Page 1

OUTDOOR REFRIGERATOR AND

BEER DISPENSER

Use and Care and Installation Guide

MODELS:

RF24R

RF24T

Page 2

Page 3

A MESSAGE TO OUR CUSTOMERS

Thank you for selecting this DCS Outdoor Refrigerator/Beer Dispenser. Because of these appliances’ unique

features we have developed this Use and Care and Installation Guide. It contains valuable information on how to

properly install, operate and maintain your new appliance for years of safe and enjoyable operation.

To help serve you better, please fill out and submit your Product Registration by vi siting our website at

www.dcsapp liances. com and selecting “Customer Care” on the home page and then select “Product

Registration”. In addition, keep this guide handy, as it will help answer questions that may arise as you use your

new appliance.

For your convenience, product questions can be answered by a DCS Customer Care Representative at

1-888-936-7872, or email:

NOTE: Please write the M odel, Code, and Serial Number on this page for references (the serial plate is located on

the upper lef t side, inner wall).

MODEL NUMBER CODE SERIAL NUMBER

NOTE: Inspect the product to ver ify that there is no shipping damage. If any damage is detected, call the shipper

and initiate a damage claim. DCS by Fisher & Paykel is not responsible for shipping damage.

customer.care@fisherpaykel.com

.

DO NOT discard any packing material (box, pallet, straps) until the unit has been inspected.

PLEASE RETAIN THIS MANUAL FOR FUTURE REFERENCE.

1

Page 4

TABLE OF CONTENTS

SAFETY PRACTICES AND PRECAUTIONS 3

INSTALLATION - ESSENTIAL REQUIREMENTS 4

INSTALLATION

Electrical connection 5

How to install your outdoor refrigerator/beer dispenser 6-7

How to install your outdoor beer dispenser components 8-11

Tapping procedures 12

USING THE REFRIGERATOR/BEER DISPENSER 13-16

CARE AND MAINTENANCE

How to clean and maintain your unit 17

Replace interior light bulb 18

Things to remember 18

Energy saving tips 18

MOVING OR STORING YOUR REFRIGERATOR 19

TROUBLESHOOTING 20-21

SERVICE 22

WARRANT Y 23-24

2

Page 5

SAFETY PRACTICES & PRECAUTIONS

To reduce the risk of fire, elec tric shock, or injur y to persons read these SAFE T Y PRAC TICES AND PREC AUTIONS

before operating this appliance. Use this appliance only for its intended purpose as described in this User Guide.

WARNING

When using this appliance always exercise basic safety precautions including the following:

DANGER!

■ This appliance is not intended for use by young children or infirm persons without super vision. Young children

should be super vised to ensure they do not play with the appliance.

■ Risk of child entrapment. Before you throw away your old refrigerator/beer dispenser:

1. Take off the doors.

2. Leave the shelves in place so that children may not easily climb inside.

ELECTRICAL

■ This appliance must be properly installed in accordance with the installation instruc tion before it is used.

■ Never unplug your refrigerator by pulling on the power cord. Always grip the plug firmly and pull straight out

from the outlet.

■ Repair or replace immediately all electric service cords that have become frayed or otherwise damaged. Do not

use a cord that shows cracks or abrasion along its length or at either the plug or appliance end. If the power

supply cord is damaged, it must only be replaced by your Fisher & Paykel Appliances Authorized Service Center

because special purpose tools are required.

■ Unplug your refrigerator before cleaning, or replacing the light bulb.

STORING FOOD AND DRINKS

■ Never store volatile or flammable materials in your refrigerator as they may explode.

■ Never freeze liquids in glass containers. Liquid expands during freezing which may cause the container to

explode.

■ Do not consume food if it is too cold. Food removed from the freezer compartment may be cold enough to cause

damage when brought into contact with bare skin, e.g. frozen ice cubes.

POWER FAILURE – FOOD SAFETY

■ Do not refreeze foods that have thawed completely. Follow the recommendations below if you discover food

that has thawed:

1. Ice crystals still visible – food may be refrozen but should be stored for a shorter period than recommended.

2. Thawed but refrigerator cold – refreezing generally not recommended. Fruits and some cooked food can be

refrozen but use as soon as possible.

Meat, fish, poultry – use immediately or cook, then refreeze.

Vegetables – discard as they usually go limp and soggy.

3. Thawed but warmer than 4ºC/40ºF – red meat can be cooked immediately and refrozen but use as soon as

possible. Discard all other frozen foods.

■ Do not refreeze frozen foods that have thawed completely. The food may be dangerous to eat.

CLEANING

■ Many commercially available cleaning products contain solvents which may attack plastic components of your

refrigerator/beer dispenser and cause them to crack . Please refer to the Care and Maintenance section of this

booklet for fur ther advice (see pages 15-16).

DISPOSAL

■ Extreme care must be taken when disposing of your old appliance to avoid hazards. The refrigerant gas must be

safely removed.

■ Your Fisher & Paykel Appliances Authorized S ervice Center will be able to give advice on environmentally friendly

methods of disposing of your old refrigerator/beer dispenser.

3

Page 6

INSTALLATION – ESSENTIAL REQUIREMENTS

POWER

■ The appliance must be installed so the power plug is accessible.

■ To ensure that the appliance is not accidentally switched off, connect your refrigerator/beer dispenser to its

own power point. Do not plug in any other appliance at this power point or use extension cords, or double

adapters, as the combined weight of both power cords can pull the double adapter from a wall outlet socket.

■ For power requirements, refer to the infor mation on the serial plate located at the front bottom right-hand side

of the refrigerator when the door is open.

■ It is essential that the appliance be properly grounded (earthed) with a three prong receptacle. Never cut or

break off the grounding prong to fit a two-prong outlet.

LOCATION

■ Your refr igerator/beer dispenser should not be located in direc t sunlight.

STABILITY

■ It is important that all four corners of the refrigerator/beer dispenser base are supported firmly on a solid level

surface to eliminate any cabinet movement.

■ Installing the appliance on a sof t or uneven or unlevel floor may result in twisting of the cabinet and poor

sealing of the doors. If the doors do not seal properly, warm air will enter the food storage areas causing the

temperature to increase, resulting in food spoilage and food loss.

■ Before moving your refrigerator/beer dispenser into its position, ensure that the

adjustable front feet are fully retracted.

■ Position your refrigerator/beer dispenser. Turn to lower the front leveling leg. Raise the

front of the appliance until it is stable and doors move towards the closed position, on

their own, when open.

■ The front leveling leg on the hinge side should take the majorit y of the weight of the

cabinet and the cabinet should be stable, i.e. cabinet should not rock or wobble.

BEFORE PLACING FOOD IN THE FRESH FOOD COMPARTMENTS

■ Remove all packaging. Ensure that all transit tape is removed from the refrigerator.

■ Clean the inside of the appliance with warm water and a little liquid detergent to remove manufac turing and

transportation dust.

■ Allow the refrigerator/beer dispenser to run empty for 2 - 3 hours to allow each compar tment to cool to the

appropriate temperature.

■ The appliance may have an odor on its initial operation, but this will go away when the refrigerator/beer

dispenser have cooled sufficiently.

Fig. 01 LEVELING LEG

4

Page 7

INSTALLATION

Grounding Type

Wall Receptacle

Power Supply Cord

with 3-Prong

Grounding

Plug

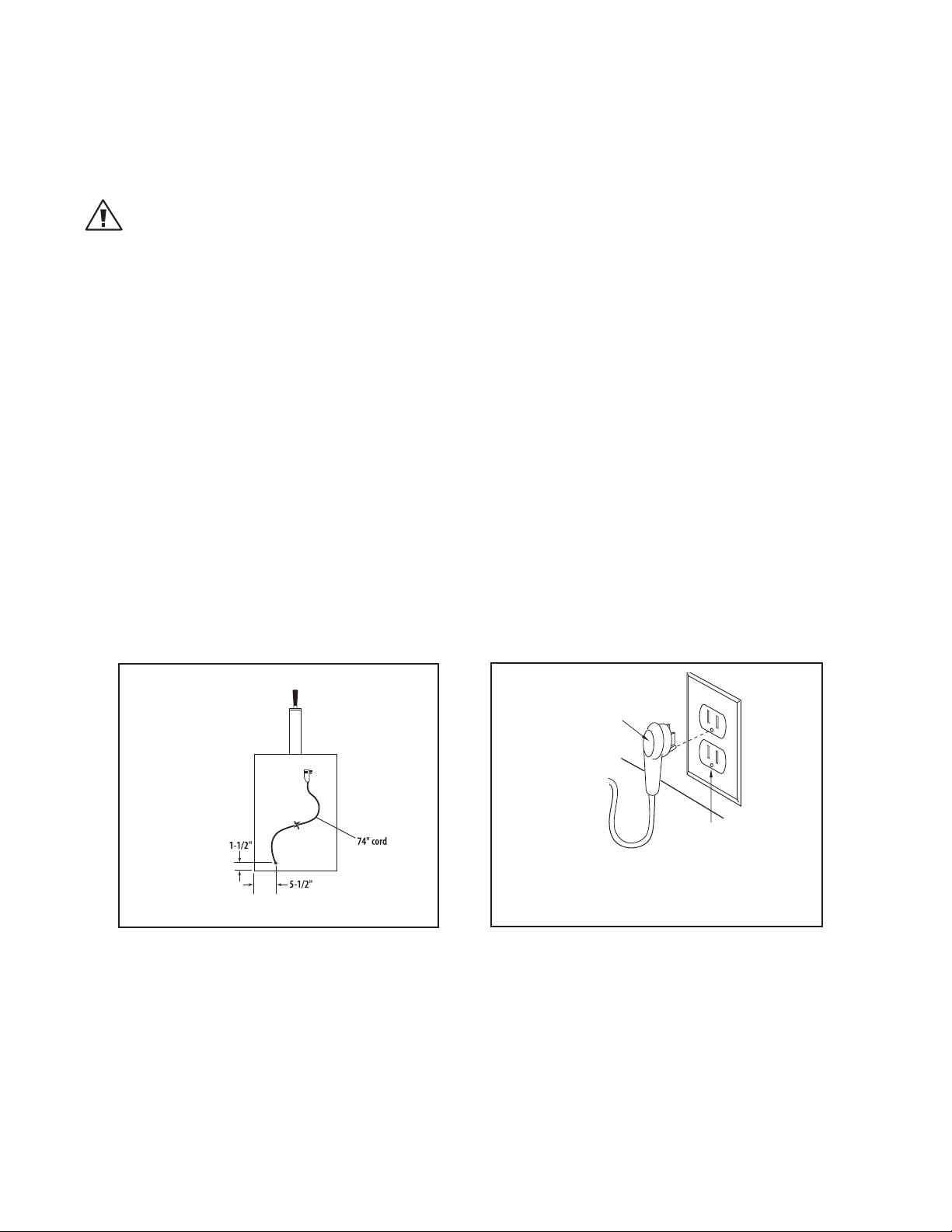

HOW TO INSTALL YOUR OUTDOOR REFRIGERATOR/BEER DISPENSER

ELECTRICAL CONNECTION:

Check serial plate for correct power supply. Use only electrical power supply as specified on your appliance

serial nameplate. Do not use an extension cord!

WARNING!

Do not splash or spray water from a hose onto the refrigerator! Doing so may cause an electrical shock, which may

result in severe injury or death.

GROUNDING METHOD

This product is factory equipped with a power supply cord that has a three -pronged grounded plug. I t must be

plugged into a mating grounding type receptacle in accordance with the National Electrical Code and applicable

local codes and ordinances. If the circuit does not have a grounding type receptacle, it is the responsibility and

obligation of the customer to exchange the existing receptacle in accordance with the National Electrical Code

and applicable local codes and ordinances. The third ground prong should not, under any circumstances, be cut

or removed. All UL listed refrigerated produc ts are equipped with this type of plug.

A ground fault circuit inter rupter (GFI) electrical receptacle is to be used to supply electrical power to the refrigerator for outdoor applications. Contact an electrician if you need to install one to supply electrical power to

your outdoor refr igerator.

POWER REQUIREMENTS:

■ 120V 60Hz

■ 1800 watt

■ 3 wire outlet

■ 15 amp circuit

AC Interface

Fig. 02

Note:

The plug shown is for 120V units.

Fig. 03

5

Page 8

INSTALLATION

13-3/4”

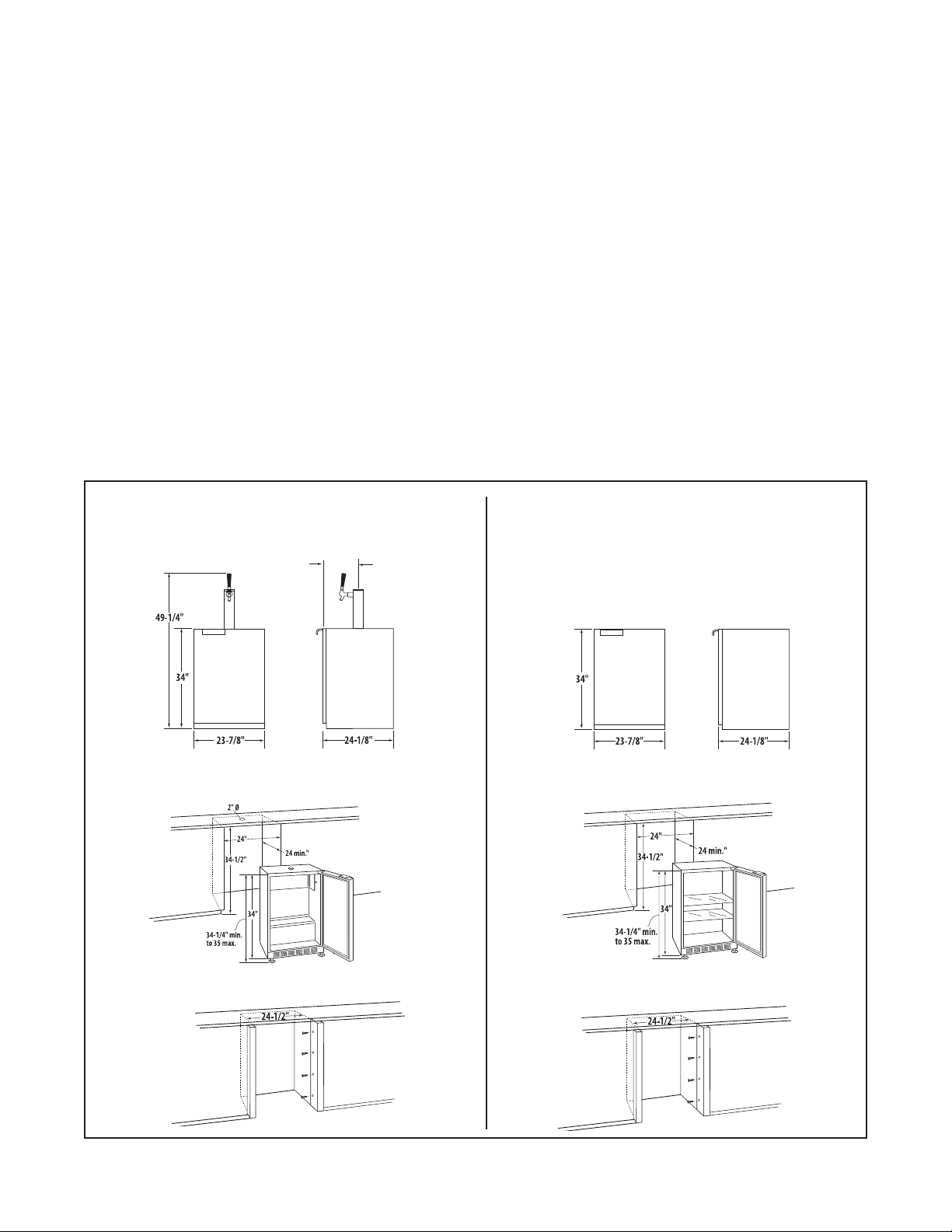

HOW TO INSTALL YOUR OUTDOOR REFRIGERATOR/BEER DISPENSER

SELECT LOCATION:

The proper location will ensure peak per formance of your appliance. Choose a location where the unit will be

out of direct sunlight, away from heat sources and moisture. Units with fan cooled condensers can be built in.

Unit should be operated in a properly ventilated area with ambient temperatures above 40 degrees and below

100 degrees Fahrenheit.

Installation should be such that the cabinet can be moved for servicing if necessary.

CABINET CLEARANCE:

Ventilation is required from the bottom front sec tion of the unit. Keep this area open and clear of any

obstructions.

The adjacent cabinets and counter top can be built around the unit as long as no top trim or counter top is

installed lower than the top of the hinge.

SIDE TRIM INSTALLATION:

Attach side tr im to the inner side of the cabinet so that the trim faces out ward (away from the appliance’s door)

and fasten with appropriate screws suitable for the type of cabinet material.

24” Outdoor Beer Dispenser

Dimensions

Island Preparation with No Side Trim

24” Outdoor Refrigerator

Dimensions

Island Preparation with No Side Trim

Island Preparation with Side Trim Installation

Mounting

screws not

provided

Island Preparation with Side Trim Installation

Mounting

screws not

provided

Fig. 04

6

Page 9

INSTALLATION

1-5/8”

2-5/8”

2-5/8”

11-3/4”

12”

HOW TO INSTALL YOUR OUTDOOR REFRIGERATOR/BEER DISPENSER

ISLAND BEER DISPENSER INSTALLATION:

When installing the Beer Dispenser under a counter and using a remote location for the Dispenser Tower, follow

instructions below. Steps need to be taken to insure proper temperatures are maintained in the dispenser.

IMPORTANT:

All holes must be sealed to prevent air leak. Placement of the tower can be done by cutting a hole in the counter top

directly above the existing hole of the Beer Dispenser unit (refer to tower template for dimensions Fig. 05).

1. Drill a 1-5/8” hole drilled thru the counter direc tly above the hole in the dispenser cabinet. Use the dimensions

shown to align both holes. When properly placed, you will see thru both holes.

2. Drill four 1/8” pilot holes at 2-5/8” apar t using the large hole as a center point (see Fig. 05).

3. Using some insulating foam rubber (not included), slide it over the beer line far enough to bring the hose up

thru the top of the cabinet and counter.

4. Connect the beer line assembly to the tower as per “Assemble and Connect Parts” on page 10.

5. Slide the insulating foam rubber into the hole in top of the dispenser, making an air tight seal.

6. Mount the tower to the top of the cabinet and fasten securely.

7. Make connections to the keg and CO2cylinder as per “Assemble and Connec t Par ts” on page 10.

NOTE:

When there is a large build up of frost or ice on the evaporator plate, the drip pan may not be large enough to retain all

of the melted ice. The evaporator plate should never have more than 1/8” of frost at any time.

Fig. 05

7

Page 10

INSTALLATION

HOW TO INSTALL YOUR OUTDOOR BEER DISPENSER COMPONENTS

Contents of Kit:

Draft Tower Assembly

Keg Coupler

Air Line with Clamps

Single Gauge Regulator

5 lb. CO2Empty Cylinder

Tools needed:

Crescent Wrench

Pliers

Screwdriver

Q. WHAT SIZE KEG WILL FIT INTO MY REFRIGERATOR?

Approximate measurements required to tap most kegs:

Quarter Barrel Half Barrel

Height 17-21 inches 25-29 inches

Diameter 16-20 inches 18-22 inches

Weight 80-85 pounds 160-180 pounds

Check with your local beer wholesaler or retailer to verify actual keg sizes, including tap heights.

Q. CAN MY REFRIGERATOR MAINTAIN TEMPERATURES BETWEEN 34º-38º F?

Draft beer is not pasteurized, so it must be kept cold, preferably 38º. Temperature above 38º may cause the beer

to become wild, turn sour and cloudy.

Draft beer should be consumed within 30-45 days. It is not pasteurized, and will lose its original brewer y fresh

taste and aroma the older it gets.

Q. HOW MUCH BEER WILL I CONSUME IN A 30 DAY PERIOD?

There are two keg sizes: the quar ter barrel containing 7-3/4 gallons or approximately 3-1/2 cases of 12 ounce

bottles or cans; the half bar rel containing 15-1/2 gallons or approximately 7 cases.

8

Page 11

INSTALLATION

HOW TO INSTALL YOUR OUTDOOR BEER DISPENSER COMPONENTS

WARNING!

CO

can be dangerous.

2

1. ALWAYS connec t CO2gas cylinder to reducing valve or re gualtor.

2. NEVER conn ect gas cylinder direc tly to keg.

3. ALWAYS secure gas cylinder in u pright position.

4. ALWAYS keep gas cylinder away from heat.

5. NEVER drop or throw g as cylinder.

6. ALWAYS ventilate after CO2leakag e.

If it becomes difficult to breathe and your head starts to ache, abnormal concentrations of carbon dioxide may be

present inthe area. Leave the room immdiately.

Gas cylinder should be stored in the coolest part of the stablishment, preferably at 70ºF.

Draft tower assembly

Beer line

Keg coupler

Air

line

Low pressure

gauge

Regular

Shut off

valve

CO2tank

Regulator coupling nut

Drum valve

Set screw

9

Page 12

INSTALLATION

HOW TO INSTALL YOUR OUTDOOR BEER DISPENSER COMPONENTS

ASSEMBLE AND CONNECT PARTS

1 . Screw the black faucet k nob onto the faucet

(Fig. 06).

2. Mount the draft tower onto the counter top using

the four furnished screws and the one mounting

gasket (Fig. 07).

3. Attach the elbow to the top of the keg coupler,

making sure to use a black washer

(Fig. 08).

4. Attach the beverage line coming from the draft

tower to the elbow. Use the black washer inside the

hex nut and tighten the beverage line securely with

a crescent wrench (Fig. 09).

5. Fasten the CO2regulator to the CO2cylinder,

tightening the CO2nut securely. Do not over

tighten; over tightening may damage the washer in

the stem of the regulator (Fig. 10. Ensure valve is

off.

Fig. 06

Fig. 07

6. Attach one end of the red air hose to the hose barb

on the CO

clamps provided (Fig. 11). Use pliers to snap the

clamp tight to assure that there is no gas leak.

7. Place the CO2cylinder and regulator inside one of

the corners of the refrigerator. It is important that

the cylinder be kept in an upright position to

operate efficiently, using a clain or heavy cord if a

wire rack is not provided (Fig. 12).

8. Fasten the other end of the red air line to the keg

coupler using the remaining snap clamp (Fig. 13).

regulator, using one of the two snap

2

Fig. 08

Fig. 10

Fig. 12

Fig. 09

Fig. 11

Fig. 13

10

Page 13

INSTALLATION

HOW TO INSTALL YOUR OUTDOOR BEER DISPENSER COMPONENTS

PARTS OF A CO2REGULATOR

1. Pressure gauge (reads the amount of internal keg pressure).

2. Regulator adjustment screw (after keg is tapped, screw clockwise until

pressure gauge indicates between 12 and 14 lbs.).

3. Adjustment lock nut (once the pressure gauge is between 12 and 14

lbs., tighten adjustment nut.)

4. Shut-off valve.

1

2

5

5. CO2nut (use to connect to the tank).

HOW TO REPLACE AN EMPTY CO2CYLINDER

1. Close shut-off valve “B”.

2. Close cylinder valve by turning clockwise “A”.

3. Remove regulator from empty cylinder “D”.

4. Remove dust cap from new c ylinder at “D”.

5. With cylinder valve “A” in closed position, reattach regulator to cylinder

at “D”. (Check condition of gasket/o-ring).

6. Open valve “A” all the way. ( This is important because the cylinder

valve seals in two places.)

7. Open shut-off valve “B”.

8. Check gauge pressure “C” (12-14 lbs.) and adjust if necessary.

CO2CYLINDERS (It is recommended to have an extra

cylinder on hand)

Cylinder Dia. Ht. Empty Weight Full Weight

1-1/2 lbs. 3-1/2” 18-1/4” 6-1/2 lbs. 9 lbs.

3

4

Fig. 14

C

A

D

CLOSED

OPEN

B

5 lbs. (provided) 5” 17-1/2” 12-1/2 lbs. 17-1/2 lbs.

Note:

It takes about 1/2 lb. of CO2to dispense an 1/2 barrel of beer. A 2-1/2 lb. CO

cylinder should dispense between 4 to 5-1/2 barrels or 8 to 10-1/4 barrels.

A 5 lb. CO2cylinder should dispense between 8 to 10-1/2 barrels or 18 to

20-1/4 barrels.

11

Fig. 15

2

2-1/2 lbs.

Fig. 16

5 lbs.

Page 14

INSTALLATION

TAPPING PROCEDURES

LEVER TYPE KEG COUPLER

(Taps most major domestic brands)

1. Align lug locks on tap head

with lug housing in top of

keg; inser t tap head.

OPTIONAL WING TYPE KEG COUPLER

(Taps most major domestic brands)

2. Turn tap head handle 1/4

1. Align lug locks on tap head

with lug housing in top of

keg; inser t tap head.

turn clock wise; the tap

head is now secured to

the keg.

2. Turn tap head handle 1/4

turn clock wise; the tap

head is now secured to

the keg.

3. Pull tap handle out and

push down to open beer

and CO2ports in the keg.

The keg is now tapped.

3. Rotate on/off valve handle

1/4 turn clockwise to open

beer and CO2ports in the

keg. The keg is now tapped.

12

Page 15

USING THE BEER DISPENSER

O

F

F

7

6

5

4

3

2

1

C

O

L

D

E

R

TEMPERATURE CONTROL

Initially set the cold control k nob midway between the numbers.

After at least 2 hours, adjust to the temperature that suits you. The

higher the number you select, the cooler the temperature (Fig. 17).

The temperature control knob is located at the bottom front of the

cabinet, just behind the square opening near the middle of the

venting grill.

DEFROSTING INSTRUCTIONS (IF NEEDED)

Never use a scraper or any tool that might scratch or pierce the

cooling plate. Follow these steps whenever 1/4 inch or more of

frost accumulates:

1. Disconnect the power cord and set the cold control knob to “OFF”

position.

2. Remove contents.

3. Place pans of hot water on the shelf under cooling plate if you wish to speed up defrosting.

Note:

Place a clean cloth under the hot pan of water to protect the glass shelf from breaking.

Fig. 17

4. Wipe out the interior and replace contents.

5. Connect power cord to outlet.

6. Set temperature control to desired level.

HELP PREVENT TRAGEDIES. . .

Each year children die because they climb inside a discarded refrigeration product, get trapped inside and

suffocate. Take precautions to prevent such tragedies by removing the door, taping or chaining it shut before

discarding.

ALL REFRIGERATOR MODELS

All refrig erator models automatically defrost their cooling plate during e ach compressor off c ycle. No

manual defrosting is required.

13

Page 16

USING THE REFRIGERATOR CONTROL

Door Switch

NOTE

During initial startup, or anytime power is interrupted, there

will be an approximate 5 minute delay before the refrigerator

starts. During this period the controller will be assessing the

temperature in the refrigerator and the display will appear erratic, this is normal. The desired temperature set point can be

programmed during this start up period.

Starting your refrigerator

The refrigerator will begin start up when initially plugged in

or when power resumes after a power outage. At this time the

refrigerator will take approximately 5 minutes to begin running

as noted above. If the refrigerator has been turned o during

use, “OFF” will appear on the display. To start the refrigerator

from the “OFF” position press and hold the ON/OFF button for

three seconds.

Set temperature

To set temperature set point, press and continue to hold “SET”

button. After one second, set point will be displayed. While

holding “SET” button use the “WARMER” or “COLDER” button to

desired set point.

NOTE: Momentarily pressing & releasing “SET” button will access information menu of control. Refer to page 15 for information on this feature.

Refrigerator operation

The available temperature range of the refrigerator is 33° to 45°

(1° to 7° C). It may take up to 24 hours for your refrigerator to

reach desired temperature. This will depend on amount of contents loaded and number of openings and closings of the door.

For best results allow refrigerator to “pull down” to desired set

point before loading. Once contents are loaded, allow at least

48 hours for temperature to stabilize before making any adjustments to the set point.

Alarms

Your refrigerator control will monitor refrigerator function and

alert you with a series of audible and visual alarms.

tDoor Ajar Alarm: If the door has been left

open for over ve (5) minutes, the alarm

will sound in one (1) second intervals. The

display panel will ash “do” and the LED light will be a steady

amber color. This will stop as soon as the door is closed.

tHigh and Low Temperature Alarm: If your

unit reaches an unacceptable temperature

outside of your set point, the alarm will

sound in one (1) second intervals. The

display panel will ash either “hi” or “Lo”

depending upon the condition and the LED light will be a

steady amber color. “hi” indicates that the temperature is 10° F

(5.5°C) above the set point and “Lo” indicates that the temperature is 10° F (5.5°C) below the set point. The alarm will remain

active until the condition is corrected.

NOTE: During initial appliance start-up, the high temperature

alarm may sound until the interior temperature reaches set

point.

tTemperature Sensor Fault: If the controller

detects that the temperature sensor is

not properly functioning, a temperature

sensor alarm will sound. “E1” will ash on the display, and an

alarm will sound. Please call Customer Service or

your dealer if this error code is displayed.

tCondenser Needs Cleaning:

When the refrigerator has reached the

recommended amount of run time to necessitate cleaning the air ow, “cL” will ash on the display as a

reminder. See the “Care and Cleaning” section for cleaning

instructions.

To clear the alarm:

1) Press and release the “SET button four times.

“cnd” will be displayed on the screen.

2) While “cnd” is displayed, press and hold the “SET” but ton. The display will show the number of weeks the

refrigerator has been running.

3) While holding the “SET” button, press and release the

ON/OFF button. The number shown on the display will

reset to 0.

4) Release the “SET” key.

Alarm Mute

Press any key to mute the audible portion of an alarm,.

NOTE-This action will only mute the alarm. If the condition that

caused the alarm continues, the alarm code will continue to

ash and will sound for 20 seconds every 60 minutes.

Turning Refrigerator O

To turn refrigerator o, press and hold “ON/OFF” button for

three (3) seconds. “OFF” will appear on the display.

Additional Features

Refer to page 15 for details on additional features available.

14

Control

Figure 3

Page 17

ADDITIONAL REFRIGERATOR CONTROL FEATURES

Information Menu:

The following features are available on the Information Menu.

t$VSSFOU5FNQFSBUVSF

t.BYJNVN4UPSFE5FNQFSBUVSF

t.JOJNVN4UPSFE5FNQFSBUVSF

t5PUBM0QFSBUJOH5JNF0G5IF$POEFOTFS

t,FZQBE-PDLPVU

To access the Information Menu Press “SET” button momentarily and release.

Once in the information menu, the WARMER and COLDER keys

may be used to scroll through the information menu. Additionally, pressing and releasing the SET key will advance the

information menu.

The information menu will automatically exit after several seconds with no key presses.

Current Interior Temperature (tI): Press and

hold the “SET” key to display the current inte rior temperature.

Maximum Stored Temperature (thi): Maxi mum stored temperature is the maximum

temperature refrigerator has achieved since

temperature set point was entered. Press and hold the “SET”

key to display the maximum temperature stored. The data

can be cleared by pressing “SET” and “ON/OFF” simultaneously

while the value is displayed. NOTE: It is normal for refrigerator

temperature to uctuate from set point by several degrees.

Keypad Lockout Feature (Loc): This feature

is useful for prohibiting changes in the

temperature set point or accidentally turning

the unit o. Press and hold the “SET” key to display the cur-

rent “Loc” setting. If “No” is displayed, Lock

out is OFF and all keys are enabled. If “Yes”

is displayed, Lockout is ON and the “ON/OFF”, “WARMER”, and

“COLDER” keys are disabled. However, the key tones remain

enabled. While holding the “SET” key, press the “WARMER” or

“COLDER” key to select the desired state. Release the “SET” key

to conrm the selection.

NOTE: The Information/Lockout Key “SET” remains enabled

regardless of the “Loc” setting.

Minimum Stored Temperature (tLO): Mini mum stored temperature is the minimum

temperature refrigerator has achieved since

temperature set point was entered. Press and hold the “SET” key

to display the minimum temperature stored. The data can be

cleared by pressing “SET” and “ON/OFF” simultaneously while

the value is displayed. NOTE: It is normal for refrigerator temperature to uctuate from set point by several degrees.

Total Operating Time of the Condenser Since

the Last Cleaning (cnd): Press and hold the

“SET” key to display the total operating hours

of the compressor since the last cleaning. The control stores

the total operating hours of the compressor to determine the

volume of air that has moved across the condenser coils. This

number is displayed in weeks. A reminder is displayed when a

cleaning is recommended (see Alarm Codes). The recommended cleaning period is the equivalent of one year of air volume.

The data can be cleared by pressing the “SET” and “ON/OFF”

keys simultaneously while the value is displayed

15

Page 18

USING THE REFRIGERATOR/BEER DISPENSER

DR AW A GLASS OF BEER

1. Star t with a clean beer

glass that has been

wetted in cold water.

Place the glass at a

45º angle, one inch

below the faucet. Do

not let the glass touch

the faucet. Open the

faucet all the way.

2. After the glass has

GLASS OF BEER

reached half full,

gradually bring the

glass to an upright

position.

3. Let the remaining

beer run straight

down the middle.

This insures proper

release of CO2by

producing a 3/4” to

1” foam head.

4. Close the faucet

completely and

quick ly.

DRAW A

16

Page 19

CARE AND MAINTENANCE

HOW TO CLEAN AND MAINTAIN YOUR UNIT

Condenser

The condenser coil under the cabinet for forced air unit does require frequent cleaning. Satisfactor y cooling

depends on adequate ventilation over the condenser coil. Be sure that nothing obstructs the air flow openings

in the lower front of the cabinet.

Cabinet

The stainless steel cabinet can be washed with mild soap and water and thoroughly rinsed with clear water.

Never use abrasive scouring powders.

Interior

It is important to keep the interior of the refrigerator/beer dispenser clean to help prevent food from becoming

contaminated dur ing storage. The amount and types of food stored determines how of ten cleaning should be

carried out (ideally once every 1 or 2 weeks) in the refrigerator. Remove the shelves from cabinet and door. Wash

shelves and storage bins in warm water and detergent; rinse in clean water and dr y before replacing. Wash

interior compartment with mild soap and water. Wipe over the interior sur faces with warm water and detergent

or baking soda dissolved in warm water (add 1 teaspoon of baking soda to each 1 pint [500 ml] of water). Do

not use an abrasive powder, solvent, polish cleaner, abrasive cloths, highly perfumed, strong smelling cleaners or

undiluted detergent on any par t of the refrigerator or beer dispenser. Rinse with clean water. To help remove “old

stale refrigerator” smells, add a few drops of vanilla essence or vinegar to the water before cleaning.

Ex terior – Stainless Exterior Door

It is important when cleaning the ex terior door surface of your refrigerator or beer dispenser, to only use liquid

dishwashing detergent, dissolved in warm water. Dr y the door with a clean, lint-free cloth. The use of any

abrasive or stainless steel cleaners and solvents will damage the door surface.

Other Ex terior Sur faces and Door Gasket

Clean all other exterior surfaces with warm water and detergent. If necessary, clean the magnetic door gasket

with an old toothbrush, warm water and detergent.

Interior – Glass Shelves

Clean with warm water and detergent or a glass cleaner. If cleaning the shelves without removing from the

cabinet, use only warm water and detergent as a glass cleaner can damage the plastic components of your

refrigerator/beer dispenser.

Important Note:

Many commercially available cleaning products contain solvents that may attack the plastic components of your

refrigerator and cause them to crack. It is important to use only warm water and a small amount of liquid dishwashing

detergent on any plastic components inside and outside your refrigerator. Avoid using anti-bacterial cleaning products

on either the interior or exterior of the cabinet as they may cause rusting of metal components and cracking of plastic

components.

17

Page 20

CARE AND MAINTENANCE

REPLACE INTERIOR LIGHT BULB

When supplied with an inter ior light, your refrigerator uses a 15 Watt appliance light bulb. To replace the light

bulb, proceed as follows:

1. Unplug the power cord from the power supply.

2. Open the cabinet door, the light bulb is located behind the display housing at the top of the unit.

3. Unscrew the existing bulb and replace with an equivalent 15 Watt, threaded, intermediate base appliance bulb.

Do not replace with a bulb higher than 15 Watts.

THINGS TO REMEMBER. . .

1. Allow 24 hours for your refrigerator to reach a new temperature setting.

2. The motor will start and stop of ten. It must do this to maintain the temperature you selec t.

3. Keep your refrigerator reasonably level.

4. Unplug the refrigerator before work ing on anything with the electrical system.

5. Exercise caution when sweeping, vacuuming, or mopping near the front of the unit. Damage to the grill and/or

the light fixture switch can occur.

6. For all cleaning of the refrigerator interior, mix 2 tablespoons bak ing soda with 1 quar t warm water or use mild

soap. Do not use strong cleaners or scouring powder or pads.

7. Keep your refrigerator out of direct sunlight.

8. Do not splash or spray water on or under the refrigerator.

9. Clean your refrigerator ’s condenser periodically to maintain proper cooling per formance.

ENERGY SAVING TIPS

1. Reduce door openings.

2. Close the door as soon as you can.

3. Keep the coils on bottom of the refrigerator clean.

4. Adjust the temperature control to a warmer setting when practical.

5. Don’t put hot foods in the refrigerator.

6. Keep unit away from the stove or other heat sources.

18

Page 21

MOVING OR STORING YOUR REFRIGERATOR

If your refrigerator or beer dispenser is turned off for any reason, wait 10 minutes before turning it back on. This

will allow the refrigeration system pressures to equalize before restarting.

MOVING YOUR REFRIGERATOR OR BEER DISPENSER

■ Turn off the appliance and unplug from the power point. Remove all food.

■ Turn the leveling legs in as far as they will turn (see page 4, Stability).

■ Ease the refrigerator out of its position. Tuck the power cord away and tape the doors closed. Tape the shelves

in place. If the cabinet needs to be placed at an angle or laid down, carefully lay it on its side (the right hand

side when viewed from the front).

■ Relocate and install. If the appliance has been left on its side for any length of time, leave it standing upright

for at least 12 hours before turning on.

STORING YOUR REFRIGERATOR OR BEER DISPENSER

■ When storing your cleaned appliance, leave the door open. This allows air to circulate and prevents the

build up of bacteria and molds.

■ Before using again, clean well using a mixture of warm water and bak ing soda (add 1 teaspoon of baking soda

to each 1 pint [500 ml] of water). Rinse with clean water.

VACATION TIME

■ We recommend you leave your refrigerator/beer dispenser operating while you are on vacation. It will prevent

mold and odors from building up.

CAUTION!

Never transport a refrigerator on it back or side for any distance. This may damage the cooling components.

19

Page 22

TROUBLESHOOTING

PROBLEM POSSIBLE CAUSE/SOLUTIONS

ODOR IN CABINET Interior needs cleaning

NOISY OPERATION

CABINET VIBRATES

CABINET LIGHT NOT WORKING

(OPTIONAL FEATURE)

APPLIANCE WILL NOT RUN

APPLIANCE RUNS TOO LONG

MOISTURE COLLECTS INSIDE

MOISTURE COLLECTS ON OUTSIDE SURFACE

Cabinet not level

Fan blade damaged. Call for service

Cabinet not level

Fan blade damaged. Call for service

Bulb burned out

Open door switch. Call for service

Temperature control turned to “OFF”

Line cord not plugged in

No power at electrical outlet

House fuse blown

Prolonged door openings

Control set too cold

Condenser needs cleaning

Too many door openings

Prolonged door openings

Hot, humid weather increases condensation

Hot, humid weather increases condensation. As humidity

decreases, moisture will disappear.

Control improperly set

INTERIOR TOO HOT/TOO COLD

Control improperly set

Faulty thermometer

Condenser needs cleaning

Air leaking into unit

20

Page 23

TROUBLESHOOTING

COMMON DRAFT PROBLEM

PROBLEM DESCRIPTION CAUSES

Beer drown improperly

Creeping regulator

Applied pressure is set too high

WILD BEER

CLOUDY BEER

FLAT BEER

Beer, when drawn, is all

foam, or too much foam

and not enough liquid

beer.

When beer in glass

appears haz y, not clear.

Foamy head disappears

quick ly ; beer lacks usual

zestful brewery fresh

flavor.

Hot spots in line

Use of non-insulated beer line

Beer runs are too long for proper cooling

Tapped into a warm keg (should be 34º-38º)

Cooler malfunctioning

Kinks, dents, twists or other obstructions in line

Faucets in bad, dirty or worn condition

Frozen or nearly frozen beer

Old beer

Beer that as been unrefrigerated for long periods of time

Dirty glass

Dirty faucet

Unrefrigerated foods placed on top of cold keg

Contaminated air source.

Dirty glasses (not beer clean)

Sluggish regulator

Applied pressure isset too low

CO2is tur ned off at night

Contaminated air source (associated with compressed air)

FALSE HEAD

UNPALATABLE

BEER

Large soap -like bubbles,

head dissolves ver y

quick ly

Off-taste

Moisture in air system

Beer too cold

Loose tap or vent connections

Applied pressure required does not correspond to beer

temperture

Small beer line into a large faucet shank

Beer lines warmer than beer in keg

Dr y glasses

Improper pour

Dirty or old beer lines

Dirty faucet

Contaminated air source, or unfiltered

Unsanitar y bar conditions

21

Page 24

SERVICE

HOW TO OBTAIN SERVICE:

For warranty service, please contact your local service provider or DCS Customer Care at (888) 936-7872. Before

you call, please have the following infor mation ready :

■ Model Number (the serial plate is located on the upper left side, inner wall).

■ Serial Number (the serial plate is located on the upper lef t side, inner wall).

■ Code (the serial plate is located on the upper left side, inner wall).

■ Date of installation

■ A brief description of the problem

Your satisfac tion is of the utmost importance to us. If a problem cannot be resolved to your satisfaction, please

write or email us at:

Write:

Fisher & Paykel Appliances, Inc.

Attention: DCS Customer Care

5900 Skylab Road

Huntington Beach, CA 92647

Email:

customer.care@fisherpaykel.com

BEFORE YOU CALL FOR SERVICE:

Check troubleshooting on page 18.

22

Page 25

WARRANTY

LIMITED WARRANTY

When you purchase any new DCS Refrigeration Produc t, you automatically receive a One Year Limited Warranty

covering parts and labor for servicing within the 48 mainland United States, Hawaii, Washington, D.C. and

Canada. In Alaska the Limited Warrant y is the same except that you must pay to ship the Product to the ser vice

shop or for the service technician’s travel to your home. Products for use in Canada must be purchased through

the authorized Canadian distribution channel to ensure regulatory compliance.

You receive an additional Four Year Limited War ranty (for a total of Five Years) covering parts for the sealed

refrigeration system (compressor, evaporator, condenser, filter dr yer, and connec ting tubing) within the 48

mainland United States, Hawaii, Washington, D.C. and Canada. In Alaska the Limited Warranty for the sealed

refrigeration system is the same except that you must pay to ship the Product to the ser vice shop or the ser vice

technician’s travel to your home.

FISHER &PAYKEL UNDERTAKES TO:

Repair without cost to the owner either for material or labor any part of the Product, the serial number of which

appears on the Product, which is found to be defective. In Alaska, you must pay to ship the Product to the

service shop or for the service technician’s travel to your home.

If we are unable to repair a defec tive part of the Produc t after a reasonable number of attempts, at our option

we may replace the part or the Produc t, or we may provide you a full refund of the purchase price of the Product

(not including installation or other charges).

This warranty extends to the original purchaser and any succeeding owner of the Product for products

purchased for ordinar y single-family home use.

All ser vice under this Limited Warranty shall be provided by Fisher & Paykel Appliances Inc. or its Authorize d DCS

Service Agent during normal business hours.

LIMITED WARRANTY

How Long Does this Limited Warranty Last?

Our liability under this Limited Warranty expires One Year from the date of purchase of the Product by the first

consumer.

Our liability for repair of defects in any sealed refrigeration system (compressor, evaporator, condenser, filter

dr yer, and connecting tubing) extends an additional Four Years, for a total of Five Years from the date of

purchase of the Product by the first consumer.

Our liability under any implied warranties, including the implied warranty of merchantability (an unwritten

warranty that the Product is fit for ordinar y use) also expires One Year (or such longer period as required by

applicable law) from the date of purchase of the Product by the first consumer. Some states do not allow

limitations on how long an implied warranty lasts, so this limit on implied warranties may not app ly to you.

THIS WARRANTY DOES NOT COVER

A. Ser vice calls that are not related to any defect in the Product. The cost of a ser vice call will be charged if the

problem is not found to be a defect of the Product. For example:

1. Correc t faulty installation of the Produc t.

2. Instruct you how to use the Product.

3. Replace house fuses, reset circuit breakers, correc t house wiring or plumbing, or replace light bulbs.

4. Correc t fault(s) caused by the user.

5. Change the set-up of the Product.

6. Unauthorized modifications of the Product.

23

Page 26

WARRANTY

7. Noise and vibration that is considered normal e.g. drain sounds, regeneration noises and user warning beeps.

8. Correc ting damage caused by pests e.g. rats, cockroaches etc.

9. Used in commercial applications.

B. Defec ts caused by factors other than:

1. Nor mal domestic use or

2. Use in accordance with the Product’s Use and Care Guide.

C. Defects to the Product caused by accident, neglect, misuses, fire, flood or Act of God.

D. The cost of repairs carried out by non-authorized repairers or the cost of correcting such unauthorized repairs.

E. Travel Fees and associated charges incurred when the product is installed in a location with limited or restricted

access.(i.e. airplane flights, ferr y charges, isolated geographic areas).

F. Normal recommended maintenance as set for th in the Product’s Use and Care Guide.

If you have an installation problem contact your dealer or installer. You are responsible for providing adequate

electrical, exhausting and other connec tion facilities.

We are not responsible for consequential or incidental damages (the cost of repairing or replacing other

property damaged if the Product is defective or any of your expenses caused if the Product is defec tive). Some

states do not allow the exclusion or limitation of incidental or consequential damages, so the above limitation or

exclusion may not apply to you.

HOW TO GET SERVICE

Please read this Use and Care Guide. If you then have any questions about operating the Product, need the name

of your local DCS Authorized Ser vice Agent, or believe the Product is defective and wish service under this

Limited Warranty, please contact your dealer or call us at:

TOLL FREE 1-888-936-7872 or contact us through our web site: www.dcsappliances.com

You may be required to provide reasonable proof of the date of purchase of the Product before the Product will

be ser viced under this Limited Warranty.

COMMERCIAL USE

This warranty applies to appliances used in residential applications; it does not cover their use in commercial

situations.

NO OTHER WARRANTIES

This Limited Warranty is the complete and exclusive agreement between you and Fisher & Paykel Appliances Inc.

regarding any defect in the Product. None of our employees (or our Authorized Service Agents) are authorized to

make any addition or modification to this Limited War ranty.

Warrantor: Fisher & Paykel Appliances, Inc.

If you need further help concer ning this Limited Warranty, please call us at the above number, or write to:

Fisher & Paykel Appliances, Inc.

5900 Skylab Road, Huntington Beach, CA 92647

This Limited Warranty gives you specific legal rights, and you may also have other rights which vary from state to

state.

Fisher & Paykel Appliances I nc. is a leading manufacturer of premium quality cook ing and specialty appliances

under the Fisher & Paykel and DCS brands.

24

Loading...

Loading...