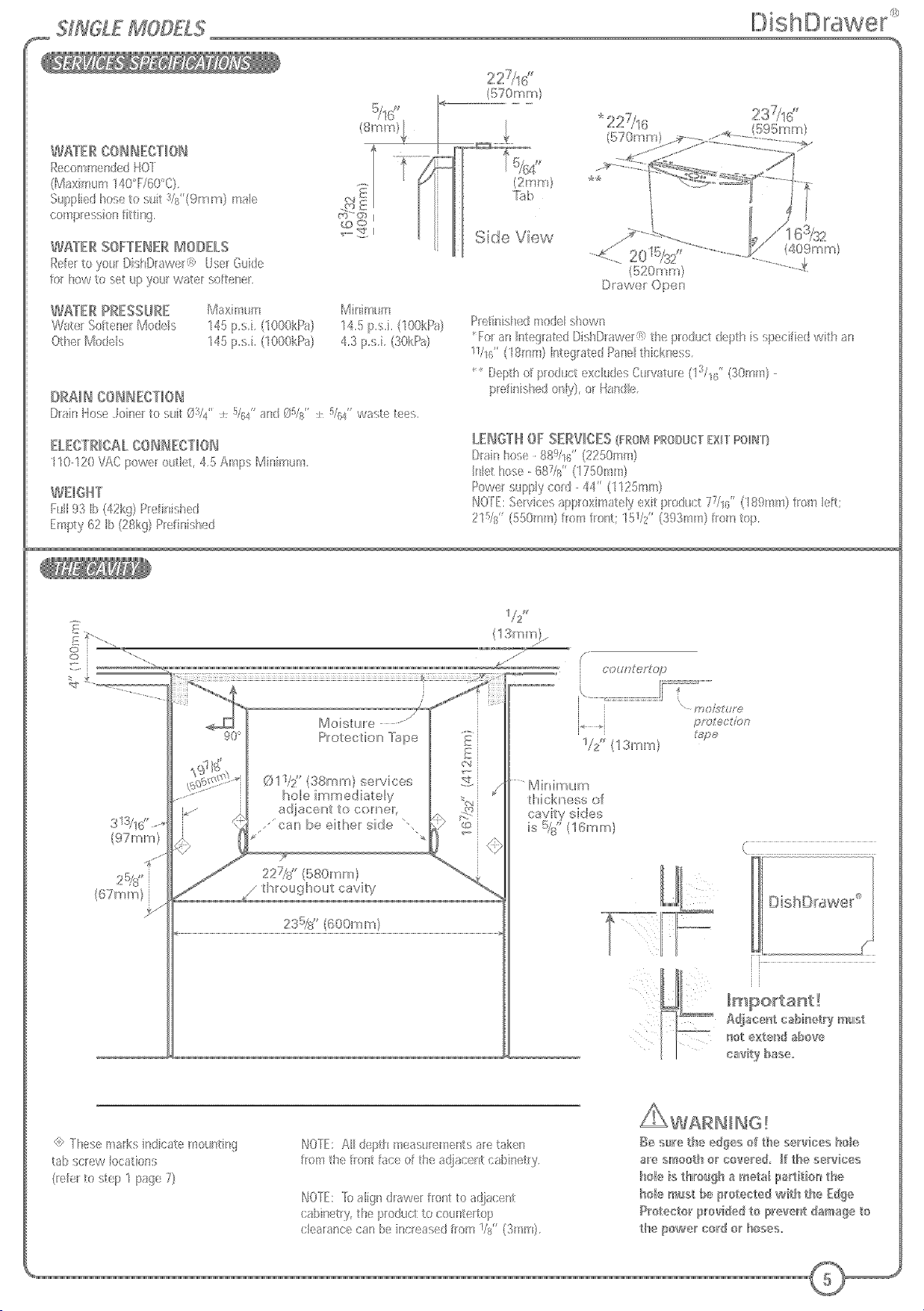

5J£6££ MOD£ZS

t8 n n!l

WAYER COIIECTIOI

Rcco iicrSc'd IiOl

(l!laxi _ _ 140T160°0},

S pplkd Noseto s(_its/s'(9mm) m _

co npressos ftsg,

WKIER SOFTEIER IIOOELS

RI toyo_ U;;rQi£

for New Re set llll yolff vvatl, r sell Isi._[.

WATER PRESSURE Mxnm /\Aili s m

WaI:_r So I .'Ier Mo:es "145p.s.. ("(I)kFa 14,5 [,,, ("00kFa

OIer I/Io:I;I'> 145 p/>,i, (1000kP_} 4,3 p,;,i, (30kPa)

ORAII COIIECTIOI

/)rialto,:>) oira to'>_i: 01/,_ ' ,i ..... s ' ,i "]6¢ ;[d (/_]s ]6¢ w_sle I )s,

ELECTRICALCOIBIECTIOI

110-120//\C pewc i ll(t, 4.F}Arlp Mir_im_n,

WEIQHT

Ill 93 II (A2kg}P dmiaIed

Enp:y 62 Ib(28kg} Pr ;fisi ;l_:d

.,: (2 m!

_o <,]>I

@ 0

"=_'_ Side View

%

(570_ r_ )

(520_ m)

D a /v{ ' ()per

P elir_is ed _od_l sows

Fela_Btegrae OsOrawer@ epro( ctdept ssp_cifeSwt a_

WI6' (18is} Isteglated Pas(I t ckses ;,

O<pt o pod c exc_ld(sC P,fa r( (s/s6' (30sn)-

pr<l _shed only}, or i18sdle,

LE/QTH OF SERVICES (F[_OMPtOOUC/EXl/ PO/_/

Olas hose 880/10, (2250s m)

Ikt hose-68Vs" ( ;G()mO

Powe sppy ce_: 44' (1125mm)

_>.,_Oll:Sep,/cesappo_na_ly._x pod{ /V%'('89mm losblt;

21%" (£;0 nn from lost; I!P/i' (393mm)los op,

(97mm)

{67mm)

IVIoisIu_e ..... /

ProIecdon I pe

©11//' {38ram} services

hole hnmediaIely

adjacer_I _o c )met,

," car_ be eiIher side

/ ......

OO M? e/q{}tI}

}

/

2 (13ram

mAs'tte

protecIio

t_Voe

....IVlhAmum

Ihick_/ess of

(Z] ZZZZZZZZZZZS

G Yles( I'{Iksindicte no_:i_g

I ) SCIIW loc os,

_f;rto :;l_p I Ig_ 7}

I',,/0[E: AI :ep:: teas r_re/tsaretak)rl

ton t e llosl lac(: el I e a:acelt caDis)ty

I',,_0[E:B_align:IIawe fro_: to ;di_{e :

<aline:y, hei ode:Rio

ce_ia_e :a_b_ ncr_as(/l_n gs'(3rs},

AwARslsQ!

Be s_e th_ edges of tie sei_@ses hob

a_'e smooth e_ co_e_ed. If the services

}_ole is thlr'o_gh a ir_elal ipa_tit olr_the

_ole mist Ir_eI_'otected with the Edge

P_otecto_'/£ovided to II)_'evelr_tdamage to

the/powe_ co_'d o_ Boses.

WASTE

WASYF

51:ND RAVqU f::K(}M VALVE

MINIMUM

OPTION1

S n_:pp @lV2"(38nn)wi Ar()G

OPTION2

Di; Daw;¢ win W_,le Di;pos_.

BEND RAOIUS f RO/v! VALVE

Ii

_ INSTALLATIONINSTRUCTIONS

PLEASE NOTE. Yourmodelof DishDrawer® maydiffer from the modelshown in the installation

diagrams.Installationis similar for all modelsfor either Singleor Doublemodels, Irlom _to[_ cfclr f7

o S_glc _o(_s e@i s 9hlgh _- i_ b_e_Installationdiagramshavebeensimplified to enable

clearerinstruction.FORINTEGRATEDPRODUCTSFOLLOWTHEINTEGRATEDPANELPREPARATION

INSTRUCTIONSPIN 526608, BEFOREMOVINGTHEPRODUCTINTOTHECAVITY.

STEP I: MOVING THEPRODUCTINTOTHECAVITY

MOUNTING TAB OPTIONS

The mounting tabs are in pairs, one on each side of the product, They are

used to secure the product to the cavity sides. Installation requires two

sets of tab pairs be used, DOUBLE MODELS ONLY - _ and _ tab pairs

OR _ and _ tab pairs may be used. All tabs would be optimum.

If the top installation tabs _ are to be used, fit to the chassis by

II

inserting into the top slots as shown. Ensure the tabs are fully

locked in place.

Optional Flexible Extrusion

tl

If the cavity is 24"x 34V2" (610mm x 876mm) flexible extrusions

can be attached along the top and sides of the product, Open the

drawer(s) to expose the chassis trim, Remove extrusion backing

and adhere to the side and top of DishDrawer®. Refer to the

drawing for correct placement.

DishDrawer ®

READTHESEINSTRUCTIONS

COMPLETELYAND CAREFULLY.

_WARNING!

Be careful of

sharp edges,

Important!

DO NOT push

middle of drawer(s).

STEP2: REMOVING THETUB

Be sure that extrusions do not prevent the drawer from closing

completely,

O Check cavity for any obstructions that may interfere with sliding

the product back. DOUBLE MODELS ONLY- loosen the feet first.

II Push product into cavity to suit adjacent cabinetry. Do not push

middle of drawer(s), Be sure inlet, drain hose(s) and power supply

cord are not restricted or damaged by carefully pulling all excess

length through the services hole, while the product is being pushed

back into the cavity,

FOR:;IN(}LE MODELS :h:,ck tha::th:, as:_ el prod c:: s _ot

low_:. [)o _ol_.:,t. gl. o_.:,onyo I r evvBen rovingl ;m

ioll_;cav y,

_po_'tant! (S_N_JLE}aOOELSONLY).

T_e _@_ct may move. }aa_Rchassis _osiitio_ o_'_cavity

SIN_LE/\ODELSOHLY. (_;_::lyo _ h,@aw;rad naklh

elassi posliononl e { wly, b(lore enovingl e

Open the drawer (bottom drawer in DOUBLE MODELS). Release

the tub by depressing the right hand tub clip and pushing it back

13116"(30ram), Repeat on the left hand side.

k

D Lift the tub up off the drawer runners.

Q Slide both runners back into the product,

Placethe tub ontothe floor,

fo MODELS,d_p_{:l _gor tl_ h_ig o e ewiy,

wi ee_ ohe s_@pode_:_-:(/on_c _r,

_ INSTALLATION INSTRUCTIONS

STEP3: ADJUSTING THEFEET (DOUBLE MODELS ONLY)

DishDrawer ®

DOUBLE MODELS ONLY

Adjust the height of the product to suit the cabinetry, by turning the

feet from inside the product using a wrench or M5 socket,

TIP - gently take the load off each foot using the slide and

then turn by hand.

NOTE. For integrated products, the upper panel may be

aligned with the top of the adjacent cabinetry, provided

a minimum 3/76" (Smm)clearance from the counter is

maintained.

Important!

The product must be levelled to within 3/3{' (2.Smm) from front to

back, and side to side.

Important!

The product should NOT support any part of the kitchen cabinetry.

TIP - Place a spirit level on the drawer runners to level the

product.

STEP4: SECURINGTHEPRODUCT

!Ix!:, ....

Ij_ S//H£;LE M'OD£L S O_d£Y

Ceck _ostol_o_ c a:_sss ,til wee nark,_:oral eeav_y,

b,'lor _:(c_ring Ihe p/od_cl,

li_ There are four 5/8" (16mm) round holes, two on the left and two on

the right hand side in the sound insulation. These provide access to

the mounting tabs.

Tosecuretheproductto the cabinetry usea 5/8"(16mm)

Phillipsscrew in eachmountingtab,

Make sure the sound insulation is positioned correctly before

continuing installation.

_]_ DOUBLE MODELS ONLY

Screw the two top tabs to theundersideof bench, Usethe supplied

Phillips5/8" (16mm)screws. Tabscan accommodatea maximumof

3/4"(19mm) verticalgap,

_ INSTALLATIONINSTRUCTIONS

STEP5: ELECTRICALCONNECTION

DishDrawer ®

7

POWER

OUTLET

This view shows the bottom left-hand rear corner with the cover removed

_WARNING!

The product MUST NOT be

plugged in at this stage,

li_Be sure there is a power outlet in reach of the supplied power cord.

If there is not a suitable outlet available then have one installed by a

qualified electrician,

Do not use an extension cord,

li_ Alternatively, the DishDrawer® be connected to a

flexible conduit,

Remove the power supply cord. Remove round knock-out for cable

clamp, Fit suitable cable clamp for the conduit and terminate the

wiring as shown. Terminate the ground wire using the saddle that

was used on the existing earth,

_WARNING!

If permanently connecting be

sure the power is isolated.

permanently

may

/_WARNING!

This must only be done by a certified person.

STEP6: REFITtiNG THETUB

Important!

Before refitting the tub, be sure the hoses are not twisted and the

latches at the rear of each drawer runner are facing forward.

li_To refit the make both of the latches the of each

drawer runner are facing forward, Ensure hoses are hooping

upward, Place the tub on the half open drawer runners and close

the drawer.

i]_ Check the tub clips have reset on both sides of the tub. If not, pull

the tub clips forward until the tub clip button is reset.

tub, sure at rear

Important!

Be sure the tub clips on both sides are reset.

_ INSTALLATIONINSTRUCTIONS

STEP7: CONNECTINGTHEDRAIN HOSE(S)

DRAIN

HOSE

_VENT

WATER

SUPPLY

DishDrawer ®

DishDrawer®with Hose Joiner(see PlumbingOptions).

Remember to slip the wire clip(s) on the drain hose(s) first,

li_ Slip a wire clip over each drain hose, then push the hoses into

the Drain Hose Joiner firmly, 5 clicks, Position the wire clip(s)

between the two positioning ribs on the Drain Hose Joiner.

Attach the Drain Hose Joiner to the waste tee (see Plumbing

Options). Ensure a snug fit. If required a hose clamp may be used.

WASTE

li_ When using the standpipe option (see Plumbing Options), hose(s)

should not extend further than 4314,, (120mm) down the standpipe,

in order to prevent siphoning,

IEI Attach the Drain Hose Support to the cabinetry (with the screw

supplied) to prevent siphoning and to keep the drain hose(s)

from kinking, If required, the Drain Hose(s) may be trimmed to a

suitable length.

STANDPIPE

STEP8: CONNECTINGTHEINLETHOSE

-- WASTE

DISPOSAL

T.--ii_

VALVE WASTE

POWER _ WATER

OUTLET SUPPLY

Important!

Minimum hole size to be connected to the waste tee is 1/2"

(12.7mm).

Be sure the Drain Hose(s) are fully extended to prevent sagging

(see diagram to the left),

The Drain Hose support must be used,

Drain Hosejoiner must not support weight of hoses. Keep

excess length of Drain Hose on the DishDrawer® side of the

Drain Hose support ortrim to suit,

_WARNING!

DO NOT plug the product in

at this stage,

_]J Connect the Inlet Hose to the water supply. Be sure the sealing

washer is in place, The hose coupling must be tightened a further

half turn after seal contact,

TIP - Turn the water valve ON to check for any leaks,

Alternatively flexible stainless steel hose can be plumbed directly to

the inlet valve using a 3/8" brass adaptor (p/n 526161) available from

the nearest Fisher & Paykel Authorized Service Agent,

Important!

DO NOT cut the inlet hose.

MINIMUM

BEND RADIUSFROMVALVE

NOTI _ _2HGL E M J/7/?S DO NOT 1IA Ill A TOE KICK TO

IH.%:72_LL_ t/_OC L? 70 7Y/?/VAL CHICK I%:Z

? E ?

_ INSTALLATIONINSTRUCTIONS

STEP9: MEASURING THETOEKICK(DOUBLEMODELS ONLY)

DishDrawer ®

!_1 Partially the bottom drawer, Turn Prefinished Toe Kick

open

upside down and hold vertically against the bottom edge of the

Tub side (not the drawer front),

Mark the position of the bottom edge of the Tub side on the Toe Kick,

Choose the nearest groove to the pencil mark which will result

in the shortest Toe Kick.

STEP10: TRIMMING THETOEKICK(DOUBLE MODELS ONLY)

Important!

Before cutting ensure the Toe Kick is positioned on a wooden

chopping board to avoid damage to surrounding area.

I_On the chosen groove cut down the vertical ribs at the centre and

the ends using a knife, Cut along full length with a knife, Turn Toe

Kick over, bend and then cut from front, Sand or scrape bottom edge

to remove rough patches,

_WARNING!

Remove all sharp edges

l_To avoid a cutting hazard remove a//sharp edges after trimming,

!

I_ Remove Toe Kick tabs by snapping them off.

_ INSTALLATIONINSTRUCTIONS

STEP11:FITTINGTHETOEKICKTOTHEPRODUCT(DOUBLEMODELS ONLIt)

Toekick

mountingrails

_"_1 Partly open bottom drawer. Position Toe Kick behind door and slide

onto the mounting rails on the underside of tub,

DishDrawer ®

!

\

|

STEP 12: FINAL CHECKLIST(DOUBLE AND SI#JGLE MODF//,,%)

_ _1111

O Be sure product is level, securely fastened to the cabinetry and TROUBLESHOOTING

opens and closes freely, The BishBrawer® must be free to close

with no resistance from the cabinetry. 0 Excessive water remaining above the filter plate, after the

O Be sure the inlet hose to valve connection is tightened a further half .. '

turn after seal contact, connec[ion.

O Be sure any knock-outs or plugs in drain connection have been 0 No water supply; check water is connected, ON and there is

drilled out and drain connection has been made, the specified water pressure.

O Turn ON the power and water supply. The DishDrawer® should O DishDrawer® does not light up when the tub is opened;

beep and light up, be sure power is connected and is switched ON,

.... rinse cycle check for kinked drain hoses or blocked waste

_ Close bottom drawer, check if flush with adjacent cabinetry,

If required open drawer and adjust,

Note. Clearance between Toe Kick and floor must be

15/32"(12mm) minimum,

When Toe Kick is in position, open bottom drawer and gently fasten

the Toe Kick screws, on each side.

Important!

DO NOT over tighten screws.

Overtightening will damage the plastic mounting detail.

O OaP:enl_l:d drh:ckr l_ean dr; h:rCk op_rrat;: n ?afcT__ fPrreOegrt:mo_a_nt,rol O Water around water supply and drainage connections - _

P Y ( ) P ' check connections, existing plumbing and hoses for leaks,

0 On the Wash Program Control Panel select Rinse and close the .

drawer(s), Start the program by pressing the Start!Pause button. , _ ., ,

O After the Rinse program has finished, be sure the machine has run

and drained correctly, O If unable to resolve, contact your Customer Care Centre,

O Check water supply and drainage connection for leakage.

0 Repeat for each Drawer, _

0 If a fault occurs consult the Fault Code Section of the

user buloe,

STEP 13: CUSTOMERCARE

If you have any questions concerning the installation of this DishDrawer®,

please contact your Fisher & Paykel Authorized Service Agent,

FORTHE UNITED STATES OF AMERICA (USA) & CANADA

Fisher& PaykelAppliances

5900Skylab Road

HuntingtonBeach

CA92647

PHONE TOLL FREE 1888 9 FNP USA

18889 367 872

www usa HsherpaykeL corn

Loading...

Loading...