Page 1

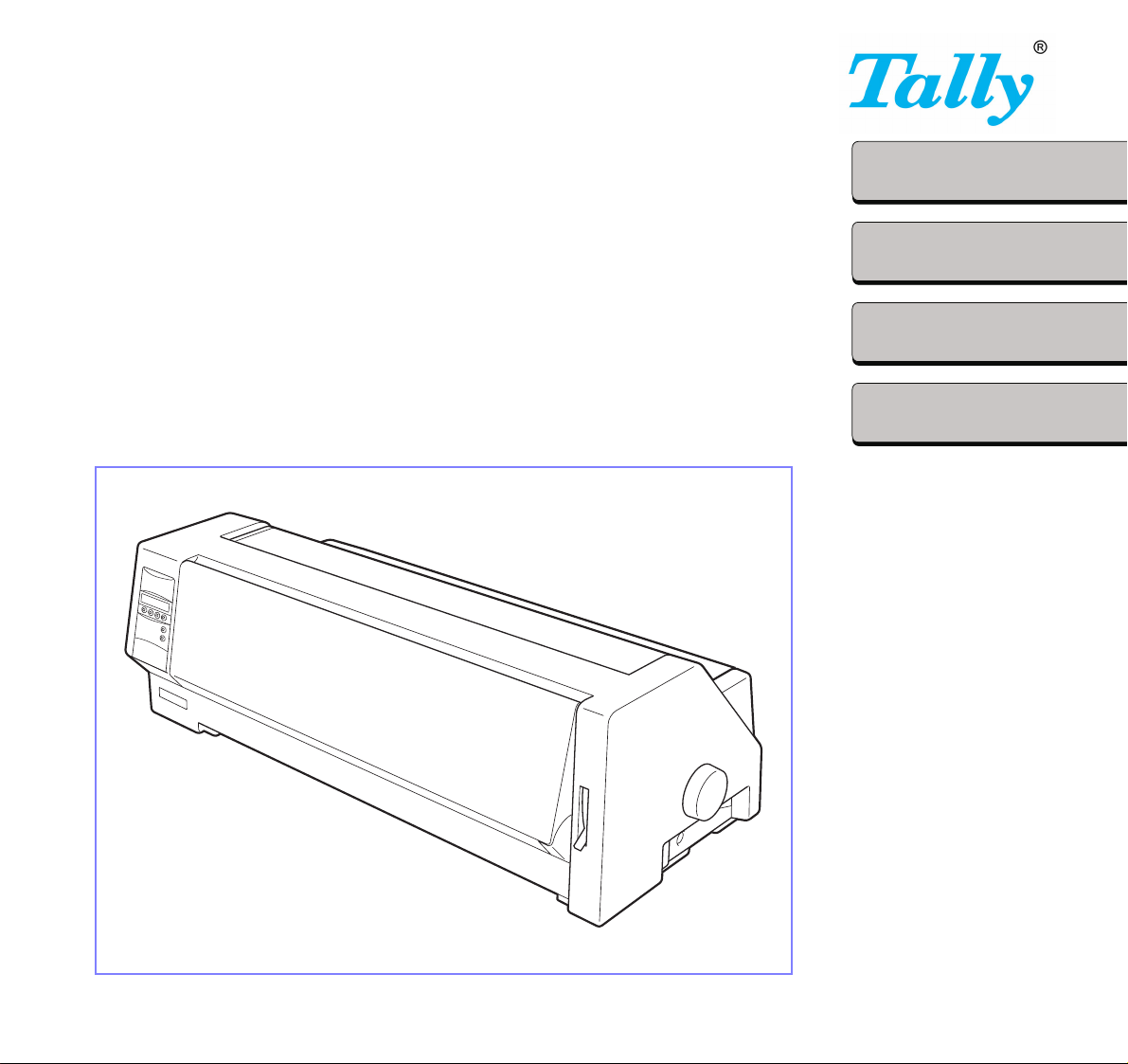

T2240/9

BACK

QUIT

?

PRINT

Contents

T2240/24

T2340/9

Reference manual Matrix printer

T2340/24

Page 2

Table of contents Introduction

BACK

QUIT

?

1 Operation

The control panel 1 - 1

The LC display 1 - 2

Messages in the LC display 1 - 3

LC display language 1 - 4

Selecting the LC display language 1 - 4

Unlock the Menu mode 1 - 4

Terminating Menu mode 1 - 6

Key functions when turning on the printer 1 - 7

Programming via the control panel 1 - 7

Calling up the menu 1 - 8

Calling up a locked menu 1 - 8

Menu configurations 1 - 8

Menu handling 1 - 10

Save settings 1 - 11

Example of the menu structure 1 - 12

Menu description table 1 - 13

Menu settings (example) 1 - 21

Bidirectional print adjustment (L/R Adj) 1 - 22

2 Emulations

General 2 - 1

Escape sequences 2 - 1

What are escape sequences? 2 - 1

MTPL sequences 2 - 1

What are control codes? 2 - 1

The $$ procedure 2 - 2

Page 3

Table of contents

BACK

QUIT

?

How are escape sequences used? 2-3

MTPL 2-4

Example in BASIC 2-4

Example in Pascal 2-4

Printout 2-4

List of available control codes 2-5

Barcode 2-17

List of available barcodes 2-17

LC printing 2-19

List of additional control codes 2-20

Configuring the printer for your computer 2-21

3 Troubleshooting, care and maintenance

Test functions and hardware settings 3-2

Printer self-test (Rolling ASCII) 3-3

Exiting Test mode 3-5

Interface test (Hex-Dump) 3-6

Printout in Hex-Dump 3-6

Terminating Hex-Dump 3-7

Setting the Formlen function 3-8

Wrap 3-9

Sound 3-10

CX-bid 3-11

CX-IF 3-12

ChTrFr 3-13

Mechanical adjustments to the printer 3-14

Setting the basical top margin and L/R adjustment 3-14

Troubleshooting 3-17

The display remains dark 3-17

The display is lit, but the printer does not print 3-18

Problems with the paper feed 3-18

Paper jam (fanfold paper) 3-19

Paper jam (single sheets) 3-20

Tear off position cannot be adjusted 3-21

Paper does not move to tear off position 3-21

Page 4

Table of contents

BACK

QUIT

?

Problems with the print quality3 - 22

Print is too pale3 - 22

Smudged print3 - 22

Prints undefined characters3 - 22

The first line is not completely printed out at the top3 - 22

Dots within characters are missing3 - 22

Error messages via the display3 - 23

Load paper from ...3 - 23

Printhead hot3 - 23

Parity Error3 - 23

Hardware Alarm3 - 23

Home Position3 - 23

Eject Error3 - 24

Load Error3 - 24

Additional display messages3 - 25

Press any key3 - 25

Loading Default3 - 25

Only available in Epson mode3 - 25

Park position3 - 25

Tear paper off3 - 25

Turn paperlever3 - 25

Care and maintenance3 - 26

Cleaning the housing 3 - 26

Cleaning the interior3 - 27

Ribbon3 - 27

A Character sets

Character sets A - 1

MTPL standard character set A - 2

MTPL international substitution characters – normal font A - 3

OCRA Character Set A - 4

OCRB Character Set A - 5

Available character sets and fonts A - 6

Page 5

Table of contents

BACK

QUIT

?

BInterfaces

Parallel interface B - 2

Jumper settings B - 3

Serial interface RS232C/V.24 B - 4

Connector assignment B - 4

Interface cable RS232C B - 5

Protocol description B - 6

Jumper settings B - 7

Serial interface RS422/V.11C B - 9

Connector assignment B - 9

Protocol description B - 9

Jumper settings B - 10

CSpecification

Printer specifications C - 1

Interface specifications C - 3

Paper specifications C - 4

DOptions and Accessories

Options D - 1

Accessories D - 2

Page 6

Introduction

BACK

QUIT

?

Introduction

About Part II of the

operator’s manual

The reference manual contains a detailed description of the printer, its characteristic features and additional information.

If you need to operate your printer as soon as possible, it is sufficient to

read

Installing the printer

and correct use of your printer the complete operator’s manual must be

read.

The reference manual is divided into three chapters with their titles printed

in the top margin of the page. The current chapter is marked by a black bar.

The chapters of this manual describe the following topics:

■ Chapter 1 Operation contains information on programming your printer via

the operating panel.

■ Chapter 2 Emulations deals with programming via the interface. The avail-

able programming sequences are listed. (Detailed information about these

codes are available in an optional Programmer’s Application Manual which

can be purchased separately.)

■ Chapter 3 Troubleshooting, care and maintenance helps you to deal with

common problems and shows you how to use the test and adjustment

functions of your printer. Hints on identifying and repairing faults yourself are

provided. At th e end of the chapter, cleaning and care of your printer are

described.

in the Operator’s manual. For further information

■ Appendix A Character sets lists the available character sets.

■ Appendix B Interfaces explains the interfaces.

■ Appendix C Specifications informs you about the technical specifications of

your printer and the paper which should be used.

■ Appendix D Options and accessories contains information about options

and accessories you can purchase for your printer.

Page 7

Introduction

BACK

QUIT

?

Explanation of symbols Notes on the symbols used:

● Texts marked with this dot describe operations which must be performed in

the given order.

■ This mark indicates a list.

STOP

Text sequences marked by this symbol must be noted and observed under

all circumstances since any misuse could injure the operator or damage

the equipment.

This symbol marks important information and notes.

Page 8

Operation 1

BACK

QUIT

?

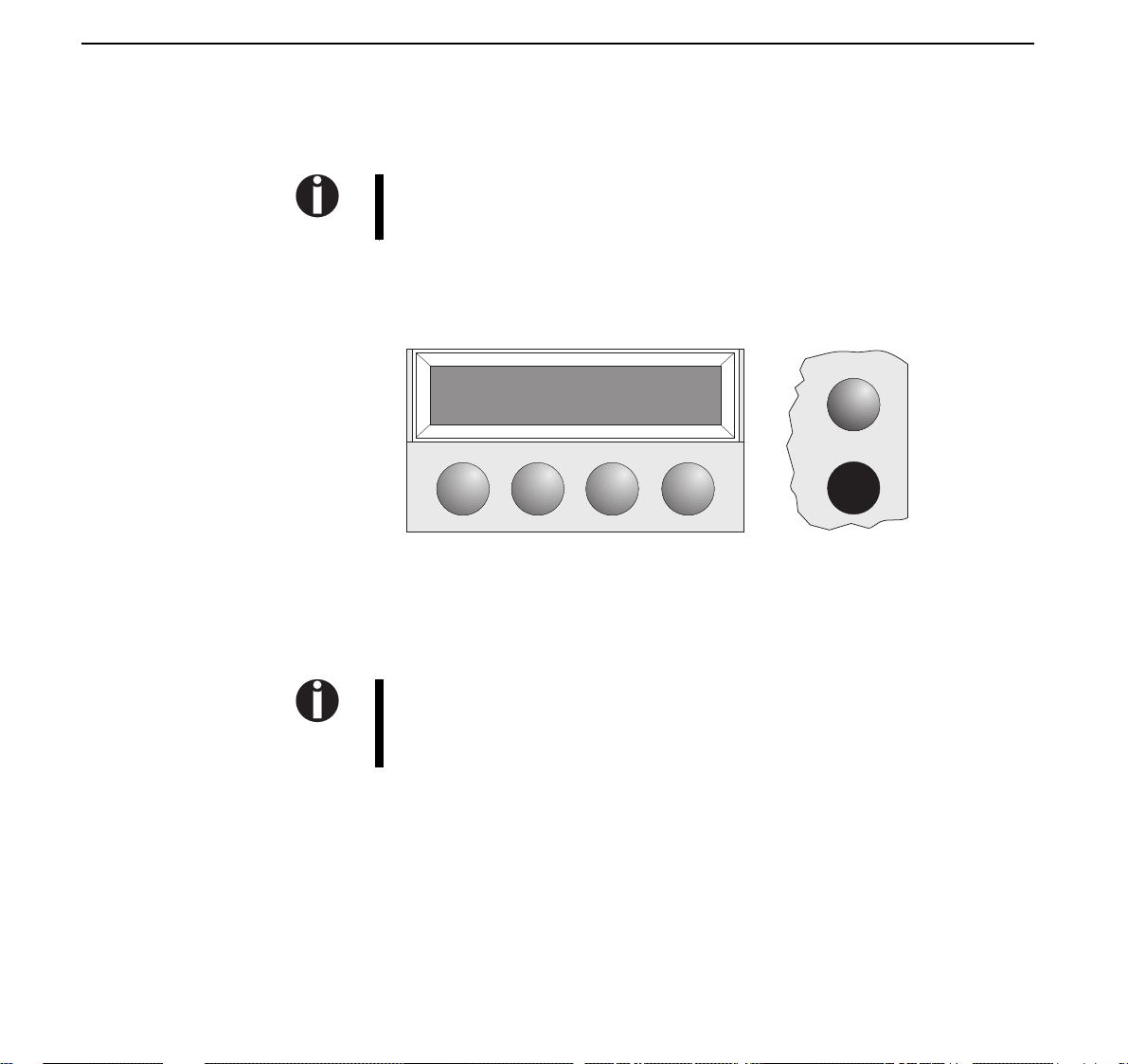

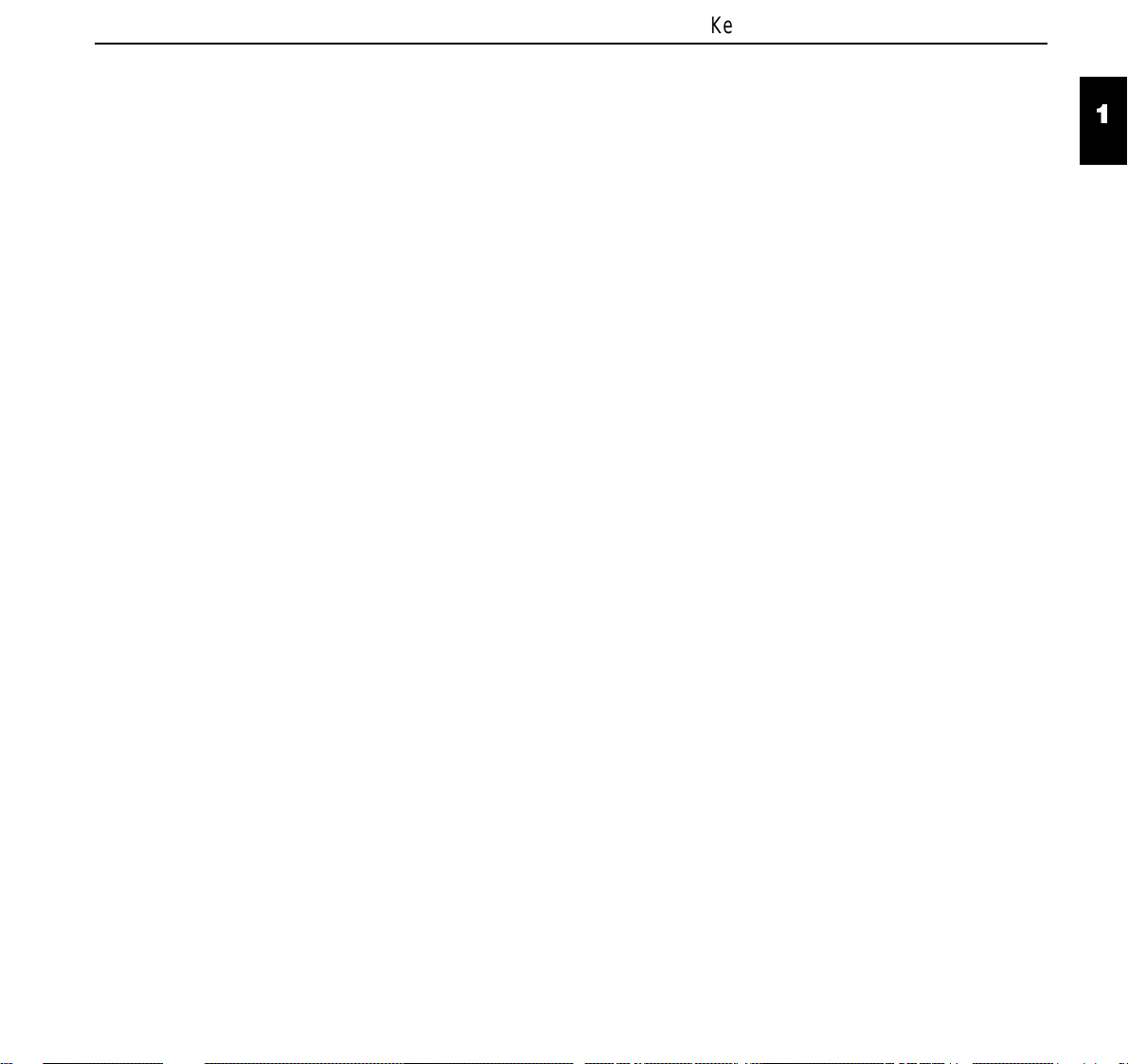

The control panel The control panel is located on the front left side of your printer and

consists of a two-line LC display and six keys.

LC display

Online

Online key

Setup

123

The functions of the keys depend on the printer’s current mode (status).

There are four basic modes.

4

Setup key

1

4

Online mode

The

computer can be received and printed.

Offline mode

In the

i.e. no data can be received and printed.

Setup mode

In the

so-called quick-switch function. The quick-switch option was included so

that you can change the most important parameters (character density,

font, paper path) directly without having to enter them via the menu. The

parameters character density, paper path and font can also be selected in

the printer menu.

Menu mode

In the

etc.) can be altered and saved permanently.

is the printer’s normal operating status. Data from your

the link between printer and computer is interrupted,

you can either select the printer menu or carry out the

printer settings (line spacing, size of the interface buffer

1 - 1

Page 9

The control panel

BACK

QUIT

?

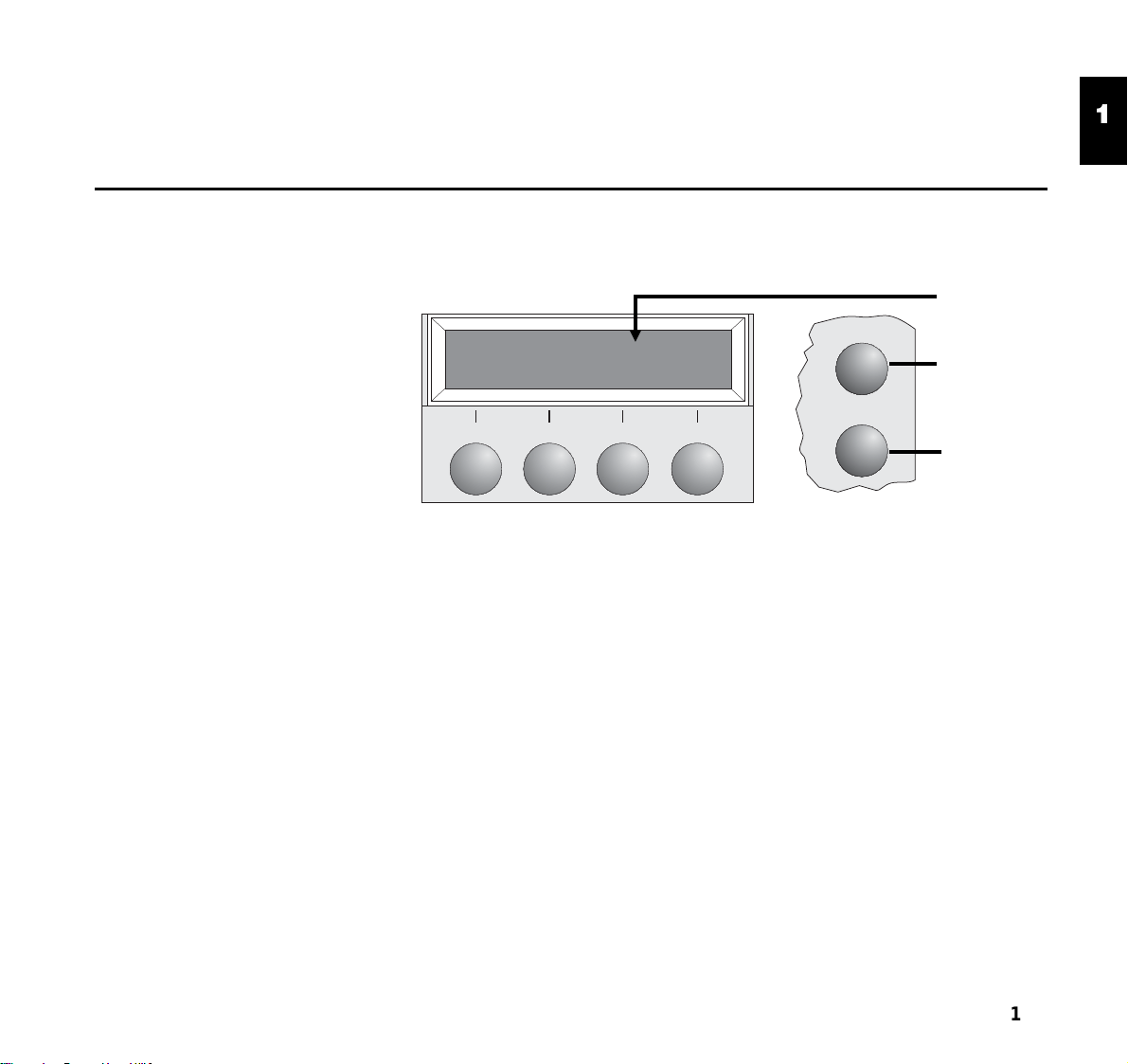

The LC display The LC display tells you all the important printer settings and informs you

which functions are currently assigned to which keys.

In Normal mode the upper line tells you the printer’s status (Online or

Offline mode – in the example below the printer is in the Online mode), and

the selected paperpath (below:

The second line informs you which functions are currently assigned to

which keys. The word or symbol directly above a key tells you the current

function of the key. In our example the right key is assigned with the Tear

function. If you were to press this key the loaded fanfold paper would be

advanced to the tear position.

Example:

Trac.1 = push tractor mode).

Key

functions

Printer status

Online Trac.1

Tear

123

4

Paperpath

Online

Setup

1 - 2

Page 10

The control panel

BACK

QUIT

?

Messages in the

LC display

If the printer detects an internal fault or user error or if it expects you to do

something, a message will appear in the LC display. Below you will find a

list of messages with brief descriptions of each message. The messages

are described in more detail in the section

Troubleshooting, care and maintenance

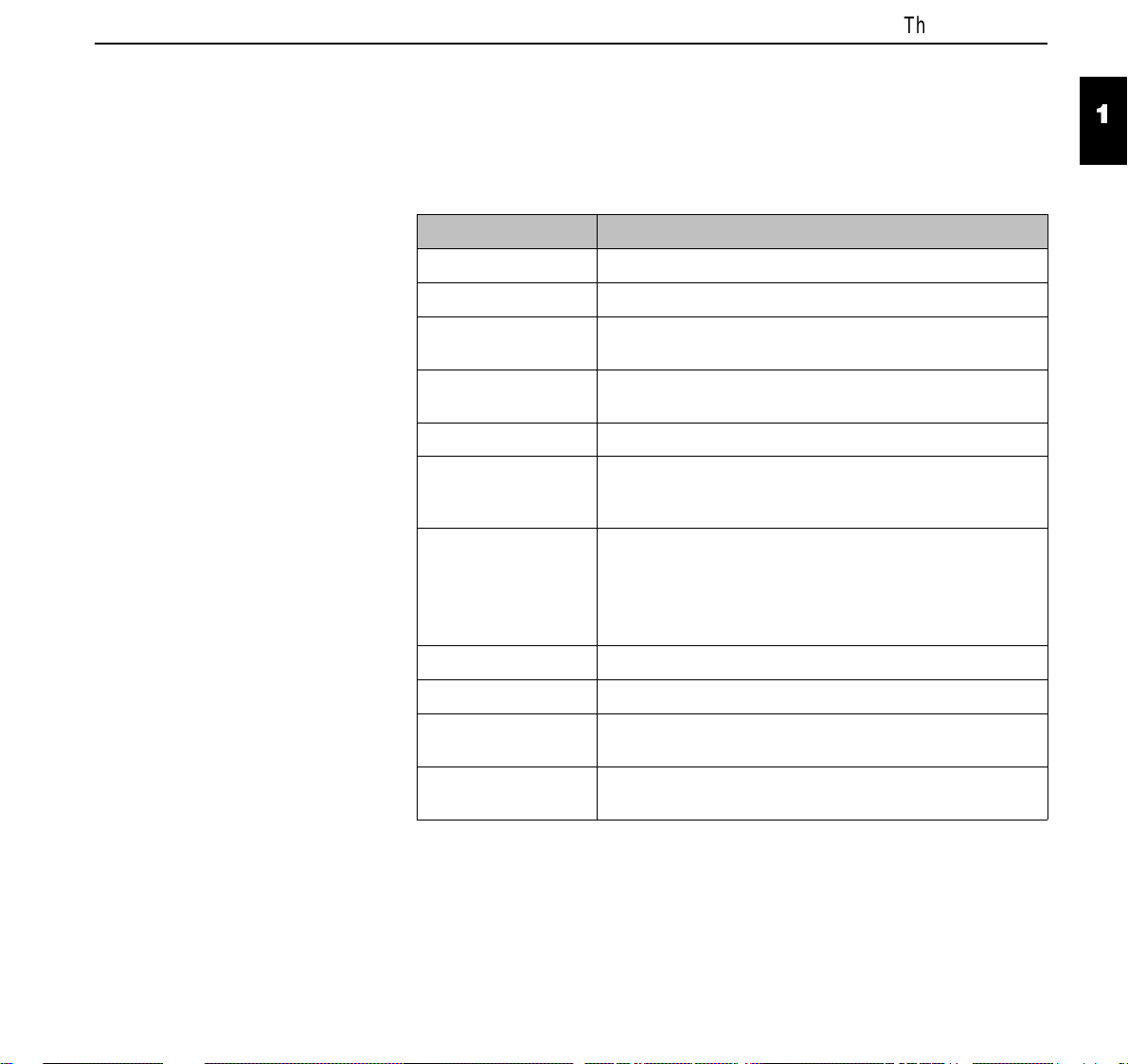

Message Meaning

Eject error

Hardware Alarm

Head hot

Initializing

Load error

Loading default

Load paper from

Single

Tractor1

Tractor2

ASFauto

Parity error

Press any key

Tear Paper off

Turn paperlever

The printer cannot eject paper/advance it to park position.

Internal hardware error/print head blocked.

The printer reports that the print head is hot and that print

speed will be reduced.

This message appears during the printer’s initializing

phase.

The printer cannot draw in the loaded paper.

Indicates that the printer is being initialised and is

carrying out the internal self-test immediately after

turning on the printer.

The printer has detected paper end during operation or

the printer was switched on with no paper loaded.

The user is requested to insert paper into the paper input

selected.

A parity error during data transmission is indicated.

The user is requested to press any key.

The user is requested to tear off paper which has been

advanced to the quick tear edge.

The user is requested to turn the paper type selection

lever.

.

Troubleshooting

in chapter 3

1

4

1 - 3

Page 11

LC display language

BACK

QUIT

?

LC display language In this manual, all the LC displays are shown in the English language. How-

ever, your printer offers the possibility of indicating the LC display text in

German, French, Italian or Spanish.

If you wish to keep the English display (default setting) or to change to

another language at a later time, you may skip the following chapter

Selecting the LC display language

.

Selecting the LC

display language

Unlock the Menu mode

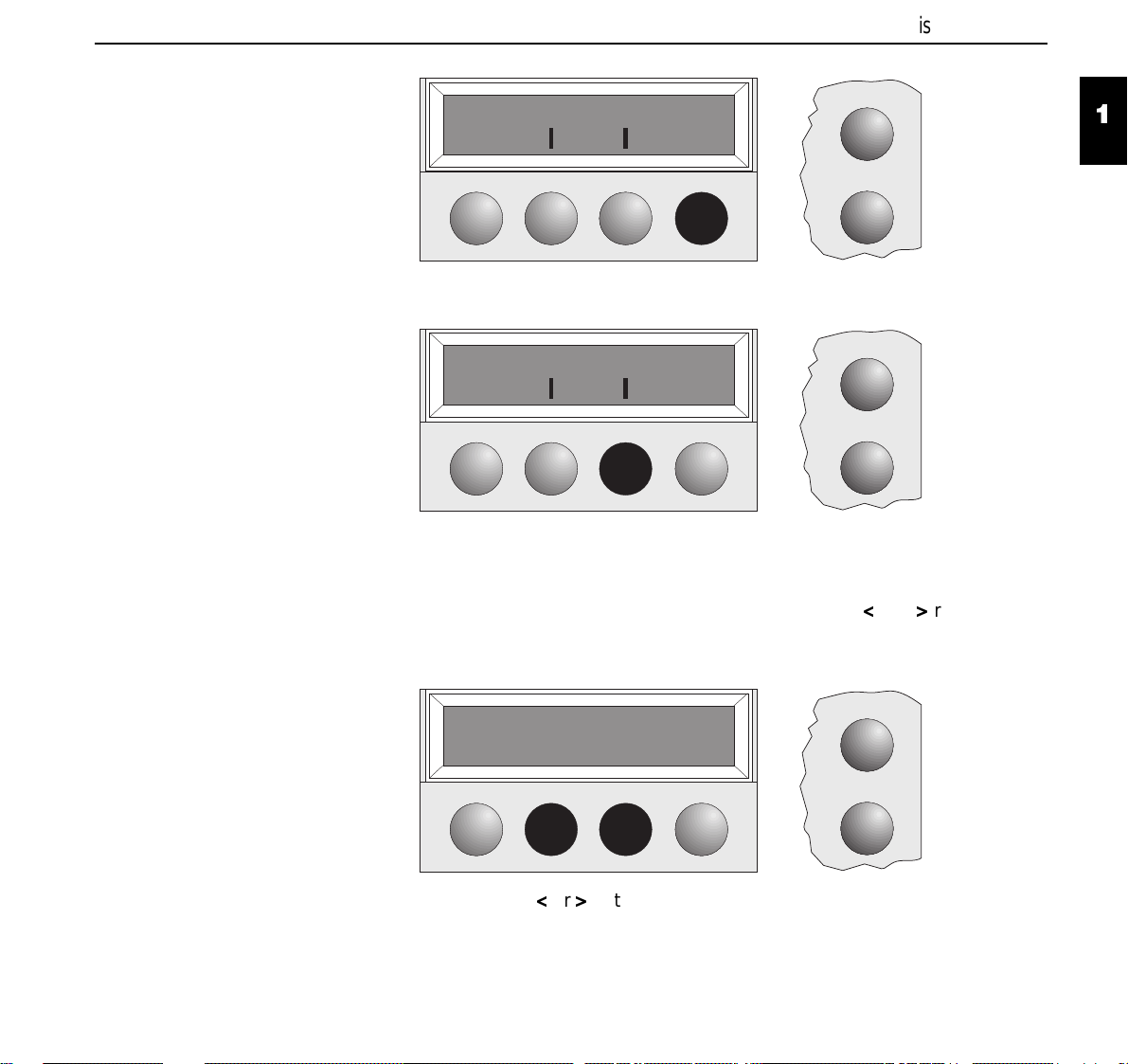

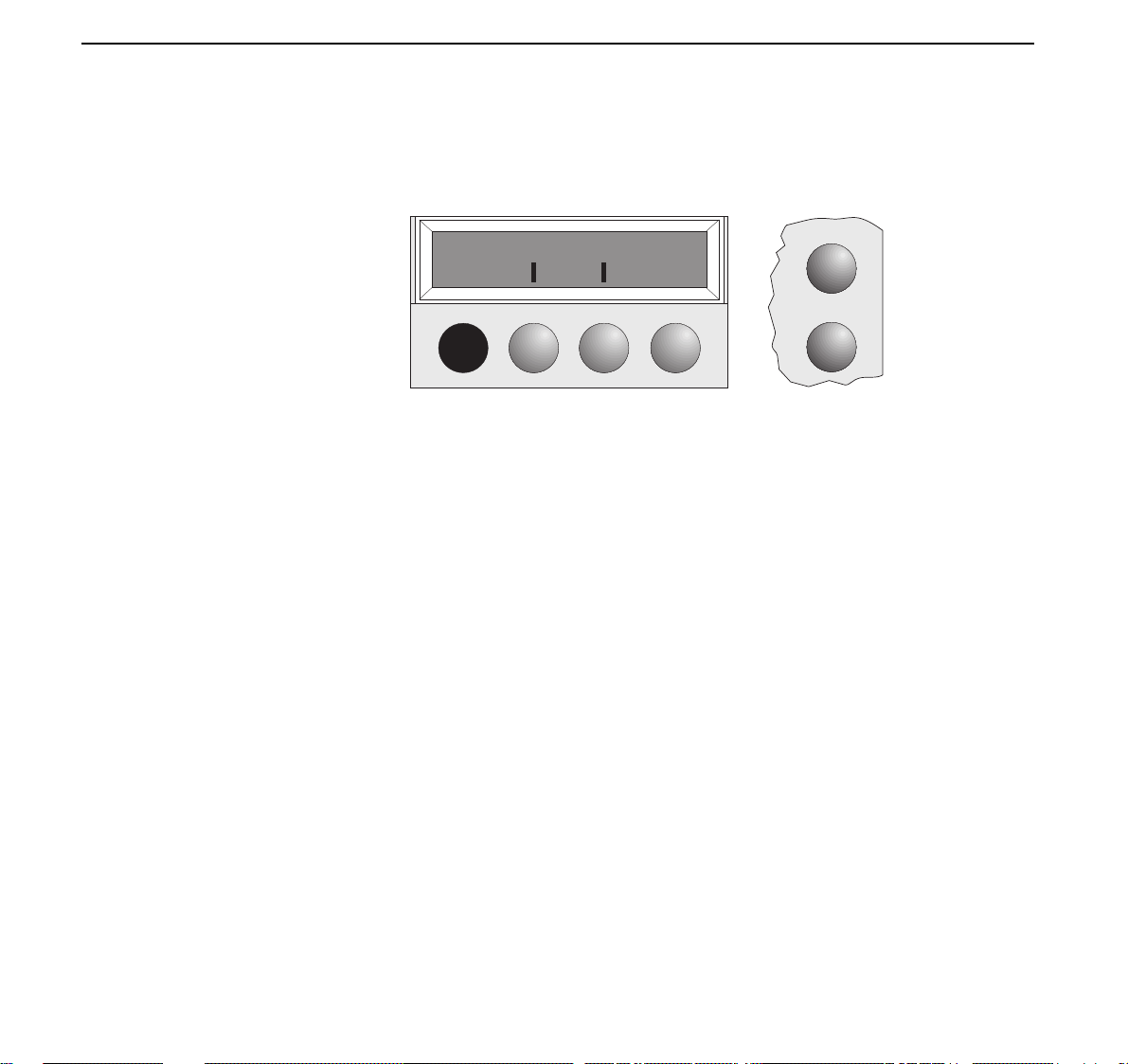

This example shows the change from the English language to the German

language. The same procedure applies for the other languages.

Online Trac.1

Online

Load

Setup

With the printer powered up, unlock the printer’s Menu mode by pressing

the key Setup.

The Menu mode may be locked. Hold down the key Setup while switching

on the printer to cancel the menu lock. If you want to permanently cancel

the lock, you must change the appropriate setting in the menu (see

description table

Press the Setup key.

in this chapter).

Menu

1 - 4

Press the Menu key.

Page 12

LC display language

BACK

QUIT

?

Print Menu

Online

Back Next

Setup

Press the key Next several times until the display indicates Language.

MenLock Language

Online

Back Next

Setup

Select the Language key. The display now changes to Parameter mode

and indicates “English” in the top line.

The lower line displays Set and Exit. The two arrows < and > represent

the symbols for parameter selection (“<” indicates descending and “>”

ascending).

1

4

English *

Online

Set < > Exit

Setup

Press the key < or > until the desired language is displayed, in our

example German.

1 - 5

Page 13

LC display language

BACK

QUIT

?

German *

Online

Set < > Exit

Setup

Save your selection by pressing the key Set. An acoustic signal verifies

this action.

You can exit Parameter mode without saving a setting by pressing the key

Exit (the old setting is retained).

After saving your setting (Set), the display in our example indicates the following text:

Ges.Men Sprache

Online

Rück Vor

Setup

Terminating Menu

mode

1 - 6

This setting is stored even after switching off your printer.

Press either the key Setup to change into Offline mode or the key Online

to change to Online mode.

Page 14

Key functions when turning on the printer

BACK

QUIT

?

Key functions when

turning on the printer

Programming via the

control panel

Key functions when turning on the printer

respective key depressed while turning on the printer. In this way you can

activate three functions:

If you keep the Online key depressed while turning on the printer, you

enter the printer’s Self-Test mode. The Self-Test mode is described in

chapter 3 of this manual.

If you keep the Setup key depressed while turning on the printer, you

regain access to the printer menu if you had locked it before with the help

MenLock

of the

description table at the end of this chapter.

If the four

turning on the power, all printer settings are reset to the default values

(except the settings for

If function keys 1 and 2 and the Online key are depressed simultaneously

while turning on the printer, basic TOF and L/R can be adjusted. See the

description in chapter 3 of this manual.

Apart from being able to control your printer via the applications software

you use, you can also program the printer directly. There are two programming options you can use:

function. The

function and select keys

MenLock

basical TOF and L/R

means that you must keep the

function is described in the Menu

are depressed simultaneously while

).

1

4

● Programming via the control panel and

● Programming via the interface using Escape sequences or control codes

Programming via the interface gives you far greater freedom for

designing your printed pages, however, it is also a more sophisticated

method and requires some experience with programming languages.

All programming via the interface is lost after you turn off the printer,

whereas the programming carried out using the control panel, is saved and

stored even after you turn off the printer.

1 - 7

Page 15

Programming via the control panel

BACK

QUIT

?

Calling up the menu You can access the menu in the following way:

Switch on the printer. Press the Setup key. The printer switches to Setup

mode. (The Setup mode can be selected both in the Online and Offline

mode).

Adjust Paperway

Online

Menu Char

Setup

To access the printer menu, press the Menu key.

Calling up a locked

menu

Menu configurations Every printer is shipped with factory default settings. Basic settings such as

As mentioned earlier in the manual you are provided with the option of locking the menu, for example to prevent others from accessing it. You can do

this using the

MenLock

(The

table). You can access a locked menu by switching on the printer while

simultaneously pressing the Setup key.

emulation, character size, form length etc., which many applications make

use of, are set. At the end of this chapter you will find a menu printout

which shows you the printer’s default settings.

Your printer allows you to set and use four independent menu configura-

tions. If one of your applications for example requires an IBM printer while

another program works better with an EPSON printer, you can set an IBM

emulation configuration with the desired settings, and set the second configuration as an EPSON emulation.

MenLock

parameter is described in detail in the menu description

parameter from within the menu itself.

1 - 8

Page 16

Programming via the control panel

BACK

QUIT

?

The active menu is always the one you used last. When you switch on the

printer for the very first time, menu no. 1 is loaded. Menu no. 1 only

remains active until you load another menu. Even after you turn off the

printer the menu that was active last remains the active menu and when

you switch the printer on again this menu is loaded automatically.

Example:

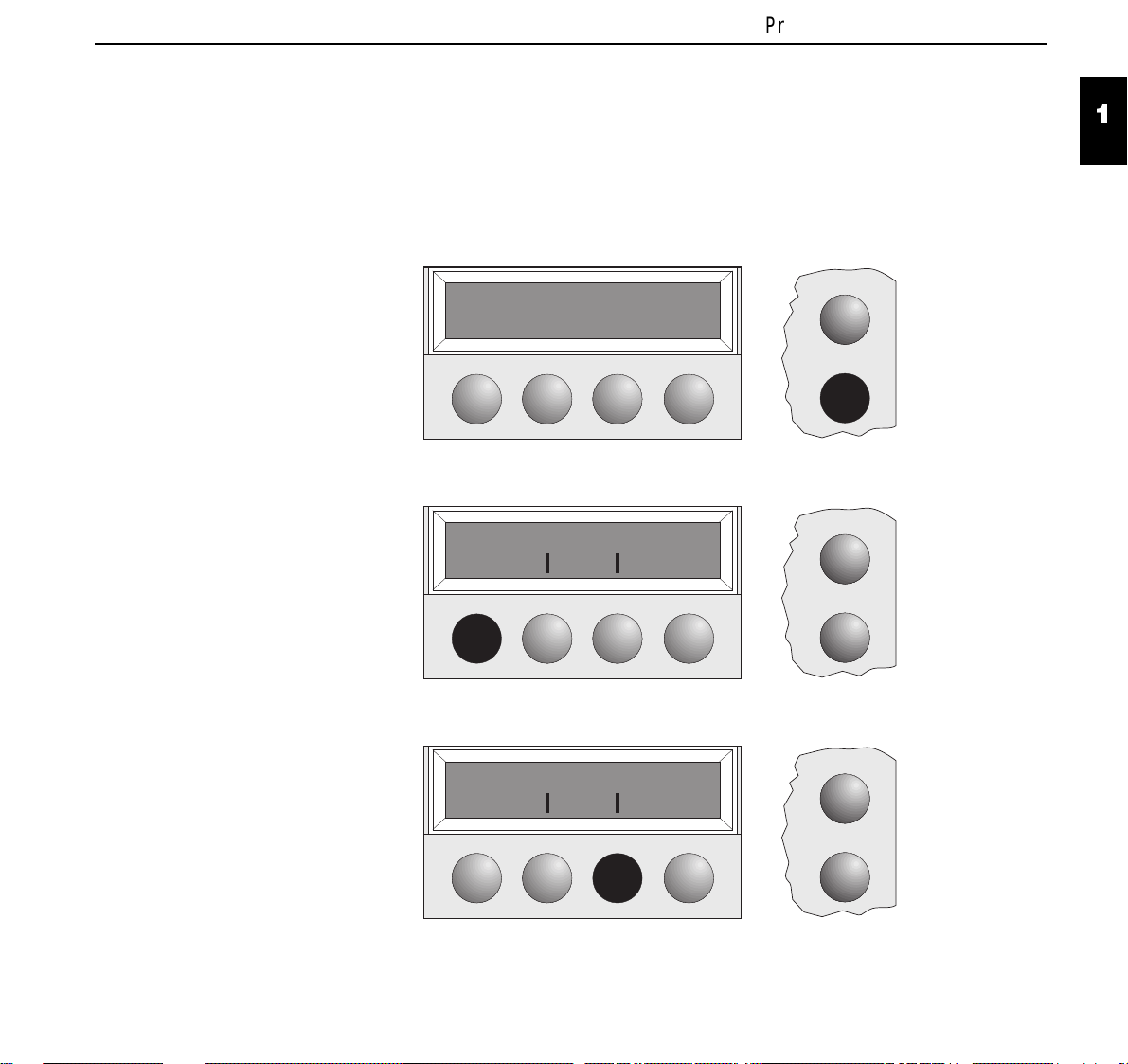

To change from menu no. 1 to menu no. 3:

1

Offline Trac.1

Park < > LF/FF

Select Setup mode (press Setup key).

Adjust Paperway

Menu Char

Select Menu mode (press key under Menu).

Print Menu

Back Next

Online

Setup

4

Online

Setup

Online

Select Menu again (press key under Menu).

Setup

1 - 9

Page 17

Programming via the control panel

BACK

QUIT

?

Now the following message appears in the LC display:

Load Menu=1 *

Online

Set < > Exit

Setup

Now press the key < or > repeatedly until “Load Menu=3” appears. Then

select menu no. 3 as the current setting using the Set key. After you have

completed this change the printer initialises itself and a corresponding

message is displayed in the LC display.

The currently valid setting ist marked by a “

Menu handling You move from menu item to menu item using the four function and selection

keys underneath the LC display. Every function and every parameter

displayed on the LC display is effected/selected by the key directly underneath. For this reason the function and selection keys are referred to in this

manual by their current assignment. Generally two parameter groups

occupy one level (in the following picture the parameter groups LPI and

Skip occupy one level).

If you do not wish to change one of the two parameters you can either

press the Next key (to access the two following parameter groups in the

menu), or you can press the Back key (to access the two previous

parameter groups in the menu). If you want to change a setting, (e.g. the

line density), then press the LPI key (LPI = lines per inch) to access the

actual parameter level. The currently valid setting is marked by a “

the example below the current setting is 6 lpi). With the “<” and “>” keys

you can view the other parameters available for this setting.

”

*

” (in

*

1 - 10

Page 18

Programming via the control panel

BACK

QUIT

?

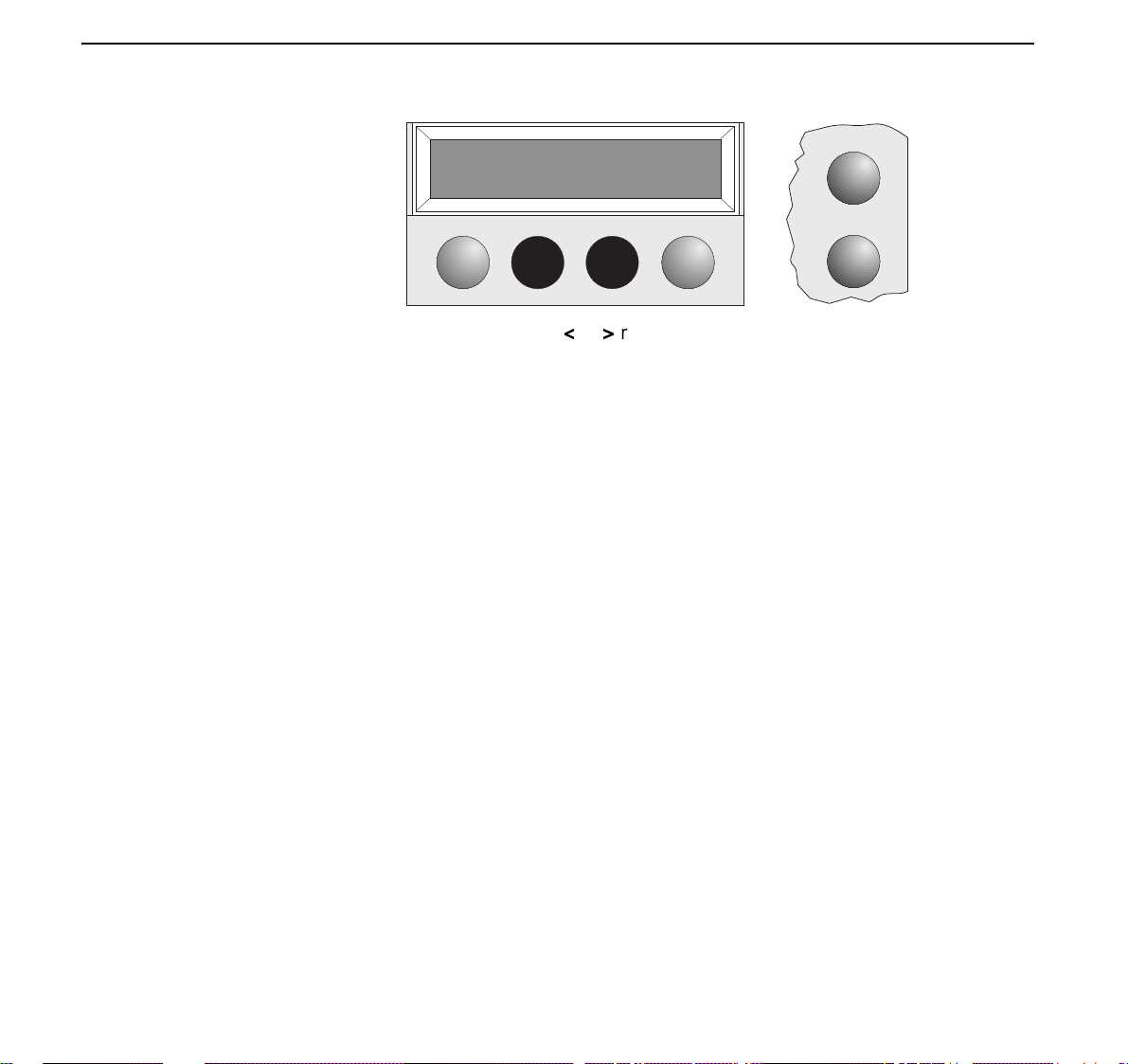

Save settings Once the desired parameter is displayed on the LC display, you can save it

by pressing the Set key. The parameter is then set and the printer automatically displays the parameter groups again. With the Exit key you can

leave the sublevel without saving your changes (see also

Menu mode

, page 1-6).

Example:

Terminating

1

Back to the

previous

parameter groups

LPI Skip

Back Next

6 LPI *

Set < > Exit

On to the next

parameter groups

4

Skip = 0.0 Inch *

Set < > Exit

1 - 11

Page 19

Example of the menu structure

BACK

QUIT

?

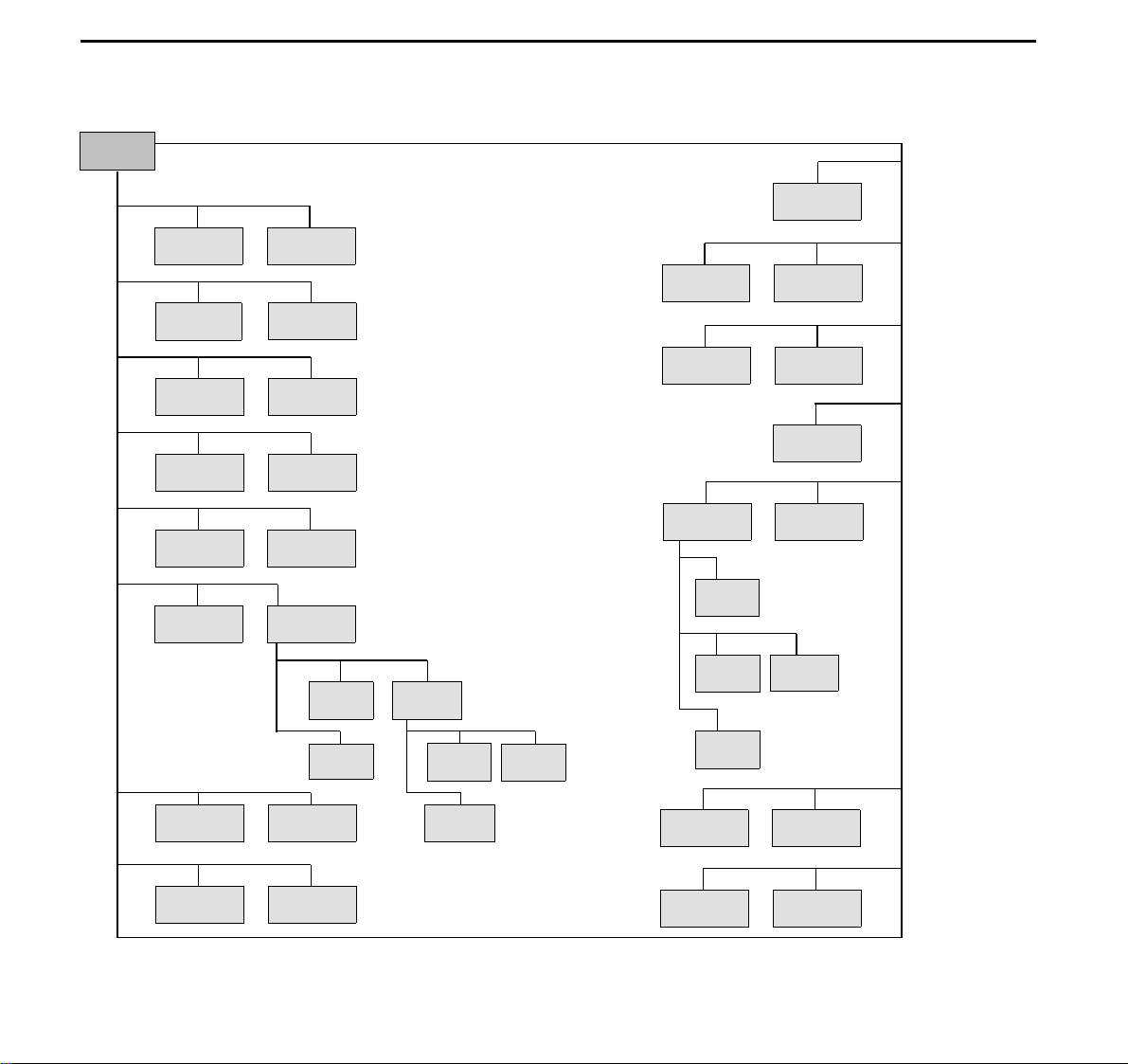

Example of the menu structure

MENU

➡

Next

➡

Back

Print

Reset

Menu

L/R Adj

CPIFont

SkipLPI

EmulateESCChar

I/OBidir

Buffer

Serial*

Prn Ipct

Barcode Barmode

F-Eject Formlen

Width

**

Auto TearPaper

Single

Trac.2

***

Trac.1

1 - 12

Next

ASFauto

Interf.

CharSetCG-Tab

SI. ZeroCountry

➡

Baud*

Protocol*

Format*

***

LanguageMenLock

Auto-LFAuto-CR

* only with serial

** only with wide

*** as an option

➡

Back

interface

printers

Page 20

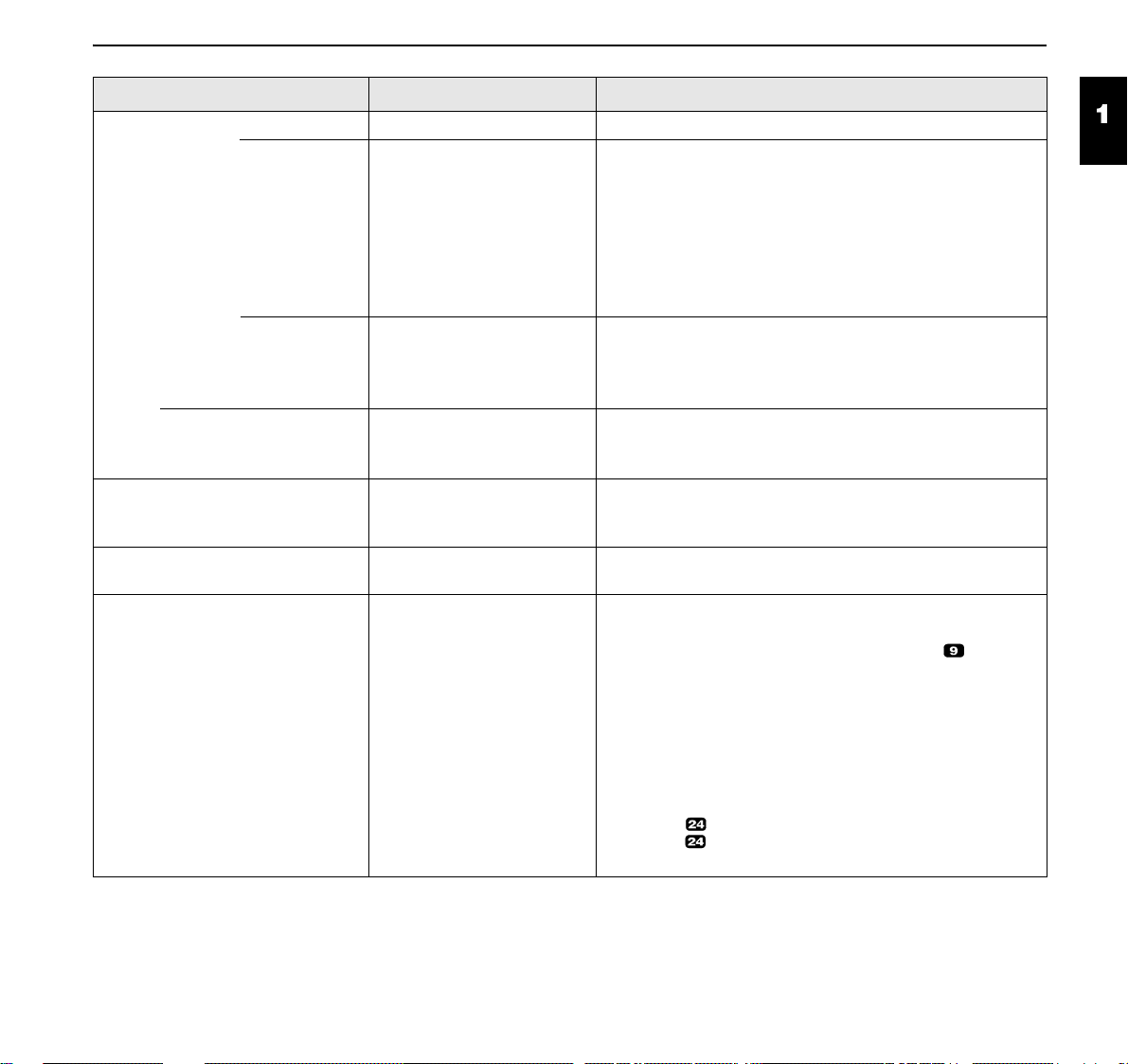

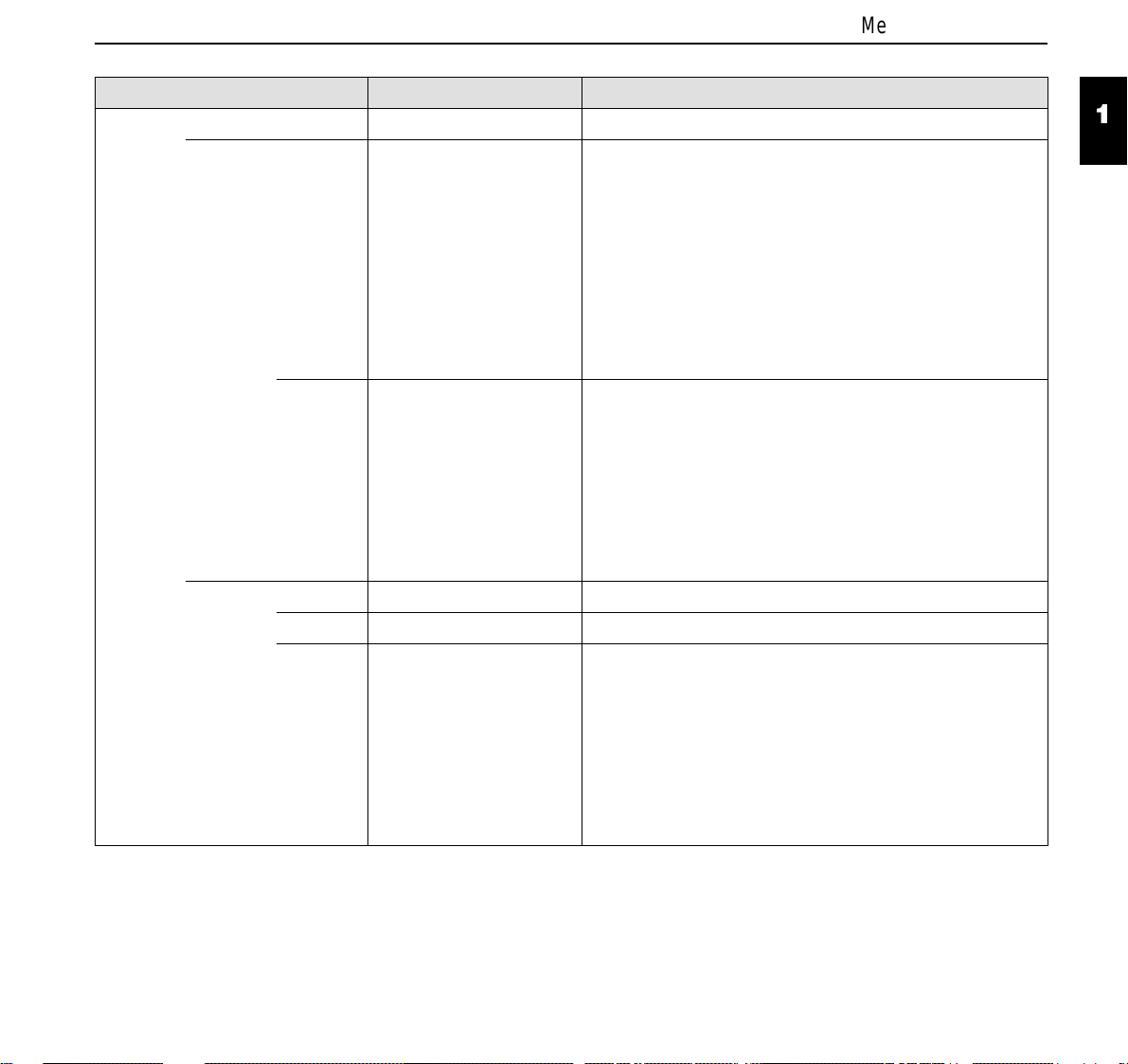

Menu description table

BACK

QUIT

?

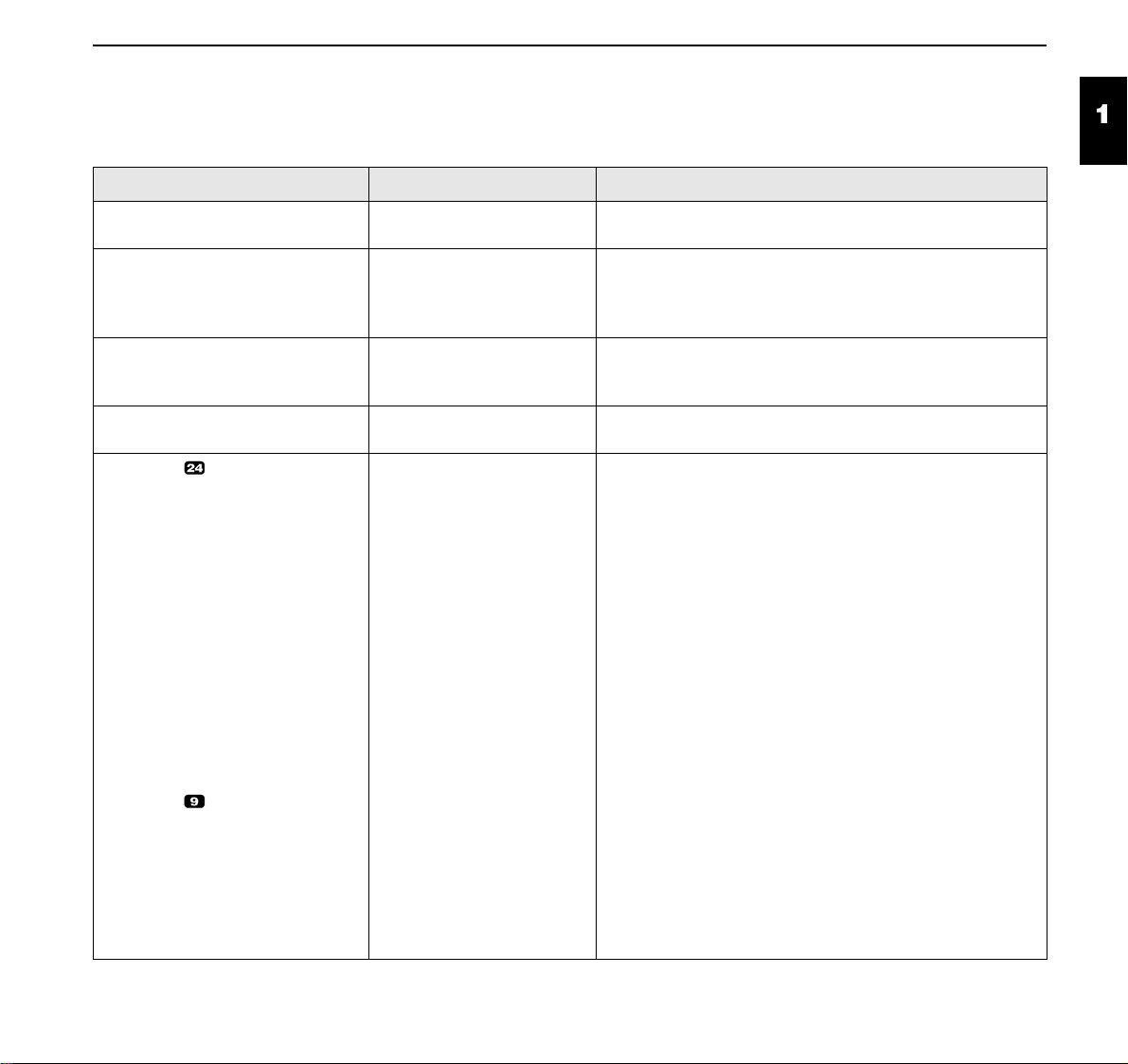

Menu description table

* Factory defaults

Parameter group Parameter Description

Print This parameter prints out all menu configurations. You will

find an example of a printout following this table.

Menu Load Menu=1 *

Load Menu=2

Load Menu=3

Load Menu=4

Reset Reset Menu?

No

Yes

L/R Adj -16 ... 00 *... +16 You will find a description of this function at the end of this

Font Draft

Draft Copy *

ROMAN

ROMAN PS

SANS SERIF

S SERIF PS

COURIER

PRESTIGE

SCRIPT

OCR B

OCR A

COURIER I

COUR I PS

ORATOR

GOTHIC

SOUVENIR

LN DRAFT

HS DRAFT

DRAFT*

QUADRATO NLQ

COURIER NLQ

OCR A/B DIN/ISO

DLL DRAFT

DLL NLQ

One of four menu configurations can be loaded.

The currently active menu configuration is reset to the

basic settings.

chapter.

The font can be selected. The fonts marked I (e.g. Courier

I PS) are IBM compatible character generators.

All fonts except Draft can be selected in LQ or in NLQ with

the 24-needle head.

If OCR A/B DIN/ISO is selected, observe the information

given with the Country parameter group.

1

4

1-13

Page 21

Menu description table

BACK

QUIT

?

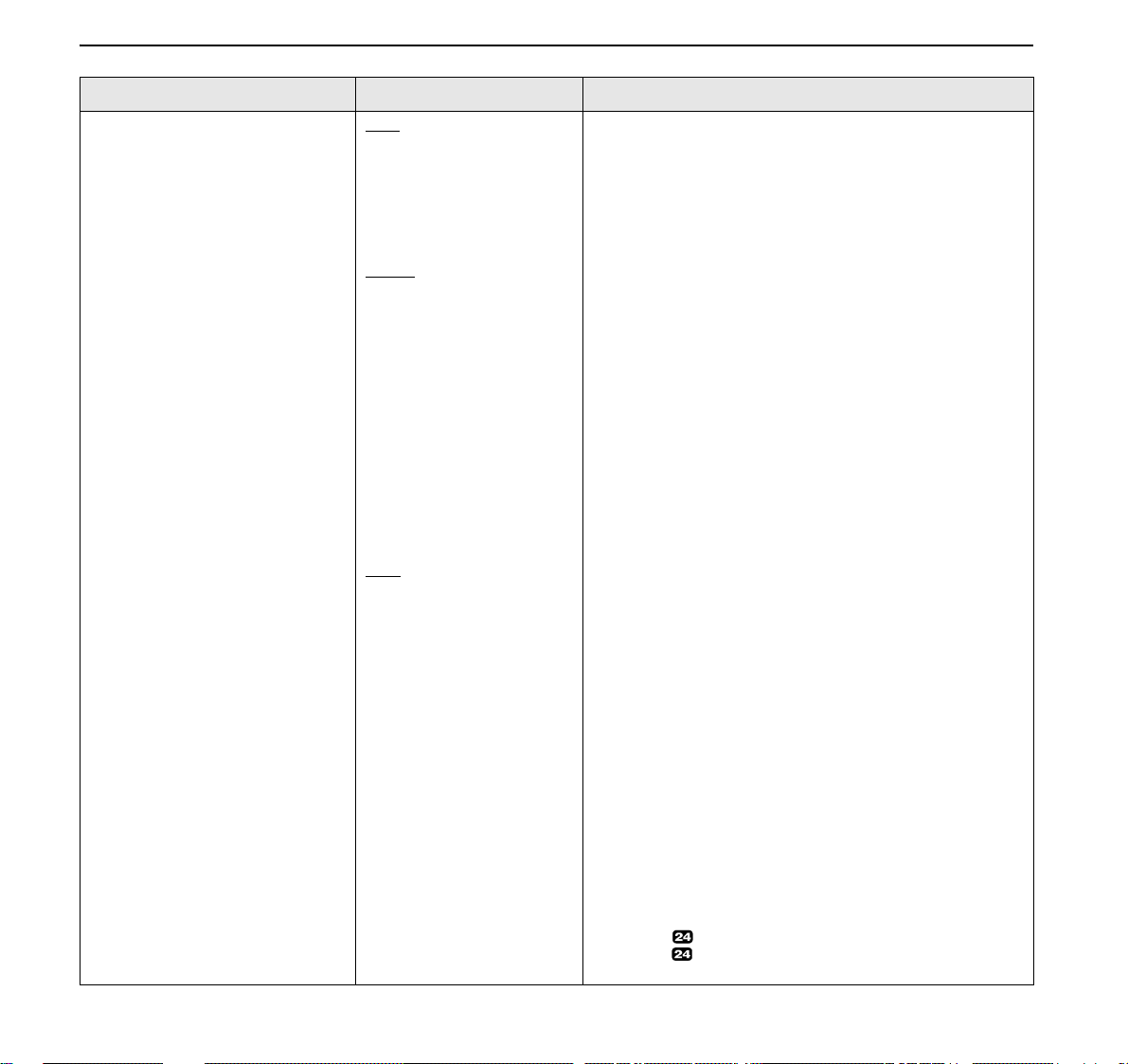

Parameter group Parameter Description

CPI 5 / 6 / 7,5 / 8,6 / 10 * /

12 / 15 / 17,1 / 20 CPI

LPI 2 / 3 / 4 / 6 * / 8 / 12 LPI Selects the line density (lpi = lines per inch).

Skip 0 * / 0,5 / ... / 3,5 inch Selects one of seven defined values for skip over the

ESCChar ESC *

ESC+$$

Emulate

MTPL

Epson LQ850+/

LQ1050+ *

IBM Propr. XL24

IBMProXL24+AGM

IBM Propr. XL *

MTPL

Epson FX 850+/

FX1050+

Bidir On *

Off

I/O

Buffer

Serial

Baud

0 / 1,7 / 10 / 40 / 64

kB

0 / 1,7 / 19 / 40 / 64 kB

19200

9600 *

4800

2400

1200

600

300

Selects the character density (cpi = characters per inch).

paper fold.

The type of escape character which leads escape

sequences can be selected. Escape character only or

escape character plus two $$ characters. (You will find a

description in chapter 2.)

Selection of the emulation mode. The MTPL emulation is

also available in the other em ulations.

The sequences of the IBM AGM mode are basically the

same as those of the IBM Proprinter XL24. The graphics

commands are similar to those of the Epson mode.

Note:

Epson LQ850+ ➨ narrow printer

Epson LQ1050+ ➨ wide printer

Switch on/off bidirectional printing.

The standard version is equipped with a parallel interface

only..

Selection of the size of the interface buffer.

Values 0 are not displayed if the serial interface is

installed.

This parameter is displayed only if the serial interface

module is installed.

Selection of Baud rate for data transmission (Baud = bits

per second).

1-14

Page 22

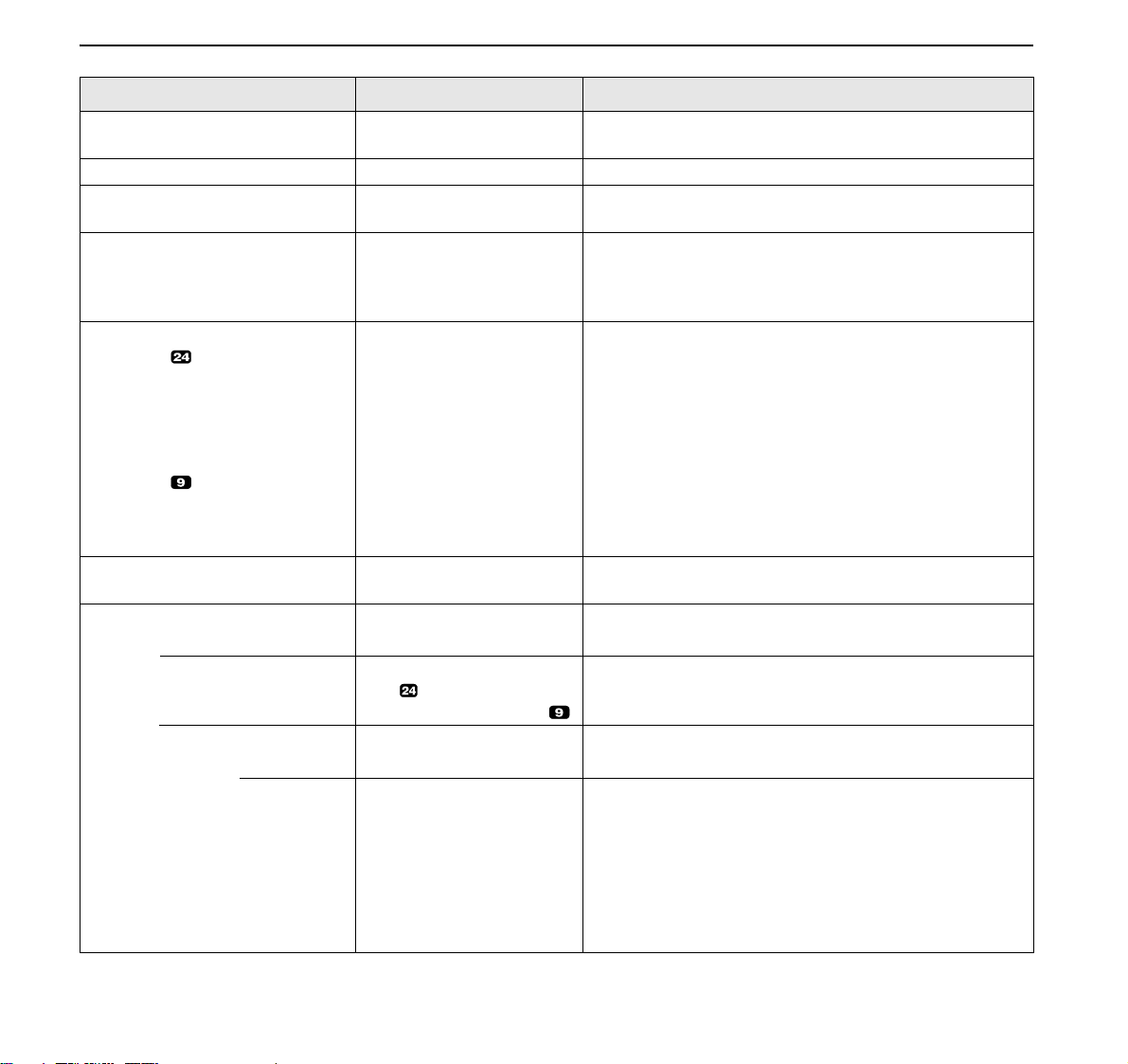

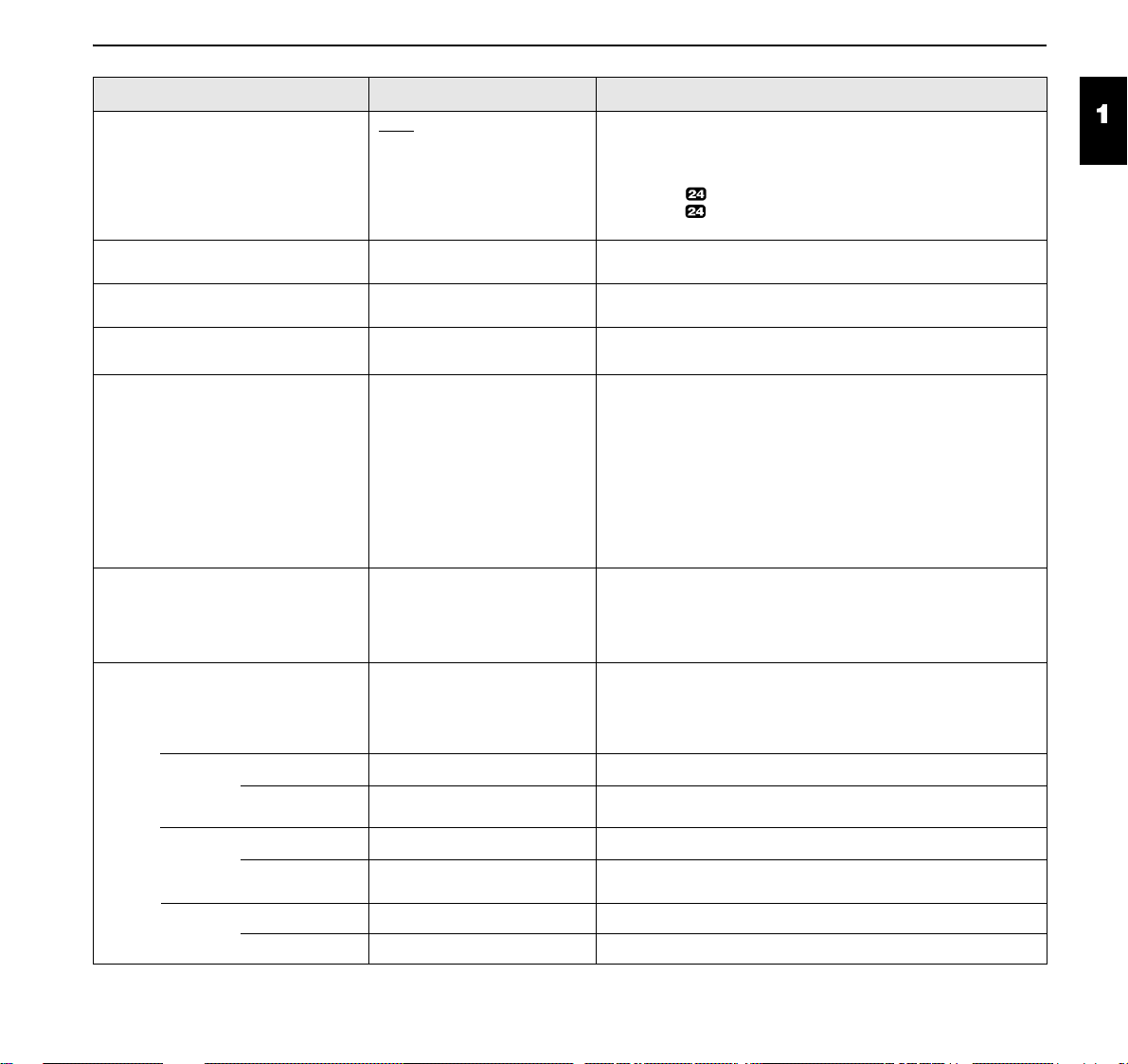

Parameter group Parameter Description

BACK

QUIT

?

Serial

Format

Protocol

Interf.

CG-Tab Graphic *

CharSet Standard

Country EPSON

8 Bit No 1Stop *

7 Bit Even 2 Stop

Odd

Mark

Spc

XON/XOFF *

Robust XON/XOFF

ENQ/STX

ETX/ACK

Dual *

Parallel

Serial

DLL

Italic

Extended *

E-US ASCII *

E-FRENCH

E-GERMAN

E-UK

E-DANISH I

E-SWEDISH

E-ITALIAN

E-SPANISH I

E-JAPANESE

E-NORWEGIAN

E-DANISH II

E-SPANISH II

E-L.AMERICAN

E-KOREAN

E-LEGAL

The number of data bits, a parity bit and the number of

stop bits per data byte can be set.

The following settings are possible for the parity bit:

NO = Transmission without parity bit

EVEN = Checking for even parity

ODD = Checking for odd parity

MARK/SPACE =T ransmission of 1 (MARK) or 0 (SP ACE)

instead of the parity bit

Selection of the protocol type.

Selection of the interface. In Dual mode the printer automatically changes between the parallel and the serial

interface (Shared mode).

Appears only if the Epson emulation has been selected.

Italic, graphics or DLL character sets can be selected.

Selects standard character set or extended character set.

Selects character sets.

If Font: OCR A/B DIN/ISO is selected for the -needle

printer, only the following parameters appear:

– OCR A DIN

– OCR B DIN

– OCR A ISO

– OCR B ISO/ANSI

– OCR A ANSI

** for the -needle version only

*** for the -needle version and Sans Serif, Roman,

Courier, Courier I only

Menu description table

1

4

1-15

Page 23

Menu description table

BACK

QUIT

?

Parameter group Parameter Description

Country ISO:

ISO 8859-1

ISO 8859-1 SAP

ISO 8859-2

ISO 8859-5

ISO 8859-7

ISO 8859-9**

ISO 8859-15

MTPL:

US ASCII

UK ASCII

FRENCH

GERMAN

ITALIAN

SWEDISH

NORWEGIAN

SPANISH

PORTUGUESE

CRO ASCII

ELOT 928**

BRASCII**

ABICOMP**

ROMAN8**

GREEK DEC**

COAX/TWINAX**

IBM:

TABLE 437

NEW 437**

TABLE 737

TABLE 850

NEW-BIG 850**

TABLE 851

TABLE 852

TABLE 857

TABLE 858

TABLE 860

OLD CODE 860**

TABLE 861

TABLE 863

FLARRO 863**

TABLE 864***

864 EXTENDED***

TABLE 865

865 HEBREW**

TABLE 866

866 BULGARIA

TABLE 1250

TABLE 1251

TABLE 1252

(Euro-Zeichen)

** for the -needle version only

*** for the -needle version and Sans Serif, Roman,

Courier, Courier I only

1-16

Page 24

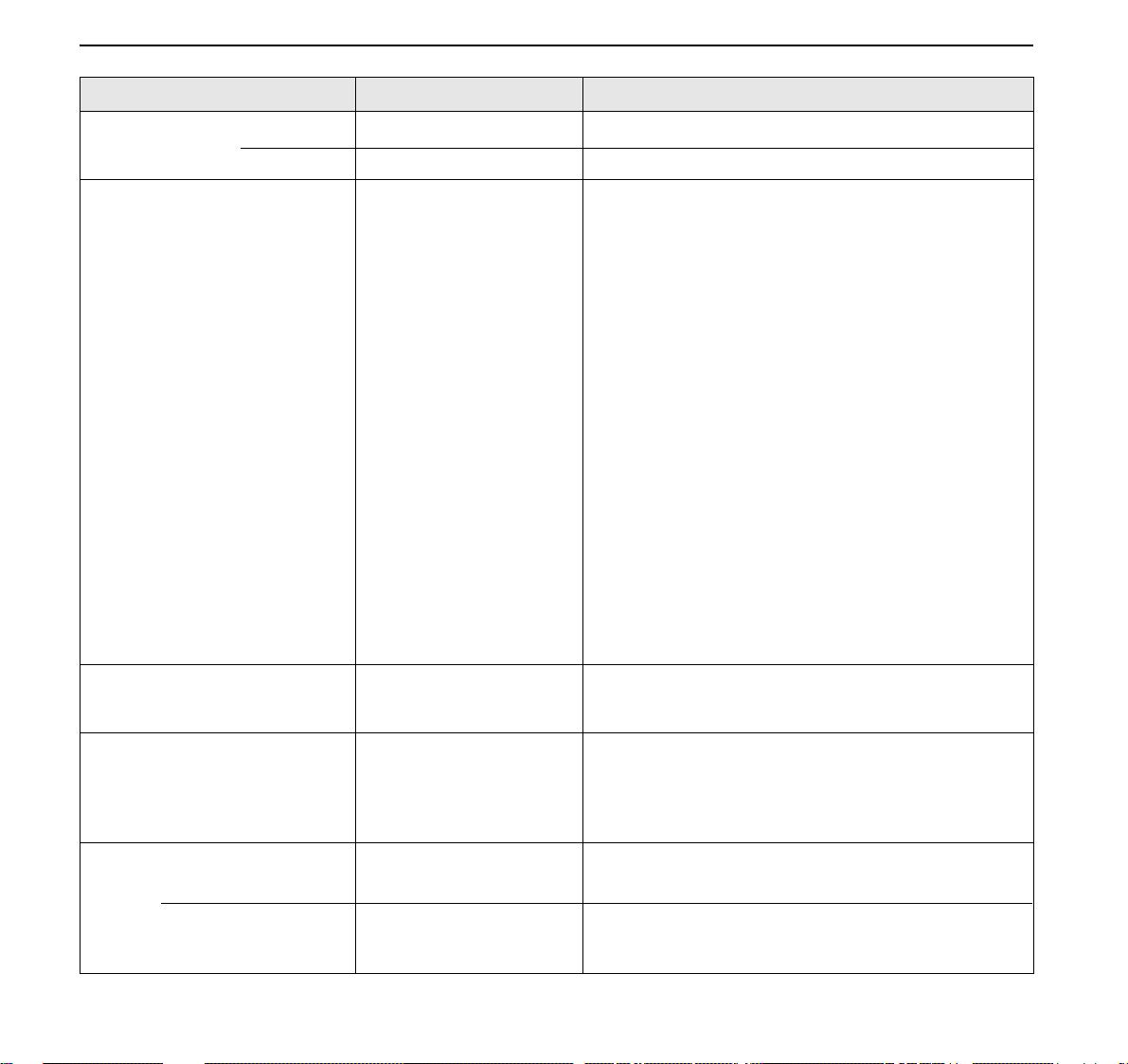

Parameter group Parameter Description

BACK

QUIT

?

Country IBM:

Sl. Zero On

Auto CR Off

Auto LF Off

MenLock Off

Language English *

Paper

TABLE 1253

TABLE 1254

FARSI***

URDO***

SIEMENS TURK**

DEC TURKISH**

Off *

On *

On *

Menu *

All

German

French

Italian

Spanish

** for the -needle version only

*** for the -needle version and Sans Serif, Roman,

Courier, Courier I only

Selects whether or not the Zero (0) is printed with a slash

(Ø).

Selection of a carriage return (CR) on every received line

feed (LF).

Selection of a line feed (LF) on every received carriage

return (CR).

With this function you can lock access to the menu or the

Setup mode. The Menu parameter is used to lock access to

the Menu mode; by selecting All, access to the Setup mode

is prevented. Only changing the paper path, loading and

ejecting the paper is allowed. If the Menu parameter is activated, access to Menu mode is also disabled, howev er,

paper path, font, character density and the head, TOF and

Tear functions can be set. The lock is removed by switching

on the printer while simultaneously pressing the Setup key.

The menu can be displayed in English, German, French,

Spanish or Italian.

The position of the first print line can be set individually for

each paper type. Values between 0/72 inch and 220/72

inch can be selected. (See also TOF, Setting the first

printing line in the operator’s manual).

Menu description table

1

4

Single

Trac. 1

Trac. 2

FormAdj

FormAdj

FormAdj

0/72 – 72/72; 12/72 *

0/72 – 220/72; 12/72 *

0/72 – 220/72; 12/72 *

Values for manual cut sheet feeding can be set.

Values for Tractor 1 can be set.

Values for Tractor 2 can be set.

1-17

Page 25

Menu description table

BACK

QUIT

?

Parameter group Parameter Description

ASF-auto

FormAdj 0/72 – 72/72; 12/72 *

AutoTear ViewTear = Off *

View =1s

3s

6s

Tear = 1s

3s

6s

Tear at TOF

Width 8 inch

13,2 inch

13,6 inch *

F-Eject Off *

ASF

Single

All

Formlen

Values for automatic sheet feeder can be set.

The Auto-Tear function, the Auto-View function or the

Tear

at TOF function can be selected optionally. With AutoView switched on, the text which was printed last can be

viewed. As soon as the printer receives data, the paper is

transported back to the “normal” print position. After the

print process has been completed, the printer waits the

preset interval and then transports th e paper back to the

Auto-View position.

With Auto-Tear switched on the paper starting position is

in the quick tear position, i.e. the paper’s quick tear perforation is positioned on the printer’s quick tear edge. As

soon as the printer receives data, the paper is transported back to the normal print position. After the print

process has been completed, the printer waits the preset

interval and then transports the paper back to the quick

tear position. If the quick tear edge is not level with the

paper perforation, this can be corrected (see the operator’s manual, Moving paper to the tear position).

If Tear at TOF is selected instead of the AutoTear or AutoView function, the printer feeds the fanfold paper up to the

tear edge when 1. no print data are queuing up and 2.

when the printer is in TOF position.

Sets the line length in inches. This parameter group is

only displayed in the menu of the wide printer.

Changes the paper outfeed of cut sheets.

Off: paper outfeed to the rear

ASF: paper outfeed to the manual sheet feeder

Single: paper outfeed to the front

All: Both to the manual sheet feeder

Form length adjustment.

You can select from two different form lengths.

1-18

Trac.1

This form length is applicable to paper in tractor 1, in the

manual cut sheet feeder and in the automatic sheet

feeder (ASF).

Page 26

Parameter group Parameter Description

BACK

QUIT

?

Formlen Trac.1

Lines 6 – 132 lines at 6 LPI; 72* If Lines is selected, the form length can be adjusted by

inputting the number of lines. The basis for this is the

adjustment of the parameter group LPI. If for example the

value 4 was set under LPI, this corresponds to a line

spacing of 1/4 of an inch. If a form length of 20 lines is now

set under Lines, the form length is calculated as follows:

20 lines x 1/4 of an inch = 5 inches.

The adjustment range is between 1 and 22 inches, which at

2 LPI means 2 – 44 lines and 12 – 264 lines at 12 LPI.

If any changes are made to the LPI parameter group at a

later time, this leaves the form length unchanged, i.e. the

number of lines changes.

Standard No Format*

DINA3 (420 mm)

DINA4 (297 mm)

DINA5 (210 mm)

DINB5 (250 mm)

DINB6 (176 mm)

DINC6 (162 mm)

Executive (10.5 inch)

Letter (11 inch)

Legal (14 inch)

Trac.2 This form length is applicable to paper in tractor 2 only.

Lines 6 – 132 lines at 6 LPI; 72* see Trac.1

Standard No Format*

DINA3 (420 mm)

DINA4 (297 mm)

DINA5 (210 mm)

DINB5 (250 mm)

DINB6 (176 mm)

DINC6 (162 mm)

Executive (10.5 inch)

Letter (11 inch)

Legal (14 inch)

Under Standard a number of different paper formats can

be selected directly, e.g. A4 Portrait, A4 Landscape, Legal,

Letter etc. If for “no format” the asterisk is displayed as the

selected setting, a form length was selected by Lines

which does not correspond to any listed standard format.

see Trac.1

Menu description table

1

4

1 - 19

Page 27

Menu description table

BACK

QUIT

?

Parameter group Parameter Description

Barcode On/Off * With this function selected it is possible to print different

barcodes and LCP (Large Character Printing). The definition and activation is performed by special sequences

through the interface. Since this selection is effective for

all emulations it must be noted that conflicts in sequence

conformity with the selected emulation may occur . For this

reason the barcode function must also be switched on

and off by MTPL sequences. (The possible barcodes,

LCP characters and their usage are described in the Barcode Programmer’s Application Manual and in chapter 2).

Barmode Secured

In secured mode, the space which the barcode characters require is “protected”. In each line, other barcode or

normal characters can also be printed. These additional

characters are printed in the current line and in the subsequent lines, without affecting the barcode. Consequently,

normal characters can be printed in every line to the right

or left of the barcode.

Unsecured *

Prn Ipct Normal *

High

1-20

In unsecured mode, the required paper transport for printing barcodes and LCP is carried out automatically and it

is not possible to print more than one line of normal characters in the barcode line. All characters in the mixed line

are printed such that their bottom edges are in a straight

line.

This function may be switched on and off by sequences.

For more information about Barmode see chapter 2.

When PrnIpct = High is set with multi-part paper, the

impact force is increased if the paper thickness lever is in

position 2 to 8. The printing speed is thereby reduced.

Page 28

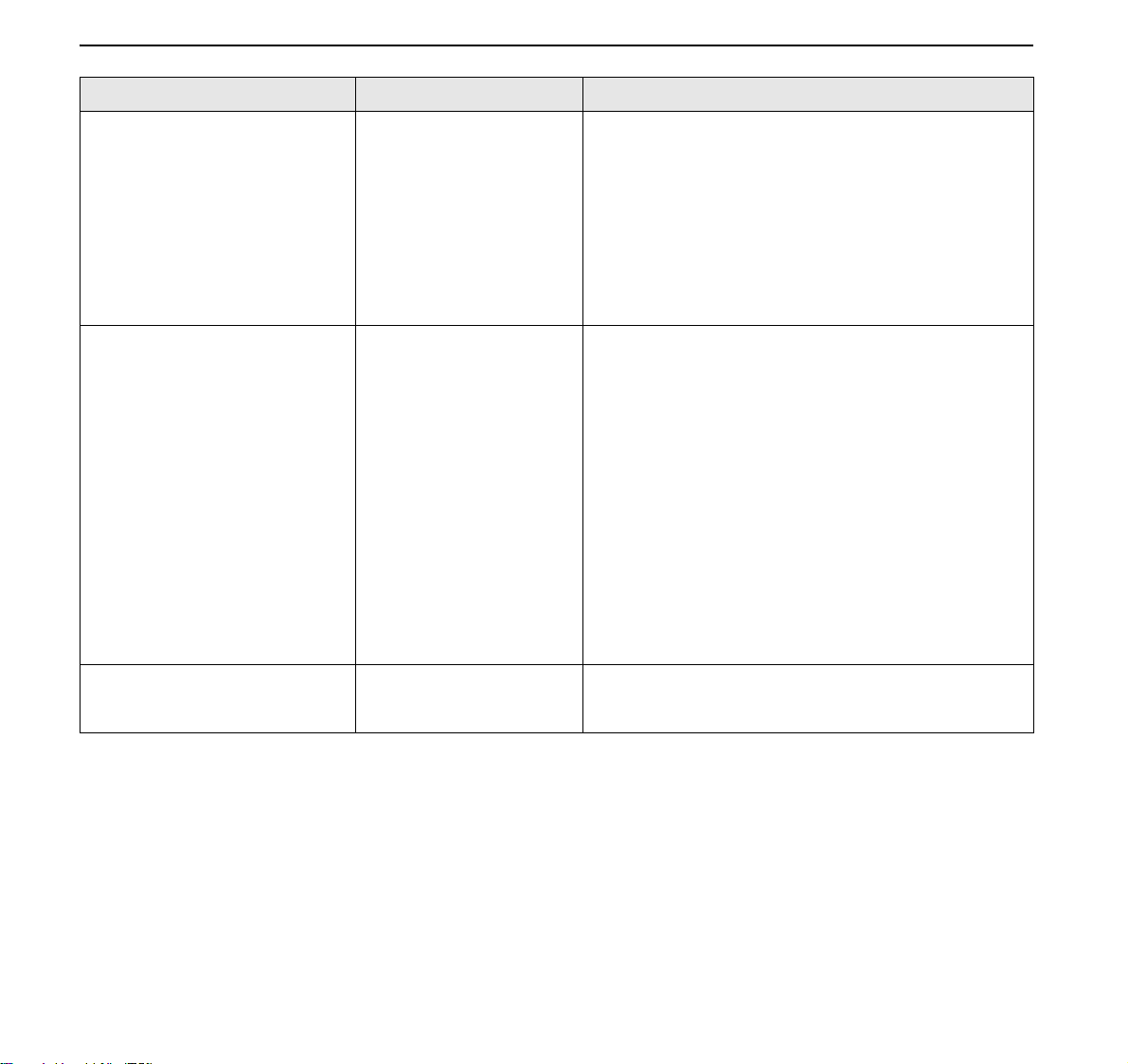

Menu settings

BACK

QUIT

?

(example)

Menu settings (example)

1-21

Page 29

Bidirectional print adjustment (L/R Adj)

BACK

QUIT

?

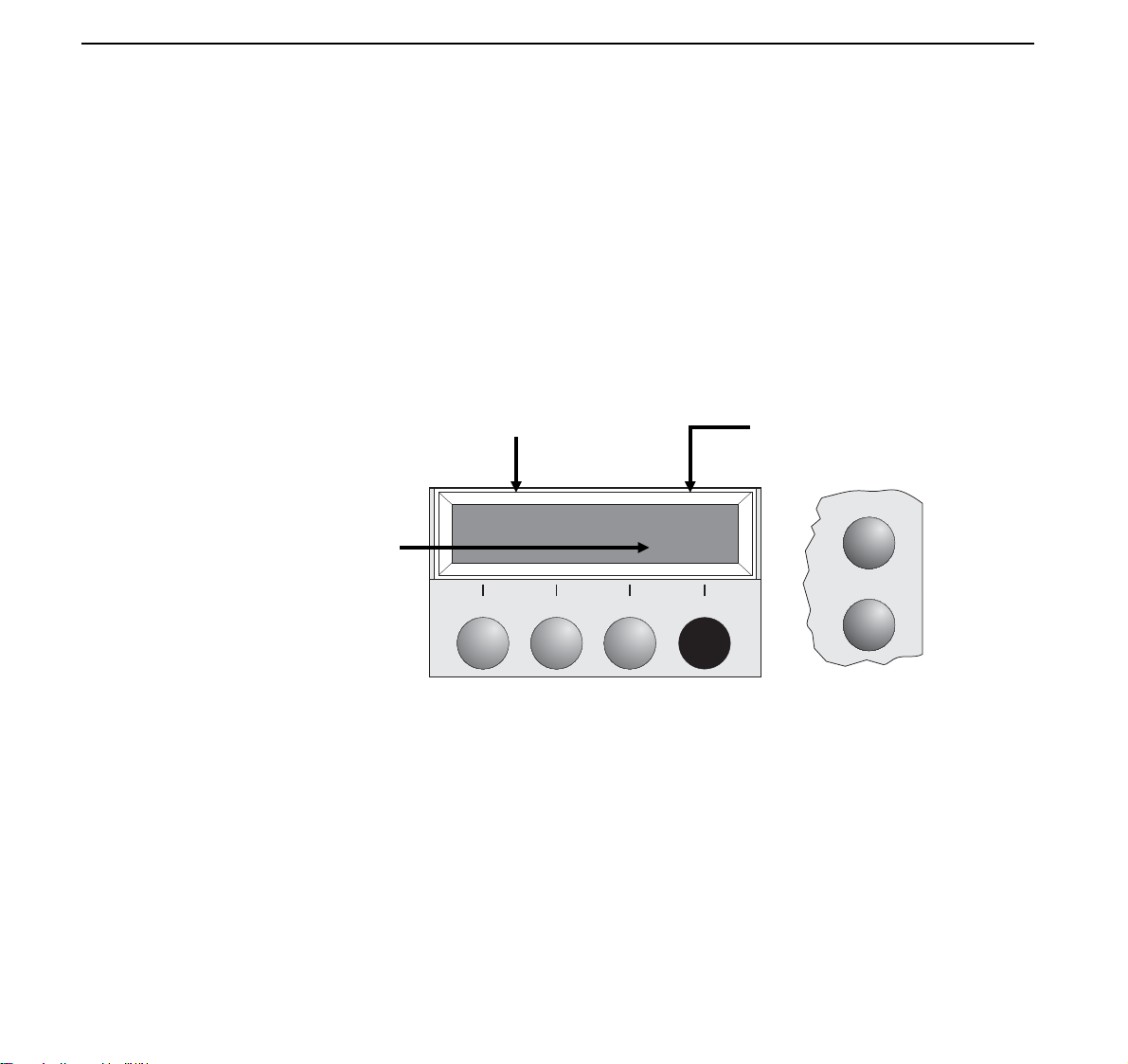

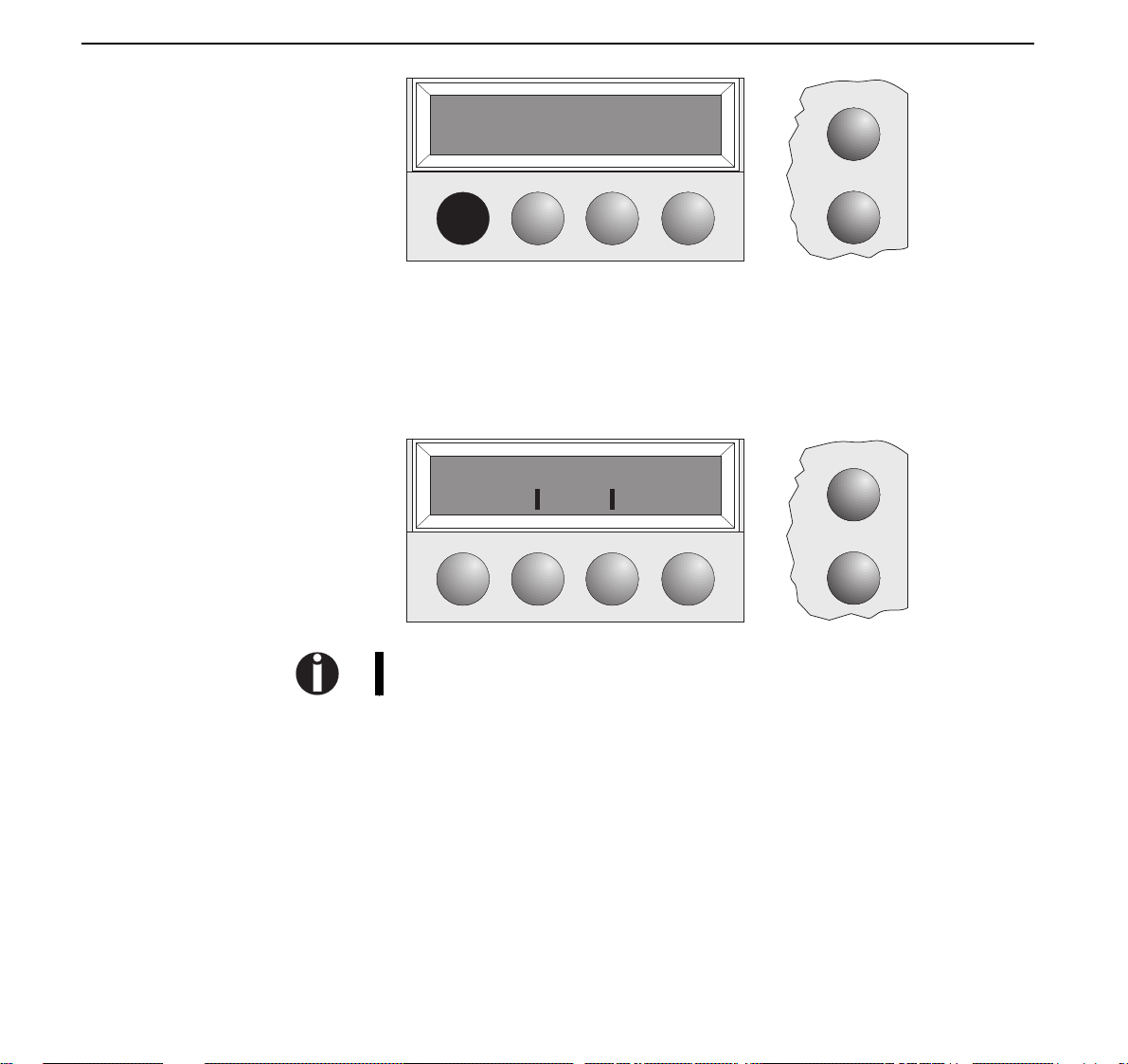

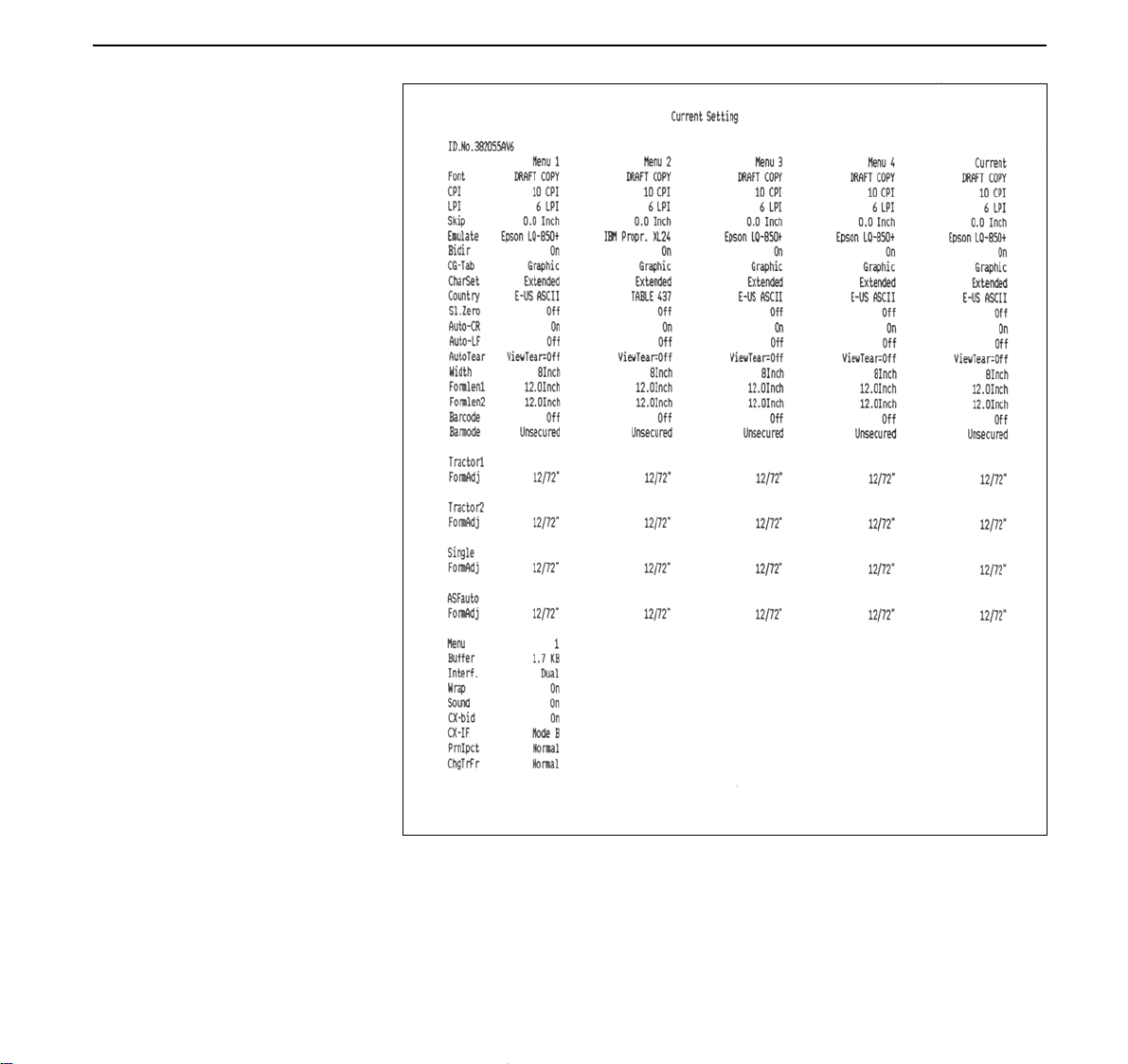

Bidirectional print

adjustment (L/R Adj)

Select from the available settings to test and adjust the divergent positions

of lines printed from right to left and from left to right.

The left/right adjustment should be made using fanfold paper, since the

paper should be positioned in the view position in order to check paper offset (which is not possible with cut sheets).

L/R Adj= 00 *

Online

Set < > Exit

Setup

For this purpose two lines with the character “I” are printed underneath

each other. The number following the printer lines designates the value

which is currently set.

Example:

1 - 22

wrong

IIIII +10 IIIII 00

IIIII IIIIII

offset

right

no offset

Page 30

Emulations 2

BACK

QUIT

?

General When a printer understands the control set written for another printer type,

it is said to emulate the other printer. Your printer emulates, i.e. “understands” the IBM Proprinter X24e/XL24e and the Epson LQ 850/1050 in its

standard 24 needle version.

Escape sequences Escape sequences or control codes tell the printer that the following trans-

mitted code is a printer command and not a printable character. They allow

the selection of printer functions or the changing of printer parameters from

the computer. By transmitting an escape sequence, you are able to change

the previously set configuration of the printer (e.g. character set).

2

4

What are escape

sequences?

Generally, an escape sequence consists of an ESCape control character

(ESC = decimal 27 or hexadecimal 1B) fol lowed by one or more characters,

which represent commands to the printer. The control character ESC followed

by the character “4” tells your printer to print the following text in italics.

MTPL sequences Apart from the standard Escape sequences and control codes your printer

is equipped with MTPL sequences (MTPL = Tally Printer Language).

These sequences provide a large number of additional ways to control

your printer. Many functions can only be carried out using the MTPL sequences as you will see when you look at the list of available command

codes.

What are control

codes?

Control codes are similar to escape sequences because they instruct the

printer to do a specific function. However, unlike escape sequences, control codes do not begin with the ESC control code. Instead, they consist of

special single-character non-printing commands (e.g. LF, FF, DC2).

2 - 1

Page 31

The $$ procedure

BACK

QUIT

?

The $$ procedure Most of the printer functions can be selected with control sequences (ESC

sequences). For this purpose, the signal character ESC, followed by the

specific sequence must be transmitted from the computer to the printer.

This ESC character is automatically substituted when two $ characters ($$)

are placed immediately after each other in the text and is transmitted to the

printer or if the parameter Escape=ESC+$$ is selected in the printer menu.

Example:

In the MTPL + IBM Proprinter emulation, bold print can be switched on by

the sequence <ESC>E and can be switched off with the sequence

<ESC>F.

Input:

Output:

This procedure is significant when you are working with older text programs that do not have any or an inadequate printer driver.

It is also possible to insert ESC sequences in normal ASCII texts (e.g.

program listings) with this procedure. The function of the ESC character

remains unaffected.

Highlight the word $$E Printer $$F with bold print

Highlight the word Printer with bold print

2 - 2

Page 32

How are escape sequences used?

BACK

QUIT

?

How are escape

sequences used?

Escape sequences are transmitted to the printer by your computer software. Many software applications allow insertion of escape sequences and

control codes within the generated text. Before you start working with

escape sequences and control codes, we recommend that you study the

computer software manual.

To enter control codes the Ctrl key and an ASCII character must be

pressed simultaneously. For instance, by pressing Ctrl and J a line feed is

accomplished (it is required to output the character string on the printer).

More information concerning this topic is contained in your computer soft-

ware manual and the corresponding Programmer’s Application Manuals

(see Appendix D

The selected emulation must correspond to the printer driver of your application program.

Settings caused by ESC sequences remain valid, until they are switched

off by another control code. All settings are reset to the original menu,

when the printer is switched off.

Options and accessories

).

2

4

2 - 3

Page 33

How are escape sequences used?

BACK

QUIT

?

MTPL As the emulations do not cover the entire scope of your printer, a new

printer language has been created. Using MTPL you are able to optimize

operation and handling.

MTPL can be used in connection with other emulations or can be used

alone.

Example in BASIC open “LPT1:” as #1

width #1,255

Text1$ = “10 characters/inch”

Text2$ = “15 characters/inch”

ESC$ = chr$(27)

print #1,ESC$;"[4w";Text1$;ESC$;"[6w";Text2$;ESC$;"[4w";Text1$

end

Example in Pascal program cpi_example;

uses printer;

const ESC = #27;

Text1 = “10 characters/inch”;

Text2 = “15 characters/inch”;

begin

writeln(lst,Esc,"[4w",Text1,ESC,"[6w",Text2,Esc,"[4w",Text1);

end.

Printout After the program has been completed the following text appears:

10 characters/inch

2 - 4

15 characters/inch 10 characters/inch

Page 34

List of available control codes

BACK

QUIT

?

List of available

control codes

The IBM Proprinter X/XL and Epson FX850/1050 emulations only apply to the

9-needle printer version, whereas the IBM Proprinter X24/XL24 and Epson

LQ850+/1050+ emulations only apply to the 24-needle versions.

In the following table the available sequences in the various emulations are

marked with the symbol ✔. MTPL sequences can be used in any of the emulation modes. For this reason they are marked with an asterisk (*) in these emulations.

MTPL Propr. Propr. FX850 LQ850+ AGM Code Function

IBM IBM Epson Epson IBMX/XL X24XL24 FX1050 LQ1050+

✔✔ ✔ ✔ ✔

✔✔ ✔ ✔ ✔

✔✔ ✔ ✔ ✔

✔✔ ✔ ✔ ✔

✔

✔

✔

✔

✔

✔

✔

✔

✔

✔

✔

✔

✔

✔

✔

✔

✔

✔

✔

*****

*****

*****

*****

*****

*****

*****

*****

*****

*****

*****

*****

*****

*****

*****

*****

*****

*****

*****

<BEL> Acoustic alarm

<BS> Backspace

<CAN> Cancel

<ESC>[<n><SP>r print the following 16 characters max. in

transparent mode (<n> = 1 - 16)

<ESC>[:y right justification and centering OFF

<ESC>[=z emphasized mode ON

<ESC>[>z emphasized mode ON

<ESC>[?1~ MTPL command set

<ESC>[?10~ end of command interpretations

<ESC>[?11~ start of Barcode interpretation

<ESC>[?3~ MTPL + IBM-Proprinter command set

<ESC>[?4~ MTPL + IBM-Proprinter-24 command set

<ESC>[?5~ MTPL + EPSON FX command set

<ESC>[?50h load character set with 256 characters

<ESC>[?50l load 2 character sets with 94 character

<ESC>[?51h Set "Proportional not in Draft“

<ESC>[?51l Reset "Proportional not in Draft“

<ESC>[?52h "Ignore print quality“ ON

<ESC>[?52l "Ignore print quality“ OFF

<ESC>[?6~ MTPL + EPSON LQ command set

<ESC>[?7h at lineoverflow CR + LF

<ESC>[?7l at lineoverflow data are lost

<ESC>[0;0r clear top and bottom margin

2

4

2 - 5

Page 35

List of available control codes

BACK

QUIT

?

MTPL Propr. Propr. FX850 LQ850+ AGM Code Function

IBM IBM Epson Epson IBMXL XL24 FX1050 LQ1050+

✔

✔

✔

✔

✔

✔

✔

✔

✔

✔

✔

✔

✔

✔

✔

✔

✔

✔

✔

✔

✔

✔

✔

✔

✔

✔

✔

✔

✔

✔

✔

✔

✔

✔

✔

*****

*****

*****

*****

*****

*****

*****

*****

*****

*****

*****

*****

*****

*****

*****

*****

*****

*****

*****

*****

*****

*****

*****

*****

*****

*****

*****

*****

*****

*****

*****

*****

*****

*****

*****

<ESC>[0;0s clear left and right margin

<ESC>[0c request for printer identification

<ESC>[0g clear horizontal tab stop at current position

<ESC>[0m clear all selected fonts

<ESC>[0n device status report: "Ready, no malfunction“

<ESC>[0<n1>;<n2>{ cut sheet paper

<ESC>[0<SP>K horizontal character spacing 10 cpi

<ESC>[0<SP>L vertical spacing 6 lpi

<ESC>[0<SP>X high print quality

<ESC>[0w horizontal spacing 5 cpi

<ESC>[0y draft print quality (DPQ)

<ESC>[0z superscript ON

<ESC>[1g clear all vertical tab stops at current position

<ESC>[1m bold or increased intensity

<ESC>[1n device status report: “Busy, no malfunction”

<ESC>[1<SP>L vertical spacing 4 lpi

<ESC>[1<SP>X medium print quality

<ESC>[1w horizontal spacing 6 cpi

<ESC>[1z subscript ON

<ESC>[10m font 0 (Draft)

<ESC>[10y right justification and centering OFF

<ESC>[10z microscript ON

<ESC>[11l reset positioning unit mode (PUM)

<ESC>[11h set positioning unit mode (PUM)

<ESC>[11m font 1 ( NLQ Quadrato, NLQ Courier)

<ESC>[11w horizontal spacing 20 cpi

<ESC>[11y high speed draft print quality

<ESC>[12m font 2 ( NLQ Courier, LQ Courier)

<ESC>[12w horizontal spacing 10 cpi

<ESC>[12y letter print quality (LQ)

<ESC>[12y high resolution print quality

<ESC>[12z double height ON (upper half)

<ESC>[13m font 3 ( HS Draft, NLQ Sans Serif)

<ESC>[13z double height ON (lower half)

<ESC>[14m font 4 ( NLQ Quadrato, LQ Sans Serif)

2 - 6

Page 36

List of available control codes

BACK

QUIT

?

MTPL Propr. Propr. FX850 LQ850+ AGM Code Function

IBM IBM Epson Epson IBMXL XL24 FX1050 LQ1050+

✔

✔

✔

✔

✔

✔

✔

✔

✔

✔

✔

✔

✔

✔

✔

✔

✔

✔

✔

✔

✔

✔

✔

✔

✔

✔

✔

✔

✔

✔

✔

✔

✔

✔

✔

*****

*****

*****

*****

*****

*****

*****

*****

*****

*****

*****

*****

*****

*****

*****

*****

*****

*****

*****

*****

*****

*****

*****

*****

*****

*****

*****

*****

*****

*****

*****

*****

*****

*****

*****

<ESC>[15m font 5 ( NLQ Courier, LQ Roman)

<ESC>[16m font 6 ( NLQ Quadrato, LQ Script)

<ESC>[17m font 7 ( NLQ Quadrato, LQ Pre st ige)

<ESC>[18m font 8 ( NLQ Quadrato, LQ OCR-B)

<ESC>[19m font 9 ( NLQ Quadrato, LQ OCR-A)

<ESC>[2g clear all horizontal tab stops at current line

<ESC>[2J eject form

<ESC>[2<SP>K horiz ontal character spacing 15 cpi

<ESC>[2<SP>L vertical spacing 3 lpi

<ESC>[2<SP>X low print quality

<ESC>[2w horizontal spacing 7.5 cpi

<ESC>[2y proportional mode ON

<ESC>[2z double height, super-/sub- and microscript OFF

<ESC>[21m double underline mode

<ESC>[21<n1>;<n2>{ bin 1 (front)

<ESC>[23m italic mode OFF

<ESC>[24m underline mode OFF

<ESC>[26m proportional mode ON

<ESC>[3g clear all horizontal tab stops

<ESC>[3m italic mode ON

<ESC>[3n device status report: “Some malfunction detected”

<ESC>[3<SP>K horiz ontal character spacing 6 cpi

<ESC>[3<SP>L vertical spacing 12 lpi

<ESC>[3w horizontal spacing 8.6

<ESC>[3z line density 6 lpi

<ESC>[4g clear all vertical tab stops

<ESC>[4m underline mode ON

<ESC>[4<SP>L vertical spacing 8 lpi

<ESC>[4w horizontal spacing 10 cpi

<ESC>[4y NLQ at 10 cpi

<ESC>[4z line density 8 lpi

<ESC>[5<n1>;<n2>{ fanfold paper tractor 1

<ESC>[6<n1>;<n2>{ fanfold paper tractor 2

<ESC>[5n request for device status report

<ESC>[5w horizontal spacing 12 cpi

2

4

2 - 7

Page 37

List of available control codes

BACK

QUIT

?

MTPL Propr. Propr. FX850 LQ850+ AGM Code Function

IBM IBM Epson Epson IBMXL XL24 FX1050 LQ1050+

✔

✔

✔

✔

✔

✔

✔

✔

✔

✔

✔

✔

✔

✔

✔

✔

✔

✔

✔

✔

✔

✔

✔

✔

✔

✔

✔

✔

✔

✔

✔

✔

✔

✔

✔

*****

*****

*****

*****

*****

*****

*****

*****

*****

*****

*****

*****

*****

*****

*****

*****

*****

*****

*****

*****

*****

*****

*****

*****

*****

*****

*****

*****

*****

*****

*****

*****

*****

*****

*****

<ESC>[5y NLQ at 12 cpi

<ESC>[5z graphics normal

<ESC>[50m proportional mode OFF

<ESC>[50<n1><n2>{ move paper to normal print position

<ESC>[51<n1><n2>{ move paper to tear-off position

<ESC>[52<n1><n2>{ move paper to view position

<ESC>[53m overline mode ON

<ESC>[55m overline mode OFF

<ESC>[6~ reset to initial state

<ESC>[6w horizontal spacing 15 cpi

<ESC>[6z graphics invers

<ESC>[7w horizontal spacing 17.1 cpi

<ESC>[7y proportional mode OFF

<ESC>[7z set bit 8 = unchanged

<ESC>[8w double strike OFF

<ESC>[8y right justification ON

<ESC>[8z set bit 8 = 0

<ESC>[9<SP>L vertical spacing 2 lpi

<ESC>[9w double strike ON

<ESC>[9y centering ON

<ESC>[9z set bit 8 = 1

<ESC>[<n>’ horizontal position absolute

<ESC>[<n>a horizontal position relative

<ESC>[<n>d vertical position absolute

<ESC>[<n>e vertical position relative

<ESC>[<n>j h orizontal position backward

<ESC>[<n>k vertical position backward

<ESC>[<n>n request for printer status

<ESC>[<n>p Hori zo n t al Motion Index

<ESC>[<n>q horizontal step

<ESC>[<n><SP>\ additional character spacing

<ESC>[<n><SP>f reduced character spacing

<ESC>[<n><SP>g character spacing

<ESC>[<n><SP>h line spacing

<ESC>[<n><SP>U line home

2 - 8

Page 38

List of available control codes

BACK

QUIT

?

MTPL Propr. Propr. FX850 LQ850+ AGM Code Function

IBM IBM Epson Epson IBMXL XL24 FX1050 LQ1050+

✔

✔

✔

✔

✔

✔

✔

✔

✔

✔

✔✔ ✔ ✔ ✔

✔✔ ✔ ✔ ✔

✔

✔

✔

✔

✔

✔

✔

✔

✔

*****

*****

*****

*****

*****

*****

*****

*****

*****

*****

✔✔

✔✔✔✔

✔✔✔✔

✔✔

✔✔

✔✔

✔✔

✔✔

*****

*****

*****

*****

*****

*****

*****

✔✔

✔

*****

*****

<ESC>[<n><SP>V line limit

<ESC>[<n>t form lenght in lines

<ESC>[<n>v vertical tab stop

<ESC>[<n1><n2><SP>B graphic size modification

<ESC>[<n1><n2>f horizontal and vertical position absolute

<ESC>[<n1><n2>r top and bott om margin

<ESC>[<n1><n2>s left and right margin

<ESC>[<n1><n2><SP>D select font

<ESC>[<n1><n2><SP>G spacing increment

<ESC>[<n1>u set horizontal tab stop

<CR> Carriage Return

<DC1> printer online

<DC2> reset condensed print

<DC4> reset enlarged print mode

<DEL> Delete

<ESC>!<n> print mode selection (<n> = 0 - 255)

<ESC># bit 8 = unchanged

<ESC>$<n1><n2> set absolute horizontal step <n1> = 0 - 255

Formula: n = absolute print position

<ESC>%<0> select ROM CG

<ESC>%<1> select Download CG

<ESC>%3<n1><n2> graphics 60 dpi

<ESC>%4<n1><n2> graphics 120 dpi

<ESC>%5<n1><n2> graphics 80 dpi

<ESC>%6<n1><n2> graphics 240 dpi

<ESC>%7<n1><n2> graphics 240 dpi

<ESC>%8<n1><n2> graphics 72 dpi

<ESC>%9<n1><n2> graphics 90 dpi

<ESC>&<0><x><y>... define Download characters

<ESC>(- Line Marking Selection

<ESC>(<n> selection of the char acter set ; see chapter“Available cha-

racter sets and fonts”

<ESC>(F designate character set G0

2

4

<n2> = 0 - 3

<n2> = INT (n/256)

<n1> = n MOD 256

2 - 9

Page 39

List of available control codes

BACK

QUIT

?

MTPL Propr. Propr. FX850 LQ850+ AGM Code Function

IBM IBM Epson Epson IBMXL XL24 FX1050 LQ1050+

✔

✔

✔

*****

*****

✔✔✔

✔✔✔

✔✔✔

✔✔✔

✔✔✔

✔✔✔

✔✔✔

✔✔✔

✔✔✔

✔✔✔

✔✔✔

✔✔✔

*****

✔✔✔✔

✔✔

✔✔✔✔

✔✔

✔✔

✔✔

✔✔

✔✔

✔✔

✔✔

✔✔

✔✔

✔✔

✔✔

✔✔✔✔

✔✔✔✔

<ESC>)F designate character set G1

<ESC>*F designate character set G2

<0><n1><n2> graphics 60 dpi

<ESC>

*

<ESC>

<1><n1><n2> graphics 120 dpi

*

<2><n1><n2> graphics 120 dpi

<ESC>

*

<3><n1><n2> graphics 240 dpi

<ESC>

*

<4><n1><n2> graphics 80 dpi

<ESC>

*

<5><n1><n2> graphics 72 dpi

<ESC>

*

<6><n1><n2> graphics 90 dpi

<ESC>

*

<32><n1><n2> graphics 60 dpi

<ESC>

*

<33><n1><n2> graphics 120 dpi

<ESC>

*

<38><n1><n2> graphics 90 dpi

<ESC>

*

<39><n1><n2> graphics 180 dpi

<ESC>

*

<40><n1><n2> graphics 360 dpi

<ESC>

*

<ESC>+F designate character set G3

✔

<ESC>+<n> set line feed to n/360 inch (<n>= 0 - 255)

<ESC>-<1> underline mode ON

<ESC>-1 underline mode ON

<ESC>-<0> underline mode OFF

<ESC>-0 underline mode OFF

<ESC>/<m> select vertical tab channel (<m> = 0 - 3)

<ESC>: set condensed print with 12 cpi

<ESC>:<0><n><m> copy ROM CG

<ESC>< set unidirectional printing for one line

<ESC><DC2> reset condensed print

<ESC><DC4> reset enlarged pri nt mode

<ESC><EM>0 deactivate sheet feeder operation

<ESC><EM>1 magazine 1 (front)

<ESC><EM>4 activate sheet feeder operation

<ESC><EM>R eject paper

<ESC><SI> set condensed print

<ESC><SO > set enlarged print mode

Formula: n = length of graphics data

<n2> = INT (n/256)

<n1> = n MOD 256

2 - 10

Page 40

List of available control codes

BACK

QUIT

?

MTPL Propr. Propr. FX850 LQ850+ AGM Code Function

✔

✔

IBM IBM Epson Epson IBMXL XL24 FX1050 LQ1050+

✔✔

✔✔

✔✔

✔✔

✔✔

✔✔

*****

*****

✔✔

✔

✔

✔

✔

✔

✔

✔

✔

✔

✔

✔

✔✔

✔✔

✔✔

✔

✔✔

<ESC><SP><n> set character spacing (<n> = 0 - 127)

<ESC>= set bit 8 = 0

<ESC>=<C1><C2>... downloading fonts/characters

<ESC>> set bit 8 = 0

<ESC>?<s><n> reassign graphics mode

<ESC>@ pri n ter initializati o n

<ESC>[?53h column 8+9 of the character table are printable characters

<ESC>[?53

<ESC>[@<n1><n2>... set double height

<ESC>[\<n1><n2>... changes vertical basic graduations

<ESC>[F sheet feeder

<ESC>[g<n1><n2><0> graphics 60 dpi

<ESC>[g<n1><n2><1> graphics 120 dpi

<ESC>[g<n1><n2><11> graphics 180 dpi

<ESC>[g<n1><n2><12> graphics 360 dpi

<ESC>[g<n1><n2><2> graphics 120 dpi

<ESC>[g<n1><n2><3> graphics 240 dpi

<ESC>[g<n1><n2><8> graphics 60 dpi

<ESC>[g<n1><n2><9> graphics 120 dpi

<ESC>[T<n1><n2> select character set

<ESC>\<n1><n2> set relative horizontal step

<ESC>\<n1><n2> transparent mode for following characters

<ESC>^ transparent mode for the following character

<ESC>^ select 9 pin graphics mode

<ESC>_<1> overscore mode ON

<s> = K, L, Y or Z

<n> = 0 - 4, 6, 32, 33, 38 - 40

l

column 8+9 of the character table are printable characters

or ignored (dependent of emulation)

Formula: n = length of graphics data bytes

Formula: n = relative print position

Formula: n = number of characters to be printed

2

4

<n2> = INT (n/256)

<n1> = n MOD 256

<n2> = INT (n/256)

<n1> = n MOD 256

<n2> = INT (n/256)

<n1> = n MOD 256

2 - 11

Page 41

List of available control codes

BACK

QUIT

?

MTPL Propr. Propr. FX850 LQ850+ AGM Code Function

IBM IBM Epson Epson IBMXL XL24 FX1050 LQ1050+

✔✔

✔✔✔✔

✔✔✔

✔✔✔✔

✔✔

✔✔

✔✔✔

✔✔

✔✔

✔✔

✔✔

✔✔

✔✔

✔✔

✔✔

✔✔

✔

✔

✔✔

✔✔

✔✔✔

✔✔

✔✔

✔✔✔✔

✔✔

✔✔

✔✔✔✔

✔✔✔✔

✔

<ESC>_<0> overscore mode OFF

<ESC>0 Set line feed to 1/8 inch

<ESC>1 Set line feed to 7/72 Inch

<ESC>2 Set line feed to 1/6 inch

<ESC>2 Set line feed to n/72 inch

<ESC>3<n> Set line feed to n/180 inch (<n> = 0 - 255)

<ESC>3<n> Set line feed to n/216 inch (<n> = 1 - 255)

<ESC>4 italic mode ON

<ESC>4 setting top of form

<ESC>5 italic mode OFF

<ESC>5<1> automatic line feed ON

<ESC>5<0> automatic line feed OFF

<ESC>6 print ASCII codes 128 to 159

<ESC>6 character set 2 (extended)

<ESC>7 suppress ASCII codes 128 to 159

<ESC>7 character set 1 (Standard)

<ESC>8 paper end detector OFF

<ESC>9 paper end detector ON

<ESC>a<n> select justification and centering mode

<n> = 0 ➵ left justification

<ESC>A<n> Set line feed to n/60 inch (<n> = 1 - 127)

<ESC>A<n> Set n/72 inch line feed (<n> = 1 - 85)

<ESC>b<m><0> clear all tab settings

<ESC>b<m><n><0> set vertical tabs in channels <m> = 0 - 3

<ESC>B<0> reset all vertical tab stops

<ESC>B<n1>..<n16><0> set vertical tab stops

<ESC>B<n1>..<n64><0> set vertical tab stops

<ESC>C<0><n> set form length in inches (<n> = 1 - 22)

<ESC>C<n> set form length in lines (<n> = 1 - 127)

<ESC>d<n1><n2> set relative horizontal step

Formula: n = relative print position

1 ➵ centered

2 ➵ right justification

3 ➵ left and right justification

<n> = 1 - 154

<n2> = INT (n/256)

<n1> = n MOD 256

2 - 12

Page 42

List of available control codes

BACK

QUIT

?

MTPL Propr. Propr. FX850 LQ850+ AGM Code Function

IBM IBM Epson Epson IBMXL XL24 FX1050 LQ1050+

✔✔✔✔

✔✔✔✔

✔✔✔✔

✔✔✔✔

✔

✔✔✔

✔

✔

✔✔✔

✔

✔

✔✔

✔

✔

✔

✔

✔✔

✔✔

✔

<ESC>D<0> clear all horizontal tab stops

<ESC>D<n1>..<n32><0> set horizontal tab stops

<ESC>E emphasized mode ON

<ESC>F emphasized mode OFF

<ESC>g set character density to 15 cpi

<ESC>G double strike print mode ON

<ESC>G print quality NLQ ON

<ESC>H print quality NLQ OFF

<ESC>H reset double strike print mode

<ESC>I<1> characters 0 - 31 and 128 - 159 transparent

<ESC>I<0> downloaded or international characters

<ESC>I<n> print mode selection

<n>

0 DPQ DPQ 10 cpi

1 DPQ –

2 NLQ NLQ/LQ 10 cpi

3 NLQ NLQ/LQ Prop.

4 DPQ (DLL) DPQ 10 cpi (DLL)

5 DPQ (DLL) –

6 NLQ (DLL) NLQ/LQ 10 cpi (DLL)

7 NLQ (DLL) NLQ/LQ Prop. (DLL)

8 – DPQ 12 cpi

10 – NLQ/LQ 12 cpi

11 Alternate NLQ II –

12 – DPQ 12 cpi (DLL)

14 – NLQ/LQ 12 cpi (DLL)

15 Alternate NLQ II (DLL) –

16 – DPQ 17 cpi

18 – NLQ/LQ 17 cpi

20 – DPQ 17 cpi (DLL)

22 – NLQ/LQ 17 cpi (DLL)

<ESC>j set printer offline

<ESC>j<n> single n/216 inch back feed (<n> = 0 - 255)

<ESC>j<n> single n/180 inch back feed (<n> = 0 - 255)

<ESC>J<n> single n/216 inch line feed (<n> = 0 - 255)

<ESC>J<n> single n/180 inch line feed (<n> = 0 - 255)

<ESC>J<n> single n/216 inch line feed (<n> = 0 - 255)

<ESC>k<n> select font type NLQ <n> = 0 ➵ Courier

2

4

1 ➵ Quadrat

2 - 13

Page 43

List of available control codes

BACK

QUIT

?

MTPL Propr. Propr. FX850 LQ850+ AGM Code Function

IBM IBM Epson Epson IBMXL XL24 FX1050 LQ1050+

✔✔✔✔✔

✔✔

✔✔✔✔✔

✔✔

✔

✔

*****

✔✔✔✔

*****

✔✔✔✔

✔✔

✔✔

✔✔

✔✔

✔✔

✔✔

✔✔

✔

✔

<ESC>k<n> select font type LQ <n> = 0 ➵ Roman

<ESC>K<n1><n2> graphics 60 dpi

Formula: n = length of graphics data

<ESC>l<n> set left margin

<n> = 1 - 80 1 - 136 (10 cpi)

<ESC>L<n1><n2> graphics 120 dpi

Formula: n = length of graphics data

<ESC>M set character density to 12 cpi (Elite)

<ESC>n locking shift 2 (LS2)

<ESC>N<n> set space before perforation (perforation skip)

<ESC>o locking shift 3 (LS3)

<ESC>O reset perforation skip

<ESC>p<1> proportional spacing ON

<ESC>p<0> proportional spacing OFF

<ESC>p1 proportional spacing ON

<ESC>p0 proportional spacing OFF

<ESC>P set character density to 10 cpi (Pica)

<ESC>P<1> proportional spacing ON

<ESC>P<0> proportional spacing OFF

<ESC>q<n> select character representation

1 ➵ Sans Serif

2 ➵ Courier

3 ➵ Prestige

4 ➵ Script

5 ➵ OCR-B

6 ➵ OCR-A

<n2> = INT (n/256)

<n1> = n MOD 256

narrow printer wide printer

1 - 96 1 - 163 (12 cpi)

1 - 120 1 - 204 (15 cpi)

1 - 136 1 - 232 (17.1 cpi)

1 - 160 1 - 272 (20 cpi)

<n2> = INT (n/256)

<n1> = n MOD 256

<n> = 1 - 127

2 - 14

Page 44

List of available control codes

BACK

QUIT

?

MTPL Propr. Propr. FX850 LQ850+ AGM Code Function

IBM IBM Epson Epson IBMXL XL24 FX1050 LQ1050+

✔✔

✔✔

✔✔

✔✔

✔✔

✔✔

✔✔✔✔

✔✔✔✔

✔✔

✔✔

✔✔

✔✔✔✔

✔✔✔✔

✔✔✔✔

✔✔

✔✔

✔

✔

✔✔✔✔

✔✔✔✔

✔✔

✔✔

✔✔

✔✔

<ESC>Q<n> deselect printer

<n> = 22 22

<ESC>Q<n> set right margin

<n> = 1 - 80 1 - 136 (10 cpi)

<ESC>R reset all tab stops

<ESC>R<n> select national character set

<n>: see chapter “Available character sets and fonts”

<ESC>s<1> half print quality ON

<ESC>s<0> half print quality OFF

<ESC>S<0> superscript mode ON

<ESC>S<1> subscript mode ON

<ESC>S0 superscript mode ON

<ESC>S1 subscript mode ON

<ESC>t<n> select character set

<n> = 0 ➵ Epson Standard Character Set

<ESC>T super/subscript mode OFF

<ESC>U<1> set unidirectional printing

<ESC>U<0> reset unidirectional printing

<ESC>U1 set unidirectional printing

<ESC>U0 reset unidirectional printing

<ESC>w<1> double height ON

<ESC>w<0> double height OFF

<ESC>W<1> set continuous enlarged print mode

<ESC>W<0> reset continuous enlarged print mode

<ESC>W1 set continuous enlarged print mode

<ESC>W0 reset continuous enlarged print mode

<ESC>x<1> set letter quality

<ESC>x<0> set draft print quality

narrow printer wide printer

➛

36 35

narrow printer wide printer

1 - 96 1 - 163 (12 cpi)

1 - 120 1 - 204 (15 cpi)

1 - 136 1 - 232 (17.1 cpi)

1 - 160 1 - 272 (20 cpi)

1 ➵ Epson Graphics Character Set

2 ➵ User-defined characters

➛

2

4

2 - 15

Page 45

List of available control codes

BACK

QUIT

?

MTPL Propr. Propr. FX850 LQ850+ AGM Code Function

IBM IBM Epson Epson IBMXL XL24 FX1050 LQ1050+

✔✔

✔✔

✔✔

✔✔✔✔✔

✔✔✔✔✔

✔

✔

✔

✔✔ ✔ ✔ ✔

✔✔ ✔ ✔ ✔

✔

✔

✔✔ ✔ ✔ ✔

✔

✔✔ ✔ ✔ ✔

✔

✔

✔

✔

✔

✔

✔✔ ✔ ✔ ✔

✔

*****

*****

*****

✔✔✔✔

✔✔✔✔

<ESC>x1 set letter quality

<ESC>x0 set draft print quality

<ESC>X<n><m> setting of left and right margins

<n>, = 1 - 80 1 - 136 (10 cpi)

<m> 1 - 96 1 - 163 (12 cpi)

<ESC>Y<n1><n2> graphics 120 dpi

<ESC>Z<n1><n2> graphics 240 dpi

Formula: n = length of graphics data

<ESC>| locking shift 4 (LS4)

<ESC>} locking shift 1 right (LS2R)

<ESC>~ locking shift 2 right (LS2R)

<FF> form feed

<HT> horizontal tab

<HTS> control code HTS

<IND> Vertical index

<LF> Line Feed

<NEL> Next line

<NUL> control code NUL

<PLD> Partial Line Down

<PLU> Partial Line Up

<RI> Reverse Index

<SI> single shift SS3

<SI> set condensed print with 17.1 cpi

<SO> set enlarged print mode

<SO> single shift SS2

<STX> Start of Text Block

<VT> Ve rtical Tab

<VTS> Control Code VTS

narrow printer wide printer

1 - 120 1 - 204 (15 cpi)

1 - 136 1 - 232 (17.1 cpi)

1 - 160 1 - 272 (20 cpi)

<n2> = INT (n/256)

<n1> = n MOD 256

2 - 16

Page 46

2

4

Barcode

BACK

QUIT

?

Barcode

List of available

barcodes

Your printer is equipped with a barcode mode; you can print up to 19 different barcodes.

Barcode mode can be accessed within every emulation. The user can

decide whether barcode is activated permanently or activated depending

on the situation by means of an escape sequence.

Type Barcode

A 2/5 Matrix (default)

B 2/5 Industrial

C 2/5 Interleaved

D Code 11

E BCD Matrix

F Code 39

G Codabar

H EAN 8 (with HRI*)

I EAN 8 (without HRI)

K EAN 13 (with HRI)

L EAN 13 (without HRI)

M MSI /modified PLESSEY

N UPC A (with HRI)

O UPC A (without HRI)

P UPC E (with HRI)

Q UPC E (without HRI)

R Delta Distance (IBM)

S Code 128

T EAN 128

U.S. POSTNET

KIX

T Royal

The barcode types K, L, N, O may be expanded by using Add-On Barcodes:

Add-On 2 and

Add-On 5

* HRI = Human Readable Index

2 - 17

Page 47

Barcode

BACK

QUIT

?

The information to be printed is transmitted in a “bracket” (DC4).

A control sequence (Header) defines the parameters of the used barcode

once (e.g. type, ratio, etc.).

If no header is defined, the information in the “bracket” will be printed in

Code 2/5 Matrix.

Please note that within the Barcode environment the barcode commands

have priority in case of conflicts with the emulation.

2 - 18

Page 48

US Postnet-Barcode

BACK

QUIT

?

US Postnet-Barcode Postnet is a special US-American type of barcode. It is printed in character si-

ze. Numeric values from 0 to 9 are printable.

After activating this barcode type, numeric characters from 0 (hex. 30) to 9

(hex. 39) are interpreted as barcode figures. All other characters terminate the

Barcode mode. Exception: the TAB function (hex. 09) is allowed within Barcode mode. The Postnet sequence is accessible in every emulation. The printer can print barcode in NLQ (180 dpi) and LQ (360 dpi). If draft print quality

(DPQ) is selected the printout is performed in NLQ.

The character (e.g. CR = carriage return, hex. 0D), which terminates the barcode is not printed or carried out.

US Postnet Barcode does not require a barcode bracket.

Example: ASCII ESC[1 SP p 12345 CR

HEX 1B 5B 31 20 70 31 32 33 34 35 0D

The numbers 1 to 5 are printed as Postnet stripes.

LC printing Certain professional applications may require unusually large character sizes.

Therefore your printer has the possibility of scaling standard size characters

up to factor 99 by means of control sequences.

2

4

The Header sequence defines the parameters (e.g. height) once. This definition remains until the printer is switched off.

The printable LCP* information is transmitted in an LCP “bracket” (SI).

Two character sets are available:

■ US ASCII and

■ German

The printout of LCP characters can be selected in all of the emulations. Prerequisite: Printer must be in Barcode mode.

* Large character printing

2-19

Page 49

List of additional control codes

BACK

QUIT

?

List of additional

control codes

Sequences Function

<ESC>[?10~ Barcode Off

<ESC>[?11~ Barcode On

<ESC> PSC 0 <ESC> \ Unsecured mode

<ESC> PSC 1 <ESC> \ Secured mode

<ESC> PLS 01 <ESC> \ LCP-CG: US ASCII

<ESC> PLS 02 <ESC> \ LCP-CG: German

<ESC>[<n><SP>s Sends a character as ASCII character; n > 0-255 decimal

Codes Function

old: new:

<DC4> <ESC>[20<SP>s Barcode bracket

<DLE> <ESC>[16<SP>s Start code LCP Header

<EM> <ESC>[25<SP>s Termination code Header

<SI> <ESC>[15<SP>s LCP bracket

<SUB> <ESC>[26<SP>s Start code barcode Header

2 - 20

Old codes as well as new codes are applicable.

Header Function

<DLE> [!] nn EM LCP Header

<SUB> [F] a [nn][;xyz] EM Barcode Header

[ ] = Optional

nn = Factor

[ ] = Optional

a = Barcode type

Additional information is provided in the Barcode Programmer’s Application Manual available from your dealer (see Appendix D).

Page 50

Configuring the printer for your computer

BACK

QUIT

?

Configuring the

printer for your

computer

Due to the great number of applications available on the market today, we

cannot give you detailed help for every program. Therefore please

refer to your software manuals for how to install your printer with your

programs.

Generally speaking, however, one can say that printer and application

must be coordinated with one another. Your printer can be adjusted to emulate the following printers.

■ IBM Proprinter X24/XL24

■ Epson LQ850+/LQ1050+

■ MTPL

■ Barcode

Many applications, however, also offer special printer drivers for our

printers.

Using an original printer driver provides the best pre-requisites for optimum

printing results. Ask your dealer for printer drivers or use our Internet homepage to obtain the current printer driver (see the back of the manual for

the homepage address).

You can download all printer drivers from our home page free of charge.

2

4

2 - 21

Page 51

Troubleshooting, care and maintenance 3

BACK

QUIT

?

Although your printer is extremely reliable and easy to use, you might run

into trouble some time.

STOP

This chapter provides information on the rectification of faults without the

assistance of specially trained personnel. Follow the advice and tips in

this chapter if your printer is not working correctly.

■ Test functions

■ Mechanical adjustments to the printer

■ Troubleshooting

Important notes on the care and maintenance of your printer can be found

at the end of this chapter.

Repairs should only be performed by authorised service personnel.

3

4

3 - 1

Page 52

Test functions and hardware settings

BACK

QUIT

?

Test functions and

hardware settings

Various tests to check proper operation of the printer are available at any

time. With these tests it is possible to check the print quality, p roper op er ation of the printhead and the mechanics, as well as efficient data transmission

from the computer to the printer.

This test menu contains three test functions ASCII 80, ASCII 136 and HDump. Menu option “Formlen” allows you to define the ba sic form length setting. Furthermore, you may select line wrap (“Wrap”) and sound when paper

is empty (“Sound”). “CX-bid” controls the bidirectional sett ing of the parallel

interface

ASCII80 ASCII136

Back Exit

H-Dump

Back Exit

Forml

Back Exit

Wrap Sound

Back Exit

ASCII test with 80 or 136 characters per line

Interface test

Setting the form length

Setting line wrap and sound when paper empty

3-2

CX-Bid CX-IF

Back Exit

ChTrFr

Back Exit

Setting for bidirectional I/O processing

and interface mode

ractor frictionSetting for t

Enter Test mode by pressing the key Online while switching on the printer.

Hold the key Online for about three seconds.

Page 53

Printer self-test (Rolling ASCII)

BACK

QUIT

?

Printer self-test

(Rolling ASCII)

To check operational readiness, your printer contains a self-test routine

which allows testing of the printer configuration, the p rint quality and correct

operation of your printer.

Before performing a self-test, your printer must be switched off. Ensure that

paper and a ribbon are insert ed. Keep the key Online pressed while switch-

ing on the printer for about three seconds.

Online

T2240/24

Initializing...

Setup

Alternatively T2240/9 is displayed. For the wide printer the display offers you

the selection between ASCII 80 (80 ASCII characters are printed per line)

and ASCII 136 (136 ASCII characters are printed per line). Fo r the narrow

printer , T2340/24 or T2340/9 is displayed and you can select ASCII 80 only.

ASCII80 ASCII136

Online

Back Exit

3

4

STOP

Setup

Note that the selected function ASCII 80 or ASCII 136 must be suitable for

your paper size. If not the printer may suffer mechanical damage.

Press the respective soft key for the ASCII 80 format ( correspo nds to Leg al

Portrait) or for ASCII 136 (Double or Legal Landscape). The display will indicate Test mode Off.

3-3

Page 54

Test functions and hardware settings

BACK

QUIT

?

It is also possible to change to Setup mode when you are in Test mode if

you want to change the configuration for the test printout.

To do this, press the key Setup. The printer then changes to Setup mode

and the first of the 15 main levels is then displayed.

Adjust Paperway

Online

Menu Char

Setup

Program your printer in the usual way for the test printout to change the

parameters. See chapter 1,

By pressing the key Setup you exit Setup mode and the printer once again

returns to Test mode.

Testmode Off

Programming via the operating panel

Online

.

Park < > LF/FF

Setup

Test mode Off is displayed. Press the key Online, the test printout starts.

3 - 4

The self-test can be interrupted by pressing the key Online which will stop

printing and put the printer into Offline status.

Before you begin printing, you can adjust the paper for the printout with

soft keys < and >.

Page 55

Test functions and hardware settings

BACK

QUIT

?

In the Rolling ASCII test, setup can be used for selecting a different font or

another CPI, without exiting the test.

Some changes in menu mode cause the printer to initialize, and consequently the Rolling ASCII test is broken off.

Example of an ASCII test printout

This test can also be used to determine and set the optimal printhead gap

(see Part I,

Setting the print head distance

).

3

4

Exiting Test mode Test mode can only be terminated by switching off the printer.

STOP

If you want to stop the test printout before you switch off the printer, then

press the key Online.

3 - 5

Page 56

Interface test (Hex-Dump)

BACK

QUIT

?

Interface test

(Hex-Dump)

With the interface test (Hex-Dump) you can test data transmission from the

computer to the printer. During this test, the data from the computer is

printed out in two columns. The text in the left column is printed in hexadecimal format and in the right column in ASCII format.

Printout in Hex-Dump Put the printer into Test mode by pressing the key Online while switching

on the printer.

Press the key Online for about three seconds.

The display shows ASCII 80/ASCII 136.

Online

ASCII80 ASCII136

Back Next

Setup

Press the key Next, the display shows the next menu level.

3 - 6

If you press the key H-Dump you put the printer into H-Dump mode and

Online H-Dump is shown on the display.

Page 57

Interface test (Hex-Dump)

BACK

QUIT

?

The printer is now ready to receive data from the computer and to print it

out in plain text if paper is loaded. The printed data can now be analyzed

and evaluated (see chapter 2

Example of a Hex-Dump printout

After the transmission you must switch the printer to Offline. Any remaining

data left in the interface buffer is then printed.

Emulations