Page 1

INSTALLATION INSTRUCTIONS

Gas cooktop

CG604DX1 & CG905DX1

models

HK SG

590633B 11.14

Page 2

1

SAFETY AND WARNINGS

WARNING!

Electrical shock hazard

Before carrying out any work on the

electrical section of the appliance, it must

be disconnected from the mains electricity

supply.

Connection to a good earth wiring system

is absolutely essential and mandatory.

Alterations to the domestic wiring

system must only be made by a qualified

electrician.

Failure to follow this advice may result in

electrical shock or death.

WARNING!

Cut hazard

Take care - some panel edges are sharp.

Failure to use caution could result in injury

or cuts.

IMPORTANT SAFETY INSTRUCTIONS!

Particular attention shall be given to the relevant

requirements regarding ventilation.

Read these instructions carefully before installing

this product.

Please make this information available to the

person installing the appliance as it could reduce

your installation costs.

This appliance is to be installed and serviced only

by an authorised person.

Installation must comply with your local building

and local gas authority codes and electricity

regulations.

Incorrect installation, for which the manufacturer

accepts no responsibility, may cause personal

injury or damage and could invalidate any

warranty or liability claims.

Appliances are factory set for LPG but are

convertible to Town gas (Singapore) and Town

gas (Hong Kong). If in doubt, refer to the local gas

network operator or gas supplier to confirm gas

type at installation site.

Do not modify this appliance.

Do not use or store flammable materials on or near

this appliance.

Do not spray aerosols in the vicinity of this

appliance while it is in operation.

Page 3

1

SAFETY AND WARNINGS

Packing elements (eg plastic bags, polystyrene

foam, staples, packing straps etc) and tools should

not be left around during and after installation,

especially if they are within easy reach of children,

as these may cause serious injuries.

Before you install the appliance,

please make sure that

the local distribution conditions (nature of gas and

pressure) and the adjustment of the appliance are

compatible. For adjustment conditions for this

appliance see ‘Gas rate summary’.

a suitable disconnection switch is incorporated in

the permanent wiring, mounted and positioned to

comply with the local wiring rules and regulations.

A means of disconnection with at least a 3 mm

air gap contact separation in all poles must be

incorporated into the fixed wiring in accordance

with the wiring rules, unless the local wiring rules

allow for alternative means.

the appliance is connected to a 220V - 240V 50Hz

(10 A) power supply only and earthed via the

power supply cable.

there is a power outlet within reach of the power

supply cable (900 mm from the centre rear of the

product). This must be accessible after installation.

The power supply cable should not touch any

metal parts.

if the power supply cable is damaged, it is replaced

only by the special cable: Part no. 534906 TRMNL

BLOCK-FLEX ASSY HITEMP GOG UK, obtainable

from authorised Fisher & Paykel Service Agents.

the supply connection point (gas shut-off valve) is

accessible after installation.

the benchtop is made of a heat resistant material.

the installation complies with all the requirements

of National and Local Authority Gas, Electric and

other relevant Codes and Regulations.

When you install the appliance

We do not recommend you seal this appliance

into the bench with silicone or glue. Doing so will

make future servicing difficult. Fisher & Paykel

will not be liable for any costs associated with

removing or replacing a sealed-in appliance, nor

for repairing any damage that may be incurred by

doing this.

If installed with an approved flexible hose, the

hose should not come in contact with the bottom

of the appliance or any sharp edges. Flexible hose

assemblies should be meet National and Local

Authority codes and regulations.

Seal exposed bare edges of the cutout with an

oil-based paint or moisture-proof polyurethane to

prevent possible moisture creeping between the

cooktop trim and the benchtop.

If, after following the instructions given, correct

performance cannot be achieved, please contact

your nearest Fisher & Paykel Authorised Service

Centre, Customer Care, or contact us through our

local website listed at the end of this document.

3

Page 4

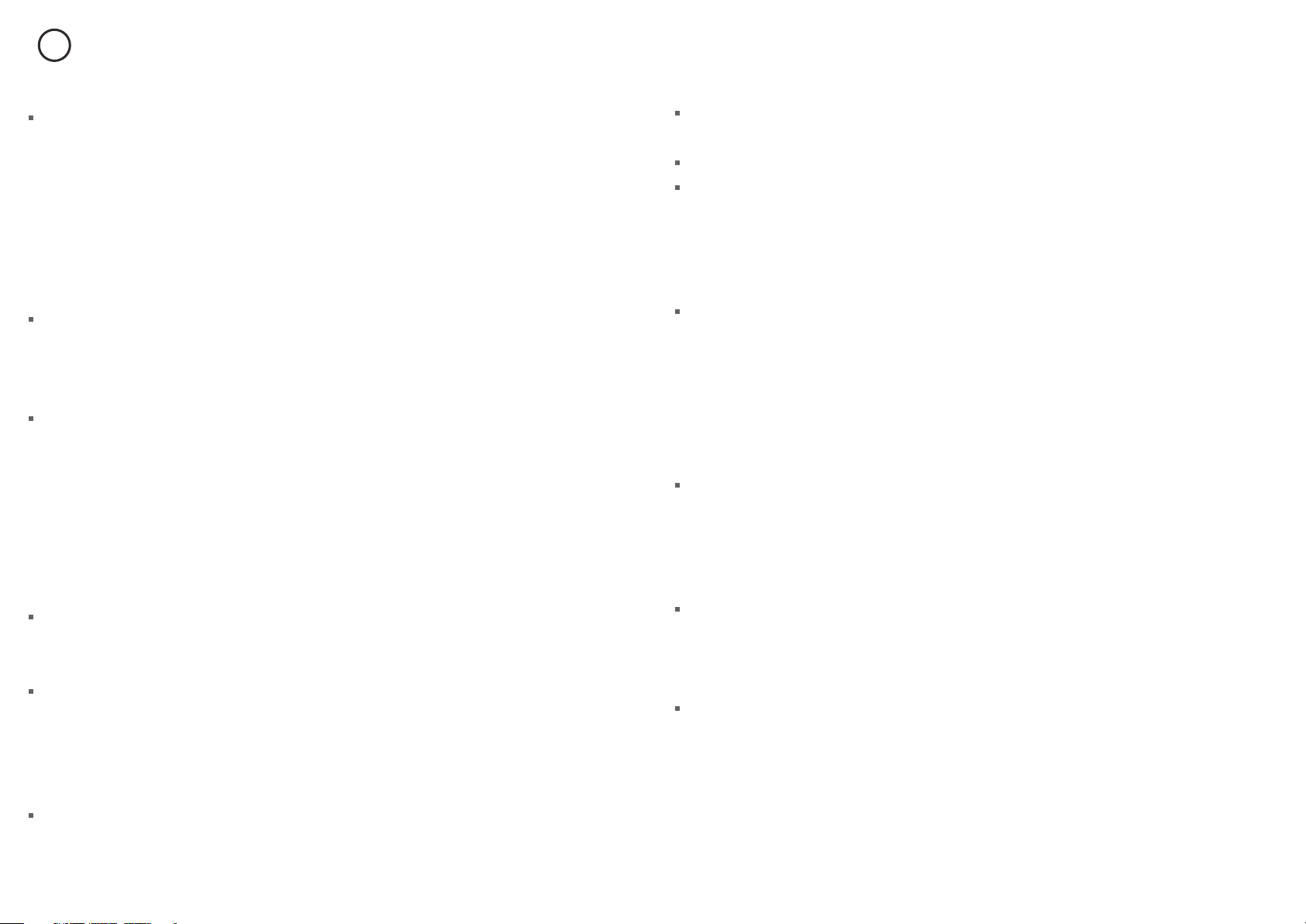

2

PARTS SUPPLIED

Wok stand (1) Fibre washers (1)Foam tape (1)

Clamping

brackets (4)

and screws (4)

3

GAS RATE SUMMARY

All appliances are factory set for LPG or Town Gas.

LPG test point

adaptor (1)

Gas Elbow (1) Elbow

external thread (1)

1

/

2

“ BSP

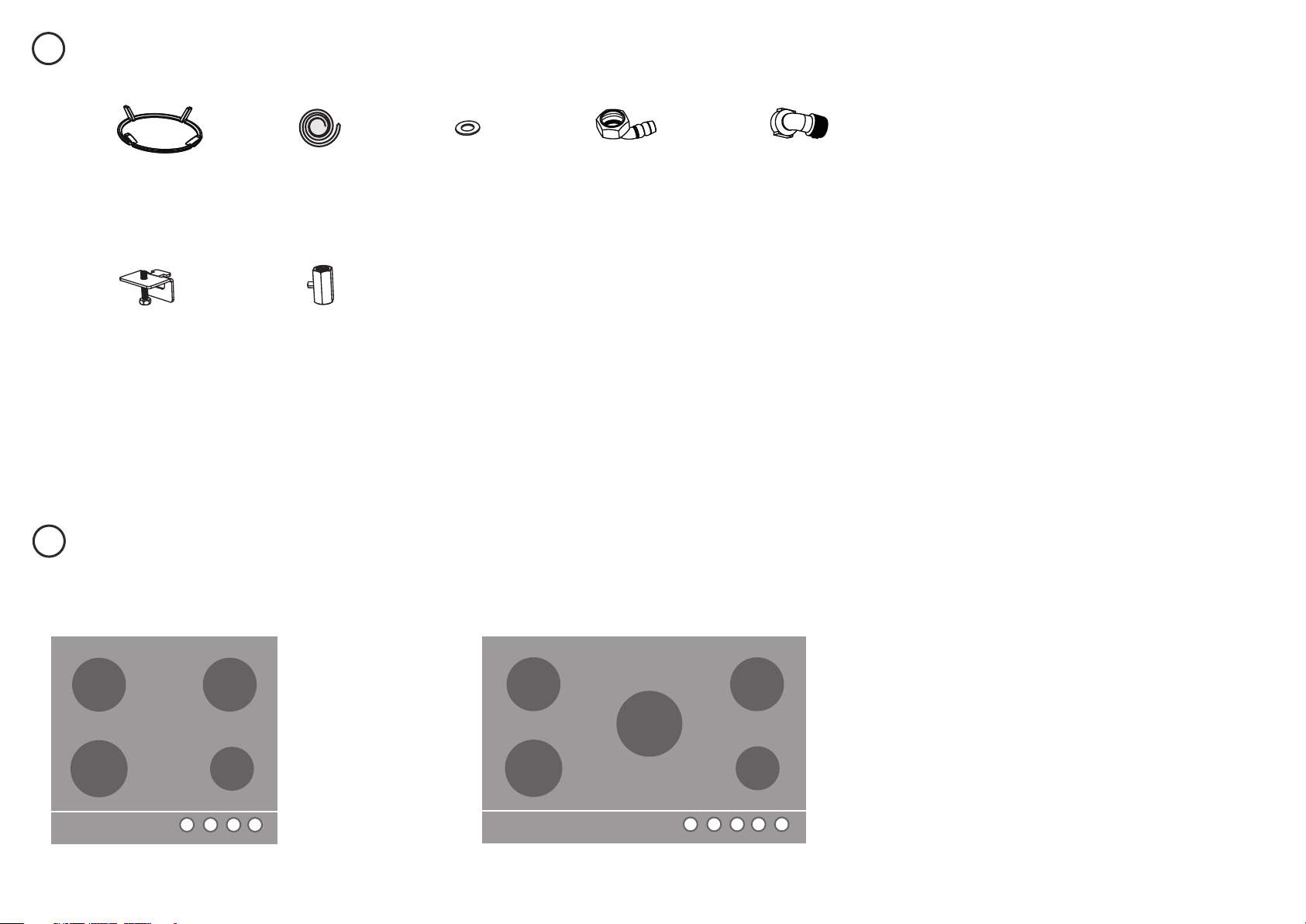

SEMI-RAPID

MINI WOK

CG604DX

SEMI-RAPID

AUX

SEMI-RAPID

RAPID

CG905DX

SEMI-RAPID

WOK

AUX

Page 5

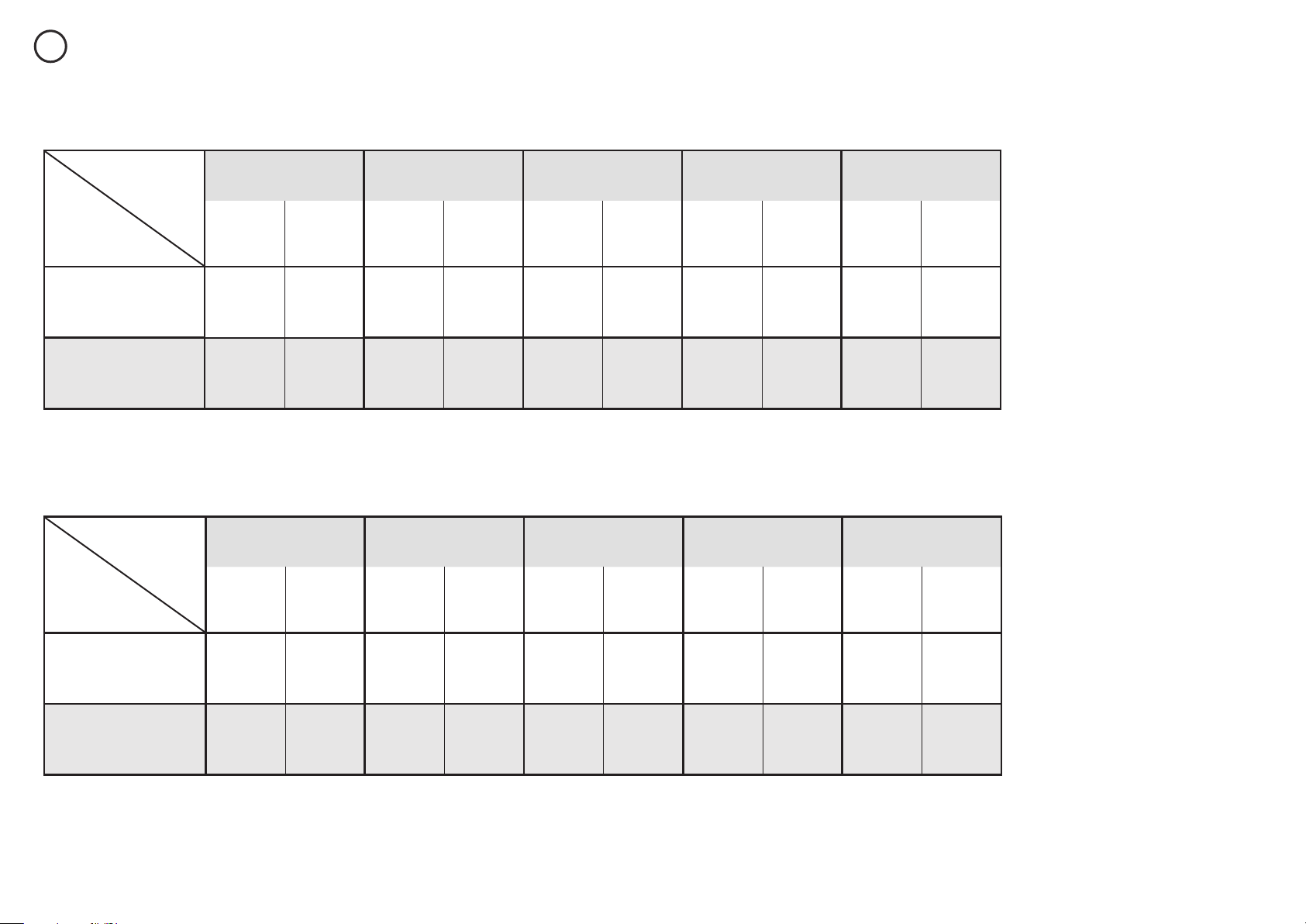

3

GAS RATE SUMMARY

HONG KONG

5

BURNER

GAS TYPE

TG (G110)

(1.5 kPa/15 mbar)*

LPG (G30)

(2.9 kPa/29 mbar)*

SINGAPORE

BURNER

GAS TYPE

AUX SEMI-RAPID RAPID MINI WOK WOK

Jet size

(mm)

1.30 1.1 1.55 2.36 2.10 3.33 2.60 3.33

0.55 1.1 0.76 2.36 0.94 3.33 0.94 3.33

Nominal

rating

(kW)

Jet size

(mm)

Nominal

rating

(kW)

Jet size

(mm)

Nominal

rating

(kW)

Jet size

(mm)

Nominal

rating

(kW)

AUX SEMI-RAPID RAPID MINI WOK WOK

Jet size

(mm)

Nominal

rating

(kW)

Jet size

(mm)

Nominal

rating

(kW)

Jet size

(mm)

Nominal

rating

(kW)

Jet size

(mm)

Nominal

rating

(kW)

Jet size

(mm)

1.10

2.30

2.30

0.73

0.73

0.50

Jet size

(mm)

Nominal

rating

(kW)

4.86

4.86

Nominal

rating

(kW)

TG (G110)

(0.8 kPa/8 mbar)*

LPG (G30)

(2.9 kPa/29 mbar)*

*Nominal pressure with the two semi-rapid burners on High.

1.50 1.1 2.07 2.36 3.20 3.33 3.50 3.33

0.55 1.1 0.76 2.36 0.94 3.33 0.94 3.33

1.30

2.50

2.50

0.73

0.73

0.50

4.86

4.86

Page 6

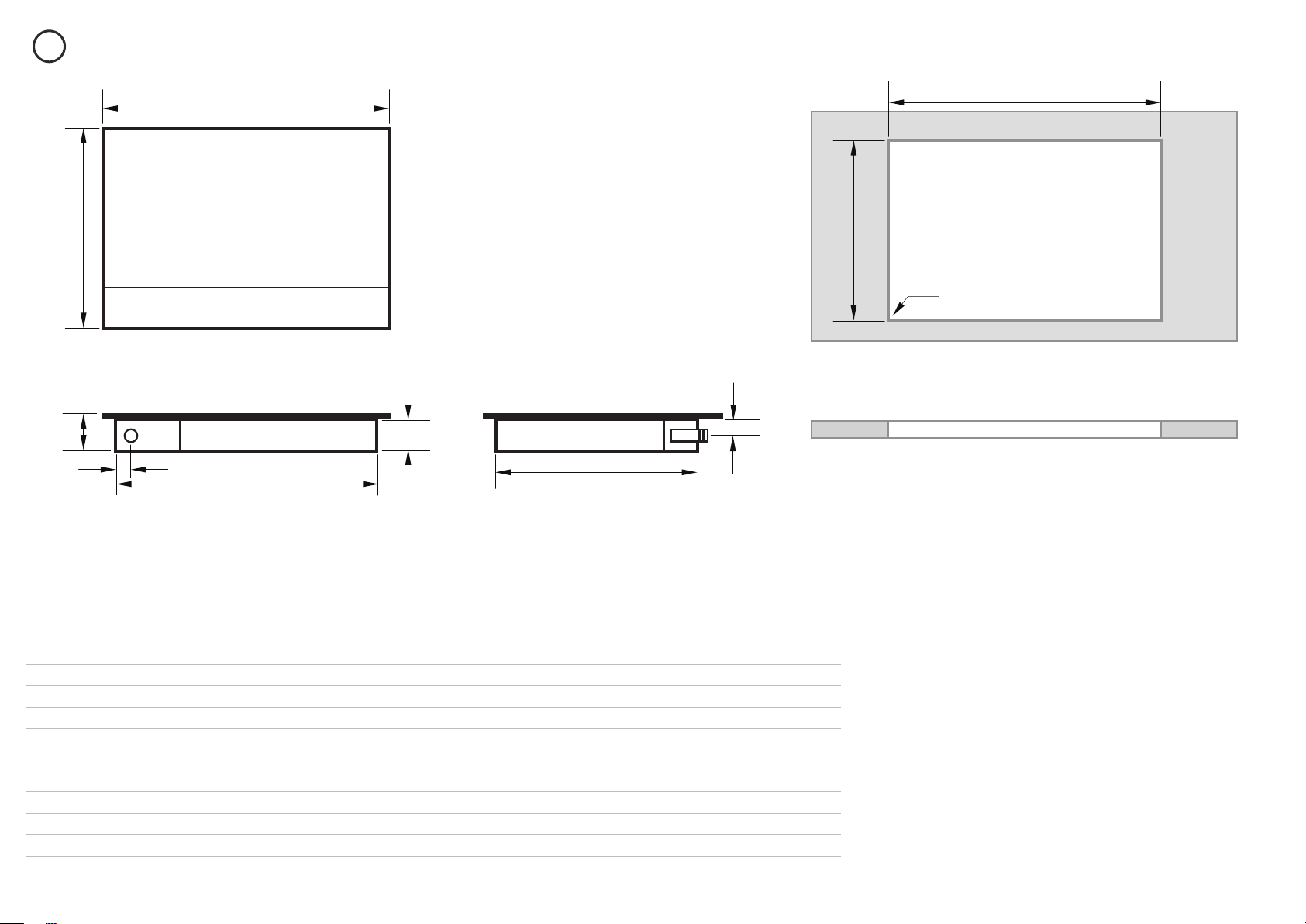

4

A

K

D

B

E

C

G

F

J

H

I

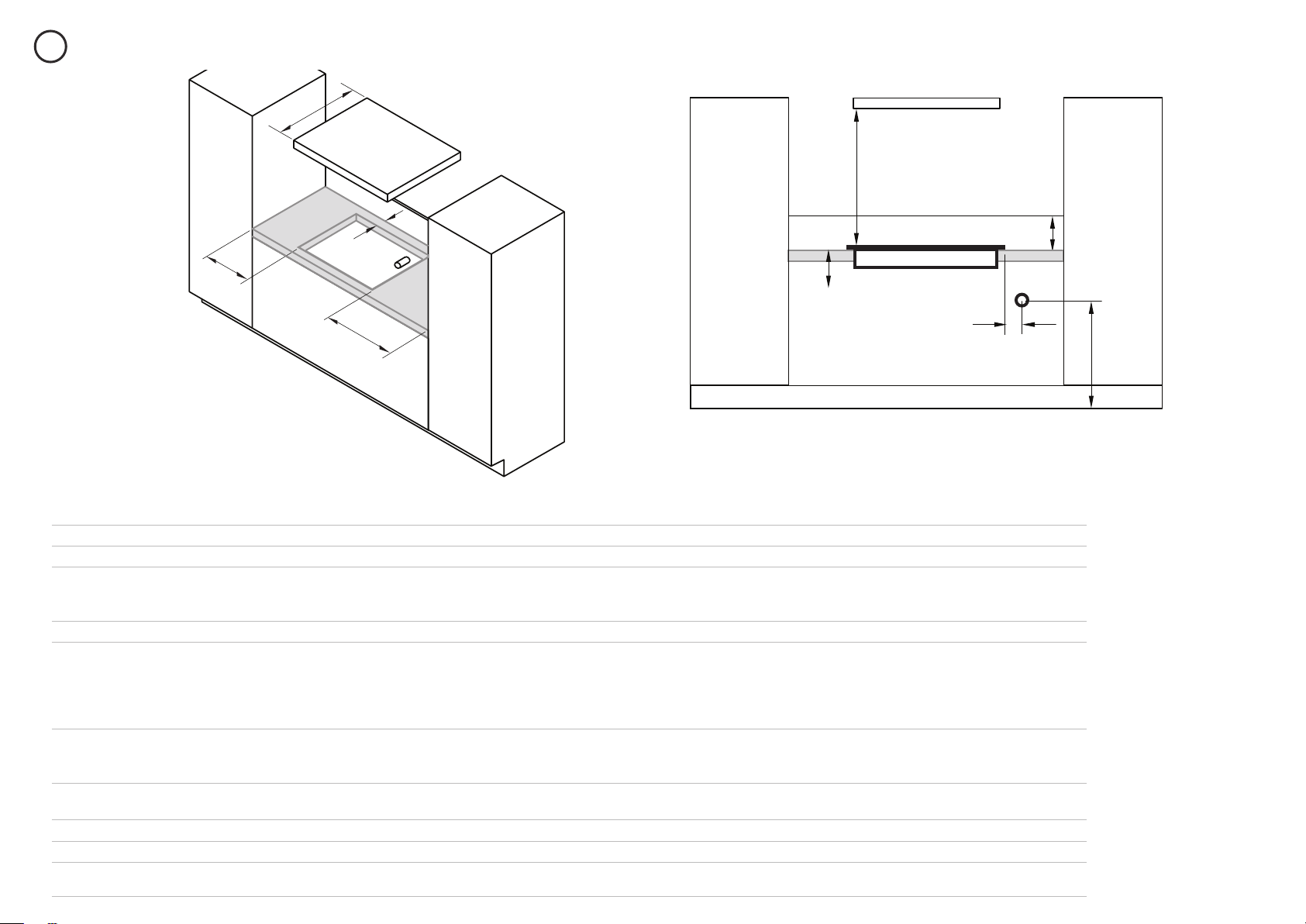

PRODUCT & CABINETRY DIMENSIONS

6

Note: Gas inlet connection is

located in the rear right corner.

Product and cabinetry dimensions (mm)

overall height of product (excluding burners, dials and pan supports) 64 64

A

overall width of product 600 900

B

overall depth of product 530 530

C

height of chassis (below top of bench) 59 59

D

width of chassis 555 856

E

depth of chassis 486 486

F

overall width of cutout 560 865

G

overall depth of cutout 490 490

H

corner radius of cutout max. 10 max. 10

I

distance from top of bench to centre of gas inlet on product 30 30

J

distance from edge of chassis to gas inlet on product 21 21

K

TOP

REAR

SIDE

CG604DX1

TOP

FRONT

CG905DX11

Page 7

5

E

H

D

F

G

CLEARANCE DIMENSIONS

7

I

E

C

F

G

FRONT

CG604DX1

160

45

650

800

650

500

70

65

250 250

A

B

ISO

Clearance dimensions (mm)

minimum clearance from left edge of cutout to nearest combustible surface 130 130

A

minimum clearance from right edge of cutout to nearest combustible surface 115 115

B

minimum clearance from rear edge of cutout to:

nearest combustible surface

C

nearest non-combustible surface

minimum height of non-combustible material when used on adjacent walls 150 150

D

minimum clearance from cooktop surface to:

rangehood

any other overhead exhaust fan

E

downward facing combustible surface

downwards-facing tiled or re resistant surface

minimum clearance below top of benchtop to:

combustible surface

F

Fisher & Paykel oven or nearest non-combustible surface

minimum distance from right edge of cooktop to gas connection point on wall

G

(if using a exible hose)

distance from oor to gas connection point on wall (if using a exible hose) min. 800 - max. 850 min. 800 - max. 850

H

maximum overall depth of overhead cabinetry 600 600

I

Note: Ensure there is an earthed power outlet within 900 mm of the centre rear of the product. The gas connector on the wall should be 800-850 mm (H) above the

oor and to a distance of at least 250 mm (G) outside the width of the product, on the right-hand side. It should be accessible with the product installed.

D

H

CG905DX1

160

45

650

800

650

500

70

65

Page 8

6

500 mm

50 mm

Foam Tape

Adhesive side

Ensure edge of tape

lines up with outer

edge of cooktop

500 mm

50 mm

500 mm

25 mm

500 mm

min

S

A

R

min

A

F

S

REAR CLAMPS FRONT CLAMPS

40 mm

40 mm

30 mm

30 mm

30 mm

30 mm

2

Foam Tape

Adhesive side

PTFE

⁄” NPT

1

2

16-20mm

20-30mm

Fibre washer

Floating nut

Elbow (½” BSP external thread)

LPG test point adaptor (if using LPG)

x 4

x 4

30-40mm

40mm+

GAS

ON

GAS

ON

NG

check all connections

yellow tiplifting o

good ame

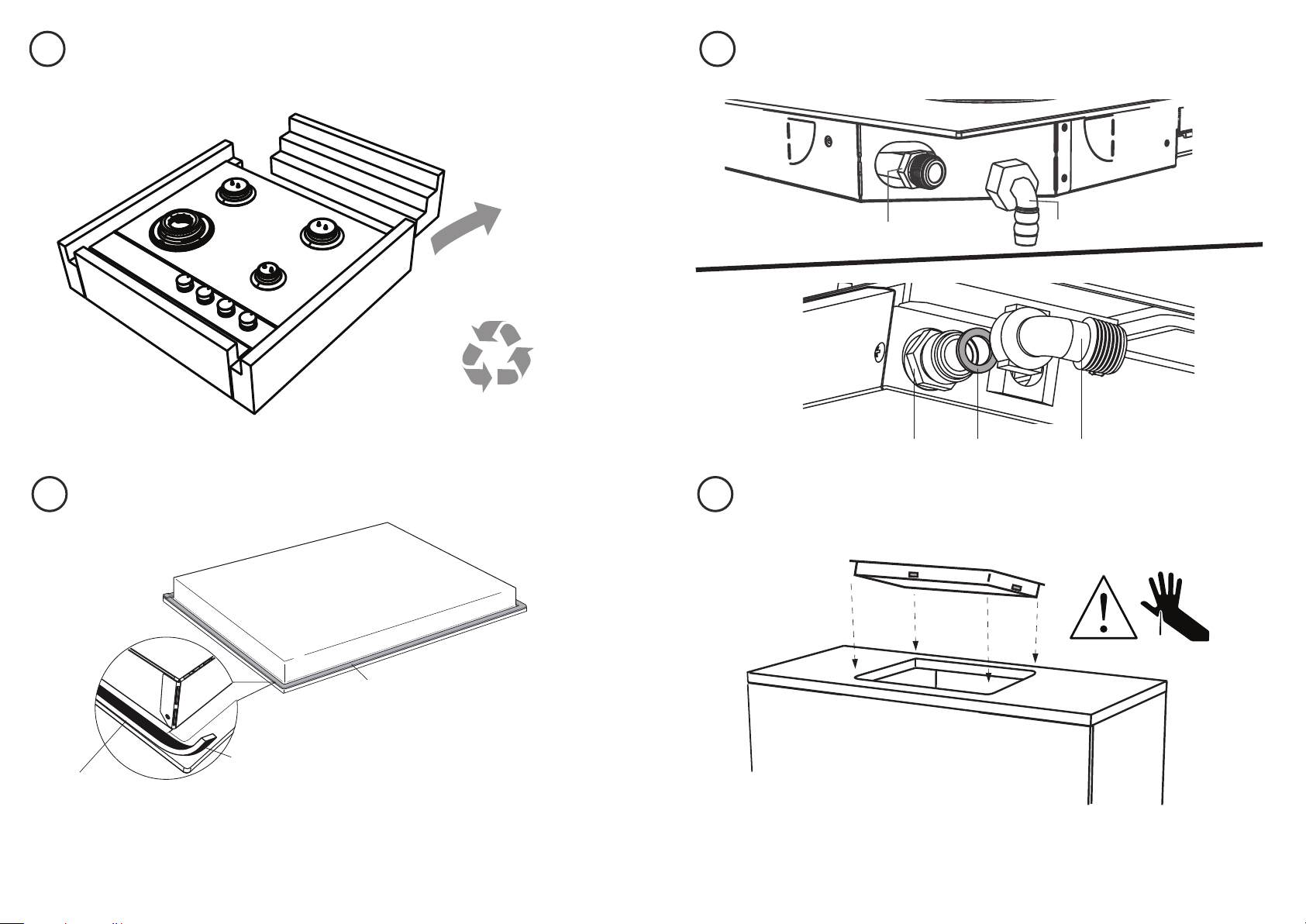

DISCARD PACKAGING

7

FIT THE ELBOW AND WASHER

8

Model may vary from illustrations shown

Recycle responsibly

HONG KONG

SINGAPORE

98

LOWER GENTLY INTO THE CUTOUTAPPLY ADHESIVE FOAM TAPE AROUND EDGE

Floating nut

Floating nut

Fibre washer

Elbow (1/2” BSP thread) & Washer

Elbow (1/2” BSP external thread)

Ensure edge of tape

lines up with outer

edge of cooktop

Adhesive side

Foam Tape

1

Turn the cooktop upside down and

place it on a soft surface.

2

Spread the seal around the edges, with

the adhesive side facing down to form a

continuous seal around the cooktop.

3

Using a sharp cutter or trimmer knife,

trim the excess sealing material around

the edge of the cooktop. Take care not

to damage the benchtop.

Page 9

GAS

ON

GAS

ON

20-30mm

LPG test point adaptor (if using LPG)

NG Models

ALL Models

Make sure the connection point will be accessible with the cooktop installed.

To enable the gas supply to be readily shut o by the customer, make sure the connection

is tted with an isolating valve close to the cooktop.

Make sure to t the supplied

washer and regulator.

Adjust to obtain a test point

pressure of 1 kPa with the two

semi-rapid burners operating at

highest setting.

Ensure the hose is long enough to allow for removal of cooktop for servicing.

Make sure the connector is located as shown in step 3 CLEARANCE DIMENSIONS.

The hose assembly must be AS/NZS 1869 Class B or D certied, with an Rp ½” (ISO 71) female thread connection.

The hose assembly must be as short as practicable and comply with relevant AS 5601/NZS 5261 requirements.

The hose must not be kinked, subjected to abrasion or permanently deformed.

The hose must not be near or in contact with any hot surfaces

(e.g. base of metal hotlplate, ue, or chassis of underbench oven etc.)

If connecting the gas with a exible hose:

Washer

yellow tiplifting o

good ame

Arrow

x 4

30-40mm

40mm+

PTFE

⁄” NPT

1

2

Fibre washer

Floating nut

Elbow (½” BSP external thread)

LPG test point adaptor (if using LPG)

x 4

Fibre washer

Elbow (½” BSP external thread)

lines up with outer

edge of cooktop

NG Models

ALL Models

Make sure the connection point will be accessible with the cooktop installed.

To enable the gas supply to be readily shut o by the customer, make sure the connection

is tted with an isolating valve close to the cooktop.

Make sure to t the supplied

washer and regulator.

Adjust to obtain a test point

pressure of 1 kPa with the two

semi-rapid burners operating at

highest setting.

LPG Models

Washer

Arrow

20-50 mm

x 4

1

1

1

2

NG

ALL Models

Make sure the connection point will be accessible with the cooktop installed.

To enable the gas supply to be readily shut o by the customer, make sure the connection

is tted with an isolating valve close to the cooktop.

Adjust to obtain a test point

pressure of 1 kPa with all the

burners operating at

highest setting.

Ensure the hose is long enough to allow for removal of cooktop for servicing.

Make sure the connector is located as shown in step 5 CLEARANCE DIMENSIONS.

The hose assembly must be AS/NZS 1869 Class B or D certied, with an Rp ½” (ISO 7‐1) female thread connection.

The hose assembly must be as short as practicable and comply with relevant AS 5601/NZS 5261 requirements.

The hose must not be kinked, subjected to abrasion or permanently deformed.

The hose must not be near or in contact with any hot surfaces

(e.g. base of metal hotlplate, ue, or chassis of underbench oven etc.)

If connecting the gas with a exible hose:

LPG

check all connections

Make sure the supply pressure

is regulated to 2.75 kPa, with

all the burners operating at

highest setting.

If converting to LPG, see 16 'Converting to a dierent gas type'

Arrow

TG

ALL Models

Make sure the connection point will be accessible with the cooktop installed.

To enable the gas supply to be readily shut o by the customer, make sure the connection

is tted with an isolating valve close to the cooktop.

Adjust to obtain a test point pressure of

1.5 kPa (Hong Kong) or 0.8 kPa (Singapore)

with all the burners operating at the

highest setting.

Ensure the hose is long enough to allow for removal of cooktop for servicing.

Make sure the connector is located as shown in step 5 CLEARANCE DIMENSIONS.

The hose assembly must be certied, with an Rp ½” (ISO 7‐1) female thread connection.

The hose assembly must be as short as practicable and comply with relevant local code and regulation requirements.

The hose must not be kinked, subjected to abrasion or permanently deformed.

The hose must not be near or in contact with any hot surfaces

(e.g. base of metal hotlplate, ue, or chassis of underbench oven etc.)

If connecting the gas with a exible hose:

LPG

Make sure the supply pressure

is regulated to 2.90 kPa, with

all the burners operating at

highest setting.

Arrow

10

FIT CLAMPING BRACKETS BASED ON THE

BENCHTOP THICKNESS

11

SECURE TO BENCHTOP

9

x 4

view from below

12

CONNECT TO GAS SUPPLY

16-20mm

20-30mm

30-40mm

40mm+

13

CHECK ALL CONNECTIONS FOR GAS LEAKS

ON

ON

GAS

GAS

Repeat on all the other sides

x 4

Page 10

14

GAS

ON

GAS

ON

ALL Models

Make sure the connection point will be accessible with the cooktop installed.

To enable the gas supply to be readily shut o by the customer, make sure the connection

is tted with an isolating valve close to the cooktop.

semi-rapid burners operating at

highest setting.

Ensure the hose is long enough to allow for removal of cooktop for servicing.

Make sure the connector is located as shown in step 3 CLEARANCE DIMENSIONS.

The hose assembly must be AS/NZS 1869 Class B or D certied, with an Rp ½” (ISO 71) female thread connection.

The hose assembly must be as short as practicable and comply with relevant AS 5601/NZS 5261 requirements.

The hose must not be kinked, subjected to abrasion or permanently deformed.

The hose must not be near or in contact with any hot surfaces

(e.g. base of metal hotlplate, ue, or chassis of underbench oven etc.)

If connecting the gas with a exible hose:

check all connections

the two semi-rapid burners

operating at highest setting.

Arrow

x 4

AFFIX DUPLICATE DATA LABEL SOMEWHERE

ACCESSIBLE & PLUG COOKTOP IN

15

FIT PAN SUPPORTS

Ensure the pan supports are located securely

and in the correct orientation (refer to User guide)

10

Duplicate data

label

16

TEST OPERATION

To check that the ignition system operates correctly, light each burner by itself, then all burners in

combination.

Check for a well‐defined blue flame without any yellow tipping.

If any abnormality is evident, check that the components of the burner assembly are located properly

If proper operation cannot be obtained, contact Customer Care or your nearest F&P Authorised

Service Centre.

The cooktop must not be used by the customer until proper operation has been achieved.

yellow tiplifting o

good ame

Page 11

17

FINAL CHECKLIST

11

TO BE COMPLETED BY THE INSTALLER

Have you installed the clamping brackets?

Have you verified that the type of model (factory-set for LPG or

Town Gas) matches the type of gas at the site of installation?

Have you used the fibre washer supplied?

Have you leak-tested all connections?

Is the appliance set to the correct working pressure?

Have you affixed the supplied duplicate data plate label on an adjacent

surface accessible to the customer?

Is the cooktop earthed?

Have you checked that the power supply cable is NOT touching the cooktop?

OPERATION:

Installer’s name:

Installer’s signature:

Installation company:

Date of installation:

LEAVE THESE INSTRUCTIONS WITH THE CUSTOMER

Important!

SAVE THESE INSTRUCTIONS

The models shown in this document may not be available in all markets and are subject to change

at any time. For current details about model and specification availability in your country, please

visit our local website listed at the end of this document or contact your local Fisher & Paykel

dealer.

Do all burners ignite both individually and in combination?

Are the flames consistent and appropriately sized?

Have you demonstrated the basic operation to the customer?

www.sherpaykel.com

Page 12

安裝說明書

氣體煮食爐

CG604DX1型和CG905DX1型

HK SG

590633B 11.14

Page 13

1

安全警告

警告!

觸電危險

在處理氣體煮食爐的電氣部分之前,必須斷

開總電源。

必須連接良好接地線。

如果要改動室內佈線,必須由資深電工進行

改動。

如不遵照此建議,可能會造成觸電甚至死

亡。

警告!

割傷危險

小心—面板邊沿很鋒利。

如不小心,可能會造成人身傷害或割傷。

重要安全須知!

必須特別注意相關的通風要求。

在安裝氣體煮食爐之前仔細閱讀本說明書。

請讓氣體煮食爐安裝人員閱讀本說明書,因為這

可以降低安裝成本。

氣體煮食爐只能由授權人士進行安裝和維修。

必須按照當地的建築法規和電氣法規要求進行安

裝。

安裝不當可能會造成人身傷害或財物損失,製造

商對此不承擔任何責任,保固或責任求償自動失

效。

氣體煮食爐在出廠前設定為使用液化石油氣,但

可以轉換使用新加坡煤氣和香港煤氣。如有疑

慮,請向當地供氣公司諮詢,確認安裝點供應哪

種氣體。

切勿改動氣體煮食爐。

切勿在氣體煮食爐上或周圍使用或存放易燃物。

切勿在使用氣體煮食爐時在周圍噴氣霧劑。

Page 14

1

安全警告

在安裝過程中和安裝之後,切勿把包裝材料(例

在安裝氣體煮食爐之後,氣源接頭(氣體截流

如塑膠袋、聚苯乙烯泡沫、搭扣和包裝帶)放在

氣體煮食爐附近,尤其不能放在兒童夠得到的地

方,否則可能會造成嚴重人身傷害。

在安裝氣體煮食爐之前確保

當地的供氣條件(氣體類型和壓力)與氣體煮食

爐調節條件一致。參看氣體氣速摘要一節瞭解氣

體煮食爐的調節條件。

在永久性佈線中安裝一個符合當地佈線法規要求

的合適斷路開關。根據當地的佈線法規,安裝在

固定佈線系統裡的斷路開關的所有電極的觸點氣

隙間隔為3mm,除非當地佈線法規允許採用替代

方法。

氣體煮食爐連接220V-240V50Hz(10A)電源,並

閥)所在位置必須便於使用者開關氣體。

灶台用耐熱材料製成。

氣體煮食爐安裝符合國家和當地供氣公司、供電

公司的要求和其他相關法律法規的要求。

在安裝氣體煮食爐時

建議你不要用矽膠或膠水把氣體煮食爐固定在灶

台上,否則日後很難維修。斐雪派克不承擔與拆

卸或安裝膠粘氣體煮食爐相關的任何費用,對在

此過程中可能發生的修理損壞不承擔任何責任。

如果安裝符合法規要求的軟管,軟管不應接觸氣

體煮食爐底面或任何鋒利邊沿。軟管應該符合國

家和當地供氣法律法規的要求。

開口裸露邊沿用油漆或防水聚氨酯密封,防止濕

通過電源線中的地線接地。

在氣體煮食爐電源線所及的地方裝有電源插座

(距氣體煮食爐後中心900mm)。在安裝氣體煮

食爐之後,插座所在位置必須便於使用者插拔插

頭。電源線不得接觸任何金屬零件。

如果電源線破損,必須用斐雪派克授權維修代

理商提供的專用電源線更換:534906 TRMNL

BLOCK-FLEX組件HITEMPGOG英國

氣滲入氣體煮食爐邊沿和灶台之間。

如果在根據氣體煮食爐安裝說明安裝之後,氣體

煮食爐達不到要求的性能,請聯絡最近的斐雪派

克授權服務中心或客戶服務部,或者登錄本指南

封底列出的地區網站聯絡我們。

Page 15

隨機提供的零件

2

鐵鍋架(1) 纖維墊圈(1)雙面膠(1)

固定支架(4)

螺絲(4)

氣體氣速摘要

3

所有的燃氣灶是在出廠時設置為與液化石油氣或天然氣的使用。

液化石油氣測試

點轉接頭(1)

氣體彎頭(1) 彎頭

紋(1)

1

/

" BSP外螺

2

中火

小鐵鍋

CG604DX型

中火

小火

中火

大火

CG905DX型

中火

鐵鍋

小火

Page 16

氣體氣速摘要

3

香港

爐頭

氣體類型

煤氣 (G110)

(1.5 kPa/15 mbar)*

液化石油氣(G30)

(2.9 kPa/29 mbar)*

新加坡

爐頭

氣體類型

小火 中火 大火 小鐵鍋 鐵鍋

噴管直徑

(mm)

1.30 1.1 1.55 2.36 2.10 3.33 2.60 3.33

0.55 1.1 0.76 2.36 0.94 3.33 0.94 3.33

額定值

(kW)

噴管直徑

(mm)

額定值

(kW)

噴管直徑

(mm)

額定值

(kW)

噴管直徑

(mm)

小火 中火 大火 小鐵鍋 鐵鍋

噴管直徑

(mm)

額定值

(kW)

噴管直徑

(mm)

額定值

(kW)

噴管直徑

(mm)

額定值

(kW)

噴管直徑

(mm)

額定值

(kW)

額定值

(kW)

噴管直徑

(mm)

1.10

2.30

2.30

0.73

0.73

0.50

噴管直徑

(mm)

額定值

(kW)

4.86

4.86

額定值

(kW)

(

G110)

煤氣

(0.8 kPa/8 mbar)*

液化石油氣(G30)

(2.9 kPa/29 mbar)*

* 兩個中火鍋爐頭打到最大時的額定壓力。

1.50 1.1 2.07 2.36 3.20 3.33 3.50 3.33

0.55 1.1 0.76 2.36 0.94 3.33 0.94 3.33

1.30

2.50

2.50

0.73

0.73

0.50

4.86

4.86

Page 17

氣體煮食爐尺寸和櫥櫃尺寸

A

K

D

B

E

C

G

F

J

H

I

4

注意:進氣管接頭位於右後方。

氣體煮食爐尺寸和櫥櫃尺寸(mm)

氣體煮食爐總高度(不包括爐頭、旋鈕和平底鍋架)

a

氣體煮食爐總寬度

B

氣體煮食爐總深度

c

底板高度(灶台上表面之下)

d

底板寬度

e

底板深度

f

開口總寬度

G

開口總深度

H

開口轉角半徑

I

灶台上表面到氣體煮食爐進氣管中心的距離

J

底板邊沿到氣體煮食爐進氣管的距離

K

頂面

背面

側面

CG604DX1型 CG905DX1型

64 64

600 900

530 530

59 59

555 856

486 486

560 865

490 490

最大10 最大10

30 30

21 21

頂面

正面

Page 18

E

H

D

F

G

間隙尺寸

5

I

E

C

A

F

B

ISO

間隙尺寸(mm)

CG604DX1型

開口左邊到最近的可燃性表面的最小間隙

a

開口右邊到最近的可燃性表面的最小間隙

B

開口後邊到下列各項的最小間隙:

最近的可燃性表面

c

最近的非可燃性表面

最小800 — 最大850 最小800 — 最大850

在背面牆壁上使用的非可燃性材料的最小高度

d

氣體煮食爐表面到下列各項的最小間隙:

抽油煙機

其他懸空排氣扇

e

面朝下的可燃性表面

面朝下的瓷磚或耐火表面

灶台上表面到下列各項的最小間隙:

可燃性表面

f

斐雪派克烤箱或最近的非可燃性表面

氣體煮食爐右邊到牆壁上進氣管接頭的最小距離(如果使用軟管)

G

地面到牆壁上進氣管接頭的距離(如果使用軟管)

H

吊櫃最大總深度

I

注意:確保在距氣體煮食爐後中心900mm範圍內裝有帶接地線的電源插座。牆壁上的進氣管接頭應該位於氣體煮食爐右邊,距地面的高度為800-850mm

(H),距氣體煮食爐的距離至少250mm (G)。在安裝氣體煮食爐之後,進氣管接頭應該便於操作閥門。

D

G

H

正面

CG905DX1型

130 130

115 115

160

45

150 150

650

800

650

500

70

65

250 250

600 600

160

45

650

800

650

500

70

65

Page 19

處置包裝材料

500 mm

50 mm

Foam Tape

Adhesive side

Ensure edge of tape

lines up with outer

edge of cooktop

500 mm

50 mm

500 mm

25 mm

500 mm

min

S

A

R

min

A

F

S

REAR CLAMPS FRONT CLAMPS

40 mm

40 mm

30 mm

30 mm

30 mm

30 mm

2

Foam Tape

Adhesive side

PTFE

⁄” NPT

1

2

16-20mm

20-30mm

Fibre washer

Floating nut

Elbow (½” BSP external thread)

LPG test point adaptor (if using LPG)

x 4

x 4

30-40mm

40mm+

GAS

ON

GAS

ON

NG

check all connections

yellow tiplifting o

good ame

6

安裝彎頭和墊圈

7

你購買的型號可能與圖中所示的型號有差異

採用負責任的方式回收利用

香港

新加坡

慢慢放入開口內在邊上貼一圈雙面膠

98

浮動螺母

浮動螺母

纖維墊圈

彎頭(1/2" BSP螺紋)和墊圈

彎頭(1/2" BSP外螺紋)

確保雙面膠邊對齊

氣體煮食爐外沿

有黏合劑的一面

雙面膠

1

把氣體煮食爐翻過來放在柔軟表面上。

2

把密封圈套在四周,讓有不乾膠的一面

朝下,使氣體煮食爐四周密封良好。

3

用鋒利刀子裁掉氣體煮食爐四周密封

圈的突出部分。注意不要損傷氣體煮食

爐。

Page 20

GAS

ON

GAS

ON

20-30mm

LPG test point adaptor (if using LPG)

NG Models

ALL Models

Make sure the connection point will be accessible with the cooktop installed.

To enable the gas supply to be readily shut o by the customer, make sure the connection

is tted with an isolating valve close to the cooktop.

Make sure to t the supplied

washer and regulator.

Adjust to obtain a test point

pressure of 1 kPa with the two

semi-rapid burners operating at

highest setting.

Ensure the hose is long enough to allow for removal of cooktop for servicing.

Make sure the connector is located as shown in step 3 CLEARANCE DIMENSIONS.

The hose assembly must be AS/NZS 1869 Class B or D certied, with an Rp ½” (ISO 71) female thread connection.

The hose assembly must be as short as practicable and comply with relevant AS 5601/NZS 5261 requirements.

The hose must not be kinked, subjected to abrasion or permanently deformed.

The hose must not be near or in contact with any hot surfaces

(e.g. base of metal hotlplate, ue, or chassis of underbench oven etc.)

If connecting the gas with a exible hose:

Washer

yellow tiplifting o

good ame

Arrow

x 4

30-40mm

40mm+

PTFE

⁄” NPT

1

2

Fibre washer

Floating nut

Elbow (½” BSP external thread)

LPG test point adaptor (if using LPG)

x 4

Fibre washer

Elbow (½” BSP external thread)

lines up with outer

edge of cooktop

NG Models

ALL Models

Make sure the connection point will be accessible with the cooktop installed.

To enable the gas supply to be readily shut o by the customer, make sure the connection

is tted with an isolating valve close to the cooktop.

Make sure to t the supplied

washer and regulator.

Adjust to obtain a test point

pressure of 1 kPa with the two

semi-rapid burners operating at

highest setting.

LPG Models

Washer

Arrow

20-50 mm

x 4

1

1

1

2

NG

ALL Models

Make sure the connection point will be accessible with the cooktop installed.

To enable the gas supply to be readily shut o by the customer, make sure the connection

is tted with an isolating valve close to the cooktop.

Adjust to obtain a test point

pressure of 1 kPa with all the

burners operating at

highest setting.

Ensure the hose is long enough to allow for removal of cooktop for servicing.

Make sure the connector is located as shown in step 5 CLEARANCE DIMENSIONS.

The hose assembly must be AS/NZS 1869 Class B or D certied, with an Rp ½” (ISO 7‐1) female thread connection.

The hose assembly must be as short as practicable and comply with relevant AS 5601/NZS 5261 requirements.

The hose must not be kinked, subjected to abrasion or permanently deformed.

The hose must not be near or in contact with any hot surfaces

(e.g. base of metal hotlplate, ue, or chassis of underbench oven etc.)

If connecting the gas with a exible hose:

LPG

check all connections

Make sure the supply pressure

is regulated to 2.75 kPa, with

all the burners operating at

highest setting.

If converting to LPG, see 16 'Converting to a dierent gas type'

Arrow

煤氣

所有型號

確保接頭在安裝氣體煮食爐之後便於接觸。

為了便於斷開氣源,確保在靠近氣體煮食爐的地方安裝隔離閥。

把測試點的壓力調節到1.5kPa(香港)

或0.8kPa(新加坡),把所有爐頭打到

最大火力。

確保軟管足夠長,便於拆除氣體煮食爐進行維修。

確保接頭位置間隙如第5步所述。

軟管必須是通過認證的Rp ½” (ISO7-1)母螺紋。

軟管必須盡可能短,必須符合當地相關法律法規的要求。

軟管不得打結,否則容易造成磨損或永久性變形。

軟管不得靠近或接觸任何發熱表面(例如金屬發熱板底部、煙道或灶台下面的烤箱底板等)。

如果用軟管連接氣源:

液化石油氣

確保把壓力調節到2.90kPa,

把所有爐頭打到最大火力。

箭頭

根據檯面厚度安裝固定支架

10

固定在檯面上

11

x 4

從下面往上看

連接氣源

12

16-20mm

20-30mm

30-40mm

40mm+

檢查所有接頭是否漏氣

13

對其他三面重複此步驟

x 4

氣體

GAS

ON

開

Page 21

在看得見的地方貼上備用資料標籤並插好氣體煮

GAS

ON

GAS

ON

ALL Models

Make sure the connection point will be accessible with the cooktop installed.

To enable the gas supply to be readily shut o by the customer, make sure the connection

is tted with an isolating valve close to the cooktop.

semi-rapid burners operating at

highest setting.

Ensure the hose is long enough to allow for removal of cooktop for servicing.

Make sure the connector is located as shown in step 3 CLEARANCE DIMENSIONS.

The hose assembly must be AS/NZS 1869 Class B or D certied, with an Rp ½” (ISO 71) female thread connection.

The hose assembly must be as short as practicable and comply with relevant AS 5601/NZS 5261 requirements.

The hose must not be kinked, subjected to abrasion or permanently deformed.

The hose must not be near or in contact with any hot surfaces

(e.g. base of metal hotlplate, ue, or chassis of underbench oven etc.)

If connecting the gas with a exible hose:

check all connections

the two semi-rapid burners

operating at highest setting.

Arrow

x 4

14

食爐電源插頭

安裝平底鍋架

15

確保平底鍋架放到位,且方向正確(參看使用者指南)

備用資料標籤

測試工作

16

分開點燃每個爐頭,然後點燃所有爐頭,檢查點火系統是否正常工作。

檢查火焰是否呈藍色,焰尾不帶黃色。

如果發現異常,檢查爐頭零件安裝是否正確。

如果氣體煮食爐無法正常工作,請聯絡客戶服務部或最近的斐雪派克授權服務中心。

在氣體煮食爐能正常工作之前,使用者不得使用氣體煮食爐。

焰尾呈黃色火焰噴離爐頭

正常火焰

Page 22

最後檢查

17

下列檢查應該由安裝人員進行

是否安裝了固定支架?

是否確認了設備類型與安裝點的氣體類型相同?

是否使用了隨機提供的纖維墊圈?

所有接頭是否進行過漏氣測試?

是否給氣體煮食爐設定了合適的工作壓力?

是否在使用者能看到的相鄰表面上貼了隨機提供的備用資料標籤?

氣體煮食爐是否接地?

是否檢查過電源線不接觸氣體煮食爐?

操作:

安裝人員姓名:

安裝人員簽名:

安裝公司:

安裝日期:

把說明書留給客戶

重要!

妥善保存本說明書

本說明書所述的型號並非在所有市場上銷售,隨時會有變動。如要詳細瞭解本國/本地區銷

售的型號和規格,請登錄本指南封底列出的地區網站,或者聯絡當地的斐雪派克經銷商。

所有爐頭是單獨點火還是同時點火?

火焰大小是否穩定合適?

你是否向客戶演示過基本操作?

www.sherpaykel.com

Page 23

Page 24

Loading...

Loading...