Fisher Manual: Mounting DVC6200/DVC2000 on 1052 Size 20 (End Mount) | Fisher Manuals & Guides

DVC6200 or DVC2000

Mounting Instructions

D103451X012

June 2010

Use these instructions to mount a Fisherr FIELDVUEt

DVC6200 or DVC2000 digital valve controller on 1052

size 20 actuators.

1052 Size 20 Actuator (End Mount)

WARNING

Avoid personal injury or property

damage from sudden release of process

pressure or bursting of parts. Before

performing any maintenance operations:

D Always wear protective clothing

and eyewear.

D Do not remove the actuator from

the valve while the valve is still

pressurized.

D Disconnect any operating lines

providing air pressure, electric power, or

a control signal to the actuator. Be sure

the actuator cannot suddenly open or

close the control valve.

D Use bypass valves or completely

shut off the process to isolate the

control valve from process pressure.

Relieve process pressure from both

sides of the control valve.

D Vent the pneumatic actuator

loading pressure and relieve any

actuator spring precompression.

D Use lock-out procedures to be sure

that the above measures stay in effect

while you work on the equipment.

D Check with your process or safety

engineer for any additional measures

that must be taken to protect against

process media.

Refer to figure 2 and the parts list for mounting parts

identification. Refer to the appropriate instrument

instruction manual listed below for instrument parts

identification. Refer to the appropriate actuator

instruction manual for actuator installation, operation,

maintenance, and parts identification.

1. Isolate the control valve from the process line

pressure and release pressure from both sides of the

valve body. Shut off all pressure lines to the actuator,

releasing all pressure from the actuator. Use lock-out

procedures to be sure that the above measures stay in

effect while you work on the equipment.

Digital Valve Controller on

2. The instrument can be mounted in four different

orientations on the 1052. Figure 1 shows the

instrument mounted upright relative to the actuator

spring barrel.

WARNING

To avoid personal injury due to the

sudden, uncontrolled movement of

parts, do not remove the actuator hub or

hub fasteners when the valve shaft has

actuator spring force applied to it.

3. Mounting the instrument on the 1052, size 20

actuator requires removal of the actuator hub to

replace the actuator travel indicator scale with a

retaining plate (key 14).

4. Remove the travel indicator and its cap screws from

the actuator hub, if present. Unscrew the machine

screws to remove the actuator hub and travel indicator

scale subassembly.

5. Once the actuator hub and travel indicator scale

subassembly has been removed from the actuator,

remove the retaining ring and the travel indicator scale

from the hub. Assemble the retaining plate (key 14) on

the hub and reinstall the retaining ring.

6. Reassemble the hub and retaining plate

subassembly to the actuator and attach the coupler

(key 1) to the actuator shaft using the pan head screws

(key 2) and tighten. For best visibility, the coupler

should be oriented on the shaft so that the pointer will

rotate in the quadrant above or below the instrument as

shown in figure 2.

7. Attach the mounting bracket (key 3) with the four

cap screws (key 13) and tighten. Ensure the hub is

positioned on the valve shaft so that the travel indicator

screw holes are aligned with the offset portion (where

the rod end bearing connects) of the lever.

Reassemble the actuator and readjust the actuator

spring.

8. Place the pointer (key 4) before attaching the

magnet assembly (key 5) to the coupler using pan

head screws (key 6) and tighten.

The magnet assembly must be oriented per figure 1,

so that the flats are approximately as shown relative

to the channel in the instrument housing when at the

mid−travel position.

www.Fisher.com

DVC6200 or DVC2000

Digital Valve Controller on

1052 Size 20 Actuator (End Mount)

9. Attach the mounting plate (key 7) to the mounting

bracket using pan head screws (key 11) and two

washers (key 9) and tighten.

10. Attach the travel indicator scale (key 8) to the

mounting plate using the remaining two plain washers

(key 9) and pan head machine screws (key 10). Refer

to figure 2.

11. Attach the digital valve controller to the mounting

bracket using hex head cap screws (key 12) but do not

tighten the screws. Visually adjust the digital valve

controller so that the magnet assembly is centered in

the housing channel and then tighten the fasteners.

Recheck the magnet assembly position again after

tightening.

12. Connect and calibrate the instrument as described

in the appropriate instruction manual.

Mounting Instructions

D103451X012

June 2010

For additional information concerning the mounting,

setup, calibration, and maintenance of the DVC6200

or the DVC2000 digital valve controller refer to the

appropriate instruction manual.

Note

Neither Emerson, Emerson Process

Management, nor any of their affiliated

entities assumes responsibility for the

selection, use, or maintenance of any

product. Responsibility for the selection,

use, and maintenance of any product

remains with the purchaser and end

user.

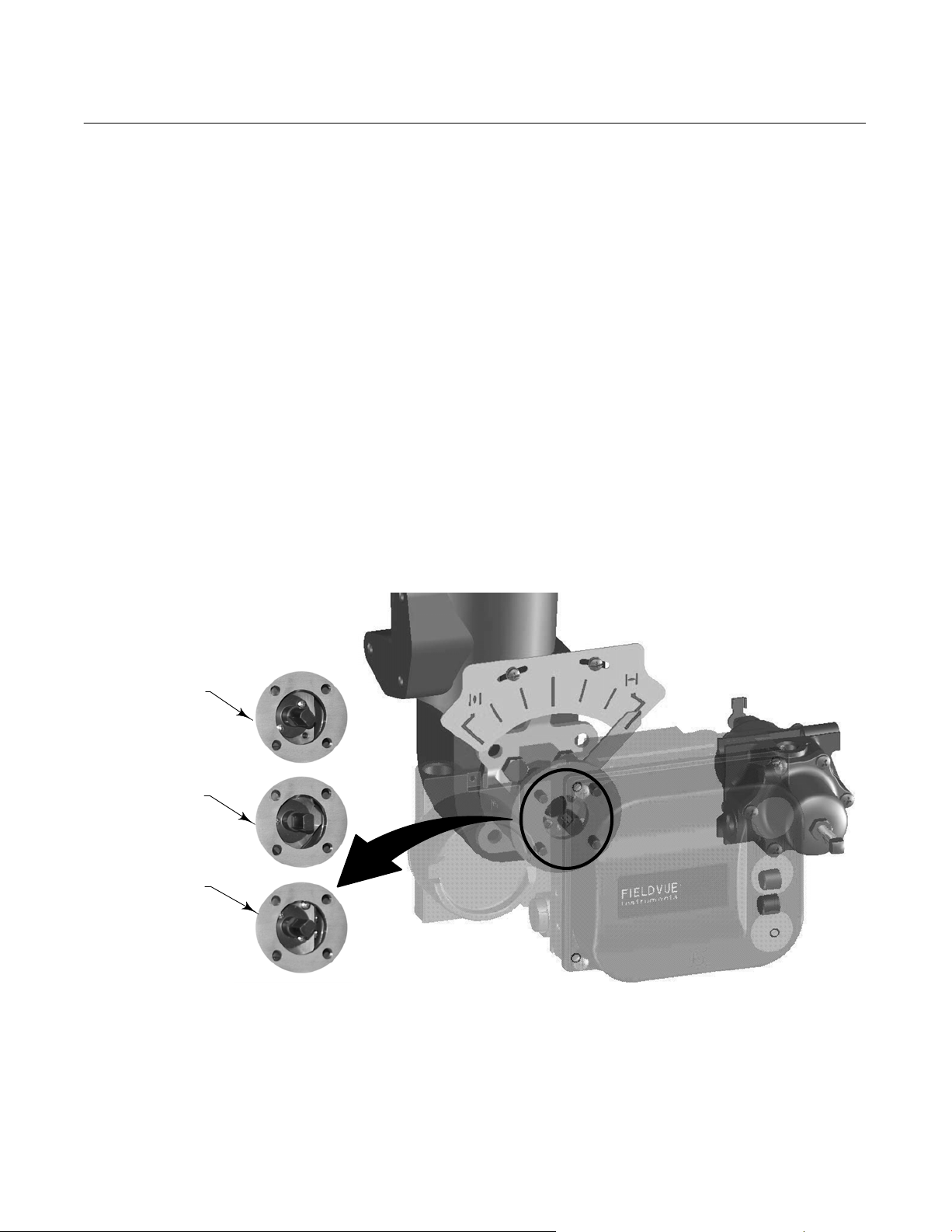

ORIENTATION AT

ONE TRAVEL

EXTREME

ORIENTATION AT

MID-TRAVEL (FLATS

PARALLEL TO

INSTRUMENT

HOUSING CHANNEL)

ORIENTATION AT

THE OTHER TRAVEL

EXTREME

W9074

Figure 1. Magnet Assembly Orientation

2

Loading...

Loading...