Page 1

DISHDRAWER®

Installation Guide

MODELS:

DD124P5

DD224P5

Page 2

US CA

Safety and warnings

WARNING!

Electrical hazard

Before installing the DishDrawer®, remove the house fuse or open the circuit

breaker.

If permanently connecting the DishDrawer®, be sure the power is isolated

and the DishDrawer® unplugged.

This appliance must be grounded. In the event of a malfunction or

breakdown, grounding will reduce the risk of electric shock by providing

a path of least resistance for electric current. This appliance is equipped

with a cord having an equipment-grounding conductor and a grounding

plug. The plug must be plugged into an appropriate outlet that is installed

and grounded in accordance with all local codes and ordinances. Improper

connection of the equipment-grounding conductor can result in a risk of

electric shock. Check with a qualified electrician or service representative if

you are in doubt as to whether the appliance is properly grounded.

Do not modify the power supply plug provided with the appliance - if it will

not fit the outlet, have a proper outlet installed by a qualified electrician. Do

not use an extension cord, adapter plug or multiple outlet box.

Failure to do so may result in electrical shock or death.

WARNING!

Cut Hazard

Take care - panel edges are sharp.

Failure to use caution could result in injury or cuts.

Important safety precautions!

Installation of this DishDrawer® requires basic mechanical and electrical skills.

Be sure to leave these Instructions with the Customer.

Installation must comply with your local building and electricity regulations.

At the completion of the DishDrawer® installation, the Installer must perform

Final Check List on Page 29.

Remove all packaging materials supplied with the DishDrawer®.

This dishwasher is manufactured for indoor use only.

Ensure all water connections are turned OFF. It is the responsibility of the plumber and

electrician to ensure that each installation complies with all Codes and Regulations.

The DishDrawer® MUST be installed to allow for future removal from the enclosure if service is

required.

The switched power outlet must be outside the DishDrawer® cavity so that it is accessible after

installation.

Care should be taken when the appliance is installed or removed to reduce the likelihood of

damage to the power supply cord.

If the DishDrawer® is to be relocated from one installation to another it must be kept upright to

avoid damage from water spillage.

Make sure only new hoses are used for connection (supplied with DishDrawer®).

Old hoses should not be reused.

Failure to install the DishDrawer® correctly could invalidate any warranty or liability claims.

If the product is installed in a motor vehicle, boat or similar mobile facility, you must bring the

vehicle, boat or mobile facility containing the product to the service shop at your expense or pay

the service technician’s travel to the location of the product.

Page 3

Contents

DOUBLE MODELS

Product and cabinetry dimensions

Installation

Cavity preparation

Optionally hard wiring the product

Route the hoses and move into the cavity

Removing the tub and levelling the product

Securing the product and refitting the tub

Fitting the toekick

Plumbing and drainage - OPTION 1

Plumbing and drainage - OPTION 1 (connection)

Plumbing and drainage - OPTION 2

Plumbing and drainage - OPTION 2 (connection)

Plumbing and drainage - OPTION 3

Plumbing and drainage - OPTION 3 (connection)

SINGLE MODELS

Product and cabinetry dimensions

Installation

Cavity preparation

Optionally hard wiring the product

Route the hoses and move into the cavity

Removing the tub and securing the product

Plumbing and drainage - OPTION 1

Plumbing and drainage - OPTION 1 (connection)

Plumbing and drainage - OPTION 2

Plumbing and drainage - OPTION 2 (connection)

Plumbing and drainage - OPTION 3

Plumbing and drainage - OPTION 3 (connection)

Refitting the tub

Final checklist

2

4

5

6

7

8

9

10

11

12

13

14

15

16

18

19

20

21

22

23

24

25

26

27

28

29

1

US CA

Important!

SAVE THESE INSTRUCTIONS

The models shown in this User Guide may not be available in all markets and are

subject to change at any time. For current details about model and specification

availability in your country, please go to our website www.dcsappliances.com or

contact your local DCS Customer Care Representative.

Page 4

US CA

2

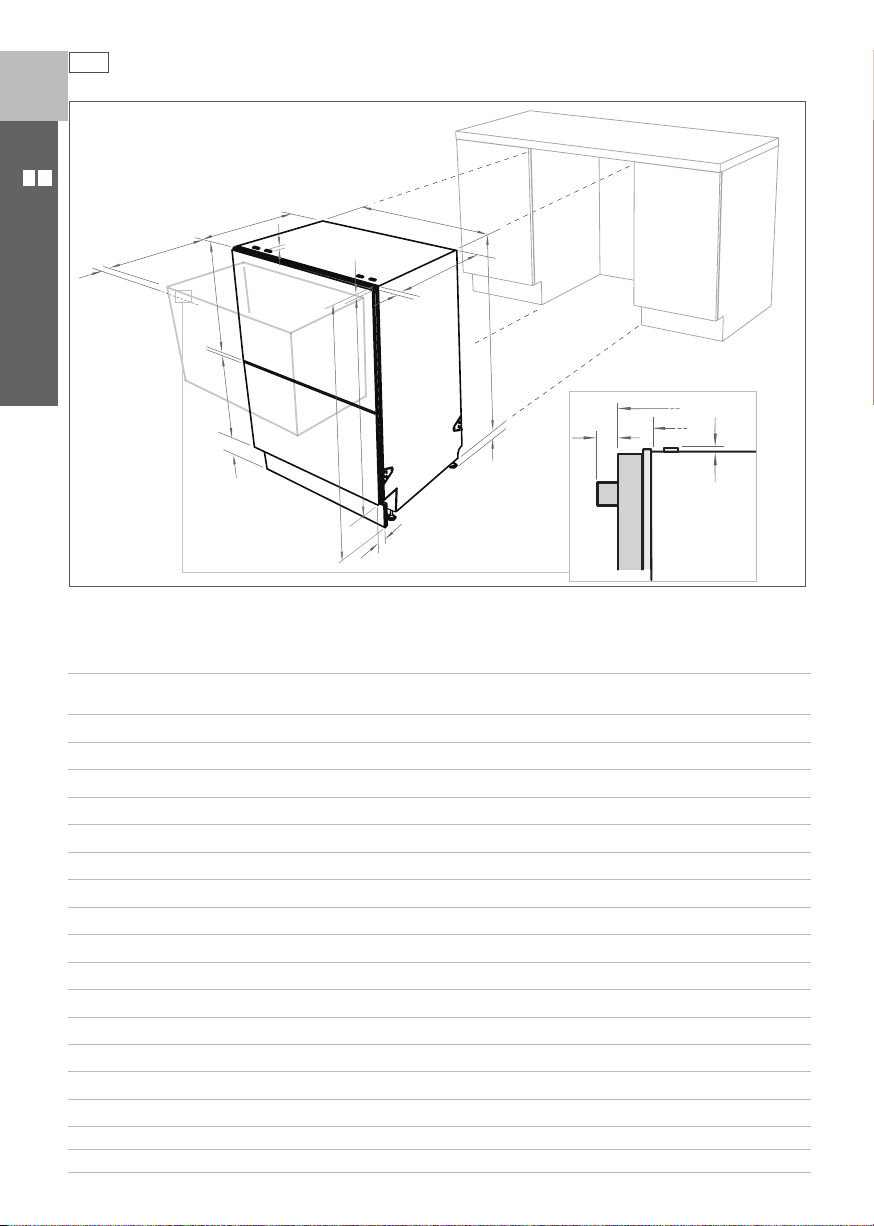

Product dimensions

Installation diagrams for illustration purposes only

C

D

I

K

DOUBLE MODELS

L

M

Product dimensions (inches (mm))

overall height* of product

A

overall width of product 23 ⁄”(605)

B

overall depth of product (excl. curvature/handle) 22 ⁄” (570)

C

depth of drawer (open) (excl. curvature/handle) 20 ⁄” (520)

D

height* of chassis 31 ⁄” (809)

E

height range of levelling feet 2 ⁄” (60)

F

depth of chassis 21 ¾ ” (552)

G

depth of drawer front panel (excl. curvature/handle) 1” (25)

H

depth of handle 3 ⁄” (81)

I

depth of kickstrip 2 - 4 ⁄” (50 - 110)

J

height of upper drawer front 15 ⁄” (398)

K

height of lower drawer front 14” (356)

L

height of kickstrip (adjustable)

M

height of installation tab slots (on top of chassis) ¾ ” (2)

N

height of drawer fronts 30 ⁄” (764)

O

height* of top of upper drawer to top of chassis ¾ ” (2)

P

* Chassis heights include tab slots

B

N

P

G

H

E

C

G

O

A

F

I

N

J

Pre nished

Flat door

DD224P5

32 ¼ - 34 ⁄”

(819.5- 879.5)

2 ¾ - 4 ¾ ” (70 - 120)

Page 5

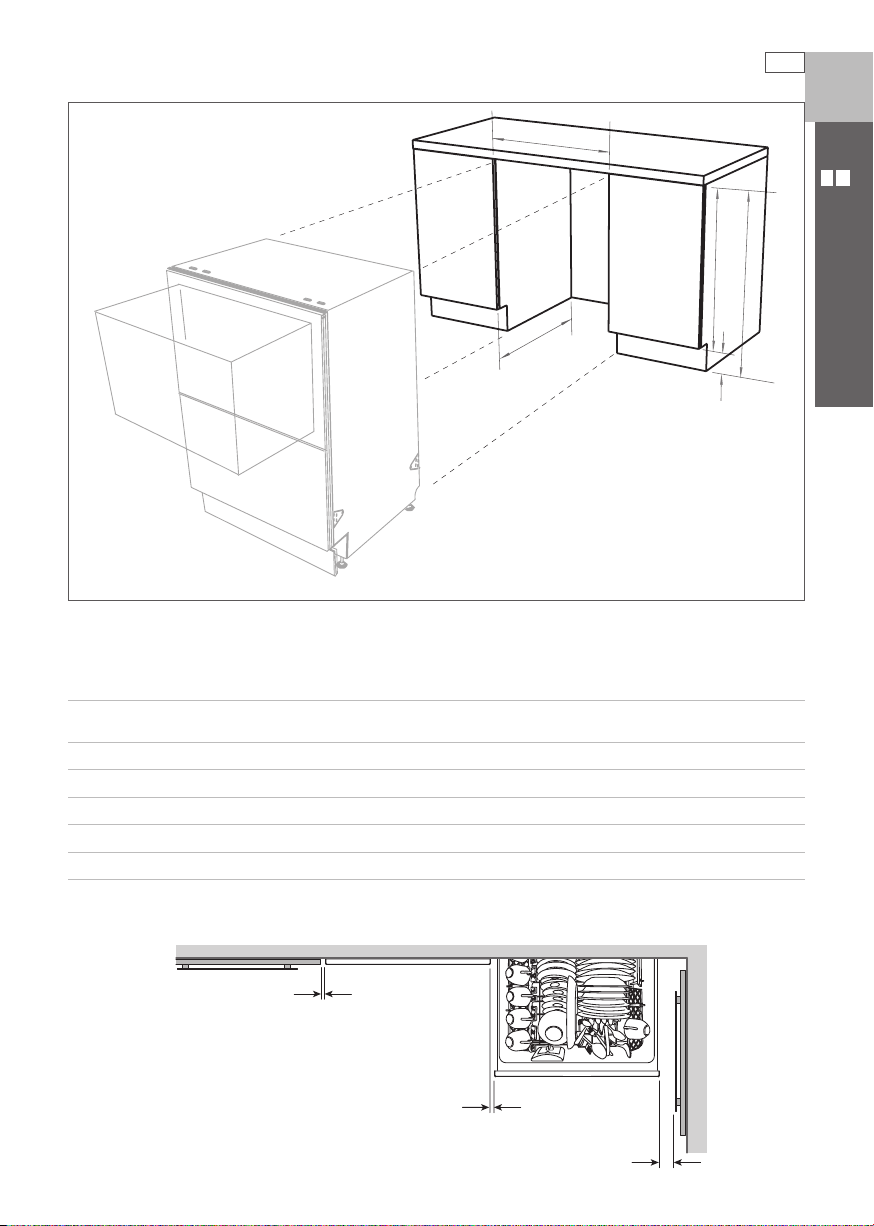

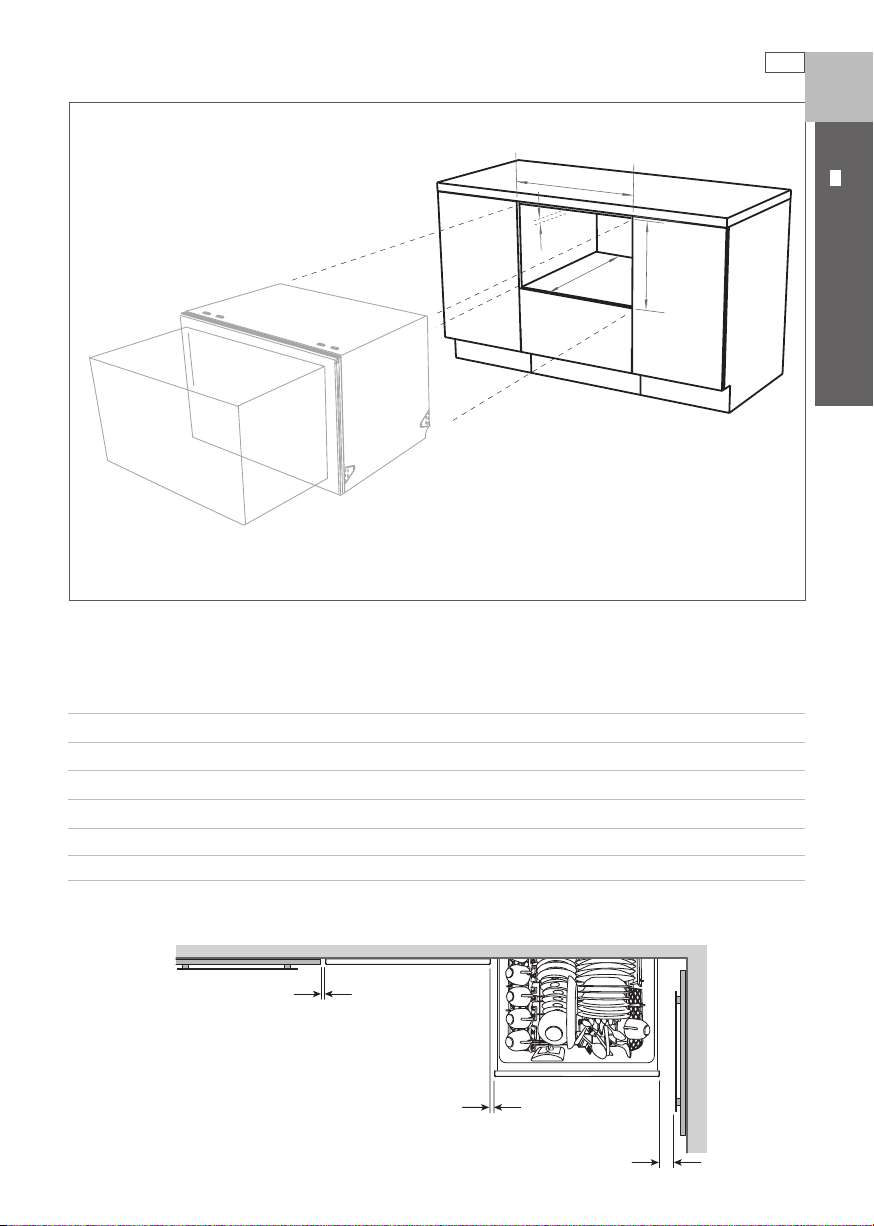

Cabinetry dimensions

Installation diagrams for illustration purposes only

B

C

Pre nished

Cabinetry dimensions (inches (mm))

Flat door

DD224P5

3

US CA

D

A

DOUBLE MODELS

E

inside height of cavity

A

inside width of cavity 24” (610)

B

inside depth of cavity (inside)

C

height of adjacent cabinetry 28 ⁄” (720)

D

height of kickstrip

E

2 ¾ - 4 ¾ ” (70 - 120)

Minimum clearances (inches (mm))

⁄” (2.5 mm)

⁄

” (2.5 mm)

” (13 mm)

½

32 ⁄ - 34 ¾ ”

(820 - 882.5)

22 ⁄” (580)

Page 6

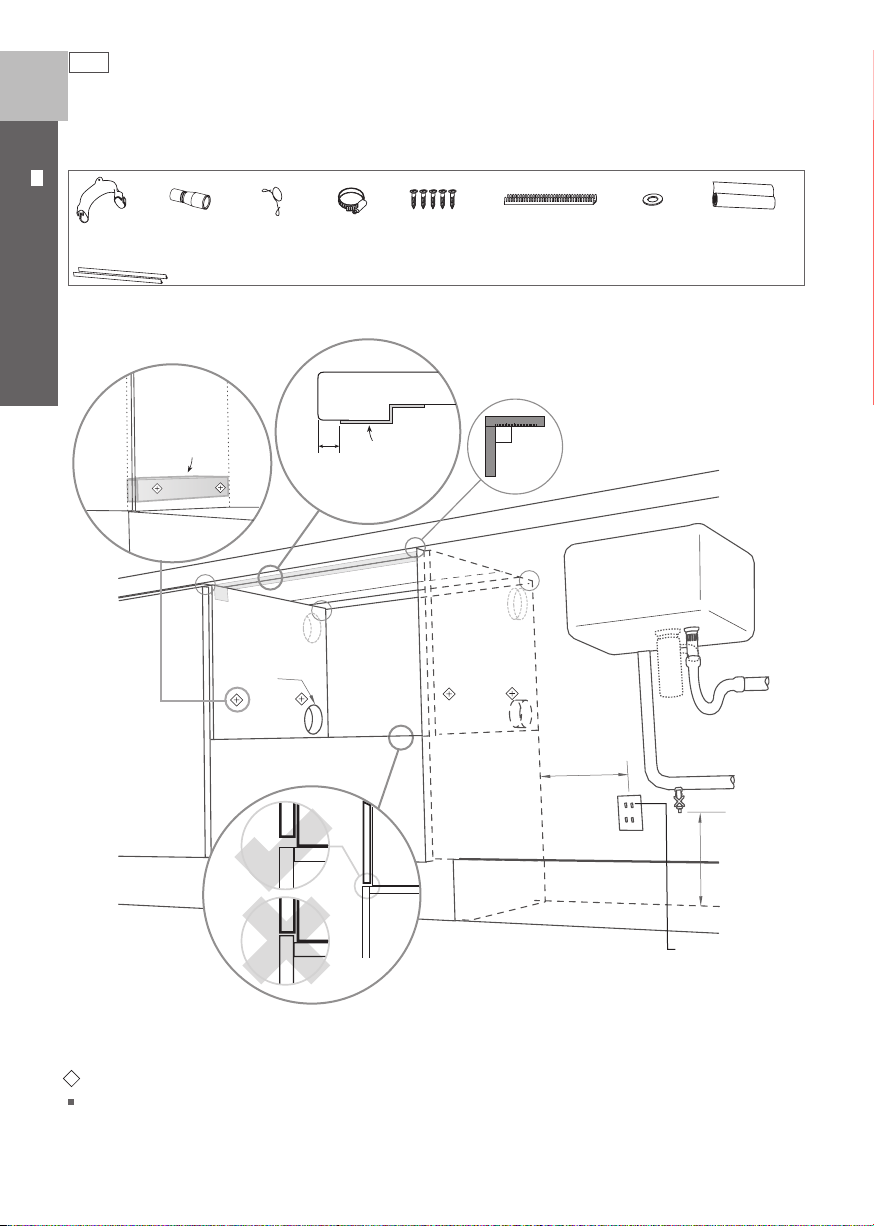

US CA

4

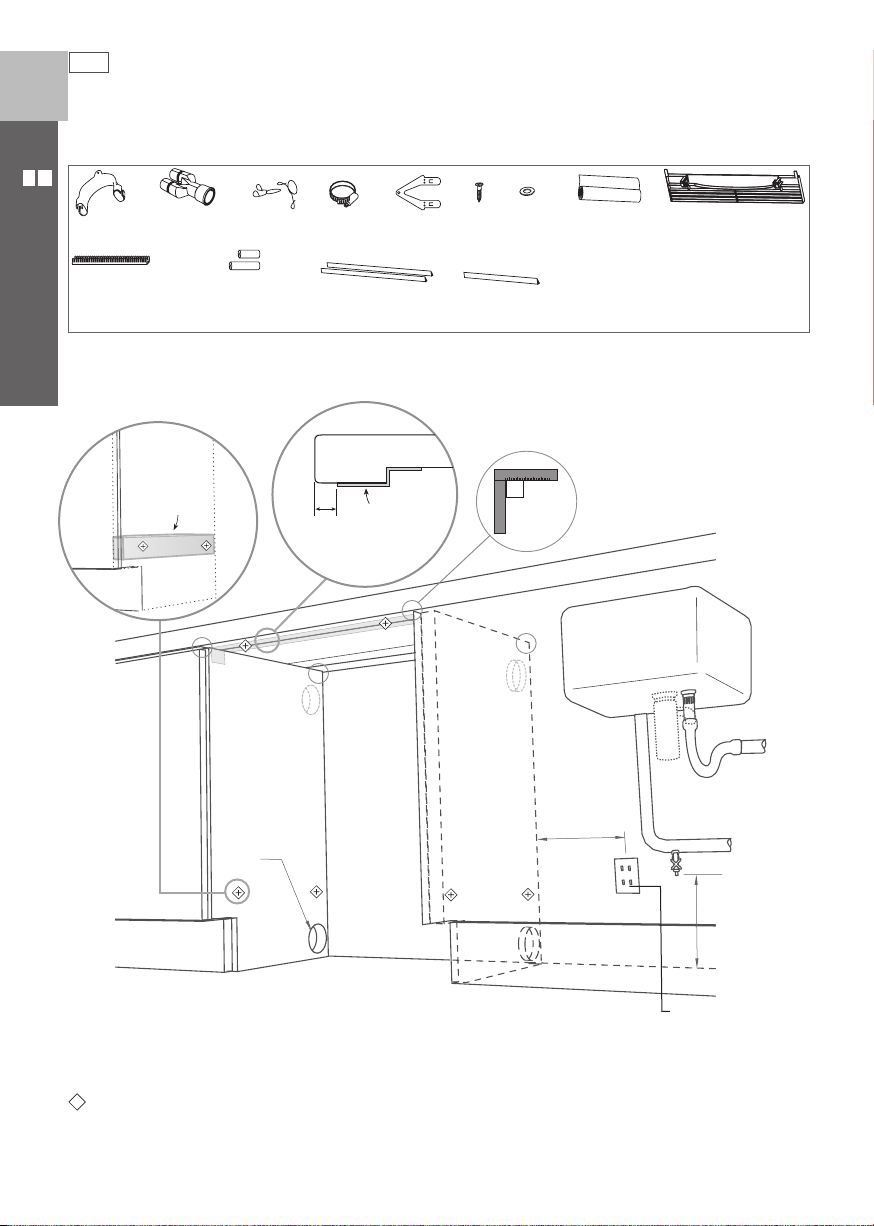

Cavity preparation

Parts supplied

1 ½ ” (

Clamp (1)

Side flexible

extrusions (2)

⁄”

(

10 mm)

38 mm)

Moisture

protection

tape must

be applied.

Drain hose

support (1)

Edge Protector (1)

(if service hole

partition is metal)

If the Drain hose(s) supplied are not long enough to reach your services, you must use a Drain Hose Extension Kit

P/N 525798 which will extend the drain hose(s) by 3.6m. The kit is available from the nearest DCS

DOUBLE MODELS

Authorized Service Agent, or by phone: 1-888-281-5698, or www.dcsappliances.com. DO NOT extend beyond this limit.

If no side partition,

use a brace for

securing.

Drain hose

joiner (1)

Hexagonal

socket (2)

(Long & Short)

2” x 4”

max. ø

Wire clip (2)

Install

tabs (2)

Phillips

16 mm

screws (9)

Top flexible

extrusion (1)

Washer (1)

o

90

max.

(

450 mm)

Moisture

protection

tape (1)

(to prevent

moisture damage)

Prefinished toe kick (1)

White or Black

Note: Services can be located

either side of DishDrawer®.

17 ⁄”

min.

7 ⁄”

(

*

*

Important!

Be sure the edges of the services hole are smooth or covered. If the service hole is through a metal partition

the hole must be protected with the Edge Protector supplied to prevent damage to the power cord or hoses.

These marks indicate mounting tab screw locations

Preferred position. If adequate clearance, services hole can be higher to clear toe kick space.

*

If hole is higher, ensure drain hose(s) are routed straight into the waste connection.

200 mm)

110-120 VAC

max. 15 A

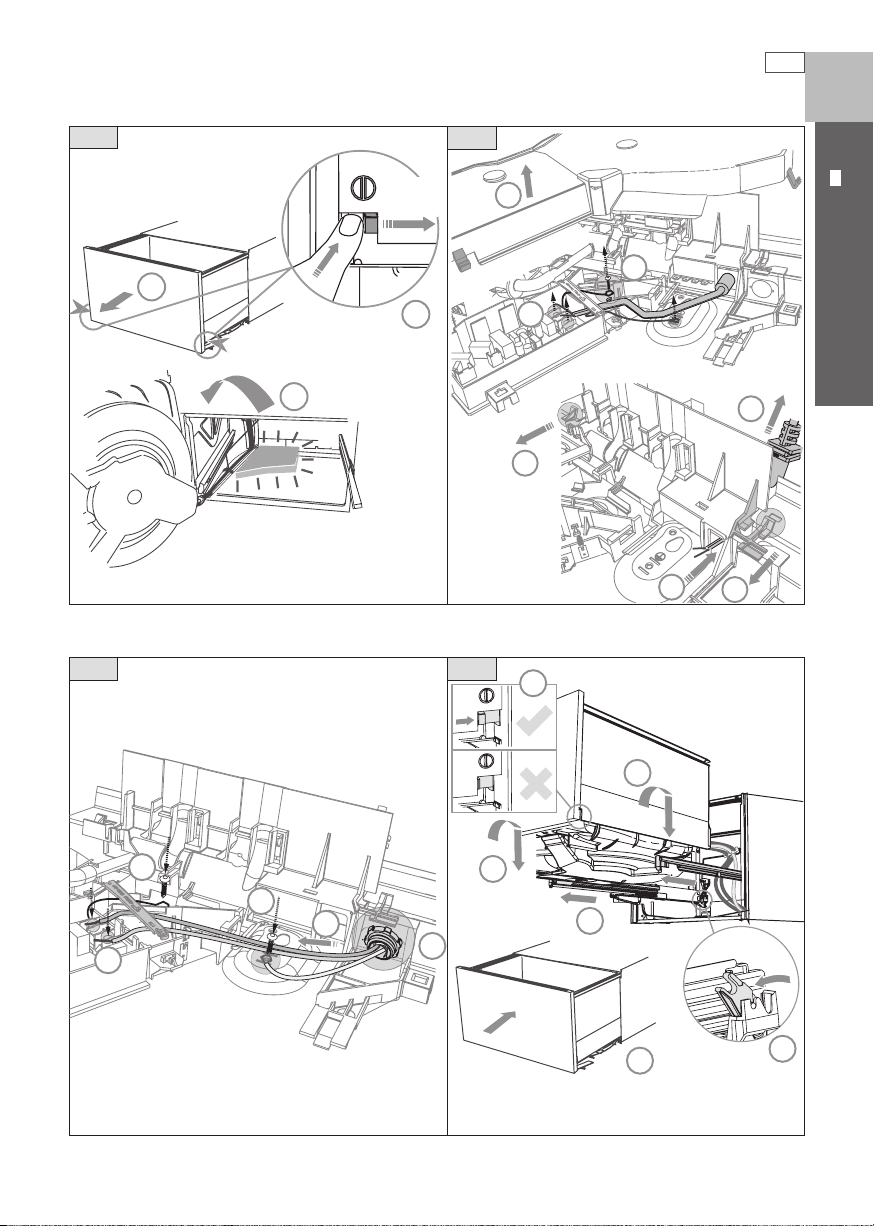

Page 7

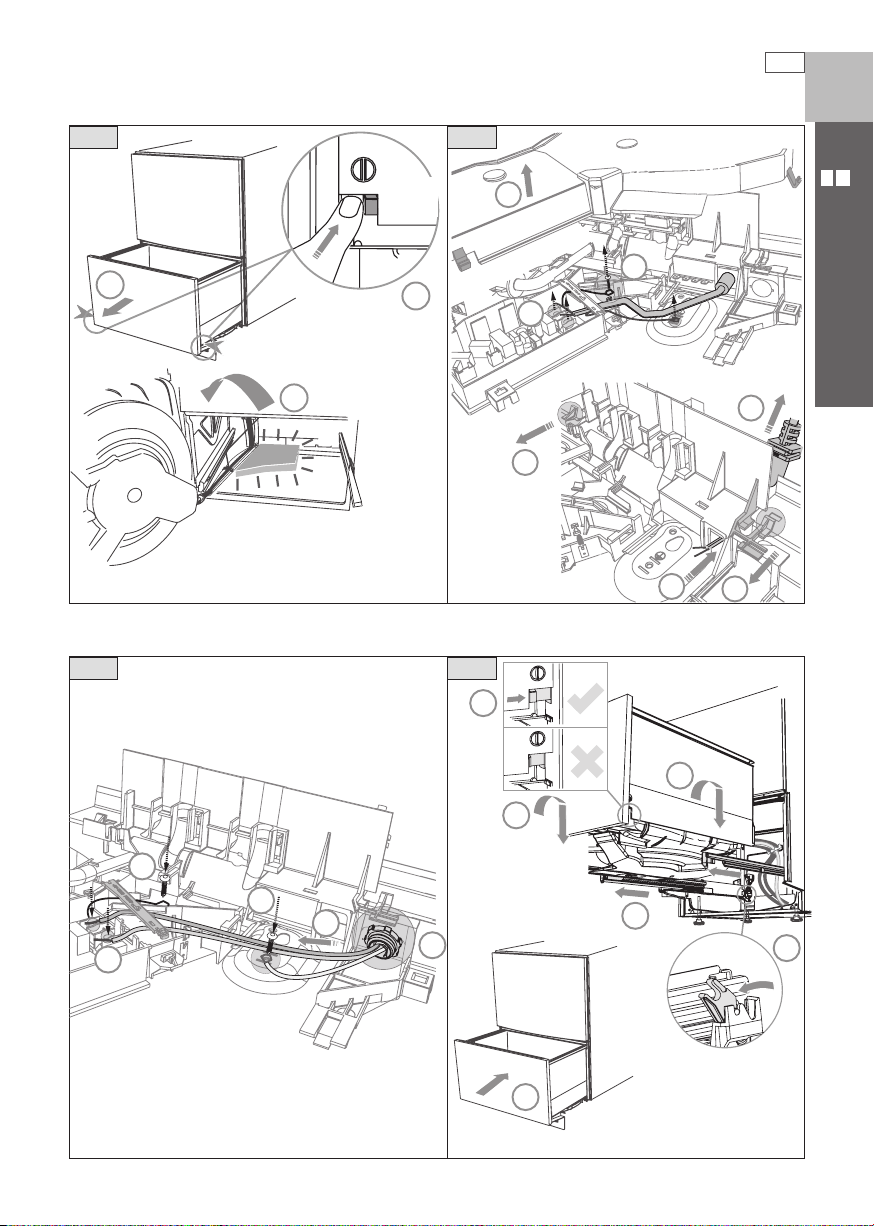

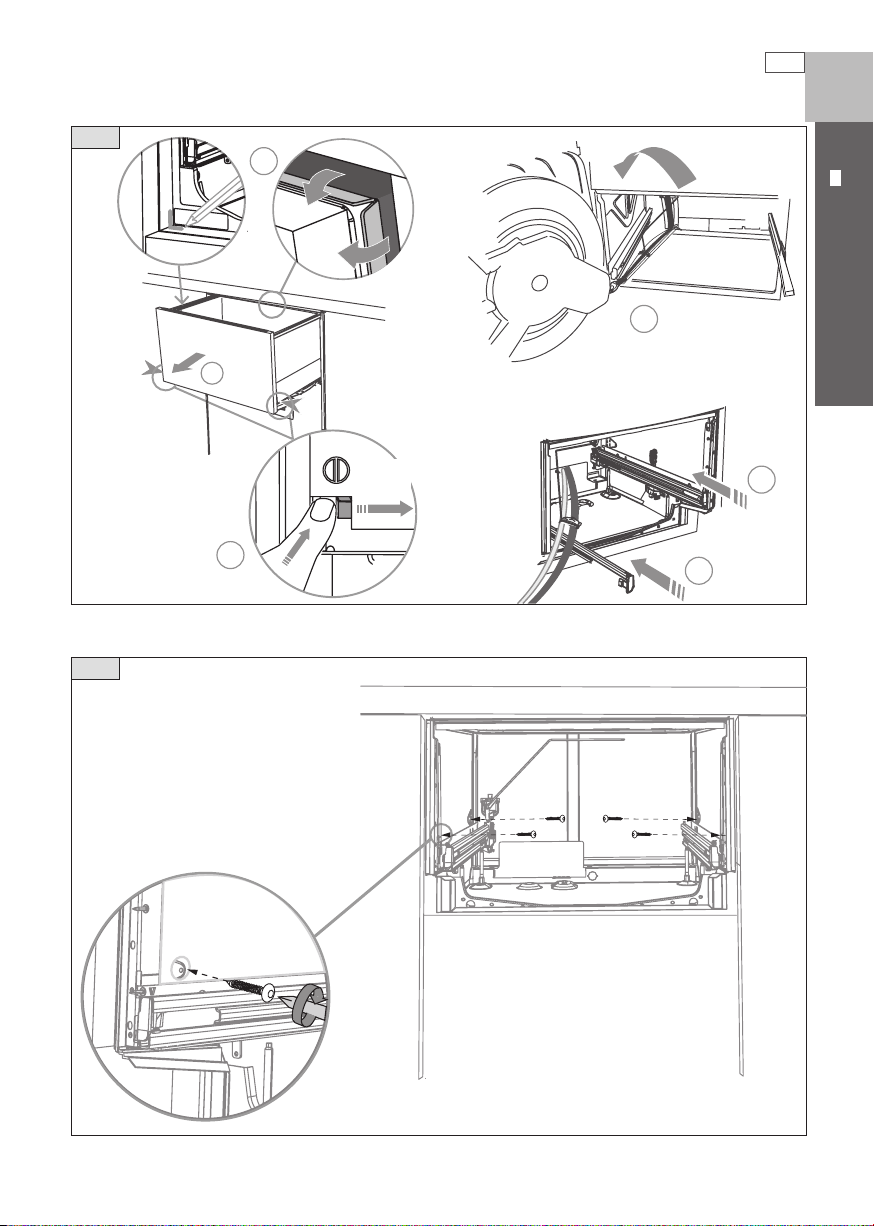

Optionally hard wiring the product

1 2

1 ⁄”

30 mm

30 mm)

(

4

5

US CA

1

3

Ensure the tub is removed and

then rotated counter-clockwise

to prevent kinked hoses.

Remove knock-out for cable

3

clamp. Fit suitable cable clamp for

the conduit and terminate the

wiring as shown.

5

2

6

DOUBLE MODELS

16

Remove power supply cord.

8

7

8

4

15

Ensure the tub clips on

both sides are reset.

15

7

12

11

11

10

Ensure the tub is

now rotated

clockwise back.

9

17

13

14

Before refitting the tub,

ensure the hoses are not

twisted and the latches at

the rear of each drawer

runner are facing forward.

Page 8

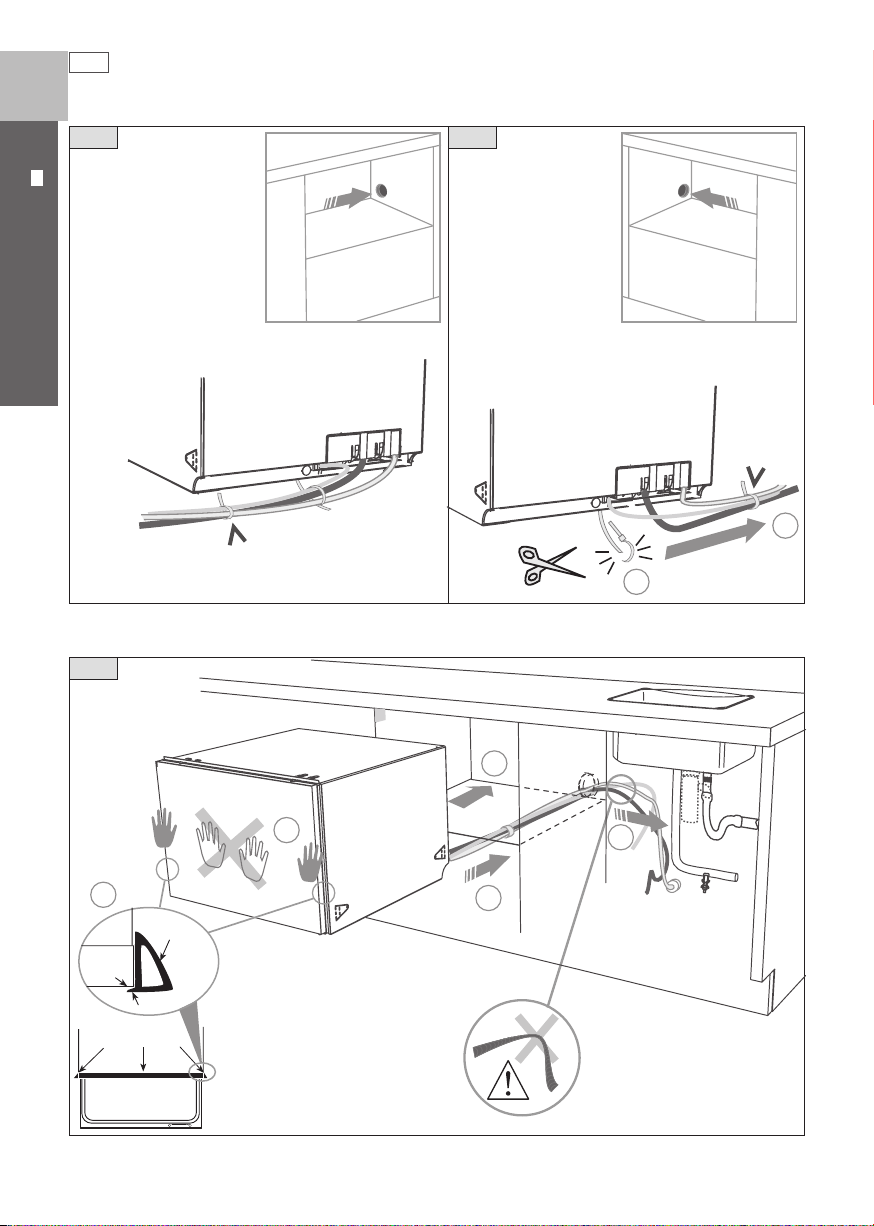

US CA

6

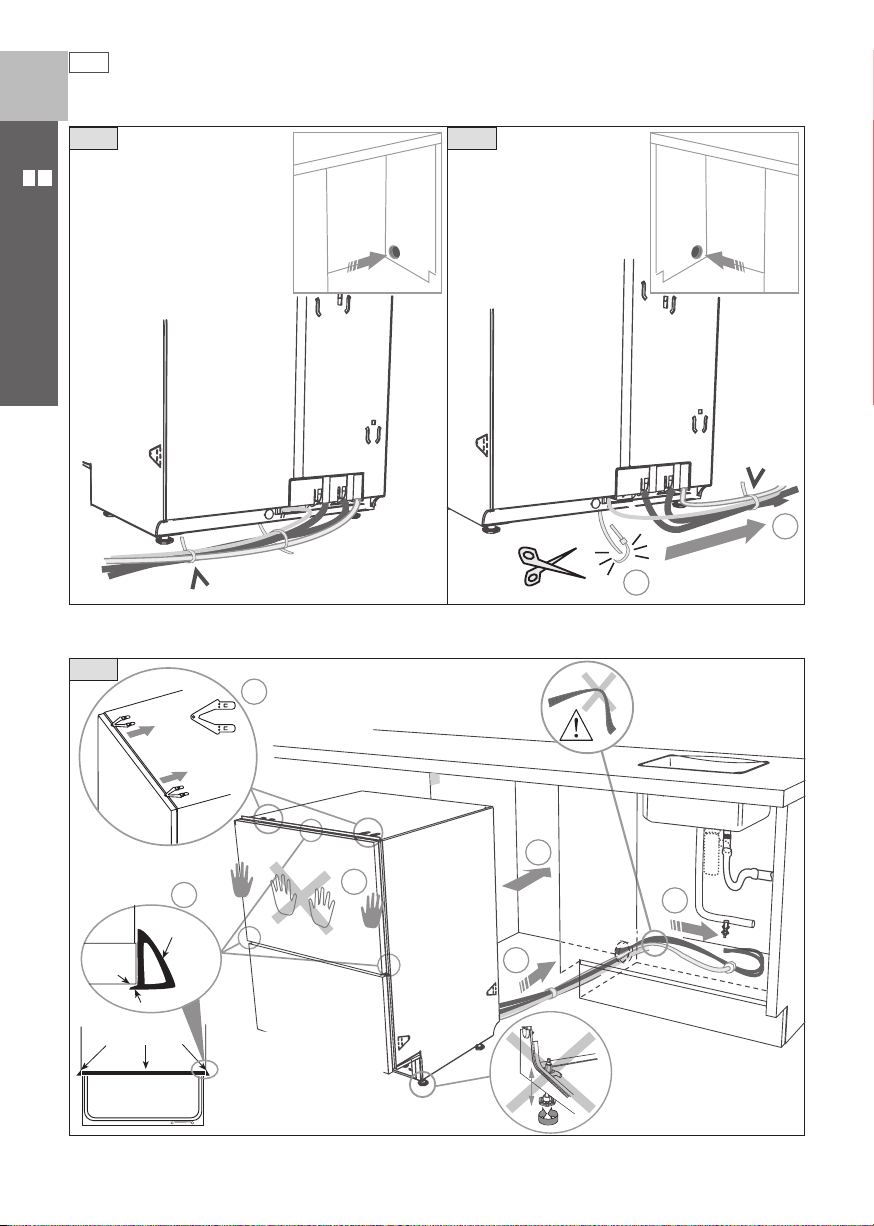

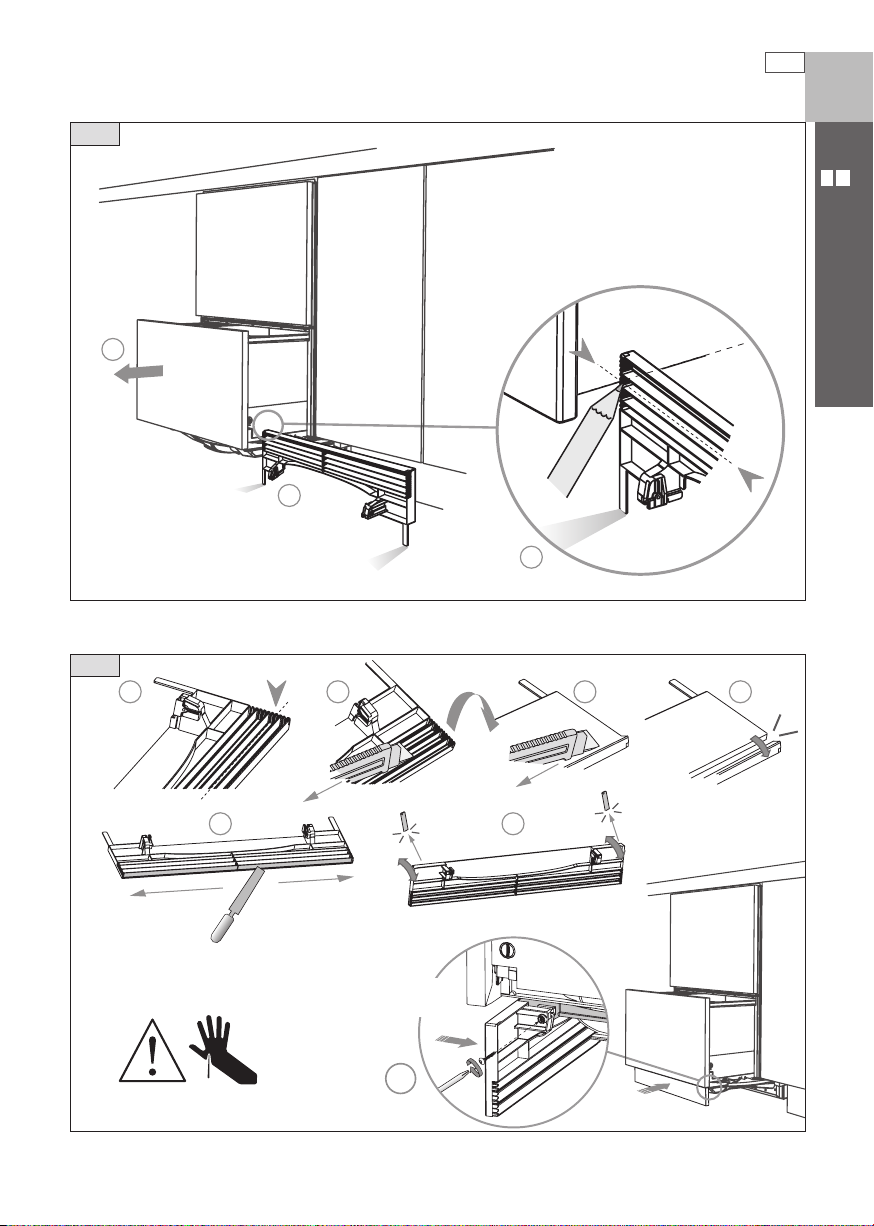

Route the hoses and move into the cavity

1a

DOUBLE MODELS

2

optional

optional

Tie together to avoid kinking.

If top two tabs are being used,

2

ensure they’re securely fitted

before sliding product into

cavity.

1b

2

1

Ensure hoses and cord

are not kinked or twisted.

Chassis

trim

edge

Flexible

extrusions

Open drawer

Side

extrusion

Lip

3

If cavity is bigger than

specified (Pg 3), flexible

extrusions can be stuck along

the top and sides of the product.

Ensure extrusions do not prevent

the drawer from closing completely.

4

4

1

1

Loosen feet first, but

do not fully extend

until product is in cavity.

Page 9

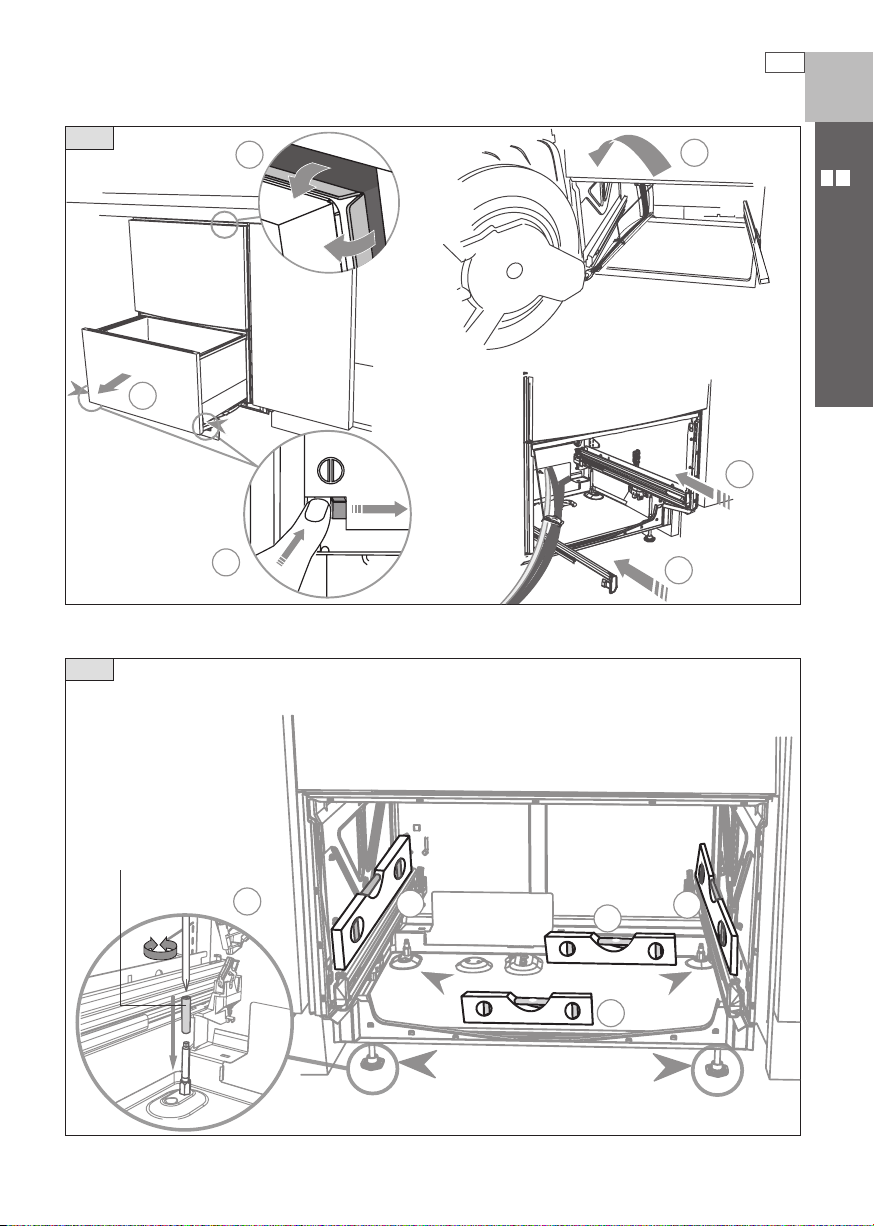

Removing the tub and levelling the product

7

US CA

3

1

Ensure the tub is removed and

then rotated counter-clockwise

to prevent kinked hoses.

4

DOUBLE MODELS

2

30 mm

3

4

Ensure product is level. Using the most appropriate length

Hexagonal socket supplied, and a screwdriver, fully extend

levelling feet up to required distance.

5

5

Hexagonal socket

1

2

4

3

5

x 4

Page 10

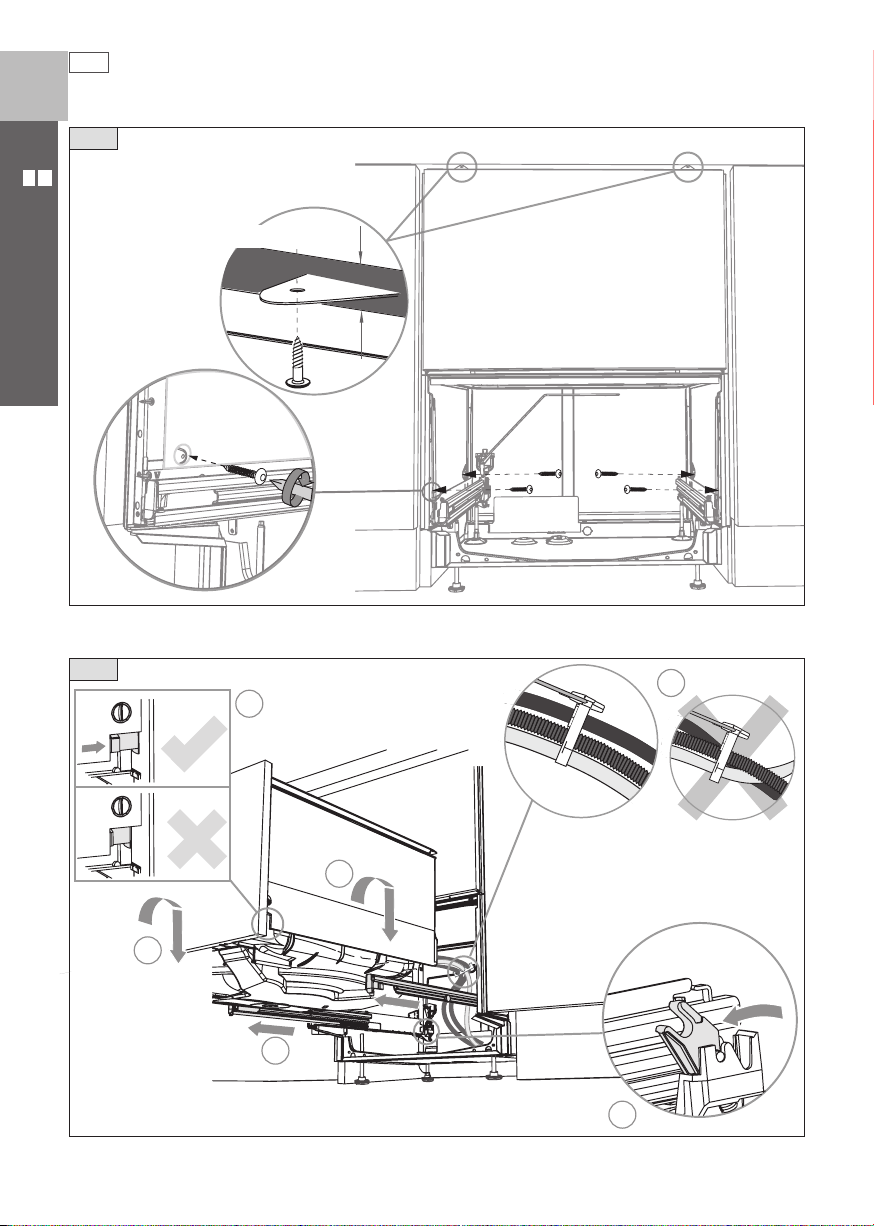

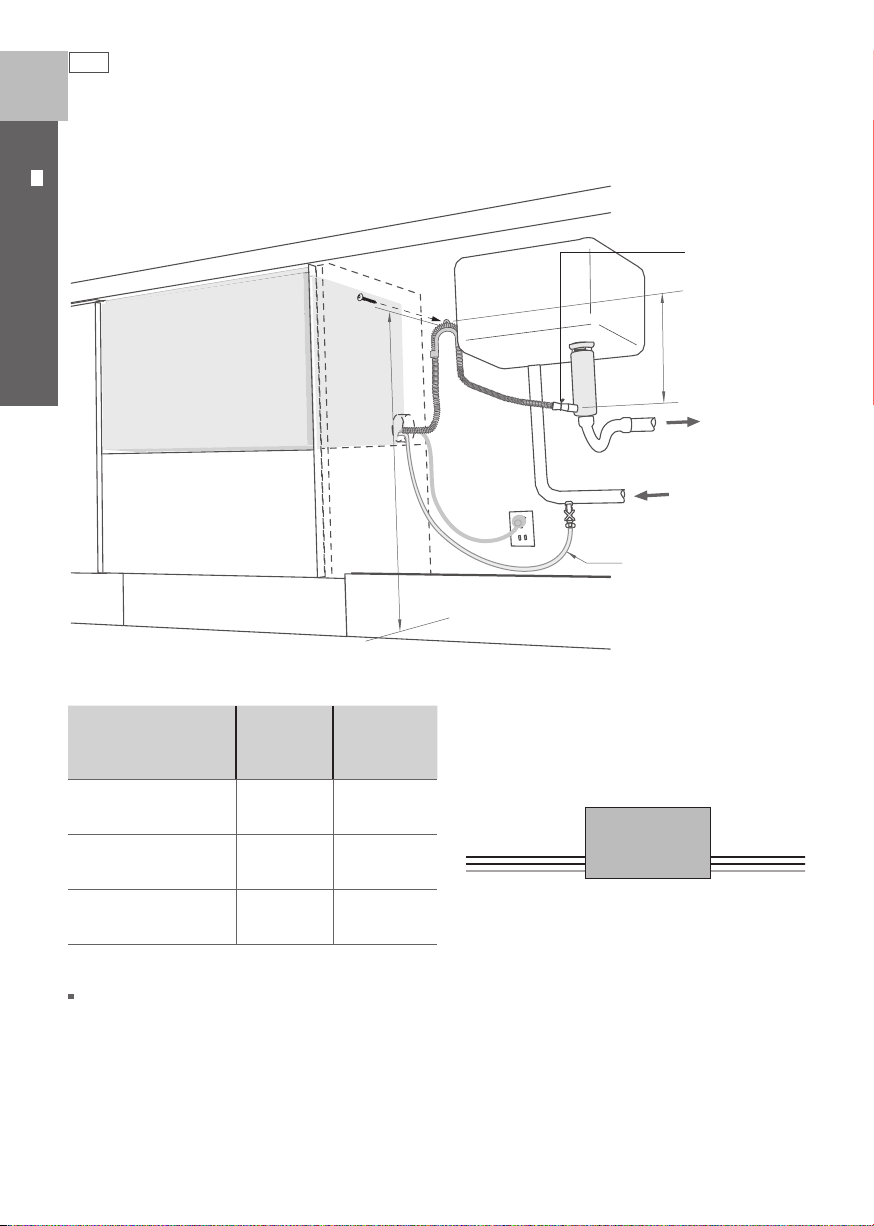

US CA

8

5

The mounting tabs

are in pairs, one on

each side of the

product. At least two

sets of tab pairs must

be used.

A and B tab pairs

OR B and C tab pairs

or all three pairs.

Ensure the sound

insulation is

repositioned

correctly.

DOUBLE MODELS

Securing the product and re tting the tub

max.

optional

¾ ” (19 mm)

C

C

6

4

Ensure the tub is

now rotated

clockwise back.

Ensure the tub clips on

both sides are reset.

5

4

1

BB

A

A

3

Before refitting the tub,

ensure the hoses are not

twisted and the latches at

the rear of each drawer

runner are facing forward.

2

Page 11

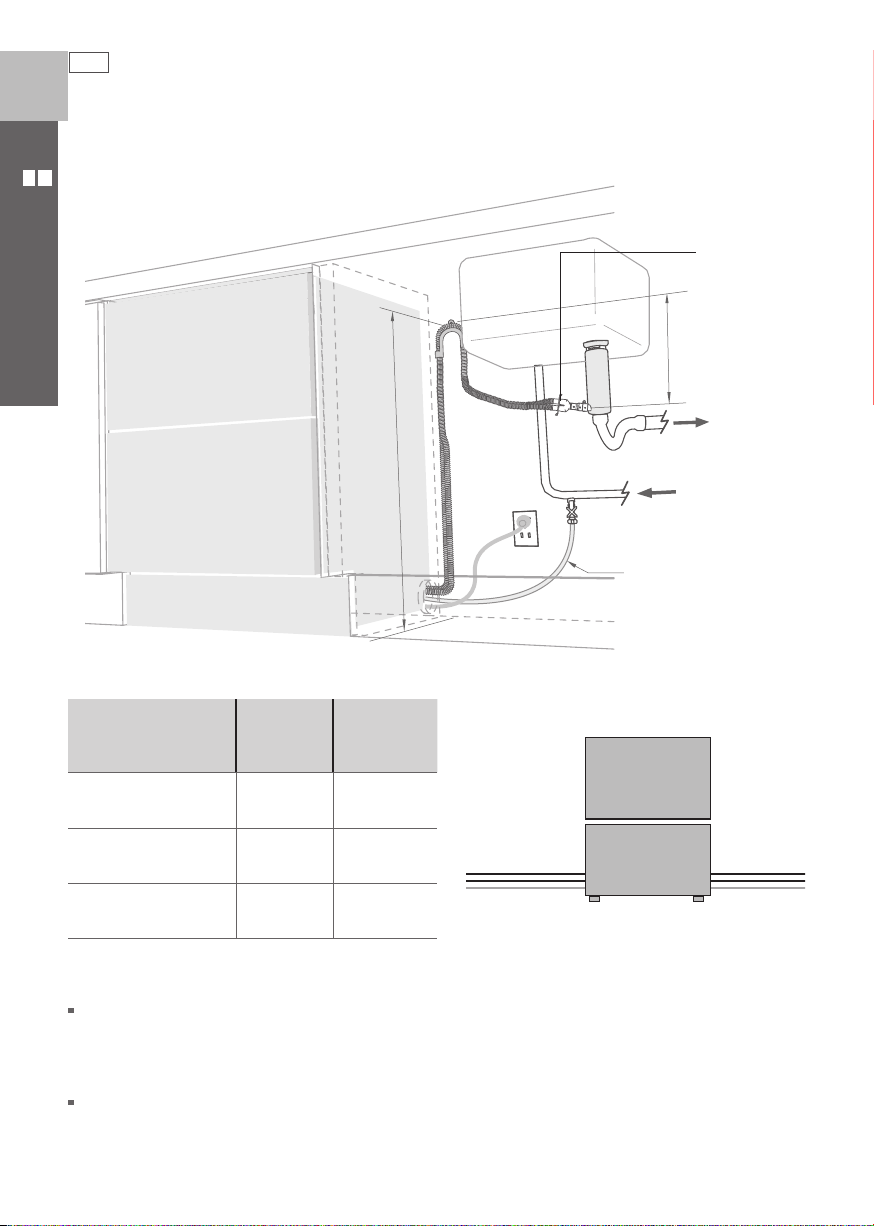

Fitting the toekick

7

1

2

3

9

US CA

DOUBLE MODELS

8

4 5 6 7

19

8 9

Important!

D o not overtighten screw.

10

Page 12

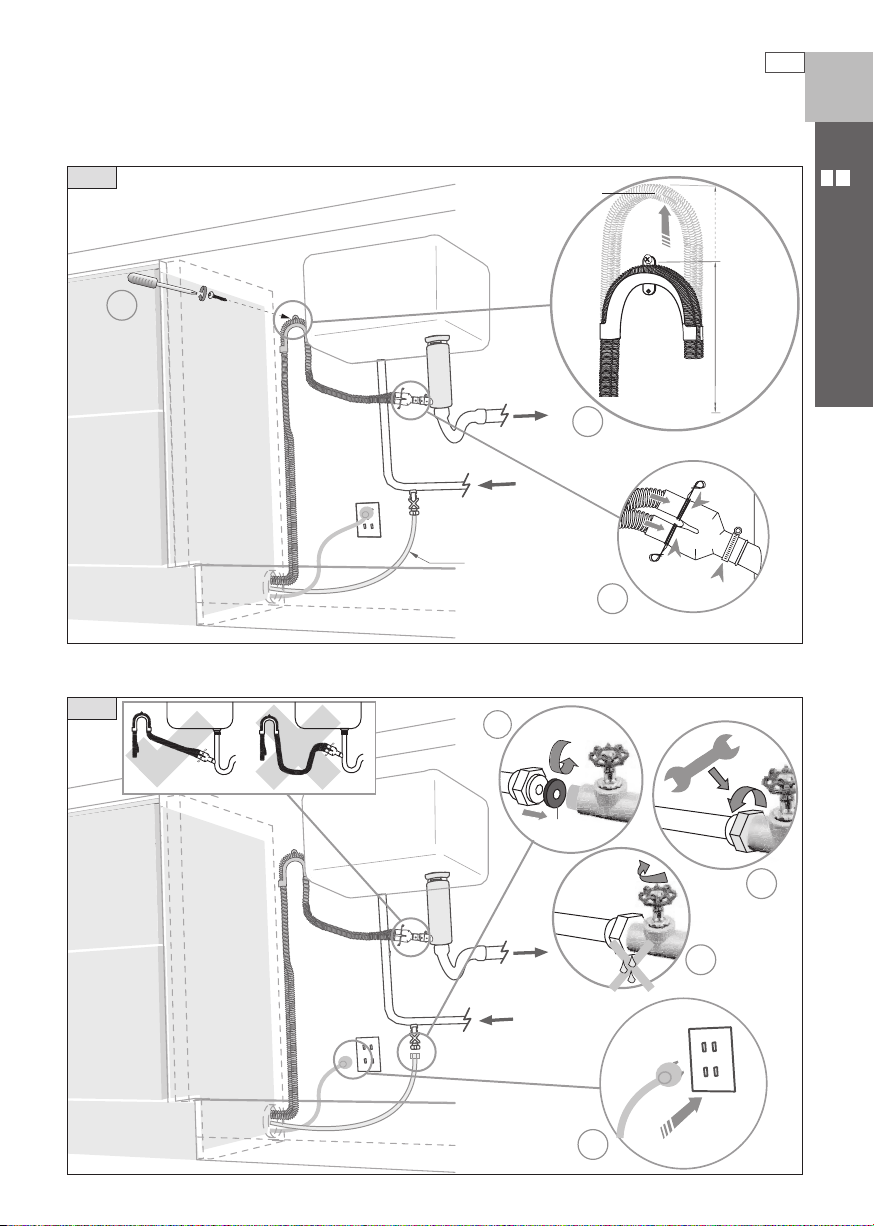

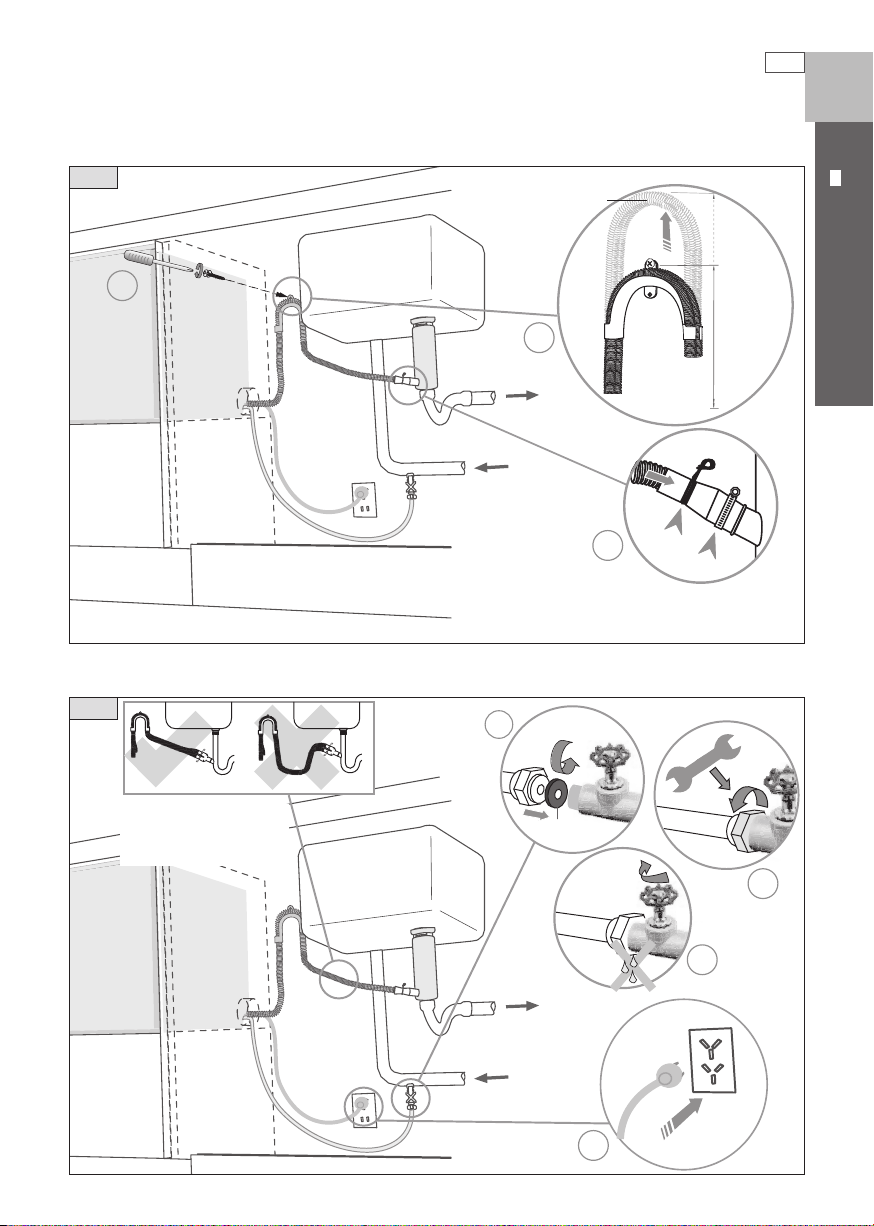

US CA

10

DishDrawer® with Waste Disposal

DOUBLE MODELS

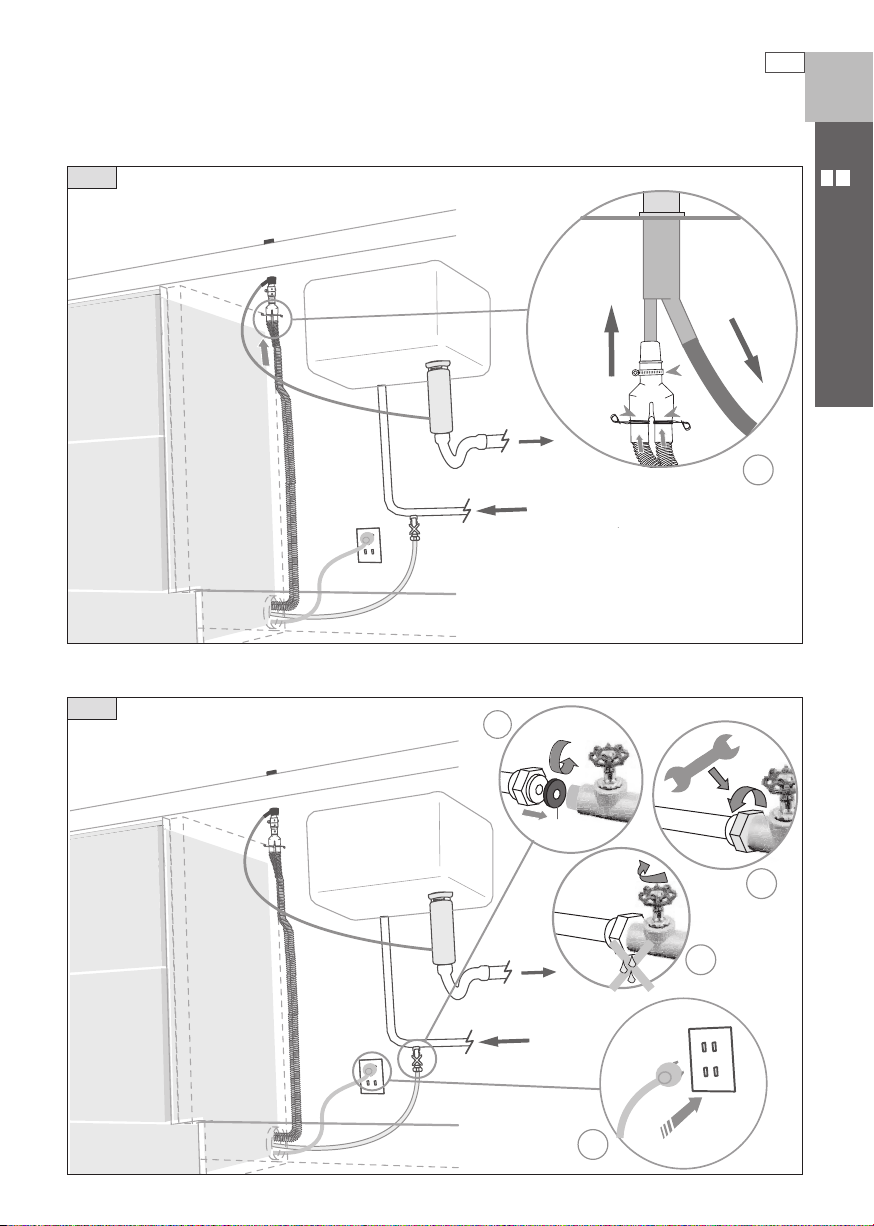

Plumbing and drainage - OPTION 1

29 ½ ” - 34 ¾ ”

750 - 882.5 mm)

(

Valve

Supplied drain

hose joiner

(ø

” (19 mm))

¾

waste tee)

HIGHLOOP

min. 6” (150 mm)

Waste

Water

supply

(HOT)

min. R 8 ” (200 mm)

Max. distance of

hoses and cord from

chassis edge

Drain hose

Inlet hose

Power cord

Water Pressure Max Min

Water softener models 1 MPa (145 psi) 0.1 MPa (14.5 psi)

Other models 1 MPa (145 psi) 0.03 MPa (4.3 psi)

Drains will need to be separated to satisfy Kosher requirements. We suggest you confirm

acceptability with your local Rabbi in respect to Kosher installations.

Left hand

side

79”

(2011 mm)

61”

(1561 mm)

70”

(1776 mm)

Right hand

side

71”

(1794 mm)

53”

(1344 mm)

61”

(1559 mm)

Left hand

side

Right hand

side

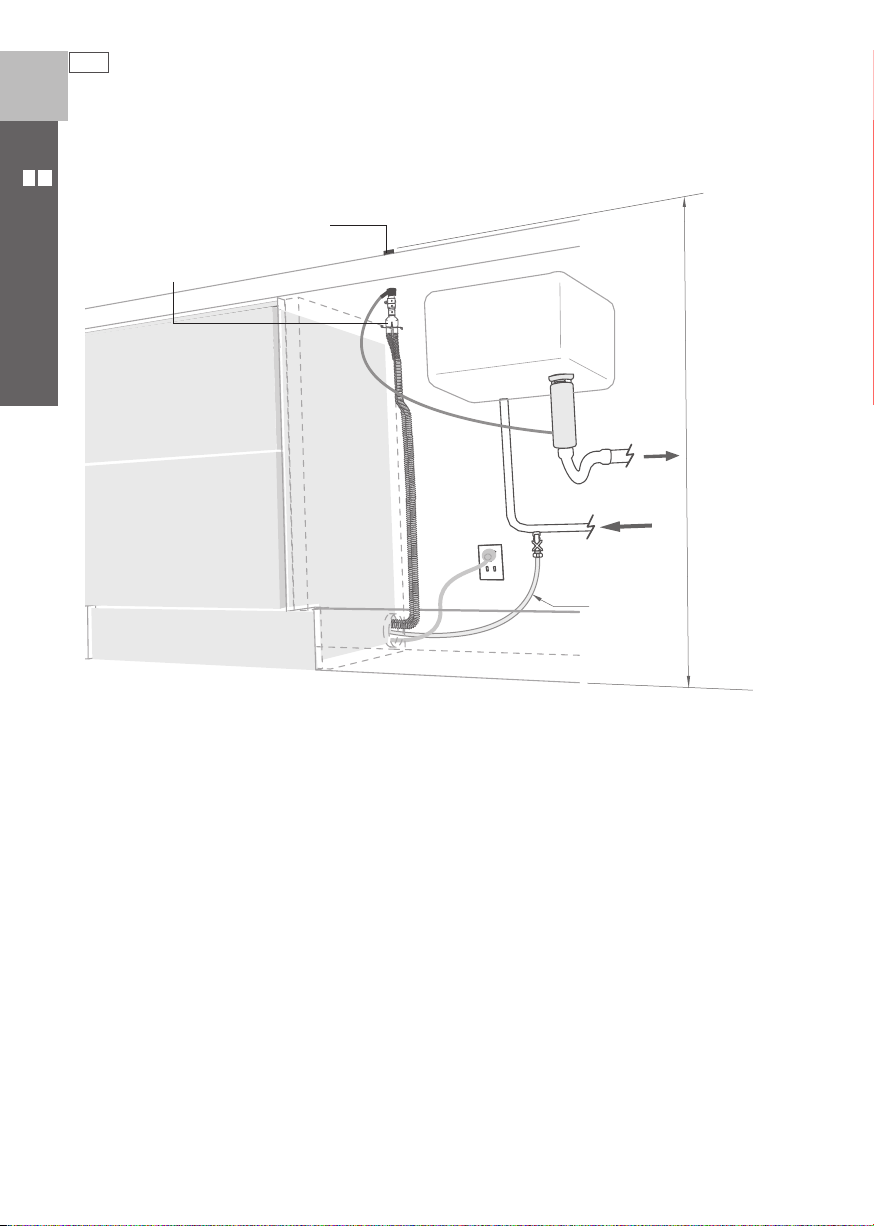

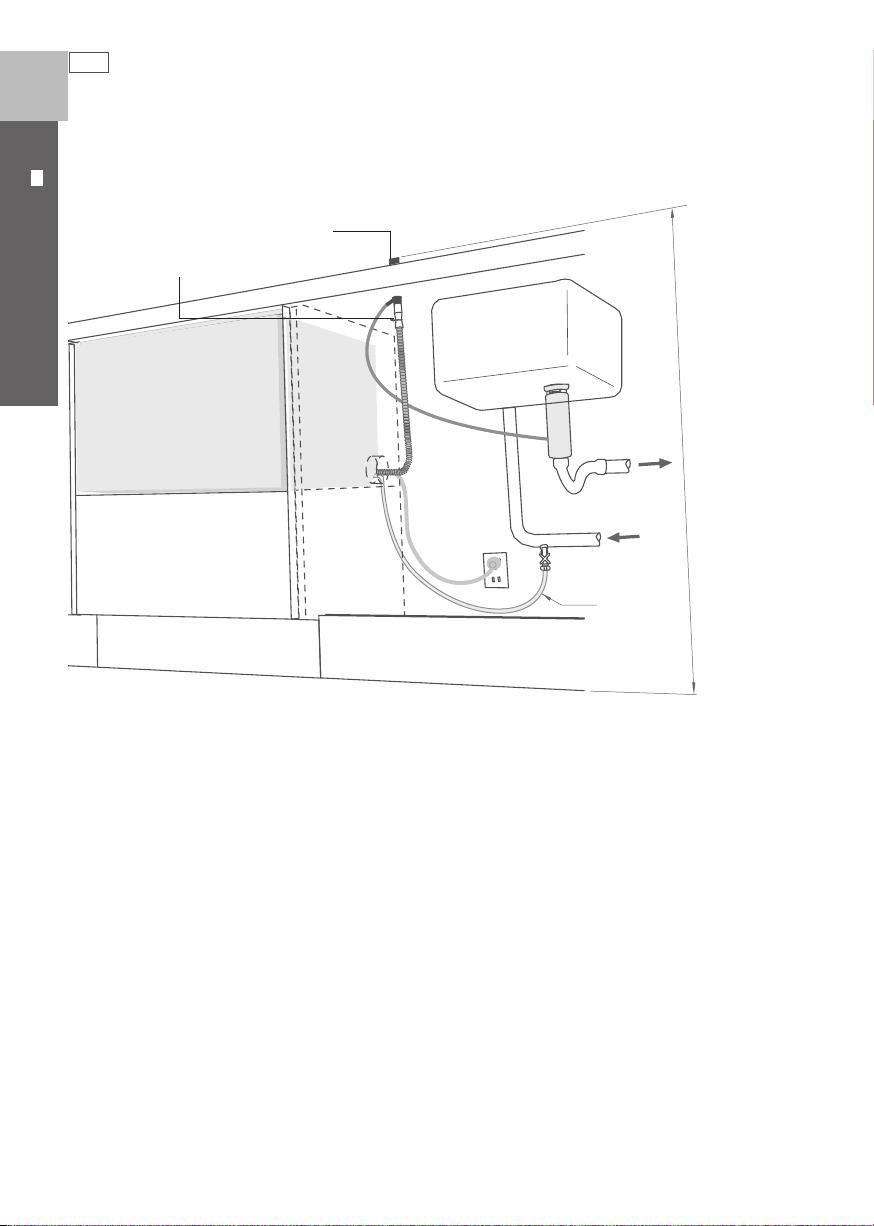

Page 13

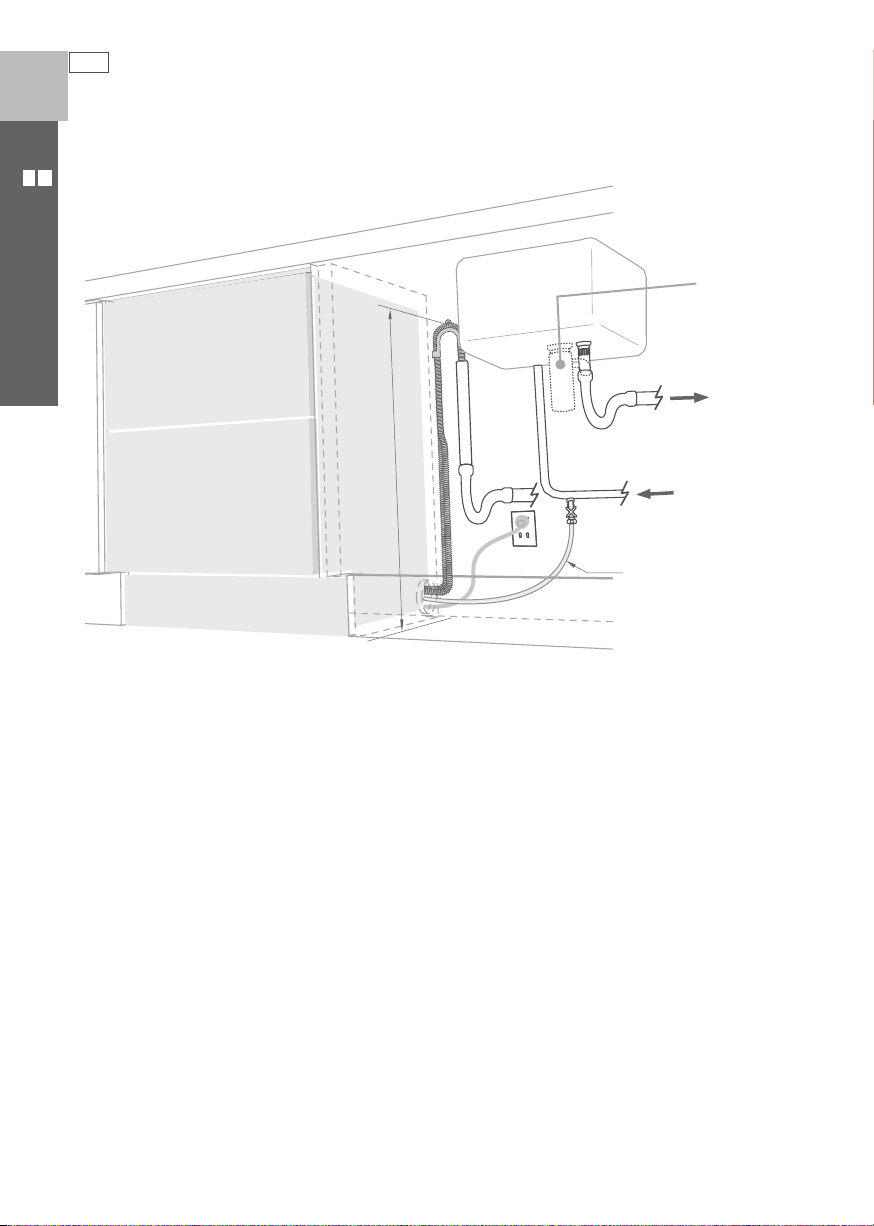

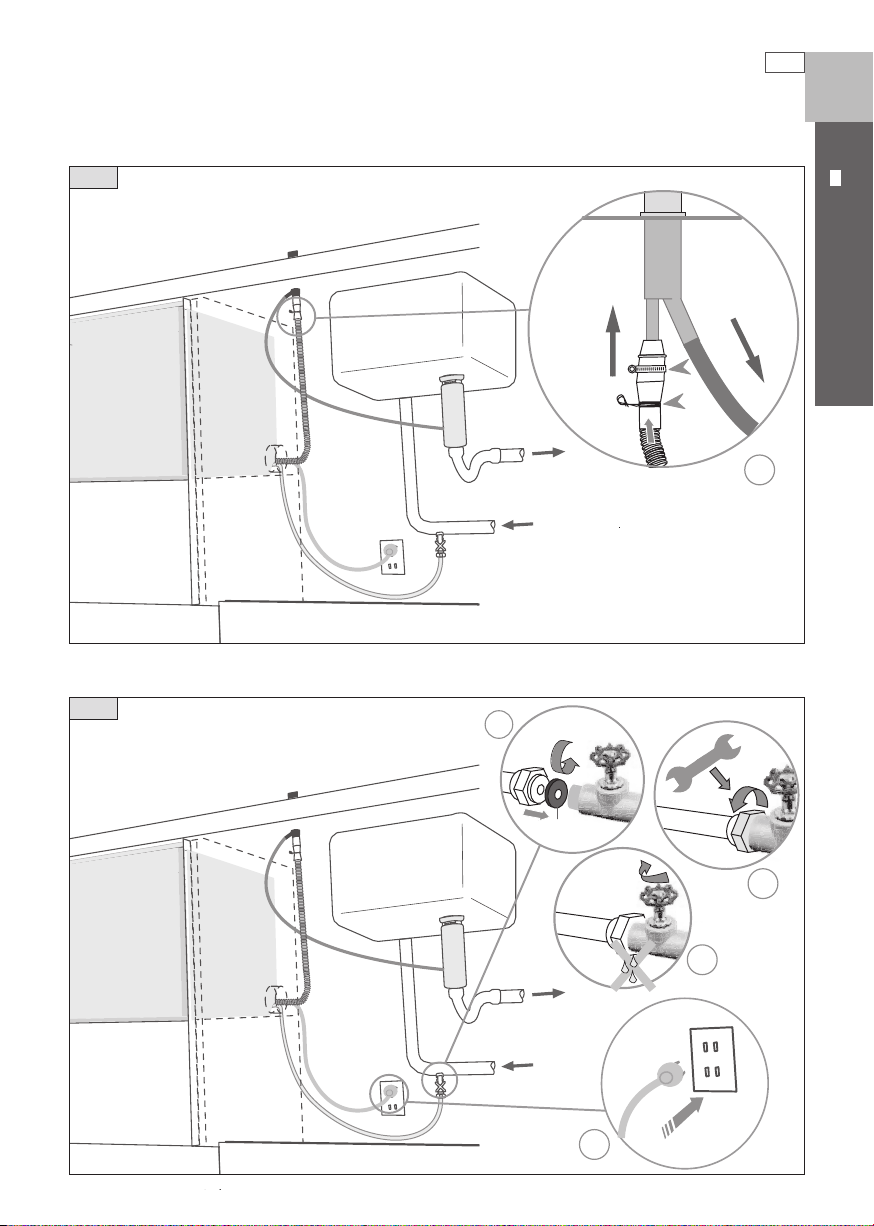

Plumbing and drainage - OPTION 1 (connection)

DishDrawer® with Waste Disposal

11

US CA

10

9

1

If space is limited

for fixing, push hose

through drain hose

support to required

height

29 ½” - 34 ¾”

(750 -

882.5 mm)

DOUBLE MODELS

2

3

1

Ensure hoses are routed

straight to joiner. Remove

excess hose material if

necessary.

Fit supplied

washer

4

2

3

Page 14

US CA

12

Plumbing and drainage - OPTION 2

DishDrawer® using Air Break with Drain Hose Joiner

Supplied drain

hose joiner

(ø

” (19 mm))

¾

waste tee)

DOUBLE MODELS

Air Break

Valve

Waste

Water

supply

(HOT)

min. R 8 ”

200 mm)

(

37 ⁄” (950 mm)

Max. height to

top of Air Break

(countertop or

wall mounted)

Page 15

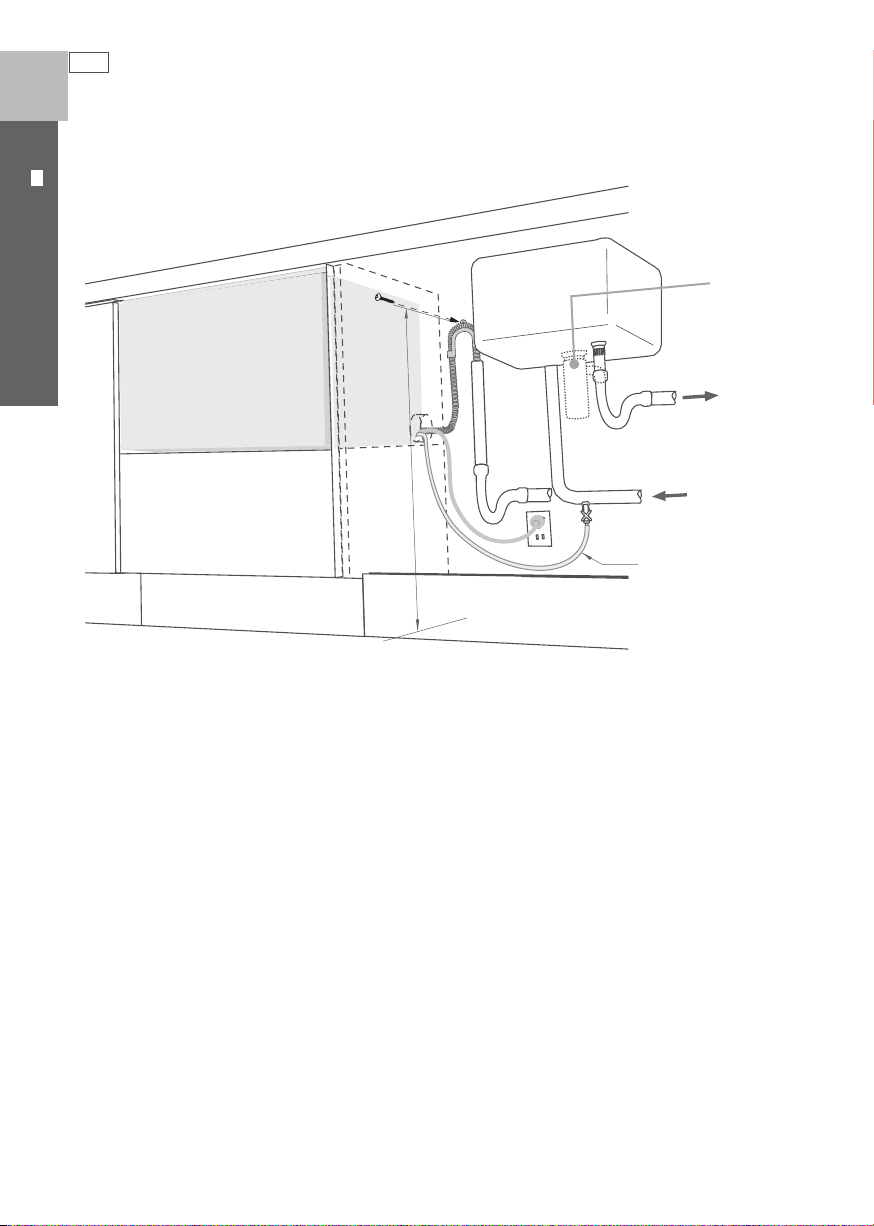

Plumbing and drainage - OPTION 2 (connection)

DishDrawer® using Air Break with Drain Hose Joiner

9

13

US CA

DOUBLE MODELS

1

10

Ensure hoses are routed

straight to joiner. Remove

excess hose material if

necessary.

1

Fit supplied

washer

4

2

3

Page 16

US CA

14

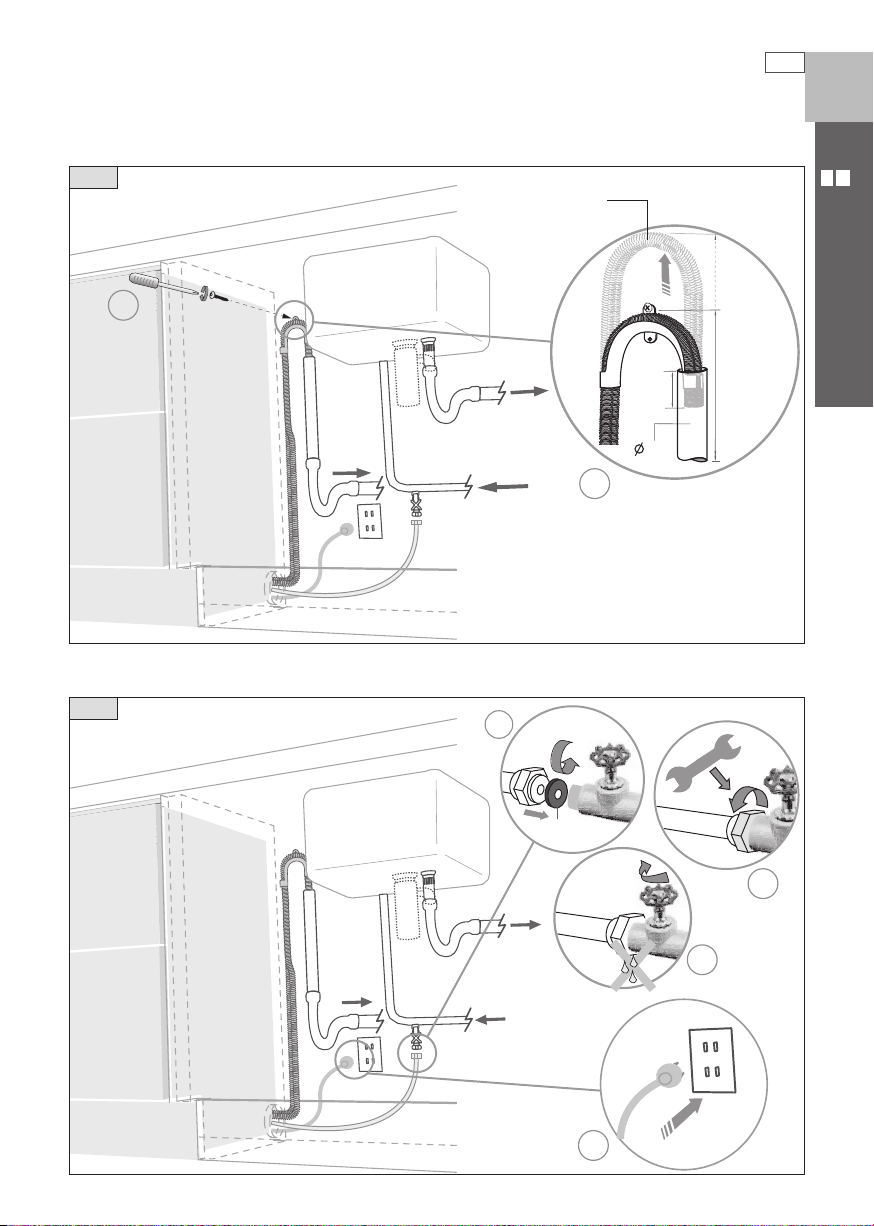

Plumbing and drainage - OPTION 3

DishDrawer® and Standpipe Ø

DOUBLE MODELS

1 ½ ”

(38 mm)

29 ½ ” - 34 ¾ ”

750 - 882.5 mm)

(

Waste

Valve

min. R 8 ” (200 mm)

Waste disposal

(optional)

Waste

Water

supply

(HOT)

Page 17

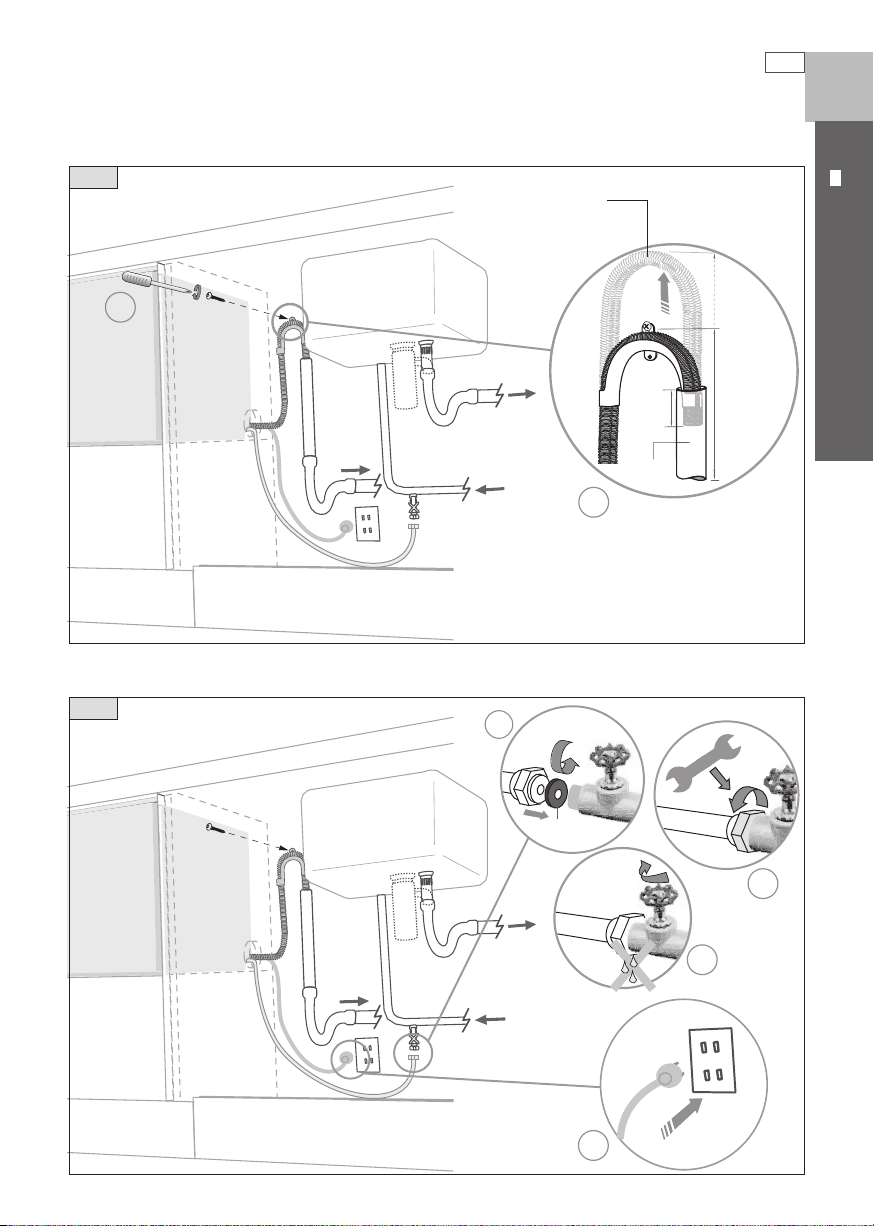

Plumbing and drainage - OPTION 3 (connection)

15

US CA

DishDrawer® and Standpipe Ø

9

1

10

1 ½ ”

(38 mm)

If space is limited

for fixing, push hose

through drain hose

support to required

height

max. 4 ¾”

(120 mm)

1 ½”

(38 mm)

29 ½” - 34 ¾”

(750 -

882.5 mm)

DOUBLE MODELS

2

1

Fit supplied

washer

4

2

3

Page 18

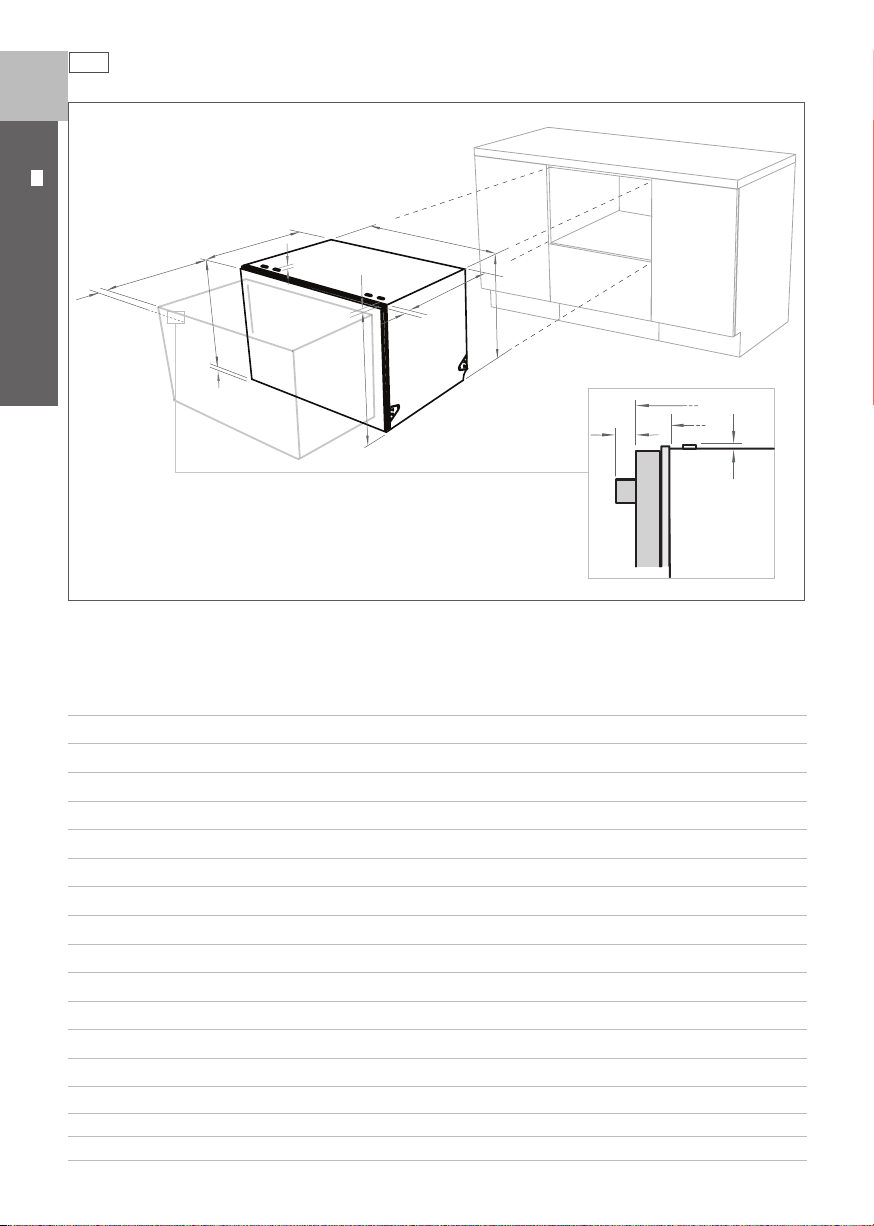

US CA

16

Installation diagrams for illustration purposes only

Product dimensions

C

D

H

I

SINGLE MODELS

J

Product dimensions (inches (mm))

overall height* of product

A

overall width of product

B

overall depth of product (excl. curvature/handle)

C

depth of drawer (open) (excl. curvature/handle)

D

height* of chassis

E

depth of chassis

F

depth of drawer front panel (excl. curvature/handle)

G

depth of handle

H

height of drawer front

I

height of venting area at base of product

J

height of installation tab slots (on top of chassis)

K

height* of top of drawer to top of chassis

L

B

K

L

F

G

E

A

C

F

H

Flat door

DD124P5

16 ⁄” (409)

23 ⁄” (605)

22 ⁄” (570)

20 ½ ” (520)

16 ⁄” (409)

21 ¾ ” (552)

1” (25)

3 ⁄” (81)

15 ⁄” (398)

⁄” (9)

⁄” (2)

⁄” (2)

Pre nished

K

*Chassis heights include tab slots

Note: for Pre nished Flat door models, the height from the top of handle to the top of door - 2 ⁄” (59.5 mm)

Page 19

Cabinetry dimensions

Installation diagrams for illustration purposes only

B

D

A

C

17

US CA

SINGLE MODELS

Cabinetry dimensions (inches (mm))

inside height of cavity

A

inside width of cavity

B

inside depth of cavity (inside)

C

clearance below benchtop

D

* Clearance is measured from the underside of benchtop to the chassis

Minimum clearances (inches (mm))

⁄” (2.5 mm)

⁄

” (2.5 mm)

” (13 mm)

½

Flat door

DD124P5

16 ¼ ” (412)

24” (610)

22 ⁄” (580)

Min. ⁄” (3)*

Pre nished

Page 20

US CA

18

Cavity

Cavity preparation

Drain hose

support (1)

If the Drain hose(s) supplied are not long enough to reach your services, you must use a Drain Hose Extension Kit

P/N 525798 which will extend the drain hose(s) by 3.6m. The kit is available from the nearest DCS

Authorized Service Agent, or by phone: 1-888-281-5698, or www.dcsappliances.com. DO NOT extend beyond this limit.

Drain hose

joiner (1)

Side flexible extrusions (2)

Wire clip (1)

Clamp (1)

Phillips 16 mm

screws (5)

Edge Protector (1)

(if service hole

partition is metal)

Washer (1)

Moisture protection

tape (1)

(to prevent

moisture damage)

SINGLE MODELS

If no side partition,

use a brace for

securing.

2” x 4”

max. ø

1 ½ ” (

*

⁄”

(

10 mm)

38 mm)

Moisture

protection

tape must

be applied.

o

90

Note: Services can be located

either side of DishDrawer®.

*

max.

17 ⁄”

(

450 mm)

min.

(

200 mm)

Important!

Adjacent cabinetry must not

extend above cavity base

Important!

Be sure the edges of the services hole are smooth or covered. If the service hole is through a metal partition

the hole must be protected with the Edge Protector supplied to prevent damage to the power cord or hoses.

These marks indicate mounting tab screw locations

Note: To align drawer front to adjacent cabinetry, the product to counter top clearance can be

⁄” (

increased to

Preferred position. If adequate clearance, services hole can be higher.

*

If hole is higher, ensure drain hose(s) are routed straight into the waste connection.

3 mm).

110-120 VAC

max. 15 A

7 ⁄”

Page 21

Optionally hard wiring the product

12

19

US CA

1

1

3

3

Ensure the tub is removed and

then rotated counter-clockwise

to prevent kinked hoses.

3

Remove knock-out for cable

clamp. Fit suitable cable clamp for

the conduit and terminate the

wiring as shown.

1 ⁄”

30 mm)

(

30 mm

2

2

4

5

6

Remove power supply cord.

SINGLE MODELS

8

7

8

4

16

Ensure the tub clips on

both sides are reset.

7

12

11

11

10

15

15

Ensure the tub is

now rotated

clockwise back.

9

Before refitting the tub, ensure the hoses are

not twisted and the latches at the rear of each

drawer runner are facing forward.

13

1

17

14

Page 22

US CA

20

Route the hoses and move into the cavity

a

5

SINGLE MODELS

6

5b

2

Tie together to avoid kinking

1

2

Chassis

trim

edge

Flexible

extrusions

Open drawer

Side

extrusion

Lip

3

If cavity is bigger than

specified (Pg 17), flexible

extrusions can be stuck along

the top and sides of the product.

Ensure extrusions do not prevent

the drawer from closing completely.

3

1

1

Ensure hoses and cord

are not kinked or twisted.

Page 23

Removing the tub and securing the product

7

1

Ensure the tub is removed and

2

then rotated counter-clockwise

to prevent kinked hoses.

21

US CA

4

SINGLE MODELS

3

8

The mounting tabs are in

pairs, one on each side of

the product.

Ensure the sound insulation

is repositioned correctly.

1 ⁄”

(

30 mm)

30 mm

5

5

Page 24

US CA

22

DishDrawer® with Waste Disposal

SINGLE MODELS

Plumbing and drainage - OPTION 1

Supplied drain

hose joiner

(ø

” (19 mm))

¾

waste tee)

HIGHLOOP

min. 6” (150 mm)

29 ½ ” - 34 ¾ ”

750 - 882.5 mm)

(

Max. distance of

hoses and cord from

chassis edge

Drain hose

Inlet hose

Power cord

Water Pressure Max Min

Water softener models 1 MPa (145 psi) 0.1 MPa (14.5 psi)

Other models 1 MPa (145 psi) 0.03 MPa (4.3 psi)

Left hand

side

79”

(2011 mm)

37”

(1561 mm)

61”

(936 mm)

Right hand

side

71”

(1794 mm)

53”

(1344 mm)

28”

(719 mm)

Left hand

side

Valve

min. R 8 ” (200 mm)

Waste

Water

supply

(HOT)

Right hand

side

Page 25

Plumbing and drainage - OPTION 1 (connection)

DishDrawer® with Waste Disposal

23

US CA

10

9

If space is limited

for fixing, push hose

through drain hose

support to required

height

1

29 ½” - 34 ¾”

2

(750 -

882.5 mm)

SINGLE MODELS

3

1

Ensure hoses are routed

straight to joiner. Remove

excess hose material if

necessary.

Fit supplied

washer

4

2

3

Page 26

US CA

24

Plumbing and drainage - OPTION 2

DishDrawer® using Air Break with Drain Hose Joiner

Supplied drain

hose joiner

ø

” (19 mm))

(

¾

waste tee)

Air Break

SINGLE MODELS

Valve

Waste

Water

supply

(HOT)

min. R 8 ”

200 mm)

(

37 ⁄” (950 mm)

Max. height to

top of Air Break

(countertop or

wall mounted)

Page 27

Plumbing and drainage - OPTION 2 (connection)

DishDrawer® using Air Break with Drain Hose Joiner

9

25

US CA

SINGLE MODELS

1

10

Ensure hoses are routed

straight to joiner. Remove

excess hose material if

necessary.

1

Fit supplied

washer

4

2

3

Page 28

US CA

26

Plumbing and drainage - OPTION 3

DishDrawer® and Standpipe Ø

SINGLE MODELS

1 ½ ”

(38 mm)

29 ½ ” - 34 ¾ ”

750 - 882.5 mm)

(

Waste

Valve

min. R 8 ” (200 mm)

Waste disposal

(optional)

Waste

Water

supply

(HOT)

Page 29

Plumbing and drainage - OPTION 3 (connection)

27

US CA

DishDrawer® and Standpipe Ø

9

1

10

1 ½ ”

(38 mm)

If space is limited

for fixing, push hose

through drain hose

support to required

height

SINGLE MODELS

max. 4 ¾”

(120 mm)

1 ½”

(38 mm)

29 ½” - 34 ¾”

(750 -

882.5 mm)

2

1

Fit supplied

washer

4

2

3

Page 30

US CA

28

11

SINGLE MODELS

Ensure the tub is

now rotated

clockwise back.

Re tting the tub

Ensure the tub clips on

both sides are reset.

5

4

1

3

Before refitting the tub,

4

ensure the hoses are not

twisted and the latches at

the rear of each drawer

runner are facing forward.

2

Page 31

Final checklist

Check all parts are installed.

Ensure product is level, securely fastened to the cabinetry and opens and closes freely. The

DishDrawer® must be free to fully close with no resistance from the cabinetry.

Ensure inlet hose to water supply has rubber washer fitted and is tightened a further half turn

after seal contact.

Ensure any knockouts or plugs in drain connection have been drilled out and drain connection

has been made.

The drain hose connector must not support the weight of excess hoses. Keep hoses as fully

extended as possible to prevent sagging. Any excess length of hose should be kept on the

dishwasher side of the high loop.

If using Plumbing and Drainage OPTION 1, ensure the Highloop is a minimum 6” (150 mm)

higher than the drain hose connector.

Turn on the power and water supply. Then press the power button to turn the DishDrawer® on.

The DishDrawer® should beep and cycle select lights light up.

Check the sprayarm(s) are in place and free to rotate.

Add three cups of water into the DishDrawer®.

On the Wash Programme Selector Panel press Rinse

and close the drawer(s). Start the programme by pressing

the Start/Pause button.

After the Rinse programme has finished, ensure machine has run and drained correctly.

Check water supply and drainage connection for leakage.

Repeat for each Drawer.

Spray arm

29

US CA

Troubleshooting

Excessive water remaining above the filter plate, after the rinse cycle

Check for kinked drain hoses or blocked waste connection, high loop not properly installed or

drain hoses not routed correctly.

No water supply ( shows on display)

Check water is connected, turned on and the spray arm(s) is correctly fitted and free to rotate.

DishDrawer® does not light up when the tub is opened

Ensure power is connected and is switched on. Check if Auto Power option is on.

Water around water supply and drainage connections

Check connections, existing plumbing and hoses for leaks. Check washer and hose clamps are

correctly fitted.

If product is tipping

Ensure the product is secured to the cabinetry. Refer to page 8 or 21.

If front panels are misaligned

Check and relevel product. Check the cabinetry is square.

Drawer(s) don’t close properly

Ensure nothing is obstructing the drawer(s) from closing properly ie sound insulation, hoses or

tub latches.

If a problem occurs, consult the Troubleshooting section of the User Guide.

If after checking these points you still need assistance, please contact us through a DCS

Customer Care Representative by phone: 1-888-281-5698, email: support@dcsappliances.com or

www.dcsappliances.com

Page 32

US CA

FR

Sécurité et mises en garde

MISE EN GARDE!

Risque de chocs électriques

Avant d’installer le DishDrawer®, retirer le fusible du boîtier de fusible

domestique ou fermer le disjoncteur.

Si le branchement du DishDrawer® est permanent, s’assurer que l’alimentation

est isolée et que le DishDrawer® n’est pas branché.

Cet appareil doit être mis à la terre. Dans le cas d’un bris ou d’une défectuosité,

la mise à la terre réduit le risque de chocs électriques en fournissant un chemin

de moindre résistance au courant électrique. Cet appareil est équipé d’un

cordon comportant un conducteur avec mise à la terre et une broche de mise

à la terre. La fiche doit être branchée à une prise appropriée correctement

raccordée et mise à la masse conformément à la réglementation locale. Le

raccordement incorrect du câble de mise à la terre de l’appareil peut accroître le

risque de chocs électriques. Vérifier auprès d’un électricien ou d’un technicien

qualifié lorsque vous êtes incertain si l’appareil est correctement mis à la terre.

Ne pas modifier la fiche d’alimentation fournie avec l’appareil – si elle ne

peut pas être insérée dans la prise murale, faire installer une prise adéquate

par un électricien qualifié. Ne pas utiliser une rallonge, un adaptateur de

branchement ni une prise multiple .

Le défaut de se conformer à ces instructions peut entraîner la mort ou un choc

électrique.

MISE EN GARDE!

Risque de coupure

Attention, le bord des panneaux est tranchant.

Le défaut de se conformer à ces instructions peut causer des blessures ou des

coupures.

Consignes de sécurité importantes!

L’installation du DishDrawer® exigent des connaissances de base en mécanique et en électricité.

S’assurer de laisser les instructions chez le client.

L’installation doit être conforme aux codes du bâtiment et de l’électricité de votre région.

Après l’installation du DishDrawer®, l’installateur doit consulter la liste de vérification finale de la

page 59.

Retirer tout le matériel d’emballage fourni avec le DishDrawer®.

Ce lave-vaisselle a été conçu pour un usage intérieur seulement.

S’assurer que toutes les entrées d’eau sont fermées (OFF). Il incombe au plombier et à l’électricien

de s’assurer que l’installation est conforme aux codes et aux règlements en vigueur.

Le DishDrawer® DOIT être installé de sorte qu’il puisse facilement être retiré de sa cavité si des

services d’entretien étaient nécessaires.

La prise d’alimentation commandée par interrupteur doit être à l’extérieur de la cavité du

DishDrawer® afin qu’elle soit accessible après l’installation.

On doit installer ou retirer l’appareil avec soin afin de ne pas endommager le cordon

d’alimentation.

Si le DishDrawer® doit être déplacé d’un endroit à un autre, il doit être transporté en position

verticale afin d’éviter les déversements d’eau.

S’assurer de n’utiliser que des tuyaux neufs pour l’installation (fournis avec le DishDrawer®).

Les anciens tuyaux ne doivent pas être réutilisés.

Le défaut d’installer adéquatement le DishDrawer peut annuler la garantie et toute réclamation de

responsabilité.

Si le lave-vaisselle est installé dans une maison mobile, un bateau ou toute installation similaire,

le propriétaise doit apporter à vos frais le véhicule, le bateau ou l’installation mobile contenant le

produit à l’atelier de réparation ou payer un technicien d’entretien pour qu’il se rende sur place.

Page 33

Table des matières

MODÈLES DOUBLES

Dimension du produit et des armoires

Installation

Préparation de la cavité

Branchement direct (en option)

Acheminement des tuyaux et installation

de l’unité dans la cavité

Retrait de la cuve et mise à niveau du lave-vaisselle

Fixation du produit et réinstallation de la cuve

Installation du coup de pied

Plomberie et vidange - OPTION 1

Plomberie et vidange - OPTION 1 (branchement)

Plomberie et vidange - OPTION 2

Plomberie et vidange - OPTION 2 (branchement)

Plomberie et vidange - OPTION 3

Plomberie et vidange - OPTION 3 (branchement)

MODÈLES SIMPLES

Dimension du produit et des armoires

Installation

Préparation de la cavité

Branchement direct (en option)

Acheminement des tuyaux et installation dans la cavité

Retrait de la cuve et mise à niveau du produit

Plomberie et vidange - OPTION 1

Plomberie et vidange - OPTION 1 (branchement)

Plomberie et vidange - OPTION 2

Plomberie et vidange - OPTION 2 (branchement)

Plomberie et vidange - OPTION 3

Plomberie et vidange - OPTION 3 (branchement)

Réinstallation de la cuve

Liste de vérification finale

32

34

35

36

37

38

39

40

41

42

43

44

45

46

48

49

50

51

52

53

54

55

56

57

58

59

31

US CA

FR

Important!

CONSERVER CES INSTRUCTIONS

Les modèles illustrés dans ce guide de l’utilisateur peuvent ne pas être offerts dans tous

les marchés et sont sujets à changement sans préavis. Pour obtenir la plus récente

information sur les modèles et les spécifications offerts dans votre pays, veuillez visiter

notre site Web à l’adresse www.dcsappliances.com ou communiquer avec le détaillant

DCS de votre région.

Page 34

US CA

FR

32

Les schémas sont à titre indicatif seulement.

Dimension du produit

C

D

I

K

MODÈLES DOUBLES

L

M

Dimension du produit (po [mm])

Hauteur hors tout * du produit

A

Largeur hors tout du produit

B

Profondeur hors tout du produit (à l’exclusion de la

C

partie incurvée et de la poignée)

Profondeur du tiroir (ouvert) (à l’exclusion de la

D

partie incurvée et de la poignée)

Hauteur du * bâti

E

Plage de réglages des pattes de mise à niveau

F

Profondeur du bâti

G

Profondeur du panneau de tiroir (à l’exclusion de la

H

partie incurvée et de la poignée)

Profondeur de la partie incurvée ou de la poignée

I

Profondeur du panneau de coup de pied

J

Hauteur de la partie supérieure du devant de tiroir

K

Hauteur de la partie inférieure du devant de tiroir

L

Hauteur du panneau de coup de pied (réglable) 2 ¾ - 4 ¾ ” (70 - 120)

M

Hauteur des languettes (dessus du bâti)

N

Hauteur des devants de tiroir

O

Hauteur * de la partie supérieure du tiroir et du

P

dessus du bâti

* La hauteur du bâti inclut les languettes

B

N

P

G

H

E

C

G

O

A

F

I

N

J

Porte plate

DD224P5

Pré ni

32 ¼ - 34 ⁄”

(819.5- 879.5)

23 ⁄”(605)

22 ⁄” (570)

20 ⁄” (520)

31 ⁄” (809)

2 ⁄” (60)

21 ¾ ” (552)

1” (25)

3 ⁄” (81)

2 - 4 ⁄” (50 - 110)

15 ⁄” (398)

14” (356)

¾ ” (2)

30 ⁄” (764)

¾ ” (2)

Page 35

Dimension des armoires

Les schémas sont à titre indicatif seulement.

B

C

33

US CA

FR

A

D

MODÈLES DOUBLES

E

Dimension de l’armoire (po [mm])

Hauteur de l’intérieur de la cavité

A

Largeur de l’intérieur de la cavité 24” (610)

B

Profondeur de l’intérieur de la cavité

C

(intérieur)

Hauteur des armoires adjacentes 28 ⁄” (720)

D

Hauteur du panneau de coup de pied

E

2 ¾ - 4 ¾ ” (70 - 120)

Dégagement minimal (po [mm])

⁄” (2.5 mm)

⁄

” (2.5 mm)

” (13 mm)

½

Porte plate

DD224P5

Pré ni

32 ⁄ - 34 ¾ ”

(820 - 882.5)

22 ⁄” (580)

Page 36

US CA

FR

34

Préparation de la cavité

Pièces fournies

Support du tuyau

de vidange (1)

Protège-arête (1)

(si le trou des installations

est dans une cloison

métallique)

Si la longueur du tuyau de vidange fourni n’est pas suffisante pour atteindre l’entrée d’eau, on doit utiliser l’ensemble de rallonge pour tuyau de vidange, n°

de pièce 525798, qui permet de rallonger le tuyau de vidange de 3,6 m. On peut se procurer cet ensemble auprès de l’atelier de service autorisé DCS de votre

MODÈLES DOUBLES

région, en composant sans frais le

Collecteur

de tuyau de

vidange (1)

Attache

métallique (2)

Douille

hexagonale (2)

(longue et courte)

1-888-281-5698

Collier de

serrage (1)

ou en visitant le www.dcsappliances.com. NE PAS ALLONGER le tuyau au-delà de cette limite.

Extrusions

flexibles pour

les côtés (2)

Languettes

de montage

(2)

Vis Phillips

Rondelle (1)

de 16 mm

(9)

Extrusion flexible

pour le dessus (1)

Ruban à l’épreuve

de l’humidité (1)

(prévenant les

dommages causés

par l’humidité)

Coup de pied préfini (1)

Blanc ou noir

S’il n’y a aucune cloison S’il n’y a aucune cloison

latérale, utiliser une latérale, utiliser une

pièce-support pour pièce-support pour

le soutenir.le soutenir.

2×4 po

2” x 4”

ø

1 ½ po (

⁄ po

(

10 mm)

38 mm) max.

Le ruban à

l’épreuve de

l’humidité doit

être utilisé.

o

Remarque : les installations électriques

90

et de plomberie peuvent être situées

d’un côté ou de l’autre du DishDrawer®.

17 ⁄ po

(450 mm) max.

7 ⁄ po

(

200 mm) min.

*

*

110–120 V. c.a.

Important!

Distance 15 A max.

S’assurer que le bord des trous des installations électriques et de plomberie est lisse et recouvert. Si le trou

des installations électriques et de plomberie se trouve dans une cloison métallique, on doit apposer le

protège-arête fourni avec l’appareil afin de ne pas endommager le cordon d’alimentation ou les tuyaux.

Ces marques indiquent l’emplacement des vis de montage.

Position recommandée. Si le dégagement est suffisant, le trou des installations électriques et de

*

plomberie peut être plus élevé pour libérer l’espace réservé au coup de pied.

Si le trou est plus haut, s’assurer que le ou les tuyaux de vidange sont insérés en ligne droite dans le

raccord de vidange.

Page 37

Branchement direct (en option)

1 2

1 ⁄ po

30 mm

30 mm)

(

4

35

US CA

FR

1

S’assurer que la cuve est retirée et

tournée dans le sens antihoraire

afin d’éviter l’entortillement des

tuyaux.

Retirer les alvéoles défonçables

3

pour le serre-câble. Installer un

serre-câble adapté au conduit et

raccorder le câblage comme le

montre l’illustration.

5

2

6

Retirer le cordon d’alimentation.

3

8

7

16

8

4

15

S’assurer que les attaches S’assurer que les attaches

de cuve des deux côtés sont de cuve des deux côtés sont

remises en position.remises en position.

15

7

MODÈLES DOUBLES

12

11

11

10

S’assurer que

la cuve tourne

maintenant dans le

sens horaire.

9

17

13

14

Avant de réinstaller la cuve, Avant de réinstaller la cuve,

s’assurer que les tuyaux ne s’assurer que les tuyaux ne

sont pas entortillés et que sont pas entortillés et que

les verrous à l’arrière de les verrous à l’arrière de

chaque glissière de tiroir chaque glissière de tiroir

sont orientés vers l’avant. sont orientés vers l’avant.

Page 38

US CA

FR

36

Acheminement des tuyaux et installation

de l’unité dans la cavité

1a

MODÈLES DOUBLES

Joindre pour éviter l’entortillement.

2

Facultatif

optional

Si les deux languettes sont

utilisées, s’assurer qu’elles sont

2

bien fixées avant d’insérer

l’unité dans la cavité.

1b

2

1

S’assurer que les tuyaux

et le cordon ne sont ni

entortillés ni repliés.

Garniture

du bâti

Extrusions

flexibles

Tiroir ouvert

Extrusion

latérale

Lèvre

3

Si la cavité est plus grande que Si la cavité est plus grande que

la dimension prescrite (page 33), la dimension prescrite (page 33),

les extrusions flexibles peuvent les extrusions flexibles peuvent

être apposées le long de la partie être apposées le long de la partie

supérieure et sur les côtés du lave-supérieure et sur les côtés du lave-

vaisselle. S’assurer que les extrusions vaisselle. S’assurer que les extrusions

n’empêchent pas la fermeture complète n’empêchent pas la fermeture complète

du tiroir.du tiroir.

4

4

1

1

Desserrer d’abord la

patte, mais ne la dévisser

entièrement que lorsque

l’unité a été insérée dans

la cavité.

Page 39

Retrait de la cuve et mise à niveau du lave-vaisselle

37

US CA

FR

3

1

S’assurer que la cuve est retirée et

tournée dans le sens antihoraire

afin d’éviter l’entortillement des

tuyaux.

4

MODÈLES DOUBLES

2

30 mm

3

4

S’assurer que l’unité est de niveau. À l’aide d’une douille

hexagonale de longueur appropriée (fournie) et d’un tournevis,

dévisser la patte de mise à niveau jusqu’à la longueur désirée.

5

5

Douille hexagonale

1

2

4

3

5

x 4

Page 40

FR

38

Fixation du produit et réinstallation de la cuve

US CA

5

Les languettes de

montage sont livrées

en paire, l’une de

chaque côté du

lave-vaisselle. Deux

ensembles de paires

de languettes doivent

au moins être utilisés.

A et B OU B et C, ou

les trois paires.

S’assurer que l’isolant

est positionné

correctement.

MODÈLES DOUBLES

Facultatif

¾

po

(19 mm) max.

C

C

6

4

S’assurer que

la cuve tourne

maintenant dans le

sens horaire.

S’assurer que les attaches

de cuve des deux côtés

5

sont remises en position.

4

1

BB

A

A

3

Avant de réinstaller la cuve,

s’assurer que les tuyaux ne sont

pas entortillés et que les verrous

à l’arrière de chaque glissière de

tiroir sont orientés vers l’avant.

2

Page 41

Installation du coup de pied

7

1

2

3

39

US CA

FR

MODÈLES DOUBLES

8

4 5 6 7

19

8 9

Important!

Ne pas trop serrer la vis.

10

Page 42

FR

40

Plomberie et vidange - OPTION 1

US CA

DishDrawer® avec évacuation des déchets

MODÈLES DOUBLES

750 - 882,5 mm)

(

29 ½ po - 34 ¾ po

BOUCLE LA PLUS

GRANDE

6 po (150 mm) min.

Valve

R8 po (200 mm) min.

Collecteur de tuyau

de vidange fourni

(té de vidange

ø ¾ po [19 mm])

Évacuation

Alimentation

en eau

(CHAUDE)

Distance maximale

des tuyaux et du

cordon au point de

sortie

Tuyau de vidange

Tuyau d’entrée

Cordon d’alimentation

Pression d’eau Max Min

Modèles avec adoucisseurs d’eau 1 MPa (145 psi) 0,1 MPa (14,5 psi)

Autres modèles 1 MPa (145 psi) 0,03 MPa (4,3 psi)

Les tuyaux de vidange devront être séparés pour répondre aux exigences d’une installation casher.

Nous suggérons de consulter votre rabbin pour confirmer les normes d’acceptation relatives aux

installations casher.

Côté

gauche

79 po

(2 011 mm)

61 po

(1 561 mm)

70 po

(1 776 mm)

Côté droit

71 po

(1 794 mm)

53 po

(1 344 mm)

61 po

(1 559 mm)

Côté

gauche

Côté droit

Page 43

Plomberie et vidange - OPTION 1 (branchement)

DishDrawer® avec évacuation des déchets

41

US CA

FR

10

9

1

Si l’espace

d’installation est

limité, pousser

le tuyau avec le

support jusqu’à la

hauteur désirée

29½-34¾ po

29 ½” - 34 ¾”

(750-

(750 -

882,5 mm)

882.5 mm)

MODÈLES DOUBLES

2

3

1

S’assurer que les tuyaux

s’insèrent en ligne droite

dans le collecteur. Enlever

tout excédent de tuyau au

besoin.

Rondelle

incluse avec

l’unité

4

2

3

Page 44

FR

42

Plomberie et vidange - OPTION 2

US CA

DishDrawer® avec coupure anti-refoulement et collecteur de tuyau de vidange

Collecteur de tuyau de

vidange fourni

(té de vidange ø

[19 mm])

MODÈLES DOUBLES

Coupure antirefoulement

po

¾

37 ⁄ po (950 mm)

Hauteur maximale

jusqu’au dessus

de la coupure

anti-refoulement

(montée sur le

comptoir ou au

mur)

Évacuation

Alimentation

en eau

(CHAUDE)

Valve

R8 po

(200 mm) min.

Page 45

Plomberie et vidange - OPTION 2

DishDrawer® avec coupure anti-refoulement et collecteur de tuyau de vidange

9

43

US CA

FR

MODÈLES DOUBLES

1

S’assurer que les tuyaux

10

s’insèrent en ligne droite

dans le collecteur. Enlever

tout excédent de tuyau au

besoin.

1

Rondelle

incluse avec

l’unité

4

2

3

Page 46

US CA

FR

44

Plomberie et vidange - OPTION 3

DishDrawer® et colonne montante Ø

MODÈLES DOUBLES

1 ½ po

(750 - 882,5 mm)

29 ½ po - 34 ¾ po

(38 mm)

Évacuation

Valve

R8 po (200 mm) min.

Évacuation

des déchets

(en option)

Évacuation

Alimentation

en eau

(CHAUDE)

Page 47

Plomberie et vidange - OPTION 3 (branchement)

45

US CA

FR

DishDrawer® et colonne montante Ø

9

1

10

1 ½ po

(38 mm)

Si l’espace

d’installation est

limité, pousser

le tuyau avec le

support jusqu’à la

hauteur désirée

1

2

max. 4 ¾”

max 4¾ po

(120 mm)

(120 mm)

ø 1½ po

1 ½”

(38 mm)

(38 mm)

29 ½” - 34 ¾”

29½-34¾ po

(750 -

(750-882,5 mm)

882.5 mm)

MODÈLES DOUBLES

Rondelle

incluse avec

l’unité

4

2

3

Page 48

US CA

46

Dimension du produit

FR

Les schémas sont à titre indicatif seulement.

C

D

H

I

MODÈLES SIMPLES

J

Dimension du produit (po [mm])

Hauteur hors tout * du produit

A

Largeur hors tout du produit

B

Profondeur hors tout du produit (à l’exclusion de la partie

C

incurvée et de la poignée)

Profondeur du tiroir (ouvert) (à l’exclusion de la partie incurvée

D

et de la poignée)

Hauteur du * bâti

E

Profondeur du bâti

F

Profondeur du panneau de tiroir (à l’exclusion de la partie

G

incurvée et de la poignée)

Profondeur de la partie incurvée ou de la poignée

H

Hauteur de la partie supérieure du devant de tiroir

I

Hauteur de la zone de ventilation à la base du produit

J

Hauteur des languettes (dessus du bâti)

K

Hauteur * de la partie supérieure du tiroir supérieur au-dessus

L

du bâti

B

K

L

F

G

E

A

C

F

H

Porte plate

DD124P5

16 ⁄” (409)

23 ⁄” (605)

22 ⁄” (570)

20 ½ ” (520)

16 ⁄” (409)

21 ¾ ” (552)

1” (25)

3 ⁄” (81)

15 ⁄” (398)

⁄” (9)

⁄” (2)

⁄” (2)

Pré ni

K

* La hauteur du bâti inclut les languettes

Remarque : pour les modèles pré nis à porte plate, la hauteur du dessus de la poignée jusqu’au dessus de la porte est - 2

po (59,5 mm)

⁄

Page 49

Dimension des armoires

Les schémas sont à titre indicatif seulement.

B

D

A

C

47

US CA

FR

MODÈLES SIMPLES

Dimension de l’armoire (po [mm])

Hauteur de l’intérieur de la cavité

A

Largeur de l’intérieur de la cavité

B

Profondeur de l’intérieur de la cavité (intérieur)

C

Dégagement sous le dessus de comptoir

D

* Le dégagement est mesuré à partir du dessous du comptoir jusqu’au bâti

Dégagement minimal (po [mm])

⁄” (2.5 mm)

⁄

” (2.5 mm)

” (13 mm)

½

Porte plate

DD124P5

16 ¼ ” (412)

24” (610)

22 ⁄” (580)

Min. ⁄” (3)*

Pré ni

Page 50

US CA

FR

48

Cavité

Préparation de la cavité

Support du tuyau

de vidange (1)

Si la longueur du tuyau de vidange fourni n’est pas suffisante pour atteindre l’entrée d’eau, on doit utiliser l’ensemble de rallonge pour tuyau de vidange, n°

de pièce 525798, qui permet de rallonger le tuyau de vidange de 3,6 m. On peut se procurer cet ensemble auprès de l’atelier de service autorisé DCS de votre

région, en composant sans frais le

S’il n’y a aucune

MODÈLES SIMPLES

cloison latérale, utiliser

Collecteur de

tuyau de

vidange (1)

Extrusions flexibles pour les côtés (2)

Attache

métallique (1)

1-888-281-5698

Collier de

serrage (1)

ou en visitant le www.dcsappliances.com. NE PAS ALLONGER le tuyau au-delà de cette limite.

Vis Phillips

de 16 mm (5)

(si le trou des installations

est dans une cloison

métallique)

Rondelle (1)Protège-arête (1)

Ruban à l’épreuve de

l’humidité (1)

(prévenant les dommages

causés par l’humidité)

une pièce-support

pour le soutenir.

2” x 4”

2×4 po

⁄ po

(

10 mm)

Le ruban à

l’épreuve de

l’humidité

doit être

Remarque : les installations électriques

o

90

et de plomberie peuvent être situées

d’un côté ou de l’autre du DishDrawer®.

utilisé.

ø

1 ½ po (

38 mm) max.

*

*

17 ⁄ po

(450 mm) max.

7 ⁄ po

(

200 mm) min.

Important!

Les armoires adjacentes ne doivent

Important!

S’assurer que le bord des trous des installations électriques et de plomberie est lisse et recouvert. Si le trou

pas dépasser la base de la cavité.

110–120 V. c.a.

15 A max.

des installations électriques et de plomberie se trouve dans une cloison métallique, on doit apposer le

protège-arête fourni avec l’appareil afin de ne pas endommager le cordon d’alimentation ou les tuyaux.

Ces marques indiquent l’emplacement des vis de montage.

Remarque : pour aligner le devant de tiroir avec les armoires adjacentes, le dégagement entre

l’unité et le dessus du comptoir peut être accru de

Position recommandée. Si le dégagement est suffisant, le trou des installations électriques et de

*

plomberie peut être plus élevé.

⁄ po (

3 mm).

Si le trou est plus haut, s’assurer que le ou les tuyaux de vidange sont insérés en ligne droite dans

le raccord de vidange.

Page 51

Branchement direct (en option)

12

49

US CA

FR

1

1

3

3

S’assurer que la cuve est retirée et

tournée dans le sens antihoraire

afin d’éviter l’entortillement des

tuyaux.

3

Retirer les alvéoles défonçables pour installer

le serre-câble. Installer un serre-câble adapté

au conduit et raccorder le câblage comme le

montre l’illustration.

1 ⁄ po

(

30 mm)

30 mm

2

2

4

5

6

Retirer le cordon d’alimentation.

MODÈLES SIMPLES

8

7

8

4

16

S’assurer que les attaches

de cuve des deux côtés sont

remises en position.

7

12

11

11

10

15

15

S’assurer que

la cuve tourne

maintenant dans le

sens horaire.

9

13

1

17

Avant de réinstaller la cuve, s’assurer que les tuyaux

ne sont pas entortillés et que les verrous à l’arrière de

chaque glissière de tiroir sont orientés vers l’avant.

14

Page 52

US CA

FR

50

Acheminement des tuyaux et installation

de l’unité dans la cavité

a

5

MODÈLES SIMPLES

Joindre pour éviter l’entortillement.

6

5b

2

1

2

Garniture

du bâti

Extrusions

flexibles

Tiroir ouvert

Extrusion

latérale

Lèvre

3

Si la cavité est plus grande que

la dimension prescrite (page 47),

les extrusions flexibles peuvent

être apposées le long de la partie

supérieure et sur les côtés du

lave-vaisselle. S’assurer que les

extrusions n’empêchent pas la

fermeture complète du tiroir.

3

1

1

S’assurer que les tuyaux

et le cordon ne sont ni

entortillés ni repliés.

Page 53

Retrait de la cuve et mise à niveau du produit

7

1

S’assurer que la cuve est

2

retirée et tournée dans le

sens antihoraire afin d’éviter

l’entortillement des tuyaux.

51

US CA

FR

4

MODÈLES SIMPLES

3

8

Les languettes de montage

sont livrées en paire, l’une de

chaque côté du lave-vaisselle.

S’assurer que l’isolant est

positionné correctement.

1 ⁄ po

(

30 mm)

30 mm

5

5

Page 54

US CA

52

FR

DishDrawer® avec évacuation des déchets

MODÈLES SIMPLES

Plomberie et vidange - OPTION 1

(750 - 882,5 mm)

29 ½ po - 34 ¾ po

Collecteur de

tuyau de vidange

fourni (té de

vidange ø 3/4 po

[19 mm])

BOUCLE LA PLUS

GRANDE

6 po (150 mm) min.

Alimentation

en eau

Valve

(CHAUDE)

R 8 po (200 mm) min.

Évacuation

Distance maximale

des tuyaux et du

cordon au point de

sortie

Tuyau de vidange

Tuyau d’entrée

Cordon d’alimentation

Pression d’eau Max Min

Modèles avec adoucisseurs d’eau 1 MPa (145 psi) 0,1 MPa (14,5 psi)

Autres modèles 1 MPa (145 psi) 0,03 MPa (4,3 psi)

Les tuyaux de vidange devront être séparés pour répondre aux exigences d’une installation casher.

Nous suggérons de consulter votre rabbin pour confirmer les normes d’acceptation relatives aux

installations casher.

Côté

gauche

79 po

(2 011 mm)

37 po

(1 561 mm)

61 po

(936 mm)

Côté droit

71 po

(1 794 mm)

53 po

(1 344 mm)

28 po

(719 mm)

Côté

gauche

Côté droit

Page 55

Plomberie et vidange - OPTION 1 (branchement)

DishDrawer® avec évacuation des déchets

53

US CA

FR

10

9

Si l’espace

d’installation est

limité, pousser

le tuyau avec le

support jusqu’à la

hauteur désirée

1

29½-34¾ po

29 ½” - 34 ¾”

(750-

(750 -

2

882,5 mm)

882.5 mm)

MODÈLES SIMPLES

3

1

S’assurer que les tuyaux

s’insèrent en ligne droite

dans le collecteur. Enlever

tout excédent de tuyau au

besoin.

Rondelle

incluse avec

l’unité

4

2

3

Page 56

US CA

FR

54

Plomberie et vidange - OPTION 2

DishDrawer® avec coupure anti-refoulement et collecteur de tuyau de vidange

Collecteur de tuyau

de vidange fourni

(té de vidange

ø 3/4 po [19 mm])

MODÈLES SIMPLES

Coupure antirefoulement

37 3/8 po (950 mm)

Hauteur maximale

jusqu’au dessus

de la coupure

anti-refoulement

(montée sur le

comptoir ou au

mur)

Évacuation

Alimentation

en eau

(CHAUDE)

Valve

R 8 po

(200 mm) min.

Page 57

Plomberie et vidange - OPTION 2

DishDrawer® avec coupure anti-refoulement et collecteur de tuyau de vidange

9

55

US CA

FR

MODÈLES SIMPLES

1

10

S’assurer que les tuyaux

s’insèrent en ligne droite

dans le collecteur. Enlever

tout excédent de tuyau au

besoin.

1

Rondelle

incluse avec

l’unité

4

2

3

Page 58

US CA

FR

56

Plomberie et vidange - OPTION 3

DishDrawer® et colonne montante Ø

MODÈLES SIMPLES

1 ½ po

(750 - 882,5 mm)

29 ½ po - 34 ¾ po

(38 mm)

Évacuation

Alimentation

en eau

Valve

(CHAUDE)

R 8 po (200 mm) min.

Évacuation

des déchets

(en option)

Évacuation

Page 59

Plomberie et vidange - OPTION 3 (branchement)

57

US CA

FR

DishDrawer® et colonne montante Ø

9

1

10

1 ½ po

Si l’espace

d’installation est

limité, pousser

le tuyau avec le

support jusqu’à la

hauteur désirée

(38 mm)

1

2

max. 4 ¾”

max 4¾ po

(120 mm)

(120 mm)

ø 1½ po

1 ½”

(38 mm)

(38 mm)

29 ½” - 34 ¾”

29½-34¾ po

(750 -

(750-882,5 mm)

882.5 mm)

MODÈLES SIMPLES

Rondelle

incluse avec

l’unité

4

2

3

Page 60

US CA

58

FR

11

MODÈLES SIMPLES

4

S’assurer que la cuve

tourne maintenant

dans le sens horaire.

Réinstallation de la cuve

S’assurer que les attaches de cuve

des deux côtés sont remises en

5

position.

4

1

3

Avant de réinstaller la cuve,

s’assurer que les tuyaux ne sont

pas entortillés et que les verrous

à l’arrière de chaque glissière de

tiroir sont orientés vers l’avant.

2

Page 61

Liste de véri cation nale

S’assurer que toutes les pièces sont installées.

S’assurer que l’unité est de niveau, qu’elle est fixée solidement aux armoires et que le tiroir s’ouvre et

se ferme facilement. Le DishDrawer® doit pouvoir se fermer facilement et entièrement sans résistance.

S’assurer que le tuyau d’entrée d’eau est pourvu d’une rondelle en caoutchouc et qu’il est serré

d’un demi-tour de plus après le contact avec la rondelle.

S’assurer que les alvéoles défonçables ou les bouchons des raccords de vidange ont été percés et

que les raccords ont été bien installés.

Le raccord du tuyau de vidange ne doit pas soutenir le poids des tuyaux. S’assurer que les tuyaux sont

bien allongés afin d’éviter le fléchissement. Placer l’excédent du tuyau du côté de la haute boucle.

Si l’OPTION 1 est sélectionnée, s’assurer que la haute boucle est d’au moins 6 po (150 mm) plus

élevée que le raccord du tuyau de vidange.

Mettre l’appareil sous tension et ouvrir la valve d’eau. Ensuite, appuyez sur le bouton

d’alimentation du DishDrawer® pour le mettre en marche. Le DishDrawer® doit émettre un bip

sonore et allumer les voyants lumineux l’un après l’autre.

S’assurer que les bras gicleurs sont en place et qu’ils peuvent

tourner librement.

Ajouter trois tasses d’eau dans le DishDrawer®.

Sélectionner Rinse (rinçage) sur le panneau de commande

de programme de lavage et fermer le(s) tiroir(s). Démarrer le

programme en appuyant sur le bouton Start/Pause (marche/pause).

Une fois le rinçage terminé, s’assurer du bon fonctionnement de

l’appareil et que l’eau a été vidangé correctement.

Vérifier si les raccords d’alimentation en eau et de vidange présentent des fuites.

Répéter la même opération pour chaque tiroir.

Bras gicleur

59

US CA

FR

Dépannage

Il y a excédent d’eau au-dessus de la plaque de filtration après le cycle de rinçage.

Vérifier si les tuyaux de vidange sont écrasés ou si des raccords sont obstrués; haute boucle

installée de façon inadéquate; tuyaux de vidange mal installés.

Aucune alimentation en eau ( s’affiche à l’écran)

S’assurer que l’alimentation en eau est raccordée, que la valve est ouverte et que les bras gicleurs

sont bien installés et qu’ils peuvent tourner librement.

Les voyants du DishDrawer® ne s’allument pas lorsque la cuve est ouverte.

S’assurer que l’alimentation est raccordée et que l’appareil est sous tension. S’assurer que l’option

Auto Power (alimentation automatique) est activée.

Il y a de l’eau autour des raccords d’alimentation et de vidange.

S’assurer que les raccords, la plomberie existante et les tuyaux ne présentent aucune fuite.

S’assurer que les rondelles et les colliers de serrage sont installés adéquatement.

L’appareil s’incline.

S’assurer que le lave-vaisselle est fixé aux armoires. Se reporter à la page 38 ou 51.

Les panneaux avant sont mal alignés.

Vérifier le niveau de l’appareil et corriger au besoin. S’assurer de l’aplomb des armoires.

Le(s) tiroir(s) ne se ferme(nt) pas correctement.

S’assurer qu’aucun élément n’empêche la fermeture du tiroir (isolant, tuyaux ou verrous de la cuve).

Si l’appareil présente une défectuosité, consulter la section Dépannage de ce guide de l’utilisateur.

Après avoir vérifié tous ces points, et qu’une assistance est tout de même nécessaire, consulter

l’atelier de service autorisé le plus près, ou communiquer avec nous par le biais de notre site Web à

l’adresse www.dcsappliances.com.

Page 62

US CA

ES

Seguridad y advertencias

¡ADVERTENCIA!

Peligro de descarga eléctrica

Antes de instalar su DishDrawer®, quite el fusible de su instalación doméstica o

abra el interruptor automático.

Si va a conectar su DishDrawer® de forma permanente, asegúrese de aislar la

energía eléctrica y de desconectar el DishDrawer®.

Este electrodoméstico deberá aterrizarse a tierra. En caso de falla o

descompostura, el aterrizaje a tierra reducirá el riesgo de descarga eléctrica

al ofrecer un camino de menor resistencia para la corriente eléctrica. Este

electrodoméstico está equipado con un cordón provisto de un equipo y una

clavija de conexión a tierra. La clavija deberá enchufarse a un tomacorriente

adecuado instalado y aterrizado a tierra, de acuerdo con todos los códigos y

reglamentaciones locales. Una conexión inadecuada del equipo conductor

de aterrizaje a tierra puede provocar una descarga eléctrica. Consulte a un

electricista calificado o representante de servicio si tuviera dudas con relación

a la adecuada conexión a tierra de su electrodoméstico.

No modifique la clavija que viene con su electrodoméstico; si no enchufa bien

dentro del tomacorriente, pida a un electricista calificado que le instale el más

adecuado. No utilice una extensión, un adaptador o un multicontactos.

El hacerlo puede ocasionar una descarga eléctrica o incluso la muerte.

¡ADVERTENCIA!

Peligro de Heridas

Tenga cuidado: los cantos del panel son filosos.

Si no tiene cuidado puede lastimarse o cortarse.

¡Medidas de seguridad importantes!

La instalación de este DishDrawer® requiere habilidades básicas de tipo mecánico y eléctrico.

Asegúrese de dejar este Instructivo con el Cliente.

La instalación debe cumplir con la reglamentación de construcción y electricidad local.

Al finalizar la instalación del DishDrawer®, el instalador deberá:

Seguir la Lista de Comprobación Final de la página 89

Retirar todo el material de empaque que viene con su DishDrawer®.

Este lavavajillas fue fabricado para su uso en interiores exclusivamente.

Asegúrese que todas las conexiones de agua estén CERRADAS. Es responsabilidad del plomero y

del electricista que cada instalación cumpla con todos los Códigos y la Reglamentación vigentes.

El DishDrawer® DEBERÁ instalarse de tal manera que pueda sacarse de la cavidad para darle

servicio, sin problema.

El interruptor de corriente deberá quedar fuera de la cavidad del DishDrawer® para que se puede

tener acceso a él después de la instalación.

Habrá que tener cuidado cuando el electrodoméstico se instale o se quite para reducir la posibilidad

de daños al cable de alimentación eléctrica.

Si el DishDrawer® se va a cambiar de ubicación, deberá mantenerse en posición vertical para evitar

daños por fugas de agua.

Sólo utilice mangueras nuevas durante la conexión (incluidas con su DishDrawer®).

No vuelva a utilizar mangueras viejas.

La incorrecta instalación de su DishDrawer® puede invalidar la garantía y cualquier reclamación de

responsabilidad civil.

Si el producto se instala en un coche-casa, bote o en cualquier instalación móvil, deberá llevar éstos

junto con el producto instalado y a expensas suyas, al taller de servicio, o deberá pagar el viaje del

técnico al lugar donde se encuentre el producto.

Page 63

Índice

MODELOS DOBLES

Dimensiones del producto y de los gabinetes

Instalación

Preparación de la cavidad

Instalación opcional del cableado del producto

Enrutar las mangueras y mover dentro de la cavidad

Sacar la tina y nivelar el producto

Asegurar el producto y volver a colocar la tina

Colocar el protector de puntapiés ahuecado

Plomería y drenaje - OPCIÓN 1

Plomería y drenaje - OPCIÓN 1 (conexión)

Plomería y drenaje - OPCIÓN 2

Plomería y drenaje - OPCIÓN 2 (conexión)

Plomería y drenaje - OPCIÓN 3

Plomería y drenaje - OPCIÓN 3 (conexión)

MODELOS INDIVIDUALES

Dimensiones del producto y de los gabinetes

Instalación

Preparación de la cavidad

Instalación opcional del cableado del producto

Enrutar las mangueras y mover dentro de la cavidad

Sacar la tina y asegurar el producto

Plomería y drenaje - OPCIÓN 1

Plomería y drenaje - OPCIÓN 1 (conexión)

Plomería y drenaje - OPCIÓN 2

Plomería y drenaje - OPCIÓN 2 (conexión)

Plomería y drenaje - OPCIÓN 3

Plomería y drenaje - OPCIÓN 3 (conexión)

Volver a colocar la tina

Lista de comprobación final

62

64

65

66

67

68

69

70

71

72

73

74

75

76

78

79

80

81

82

83

84

85

86

87

88

89

61

US CA

ES

¡Importante!

CONSERVE ESTE INSTRUCTIVO

Los modelos que aparecen en esta Guía de Usuario pudieran no estar disponibles

en todos los mercado y están sujetos a cambio en cualquier momento. Para más

información sobre la disponibilidad de modelos y especificaciones en su país de origen,

favor de visitar nuestra página www.dcsappliances.com o póngase en contacto con su

distribuidor DCS local.

Page 64

US CA

62

Dimensiones del producto

ES

Diagramas de instalación para fines ilustrativos exclusivamente

C

D

N

I

K

MODELOS DOBLES

L

A

M

Dimensiones del producto (pulg. (mm))

altura total* del producto

A

ancho total del producto 23 ⁄”(605)

B

profundidad total del producto (no incluye la curvatura/manija) 22 ⁄” (570)

C

profundidad del cajón (abierto) (no incluye la curvatura/manija) 20 ⁄” (520)

D

altura* del chasis 31 ⁄” (809)

E

rango de altura de las patas de nivelación 2 ⁄” (60)

F

profundidad del chasis 21 ¾ ” (552)

G

profundidad del panel frontal del cajón

H

(no incluye la curvatura/manija)

profundidad de la curvatura o manija 3 ⁄” (81)

I

profundidad del rodapié 2 - 4 ⁄” (50 - 110)

J

altura de la parte frontal superior del cajón 15 ⁄” (398)

K

altura de la parte frontal inferior del cajón 14” (356)

L

altura del rodapié (ajustable)

M

altura de la instalación de ranuras de pestaña (en la parte

N

superior del chasis)

altura de las partes frontales del cajón 30 ⁄” (764)

O

altura* de la super cie del cajón superior a la super cie del

P

chasis

* las alturas del chasis incluyen las ranuras de pestaña

B

P

G

H

E

C

G

O

I

N

F

J

Preacabado

DD224P5

Puerta

plana

r

32 ¼ - 34 ⁄”

(819.5- 879.5)

1” (25)

2 ¾ - 4 ¾ ” (70 - 120)

¾ ” (2)

¾ ” (2)

Page 65

Dimensiones de los gabinetes

Diagramas de instalación para fines ilustrativos exclusivamente

B

C

Preacabado

Dimensiones de los gabinetes (pulg. (mm))

DD224P5

Puerta

plana

63

US CA

ES

D

A

MODELOS DOBLES

E

altura interior de la cavidad

A

ancho interior de la cavidad 24” (610)

B

profundidad interior de la cavidad (interior)

C

altura de los gabinetes adyacentes 28 ⁄” (720)

D

altura del rodapié

E

2 ¾ - 4 ¾ ” (70 - 120)

Espacios libres mínimos (pulg. (mm))

⁄” (2.5 mm)

⁄

” (2.5 mm)

” (13 mm)

½

32 ⁄ - 34 ¾ ”

(820 - 882.5)

22 ⁄” (580)

Page 66

US CA

ES

64

Preparación de la cavidad

Partes que se incluyen

Soporte de la

manguera de

drenaje (1)

Protector de Canto (1)

(si el hoyo de servicio está en

una mampara de metal)

Si la(s) Manguera(s) incluidas no son lo suficientemente largas para llegar al desagüe, deberá utilizar un Juego de Extensión de Mangueras de

Drenaje P/N 525798 que extenderá la(s) manguera(s) de drenaje hasta en 3.6m. Este juego lo podrá adquirir con su Agente Autorizado DCS

MODELOS DOBLES

más cercano, llame sin costo al

Unión de la

manguera de

drenaje (1)

Clip para cables (2)

Llave

hexagonal (2)

(Larga y Corta)

1-888-281-5698

Abrazadera (2)

Pestañas de

instalación (2)

Extrusiones de

costado flexibles (2)

o visite: www.dcsappliances.com. NO extienda las mangueras más allá de este límite.

Phillips 16 mm

tornillos (9)

Extrusión flexible de

superficie (1)

Lavadora (1)

Cinta de protección

de humedad (1)

(para prevenir daños

por humedad)

Protector de puntapiés ahuecado

preacabado (1)

Blanco o Negro

Si no hay mampara

lateral, utilice una

abrazadera para sujetar.

2×4 pulg.

2” x 4”

⁄ pulg.

(

10 mm)

Deberá aplicar

la cinta de

protección

contra

humedad.

o

90

Nota: Los servicios pueden ubicarse

a ambos lados del DishDrawer®.

max.

17 ⁄ pulg.

(

450 mm)

max. ø

¡Importante!

1 ½ pulg. (

38 mm)

min.

7 ⁄ pulg.

(

*

*

200 mm)

110–120 VAC

max. 15 A

Asegúrese que los cantos del hoyo de servicios queden lisos o cubiertos. Si el hoyo de servicios está

en una mampara metálica, el hoyo deberá protegerse con el Protector de Bordes incluido para

evitar daños al cable eléctrico o a las mangueras.

Estas marcas indican el lugar de montaje de los tornillos de pestaña.

Posición preferida. Si existe el espacio libre adecuado, el hoyo de servicios puede quedar más alto

*

para que haya espacio libre en el protector de puntapiés ahuecado.

Si el hoyo queda más arriba, asegúrese que la(s) manguera(s) de drenaje esté(n) enrutadas

directamente a la conexión de desagüe.

Page 67

Instalación opcional del cableado del producto

12

1 ⁄ pulg.

30 mm

30 mm)

(

4

65

US CA

ES

1

3

Asegúrese de sacar la tina y rotarla

de acuerdo con las manecillas

del reloj para prevenir que las

mangueras se enreden.

Saque la tapa ciega de la abrazadera

3

del cable. Coloque la abrazadera del

cable adecuada para el tubo metálico

de instalación eléctrica y concluya el

cableado como se muestra.

5

2

6

16

Quite el cordón eléctrico.

8

7

8

4

15

Asegúrese de volver a colocar los

clips de la tina en ambos lados.

15

7

MODELOS DOBLES

12

11

11

10

Asegúrese que la

tina quede rotada

al contrario de las

manecillas del reloj.

9

17

13

14

Antes de volver a colocar la tina,

asegúrese que las mangueras no

estén torcidas y que los pestillos en

la parte trasera de cada corredera

de cajón miren hacia adelante.

Page 68

US CA

ES

66

Enrutar las mangueras y mover dentro de la cavidad

1a

MODELOS DOBLES

Átelas juntas para que no se enreden.

2

opcional

optional

Si se utilizan las dos pestañas de la

superficie, asegúrese que queden

2

bien colocadas, antes de deslizar el

producto dentro de la cavidad.

1b

1

Asegúrese que las

mangueras y el cordón no

se enrosquen o tuerzan.

2

Revestimiento Revestimiento

de cantos del de cantos del

chasischasis

Extrusiones

flexibles

Abra el cajón

Extrusión

lateral

Reborde

3

Si la cavidad es más grande

de lo que se especifica (Pág.

63), las extrusiones pueden

atorarse a lo largo de la superficie

y a los costados de la unidad. Asegúrese que las

extrusiones no obstaculicen el cierre total del cajón.

4

4

1

1

Primero desenrosque las patas

pero no a su extensión máxima,

hasta que el producto esté en la

cavidad.

Page 69

Sacar la tina y nivelación del producto

67

US CA

ES

3

1

Asegúrese de sacar la tina y rotar

de acuerdo con las manecillas

del reloj para prevenir que las

mangueras se enreden.

4

MODELOS DOBLES

2

30 mm

3

4

Asegúrese que el producto quede nivelado. Mediante el uso

de la llave hexagonal con la longitud más apropiada que ya se

incluye, y un desarmador, extienda en su totalidad las patas de

nivelación hasta la distancia que se requiera.

5

5

Llave hexagonal

1

2

4

3

5

x 4

Page 70

US CA

68

ES

5

Las pestañas de

montaje vienen en

pares: una en cada

lado de la unidad.

Se deberá utilizar al

menos dos juegos de

pares de pestañas.

Pares de pestañas A

y B o B y C, o los tres

pares.

Asegúrese de volver a

colocar correctamente

el aislante acústico.

MODELOS DOBLES

Fijar la unidad y volver a colocar la tina

opcional

max. ¾ pulg. (19 mm)

C

C

6

4

Asegúrese que la

tina quede rotada

al contrario de

las manecillas del

reloj.

Asegúrese de volver a

colocar los clips de la tina

5

en ambos lados.

4

1

BB

A

A

3

Antes de volver a colocar la tina,

asegúrese que las mangueras no

estén torcidas y que los pestillos

en la parte trasera de cada

corredera de cajón miren hacia

adelante.

2

Page 71

Colocación del protector de puntapiés ahuecado

7

1

2

3

69

US CA

ES

MODELOS DOBLES

8

4 5 6 7

19

8 9

¡Importante!

No apriete demasiado los tornillos

10

Page 72

US CA

ES

70

Plomería y drenaje - OPCIÓN 1

DishDrawer® con Triturador Integrado

Unión de manguera

de drenaje incluida

(ø

pulg. (19 mm)

¾

conexión de

desperdicios en ‘T’)

MODELOS DOBLES

max. distancia de

las mangueras y del

cordón del punto de

salida del producto