Installation Instructions

NZ & AU

CG603 SERIES

CG903 SERIES

CG913 SERIES

599284 B 07.2006 NZ & AU

Safety & Warnings

WARNING

Cut Hazard

Beware of sharp

edges when handling

stainless steel

appliances.

Failure to use caution

could result in injury

or cuts.

WARNINGS!

Particular attention shall be given to

the relevant requirements regarding

ventilation.

This product should not be sealed into

the bench with silicone or glue. Doing

so will make future servicing difficult.

Fisher & Paykel will not be liable for costs

associated with releasing such a product,

nor for repairing damage that may be

incurred in doing this.

When this product is installed it shall not

be used as a space heater, especially if

installed in boats or caravans.

No combustible material or products

should be placed on this product at any

time.

Do not spray aerosols in the vicinity of

this product while it is in operation.

CAUTION!

This product must be installed according

to these installation instructions and must

comply with local building regulations,

local gas authority codes and electrical

regulations.

Failure to install the product correctly could

invalidate any warranty or liability claims.

IMPORTANT!

Read these instructions carefully before

installing or using this product.

Please make this information available to the

person responsible for installing the product

as it could reduce your installation costs.

These products are registered:

in New Zealand at www.ess.govt.nz and

in Australia with AGA at www.gas.asn.au.

Before You Start

Prior to installation, ensure that the local

distribution conditions (nature of gas and

pressure) and the adjustment of the product

are compatible. For adjustment conditions

for this product see Gas Rate Summary.

This gas hob must be connected to a

220V - 240V 50Hz power supply only and

must be earthed via the power cord.

Ensure a suitable disconnection switch

is incorporated in the permanent wiring,

mounted and positioned to comply with

the local wiring rules and regulations. A

means of disconnection with at least a

3 mm air gap contact separation in all poles

must be incorporated into the fixed wiring in

accordance with the wiring rules, unless the

local wiring rules allow for alternative means.

Ensure that there is a power outlet within

reach of the cooktop cable (900 mm from

the rear right of the product). This must be

accessible after installation. The mains cable

should not touch any metal parts.

Make the bench top of a heat resistant

material.

Seal exposed bare edges of the cutout

with an oil-based paint or moisture proof

polyurethane to prevent possible damage

from moisture creeping between the

cooktop trim and the benchtop.

2

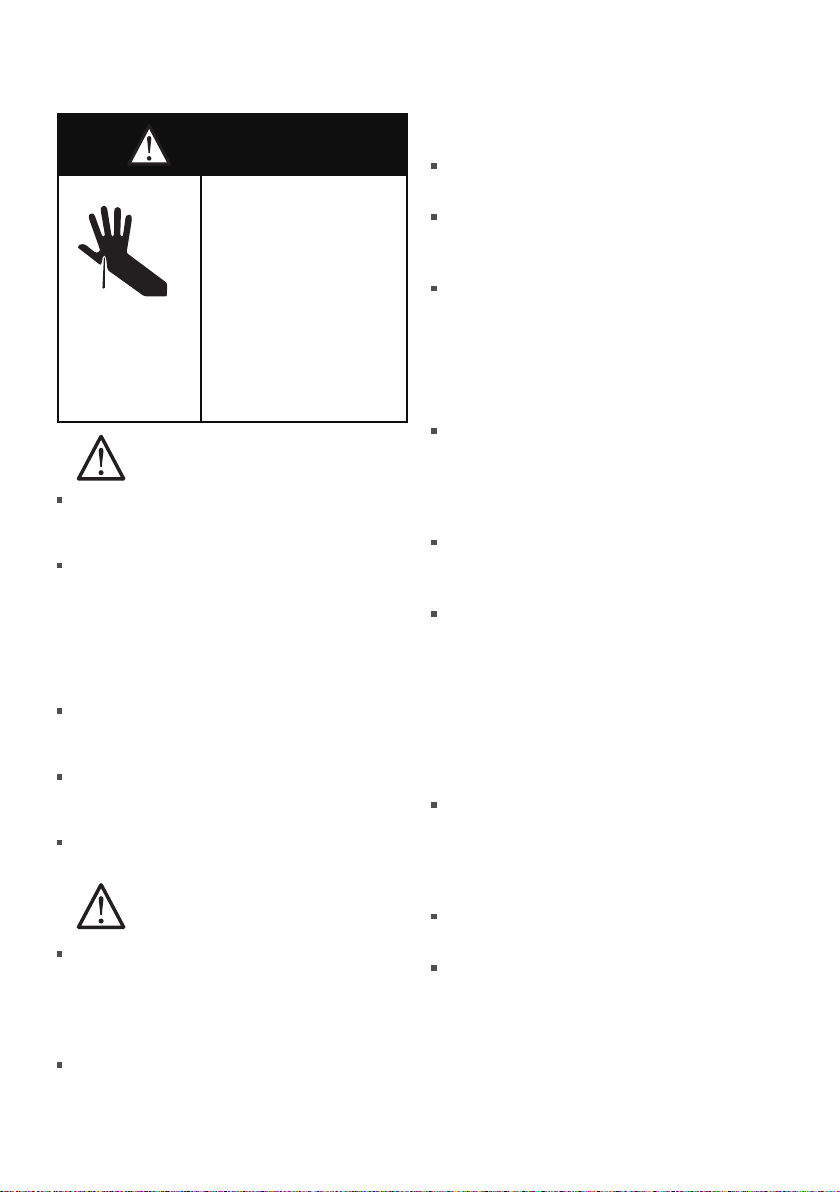

Dimensions

B

C

A

manifold

F

J

centre line

H

E

gas inlet

G

D

Product

Width 578 914 914

A

Depth 511 533 546

B

Height 40 40 76

C

Pan support

to Benchtop

Cutout

Width 560 (558-562) 870 (846-882) 870 (860-882)

D

Depth 490 (485-495) 494 (478-501) 494 (486-524)

E

Radius R10 R10 R10

F

G

H

Clearance to nearest

J

combustible surface

CG603 series CG903 series CG913 series

43 43 22

CG603 series CG903 series CG913 series

30 30 30

40 47 35

60 60 81

Note:

All measurements given in millimetres (mm).

Cutout dimensions are given as an ‘ideal measurement’ e.g. for new cutouts, followed by an

‘otherwise acceptable range’ (in brackets) e.g. for existing cutouts or replacement products.

3

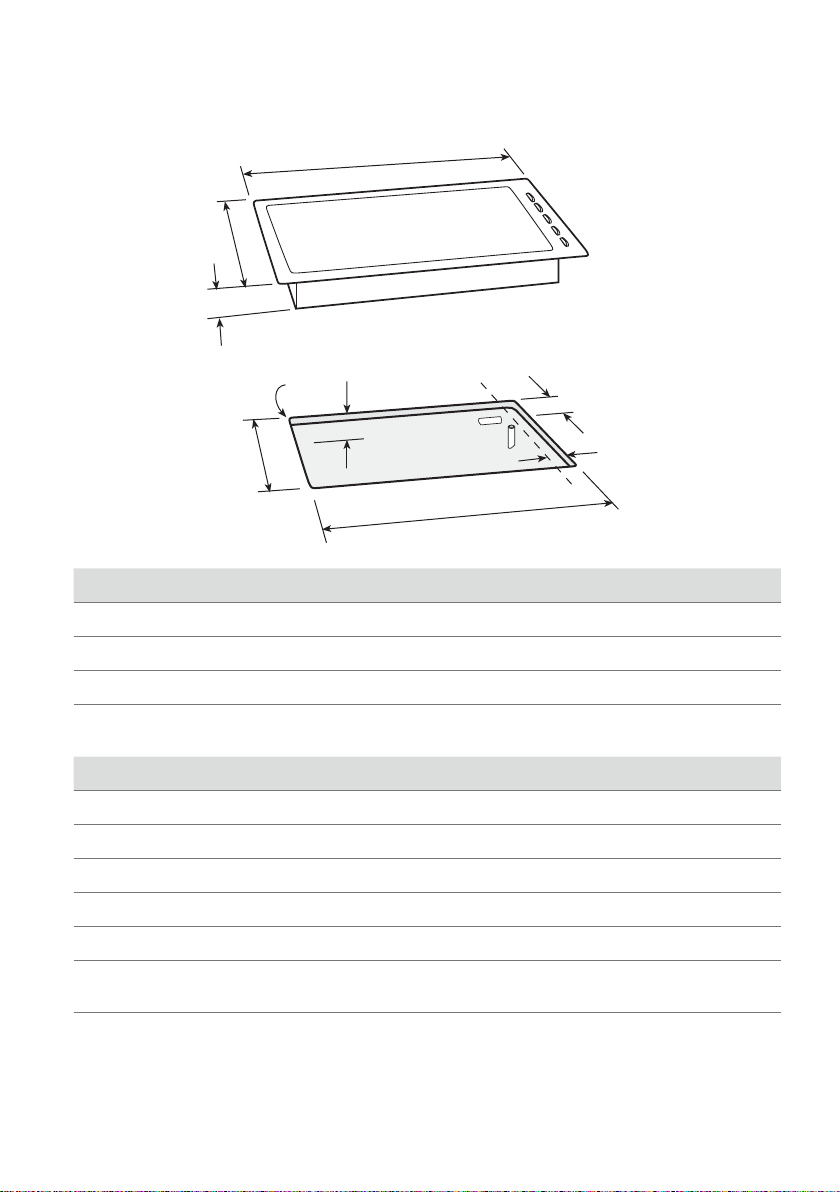

Clearances

a

d

e

f

b

g

c

600 mm minimum from top of trivet to rangehood.

a

750 mm minimum from top of trivet to overhead exhaust fan. (Fisher & Paykel splashbacks are

750 mm high).

600 mm minimum from top of trivet to downward facing combustable surface. (450 mm

b

minimum if protected by tiles or fire resistant materials).

CG603 SERIES CG903 SERIES CG913 SERIES

Clearance from side edge of

c

product to any combustible surface

Clearance from rear edge of

d

product to any combustible surface

Clearance from rear edge of

product to any non-combustible

surface

Clearance below benchtop to any

e

combustible surface

130 mm 120 mm 80 mm

100 mm 90 mm 90 mm

10 mm 10 mm 10 mm

60 mm 60 mm 81 mm

Clearance below benchtop to

F&P DishDrawer® or F&P oven

f

Ensure there is an earthed power outlet within 900 mm of the rear right-hand corner of the

product. When used with a flexible hose, the connector on the wall should be between 800

mm to 850 mm above the floor and in the region outside the width of the appliance to a

distance of 250 mm. This should be accessible with the appliance installed.

g

When protecting a wall with non-combustible material it must be at least 150 mm high.

4

45 mm 45 mm 81 mm

Installation Instructions

Standards Requirements

Australian and New Zealand Gas Installation

Standards (AS5601, NZS 5261) require a

cooktop to be installed so that the surface

temperature of any nearby combustible

surface will not exceed 65

Typically this is achieved by:

A

Having the cooktop spaced away from

the wall (see “Clearances” for dimensions)

c

[Dimension

OR

B

by protecting the wall, to at least 150 mm

high [Dimension

non-combustible surface materials, such as:

- 5 mm thick ceramic tiles alone are

adequate.

- Tempered glass or sheetmetal (min. 0.4 mm

thick) is acceptable when used in front of a

fire resistant material.

- Fisher & Paykel Splashback (not available

in Australia): This is stainless steel with a 10

mm air gap to the wall. When used with

a 10 mm gap behind the product to the

front of the splashback. (Only with SB90

series and SB1216 splashbacks.)

and d]

g

o

C above ambient.

] along it’s length, with

Gas Supply Connection

This cooktop is supplied set up for

Natural Gas but is suitable for installation

with either Natural Gas or LPG. Refer to

relevant table for pressures and appropriate

orifice sizes.

Gas connection to the product MUST use

the elbow supplied. The regulator will not

seal if installed without it.

Ensure the blue washer (supplied) is located

between the elbow (supplied) and product

inlet as below. Failure to use this washer

will cause the product to leak. Tighten the

floating nut to firm finger tight, plus an

additional

CG603, CG903

Blue washer Elbow (1/2” BSP male)

1

/4 turn (90o).

These products meet the Standards

requirements when installed to the

dimensions in these Instructions. (They have

been tested by an Independent Testing Lab).

Clamping Down the Cooktop

This cooktop is supplied with fastening

clamps that will cope with a bench thickness

of 20-50 mm. For benchtops thicker than 50

mm, recess the underside to a thickness of

20-50 mm.

50 mm

20 mm

recessed to

50 mm

CG913 series

Gas Inlet (1/2” BSP internal thread)

After installation, make sure all

connections are gas tight.

A duplicate data plate enclosed inside the

accessories pack should be placed on an

accessible surface adjacent to the cooktop.

Flexible Hoses

Flexible hose assemblies should be AS/NZS

1869 Class B or Class D certified.

Flexible hoses should not be exposed to

temperatures exceeding their certified value.

They should not touch hot surfaces on the

cooktop or neighbouring products.

Flexible hoses should not be subject to

abrasion, kinking or permanent deformation.

5

Installation Instructions

Natural Gas

For Natural Gas usage the gas supply is

connected to the regulator which is supplied

loose with a built in test point - 1kPa (4” WG)

and the inlet connection of 1/2 “ B.S.P. (male

thread). Do not over tighten.

The test point pressure should be preset

to 1.0 kPa with the wok and semi - rapid

burners operating at maximum.

LP Gas

For LPG usage the gas supply for the

appliance must be regulated to a pressure

of 2.75kPa (11” WG). See ‘Conversion to a

different gas type’ .

Gas Supply Connection Check

The connection point shall be accessible

with the appliance installed.

To enable the gas supply to be readily shut

off, the gas supply must be connected with

an isolating valve close to the product.

After installation and making all connections

check thoroughly for possible leaks.

1

Turn all control knobs on the unit to “off”

position.

2

Open the valve on the gas supply.

3

Using a suitable leak detection fluid solution

(e.g. Rocol) check each gas connection one

at a time by brushing the solution over the

connection.

4

The presence of bubbles will indicate a leak.

Tighten the fitting and recheck for leaks.

Ensure the washer (supplied) is located

between elbow and product gas inlet.

5

Turn on each gas valve and light each

burner.

6

Check for a clear blue flame without yellow

tipping. If burners show any abnormalities,

check that they are located and assembled

properly. Check correct orifices are installed.

6

The operation of the appliance, including

the ignition system, must be tested

before installation is complete.

If after following the instructions given,

satisfactory performance cannot be

obtained, contact the local gas authority

or your local Approved Service Agent for

advice and assistance.

Conversion to Different Gas Type

Burners can be used with NG or LPG,

provided that the orifices appropriate for the

gas supply are installed.

To change the orifices, you will need a 7 mm

box spanner (and a 10 mm ring spanner for

CG913TM).

1

Turn off the main electrical supply.

WARNING!

Electrical Shock Hazard.

Disconnect product from main power

supply before continuing.

2

Ensure all gas valves are turned off.

3

Remove all trivets and burner heads.

4

Pull off knobs.

5

Unscrew the orifices and replace them

with the correct ones. (size numbers are

stamped on the side, eg. 70= 0.70 mm)

(see figure 1)

6

Remove the 2 screws holding each burner

(3 on the wok burner).

7

Lift hob tray from the product.

WARNING!

Cut Hazard.

Beware of sharp edges.

8

Replace the wok orifice with the correct

one using a 10 mm spanner.

9

Reset the venturi (see fig.2). Loosen the

CG913TM only

venturi screw, move the venturi toward the

orifice approx. 2 mm.

10

To refit the CG913 series hob tray, repeat

steps 6 and 7 in reverse.

11

Check insulation resistance and earth

continuity.

continued...

Installation Instructions

12

Turn on main electrical supply and light the

burners.

13

Important! Reset the minimum setting

(see ‘Minimum Setting or Turndown’).

14

Check all burners have good flame (see

fig.3,4,5).

Venturi

figure 2figure 1

figure 3 figure 4

Minimum Setting or Turn Down

This has been set at the factory for NG but

may need adjusting for local conditions.

When converting to LPG, the minimum

setting MUST be reset for each burner.

To adjust the minimum setting you will need

a Ø 2.5 x 45 mm screwdriver.

1

Ignite the burner and set the knob to its

minimum position.

2

Remove the knob.

3

Rotate the turn down screw slowly until

a minimum regular flame is achieved.

(The flame will diminish when the screw

is turned clockwise and increase when

turned anti-clockwise (see fig.6).

4

Replace the knob.

5

When the setting is right check regulation

by quickly rotating the knob from the

maximum to the minimum delivery

position. The flame must not go out.

figure 5

Note: CG913TM models may require

progressive venturi adjustment on the wok

burner:

Fig.3 Lifting Off - move the venturi closer to

the orifice.

Fig.4 Yellow Tipping - move the venturi

away from the orifice.

Fig.5 Good Flame.

The label supplied with the orifices should

be placed over the existing gas type label

located on the underside of the product to

indicate the gas change.

figure 6

7

Installation Instructions

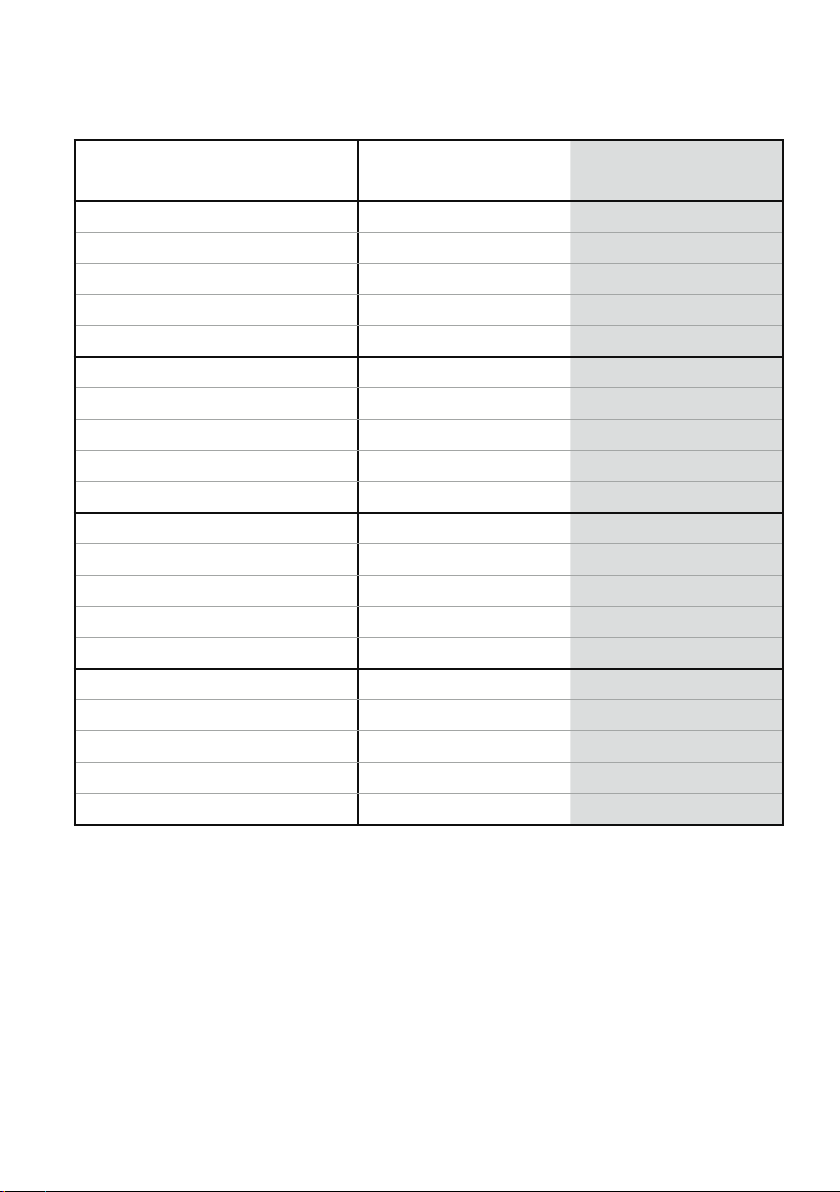

Gas Rate Summary

Burners Natural Gas LPG

Orifice size MJ/h@1 kPa Orifice size MJ/h@2.75 kPa

CG603

Auxiliary Burner (RH front) 0.85 mm 3.6 MJ/h 0.55 mm 4.0 MJ/h

Semi-Rapid Burner (LH & RH rear) 1.3 mm 8.5 MJ/h 0.8 mm 8.5 MJ/h

Wok Burner (LF front) 1.75 mm 15 MJ/h 1.00 mm 13.5 MJ/h

Rapid Burner (LH front) 1.55 mm 12 MJ/h 0.95 mm 12 MJ/h

CG903

Auxiliary Burner (RH front) 0.85 mm 3.6 MJ/h 0.55 mm 4.0 MJ/h

Semi-Rapid Burner (LH & RH rear) 1.3 mm 8.5 MJ/h 0.80 mm 8.5 MJ/h

Fish Burner (Centre) 1.55 mm 12 MJ/h 0.95 mm 12 MJ/h

Wok Burner (LH front) 1.75 mm 15 MJ/h 1.00 mm 13.5 MJ/h

GC913T

Simmer Burner (RH front) 0.85 mm 3.6 MJ/h 0.45 mm 2.7 MJ/h

Semi-Rapid Burner (LH rear) 1.22 mm 7.2 MJ/h 0.7 mm 6.2 MJ/h

Rapid Burner (LH front & RH rear) 1.45 mm 10.5 MJ/h 0.85 mm 9.3 MJ/h

Wok Burner (Centre) 1.80 mm 15.5 MJ/h 1.05 mm 14.5 MJ/h

CG913TM

Simmer Burner (RH front) 0.85 mm 3.6 MJ/h 0.45 mm 2.7 MJ/h

Semi-Rapid Burner (LH rear) 1.22 mm 7.2 MJ/h 0.7 mm 6.2 MJ/h

Rapid Burner (LH front & RH rear) 1.45 mm 10.5 MJ/h 0.85 mm 9.3 MJ/h

Wok Burner (Centre) 1.90 mm 16.3 MJ/h 1.10 mm 15.3 MJ/h

Customer Care

New Zealand

P.O. Box 58732, Greenmount, Auckland.

Toll Free 0800 FP CARE (0800 37 2273)

Fax 09 273 0656

Email customer.care@fp.co.nz

Current Information

Current Installation Instructions, Product

dimensions and specifications are available

on the Fisher & Paykel web site:

www.fisherpaykel.com

Australia

P.O. Box 798, Cleveland, QLD 4163.

Toll Free 1300 650 590

Tel 07 3826 9100

Fax 07 3826 9298

Email customer.care@fp.com.au

8

Loading...

Loading...