Page 1

790 ACTIVE SMART

REFRIGERATOR FREEZER

517800

Page 2

2

Page 3

3

MANUAL 517800 - DATE OF ISSUE MAY 2004

The specifications and servicing procedures outlined in this manual are subject to change without notice.

The latest version is indicated by the reprint date and replaces any earlier editions.

Fisher & Paykel Appliances Inc

27 Hubble, Irvine

California, CA92618

USA

Telephone: 949 790 8900

Facsimile: 949 790 8911

Fisher & Paykel Appliances Ltd

Technical Publications

PO Box 58-732, Greenmount, Auckland

78 Springs Road, East Tamaki

New Zealand

Telephone: 09 273 0600

Facsimile: 09 273 0656

COPYRIGHT FISHER & PAYKEL LTD 2004

Page 4

4

C O N T E N T S

1 TERMINOLOGY ..........................................................................................................6

2 SPECIFICATIONS.......................................................................................................7

2.1 Cabinet Specifications.........................................................................................................................7

2.2 Model Number Identification................................................................................................................8

2.3 Serial Number Identification ................................................................................................................8

3 SERVICING REQUIREMENTS ...................................................................................9

3.1 Interface Pen Mk 2 ..............................................................................................................................9

3.2 Health & Safety....................................................................................................................................9

3.2.1 Good Work Practices ...........................................................................................................9

3.2.2 Environmental Health And Safety........................................................................................9

3.2.3 Good Practice And Safety....................................................................................................9

4 INSTALLATION INSTRUCTIONS .............................................................................10

4.1 Levelling ........................................................................................................................................... 10

4.2 Air Space Requirements .................................................................................................................. 11

4.3 Temperature Adjustment.................................................................................................................. 11

5 THEORY OF OPERATION........................................................................................12

5.1 Internal Air Flow ............................................................................................................................... 12

5.2 Defrost Cycle .................................................................................................................................... 13

5.3 The Refrigeration Circuit .................................................................................................................. 14

5.4 Servicing Features ........................................................................................................................... 15

5.4.1 Condensate Disposal........................................................................................................15

5.4.2 Internal Condenser ........................................................................................................... 16

5.4.3 Cross Rail.......................................................................................................................... 19

5.4.4 Divider Partition................................................................................................................. 19

6 ELECTRONICS SECTION ........................................................................................20

6.1 Overview Function Description......................................................................................................... 20

6.1.1 Control & Peripheral Functions ......................................................................................... 20

6.1.2 Power/Control Module ...................................................................................................... 20

6.1.3 Display Module ................................................................................................................. 21

6.1.4 Door Switches................................................................................................................... 21

6.1.5 Compressor....................................................................................................................... 22

6.1.5.1 Variable Capacity Compressor Control Overview ....................................................... 22

6.1.5.2 Built-in Electronic Protections (Within the Module/Inverter) ........................................ 23

6.1.5.2.1 Compressor Start-up............................................................................................ 23

6.1.5.2.2 Overload Detection and Protection ...................................................................... 23

6.1.5.2.3 Power Limitation (Temperature Protection) ......................................................... 23

6.1.5.2.4 Short Circuit Protection ........................................................................................ 23

6.1.5.3 VCC Module/Inverter Identification.............................................................................. 23

6.1.5.4 Fault Finding ................................................................................................................ 23

6.1.5.4.1 High Voltage Power Supply Circuit ...................................................................... 23

6.1.5.4.2 Signal Circuit ........................................................................................................ 23

6.1.6 Defrost Heater................................................................................................................... 24

6.1.7 Thermal Fuses .................................................................................................................. 25

6.1.8 Low Ambient Heater .........................................................................................................25

6.1.9 PC / FC Fans .................................................................................................................... 26

6.1.10 Light .................................................................................................................................. 26

6.1.11 Thermistor Temperature Sensors ..................................................................................... 27

Page 5

5

6.2 Fault Finding Procedure....................................................................................................................28

6.2.1 Fault Code Display Status .................................................................................................28

6.2.2 Diagnostic Mode ................................................................................................................ 31

6.2.3 Sensor Temperature Conversion ......................................................................................31

6.2.4 Input/Output Status............................................................................................................ 32

6.2.5 Data Download ..................................................................................................................33

6.2.6 Manual Defrost ..................................................................................................................33

6.2.7 Show Room Mode .............................................................................................................33

6.2.8 Special Option Mode (Israel) .............................................................................................34

6.3 Door Gasket - (Integral) ....................................................................................................................34

7 REMOVING AND REFITTING OF COMPONENTS.................................................. 35

7.1 Removal Of Power/Control Module ..................................................................................................35

7.2 PC Sensor Replacement...................................................................................................................35

7.3 FC Sensor Replacement................................................................................................................... 35

7.4 PC Fan Motor - “T” Model .................................................................................................................36

7.5 PC Fan Motor - “B” Models ...............................................................................................................36

7.6 Cross / Base Rail Door Reed Switches ............................................................................................36

7.7 Defrost Heating Element...................................................................................................................36

7.8 Removal Of Display Module .............................................................................................................37

7.9 Thermal Fuse ....................................................................................................................................37

7.10 Replacement Of Interior Lamp..........................................................................................................37

7.11 Replacement Of Low Ambient Heater - “T” Model..........................................................................37

7.12 Replacement Of Low Ambient Heater - “B” Model .........................................................................38

7.13 Replacement Of Low Ambient Heater - “B” Model (In Return Air Grill) ..........................................38

7.14 Evaporator Replacement ..................................................................................................................38

7.15 Removal Of The FC Evaporator Cover.............................................................................................39

7.16 Pressure Testing Of The Refrigeration System ................................................................................40

7.17 Transporting Of Refrigerators ...........................................................................................................41

8 WIRING DIAGRAM ................................................................................................... 42

9 SERVICE REFERENCE ........................................................................................... 43

9.1 “B” Models.........................................................................................................................................43

9.2 “T” Models .........................................................................................................................................46

10 FLOW DIAGRAMS.................................................................................................... 48

10.1 Refrigerator Not Operating................................................................................................................48

10.2 No Power To Power/Control Module And/Or Display Module ..........................................................49

10.3 PC/FC Warm.....................................................................................................................................50

10.4 FC Too Cold – PC Too Warm...........................................................................................................51

10.5 PC Too Cold......................................................................................................................................52

10.6 Ice/Condensation Forming................................................................................................................53

10.7 No Light.............................................................................................................................................54

10.8 Door Switch Not Operating ...............................................................................................................55

10.9 Defrost Heater Faults ........................................................................................................................56

10.10 Compressor Faults.......................................................................................................................57

10.11 Compressor Runs Continuously ..................................................................................................57

10.12 Compressor Will Not Run And Is Hot To Touch ..........................................................................58

10.13 Compressor Electrical Tests ........................................................................................................ 58

10.14 Refrigeration System Faults.........................................................................................................59

Page 6

6

1 TERMINOLOGY

The following are terms used in this manual:

“B” MODELS

Dual temperature refrigerator/freezers in which the freezer compartment is below the refrigerator

compartment.

“T” MODELS

Dual temperature refrigerator/freezers in which the freezer compartment is above the refrigerator

compartment.

FC COMPARTMENT

Freezer compartment. The compartment in a dual temperature refrigerator used for keeping frozen food,

where the temperature is maintained at approximately –16

o

C (3oF).

PC COMPARTMENT

Provision compartment. The compartment in a dual temperature refrigerator used for keeping fresh food,

where the temperature is maintained at approximately 4

o

C (39oF).

CABINET WRAPPER

Pre-painted steel.

LINER

A one-piece vacuum formed ABS liner with a plug-in divider.

DIVIDER PARTITION

Injected moulding of HIPS, with two outer injected moulded housings, and an insulated ducted moulded

polystyrene inner core.

FAN MOTORS

DC 12 volt brushless variable speed fan motors for air circulation in both the FC and PC compartments.

EVAPORATOR

Aluminium corrugated type mounted vertically on the back wall of the FC.

SUCTION & CAPILLARY LINE

Foamed into the back of the cabinet with all joints of the evaporator in the FC.

POWER/CONTROL MODULE

Contains the microprocessor that controls all functions of the refrigerator and gathers data from the sensors.

This module also contains support circuitry to switch the various outputs.

DISPLAY MODULE

Using signals from the Power Module, this module generates the L.E.D. display. The lamp is also switched

via this module.

REED SENSORS

A reed switch encapsulated within a plastic housing, mounted on the cross and base rails behind a plastic

cover. A magnet housed just under the lower end cap of each door activates this sensor when the door is

closed.

LOW AMBIENT HEATER

Two types are used. A PCB type is used in the air duct of “T” models. A blanket wire type is used in the

divider of “B” models.

Page 7

7

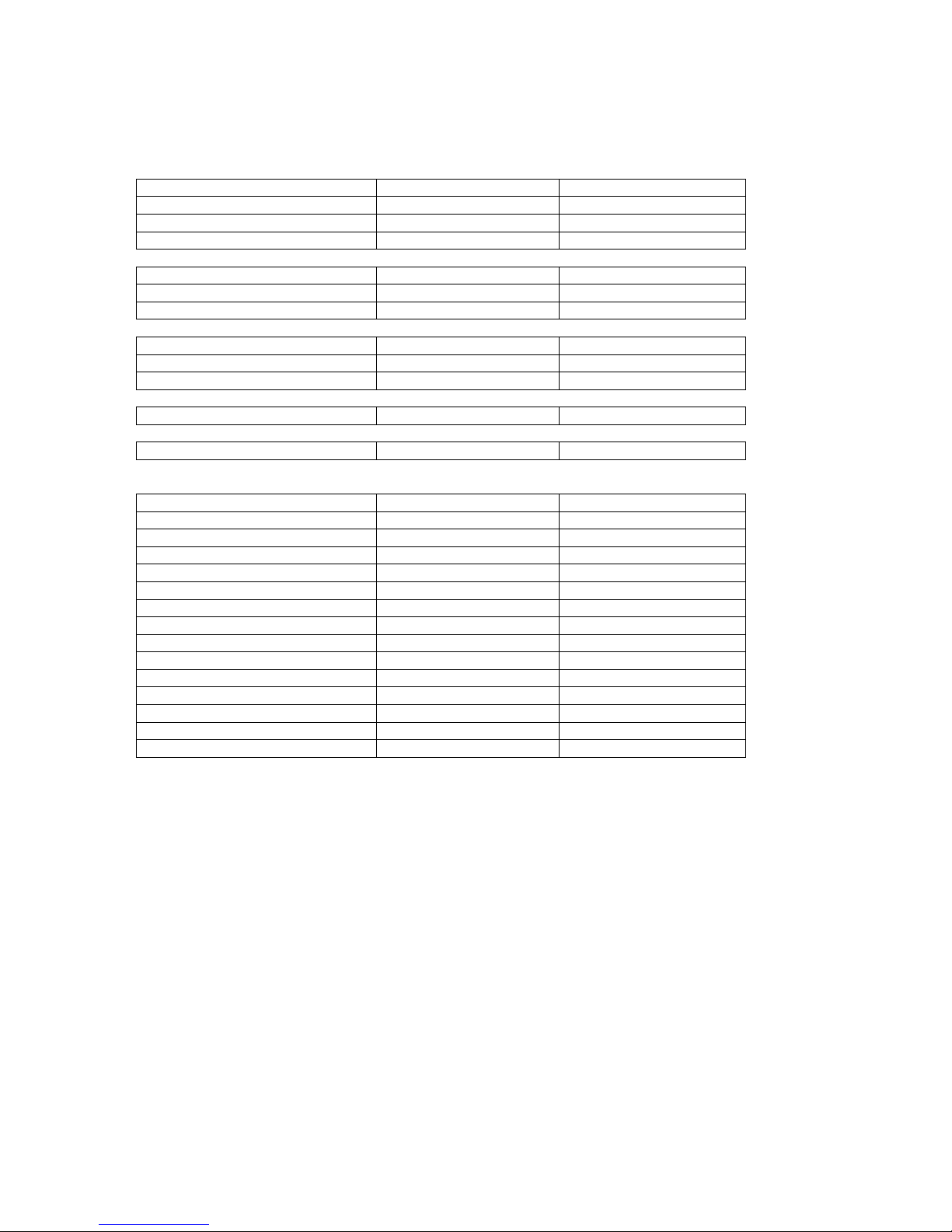

2 SPECIFICATIONS

2.1 Cabinet Specifications

DIMENSIONS E521T E522B

Height 1695mm (67.8 inches) 1695mm (67.8 inches)

Depth 703mm (28.7 inches) 703mm (28.7 inches)

Width 790mm (31.1 inches) 790mm (31.1 inches)

CAPACITY GROSS VOLUME IN LITRES (AS 1430)

Provision Compartment 400 litres (14.1 cu.ft.) 360 litres (12.7 cu.ft.)

Freezer Compartment 117 litres (4.13 cu.ft.) 160 litres (5.65 cu.ft.)

TOTAL 517 litres (18.25 cu.ft.) 520 litres (18.36 cu.ft.)

ELECTRONICS 110 volt

Display Module Part No. 881218 Part No. 881218

Power/Control Module Part No. 884252 Part No. 884252

Module/Inverter Part No. 884260 Part No. 884260

SUCTION LINE ASSEMBLY

Part Number 875113 874810

DEFROST ELEMENT

Part Number 881414 881414

COMPRESSOR SPECIFICATIONS

Make Embraco Embraco

Model VEG Y6H VEG Y6H

Part Number 884259 884259

Volts 110 110

Hertz 53 - 150 53 - 150

Phase 3 3

Input Watts 55.7 - 205 55.7 - 205

Output Watts 97 - 468 97 - 468

Nominal BTU 330 - 1596 330 - 1596

Start Resistance (Ohms) 6.40 6.40

Run Resistance (Ohms) 6.40 6.40

Starting Device Type Inverter Inverter

Oil Charge (cm3) 430 430

Refrigerant Type R134a R134a

Gas Charge 140 Grams of R134a 135 Grams of R134a

Page 8

8

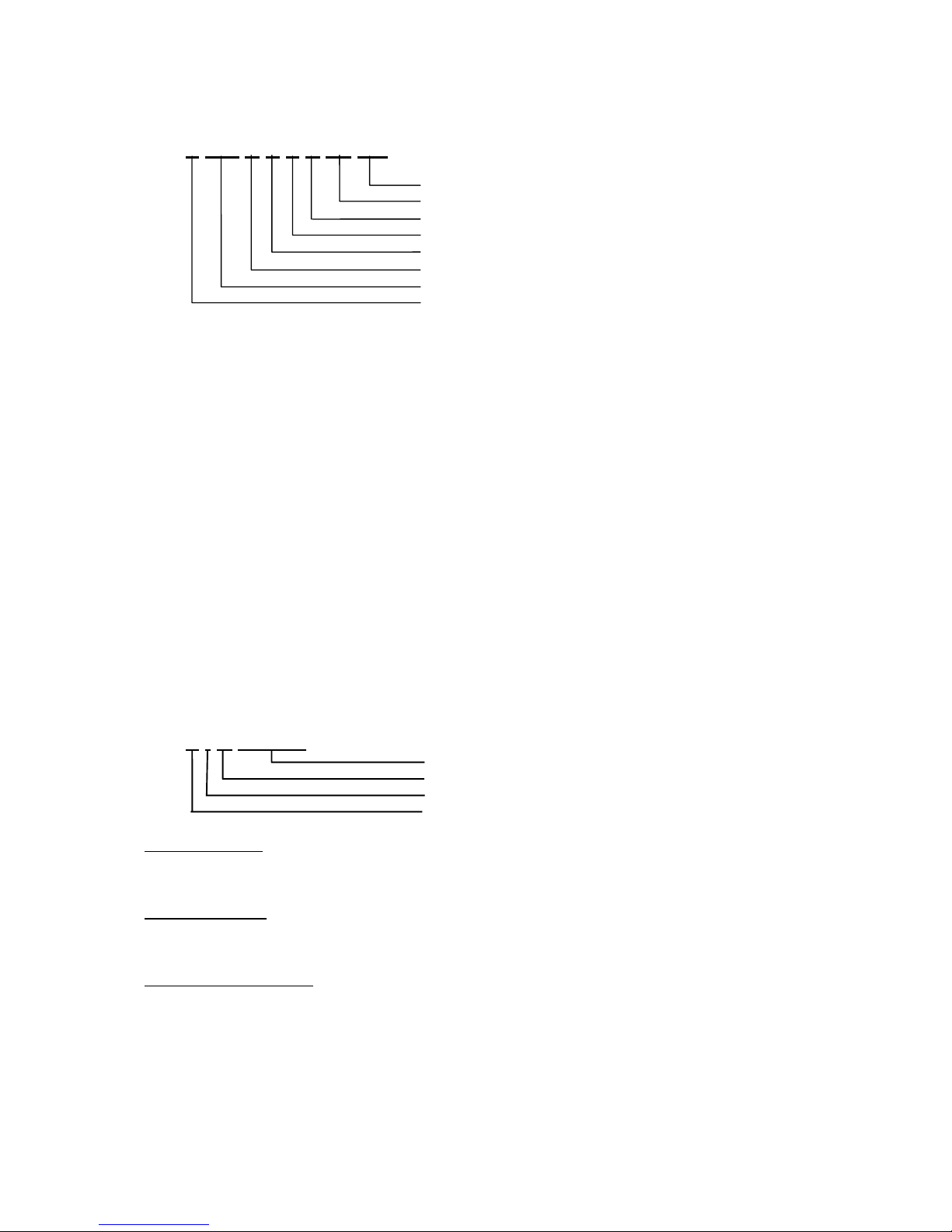

2.2 Model Number Identification

The following is an example of the model number identification for Fisher & Paykel Appliances:

E 522 B R E D FP SM

Cabinet/Door Colour (1)

Brand (Fisher & Paykel)

Series (2)

Style (3)

Door Hinging Side (4)

Freezer Location (5)

Approximate Capacity in Litres (6)

Type of System (7)

(1) Colour of Cabinet/Door WW = White Cabinet/White Doors

SM = Silver Wrapper/Matt Stainless Steel Doors

SX = Silver Wrapper/Brushed Stainless Steel Doors

(2) Series The series of the cabinet is located on the serial plate as Series A, B, etc.

(3) Style E = Elegence

I = Inox

M = Iridium

(4) Door Hinging L = Left Hand

R = Right Hand

(5) Freezer Location B = Bottom

T=Top

(6) Litreage of Cabinet Approximate total capacity.

(7) Type of System E = Electronic

N=No Frost

C=Cyclic

2.3 Serial Number Identification

The serial number consists of three letters and six digits and contains the following information:

Example:

B I Q 123456

Sequential Serial Number

Manufacturing Plant Code

FISHERPAYKUL Code indicates month of manufacture

CUMBERLAND Code indicates year of manufacture

Cumberland Code

Letter C U M B E R L A N D

Year 1234567890

Fisherpaykul Code

Letter F I S H E R P A Y K U L

Month 1 2 3 4 5 6 7 8 9 10 11 12

Manufacturing Plant Code

A Laundry – Australia

F Refrigeration – New Zealand

M Range & Dishwasher

N Laundry – New Zealand

Q Refrigeration - Australia

In the example above, the appliance was manufactured in the second month of the fourth year (2004) at the

New Zealand Refrigeration plant.

Page 9

9

3 SERVICING REQUIREMENTS

3.1 Interface Pen Mk 2

Used to retrieve and download data from the electronic control module when used in conjunction with the

Fisher & Paykel Smart Tool diagnostic program on a laptop computer. The part number of the interface pen

is 425930.

3.2 Health & Safety

3.2.1 Good Work Practices

1. Take care while removing all plastic components especially when cold.

2. Leave the product clean and tidy when service work is completed.

3. Extreme heat in cabinets will cause plastic deterioration or distortion and thermal fuses in the defrost

heater to go open circuit (be careful with heat guns).

3.2.2 Environmental Health And Safety

When servicing products, consider safety and health issues and requirements which must be adhered to at

all times. Specific safety issues are:

1. Electrical safety.

2. Electrostatic discharge.

3. Mixing of foam insulation.

4. Vapours while brazing.

5. Reclaiming of refrigerant.

3.2.3 Good Practice And Safety

1. Take care when removing or servicing any electrical components to avoid electrical shock or short circuit

conditions.

2. Take care when removing plastic components at low temperatures as breakages can occur with these

components.

3. Extreme heating of plastic components can cause distortion of those parts being heated.

4. Avoid overheating temperature sensitive devices such as the element thermal fuses and cabinet sensors.

5. Avoid using solvents, citrus-based cleaners on all plastic parts. We advise only warm soapy water be

used.

Page 10

10

4 INSTALLATION INSTRUCTIONS

4.1 Levelling

The word 'level' is somewhat of a misnomer as a 'spirit level' need not be used to set the appliance level. It

is preferable to have the appliance level in appearance where both doors will close with the aid of the door

closing components. It is also important that the appliance sits solidly on the floor.

• Front and rear rollers are fitted ex factory.

• Cabinet levelling can be done by adjustment of the front roller levelling wheel fitted ex factory. See

diagram 4.1B.

• Weight should be lifted off the cabinet for ease of adjustment.

• The product should be levelled with the majority of the weight on the hinge side front foot. The opposite

side front foot should then be adjusted to stabilise the product.

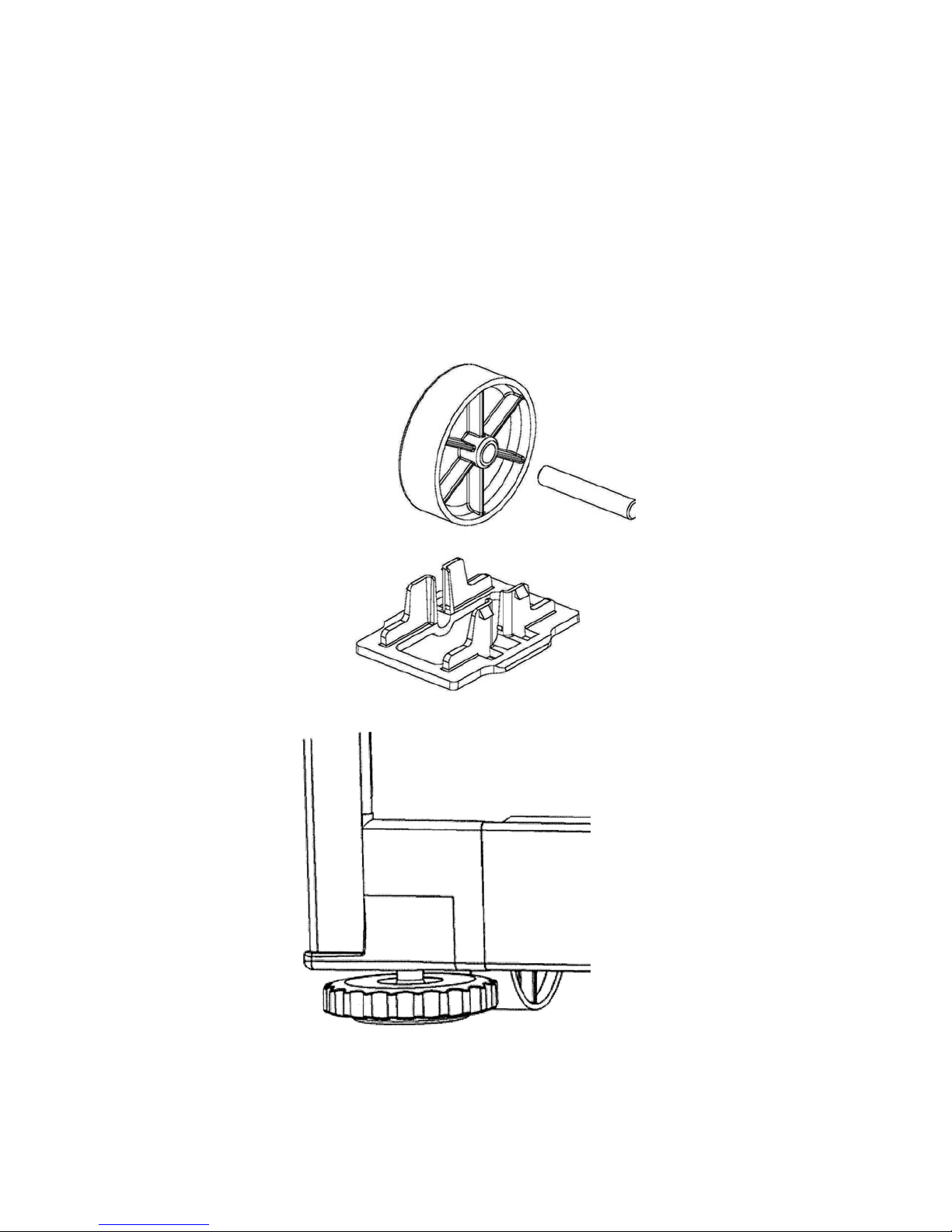

REAR ROLLERS

Diagram 4.1A

FRONT ROLLER/LEVELLING WHEEL

Diagram 4.1B

Page 11

11

4.2 Air Space Requirements

On all refrigerators and freezers it is important that an air gap is left around the product:

• 2 inches clearance at top

• 1 inch clearance each side

4.3 Temperature Adjustment

Refer DISPLAY MODULE in Section 6.1.3.

Page 12

12

5 THEORY OF OPERATION

5.1 Internal Air Flow

The freezer fan draws air through the evaporator and into a duct in the rear wall of the freezer compartment.

This air exits through the fan grill at the top of the freezer compartment. The air behind the freezer coil cover

is also diverted through the divider partition to another fan which supplies the cold air into the provision

compartment. The amount of air is controlled electronically by two sensors which in turn regulate the speed

of both PC and FC fans to maintain selected temperatures in each compartment.

Air from the PC returns to the FC evaporator by way of the return air duct which is built into the divider

partition. This air is drawn across the evaporator by the evaporator FC fan motor to be recirculated again

throughout the PC / FC compartments.

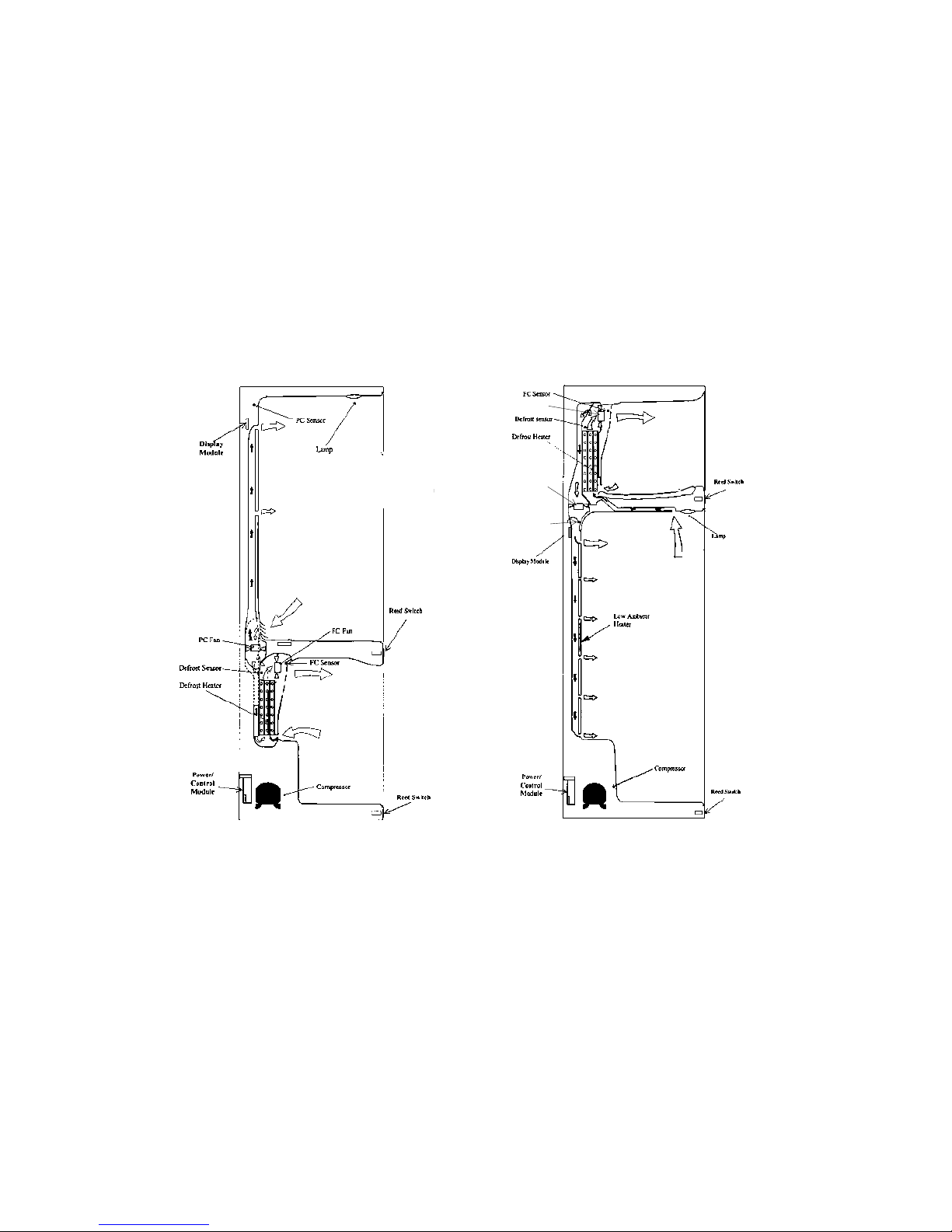

“B” Model

Active Smart

Diagram 5.1A

“T” Model

Active Smart

PC Fan

PC Sensor

FC Fan

Diagram 5.1B

Page 13

13

5.2 Defrost Cycle

A heating element is used to defrost the ice accumulated on the evaporator. The defrosts are adaptive to

the usage and environment and are controlled by the power/control module. During a defrost, the

temperature above the evaporator is sensed by the defrost sensor located on the evaporator chassis. This

sensor must register +8

o

C (46oF) before terminating the defrost heater element. If the sensor does not

register a temperature of +8

o

C (46oF) within 30 minutes of the commencement of the defrost cycle, the

defrost will be terminated. If two successive defrost attempts fail to reach this temperature, a fault code is

displayed (refer Section 6.2.1). Previous defrost history, the number of door openings, and the compressor

run time are used to determine the interval between defrosting. The typical time interval for defrosts is

between 12 and 24 hours. However, it can be as short as 5 hours or as long as 96 hours depending on the

usage and environment.

NOTE: The defrost cycle will not start if the defrost sensor is above +8°C (46

o

F).

The defrost cycle follows a predefined sequence:

There is a delay of 2 minutes before the element starts to heat (commonly known as evaporator

warm up time).

The defrost element will remain on until the defrost sensor has reached +8

o

C (46oF).

The compressor will remain off for a further 4 minutes (commonly known as drip time).

The compressor will restart, and a further 30 seconds later both fans will restart.

The following table outlines the defrost cycle of an Active Smart refrigerator.

Diagram 5.2

Page 14

14

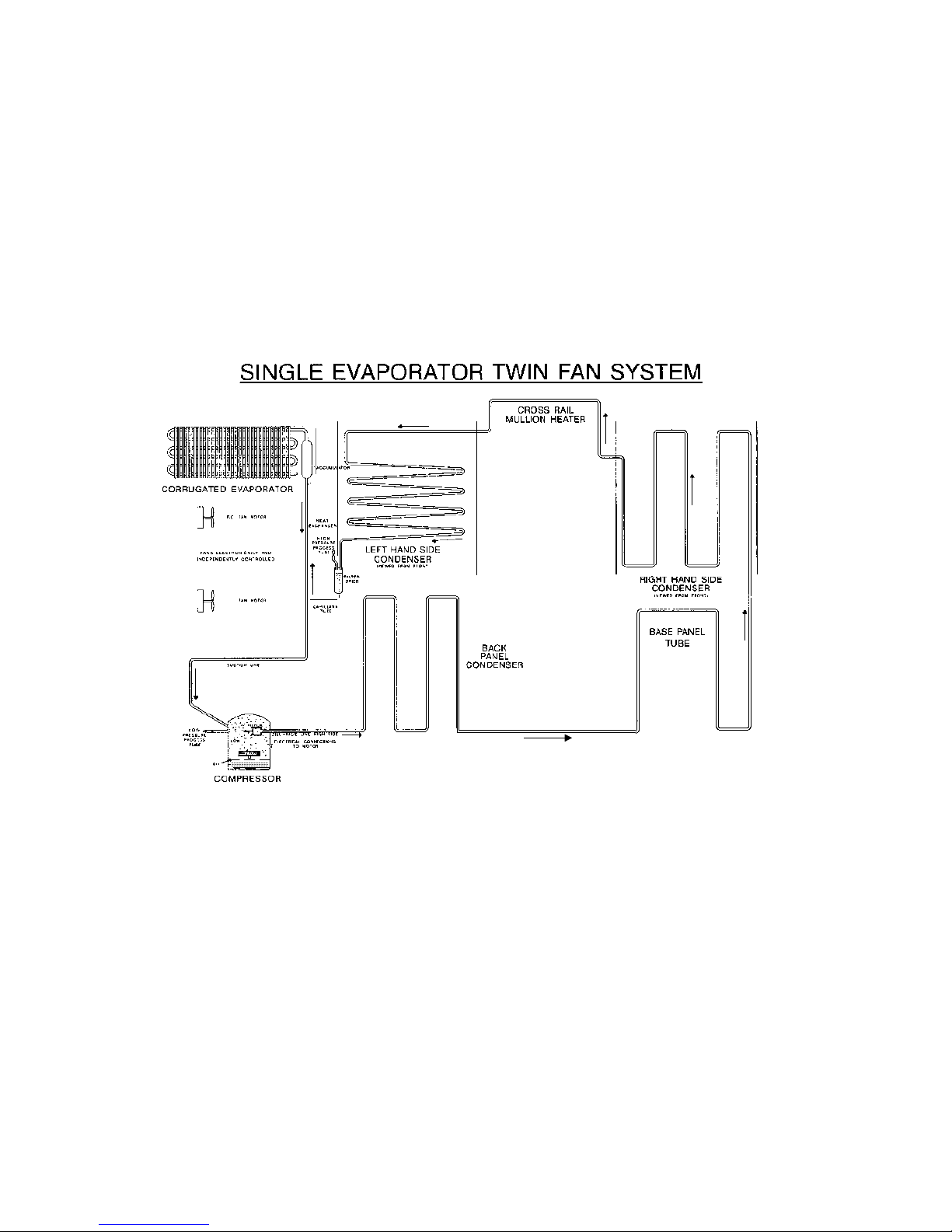

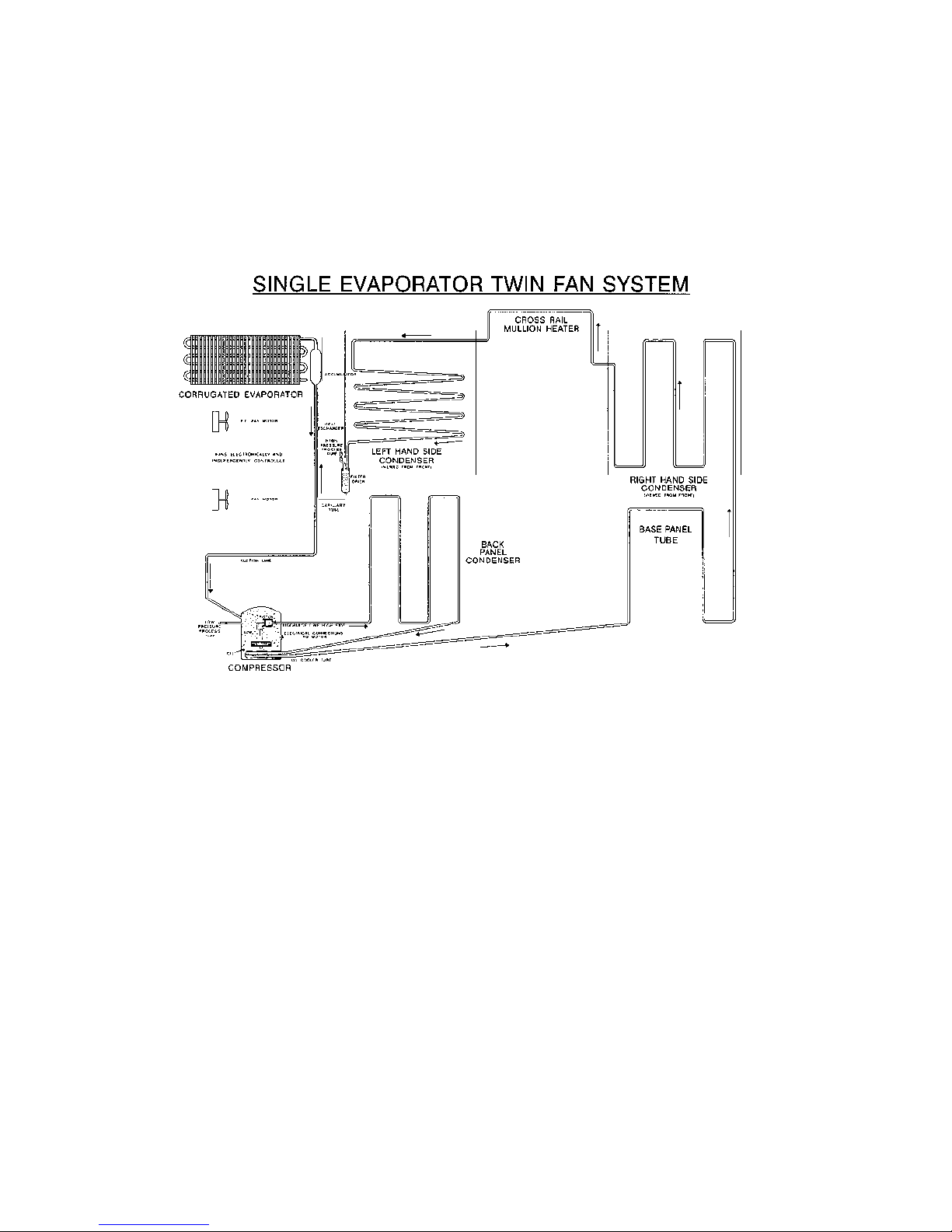

5.3 The Refrigeration Circuit

The compressor discharges high pressure, high temperature gas into the back panel condenser circuit first,

and then into the right hand side condenser in the cabinet by way of the base tube. This tube runs from the

compressor compartment forward to the front bottom edge of the cabinet, returning down the left hand side

to be connected to the left hand side condenser coil.

A loop from this condenser coil forms the cross rail mullion on dual temperature cabinets. The condenser

then continues across the top front edge of the cabinet to form the right hand side condenser before entering

the filter drier which is mounted vertically in the unit compartment.

Now the high pressure gas has been condensed, the liquid refrigerant flows through the capillary tube,

entering the evaporator mounted in the freezer compartment. The liquid refrigerant then boils off due to the

low suction pressure applied to within the evaporator from the compressor. The heat laden vapour is drawn

back to the compressor by way of the suction line to start the cycle all over again.

The above information relates to the cabinet, not the drawing below.

F.F.C.

Diagram 5.3

Page 15

15

5.4 Servicing Features

5.4.1 Condensate Disposal

During the defrost cycle, which is electronically timed and controlled, live frost is melted off the evaporator by

means of heat from the defrost element. Condensate from the evaporator defrosting drops into a collection

trough, which has an outlet hole in the centre of the liner. A tube then allows the condensate to flow into a

water evaporation tray above the compressor.

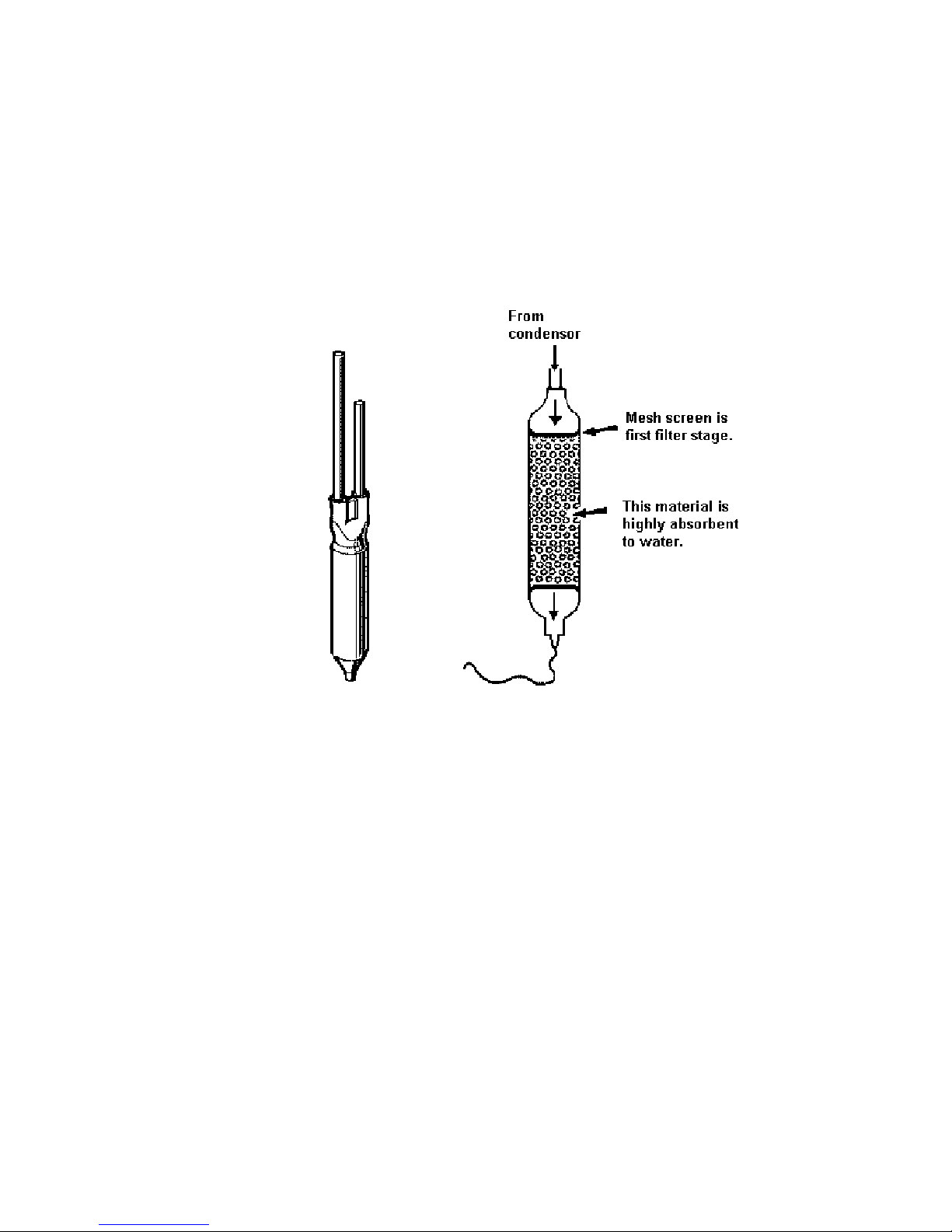

FILTER DRIER

Diagram 5.4.1

The filter drier or molecular sieve, as the name suggests, is both a filter and a drier. Whenever a system is

opened, it is essential that the filter drier is replaced. ALWAYS ensure that replacement filter driers are kept

well sealed and airtight prior to being fitted to a system.

PLEASE NOTE: When filter driers are replaced on systems being serviced, it is important that the filter

drier is either cut from the system or the desiccant is removed before heat is applied to the old filter

drier. Failure to do so will drive any moisture held in the desiccant back into the system.

ALWAYS mount vertically or as near to vertical as possible and use the correct desiccant to suit the

refrigerant being used.

XH7 or XH9 suits R134a.

Page 16

16

5.4.2 Internal Condenser

The internal condenser is made in three sections (see circuit diagram below). One third of the condenser is

attached to the back panel, and the other parts are attached to the inside of the right and left sides of the

cabinet wrapper (as viewed from the back) all being foamed into place. It is very important, if pressure

testing the high side circuit, to split the condenser into its 3 sections to locate which section is at fault.

Always ease the back panel away from the cabinet slightly before pressure testing the internal pipework.

This will prevent a pressure build-up within the cabinet should any leak be found internally in the foam

insulation. Such a leak could pressurise and damage the cabinet liner.

The back panel condenser comes as part of the back panel and should always be replaced as a complete

assembly if the back panel is ever removed.

F.F.C.

Diagram 5.4.2A

Page 17

17

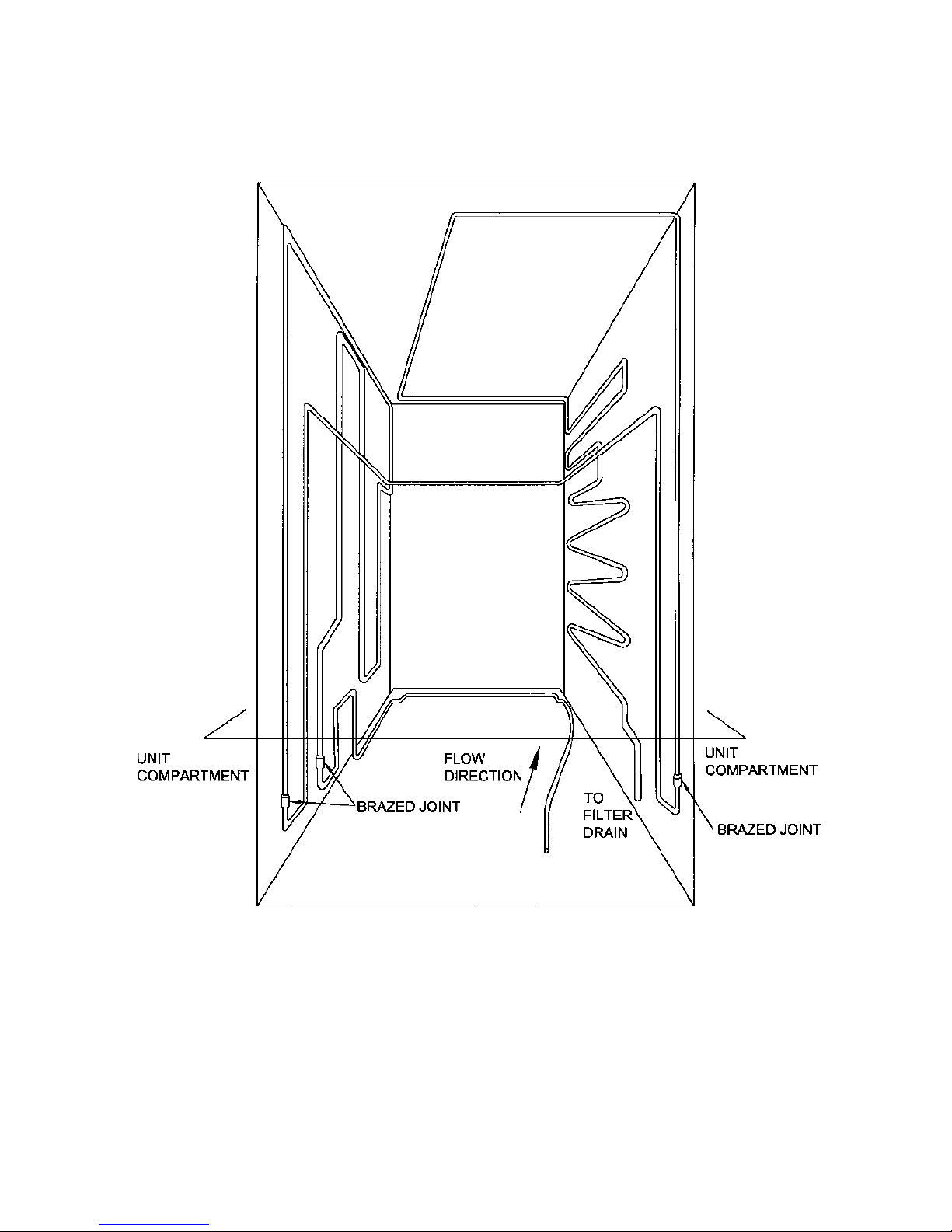

CONDENSER LAY OUT 680 / 790

"T" MODELS

CONDENSER WITH TUBE CROSS RAIL

FROM BACK PANEL

CONDENSER

BACK PANEL CIRCUIT REMOVED FOR CLARITY

ALL BRAZED CONDENSER JOINTS ARE EXTERNAL IN UNIT COMPARTMENT

Diagram 5.4.2B

Page 18

18

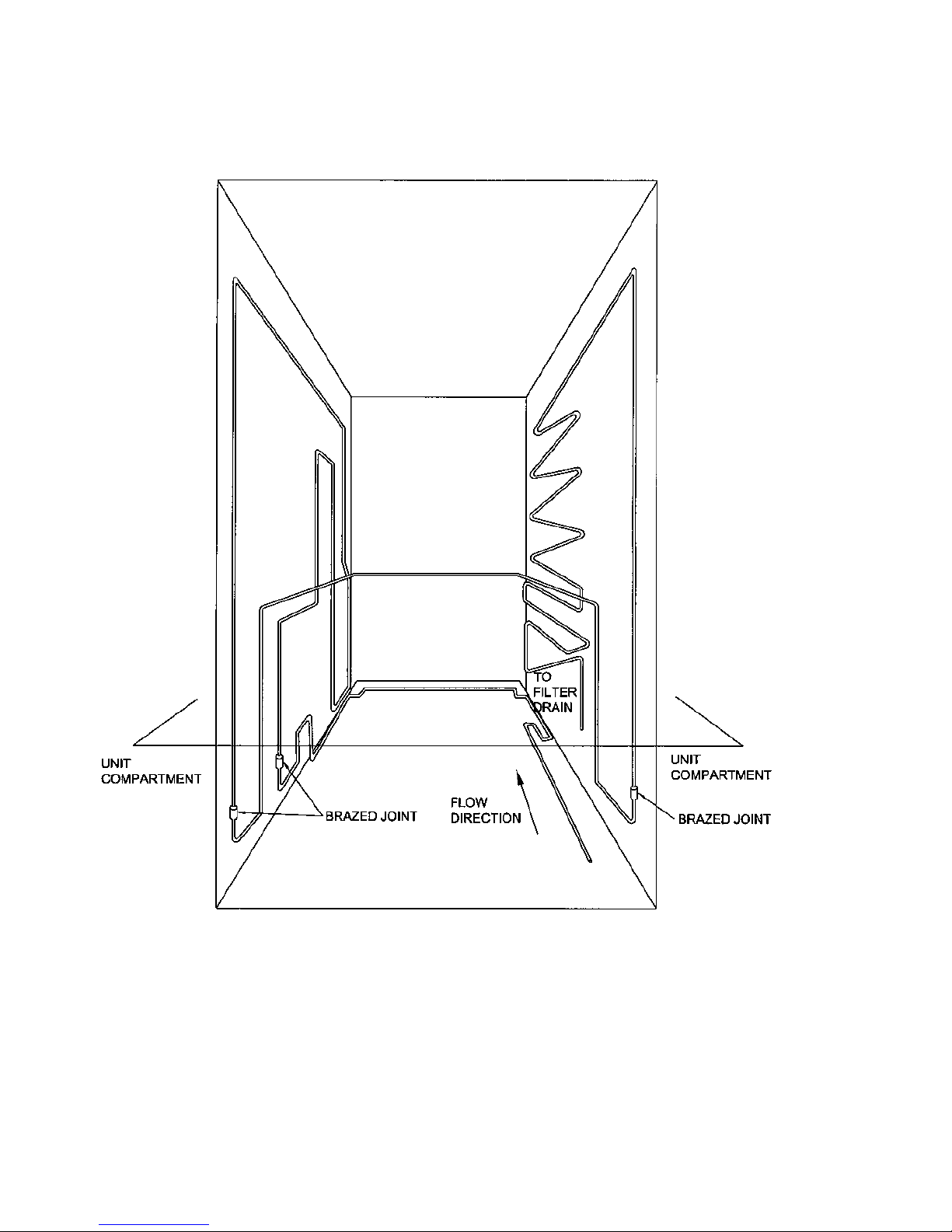

CONDENSER LAY OUT 680 / 790

"B" MODELS

CONDENSER WITH TUBE CROSS RAIL

FROM BACK PANEL

CONDENSER

ALL BRAZED CONDENSER JOINTS ARE EXTERNAL IN UNIT COMPARTMENT

Diagram 5.4.2C

Page 19

19

5.4.3 Cross Rail

The cross rail contains part of the condenser copper tubing (mullion heater) providing heat to the gasket area

between the PC and FC compartments, preventing sweating of the gasket. Also mounted on the cross rail is

the Reed Sensor, under the plastic cover in the centre.

5.4.4 Divider Partition

This is moulded in two outer pieces and has an inner polystyrene moulded duct assembly that is wax coated.

This provides a barrier between the FC and PC compartments, also allowing return air from the PC to move

back to the FC evaporator in ‘T’ models. In both models it houses the PC fan motor. The divider is fitted into

the cabinet as an assembly and cannot be replaced.

“B” DIVIDER PARTITION

Diagram 5.4.4

Page 20

20

6 ELECTRONICS SECTION

6.1 Overview Function Description

The electronic system consists of several parts:

Power/control module, display module, compressor, defrost heater, ambient heater, provision compartment

fan, freezer compartment fan, light, temperature sensors and door sensors.

The purpose of the power/control module is to turn on the compressor, which cools the evaporator, then to

use the fans to efficiently cool the compartments. Both fans turn on with the compressor. The freezer

compartment (FC) fan is kept at a constant speed while the provision compartment (PC) fan is regulated to

provide the balanced cooling for both compartments. The function of the microprocessor in the

power/control module is to provide independence of both compartments to their set temperatures, although

the environment of one compartment effects the other as they are linked by the ducts as can seen by the

diagrams showing internal air flow of the cabinet (diagrams 5.1A and 5.1B).

6.1.1 Control & Peripheral Functions

The control system consists of the power/control module located in the unit compartment of the refrigerator,

the slave display module located in the back of the refrigerator compartment and various sensors and

actuators controlled by the power module. The function and brief description of each of these units is

defined below.

6.1.2 Power/Control Module

This module is the electronic brain and control centre of the refrigerator. It contains a microprocessor,

support circuitry and switching devices. The power/control module controls the Provision Compartment (PC)

and Freezer Compartment (FC) temperatures by sensing the temperature and door state and operating the

compressor and fans accordingly. This module also houses the alarm beeper.

The power/control module collects information on the refrigerator operation. Faults and diagnostic

information is stored in its memory. They include the temperature setting, the history of FC and PC

temperatures (approx 18 hours), defrost history (the last 12 defrosts) and fault history. This will help the

service technician find and remedy the cause of failure. All this memory will be retained even when the

fridge is disconnected from mains power supply.

The beeper is used to signal prolonged door opening and other fault conditions:

1. If the door is left open longer than 90 seconds, the alarm will sound. This will repeat every 30 seconds

until the door is closed.

2. If the doors are left open longer than 5 minutes, the alarm will sound continuously and the PC light will

turn off. The alarm will stop with the closing of the door.

3. All electronic faults, when detected, will sound the alarm and the L.E.D.’s on the display module will flash

indicating the fault code. The pressing of any button will cancel the alarm but the fault code will remain

until the cabinet has been serviced.

Page 21

21

STAGE 4.2 POWER/CONTROL MODULE

Diagram 6.1.2

6.1.3 Display Module

This module contains the user interface, and also the circuitry to drive the lamp. It is controlled via a 5-wire

communications interface from the power/control module.

The user interface of push button switches and Light Emitting Diode (L.E.D.) display on the display module

printed circuit board is used to input and display the required set temperatures for the refrigerator

compartments.

The user interface is positioned at the rear of the provision compartment (PC). The interface automatically

displays the current temperature setting for the PC compartment. This is shown as a series of L.E.D. lights

on a thermometer symbol. To adjust the temperature of the PC, simply press the temperature up or down

buttons to the appropriate setting.

Press the mode button on the left-hand side of the interface to select the FC compartment. The indicator

light will flash for 8 seconds to show a new compartment has been selected. Press the up or down buttons

to adjust the temperature as necessary.

Further presses of the mode button will toggle between the PC and FC compartments.

DISPLAY MODULE (Stage 4.2)

Diagram 6.1.3

6.1.4 Door Switches

“Reed” switches are used to detect the opening and closing of the doors. Two small magnets that are built

into the PC and FC doors activate them. The reed switches are encapsulated within a plastic housing, which

is clipped under the plastic covers on the base and cross rails.

Page 22

22

6.1.5 Compressor

The compressor is turned on when cooling is required. It is switched by the power/control module sending a

low voltage frequency signal to the inverter.

The refrigerator is fitted with a variable capacity compressor (VCC). This improves energy efficiency and

maintains a more stable temperature in both the provision compartment and the freezer compartment. The

compressor windings are wired in a 3 phase star formation with the resistance between any two pins being

the same (6.4 ohms).

6.1.5.1 Variable Capacity Compressor Control Overview

The V4.2 power/control module on VCC product is identical to that on non-VCC product. The stage 4.2

power/control module senses if it is connected to a VCC compressor and uses the appropriate algorithm.

The compressor can operate at speeds between 1590 and 4500 rpm inclusive. On the Fisher & Paykel

product we operate the compressor at a select number of different speeds between 1590 and 4500 rpm to

reduce the variation in sound produced by the compressor. An electronic module/inverter connected

between the power/control module and the compressor controls the speed. (Refer Photo 6.1.5.1) This it

does by supplying a modulated DC 3 phase supply to the compressor. Warning: Permanent damage will

occur if the compressor is directly connected to the AC supply line.

The power/control module monitors, amongst other things, the refrigerator compartment temperatures (via

thermistors) and the defrost cycle, and from this information sends signals to the electronic module/inverter

to determine compressor speeds.

Whenever the compressor starts, it is run at 2200 rpm for 2.5 seconds to establish lubrication, and is then

run at 1590 rpm for a further 27 seconds before changing to any other higher speed as requested by the

power/control module. This is to provide a softer start before the compressor potentially ramps up to some

higher speed.

Whenever the fridge is plugged in/turned on, and/or after a defrost, in the first cooling cycle the control will

run the compressor, after its initial start procedure, at its maximum speed, which is 4500 rpm. The

compressor will stay at its maximum speed until both compartments have reached their cut-out temperature,

at which point the compressor will switch off and the refrigerator goes into the warm-up cycle.

In the subsequent cooling cycles the algorithm will vary the compressor speed according to the amount of

cooling required to achieve an average temperature in each compartment (as measured by the thermistors),

equal to the compartment set temperatures with a 1 hour run-time.

In low ambients where the heat load and/or cabinet usage is low, the compressor will be likely to run at its

minimum speed (1590rpm), and switch off more frequently than once every hour, similar to most non-VCC

product.

When the compressor is running at slow speeds, the evaporator may not be fully flooded, but this is normal.

Photo 6.1.5.1

Power/control

module

Module/inverter

Variable Capacity

Compressor

Page 23

23

6.1.5.2 Built-in Electronic Protections (Within the Module/Inverter)

6.1.5.2.1 Compressor Start-up

In case any anomaly occurs during compressor starting, the control will wait 6 seconds before repeating the

start-up. If the compressor doesn’t start after 12 trials, the control will wait 8 minutes before repeating the

start-up procedure (this condition may be when pressures are not equalised between suction and discharge

sides in the refrigeration system, eg; after an interruption in the mains supply).

6.1.5.2.2 Overload Detection and Protection

The control can detect an overload condition by monitoring the current consumed by the compressor. If

overload is detected the control reduces the current by reducing the speed of the compressor until the

overload disappears, when the speed will return to the required value.

If the overload increases, the control will continue to decrease the current until the minimum speed of 1590

rpm may be reached, at which point the compressor may “stall”, and the control will return to the start-up

procedure.

6.1.5.2.3 Power Limitation (Temperature Protection)

The control limits the power supplied to the compressor to 200 watts to keep all electrical components below

a safe operating limit. The power is limited in the same way as the current in the overload protection.

6.1.5.2.4 Short Circuit Protection

In a case where a short circuit occurs, (eg; motor winding damage, connection faults etc), the same current

limiting control is actuated to reduce further damage. In the case of a major failure, a fuse within the inverter

will break the current supplied to the control. This fuse cannot be replaced in servicing.

6.1.5.3 VCC Module/Inverter Identification

The module/inverter has an identification label giving the following information:

6.1.5.4 Fault Finding

6.1.5.4.1 High Voltage Power Supply Circuit

Whenever power is supplied to the refrigerator, there should always be 110V mains voltage in the high

voltage harness between the power/control module and the VCC module/inverter. This can be checked by

removing the rear cover of the VCC module/inverter and testing with a multimeter. There should be 110V

across the spade terminals above the edge connector at the top of the module (refer Photo 6.1.5.4). If this is

not present, check the continuity of the harness from the power/control module. If there is continuity through

the harness, replace the power/control module.

6.1.5.4.2 Signal Circuit

With a multimeter that can measure frequency, the signal circuit between the power/control module and the

VCC module/inverter can be checked. Remove the rear cover of the VCC module/inverter and connect the

multimeter across the two pins beside the signal harness edge connector. When the compressor is meant to

be running, the frequency should be between 53Hz and 150Hz. At start up the frequency will be 75Hz for

2.5 seconds, then 53Hz for 27 seconds before changing to 150Hz. Multiplying the frequency of the signal

circuit by 30 will give the compressor speed, so if the frequency is 53Hz the compressor speed will be

1590rpm, and if it is 150Hz the compressor speed will be 4500rpm.

VCC3

11

56

XX

A

XX

Inverter Version

Voltage:

11 = 115-127V

24 = 220-240V

Frequency:

50 – 60 Hz

Electronic board version

A = Stand alone version box

F = Attached version box

Cable configeration

Page 24

24

Photo 6.1.5.4

6.1.6 Defrost Heater

A heating element is used to defrost the ice accumulated on the evaporator. The defrosts are adaptive to

the usage and environment and are controlled by the power/control module. During a defrost, the

temperature above the evaporator is sensed by the defrost sensor located on the evaporator chassis. This

sensor must register +8

o

C (46oF) before terminating the defrost heater element. Previous defrost history, the

number of door openings, and the compressor percentage run time are used to determine the interval

between defrosting. The typical time interval for defrosts is between 12 and 24 hours. However, it can be as

short as 5 hours or as long as 96 hours depending on the usage and environment.

DEFROST ELEMENT

Diagram 6.1.6

High voltage

test point

Signal circuit

test point

Page 25

25

6.1.7 Thermal Fuses

There are two thermal fuses mounted in the wiring harness of the defrost element, having a tripping

temperature of 72

0

C (1610F). Once open circuit they can not be reset. Replacement is part of the element

heater assembly.

These fuses in both leads of the element protect the refrigerator from any over heating through failure of the

element itself or a triac failure in the power/control module. Both sides are protected in case phase and

neutral are reversed.

NOTE: Care should be taken if manually defrosting the evaporator (i.e.. using heat guns), to ensure that the

thermal fuses are not over heated.

6.1.8 Low Ambient Heater

In low ambient temperatures a 12 Volt, 7 Watt low power heater is used to keep the temperature in the

provision compartment above freezing. The ambient heater is controlled by the power/control module which

runs the heater at 58% duty cycle to give 4.1 watts of heat. This is achieved by the use of pulse width

modulation (PWM). The heater is situated in the air duct of the “T” models and in the divider partition on “B”

models. The purpose of the element is to warm the area if the ambient becomes too low. The element is on

when the cabinet cycles off. The low ambient heater operates during both the compressor on and off cycles

when the percentage of compressor run time averaged over the previous four cycles drops below 65%. It

switches off when the percentage run time increases to above 70%. The heater will always be switched off

during the defrost cycle and whenever the PC door is open. There may be less than 4 cycles in the

calculation if a defrost has occurred or there were long cycle times.

“T” MODEL

Diagram 6.1.8

Page 26

26

6.1.9 PC / FC Fans

There are two 12 Volt DC electrically commutated motor (ECM) fans. They provide the required cooling

power to both compartments. The motors are provided with from 18% to 100% voltage by using a pulse

width modulating (PWM) technique. The power/control module controls the switching on and off of the

compressor and the fans. The speed of the FC fan is set and the speed of the PC fan is regulated by

altering the voltage supplied to it.

The FC fan will always runs at a constant speed.

The PC fan speed can be adjusted to meet the requirement of that compartment. Therefore the PC fan

speed will be set at the average speed used from the previous cycles under normal door openings and

loading conditions. During the off cycle of the compressor the PC fan will run at a very low speed to prevent

air transfer in the ducts between the two compartments.

When the compressor is turned on, the fans will also be switched on, except immediately following a defrost

cycle where there is a delay of 30 seconds after the compressor has started before the fans switch on.

Diagram 6.1.9

6.1.10 Light

A 12 volt, 10 watt halogen lamp is used in the PC. To prevent overheating, the lamp is turned off after 5

minutes of the door being left open. The power/control module controls this.

LIGHT FITTING, LAMP AND COVER

Diagram 6.1.10

NOTE: It is important that the lamp pins are tight in the lamp socket.

FC FAN (Viewed from front

)

PC FAN (Viewed from FC side)

Page 27

27

6.1.11 Thermistor Temperature Sensors

These sensors are used to monitor temperatures within the refrigerator. There are 3 of them:

1. Defrost sensor mounted on the evaporator chassis above the evaporator, used to measure the

temperature when in defrost. (Colour Black)

2. FC sensor mounted on the FC fan cover, used to measure the temperature in the FC. (Colour White)

3. PC sensor mounted in the PC on the duct cover and used to sense the PC temperature. (Colour White)

Thermistor sensors are used for temperature measurement, therefore once the temperature of the

refrigerator has reached its set temperature, the power/control module will turn the compressor off.

Their electrical resistance changes as the temperature changes. The table below lists some typical

resistance values. The temperature can be read using Diagnostic Mode as described in the next section.

Diagram 6.1.11

THERMISTOR SENSOR RESISTANCE TABLE

TEMPERATURE

(°C/°F)

RESISTANCE

(K Ohms ±5%)

-30 / -22 25.17

-25 / -13 19.43

-20 / -4 15.13

-15 / 5 11.88

-10 / 14 9.392

-5 / 23 7.481

0 / 32 6.000

5 / 41 4.844

10 / 50 3.935

15 / 59 3.217

20 / 68 2.644

25 / 77 2.186

30 / 86 1.817

35 / 95 1.518

40 / 104 1.274

45 / 113 1.075

50 / 122 0.9106

Page 28

28

6.2 Fault Finding Procedure

6.2.1 Fault Code Display Status

If a fault should develop in the temperature measurement system, defrost system, fans or low ambient

heater, a fault code will be shown automatically on the display and the fault audio alarm will sound. At the

same time, the bottom L.E.D. will flash red alternately with the fault L.E.D.(s) When any control button is

pressed, the audio alarm is turned off although the display will continue to be “flashed” instead of the normal

“back-lit” display.

The refrigerator goes through a sequence of tests whenever it is turned on at the power supply or whenever

the door is closed while it is on. It takes 20 seconds to complete the test sequence, and opening a door will

interrupt it. If, for example, there is a fault with the fans/low ambient heater connector at the power module

(it may be unplugged) and a door is opened as soon as the fault audio alarm sounds, the fault code shown

will be code 13 (low ambient heater drawing less current than expected). This is because the low ambient

heater is the first item tested and so the refrigerator will fault for this but carry on with more tests. If the doors

are left closed until the tests are completed, the fault code shown will be code 11 (the current measured for

the ambient heater, PC fan and FC fan is lower than expected). It is therefore recommended that if the fault

audio alarm sounds as soon as the refrigerator is turned on, or as soon as the doors are closed, the service

technician should wait for 20 seconds before opening the door to check the fault code. This will allow the

refrigerator to complete the sequence of tests and will ensure that the fault code displayed is the correct one.

To reset the audio alarm, disconnect the refrigerator from the power supply for a few seconds. If this is not

done, the audio alarm will automatically reset after 72 hours.

Fault codes will be in a binary code and the L.E.D.s that flash will have the following binary values:

To determine the value of the displayed fault code, add up the values of the L.E.D.s that are flashing (ignore

the flashing red L.E.D.). The faults and their respective fault code that can be checked and serviced in the

field are as follows:

Display Code: 1

Reason: On the last power up, the power/control module failed its self-test.

Primary Action: Replace power/control module.

Display Code: 2

Reason: The previous 2 defrosts were aborted after 30 minutes.

Primary Action: Check defrost heater assembly in the FC. If faulty, replace.

Secondary Action: Check power module is supplying 230V to heater during defrost. If not, replace

power module.

Display Code: 3

Reason: The resistance of all the temperature sensors is outside the normal range. (> 45K

Ohms).

Primary Action: Check the 6 way RAST connector at the power module.

Secondary Action: Re-terminate the 6 way RAST connector.

Tertiary Action: Replace the power module.

Mode

Temperature Down

Temperature Up

1

2

4

8

16

32

64

128

Page 29

29

Display Code: 4

Reason: The resistance of all the temperature sensors is outside the normal range. (< 660

Ohms).

Primary Action: Check the 6 way RAST connector at the power module.

Secondary Action: Re-terminate the 6 way RAST connector.

Tertiary Action: Replace the power module.

Display Code: 5

Reason: The resistance of the FC sensor is outside the normal range. (> 45K Ohms).

Primary Action: Check the sensor connection at the power module.

Secondary Action: Replace the sensor.

Display Code: 6

Reason: The resistance of the FC sensor is outside the normal range. (< 660 Ohms).

Primary Action: Check the sensor connection at the power module.

Secondary Action: Replace the sensor.

Display Code: 7

Reason: The resistance of the evaporator sensor is outside the normal range. (> 45K

Ohms).

Primary Action: Check the sensor connection at the power module.

Secondary Action: Replace the sensor.

Display Code: 8

Reason: The resistance of the evaporator sensor is outside the normal range. (< 660

Ohms).

Primary Action: Check the sensor connection at the power module.

Secondary Action: Replace the sensor.

Display Code: 9

Reason: The resistance of the PC sensor is outside the normal range. (> 45K Ohms).

Primary Action: Check the sensor connection at the power module.

Secondary Action: Replace the sensor.

Display Code: 10

Reason: The resistance of the PC sensor is outside the normal range. (< 660 Ohms).

Primary Action: Check the sensor connection at the power module.

Secondary Action: Replace the sensor.

Display Code: 11

Reason: The current measured for the ambient heater, PC fan and FC fan is lower than

expected.

Primary Action: Check the 6 way fan/LAH RAST connector at the power module.

Secondary Action: Reterminate the 6 way fan/LAH RAST connector.

Tertiary Action: Replace the power module.

Display Code: 12

Reason: The current measured for the ambient heater, PC fan and FC fan is higher than

expected.

Primary Action: Check the 6 way fan/LAH RAST connector at the power module.

Secondary Action: Reterminate the 6 way fan/LAH RAST connector.

Tertiary Action: Replace the power module.

Display Code: 13

Reason: Low ambient heater is drawing less current than expected. Either the heater or

wiring is open circuit or the heater is faulty.

Primary Action: Check wiring and connections at both heater and power module.

Secondary Action: Check ambient heater resistance. If not within limits, replace.

Page 30

30

Display Code: 14

Reason: Low ambient heater is drawing more current than expected. Either there is a short

in the heater or wiring, or the heater is faulty.

Primary Action: Check wiring and connections at both heater and power module.

Secondary Action: Check ambient heater resistance. If not within limits, replace.

Display Code: 15

Reason: The PC fan is drawing less current than expected. Either the wiring is open circuit

or the fan is faulty.

Primary Action: Check PC fan wiring and connections at both fan and power module.

Secondary Action: Check fan. If faulty, replace.

Display Code: 16

Reason: The PC fan is drawing more current than expected. Either the wiring is shorted or

the fan is faulty.

Primary Action: Check PC fan wiring and connections at both fan and power module.

Secondary Action: Check fan. If faulty, replace.

Display Code: 17

Reason: The FC fan is drawing less current than expected. Either the wiring is open circuit

or the fan is faulty.

Primary Action: Check FC fan wiring and connections at both fan and power module.

Secondary Action: Check fan. If faulty, replace.

Display Code: 18

Reason: The FC fan is drawing more current than expected. Either the wiring is shorted or

the fan is faulty.

Primary Action: Check FC fan wiring and connections at both fan and power module.

Secondary Action: Check fan. If faulty, replace.

Example Fault Code: 8 + 4 + 1 = 13

13 = Low Ambient Heater Open Circuit

Page 31

31

6.2.2 Diagnostic Mode

To enter the diagnostic mode, Press and hold the MODE button, then press the TEMPERATURE UP button.

The L.E.D.s indicate the PC sensor temperature. The current PC sensor temperature is displayed in a code

form (refer Section 6.2.3 Sensor Temperature Conversion).

Return to normal operation by pressing the MODE button.

CAUTION: In reading temperatures there is a need to enter the required mode when the door is first opened

as all temperature readings are only sensor temperature/air temperatures and these will change rapidly with

the increase in air temperature as soon as the door is opened.

Press the up button.

1 time = FC sensor temperature. The current FC sensor temperature is displayed in a code form

(refer Section 6.2.3 Sensor Temperature Conversion).

2 times = Defrost sensor temperature. The current defrost sensor temperature is displayed in a code

form (refer Section 6.2.3 Sensor Temperature Conversion).

3 times = Inputs/outputs status (refer Section 6.2.4 Input/Output Status).

To exit the diagnostic mode, press the MODE button. If not terminated manually, diagnostic mode will time

out and go back to default display after 5 minutes.

Note: The door alarms do not operate when the appliance is in diagnostic mode.

6.2.3 Sensor Temperature Conversion

To obtain the temperature of either compartment sensor or defrost sensor:

1. Enter the diagnostic mode (refer Section 6.2.2 – Diagnostic Mode) and scroll to the appropriate sensor

temperature.

2. Add up the binary number indicated by the L.E.D. light pattern (refer figure below).

3. Subtract 40 from the result to get the temperature.

0.5

1

2

4

8

16

32

Page 32

32

Example:

Add up the number corresponding to each L.E.D. that is on:

0.5 + 4 + 8 + 32 = 44.5

Subtract 40 from the result

44.5 - 40 = 4.5

o

C

Hence the temperature is 4.5

o

C

6.2.4 Input/Output Status

The Input/Output Status menu displays what devices (e.g. light, PC door, FC door, compressor, etc) are

currently running or turned on.

To enter the menu, the steps are:

1a. Press and hold the MODE button (a short beep will sound).

1b. Whilst still holding the MODE button, briefly press the TEMPERATURE UP button (a short beep will

sound); this enters diagnostic mode.

Steps 1a and 1b need to be completed within 8 seconds.

2. Press the TEMPERATURE UP button 3 times.

The respective L.E.D. turns on when a device is running, as shown below.

3. Return to normal operation by pressing the MODE button.

Upper door open

Lower door open

PC fan on

Low ambient heater on

Light on

FC fan on

Defrost heater on

Compressor on

Page 33

33

6.2.5 Data Download

To retrieve information from the control module, one of the following is required:

• A Light Pen (part number 425930) and a Cassiopeia Smart Tool.

• A Light Pen (part number 425930) and a laptop computer with the Fisher & Paykel Smart Tool

diagnostic program loaded.

The steps to download data are:

1a. Press and hold the MODE button (a short beep will sound).

1b. Whilst still holding the MODE button, briefly press the TEMPERATURE UP button (a short beep will

sound); this enters diagnostic mode.

Steps 1a and 1b need to be completed within 8 seconds.

2. Press the TEMPERATURE DOWN button once; this enters data download mode.

A red L.E.D. turns on and should be visible on the display.

3. Place the Light Pen over the top of the red L.E.D. until downloading is complete.

4. Return to normal operation by pressing the MODE button.

If additional help or information is required, please refer to the instructions provided with the Smart Tool, or

ask your Technical Representative.

6.2.6 Manual Defrost

To manually force a defrost, the steps are:

1a. Press and hold the MODE button (a short beep will sound).

1b. Whilst still holding the MODE button, briefly press the TEMPERATURE DOWN button (a long beep

will sound).

Steps 1a and 1b need to be completed within 8 seconds.

2. To check if the fridge is in defrost mode, repeat step 1a & 1b.

If a long beep sounds, then the defrost cycle has started.

3. To exit manual defrost mode, turn the refrigerator off at the power supply, and then while pressing the

MODE button, switch the refrigerator on again at the power supply. If this is not done, the refrigerator

will automatically exit from the manual defrost mode when the defrost is completed.

NOTE: The defrost cycle will not start if the defrost sensor is above +8°C (46°F).

The defrost cycle follows a predefined sequence:

There is a delay of 2 minutes before the element starts to heat (commonly known as evaporator warm

up time).

The defrost element will remain on until the defrost sensor has reached +8

o

C (46°F), or until 30

minutes has elapsed if the defrost sensor does not reach +8°C (46°F).

The compressor will remain off for a further 4 minutes (commonly known as drip time).

The compressor will restart and a further 30 seconds later both fans will restart.

6.2.7 Show Room Mode

Go into diagnostic mode (press MODE and TEMPERATURE UP buttons together) then hold the

TEMPERATURE UP button only for 3 seconds. The Show Room Mode will be entered, which turns off the

normal system control leaving only the PC light operating with no door alarms. There will be a “long” beep

and while the doors are opened the L.E.D. display will go through an attention grabbing sequence unless

buttons are pressed, at which time the display will respond as normal. 8 seconds after the last button press

the display sequence will continue. The mode may be exited by switching off the appliance at the power

supply.

Page 34

34

6.2.8 Special Option Mode (Israel)

The Active Smart refrigerator is fitted with a special option mode, should the customer wish to disconnect the

operation of the interior lights and the alarm.

To enter this mode the customer is required to push and hold the compartment select MODE button on the

display board for 10 seconds.

When the cabinet is in this special option mode the following will not operate:

The interior light will not turn on when the PC door is opened.

There will be no set temperature lights (L.E.D.s) displayed on the display module.

The door alarm will be disconnected and will not sound even if the doors were to be left open.

The customer may exit this mode at anytime by pushing and holding the compartment select MODE button

for 10 seconds.

Note: When in the special option mode the Active Smart will operate as normal without the above being

used. In normal operation, the set temperature L.E.D.s and interior light will be seen when the PC door is

opened.

6.3 Door Gasket - (Integral)

The door gasket is able to be replaced as a separate part.

All replacement doors are supplied minus the door gasket. The door gasket is a replaceable part of the

door. It is held in place against the door liner by means of a moulding which locks the gasket in place once

pushed into it. There are no screws or retainers to remove or fit.

To Remove the Gasket

Pull on any section of the gasket to pull it away from the moulding.

To Replace the Gasket

Having removed the old gasket, lay the new gasket around the door gasket moulding. First fit all corners,

then push the remaining gasket into place around the door.

Diagram 6.3

Page 35

35

7 REMOVING AND REFITTING OF

COMPONENTS

7.1 Removal Of Power/Control Module

Located in the unit compartment on the right hand side and held in place by 2 self-tapping screws.

1. Unplug the refrigerator from the power supply.

2. Remove both mounting screws and earth screw (on the green / yellow earth wire) on the compressor

mounting tray.

3. Pull the power/control module outwards to disengage the mounting lugs at the back of the module.

4. Remove all connectors along the top edge of the power/control module.

5. Remove the defrost connector (brown wires) and the VCC high voltage supply connector which is

connected to the terminals marked “H Rail” on the side of the power/control module.

6. Refit in reverse order.

Note: It is important that the power/control module is clipped securely to the side of the unit compartment

and the copper earth spring clip is not damaged as this maintains good earthing and provides a low

inductance path to the chassis for RF voltage. Check that the flat pins at the back of the module are properly

engaged with the lugs on the unit compartment when refitting.

Initialisation Of The Power/Control Module After Installation

The power/control module needs to know whether it is fitted into a “B” or “T” model upon installation because

it performs different functions when either the PC or FC doors are opened. To do this, we need to “initialise”

the power/control module.

To initialise the power/control module, the service technician must have the FC door closed and the PC door

open, then press any of the buttons on the user interface in the PC. The power/control module then knows

that the reed switch that is open circuit is controlled by the PC door, and the one that is closed circuit is

controlled by the FC door.

If the power/control module is not initialised, as may be the situation for a new service module, the lights will

not turn on and the fans will run with the door open. If the operator presses a button with both doors opened,

the illegal raspberry audible feedback will sound, indicating that the module is unable to be initialised.

7.2 PC Sensor Replacement

1. Unplug the refrigerator from the power supply.

2. Remove all PC shelving.

3. Remove bottom PC air duct cover.

4. Remove polystyrene duct cover insulation.

5. Disconnect low ambient heater - “T” model only.

6. Remove 1 screw from top duct cover and unclip - “T” model only.

7. Remove PC sensor from its location.

8. Replacement of the new sensor is done by cutting the wiring back from the sensor end, and soldering

in a new sensor, making sure both connecting wires are not shorting but are insulated with heat shrink

sleeving.

9. Refit in reverse order.

7.3 FC Sensor Replacement

1. Unplug the refrigerator from the power supply.

2. Prise out the fan shroud using a flat blade screwdriver at the bottom of the grill cover.

3. Remove the FC fan motor plug connection.

4. Unclip the FC sensor and remove the evaporator coil cover.

5. Replacement of the new sensor is done by cutting the wiring back from the sensor end and soldering

in a new sensor, making sure both connecting wires are not shorting but are insulated with heat shrink

sleeving.

6. Refit in reverse order.

Page 36

36

7.4 PC Fan Motor - “T” Model

1. Unplug the refrigerator from the power supply.

2. Remove all PC shelving.

3. Remove bottom PC air duct cover.

4. Remove polystyrene duct cover insulation.

5. Disconnect low ambient heater.

6. Remove 1 screw from top duct cover and unclip.

7. Unplug PC fan motor plug.

8. Withdraw downwards.

9. Refit in reverse order.

Note: When refitting the PC fan motor, the back of the fan motor faces downwards. Ensure there is a loop

in the wiring harness between the fan motor and its housing.

7.5 PC Fan Motor - “B” Models

1. Unplug the refrigerator from the power supply.

2. Remove all PC shelving.

3. Remove the duct grill in the PC.

4. Remove the PC duct cover and polystyrene insulation.

5. Using 2 fingers, withdraw the fan motor upwards. It is mounted horizontally in the divider partition.

6. With the motor out, this will expose a small multi plug and socket connection to the fan motor and

wiring harness. Unplug.

7. To refit back together, fit the wiring harness multi plug first into the pocket of the divider partition.

8. Using your 2 fingers, slip the motor back into the divider partition to fit horizontally. Note: The back of

the fan motor faces upwards.

9. Refit duct covers and test.

The PC fan is supported by a rubber band type suspension. It is important that the fan sits central to the

housing and that there is a loop in the fan motor wiring harness between the motor and the housing. This

loop should be on a horizontal plane to the fan motor. This also applies to the FC suspended fan.

7.6 Cross / Base Rail Door Reed Switches

1. Unplug the refrigerator from the power supply.

2. Remove the door switch cover (located in the center of the cross and base rails).

3. Unclip the encapsulated reed switch from the housing.

4. Replacement of the new switch is done by cutting the wiring back from the switch end and soldering in

a new switch, making sure both connecting wires are not shorting but are insulated with heat shrink

sleeving. Take care not to leave too much excess wire as the reed switch must be able to be fitted

back in to the housing.

5. Refit in reverse order.

7.7 Defrost Heating Element

1. Unplug the refrigerator from the power supply.

2. Remove the fan grill cover. This unclips with the aid of a small screwdriver.

3. Unplug the fan motor and unclip the evaporator sensor.

4. Remove the evaporator cover.

5. Lift the evaporator upwards to clear the bottom of the divider partition and pull the bottom edge of the

evaporator forward.

6. Remove the cable ties from the thermal fuses.

7. Bend the first half of the evaporator clips and side deflectors away from the front bank of the

evaporator on both sides.

8. Drop the element down and out of the evaporator bank.

9. Refit in reverse order.

Page 37

37

7.8 Removal Of Display Module

1. Unplug the refrigerator from the power supply.

2. Remove all PC shelving.

3. Remove bottom PC air duct cover.

4. Remove polystyrene duct cover insulation.

5. Disconnect low ambient heater – “T” model only.

6. Remove 1 screw from top duct cover and unclip – “T” model only.

7. Compress clips on display module and release it from the top duct cover.

8. Unplug the 5 and 3 way edge connectors from the display module.

9. Refit in reverse order.

7.9 Thermal Fuse

This is part of the element assembly and is to be replaced as part of the defrost heater element assembly.

Having a tripping temperature of 72

o

C (162oF), they are not resettable.

7.10 Replacement Of Interior Lamp

1. Unplug the refrigerator from the power supply.

2. Remove the lens cover with the aid of a small flat bladed screwdriver.

3. Remove the faulty lamp.

4. With the protective wrapper still covering the new lamp, fit it into the holder.

5. Cut the wrapper from the lamp. Avoid handling of the new lamp as this will shorten the life of the

new lamp.

6. Refit the lens cover and test.

NB: Only a 12 volt 10 watt halogen lamp should be fitted. It is important that the lamp terminal is tight in the

lamp socket.

Diagram 7.10

7.11 Replacement Of Low Ambient Heater - “T”

Model

1. Unplug the refrigerator from the power supply.

2. Remove all PC shelving.

3. Remove bottom PC air duct cover.

4. Remove polystyrene duct cover insulation.

5. Disconnect low ambient heater.

6. Refit in reverse order.

Page 38

38

7.12 Replacement Of Low Ambient Heater - “B”

Model

This element is mounted in the floor of the divider and is not replaceable. If it should be found to be open

circuit, a replacement low ambient heater can be fitted to the return air grill.

7.13 Replacement Of Low Ambient Heater - “B”

Model (In Return Air Grill)

This element is mounted in the return grill of the divider. It is of the blanket wire type on an aluminium tape

stuck to the grill itself.

1. Unplug the refrigerator from the power supply.

2. Remove all the PC shelving and crisper bins.

3. Remove the PC duct cover.

4. Remove the PC air return grill and unplug the element from the harness.

5. Peel off the old element and replace with the new.

6. Refit in reverse order.

7.14 Evaporator Replacement

The evaporator is located in the FC compartment mounted on the back wall on its own carrier, with a grill

covering a fan motor which is housed in the front cover.

Having determined that the evaporator needs replacing:

1. Unplug the refrigerator from the power supply.

2. Recover the refrigerant.

3. Remove the FC door.

4. Remove the evaporator coil cover.

5. Clean both suction and capillary pipes with emery cloth.

6. With the tube cutter, cut the suction pipe as close as possible to the induction brazed joint (cutting the

suction capillary side of the joint).

7. With a file or knife cut the capillary where it enters the transition joint on the evaporator.

8. With the element wiring disconnected, the evaporator can be removed.

9. Take the replacement evaporator and fit it to the carrier, fitting the defrost element assembly and the 2

heat shrink sleeving onto the pipes.

10.Align the evaporator and joints ready to be soldered into position.

11.Lay the product on its back.

12.Place a protective covering over the back of the liner to protect it should solder drop onto it while the

joint connections are being made.

13.Having fitted the suction and capillary lines together with a protective heat shrink sleeving placed on

the pipe first away from the heated area, heat the “J” type soldering iron to temperature with the oxyacetylene or LPG. This should be cleaned and tinned prior to the soldering operation.

14.Hook the iron over the joint area and allow the pipework to heat while applying the solder. Once the

joint appears to have a full puddle of solder around the joint area, remove the iron and allow the joint

to cool.

15.The same applies for the capillary, applying more heat to the transition joint as it is heavier in material

than the capillary.

16.Pressure test both joints.

17.Fit heat shrink sleeving over the joint and heat, having placed damp rags around the area of the ABS

liner as heating the heat shrink can cause the liner to be overheated. It is also important to keep the

thermal fuse in the element circuit away from the heat gun, as heat from the heat gun can cause the

thermal fuse to go open circuit.

Note: The solder used to solder these FC joints is a special solder containing 5% antimony and 95% tin and

is supplied with the evaporator kit. Also, the solder contains a special flux as a resin core in itself. No other

type of solder should ever be used.

Page 39

39

7.15 Removal Of The FC Evaporator Cover

Fan cover Removal Tool (T models only)

The following illustration shows a tool that can be made in your workshop. This tool can be used to release

and remove the freezer compartment fan cover in the Active Smart “T” model refrigerators. If preferred, the

tool can be made from a screwdriver with a shaft length of approximately 200mm (7 to 8 inches) long and 4.5

mm (¼ inch) diameter.

B models are removed by grasping the bottom of the evaporator cover and pulling up and forward.

Diagram 7.15

Page 40

40

7.16 Pressure Testing Of The Refrigeration System

The use of the in-line pressure gauge can speed up and eliminate the incorrect diagnosis of a leak within a

refrigeration system. In some cases it has been found to be the service manifold that was being used that

was leaking and not the system. There are very few parts on the in-line pressure gauge that can leak.

Rule one:

In pressure testing any cabinet, before disconnecting any joint please be 100% sure that it is not the joint

that is at fault, otherwise a lot of time can be lost looking for a joint/leak that doesn't exist.

Rule two:

Only use dry nitrogen to pressure test a system, NOT REFRIGERANT OR COMPRESSED AIR.

NEVER

OXYGEN

Rule three:

Don’t over pressurise the system. It could be dangerous.

How to use the In-line Pressure Gauge

Step 1:

Cut and connect the pipe circuit to be tested to the in-line pressure gauge and braze this joint.

Step 2:

At the other end of the pipe circuit being tested, crimp off the pipe with crimp off pliers and braze this end off

to totally seal the circuit.

Step 3:

Connect a nitrogen bottle to the in-line pressure gauge by means of a hose with a Schrader valvedepressing key in the hose coupling.

Step 4:

Open the nitrogen bottle fully with the regulator backed off.

Step 5:

Increase the regulator pressure in the circuit being tested to 150 psi.

Step 6:

Close nitrogen bottle valve, back off pressure regulator.

Step 7:

Disconnect the hose coupling to the Schrader valve fitting.

Step 8:

Seal the Schrader valve with its sealing cap.

Step 9:

Use a bit of masking tape to mark the face of the pressure gauge at the set pressure. Record date and time

also.

Step 10:

Check all exposed brazed joints with soap bubbles including the joints on the in-line pressure gauge.

Step 11:

Allow pipe circuit under test to sit on drop off test. This could take a number of days for a result.

NOTE: In some cases a leak may not be found by pressurising the circuit whereas a vacuum pulled on the

same circuit will find it. Keep this in mind as oil within the circuit can block a hole.

In some cases, if the brazed joint is warmed while under pressure, this can thin the oil and help to expose

the leak. A heat gun or hair drier is useful.

Page 41

41

7.17 Transporting Of Refrigerators

It is preferable to transport the refrigerator in an upright position.

It is recommended that:

If a cabinet is to be transported lying down, then the cabinet should be placed on the right-hand side when

standing facing the front of the refrigerator. If looking at the back of the refrigerator when it is laid down in

this manner, you will see the power cord entering the cabinet at the bottom and the discharge and suction

pipes on the compressor uppermost. (Refer diagram).

Diagram 7.17A

Note: We mark all our refrigerator and freezer cartons with a number of stars on one side of the carton. If

the product is to be laid on its side for transporting at any time, the side of the carton with stars on should

face upwards (see diagram). If transporting a cabinet that has been used, be sure to empty the water

evaporator tray prior to laying the cabinet down as water from the water evaporator tray can enter the

electronic power module which is attached to the side of the unit compartment.

Ideally, the product should be transported standing upright.

Diagram 7.17B

Page 42

42

8 WIRING DIAGRAM

??

??

??

?

Page 43

43

9 SERVICE REFERENCE

9.1 “B” Models

PC TOO COLD

Cold Crispers * Ambient heater open circuit

(alarm will sound and fault

code will be displayed)