Instruction Manual

D500243X012

Fisherr POSI-SEAL™ 1035/El-O-Matic

Rack-and-Pinion Rotary Actuator

1035/El-O-Matic Actuator

August 2012

Contents

Introduction 1.................................

Scope of Manual 1.............................

Description 2.................................

Specifications 2...............................

Installation 4..................................

Operation 6...................................

Adjustment 12................................

Troubleshooting 12.............................

Maintenance 13................................

Actuator Disassembly 13.......................

Actuator Assembly 16..........................

Changing Rotation Direction 18..............

Spring Return E Series Actuators 20...........

Spring Return P Series Actuators 20...........

Installing the Bypass Valve 20................

Parts Ordering 21...............................

Parts Kits 22...................................

Parts List 23...................................

Figure 1. Fisher POSI-SEAL 1035/El-O-Matic Actuator

with A41 Valve

W9255

Introduction

Scope of Manual

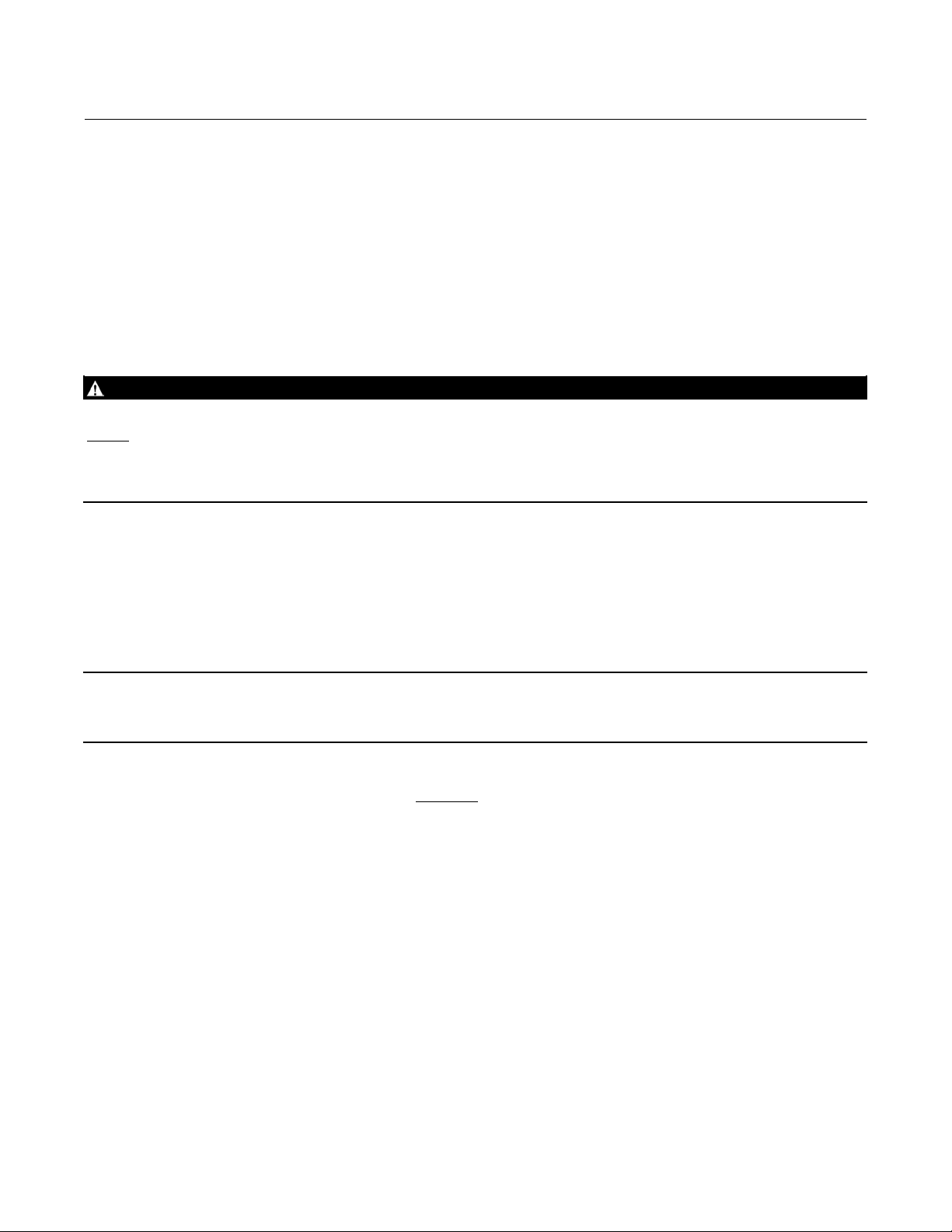

This instruction manual includes installation, maintenance, and parts ordering information for Fisher POSI-SEAL

1035/El-O-Matic rack-and-pinion rotary actuators (figure 1). These actuators are available in both double-acting and

spring-return (figure 2) configurations. Spring return units provide fail action in response to spring compression. The

actuator is field reversible. Instructions for the valve and for any accessories used with the actuator are found in

separate manuals.

Do not install, operate, or maintain a 1035 actuator without being fully trained and qualified in valve, actuator, and

accessory installation, operation, and maintenance. To avoid personal injury or property damage, it is important to

carefully read, understand, and follow all the contents of this manual, including all safety cautions and warnings. If you

have any questions about these instructions, contact your Emerson Process Management sales office before

proceeding.

www.Fisher.com

1035/El-O-Matic Actuator

August 2012

Table 1. Specifications

Instruction Manual

D500243X012

1035 Actuator:

Double Acting Spring Return.

EDA 25 ESA 25

EDA 40 ESA 40

EDA 65 ESA 65

EDA 100 ESA 100

EDA 200 ESA 200

EDA 350 ESA 350

EDA 600 ESA 600

EDA 950 ESA 950

EDA 1600 ESA 1600

PDA 2500 PSA 2505

PDA 4000 PSA 4005

Output Shaft:

J Optional ISO 5211 square insert, J Recessed ISO

J Double D insert for A41 valves

5211 square drive for P Series actuators

Dual Stop Adjustment:

J ESeriesactuatorsare

furnishedwithdualstopadjustments(DSA)asa

standard feature.

J P Series actuators provide dual

stops with the use of the “Limit Stop Plate” (LSP)

option. The LSP is mounted between the actuator and

yoke.

Supply Pressure

(1)

(Operating Pressure)

Temperature: -40 to 79_C(-40to175_F) with EPDM

and special lubricant (an “LT” in model number)

Performance Characteristics

See tables 2 and 3

Rotation for Code A Construction

Rotation is counterclockwise with port “A”

pressurized with standard code A construction.

Spring return actuators fail clockwise with standard

construction for standard code A actuators (see

figure 3 for optional constructions)

Maximum Output Torque

See Catalog 14

Lubrication

Factory lubricated for the normal life of the actuator

(see temperature range shown above)

Coating

All units feature a two component polyurethane

coating system as standard

2.8 to 8.3 bar (40 to 120 psig) for both double acting

andspringreturnactuators

Temperature Range

(1)

Standard: -20 to 79_C (-4 to 175_F) with Nitrile

O-rings

Optional:

High Temperature: -20 to 121_C (-4 to 250_F) with

fluorocarbon O-rings (a “V” in model number), or Low

1. The pressure-temperaturelimits in this manual and any applicable code or standard installationshould not be exceeded.

2. For more information, contact your Emerson Process Management sales office.

Actuator Tubing Size

3/8 inch O.D. standard for all sizes

Options

J Parts kits: O-ring kits provides O-rings only, and

repair kits provide O-rings, guide bushings and soft

parts. Kits are available for standard and high

temperature or for low temperature applications

J Unit is field reversible

Description

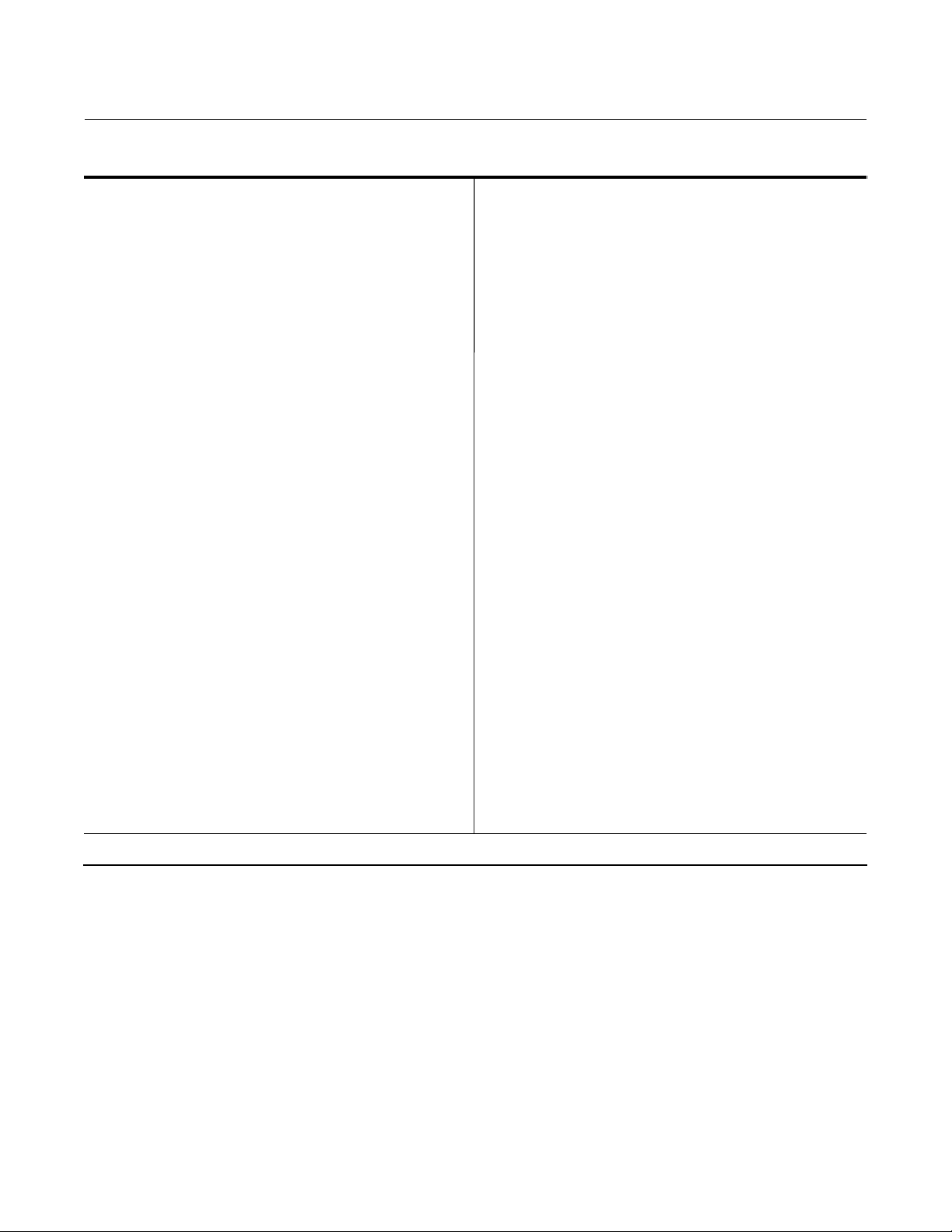

The 1035 actuator is a rack-and-pinion, pneumatic quarter-turn actuator. The actuator utilizes a double rack and single

pinion design (see figure 2). The actuator uses three carbon filled PTFE guide bands, with a balanced piston which

prevents metal-to-metal contact between the pistons and cylinder wall.

The E Series actuator uses a recessed bushing inserted into the end of the actuator drive shaft. Standard recessed

double-D bushings match the A41 valve drive shaft. In most applications, the valve shaft is inserted directly into the

recessed actuator shaft bushing. The P Series actuators provide a recessed s quare output shaft for coupling the

actuator to the valve shaft. The A41 valve uses a square-to-double-D drive coupler construction. Optional couplings

are available for other applications.

2

Instruction Manual

D500243X012

1035/El-O-Matic Actuator

August 2012

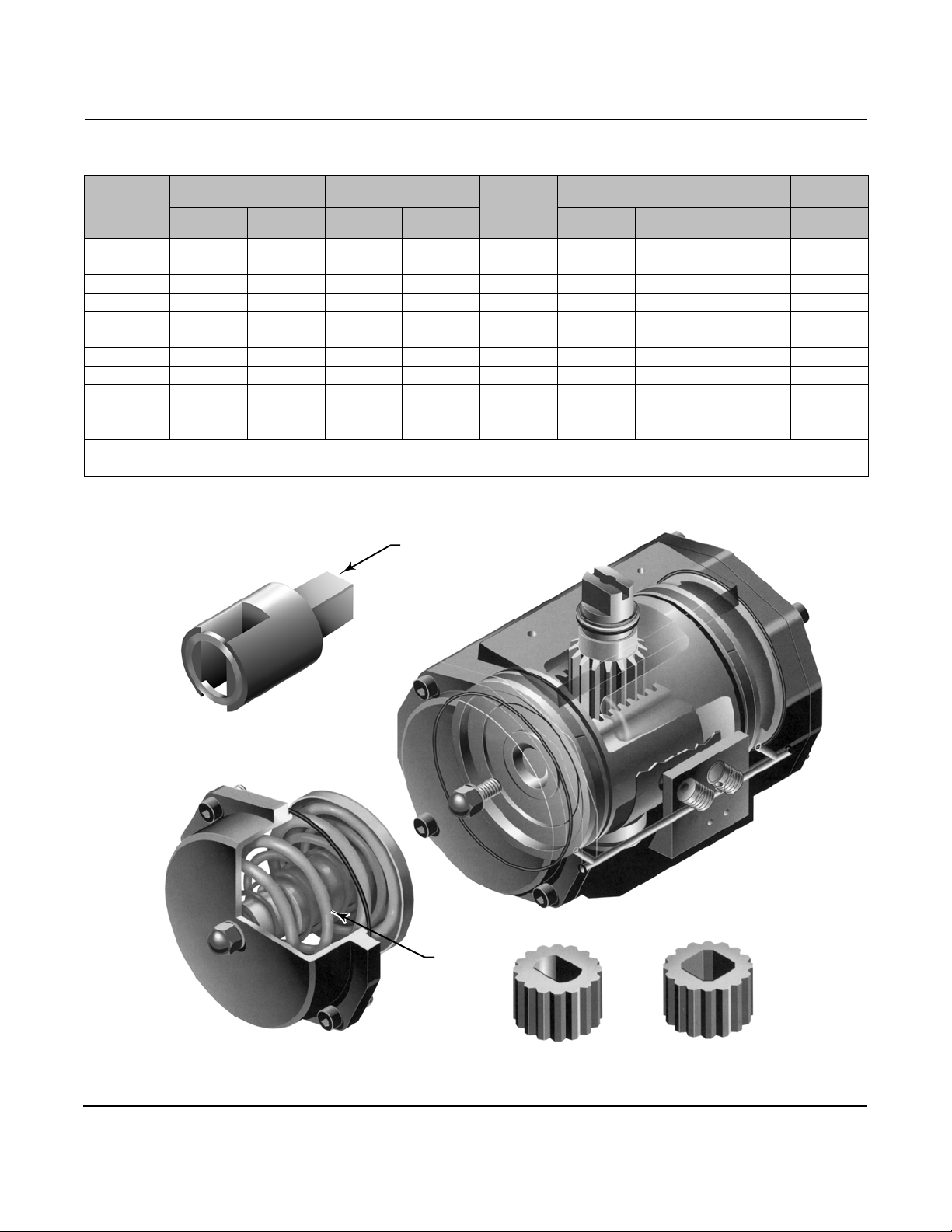

Table 2. Performance Characteristics

ESERIES

ACTUATOR

SIZE

E25 56 2.2 15.7 0.62 0.5 0.1 6.1 0.11 6.7

E40 70 2.8 18.8 0.74 0.7 0.16 9.8 0.22 13.4

E85 80 3.1 22.0 0.87 1.1 0.33 20.1 0.36 22.0

E100 91 3.6 25.1 0.99 1.2 0.35 21.4 0.49 29.9

E200 110 4.3 37.7 1.48 2.2 0.8 48.8 1.0 61.0

E350 145 5.7 37.7 1.48 3.7 1.8 110 1.9 116

E600 175 6.9 44.0 1.73 3.3 2.9 177 3.1 189

E950 200 7.9 50.3 1.98 5.4 4.7 287 4.9 299

E1600 230 9.1 62.8 2.47 5.8 7.3 445 8.0 488

P2500/P2505 300 11.8 56.5 2.22 6.7 8.0 488 9.3 567

P4000/P4005 325 12.8 81.7 3.22 12.4 13.5 824 17.5 1068

1. These times assume smaller solenoids for smalleractuators and larger solenoidsfor larger actuators with varying Cvs, but a constant air supplypressure of 80 psi (5.51 bar). E25 to E350

assume a 0.09 Cv (0.08Kv); E600 & E9500 a 0.26 Cv (0.22 Kv); E1600, P2505 & P4005 a0.51 Cv (0.44 Kv).

2. To calculate air consumption per stroke multiply free air volume X air supply pressure (absolute).

BORE STROKE

mm Inch mm Inch

AVERAGE

STROKE

TIME

(1)

(SEC)

Port

“A”(liter)

FREE AIRVOLUME

Port

“A”(in

(2)

3

)

Port

“B”(liter)

FREE AIR

VOLUME

Port

“B”(in

Figure 2. Typical Actuator Assembly

(2)

3

)

COUPLER

STANDARD SQUARE END

DOUBLE ACTING

ACTUATOR

SPRING

W6954

END CAP SPRING RETURN

STANDARD SQUAREDOUBLED CONNECTION

E SERIES INSERT

3

1035/El-O-Matic Actuator

August 2012

Instruction Manual

Table 3. Approximate Weights

ACTUATOR SIZE

E25 1.2 1.7 2.7 3.7

E40 1.8 2.4 4.0 5.3

E65 2.4 3.6 5.3 7.9

E100 2.8 4.6 6.1 10.1

E200 5.8 9.1 12.8 20.1

E350 10.4 16.9 22.9 37.3

E600 19.4 27.6 42.8 60.8

E900 26.4 38.6 58.2 85.0

E1600 42.7 65.8 94.1 145

P2500/P2505 56.7 88.0 125 194

P4000/P4005 86.2 132.0 190 291

EDA ESA EDA ESA

kg lbs

Table 4. Bolting Torques between 1035 and Yoke

ACTUATOR SIZE Bolt Diameter, Inches Torque, NSm Torque, lbfSft

E25 1/4 11 8.3

E40

E65

E100

E200

E350

E600 1/2 91 67

E950 5/8 163 120

E1600 3/4 258 190

P2500/P2505

P4000/P4005

5/16 22 16.5

3/8 39 29

3/4 203 150

D500243X012

Installation

When an actuator and a valve are shipped together, the actuator is normally mounted on the valve. Follow the valve

body instructions when installing the control valve in the pipeline. If the actuator is shipped separately from the valve

or if it is necessary to mount the actuator on the valve, perform the procedures in the Actuator Mounting section.

WARNING

Always wear protective gloves, clothing, and eyewear when performing any installation operations to avoid personal

injury.

To avoid personal injury or property damage caused by bursting of pressure-retaining parts, be certain the service

conditions do not exceed the limits given in table 1. Use pressure-limiting devices or pressure-relieving devices to prevent

the cylinder pressure from exceeding these limits.

If hoisting the valve and actuator assembly or the actuator by itself, take precautions to prevent people from being injured

in case the hoist or sling slips unexpectedly. Refer to table 3 for actuator weights. Carefully position the sling to prevent

damage to tubing or any accessories.

Check with your process or safety engineer for any additional measures that must be taken to protect against process

media.

If installing into an existing application, also refer to the WARNING at the beginning of the Maintenance section in this

instruction manual.

4

Instruction Manual

D500243X012

1035/El-O-Matic Actuator

August 2012

Actuator Mounting

Use the following steps to connect a valve and actuator that has been ordered separately.

The 1035 E Series is offered with a Double D insert as standard to allow direct coupling to the A41 valve drive shaft. A

few actuator/valve combinations will require the use of an external coupler: E100 with a 1-inch drive shaft, E200 and

E350 with a 1-1/2-inch drive shaft.

P Series applications, the actuators feature an ISO 5211 recessed square drive shaft and requires an external coupler to

engage the valve drive shaft. P Series actuators also require the use of a Limit Stop Plate (LSP) if a Fisher 1080

Declutchable Manual actuator is not being used.

Assemble the bracket, actuator, LSP (if necessary) and valve assembly as follows:

1. Rotate the valve drive shaft to the position necessary to match the valve/actuator operation. See figure 3 for

mounting style codes and positions.

2. Attach the yoke/mounting bracket to the actuator or the LSP (if necessary). Do not fully tighten cap screws at this

time. You will need to align the valve and actuator, or valve, coupler, LSP and actuator before tightening the

mounting screws to the required torque. The 5/8-inch screws should not be used to mount the actuator to the

yoke/mounting bracket. These screws are only to be used for mounting the LSP. Only the 3/4-inch screws are to be

used to mount the actuator to the yoke/mounting actuator.

WARNING

Exceeding any torque requirement may impair the safe operation of this actuator by causing broken or damaged parts.

Refer to table 4 for bolting torque requirements.

The LSP, if used, will also have to be attached to the 1035. Use 4 screws for size P2500/P2505 and 8 screws for size

P4000/P4005. The bolting torque for these 5/8-inch screws will be 10.2 NSm(90inSlb).

3. The P Series and a few E Series actuator combinations require a coupler. Insert the square end of the coupler into

the drive shaft recess in the actuator, making sure the coupler engages properly.

4. Lower the actuator, and coupling assembly onto the valve, making sure that the male valve stem engages into the

coupler or insert.

a. Secure the mounting bracket to the valve using cap screws and lock washers provided in the mounting kit.

b. At this time, make sure that the actuator is in the operation mode desired, and that the valve is in the correct

position required foryourapplication.

5. For E Series actuators with A41 valves, insert the valve drive shaft end (double-D) into the recessed insert.

6. Align the valve shaft with the actuator drive shaft by changing the positioning on the mounting bracket between

them.

5

1035/El-O-Matic Actuator

August 2012

Instruction Manual

D500243X012

Operation

Units supplied from the factory as an assembly are adjusted per specifications supplied to the factory on the original

order.

Unless the valve/actuator assembly has been damaged during shipment, or the actuator removed for maintenance,

the assembly should be factory adjusted and ready for service.

Actuator Orientation: The 1035 actuator is normally installed with its major axis parallel to the pipeline (see code A,

figure 3). However, the actuator can also be oriented 90 degrees to thepipeline.Seefigure3forstandardandoptional

orientations. (Note: Code B is not available in the E Series.)

The P or E Series actuator drive shaft turns a full 90 degrees and the stroke is adjustable for the valve closed position.

When necessary, refer to the actuator adjustment steps in this manual.

Note

The A41 High Performance Butterfly valve should not be turned by the power actuator more than 90 degrees of rotation.

Pre-adjust actuator stops to limit travel to 90 degrees or less until adjustment steps are completed.

Adoubleactingactuatorcanbechangedinthefieldtoaspringreturn unit, or vice-versa (requires different end caps).

Code A actuators can be converted to a code D unit by turning the pistons 180 degrees from the position shown for

code A (See figure 3 for piston and shaft orientation).

Adjustments

ESeriesactuatorsprovide end cap adjustment screws to limit outward travel of the piston. The inward movement of

the piston is limited by the housing stop (see figure 4).

PSeriesactuatorshave a Limit Stop Plate option (LSP) which is used with standard actuator constructions. The LSP is

not used when a Fisher 1080 is used. T he LSP, or the 1080, limits travel in either direction for any construction. Refer to

figure 4.

To adjust the travel stops, refer to the valve instruction manual for open and closed positions of the valve. Upon

assembly, ensure that the power actuator does not drive the valve past 90 degrees of rotation. Valve component parts

can be damaged if high actuator air pressure is applied past 90 degrees. Travel limits must be set in the actuator, not in

the valve. It is recommended that the valve be out of the pipeline when adjusting travel limits.

6

Instruction Manual

)

D500243X012

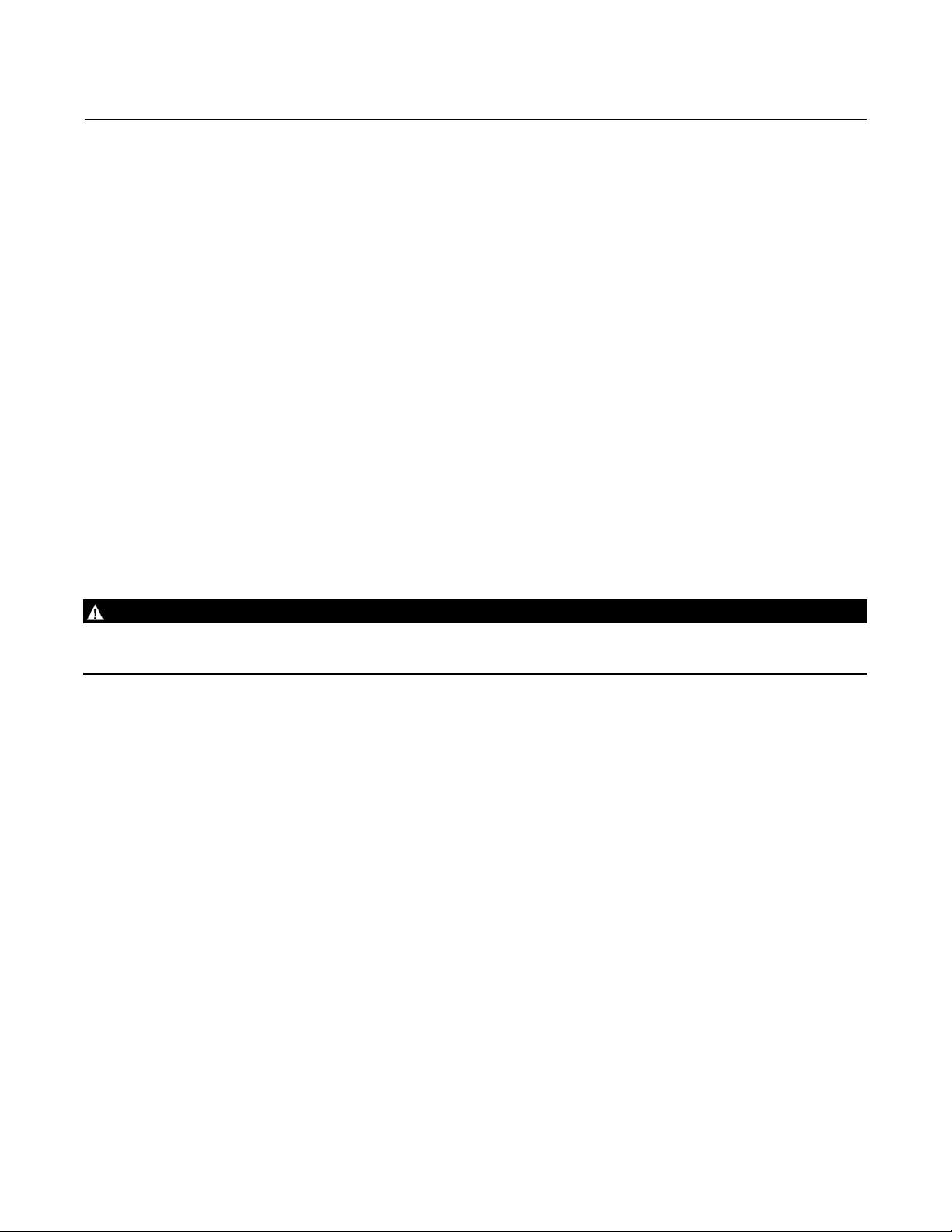

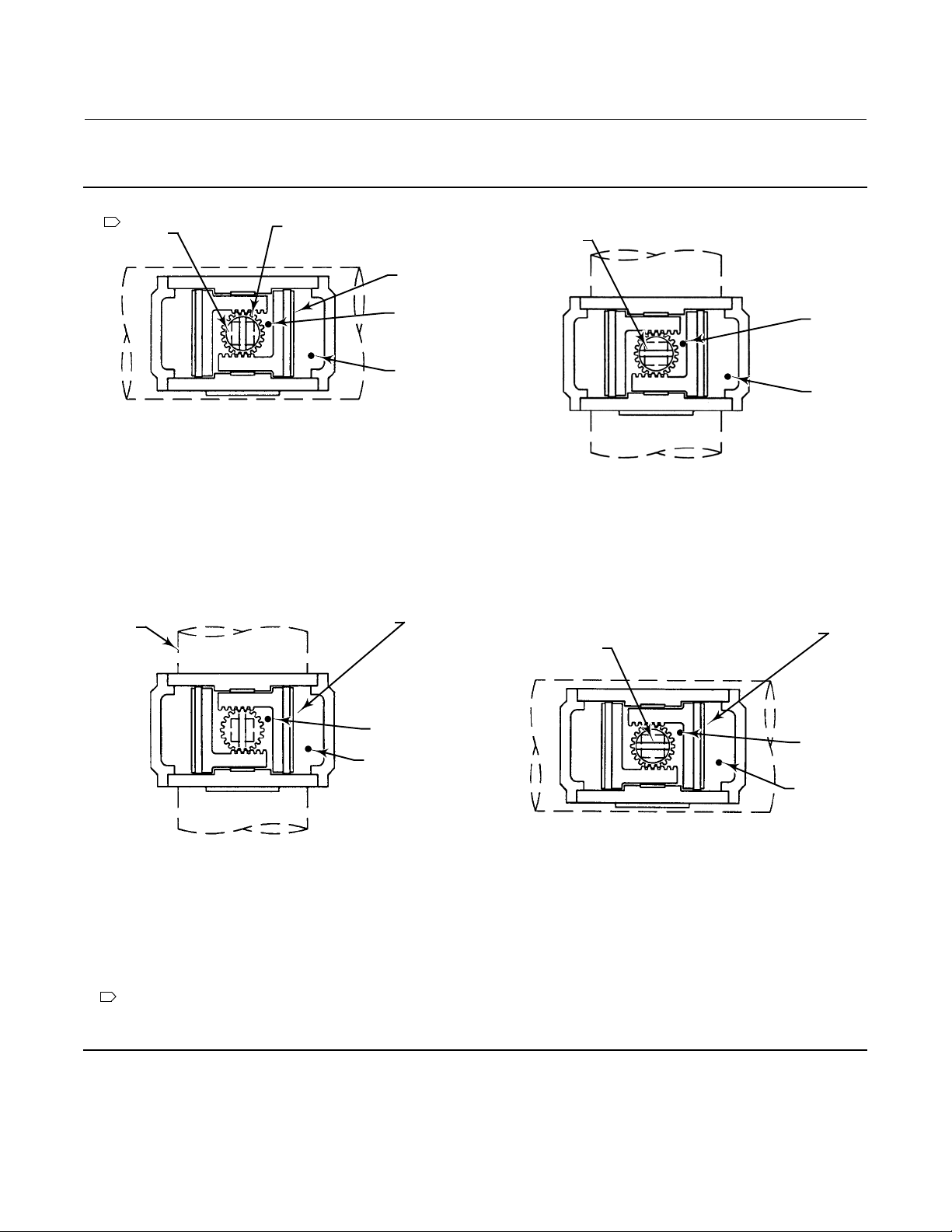

Figure 3. Mounting Style Codes and Positions (Section 1)

DOUBLE-D

POSITION

1

ACTUATOR DRIVE SHAFT

AND PINION GEAR

PISTON

PORT A

CHAMBER

PORT B

CHAMBER

(BOTH E NDS)

1035/El-O-Matic Actuator

THIS CONSTRUCTION CANNOT BE USED

BECAUSE THE HOUSING TRAVEL STOP

CAN NOT BE USED TO ADJUST THE CLOSED

POSITION OF THE DISC, AND THE SLOT IN

THE TOP OF THE ACTUATOR SHAFT WILL

NOT INDICATE DISCPOSITION.

August 2012

END CAP TRAVEL

STOP ADJUSTS OPEN

POSITION

HOUSING TRAVEL

STOP ADJUSTS CLOSED

POSITION

CODE A STANDARD CONSTRUCTION

• CODE A VALVE-ACTUATOR POSITION IS SHOWN.

• ACTUATOR IS PARALLEL WITH PIPELINE (TOP VIEW).

• AIRATPORTAROTATESPINIONGEARCCW,AND

AIRATPORTBROTATES PINION CW.

• HOUSING TRAVEL STOP ADJUSTS VALVE CLOSED

POSITION, AND END CAP TRAVEL STOP ADJUSTS

VALVE OPEN POSITION.

PIPELINE

END CAP TRAVEL

STOP ADJUSTS

CLOSED POSITION

(BOTH ENDS)

2

PISTONS INSTALLED 180_

FROM STANDARD CODE A

ADJUSTMENT

SCREW REMOVED

CODE C OPTIONAL CONSTRUCTION

• CODE C VALVE-ACTUATOR POSITION IS SHOWN.

• ACTUATOR IS PERPENDICULAR WITH PIPELINE.

• AIRATPORTAROTATESPINIONGEARCW,AND

AIRATPORTBROTATESPINIONCCW.

75B0451

A7043

NOTES:

1

THE SHAFT WITH RESPECT TO THE SLOT IN THE TOP OF THE DRIVE SHAFT.

2

3

AND REPLACE IT WITH A CAP SCREW FOR CODE C AND D.

• END CAP TRAVEL STOPADJUSTS VALVE CLOSED

POSITION, AND HOUSING STOP IS NOT AVAILABLE.

DRAWING SHOWS THE ORIENTATION OF THE DOUBLE-D VALVE CONNECTION ON

ADJUST THE TRAVEL STOP SCREWS EQUALLY ON BOTHENDS OF THE ACTUATOR.

FROM A STANDARD CONSTRUCTION CODE A, REMOVE HOUSINGADJUSTMENT SCREW AND LOCKNUT,

ESERIESDOUBLEACTINGACTUATORCODES

PORT A

CHAMBER

PORT B

CHAMBER

(BOTH ENDS)

3

• CODE B VALVE-ACTUATOR POSITION IS SHOWN.

• NOT AVAILABLE.

ACTUATOR DRIVE

1

SHAFT ROTATED 90_

FROM STANDARD

END CAP TRAVEL

STOP ADJUSTS

CLOSED POSITION

(BOTH ENDS)

• CODE DVALVE-ACTUATOR POSITION IS SHOWN.

• ACTUATOR IS PARALLEL WITH PIPELINE (TOP VIEW).

• AIR AT PORT A ROTATES PINION GEAR CW, AND

AIRATPORTBROTATESPINIONCCW.

• END CAP TRAVEL STOP ADJUSTS VALVE CLOSED

POSITION, AND HOUSINGSTOP IS NOT AVAILABLE.

NOT AVAILABLE

CODE B CONSTRUCTION

PISTONS INSTALLED 180_

FROM STANDARD CODE A

ADJUSTMENT

SCREW REMOVED

2

CODE D OPTIONAL CONSTRUCTION

PORT A

CHAMBER

PORT B

CHAMBER

(BOTH ENDS

3

7

1035/El-O-Matic Actuator

August 2012

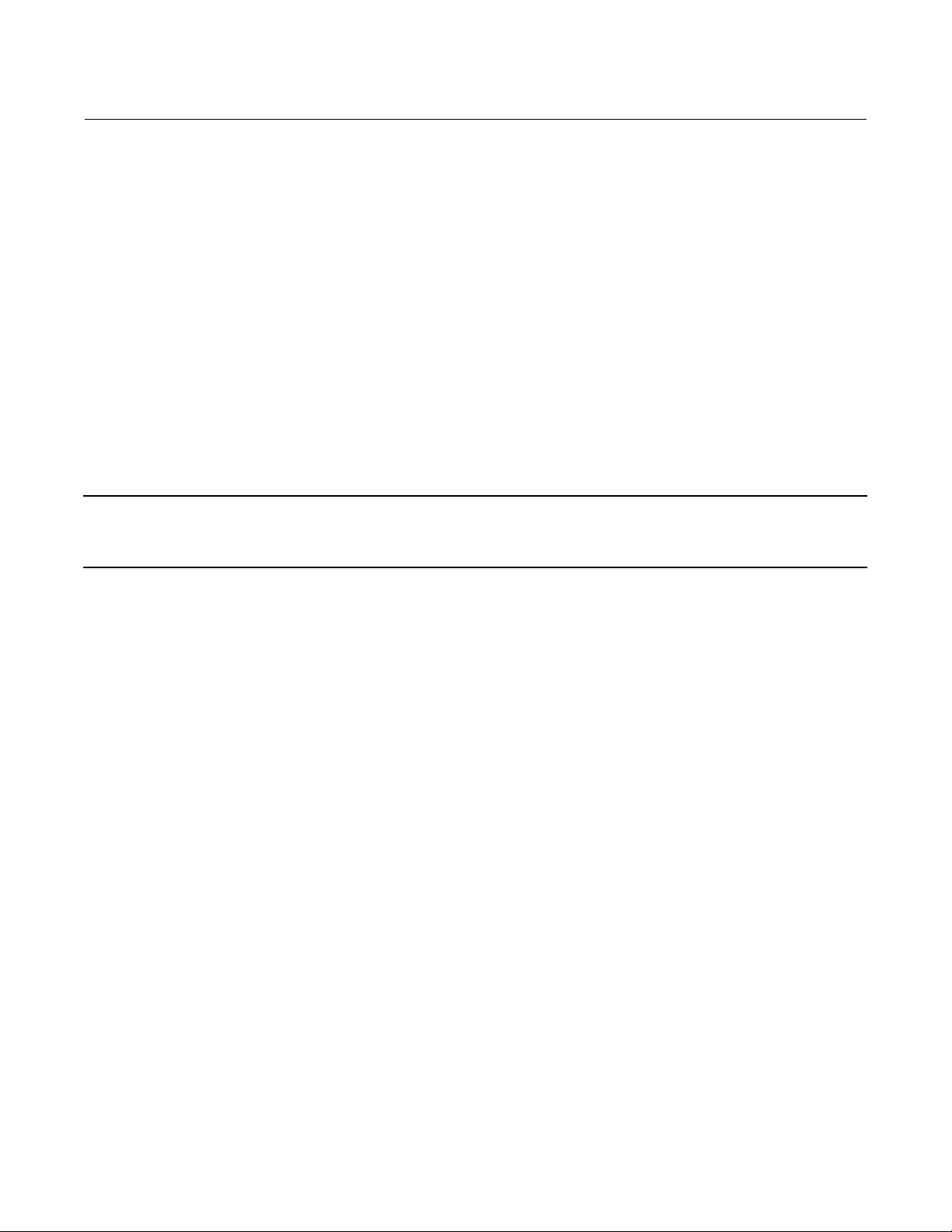

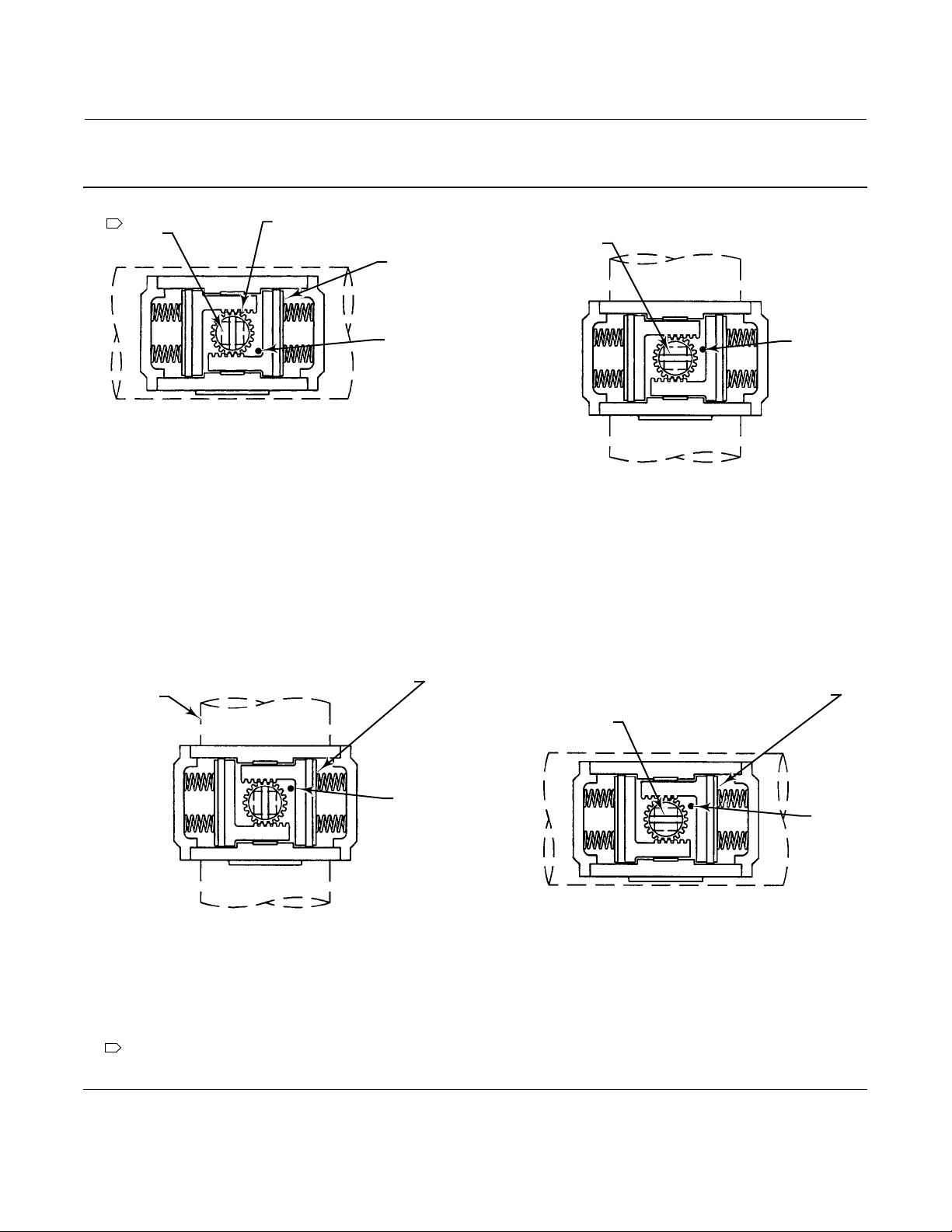

Figure 3. Mounting Style Codes and Positions (Section 2)

1

DOUBLE-D

POSITION

CODE A STANDARD CONSTRUCTION

• CODE A VALVE-ACTUATOR POSITION IS SHOWN.

• ACTUATOR IS PARALLEL WITH PIPELINE (TOP VIEW).

• AIRATPORTAROTATESPINIONGEARCCW,AND

SPRING COMPRESSION ROTATES PINION CW.

• SPRING FAILS DISC TO CLOSED POSITION.

• HOUSING TRAVEL STOP ADJUSTS VALVE CLOSED

POSITION, AND END CAP TRAVEL STOP ADJUSTS

VALVE OPEN POSITION.

ACTUATOR DRIVE SHAFT

AND PINION GEAR

PISTON

PORT A

CHAMBER

HOUSING TRAVEL STOP

ADJUSTS CLOSED POSITION

Instruction Manual

THIS CONSTRUCTION CANNOT BE USED

BECAUSE THE HOUSING TRAVEL STOP

CAN NOT BE USED TO ADJUST THE CLOSED

POSITION OF THE DISC, AND THE SLOT IN

THE TOP OF THE ACTUATOR SHAFT WILL

NOT INDICATE DISC POSITION.

CODE B CONSTRUCTION

• CODE B VALVE-ACTUATOR POSITION IS SHOWN.

• NOT AVAILABLE.

D500243X012

NOT AVAILABLE

PISTONS INSTALLED 180_

PIPELINE

END CAP TRAVEL

STOP ADJUSTS

CLOSED POSITION

(BOTH ENDS)

2

FROM STANDARD CODE A

ADJUSTMENT

SCREW REMOVED

CODE C OPTIONAL CONSTRUCTION

• CODE C VALVE-ACTUATOR POSITION IS SHOWN.

• ACTUATOR IS PERPENDICULAR WITH PIPELINE.

• AIRATPORTAROTATESPINIONGEARCW,AND

75B0442

A7044

SPRING COMPRESSION ROTATES PINION CCW.

• SPRING FAILS DISC TO OPEN POSITION.

• END CAP TRAVEL STOPADJUSTS VALVE CLOSED

POSITION, AND HOUSING STOP IS NOT AVAILABLE.

NOTES:

1

THE SHAFT WITH RESPECT TO THE SLOT IN THE TOP OF THE DRIVE SHAFT.

2

3

AND REPLACE IT WITH A CAP SCREW FOR CODE CAND D.

DRAWING SHOWS THEORIENTATION OF THE DOUBLE-D VALVE CONNECTION ON

ADJUST THE TRAVEL STOP SCREWS EQUALLY ON BOTH ENDS OF THE ACTUATOR.

FROM A STANDARD CONSTRUCTION CODE A, REMOVE HOUSINGADJUSTMENT SCREW AND LOCKNUT,

E SERIES SPRING RETURN ACTUATOR CODES

PORT A

CHAMBER

3

ACTUATOR DRIVE

1

SHAFT ROTATED 90_

FROM STANDARD

END CAP TRAVEL

STOP ADJUSTS

CLOSED POSITION

(BOTH ENDS)

PISTONS INSTALLED 180_

FROM STANDARDCODE A

ADJUSTMENT

SCREW REMOVED

2

CODE D OPTIONAL CONSTRUCTION

• CODE D VALVE-ACTUATOR POSITION IS SHOWN.

• ACTUATOR IS PARALLEL WITH PIPELINE (TOP VIEW).

• AIRATPORTAROTATESPINIONGEARCW,AND

SPRING COMPRESSION ROTATES PINION CCW.

• SPRING FAILS DISC TO OPEN POSITION.

• END CAP TRAVEL STOPADJUSTS VALVE CLOSED

POSITION, AND HOUSING STOP IS NOT AVAILABLE.

PORT A

CHAMBER

3

8

Instruction Manual

D500243X012

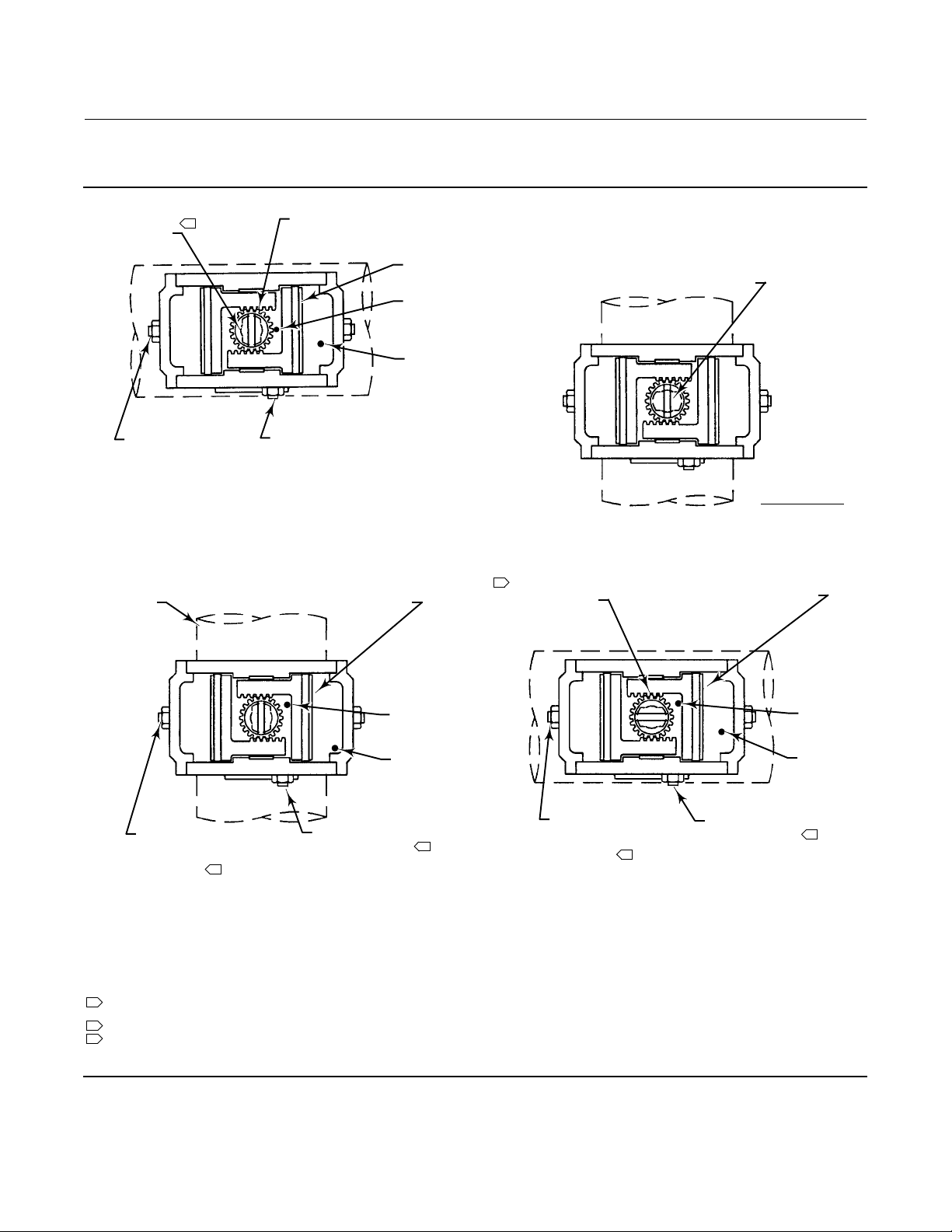

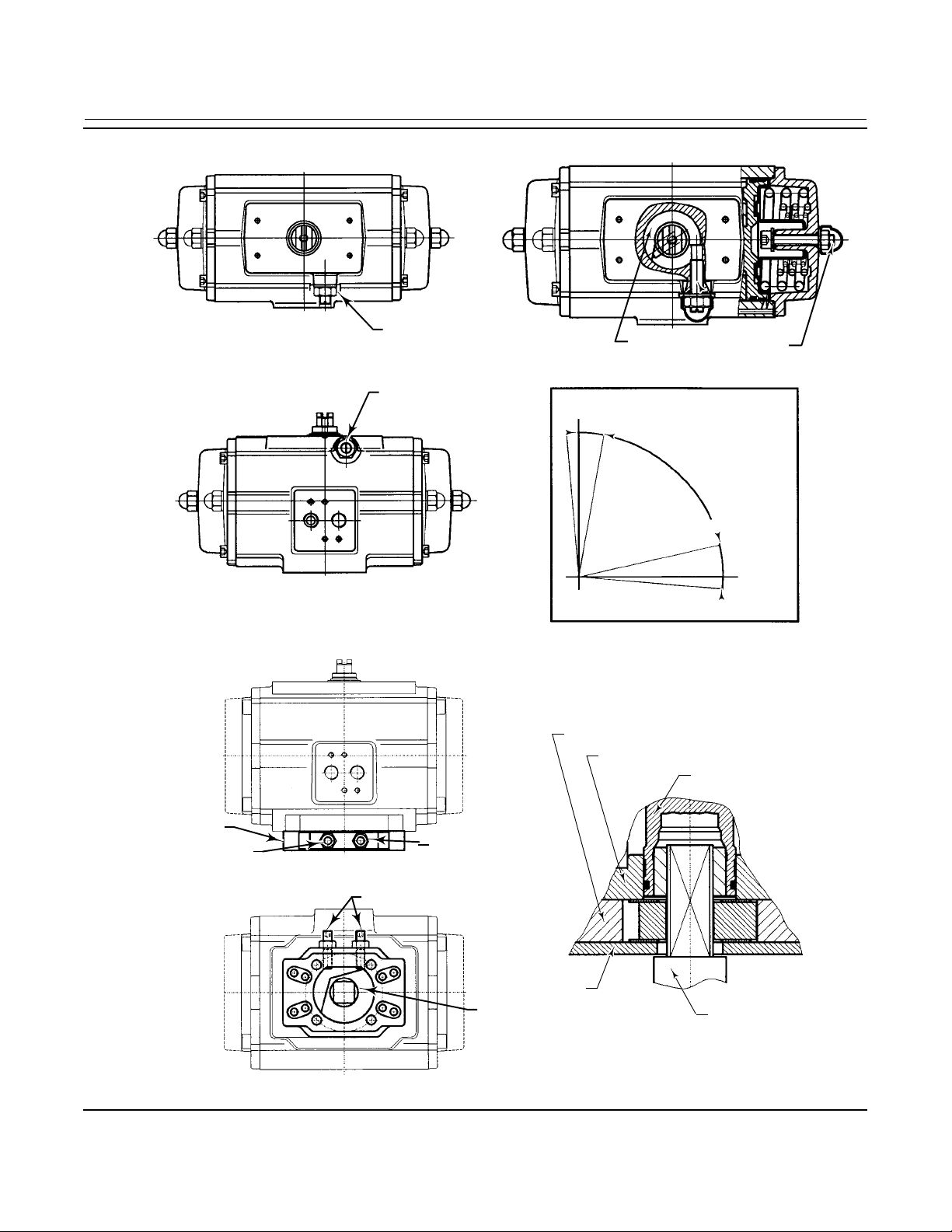

Figure 3. Mounting Style Codes and Positions (Section 3)

1

SQUARE

INSERT

ACTUATOR DRIVE SHAFT

AND PINION GEAR

PISTON

1035/El-O-Matic Actuator

August 2012

ACTUATOR DRIVE

SHAFT ROTATED 90_

FROM STANDARD

CODE A STANDARD CONSTRUCTION

• CODE A VALVE-ACTUATOR POSITION IS SHOWN.

• ACTUATOR IS PARALLEL WITH PIPELINE (TOP VIEW).

• AIR AT PORT A ROTATES PINION GEAR CCW, AND

AIRATPORTBROTATESPINIONCW.

• LIMIT STOP PLATE ADJUSTS BOTH OPEN AND CLOSE POSITIONS.

LSP IS MOUNTEDBETWEEN ACTUATOR AND MOUNTING BRACKET.

SEE FIGURE 4 FOR DETAILS.

PISTONS INSTALLED 180_

PIPELINE

FROM STANDARD CODE A

PORT A

CHAMBER

PORT B

CHAMBER

PORT A

CHAMBER

PORT B

CHAMBER

CODE B OPTIONAL CONSTRUCTION

• CODE B VALVE-ACTUATOR POSITION IS SHOWN.

• ACTUATOR IS PERPENDICULAR WITH PIPELINE.

• AIR AT PORT A ROTATES PINION GEAR CCW, AND

AIRATPORTBROTATESPINIONCW.

• LIMIT STOP PLATE ADJUSTS BOTH OPEN AND CLOSEPOSITIONS. LSP

IS MOUNTED BETWEEN ACTUATOR AND MOUNTING BRACKET. SEE

FIGURE 4 FOR DETAILS.

ACTUATOR DRIVE

SHAFT ROTATED 90_

FROM STANDARD

PISTONS INSTALLED 180_

FROM STANDARDCODE A

PORT A

CHAMBER

PORT B

CHAMBER

PORT A

CHAMBER

PORT B

CHAMBER

CODE C OPTIONAL CONSTRUCTION

• CODE C VALVE-ACTUATOR POSITION IS SHOWN.

• ACTUATOR IS PERPENDICULAR WITH PIPELINE.

• AIR AT PORT A ROTATES PINION GEARCW, AND

AIR AT PORT B ROTATES PINION GEAR CCW.

• LIMIT STOP PLATE ADJUSTS BOTH OPEN AND CLOSE POSITIONS.

LSP IS MOUNTEDBETWEEN ACTUATORAND MOUNTING BRACKET.

SEEFIGURE4FORDETAILS.

75B0452

A7045

NOTES:

1

ON THE SHAFT WITH RESPECT TO THE SLOT IN THE TOP OF THE DRIVE SHAFT.

DRAWING SHOWS THE ORIENTATION OF THE SQUARE INSERT VALVE CONNECTION

P SERIES DOUBLE ACTING ACTUATOR CODES

CODE D OPTIONAL CONSTRUCTION

• CODE D VALVE-ACTUATOR POSITION IS SHOWN.

• ACTUATOR ISPARALLEL WITH PIPELINE(TOP VIEW).

• AIR AT PORT A ROTATES PINION GEAR CW, AND

AIR AT PORT B ROTATESPINION CCW.

• LIMIT STOP PLATE ADJUSTS BOTH OPEN AND CLOSE POSITIONS.

LSP IS MOUNTED BETWEEN ACTUATOR AND MOUNTING BRACKET.

SEEFIGURE4FORDETAILS.

9

1035/El-O-Matic Actuator

August 2012

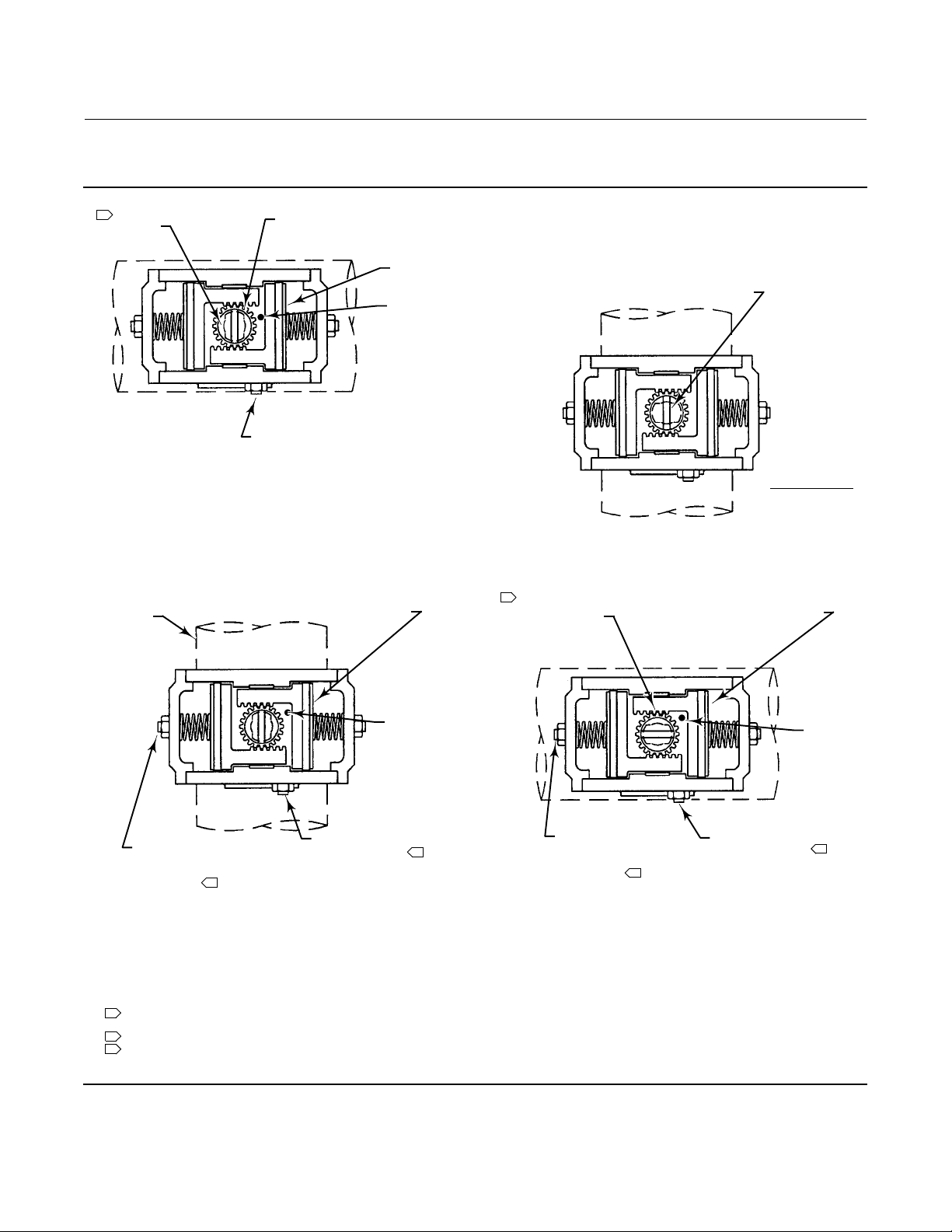

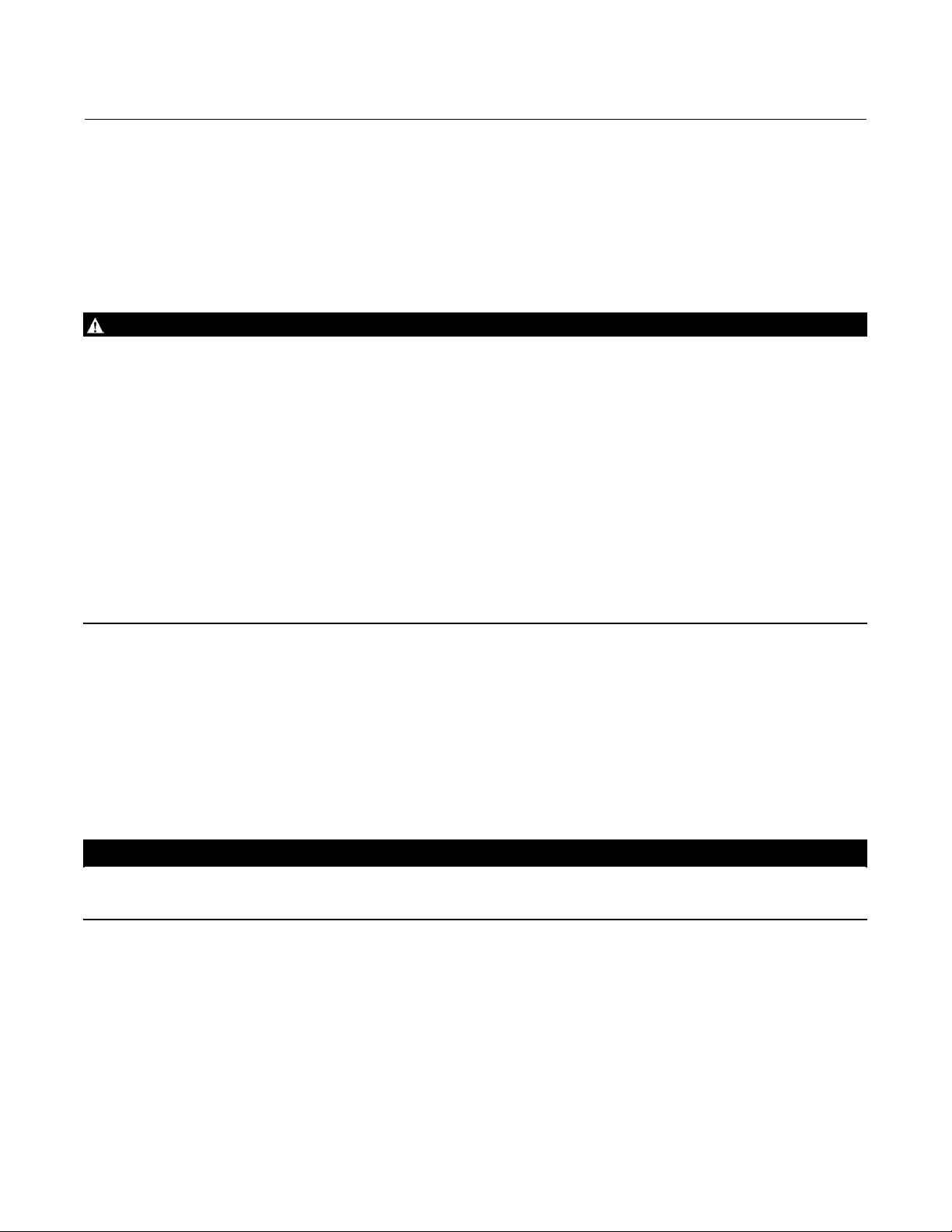

Figure 3. Mounting Style Codes and Positions (Section 4)

SQUARE

1

INSERT

ACTUATOR DRIVE SHAFT

AND PINION GEAR

PISTON

Instruction Manual

D500243X012

ACTUATOR DRIVE

SHAFT ROTATED 90_

FROM STANDARD

CODE A STANDARD CONSTRUCTION

• CODE A VALVE-ACTUATOR POSITION IS SHOWN.

• ACTUATOR IS PARALLEL WITH PIPELINE (TOP VIEW).

• AIR AT PORT A ROTATES PINION GEAR CCW, AND

SPRING COMPRESSION ROTATESPINION CW.

• SPRING FAILS DISC TO CLOSED POSITION.

• LIMIT STOP PLATE ADJUSTS BOTH OPEN AND CLOSE POSITIONS.

LSP IS MOUNTED BETWEEN ACTUATOR AND MOUNTING BRACKET.

SEEFIGURE4FORDETAILS.

PISTONS INSTALLED 180_

FROM STANDARD CODE A

PIPELINE

PORT A

CHAMBER

• CODE B VALVE-ACTUATOR POSITION IS SHOWN.

• ACTUATOR IS PERPENDICULAR WITH PIPELINE.

• AIR AT PORT A ROTATES PINION GEAR CCW, AND

SPRING COMPRESSION ROTATES PINION CW.

• SPRING FAILS DISC TO CLOSED POSITION.

• LIMIT STOP PLATE ADJUSTS BOTH OPEN AND CLOSE POSITIONS.

LSP IS MOUNTED BETWEENACTUATOR ANDMOUNTING BRACKET.

SEE FIGURE 4 FOR DETAILS.

ACTUATOR DRIVE

SHAFT ROTATED 90_

FROM STANDARD

PORT A

CHAMBER

CODE B CONSTRUCTION

PISTONS INSTALLED 180_

FROM STANDARD CODE A

CODE C OPTIONAL CONSTRUCTION

• CODE C VALVE-ACTUATOR POSITIONIS SHOWN.

• ACTUATOR IS PERPENDICULAR WITH PIPELINE.

• AIR AT PORT A ROTATES PINION GEAR CW, AND

SPRING COMPRESSION ROTATESPINION CCW.

• SPRING FAILS DISC TOOPEN POSITION.

• LIMIT STOP PLATE ADJUSTS BOTH OPEN AND CLOSE POSITIONS.

75B0443

A7046

NOTES:

ON THE SHAFT WITH RESPECT TO THE SLOT IN THE TOP OF THE DRIVE SHAFT.

LSP IS MOUNTEDBETWEEN ACTUATORAND MOUNTING BRACKET.

SEE FIGURE 4 FOR DETAILS.

1

DRAWING SHOWS THEORIENTATION OF THE SQUARE INSERT VALVE CONNECTION

P SERIES SPRING RETURN ACTUATOR CODES

10

PORT A

CHAMBER

CODE D OPTIONAL CONSTRUCTION

• CODE D VALVE-ACTUATOR POSITIONIS SHOWN.

• ACTUATOR IS PARALLEL WITH PIPELINE (TOP VIEW).

• AIR AT PORT A ROTATES PINION GEARCW, AND

SPRING COMPRESSION ROTATES PINION CCW.

• SPRING FAILS DISC TO OPEN POSITION.

• LIMIT STOP PLATE ADJUSTS BOTH OPEN AND CLOSE POSITIONS.

LSP IS MOUNTED BETWEENACTUATOR ANDMOUNTING BRACKET.

SEEFIGURE4FORDETAILS.

PORT A

CHAMBER

Instruction Manual

D500243X012

Figure 4. Travel Stop Adjustments

1035/El-O-Matic Actuator

August 2012

TOP VIEW

SIDE VIEW

LOCK NUT

HOUSING ADJUSTMENT

OPEN

3_ 10_

ADJUSTABLE RANGE

DUAL STOP DETAIL FOR E-SERIES ACTUATORS

STOP PLATE

STROKE

ADJUSTMENT

CAM

STOP 2

ACTUATOR BASE

END CAP

ADJUSTMENT

STOP 1

15_

3_

CLOSED

DRIVE SHAFT

LIMIT STOP PLATE

STOP ADJUSTMENT 1

ELO A 1.501.055/96

ELO A 1.503.055/96

A6952-1

STOP ADJUSTMENT 2

SIDE VIEW

LOCKNUTS

MOUNTING

BRACKET

CAM

BOTTOM VIEW

LIMIT STOP PLATE DETAIL FOR P SERIES ACTUATORS

DRIVE ADAPTOR

11

1035/El-O-Matic Actuator

August 2012

Figure 5 . Code A Assemblies

Instruction Manual

D500243X012

A7047

AB

DOUBLE ACTING SPRING RETURN

AB

Troubleshooting

If the actuator does not function, make the following checks:

1. Check for worn teeth on piston racks, if the actuator exhibits excessive amounts of backlash. If worn, replace

piston/gear rack assembly.

2. Check supply pressure to ensure the air supply is reaching the actuator. Place a gauge in the line at the inlet of the

actuator. Monitor the gauge for unexpected pressure drops when operating pressure is applied to the actuator.

3. Check piston seal leakage. For spring return actuators , piston seal leakage will show at port B when port A is

pressurized. For double acting actuators, piston seal leakage will show at port B when port A is pressurized, or vice

versa.

4. Check actuator movement. Remove the actuator from the valve. Apply reduced air pressure [0.7 to 1.0 bar (10 to

15 psi) for double acting, or 1.4 to 2.0 bar (20 to 30 psi) for spring return] to see if the actuator will cycle under a

no-load condition.

D If the actuator cycles under a no-load condition, please refer to the valve instruction manual for valve

troubleshooting or contact your Emerson Process Management sales office.

D If the spring set number is 5 or 6, it may not cycle with the reduced air pressure amounts listed above and may

require retesting with up to 5.5 bar (80 psi) to stroke a full 90 degrees.

D If the actuator does not

cycle, disassemble the actuator using the Actuator Disassembly procedures. Inspect and

replace parts as necessary.

If the actuator and valve are moving freely, reassemble the valve/actuator assembly and re-test. If unit still fails to

operate, consult your Emerson Process Management sales office for assistance.

12

Instruction Manual

D500243X012

1035/El-O-Matic Actuator

August 2012

Maintenance

Actuators parts are subject to normal wear and must be inspected and replaced as necessary. The frequency of

inspection and replacement depends upon the severity of service conditions. Instructions are given in subsequent

sections for disassembly and assembly of the actuator and for inspecting the actuator parts.

WARNING

Avoid personal injury from sudden release of process pressure. Before performing any maintenance operations:

D Do not remove the actuator from the valve while the valve is still pressurized.

D Always wear protective gloves, clothing, and eyewear when performing any maintenance operations to avoid personal

injury.

D Disconnect any operating lines providing air pressure, or a control signal to the actuator. Be sure the actuator cannot

suddenly open or close the valve during maintenance.

D Use bypass valves or completely shut off the process pressure. Relieve process pressure on both sides of the valve. Drain

the process media from both sides of the valve.

D Vent the power actuator loading pressure and relieve any actuator spring precompression.

D Use lock-out procedures to be sure that the above measures stay in effect while you are work on the equipment.

D The valve packing area may contain process fluids that are pressurized, even when the valve has been removed from the

pipeline. Process fluids may spray out under pressure when removing the packing hardware or packing rings.

D Check with your process or safety engineer for any additional measures that must be taken to protect against process

media.

Actuator Disassembly

Remove the actuator from the valve, and remove any other auxiliary equipment from the actuator. (Note the positions

of the mounting bracket and accessories for re-assembly). Steps explaining the disassembly and assembly of parts

apply to both ends of the actuator. If necessary, refer to the valve instruction manual for removing and replacing the

valve in the pipeline.

Key numbers are shown in figure 11 for E Series, and figure 12 for P Series actuators, unless otherwise noted.

CAUTION

Butterfly valves must be in the closed position before attempting to remove them from the pipeline. The valve disc can be

damaged if the disc is not moved to the closed position.

1. Remove the actuator mountingbracketandanyaccessories.

2. When removing the actuator end caps, carefully follow the steps below.

Operationally check the actuator to ensure that the pistons are moved all the way to the center (towards the drive

shaft), before removing the actuator end caps. Use the index mark on the top of the drive shaft (see figure 4).

a. For Double Acting E and P Series Actuators: Remove socket head screws from both end caps with a metric hex

key. After the screws are removed, gently pry off each end cap. Be careful not to damage the end cap sealing

surfaces.

13

1035/El-O-Matic Actuator

August 2012

Instruction Manual

D500243X012

b. For Spring Return E Series Actuators

It is very important to ensure that the springs are fully extended by retracting the piston (key 2) inwards toward the

drive shaft (key 3). Refer to figure 6.

WARNING

The pre-loaded spring pressure rests on the pistons when they are extended outward. If the end cap screws are removed

the spring loading is reduced, the end cap (key 5) can fly off the end of the actuator causing personal injury or

before

property damage.

Ensure that the pistons are moved fully toward the drive shaft. If this is not possible, provide a means of containing the end

capwhileremovingthesocketheadcapscrews.

The springs are retained within the end cap by the spring holder (key 9).

D Unscrew end cap socket head screws (key 36) a few turns

. Be sure the spring compression is resting on the socket

head cap screws. Equally release the spring compression while removing the socket head cap screws. The spring

precompression should be released before the screws are completely removed. Remove the spring cap assembly

from the actuator body.

Figure 6. Spring Return End Cap Assembly

TRAVEL STOP

SCREW

(KEY 37)

HEX (LOCK)

NUT

(KEY 38)

WASHER

(KEY 34)

ELO A4.204.03

A7038

NOTE:

THE PISTON IS SHOWN IN THE FULLY RETRACTED POSITION.

SPRINGS ARE FULLYEXTENDED AND CONTAINED WITHIN THE SPRING HOLDER BYTHE WASHER (KEYS 9 AND 34).

THE WASHER KEEPS THE SPRING RETAINER CONNECTED TOTHE END CAP.

PISTON

(KEY 2)

SPRING HOLDER

(KEY 9)

Note

If re-using springs, mark the springs and their location during disassembly. The springs must be replaced in the same location as

removed when re-assembling the actuator (see figure 8).

D Disassembly of the spring end cap assembly: Remove the nut cover (key 42). Remove the hex (lock) nut, washer,

andO-ring(keys38,22,and29).Springprecompressiononthespringholderisreleasedwhileunscrewingthe

14

Instruction Manual

D500243X012

1035/El-O-Matic Actuator

August 2012

travel stop screw (key 37). When the travel stop screw (key 37) is removed from the end cap assembly, it will release

the spring clip, washer (key 34), and spring(s) (key 9, 34, and 6, 7, and 8 if used). If reusing springs, return them to

thesamelocationasremoved.Ifreplacingsprings,replaceallthespringsinbothendcaps.

c. For Spring Return P Series Actuators

It is very important to ensure that the springs are fully extended by retracting the piston (key 2) inwards toward the

drive shaft (key 3).

Operationally check the actuator to ensure that the pistons are moved all the way to the center (towards the drive

shaft), before removing the socket head cap screws (key 25, figure 12). Read the steps in this sub-section before

removing the end cap screws (key 25).

WARNING

The pre-loaded spring pressure rests on the pistons when they are extended outward. If the end cap screws are removed

the spring loading is reduced, the end cap (key 5) can fly off the end of the actuator causing personal injury or

before

property damage.

Ensure that the pistons are moved fully toward the drive shaft. If this is not possible, provide a means of containing the end

capwhileremovingthesocketheadcapscrews.

D Thespringsarein-betweentheendcapandpiston.Becarefulwhenremovingtheendcapasthespringsmayfall

out of the body or end cap. If reusing the springs, re-install them in the same position as removed.

D On a flat working surface, block-up the actuator so it is vertical to avoid the springs falling out of the actuator while

removing the end cap. Repeat on both ends of the actuator.

Note

If re-using springs, mark the springs and their location during disassembly. The springs must be replaced in the same location as

removed when re-assembling the actuator (see figure 9).

D Unscrew end cap socket head screws (key 25) a few turns. Be sure the spring compression is resting on the socket

head cap screws. Equally release the spring compression while removing the socket head cap screws. The spring

precompression should be released before the screws are completely removed. Remove the spring cap assembly

from the actuator body.

3. Clean, inspect, and/or obtain replacement parts. When reassembling the actuator, replace all soft parts provided in

the Parts Kits listed at the end of this manual.

4. Removetheadjustabletravelstop/housingadjustment(seefigure4).

5. Removing the Pistons: The two pistons (key 2) can now be removed by rotating the drive shaft, moving the piston

assemblies outward until the pinion gear has released them.

The gear rack in E Series actuators is machined into the piston, and so does not have to be removed separately. If the

gear rack is damaged, replace both pistons.

Removing the Drive Shaft

1. Remove the spring clip (E Series key 35, P Series key 20) with a pin spanner. Use caution, as the spring clip is under a

great deal of tension. Also, remove the E Series washers (keys 27 and 21) or P Series washer and O-ring (keys 21 and

19) from the shaft.

15

1035/El-O-Matic Actuator

August 2012

2. Remove the drive shaft (E Series key 3, P Series key 5, figures 11 and 12) through the bottom of the actuator.

3. For P Series actuators: remove the Piston Gear Rack. The gear rack in the P Series actuators is a separate part (key 6)

and is held in place with a socket head cap screw (key 22). Both gear racks can be removed and replaced by

removing them from the pistons.

4. Ensure that all actuator parts are clean and ready for assembly. Inspect the actuator body and component parts for

wear or scratches. If the inside wall of the body is scored the actuator will leak. Light traces of scoring, barely

detectable to the touch, are acceptable. Obtain replacement parts from your Emerson Process Management sales

office.

Instruction Manual

D500243X012

Actuator Assembly

Repair Kits

Repair kits are available for re-assembly. The large repair kit provides O-rings, guide bands, bushings, and bearings.

The small kit provides a set of soft parts only for the actuator. Repair kits are available for standard, low temperature,

and high temperature actuators. Refer to the Repair Kits table at the end of this manual.

Lubrication

Refer to the Specifications table for temperature ranges.

Standard and High Temperature Actuator: Lubricate the actuator moderately with a complex calcium sulphonate

grease suitable for the application's temperature range. Use the Parts Kit for the appropriate temperature application.

Low Temperature Actuator: Lubricate the actuator moderately with low temperature silicone grease. Use the Parts Kit

for standard and low temperature applications.

Lubricate the actuator moderately with an appropriate grease. Apply a light film of grease to all O-rings, gear racks,

bearings, bushings, and guide bands. In the following steps, lubricate all moving parts during re-assembly.

Installing the Drive Shaft

ESeriesactuators:Some constructions use a Dual Stop arrangement. The housing adjustment screw is used with a pin

located in the drive shaft, and a stroking adjustment cam mounted on the shaft for the stop. Ensure the cam is aligned

correctly with respect to the housing adjustment screw. Use figure 4 as a guide for alignment.

1. Replace the top and bottom shaft bearings (keys 20 and 12) in the actuator body.

2. Insert the adjustment screw, if applicable, and thread it into the body a few turns, and hand tighten the hex nut. The

adjustment screw should be loose enough to allow full travel of the cam and pistons.

3. Placethecam(seefigure4)onthesmallendofthedriveshaft.Positionthecamontheshaftsothepinislocatedin

the open section of the cam.

4. Install the O-rings and guide bushing on the drive shaft. The guide bushing may have to be cleaned of grease, rolled

tightly around the drive shaft and held in place while inserting into the actuator housing.

CAUTION

When inserting the drive shaft, be sure to keep the O-Rings from becoming trapped and damaged between the pinion and

the actuator body. To verify the condition of the O-Rings at the end of the installation, cycle the actuator 5 times and run a

soap bubble test on the seal on both the top and bottom of the drive shaft.

16

Instruction Manual

D500243X012

Note

Some constructions do not have a housing adjustment screw. If your construction does not use the adjustment screw, install the

drive shaft, and go to step 6 below.

1035/El-O-Matic Actuator

August 2012

5. Note the alignment of the cam with respect to the housing adjustment screw while installing the shaft into the

body. Install the drive shaft.

6. Install the washer, thrust washer, and spring clip (keys 27, 21 and 35) onto the drive shaft. Use the pin spanner

carefully to install the spring clip.

7. Go to the Installing Pistons steps below.

PSeriesActuators(without a 1080) use a Limit Stop Plate (see figure 4) for travel stops. The cam for the travel stops is

mounted on the actuator after the actuator is fully assembled.

1. Replace the top and bottom shaft bearings in the actuator body. Install the O-ring and guide bushing in the shaft.

The guide bushing may have to be cleaned of grease, rolled tightly around the drive shaft and held in place while

inserting into the actuator housing.

2. Insertthesmallendofthedriveshaft(key5) into the bottom of the actuator housing.

3. Install the thrust washer, and spring clip (keys 21 and 20) onto the drive shaft. Use the pin spanner carefully to

install the spring clip.

Installing Pistons

Figure7showsthealignmentoftheslotinthetopoftheshaftwiththepistonsforcodeAconstructions.Seefigure3

for piston and slot alignment for other constructions.

1. Install the O-ring and guide bushing on both pistons. For P Series actuators: you will need to install the gear racks on

the pistons if they were removed.

2. Lightly lubricate parts and inside of actuator bore before final assembly.

3. If you have not already done so, follow the steps in the Installing the Drive Shaft section.

4. Very carefully align the pistons square to the actuator housing.

5. Align the drive shaft so that the teeth on the center gear will “pick-up” the piston assembly rack teeth when turning

the top extension of the center gear clockwise.

To ensure proper meshing of teeth, rotate the index mark on the drive shaft 45 degrees beyond the open mark on the

top of the housing.

Note

Figure 3 shows the different orientation of the piston in relationship to the slot in the shaft, versus the actuator body.

6. With the piston assemblies in the actuator body, gently push them simultaneously into the housing. Turn the top

shaft extension clockwise. At the proper point of engagement between the center gear and piston assemblies, both

piston assemblies will move toward the center of the housing.

7. Once the drive shaft and pistons are properly engaged, ensure smooth movement at 90 degree operation can occur

without moving the pistons out of the actuator body. Do this by turning the top shaft extension to the closed

position and back a few times.

17

1035/El-O-Matic Actuator

August 2012

Instruction Manual

D500243X012

8. If not already done, replace the washer over the top shaft extension. Install the spring clip onto the mating groove

on the top shaft extension with a pin spanner.

9. Replace the actuator end caps taking care to properly seal them with O-rings. Use the metric hex keys to replace the

socket head screws.

10. The adjustment screw and nut, if applicable, shouldnowbesettostoptravelatthedesiredposition.

Changing Rotation Direction

Use the disassembly and assembly procedures provided in this section. In general, you will be removing the pistons,

turning them 180 degrees and reinstalling them. This action changes the direction of rotation. In figure 3, compare

Code A and Code D piston positions.

Figure 7. Installing Actuator Pistons

0_

45_

NOTE:PISTONSARESHOWNINTHECODEAPOSITION

75B0509-A

A7042

START

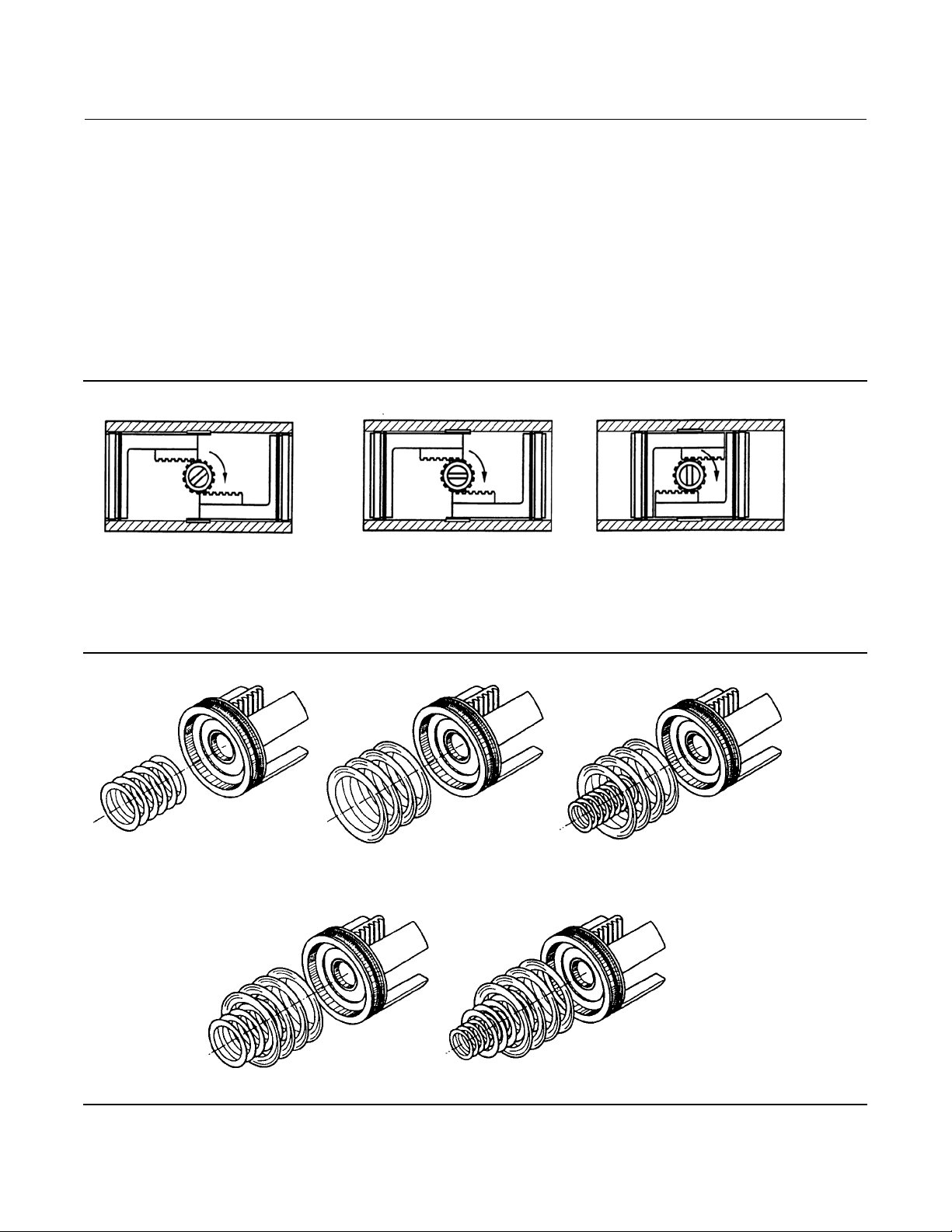

Figure 8. Spring Arrangement for E Series Actuators

PISTONS AT

BODY ENDS

90_

PISTONS AT

BODY CENTER

18

ELO A 4.202

A7040

SPRING SET 2

MID SPRING

(OR MID +INNER SPRING AS AN ALTERNATE)

SPRING SET 5

MID AND OUTER SPRING

SPRING SET 3

OUTER SPRING

SPRING SET 4

INNER AND OUTER SPRING

SPRING SET 6

INNER, MID AND OUTER SPRING

Instruction Manual

D500243X012

Figure 9. Spring Arrangement for P Series Actuators

1035/El-O-Matic Actuator

August 2012

8SPRINGS

12 SPRINGS

ELO A 4.201

A7041-1

Figure 10. Bypass Valve

1F1137 - ANGLE NEEDLE VALVE

10 SPRINGS

14 SPRINGS

1C4882 - PIPE NIPPLE

4 X 1/4-NPT

E0059

BYPASS ASSEMBLY

SCALE 1=1

SECTION C-C

11A8741

5/8X3/4X1/16

19

1035/El-O-Matic Actuator

August 2012

Instruction Manual

D500243X012

Spring Return E Series Actuators

Spring return E Series actuators use from two to a maximum of six springs. One, two, or three springs are inserted into

each end cap (see figure 8). R efer to the nameplate to verify the number of springs required.

Each end cap spring pack incorporates a travel stop adjustment screw (key 37). This may be used to adjust the end of

the stroke for valve seating in either the “fail open” or “fail closed” arrangements.

1. When installing used springs in a spring return actuator, ensure that the springs are replaced in the identical

position from which they were removed.

2. If a spring return actuator is being repaired due to spring failure, replace all the springs in the actuator.

3. To assemble the spring assembly, install the spring(s) into the end cap. Be sure that all springs are seated correctly

intheendcap(key5)andinthespringholder(key9).Placethespringholderandwasherontopofthesprings,and

install the adjustment screw (keys 34 and 37).

4. Place the end cap bolts through the retention holes of the end cap. If converting a double acting unit to a spring

return unit, be sure to use new end cap screws (key 25, figure 12).

5. Engage the bolts with the tapped holes in the actuator body by forcing down slightly on the cap. Tighten each bolt

in small, equal amount of turns, compressing the springs equally.

Spring Return P Series Actuators

Spring return actuators use from four to a maximum of fourteen springs. One through seven springs are inserted into

each end cap (see figure 9). R efer to the nameplate to verify the number of springs required.

1. When installing used springs in a spring return actuator, ensure that the springs are replaced in their identical

position in the end cap from where they were removed.

Note

When less than the standard number of seven springs are used in each end cap, the springs should be positioned as shown in

figure 9.

2. If a spring return actuator is being repaired due to a failed spring, replace all the springs in the actuator.

3. Ensure that the pistons are stroked fully inward, towards the center of the actuator (this may be done by rotating

the actuator shaft with a wrench).

4. When replacing the springs in a P Series spring-return actuator, position the actuator so that it stands on one end.

5. Place the springs on the piston face, engaging them with the alignment nibs cast into the piston.

6. Place the end cap over the springs. Align them with the corresponding nibs which are cast into the end cap.

7. If converting a double acting unit to a spring return unit, be sure to use new end cap screws (key 25, figure 12).

Install the end cap screws.

8. Engage the screws w ith the tapped holes in the actuator body by forcing down slightly on the cap. Tighten each

bolt in small, equal amount of turns, compressing the springs equally.

Installing the Bypass Valve

The optional bypass valve should be used when pressure needs to be stabilized between port A and port B (see figure

10). The following steps provide installation of the bypass valve. Removing the bypass valve simply requires

performing these steps in the reverse order.

20

Instruction Manual

D500243X012

1. Position the O-rings between the bypass block and the Namur mounting area. Attach the screws through the

bypass block to the Namur mounting area.

2. Attach the tubing to the fittings.

3. Attach the angle needle valve and the bypass block to the tubing.

4. Pressure the ports and check for leakage. Check the pressure to both ports A and B.

1035/El-O-Matic Actuator

August 2012

Parts Ordering

Two types of kits are available. The repair kits provide O-rings and guide bushing/bearings, and the O-ring kit provides

the O-rings only. Refer to tables 5 and 6 for kit numbers.

WARNING

Use only genuine Fisher replacement parts. Components that are not supplied by Emerson Process Management should

not, under any circumstances, be used in any Fisher valve, because they may void your warranty, might adversely affect the

performance of the valve, and could cause personal injury and property damage.

Key numbers and part descriptions are shown in tables 7 and 8.

Recommended spare parts are marked with an asterisk (*) following the key number.

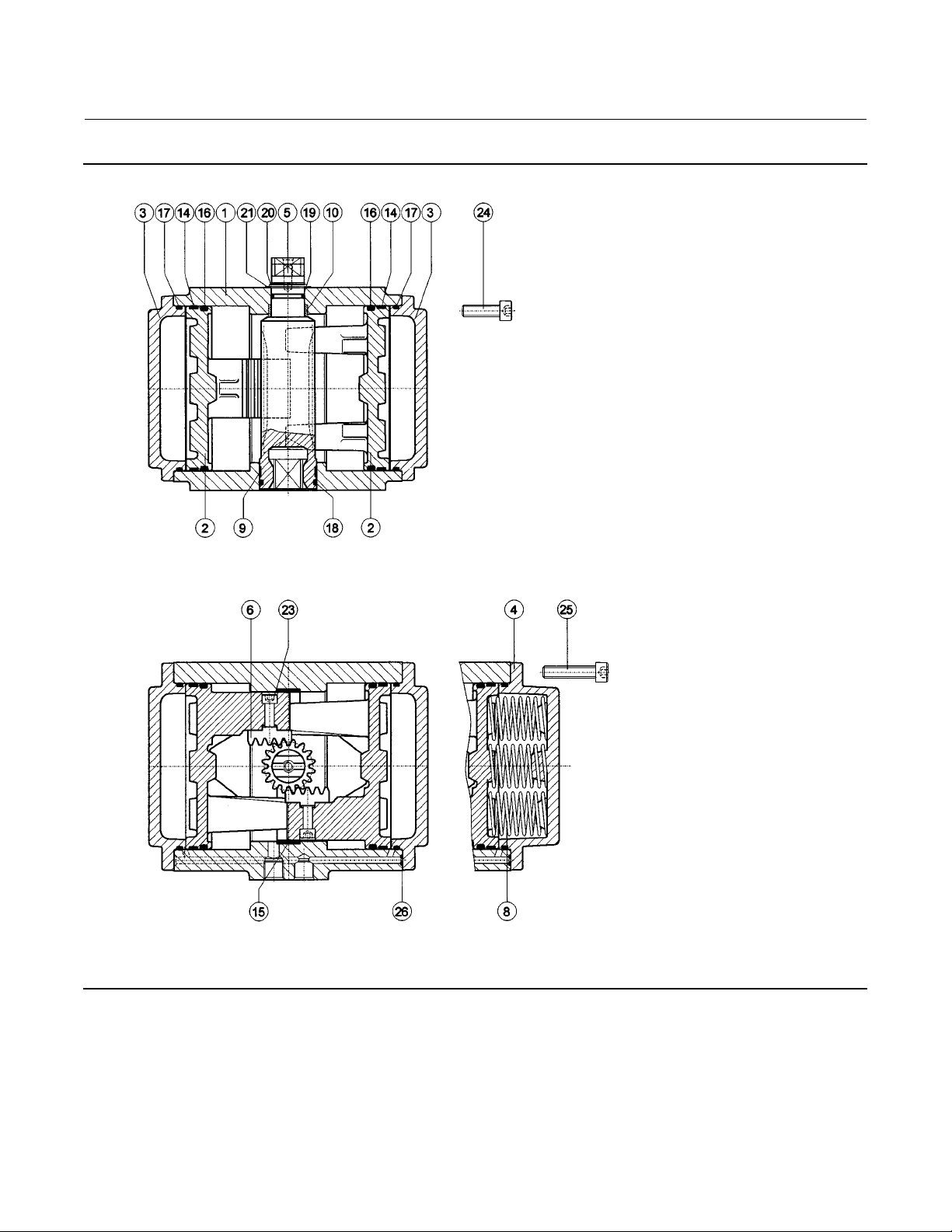

Typical actuator assemblies are shown in figures 11 and 12.

When corresponding with your Emerson Process Management sales office, please identify the Actuator as a Fisher

1035 and provide the actuator serial number located on the nameplate.

21

1035/El-O-Matic Actuator

August 2012

Parts Kits

Table 5. Repair Kits

Actuator

E25 75B0594X012 75B0595X012 75B0596X012

E40 75B0594X022 75B0595X022 75B0596X022

E65 75B0594X032 75B0595X032 75B0596X032

E100 75B0594X042 75B0595X042 75B0596X042

E200 75B0594X052 75B0595X052 75B0596X052

E350 75B0594X062 75B0595X062 75B0596X062

E600 75B0594X122 75B0595X122 75B0596X122

E950 75B0594X132 75B0595X132 75B0596X132

E1600 75B0594X142 75B0595X142 75B0596X142

P2500/P2505 75B0594X102 75B0595X102 75B0596X102

P4000/P4005 75B0594X112 75B0595X112 75B0596X112

Table 6. O-Ring Kits

Actuator High Temperature Fluorocarbon Low Temperature EPDM

E25 75B0592X012 75B0593X012

E40 75B0592X022 75B0593X022

E65 75B0592X032 75B0593X032

E100 75B0592X042 75B0593X042

E200 75B0592X052 75B0593X052

E350 75B0592X062 75B0593X062

E600 75B0592X122 75B0593X122

E950 75B0592X132 75B0593X132

E1600 75B0592X142 75B0593X142

P2500/P2505 75B0592X102 75B0593X102

P4000/P4005 75B0592X112 75B0593X112

Standard Construction

Nitrile O-Rings

High Temperature

Fluorocarbon O-Rings

Instruction Manual

D500243X012

Low Temperature

EPDM O-Rings

22

Instruction Manual

D500243X012

Parts Reference

Table 7. E Series Parts List

Key Number Description Quantity

1

2 Piston, Aluminum alloy 2

3 Drive shaft, Aluminum 1

4 End cap (EDN), Aluminum alloy 2

5 End cap (ESN), Aluminum alloy 2

6 Spring - inner, Steel 2

7 Spring - mid, Steel 2

8 Spring - outer, Steel 2

9 Spring holder, Steel 2

10* Guide band, Nylon 1

11* Guide band, PTFE carbon filled 2

12* Bearing Bushing Bottom, Nylon 1

20* Top bearing bushing, POM

21* Trust washer, POM

22* Washer, PTF 1

23* Washer, PTF 1

22* Body O-ring, Nitrile 2

23* Piston O-ring, Nitrile 2

25* Endcap O-ring, Nitrile 1

26* Shaft Bottom O-ring, Nitrile 1

27* Washer, PTFE 1

28* O-ring, Nitrile 1

29* Endcap O-ring, Nitrile 2

30* Endcap O-ring, Nitrile 2

34 Washer, steel 2

35* Spring clip 1

36 Socket Head Cap Screw, Steel 8

37 Travel Stop Screw (ESN), Steel 2

38 Hex nut, Steel 2

39 Nut cover, Polyethylene 2

40 Travel stop screw (EDN),Screw 2

41 Hex nut, steel 2

42 Nut cover, polyethylene 2

43* O-ring, Nitrile 2

44 Insert 1

---

---

--- Hex (lock) nut, steel (figure 4) 1

--- Hex (lock) nut, polyethylene (figure 4) 1

--- Lubricant, Standard andHigh Temperature Construction CCSG

--- Lubricant, Low TemperatureConstruction

* Recommended spare parts (contained in a repair kit).

1. Polyoxymethylene.

2. Complex Calcium Sulphonate Grease.

Body, If you need an actuator body (key 1) as a replacement part , order by

actuator size, serial number, and desired material. Contact your Emerson sales

office.

(1)

(1)

Housing adjustment screw, steel

(figure 4)

Stroking adjustment cam, steel

(figure 4)

1035/El-O-Matic Actuator

August 2012

1

1

1

1

1

(2)

Low Temperature Silicone Grease

1M5964X0012

23

1035/El-O-Matic Actuator

August 2012

Table 8. P Series Parts List

Key Number Description Quantity

1

2 Piston, Aluminum alloy 2

3 End cap (EDN), Aluminum alloy 2

4 End cap (ESN), Aluminum alloy 2

5 Central drive shaft, steel 1

6 Gear rack, steel 2

8 Spring, steel 14

9* Bearing bushing,Nylon 1

10* Bearing bushing, POM

14* Guide band, PTF 2

15* Guide band, PTF 2

16* Piston O-ring, Nitrile 2

17* End cap O-ring, Nitrile 2

18* Shaft O-ring, Nitrile 1

19* Shaft O-ring, Nitrile 1

20* Springclip, steel 1

21* Trust washer, POM

22 Socket head cap screw 2

24 Socket head cap screw 8

25 Socket head cap screw 8

26* O-ring, Nitrile 2

--- Limit stop plate, steel (figure 4) 1

--- Cam, steel (figure 4) 1

--- Adjustment screw, steel (figure 4) 2

--- Hex (lock) nut, steel (figure 4) 2

--- Socket head cap screw, steel (not shown) 4

--- Drive adapter, steel(figure 4) 1

--- Lubricant, Standard andHigh Temperature Construction CCSG

--- Lubricant, Low TemperatureConstruction

* Recommended spare parts (contained in a repair kit).

1. Polyoxymethylene.

2. Complex Calcium Sulphonate Grease.

Body, If you need an actuator body (key 1) as a replacement part , order by

actuator size, serial number, and desired material. Contact your Emerson sales

office.

(1)

(1)

Instruction Manual

D500243X012

1

1

1

(2)

Low Temperature Silicone Grease

1M5964X0012

24

Instruction Manual

D500243X012

Figure 11. Fisher 1035 E Series Actuator Assembly

1035/El-O-Matic Actuator

August 2012

OPTIONAL CENTER-PLATE

DOUBLE ACTING

NOTE:

PARTS NOT SHOWN ARE HOUSING ADJUSTMENT SCREW, HEX (LOCK) NUT AND

STROKING CAM. REFER TO FIGURE 4 FOR LOCATION OF PARTS.

ELO A 1.101.33 (3-96)

SPRING RETURN

END CAP

25

1035/El-O-Matic Actuator

August 2012

Figure 12. Fisher 1035 P Series Actuator Assembly

Instruction Manual

D500243X012

A 1.101.30 (3-9 6)

SIDE VIEW

DOUBLE ACTING SPRING RETURN

TOP VIEW

26

Instruction Manual

D500243X012

1035/El-O-Matic Actuator

August 2012

27

1035/El-O-Matic Actuator

August 2012

Instruction Manual

D500243X012

Neither Emerson, Emerson Process Management, nor any of their affiliated entities assumes responsibility for the selection, use or maintenance

of any product. Responsibility for proper selection,use, and maintenance of any product remainssolely with the purchaser and end user.

Fisher and POSI-SEAL are marks owned by one of the companies in the Emerson Process Management business unit of Emerson Electric Co. Emerson Process

Management, Emerson, and the Emerson logo are trademarks and servicemarks of Emerson ElectricCo. Allother marks are the property of their respective

owners.

The contents of this publication are presented for informational purposes only, and while every effort has been made to ensure their accuracy, they arenot

to be construed as warranties or guarantees, express or implied, regarding the products or services described herein or their use or applicability. All sales are

governed by our terms and conditions, which are availableupon request. We reserve the right to modify or improve the designs or specifications of such

products at any time without notice.

Emerson Process Management

Marshalltown, Iowa 50158 USA

Sorocaba, 18087 Brazil

Chatham, Kent ME4 4QZ UK

Dubai, United Arab Emirates

Singapore 128461 Singapore

www.Fisher.com

28

E 1997, 2012 Fisher Controls International LLC. All rights reserved.

Loading...

Loading...