Fisher IM Supplement: Simulation of Process Conditions for Calibration of Fisher Level Controllers and Transmitters (249 Sensors) Manuals & Guides

Instruction Manual Supplement

D103066X012

249 Sensors

September 2017

Simulation of Process Conditions for Calibration

™

of Fisher

Level Controllers and

Transmitters—Supplement to 249 Sensor

Instruction Manuals

Displacer / torque tube sensors are transducers that convert a buoyancy change into a shaft rotation. The change in

buoyancy is proportional to the volume of fluid displaced, and the density of the fluid. The change in rotation is

proportional to the change in buoyancy, the moment arm of the displacer about the torque tube, and the torque rate.

The torque rate itself is a function of the torque tube material, the temperature of the material, the wall thickness, and

the length. If the density of the process fluid, process temperature, and torque tube material of the sensor are known,

simulation of process conditions may be accomplished by one of the following means

1. Weight or Force Method:

The interface application is the most general case. The level application can be considered an interface with the upper

fluid SG = 0, and the density application can be considered as a variable SG application with the interface at the top of

the displacer. The buoyancy for a given interface level on the displacer is given by:

(1)

:

=

F

B

Where:

F

B

ρ

w

V

D

H

disp

SG

U

SG

L

* V

*

ρ

w

SGU)H

D

[

= buoyant force

= density of water at 4_C, 1

atmosphere = 1.0000 Kg/liter

(0.03613 lb/in

= displacer volume

= height of interface on displacer,

normalized to displacer length

= specific gravity of upper fluid

(0.0 for Level)

= specific gravity of lower fluid

disp

SG

*

(

3

)

L

- SG

(1)

)

U

]

Figure 1. Cutaway View of Fisher 249 Displacer

Sensor

DRIVER ROD

TORQUE TUBE

SUSPENSION ROD

LIQUID DISPLACER

W2141-1

1. Note that this document does not consider the effects of the thermal expansion of

the moment arm, or the thermal expansion of displacer volume.

www.Fisher.com

249 Sensors

September 2017

Instruction Manual Supplement

D103066X012

Figure 2. Fisher 2500 or 2503 Level Controller

Transmitter on Caged 249 Sensor

2500 OR 2503

CONTROLLER/

TRANSMITTER

249 SENSOR

W8334

For the density application, H

= 1.0, SGu = lowest expected density, and SGL becomes the independent variable, the

disp

Figure 3. FIELDVUE™ DLC3010 Digital Level

Controller

actual process density.

The net load on the driver rod is then computed from the equation:

W7977-2

(2)

net

=

W

- F

D

B

W

Where:

W

W

net

D

= net load on driver rod

= weight of displacer

To simplify equations in the following discussion, let us define a few intermediate terms:

The minimum buoyancy, developed when the interface level is at the bottom of the displacer, is given by:

(3)

SG

V

*

FB

min

ρ

=

*

w

U

D

The change in buoyant force as the normalized interface level rises on the displacer is:

(4)

ΔF

=

ρ

*

V

B

w

D

- SGU) *

(SG

*

L

H

disp

The maximum change in buoyancy, developed when the interface level is at the top of the displacer is:

(5)

B)max

=

ρ

*

V

*

(SG

- SGU)

w

D

L

(ΔF

2

Instruction Manual Supplement

D103066X012

249 Sensors

September 2017

Temperature Effect

As process temperature increases, the torque rate decreases due to the change in modulus of rigidity. This effect can

be represented by normalizing the modulus vs. temperature curve for a given material to the room temperature value,

and using it as a scale factor on the torque rate. See figure 4 and table 1 or 2.

Because we can simulate the rotation of a more compliant torque tube by increasing the load, the weight value may be

divided by the same scale factor to simulate the process condition:

(6)

W

- F

D

W

Where:

W

net_test

G

norm

net_test

=

= net load adjusted to simulate

process temperature effect

= normalized modulus of torque

tube material, a function of

temperature.

G

B

norm

Displacer Rise Effect

Note that equation 6 simulates the process level on the displacer. The actual level in the cage or vessel will be

different, due to the rise of the displacer as the torque tube load is decreased by the increasing buoyancy.

On a 14‐inch displacer, or on a 249VS with a long driver rod, the displacer rise can become a significant fraction of the

span. If the torque tube rate and driver rod length are known, change in rotation can be computed by dividing the

torque change by the rate.

(7)

*

ΔF

ΔAngle

=

R

Where:

ΔAngle = resulting change in torque tube

Driver = driver rod length

R

amb

= Torque rate (torque per

Driver

B

amb

*

G

norm

(

*

angle in radians

_rotation) at ambient

temperature

π

/

180_

)

3

249 Sensors

Instruction Manual Supplement

September 2017

Figure 4. “Gnorm”: Theoretical Temperature Effect on Torque Rate for Most Commonly Used Materials

TORQUE RATE REDUCTION

1.00

0.98

0.96

0.94

(NORMALIZED MODULUS OF RIGIDITY)

D103066X012

0.92

0.90

norm

G

0.88

0.86

0.84

0.82

0.80

20 40 60 80 100 120 140 160 180 200 220 240 260 280 300 320 340 360 380 400 420

TEMPERATURE (_C)

TORQUE RATE REDUCTION

(NORMALIZED MODULUS OF RIGIDITY)

1.00

0.98

0.96

0.94

0.92

norm

0.90

G

0.88

N05500

N06600

N10276

S31600

N05500

N06600

N10276

0.86

0.84

0.82

0.80

50 100 150 200 250 300 350 400 450 500 550 600 650 700 750 800

S31600

TEMPERATURE (_F)

NOTE: THIS CHART DEPICTS THE REVERSIBLE CHANGE ONLY. THE IRREVERSIBLE DRIFT IS A FUNCTION OF THE NET LOAD, THE ALLOY, AND THE LEVEL OF STRESS EQUALIZATION

ACHIEVED IN MANUFACTURING. (THE IRREVERSIBLE EFFECT CAN ONLY BE COMPENSATED BY PERIODIC ZERO TRIM.) N05500 IS AN APPROPRIATE SPRING MATERIAL FOR

TEMPERATURES BELOW AMBIENT AND UP TO 232_C (450_F). ABOVE 260_C (500_F), THE INDUSTRY DOES NOT RECOMMEND USING IT AS A SPRING MATERIAL. N06600 IS

CONSIDERED ACCEPTABLE TO APPROXIMATELY 399_C (750_F) WITH PROPER STRESS EQUALIZATION.

4

Instruction Manual Supplement

D103066X012

249 Sensors

September 2017

Recognizing that the displacer rise is the side opposite this changing angle, in a triangle of which the drive rod is the

hypotenuse, the displacer rise can be approximated applying the small‐angle sine approximation to the result of

equation 7.

(8)

ΔRise

disp

2

R

B

amb

*

(

Driver

G

*

norm

)

ΔF

=

*

π

180_

The above expression may be factored to produce an ambient‐temperature displacer‐rise rate.

(9)

RiseRate

amb

π

180_

R

)

amb

*

(

/

=

Driver

2

The net rise is then restated with aid of the temperature correction term Gnorm.

(10)

ΔRise

disp

ΔF

=

B

RiseRate

*

G

norm

amb

The digital instrument firmware makes an internal correction for the displacer rise, so we must account for it in our

weight calculation to make sure that we get the expected digital value of interface level in the cage. (Analog electronic

and pneumatic devices don't have this correction capability, but the accuracy of the calibration would still be improved

by accounting for the effect during simulation.) The ratio of the level change on the displacer to the level change in the

cage needed to produce it is:

(11)

L

)

max

D

*

RiseRate

amb

G

/

norm

ΔH

ΔH

disp

cage

proc

=

)

L

ΔF

(

D

B

Where:

L

D

H

cage

The above equation is valid only for 0.0 < H

= length of displacer

= interface level in cage, normalized to displacer length.

< 1.0 (since interface level excursions above or below the displacer

disp

produce no additional change in buoyancy)

The % span error introduced by neglecting the displacer rise effect becomes smaller as the displacer length increases.

The displacer rise at the initial condition, (displacer completely submerged in the upper fluid), is given by:

(12)

RiseRate

Rise

0proc

FB

min_eff

=

G

*

norm

amb

Where:

FB

min_eff

W

max

Max( (W

disp

W

= [ FB

= the load that will cause the linkage to contact the lower travel stop.

), 0.0 ) = the amount of buoyancy required to lift the displacer off the travel stop so that rise can

max

Max( (W

min

disp

W

max

), 0.0) ]

actually commence. The maximum available shift below the zero rest position at ambient temperature is also limited

by this travel stop, so the value of W

(W

max_ambient

Note that W

* G

norm

max_ambient

) in the FB

min_eff

would have to be determined by experiment on the specific physical hardware, but for a first

will be a function of temperature. To account for this, replace W

max

equation.

max

by

approximation, you could use the ‘maximum unbuoyed displacer weight’ value given in table 5.

5

249 Sensors

September 2017

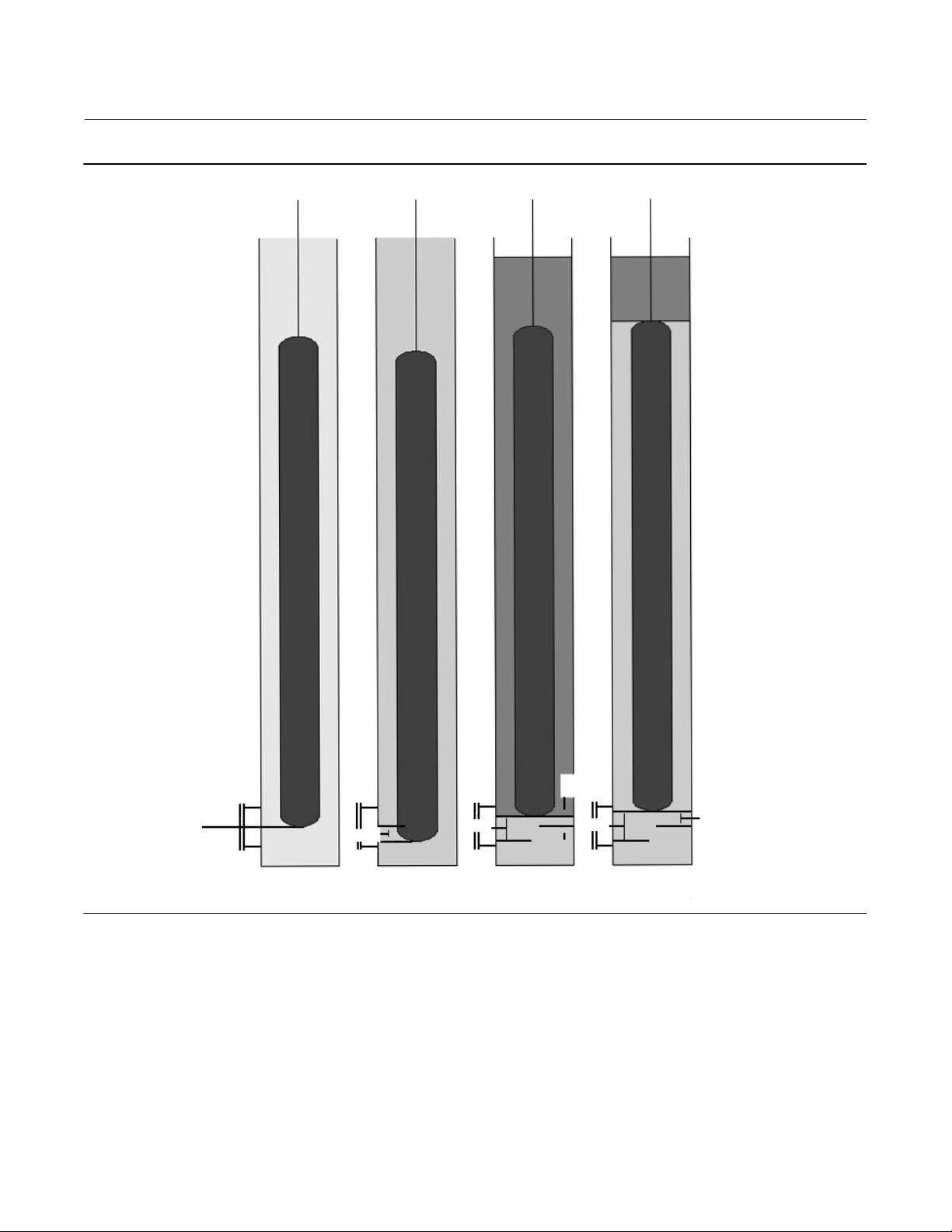

Figure 5. Illustration of Displacer Rise Effect

Instruction Manual Supplement

D103066X012

Initial

Offset

Ref

T = amb

F

= 0

b

Zero Shift

Y

B

T = proc

F

= 0

b

Rise

i

Y

B

T = proc

F

= f(SGU)

b

Rise

f

T = proc

F

Y

B

= f(SGL)

b

Y

B

Final Offset

6

Instruction Manual Supplement

D103066X012

249 Sensors

September 2017

Temperature‐Induced Zero‐Shift at Zero Buoyancy

If the physical zero reference was established at zero buoyancy and ambient temperature, there is an additional

zero‐shift to take into account. The zero buoyancy position of the bottom of the displacer at process temperature will

be lower, because of the reduction in torque rate.

(13)

*

W

RiseRate

ZeroShift

proc

D

=

G

Note that the combination of:

a. the location of the displacer bottom relative to the external reference at ambient,

b. the zero-shift at process temperature, and

c. the initial displacer rise at process temperature,

will determine the extent of any unobservable region between the external zero reference and the displacer bottom.

amb

norm

*

G

norm

-1.0

)

(

We must decide what our process variable (PV) calculation is going to use for a zero reference. Since any interface level

excursion below the bottom of the displacer cannot change the output, it is convenient to call the displacer bottom

“zero” for the test, and this has been standard procedure in pilot mounting. In the digital level controller, Level Offset

is used to adjust the digital output to zero at this condition.

Lowest Observable Cage Interface Level

If it is desired to line up the calculation with the physical external reference, the Level Offset (and range values) can be

adjusted according to the following.

(14)

H

cage0

ZeroShift

=

proc

L

Rise

)

0proc

D

Where:

H

cage0

= highest possible value of cage

interface level (normalized to

displacer length), relative to zero

buoyancy, ambient temperature

coupling point, when displacer

interface level is 0.0 (bottom of

displacer).

This is the physical interface level below which a change is unobservable. The range values or alarm values should be

set within the observable range of PV to make sure that over‐ and under‐flow conditions are reported to the control

system.

7

249 Sensors

September 2017

Instruction Manual Supplement

D103066X012

Weight Calculation Procedure

To compute the weight required, at room temperature, to simulate a given process‐condition cage interface level:

a. Start with an initial buoyancy based on the SG of the upper fluid,

b. subtract it from the displacer weight, and

c. correct the result for process temperature.

This will give the test weight for the lowest observable process condition.

W

-

F

D

W

net_test

J

=

i

G

Bmin

norm

The change in weight for a process‐temperature, cage (or vessel) interface level condition, one displacer length higher

than the above state, is given by:

(16)

(15)

ΔW

(

J

f

disp

=

cage

G

)

norm

ΔH

/

ΔH

proc

ΔF

*

(

)

B max

The net weight for the 100% cage process condition is:

(17)

W

net_test

W

J

=

f

net_test

J

i

−

ΔW

J

f

Other values of ΔW can be computed from:

(18)

ΔW

ΔH

=

cage

*

(

ΔH

disp

/

G

ΔH

norm

cage

)

proc

*

(ΔFB)

max

Where:

cage

cage0

=H

< H

ΔH

Valid for H

Remember that it is common to arbitrarily set H

cage

cage

− H

cage0

< [1/ (ΔH

disp

/ ΔH

cage)proc

]

to zero for test purposes when using weights. (For water column

cage0

calculations in the next section, it is more important to keep track of the initial process‐condition cage level to

simulate the initial buoyancy correctly.) The resultant net weights for the intermediate levels are given by:

(19)

J

-

W

net_test

W

=

net_test

ΔW

i

This assumes that the net weights do not violate the maximum or minimum load for the torque tube. Refer to table 5.

8

Instruction Manual Supplement

D103066X012

249 Sensors

September 2017

2. Water Column Method:

It is possible to simulate a range of buoyancy adjusted for process temperature effect by using a water column at room

temperature. At the ambient SG = 1.0 level application, the corrections should all cancel out, leaving H

PV.

Cage Water Level Required to Simulate Interface Levels

If we have computed an equivalent weight for a given process condition in section 1, the ambient temperature water

level on the displacer that will produce the same torque tube rotation is:

(20)

W

W

-

net

H

disp_eq

=

For high temperatures and high SG, the range of conditions that can be simulated will contract, since we are limited by

the actual displacer weight and the nominal density of water.

We must next convert this equivalent displacer level into an equivalent cage level using the inverse of the relationship

in equation 11, without the temperature compensation.

D

V

ρ

*

D

w

= desired

cage

(21)

)

*

ΔH

ΔH

disp

cage

amb

ρ

L

D

=

w

V

D

*

RiseRate

L

D

amb

The result is:

(22)

*

W

-

H

cage_eq

disp

ΔH

/

cage

ρ

w

amb

*

V

D

ΔH

()

=

W

(

D

net

)

Process Interface Level Simulated by a Given Cage Water Level

We can also write a generic equation for the process‐condition displacer interface level simulated by a given

room‐temperature displacer water level:

First, convert the ambient cage water level to an ambient displacer water level:

(23)

H

H

disp_eq

=

(

Next, define an intermediate variable to compute the apparent SG being simulated at process conditions by the

ambient displacer water level:

ΔH

cage

cage

/

ΔH

disp

)

amb

SGapp

sim

(24)

norm

*

)

1-

G

(

=

)

W

ρ

*

w

G

D

V

norm

D

*

H

disp_eq

9

249 Sensors

September 2017

Instruction Manual Supplement

D103066X012

Now use this apparent SG value to compute the simulated interface level on the displacer:

(25)

sim

SGL-SG

-SG

U

U

H

disp

sim

SGapp

=

Finally convert the simulated process‐conditions displacer interface level to simulated process‐condition cage

interface level, by the equation:

H

disp

H

cage

Where H

H

=

sim

is either 0.0 or the value computed in equation 14, per the practice being followed for PV reference.

cage0

cage0

)

ΔH

disp

()

sim

ΔH

/

cage

proc

3. Tables of Nominal Values

If the calibration is being run per standard practice the values of the parameters for the above equations are generally

available for observation in the instrument memory. For analog instruments, a table of nominal values may be

consulted to generate good approximations.

Table 1. Gnorm for Common Torque Tube Materials Above Room Temperature

Gnorm

(26)

Material

N05500 1 0.9923 0.9866 0.9808 0.9692 0.9577 0.9385 0.9192

N06600 1 0.9861 0.9759 0.9657 0.9529 0.9401 0.9256 0.9111

N10276 1 0.9802 0.9649 0.9497 0.9329 0.9161 0.9010 0.8859

S31600 1 0.9609 0.9378 0.9108 0.8837 0.8597 0.8277 0.7993

These values are approximations derived from various metal-alloy industry publications

Table 2. Gnorm for 316 SST Below Room Temperature

Material

S31600 1.0836 1.0807 1.0635 1.0179 1

Low temperature data for N05500, N06600, and N10276 not available at time of publication.

_C _F _C _F _C _F _C _F _C _F _C _F _C _F _C _F

21 70 93 200 149 300 204 400 260 500 316 600 371 700 427 800

Gnorm

_C _F _C _F _C _F _C _F _C _F

-240 -400 -184 -300 -129 -200 -18 0 21 70

Table 3 provides the theoretical unloaded rate, and the composite or effective torque rate measured by the digital

level controller at the end of the pilot shaft. The physical rotation at the far end of the torque tube may be a bit greater

than what these tables would predict, due to some wind‐up of the pilot shaft.

Table 3. Theoretical Room Temperature Torque Rates

Composite Rate

Family / Wall Material

249, 249B,

249BF 249BP, 259B,

249P (CL150-600),

249W

HEAVY

1. N05500 is the default material.

2. Appropriate for 2500 controllers only.

10

N05500

N06600 1P8662X0012 1.66 14.7 2.07 18.3 2.18 19.3

S31600 1K4541000A2 1.76 15.5 2.18 19.3 2.29 20.3

N10276 1K453140152 1.75 15.5 2.16 19.1 2.27 20.1

Torque Tube

Part Number

(1)

1K4497X0012 1.48 13.1 1.90 16.8 2.01 17.8

Unloaded Rate

Nwm/deg lbfwin/deg Nwm/deg lbfwin/deg Nwm/deg lbfwin/deg

(2)

-continued-

W/O Insulator W/Insulator

Instruction Manual Supplement

D103066X012

Table 3. Theoretical Room Temperature Torque Rates (continued)

Family / Wall Material

249,

249B, 249BF

249BP,

259B,

249P

(

CL150-600),

249C

249CP

249PT

249VT

249W

STANDARD

1. N05500 is the default material.

2. Appropriate for 2500 controllers only.

HEAVY

Family / Wall Material

249B

249,

249BP,

259B,

249P

(CL150-600),

249C

249CP

249PT

249VT

249W

THIN

1. N05500 is the default material.

2. Appropriate for 2500 controllers only.

STANDARD

Family / Wall Material

249K,

249L, 249N, 249VS,

249P (CL900‐2500),

STANDARD

1. N05500 is the default material.

2. Appropriate for 2500 controllers only.

Family / Wall Material

249K,

249L, 249N, 249VS,

249P (CL900‐2500)

THIN

1. N05500 is the default material.

2. Appropriate for 2500 controllers only.

Unloaded Rate

Nwm/deg lbfwin/deg Nwm/deg lbfwin/deg Nwm/deg lbfwin/deg

N05500

Torque Tube

Part Number

(1)

1K4493X0012 0.764 6.76 0.988 8.75 1.05 9.27

N06600 1K4515000A2 0.758 6.71 0.952 8.42 1.00 8.87

S31600 1K4503000A2 0.848 7.50 1.06 9.36 1.11 9.85

N10276 1K4527000A2 0.799 7.07 0.993 8.79 1.04 9.23

Unloaded Rate

Nwm/deg lbfwin/deg Nwm/deg lbfwin/deg Nwm/deg lbfwin/deg

N05500

Torque Tube

Part Number

(1)

1K4495X0012 0.384 3.40 0.502 4.44 0.532 4.70

N06600 1K4517000A2 0.405 3.58 0.513 4.54 0.540 4.78

S31600 1K4505000A2 0.416 3.68 0.524 4.64 0.551 4.87

N10276 1K4529X0012 0.427 3.78 0.535 4.73 0.562 4.97

Unloaded Rate

Nwm/deg lbfwin/deg Nwm/deg lbfwin/deg Nwm/deg lbfwin/deg

N05500

Torque Tube

Part Number

(1)

1K4499X0012 1.06 9.41 1.46 13.0 1.54 13.7

N06600 1K4519000A2 1.20 10.6 1.58 14.0 1.66 14.7

S31600 1K4507000A2 1.26 11.2 1.66 14.7 1.75 15.4

N10276 1K9159X0012 1.26 11.2 1.65 14.6 1.73 15.3

Unloaded Rate

Nwm/deg lbfwin/deg Nwm/deg lbfwin/deg Nwm/deg lbfwin/deg

N05500

Torque Tube

Part Number

(1)

1K4501X0012 0.550 4.87 0.762 6.74 0.804 7.12

N06600 1P747040042 0.546 4.83 0.729 6.45 0.765 6.77

S31600 1K450935072 0.611 5.40 0.809 7.16 0.848 7.51

(2)

(2)

(2)

(2)

249 Sensors

September 2017

Composite Rate

W/O Insulator W/Insulator

Composite Rate

W/O Insulator W/Insulator

Composite Rate

W/O Insulator W/Insulator

Composite Rate

W/O Insulator W/Insulator

11

249 Sensors

September 2017

Instruction Manual Supplement

D103066X012

Additional Information

Table 4. Moment Arm (Driver Rod) Length

Sensor Type

(2)

249 203 8.01

249B 203 8.01

249BF 203 8.01

249BP 203 8.01

249C 169 6.64

249CP 169 6.64

249K 267 10.5

249L 229 9.01

249N 267 10.5

249P

(CL125-600)

249P

(CL900-2500)

249VS (Special)

(1)

See serial card See serial card

249VS (Std) 343 13.5

249W 203 8.01

1. Moment arm (driver rod) length is the perpendicular distance between the vertical

centerline of the displacer and the horizontal centerline of the torque tube. See figure

6. If you cannot determine the driver rod length, contact your Emerson sales office

Local Business Partner and provide the serial number of the sensor.

2. This table applies to sensors with vertical displacers only. For sensor types not listed,

or sensors with horizontal displacers, contact your Emerson sales office for the driver

rod length. For other manufacturers' sensors, see the installation instructions for that

mounting.

Moment Arm

mm Inch

203 8.01

229 9.01

Table 5. Maximum Unbuoyed Displacer Weight

Sensor Type

249, 249B, 249BF,

249BP, 249W

249C, 249CP

249VS

249L, 249P

(1)

249K

1. High pressure CL900 through 2500.

Torque Tube Wall

Thickness

Thin

Standard

Heavy

Standard

Heavy

Thin

Standard

Thin

Standard

Thin

Standard

(1)

Displacer Weight,

W

(lb)

T

3.3

5.0

9.5

4.0

6.4

3.0

5.5

4.5

8.5

3.8

7.3

Figure 6. Method of Determining Moment Arm from

External Measurements

E0283

L

MOMENT

ARM

LENGTH

HORIZONTAL C

OF TORQUE TUBE

L

VERTICAL C

OF DISPLACER

Table 6. Related Documents

Document Part Number

249 Caged Displacer Sensors Instruction Manual D200099X012

249 Cageless Displacer Sensors Instruction Manual D200100X012

249VS Cageless Displacer Sensor Instruction Manual D103288X012

or

249W Cageless Wafer Style Level Sensor Instruction

Manual

2500 and 2503 Level Controllers and Transmitters

Instruction Manual

DLC3010 Digital Level Controller Quick Start Guide D103214X012

DLC3010 Digital Level Controller Instruction Manual D102748X012

2502 Level Controller D200126X012

These documents are available from your Emerson sales office or Local Business

Partner. Also visit our website at Fisher.com

.

D102803X012

D200124X012

Neither Emerson, Emerson Automation Solutions, nor any of their affiliated entities assumes responsibility for the selection, use or maintenance

of any product. Responsibility for proper selection, use, and maintenance of any product remains solely with the purchaser and end user.

Fisher and FIELDUVE are marks owned by one of the companies in the Emerson Automation Solutions business unit of Emerson Electric Co. Emerson

Automation Solutions, Emerson, and the Emerson logo are trademarks and service marks of Emerson Electric Co. All other marks are the property of their

respective owners.

The contents of this publication are presented for informational purposes only, and while every effort has been made to ensure their accuracy, they are not

to be construed as warranties or guarantees, express or implied, regarding the products or services described herein or their use or applicability. All sales are

governed by our terms and conditions, which are available upon request. We reserve the right to modify or improve the designs or specifications of such

products at any time without notice.

Emerson Automation Solutions

Marshalltown, Iowa 50158 USA

Sorocaba, 18087 Brazil

Cernay, 68700 France

Dubai, United Arab Emirates

Singapore 128461 Singapore

www.Fisher.com

12

E 2003, 2017 Fisher Controls International LLC. All rights reserved.

Loading...

Loading...