Instruction Manual

MCK-1023

May 1980

Type N201

Type N201

Install, use, and maintain this equipment

according to Fisher instructions and all

federal, state, local laws and codes, and

NFPA Pamphlet 58. Periodic inspection and

maintenance is essential.

Introduction

Type N201 automatic cylinder filling valve is supplied

completely piped up, and consists of a filler valve assembly,

two Type 67 regulators with pressure gauges, a trip valve,

and special parts for alternate scale installations.

Principle of Operation

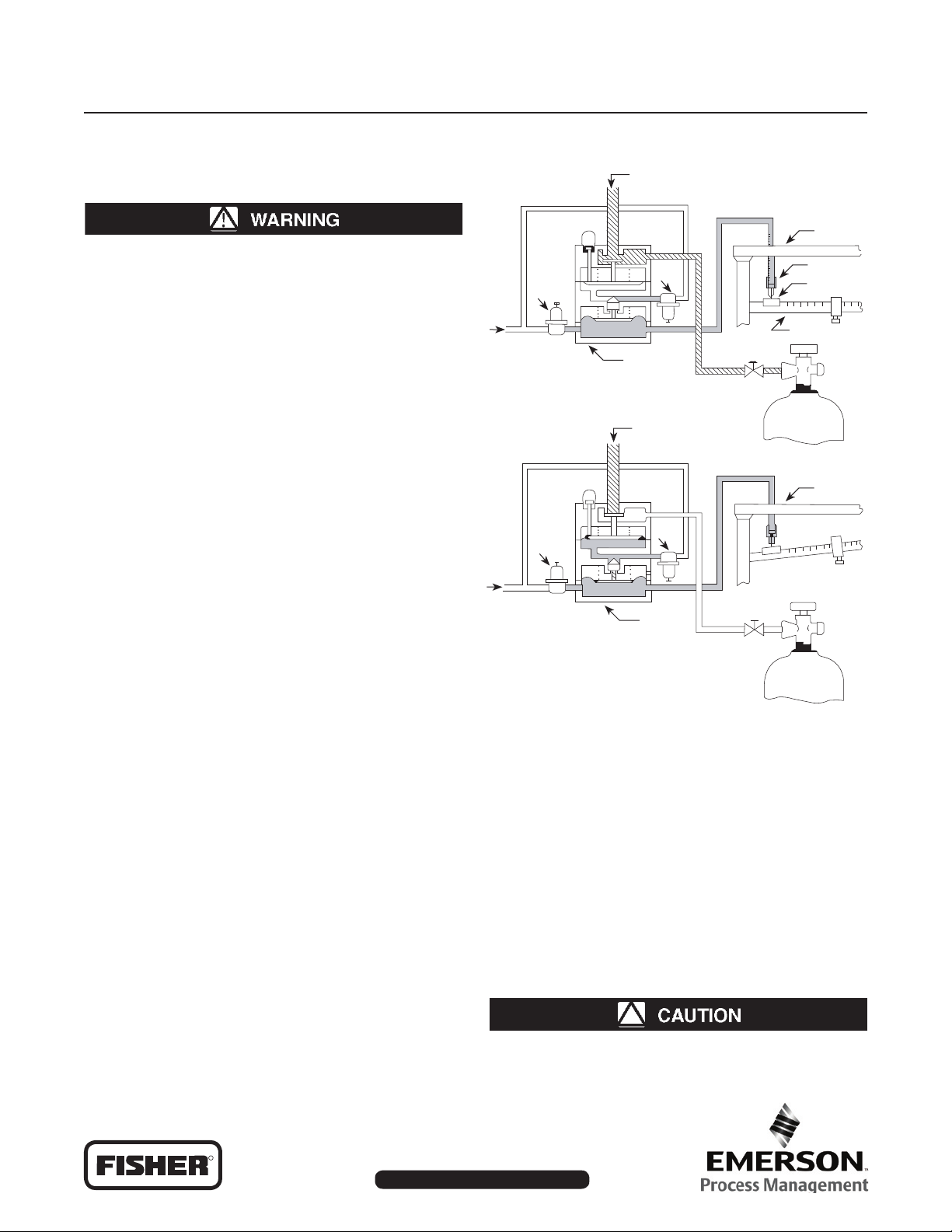

Refer to Figure 1. Supply pressure registers at

regulators 1 and 2. Pressure from regulator 1 registers

beneath the lower diaphragm of the filler valve, see “A”

in Figure 1. This pressure holds the lower valve closed,

preventing pressure from regulator 2 from registering on

the upper diaphragm. Spring force holds the upper valve

open, and liquid from the charging pump can enter the

cylinder to be filled.

When the cylinder reaches the predetermined weight set on

the scale, the beam button on the scale beam contacts the

trip valve, see “B” in Figure 1. The trip valve opens to exhaust

pressure from under the lower diaphragm. Spring force opens

the lower valve, allowing pressure from regulator 2 to register

on the upper diaphragm. This closes the upper valve, and

stops flow through the orifice. A red button indicates that the

filler valve is closed and that the cylinder is full. Removing the

full cylinder from the scale closes the trip valve and permits

the system to reset itself for the next cylinder.

Installation

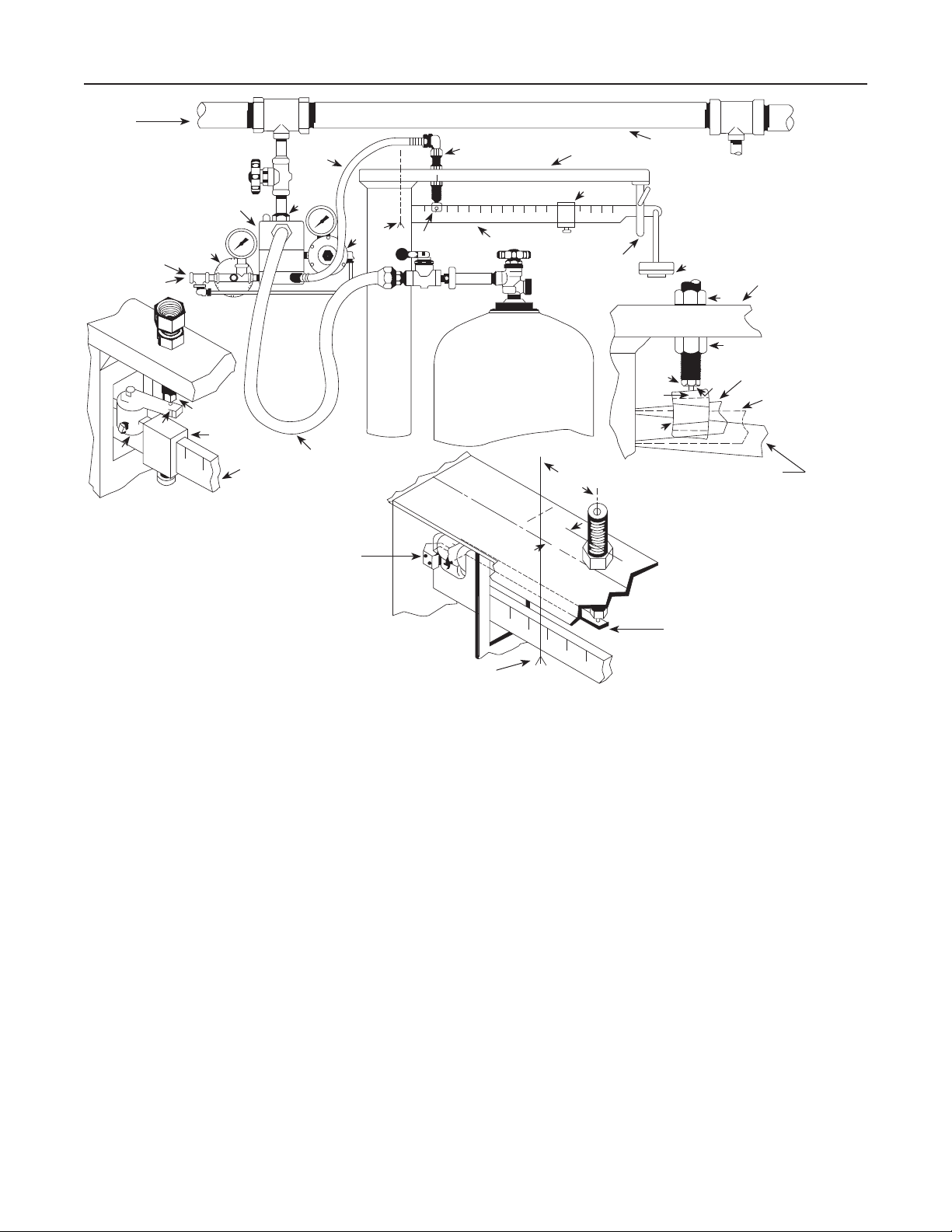

Refer to Figure 2.

1. Connect the top 1/2-inch FNPT connection “C” of the

filler valve to the charging manifold.

2. Determine if the trip valve hose is long enough to reach

the scale frame as shown. If not, insert 1/8-inch pipe

as needed.

3. Standard trip valve installation (also see alternate

methods, 3.A and 3.B):

a. The trip valve should be installed at approximately 1/5

of the scale beam length, measured from the pivot point to

FROM CHARGING

PUMP

SCALE

FRAME

REG

# 1

SUPPLY

PRESSURE

A. FILLING CYLINDER

REG

# 1

SUPPLY

PRESSURE

B. FULL CYLINDER

REG

# 2

FILLER

VALVE

FROM CHARGING

PUMP

REG

# 2

FILLER

VALVE

TRIP VALVE

BEAM

BUTTON

SCALE BEAM

SCALE

FRAME

Figure 1. Operational Schematic

the beam stop, see drawing. Although the trip valve can

be installed to operate directly off the scale beam, it is not

recommended because of the side play in most scale beams

can resuIt in failure to contact the trip valve.

b. Drill a 5/8-inch (16 mm) hole through the scale frame

directly above the point on the scale beam, determined in

step 3 (a).

c. Remove locknut “D” and insert trip valve through the

5/8-inch (16 mm) hole. Replace locknut.

d. Place beam button “J” on the scale beam directly

beneath the trip valve.

e. Using locknuts “D” and “E”, position trip valve stem “B”

so that it barely contacts beam button “J” with the scale

beam in a level position, see drawing.

Be certain that the beam button cannot

contact the trip valve housing at point “A”

when the scale beam is in the uppemost

D450003T012

R

www.FISHERregulators.com/lp

Type N201

FROM CHARGING PUMP

PILOT VAPOR

PRESSURE FROM

AIR COMPRESSOR

STORAGE TANK,

OR AUXILIARY

PROPANE CYLINDER

P

K

J

ALTERNATIVE TRIP VALVE

INSTALLATION #1

TYPE 201

FILLER VALVE

I

TRIP VALVE

H

SCALE BEAM

TRIP VALVE

HOSE

C

FILLING HOSE

APPROX. 1/5

LENGTH OF

SCALE BEAM

TRIP VALVE

PIVOT

2

POINT

M

J

SCALE BEAM

1 1/4

(31,8)

SCALE FRAME

H

BEAM STOP

3

(76,2)

MANIFOLD

STANDARD TRIP VALVE

INSTALLATION

F

TRIP

VALVE

B

J

BEAM WHEN CYLINDER

IS NOT FILLED

SCALE

FRAME

E

D

BEAM IN RAISED

POSITION

A

BEAM

HORIZONTAL

(LEVEL)

Figure 2. N201 Installation

position (full cylinder). To correct this, try

raising the trip valve slightly and retighten

locknuts “D” and “E”. If raising the trip valve

does not correct the situation the 5/8-inch

(16 mm) hole on the scale frame will have to

be drilled closer to the pivot point.

3.A On installations where the slide weight “H” must be

moved to zero, alternate trip valve installation no. 1 can be

made. (This is usually necessary when both 20 pounds

(9 kg) and 100 pounds (45,4 kg) cylinders are to be filled.)

Follow steps 3 (a), (b), (c) and:

d. Place the beam button “J” on the scale beam close

enough to the pivot point to allow the slide weight to move to

zero, see drawing. If there is not enough room to permit this,

either the beam button must be ground down or the user

must make a special beam button.

e. Mount beam bar “K” on the beam button so that it extends

directly under the trip valve. The beam bar can be bent if

necessary and extra length can be cut off.

f. Make certain the beam barely contacts the trip valve

stem when the scale beam is in a level position.

L

INCH

(mm)

PIVOT

POINT

ALTERNATE TRIP VALVE INSTALLATION # 2

(FOR TYPE 1124A AND 1280A FAIRBANKS MORSE SCALE)

3.B For Fairbanks Morse Type 1124A and 1280A scales,

alternate trip valve installation no. 2 must be made, see drawing.

a. Measure 3-inch (76,2 mm) from the pivot point as shown.

b. Measure 1 1/4-inch (31,75mm) from the scale frame

center line toward the back of the scale.

c. Drill a 5/8-inch (16 mm) hole through the scale frame

at this point.

d. Attach the beam bar “L” to the clamp “M” with two

screws, and attach the clamp to the rear of the scale beam

with two screws.

e. Remove locknut “D” and insert the trip valve through the

5/8-inch (16 mm) hole. Replace locknut.

f. Using locknut “D” and “E”, position trip valve so that

it barely contacts the beam bar ”L” with the scale in a

level position.

4. Connect supply pressure (air or gas) at point “P”.

Recommended supply pressure is at least 30 psig (2,1 bar),

since regulator 2 is set at 30 psig (2,1 bar) outlet pressure.

A 30 psig (2,1 bar) supply is sufficient for pump discharge

pressures up to 350 psig (24,1 bar). Regulator 1 is set at

3 psig (0,21 bar).

2

Type N201

Note

If propane vapor pressure is used, atmospheric

or room temperature below 8°F (-13,3°C) will

limit supply pressure to below 30 psig (2,1 bar).

To assure tight shutoff of the filler valve in this

event, refer to the table below.

MINIMUM SUPPLY

PRESSURE, PSIG (bar)

21 (1,4) 200 (13,8)

19 (1,3) 150 (10,3)

17 (1,2) 100 (6,9)

14 (0,97) 50 (3,4)

13 (0,90) 25 (1,7)

5. Attach the propane filling hose to one of the filler valve

outlets. Plug the other outlet. The filling hose must be

complete with a shutoff valve and suitable cylinder valve

connection. The filling hose and shutoff valve can be

counterbalanced for easy handling if desired.

PUMP DISCHARGE, PSIG (bar)

MAXIMUM RECOMMENDED

Operation

1. Place cylinder on scale platform and connect filler hose.

2. Slide beam weight “H” to tare weight stamped on cylinder.

3. Balance scales to compensate for the weight added by

the filler hose and shutoff valve. On some scales this can be

done by means of a small weight near the beam pivot pin. On

others a suitable weight can be added to scale pan “F”.

4. Add a 100 pounds (45,4 kg) weight (or the net weight

desired) to scale pan “F”, and open the cylinder and hose

valve for trial automatic filling operation.

5. Proceed with filling operation until scale beam rises and

contacts the trip valve stem. The filler valve will close and

the filling operation is complete. This is indicated by the red

button on top of the filler valve. Close the hose shutoff valve

and the cylinder valve.

6. Check weight of full cylinder on another

weight or the weight in scale pan “F” may have to be

readjusted slightly until the correct cylinder weight is

obtained. Filling accuracy is largely dependent upon the

condition of the scale used with Type N201.

7. After the scales have been checked and adjusted, simply

position the empty cylinder on the scale, connect the filling

hose, slide beam weight “H” to the tare weight stamped on

the cylinder, open the hose shutoff valve and the cylinder

valve, and the N201 will fill the cylinder to the weight added

on the scale pan.

Note

When operating with high pump pressure,

the filler valve may close off, then reopen

for a short spurt and close off again. This

is due to the force of

stream. If the proper cylinder weight has

been obtained before the additional spurt,

the incoming liquid

scale. Balance

the operator should immediately close the

hose shutoff valve when the scale beam

contacts the trip valve stem. If the scales

are balanced after the additional spurt, the

operator should wait for this before closing

the hose shutoff valve.

In Case of Trouble

1. If sticking of the main (upper) valve should occur, place a

few drops of oil below the disc holder, Key No.5 in Figure 3.

This can be done with an eye dropper or oil can through one

of the outlet ports. Refer to the disassembly instructions if this

does not correct the situation.

2. If the disc holder wears out quickly, check the outlet

pressure of regulator no. 2. Too high a regulator setting will

cause the disc to fail. Refer to step 4 under “Installation”.

3. If the trip valve stem “B” should stick, remove the lower

trip valve body, and clean out all oil or grease. Polish the

seat in the trip valve body by rotating the eraser end of a

pencil against the seat 10 or 12 times.

Disassembly

To check disc holder assembly, O-ring, and diaphragms

proceed as follows (numbers in parenthesis refer to Key Nos.

in Figure 3):

1. Remove tubing connection from the angle adaptor in

Type 67/683 (key 30).

2. Mark the valve body (key 17), valve housing (key 2),

and valve head (key 1) so that they can be aligned easily

when reassembling.

3. Remove cap screws (key 22).

4. Separate the valve head (key 1), valve housing (key 2), and

valve body (key 17). Examine the upper and lower diaphragms

(keys 10 and 32). Replace if necessary.

5. Remove orifice (key 3) and unscrew the disc holder

assembly (key 5). Examine and replace if necessary.

6. Remove bushing (key 8) and take out the O-ring (key 7).

Examine and replace if necessary. Put Dow Corning #3 grease

(or equivalent) on the O-ring.

7. Make sure all parts are clean before reassembling.

To reassemble

1. Replace orifice (key 3) in valve head (key 1).

2. Replace O-ring (key 7) and screw in bushing (key 8).

3. Replace disc holder assembly (key 5) and

spring (key 21). Screw the disc holder into the diaphragm

head (key 9).

4. Replace upper diaphragm (key 10) on the valve head

(key 1). Align the valve housing (key 2), spring (key 35),

lower diaphragm assembly (key 32), and valve body (key 17)

so that the cap screws (key 22) can be inserted.

5. Connect tubing (key 39) to angle adaptor in

(key 30).

Type 67/683

3

Type N201

34

39 30 15 9 20 5 7 8 21 13 31 38 40

33 11 10 18 19 3 6 1 45 2

46

47

44

36

42

17 16 32

22 26 14 35

23 24

25 37

43 41

BUTTON AND BAR FOR

ATTACHMENT TO SCALE BEAM

Figure 3. Type N201

Parts List

Key Description

1 Valve Head

2 Valve Housing

3 Orifice

5* Disc Holder Assembly

6 Control Valve Stem

7* O-Ring

8 Bushing

9 Diaphragm Head

10* Upper Diaphragm

11 Bushing

13 Pilot Valve

14 O-Ring Washer

15* O-Ring

16 Pilot Valve Stem

17 Valve Body

18 Indicator Rod

19 Sight Glass

20 Indicator Cap

21 Control Valve Spring

22 Cap Screw (6 required)

23 Trip Valve Stem

* Recommended spare parts for stock.

Fisher and Fisher Regulators are marks owned by Fisher Controls International, LLC. The Emerson logo is a trademark and service mark of Emerson Electric Co. All other marks are the

property of their respective owners.

The contents of this publication are presented for informational purposes only, and while every effort has been made to ensure their accuracy, they are not to be construed as warranties or guarantees, express

or implied, regarding the products or services described herein or their use or applicability. We reserve the right to modify or improve the designs or specifications of such products at any time

without notice.

Fisher does not assume responsibility for the selection, use or maintenance of any product. Responsibility for proper selection, use and maintenance of any Fisher product remains solely with

the purchaser.

Emerson Process Management

Key Description

24 Trip Valve

25 Inner Valve

26 Screen Holder Assembly (2 required)

30 Type 67/683

31 Type 67/685

32* Diaphragm Assembly

33 Pipe Nipple (3 required)

34 Tee

35 Spring

36 Inverted Flare Elbow (2 required)

37 Nut (2 required)

38 Hose Assembly

39 Tubing Assembly

40 Street Elbow

41 Beam Button

42 Beam Bar

43 Set Screw

44 Machine Screw

45 Vent Screen (2 required)

46 Trip Valve Spring

47 Spring Set

ed

Fisher Controls International, LLC.

P.O. Box 8004

McKinney, Texas 75070, USA

Telephone: 1 (800) 588-5853

Telephone: 1 (469) 293-4201

©Fis her Controls Inte rnation al, LLC., 1980; All Rights Rese rved

www.FISHERregulators.com/lp

Loading...

Loading...