Fiat Sedici User Manual

IMPORTANT

WARNING/CAUTION/NOTE

Please read this manual and follow its instructions carefully. To emphasize special information, the words

!

WARNING

lighted by these signal words.

!

WARNING

Indicates a potential hazard that could result in death or injury.

!

CAUTION

Indicates a potential hazard that could result in vehicle damage.

NOTE:

Indicates special information to make maintenance easier or instructions clearer.

!

WARNING

This service manual is intended for authorized Suzuki dealers and qualified service technicians only.

Inexperienced technicians or technicians without the proper tools and equipment may not be able to

properly perform the services described in this manual.

Improper repair may result in injury to the technician and may render the vehicle unsafe for the driver

and passengers.

!

, and NOTE have special meanings. Pay special attention to the messages high-

CAUTION

!

WARNING

For vehicles equipped with a Supplemental Restraint (Air Bag) System:

• Service on and around the air bag system components or wiring must be performed only by an

authorized SUZUKI dealer. Refer to “Air Bag System Components and Wiring Location View” under

“General Description” in air bag system section in order to confirm whether you are performing service on or near the air bag system components or wiring. Please observe all WARNINGS and “Service Precautions” under “On-Vehicle Service” in air bag system section before performing service

on or around the air bag system components or wiring. Failure to follow WARNINGS could result in

unintentional activation of the system or could render the system inoperative. Either of these two

conditions may result in severe injury.

• If the air bag system and another vehicle system both need repair, Suzuki recommends that the air

bag system be repaired first, to help avoid unintended air bag system activation.

• Do not modify the steering wheel, instrument panel or any other air bag system component on or

around air bag system components or wiring. Modifications can adversely affect air bag system

performance and lead to injury.

• If the vehicle will be exposed to temperatures over 93 °C (200 °F), for example, during a paint baking

process, remove the air bag system components, that is air bag (inflator) modules, SDM and/or seat

belt with pretensioner, beforehand to avoid component damage or unintended activation.

The circle with a slash in this manual means “Don’t do this” or “Don’t let this happen”.

FOREWORD

This SUPPLEMENTARY SERVICE MANUAL is a supplement to SX4 (RW415/RW416) SERVICE MANUAL.

It has been prepared exclusively for the following applicable model.

Applicable model:

SX4 with D19AA diesel engine (RW419D)

This supplementary service manual describes only different service information of the above applicable model

as compared with SX4 (RW415/RW416) SERVICE MANUAL. Therefore, whenever servicing the above applicable models, consult this supplement first. And for any section, item or description not found in this supplement,

refer to the related manual below.

When replacing parts or servicing by disassembling, it is recommended to use SUZUKI genuine parts, tools and

service materials as specified in each description.

All information, illustrations and specifications contained in this literature are based on the latest product information available at the time of publication approval. And used as the main subject of description is the vehicle of

standard specifications among others.

Therefore, note that illustrations may differ from the vehicle being actually serviced.

The right is reserved to make changes at any time without notice.

Related Manuals:

Manual Name Manual No.

SX4 (RW415/RW416) SERVICE MANUAL 99500-79J00-01E

© COPYRIGHT SUZUKI MOTOR CORPORATION 2006

RECOMMENDATON OF GENUINE SUZUKI PARTS AND ACCESSORIES USE

SUZUKI strongly recommends the use of genuine SUZUKI parts* and accessories. Genuine SUZUKI parts and

accessories are built to the highest standards of quality and performance, and are designed to fit the vehicle's

exact specifications.

A wide variety of non-genuine replacement parts and accessories for SUZUKI vehicles are currently available in

the market. Using these parts and accessories can affect the vehicle performance and shorten its useful life.

Therefore, installation of non-genuine SUZUKI parts and accessories is not covered under warranty.

Non-Genuine SUZUKI Parts and Accessories

Some parts and accessories may be approved by certain authorities in your country.

Some parts and accessories are sold as SUZUKI authorized replacement parts and accessories. Some genuine SUZUKI parts and accessories are sold as re-use parts and accessories. These parts and accessories are

non-genuine Suzuki parts and accessories and use of these parts are not covered under warranty.

Re-use of Genuine SUZUKI Parts and Accessories

The resale or re-use of the following items which could give rise to safety hazards for users is expressly forbidden:

1) Air bag components and all other pyrotechnic items, including their components (e.g. cushion, control

devices and sensors)

2) Seatbelt system, including their components (e.g. webbing, buckles, and retractors)

The air bag and seat belt pretensioner components contain explosive chemicals. These components should be

removed and disposed of properly by SUZUKI authorized service shop or scrap yard to avoid unintended explosion before scrapping.

*The parts remanufactured under SUZUKI's approval can be used as genuine SUZUKI parts in Europe.

TABLE OF CONTENTS

NOTE

For the screen toned sections with asterisk (*) in the “TABLE OF CONTENTS” below, refer to the same

sections of the service manual mentioned in the “FOREWORD” of this manual.

00

0

Precautions............................................................... 00-i

Precautions ............................................................ 00-1

General Information ................................................... 0-i

General Information ............................................... 0A-1

Maintenance and Lubrication ................................. 0B-1

Engine ......................................................................... 1-i

Precautions .............................................................. 1-1

Engine General Information and Diagnosis ...........1A-1

Aux. Emission Control Devices ..............................1B-1

Engine Electrical Devices.......................................1C-1

Engine Mechanical.................................................1D-1

Engine Lubrication System .................................... 1E-1

Engine Cooling System.......................................... 1F-1

Fuel System ...........................................................1G-1

Starting System....................................................... 1I-1

Charging System.....................................................1J-1

Exhaust System ..................................................... 1K-1

Suspension.................................................................2-*

Precautions ............................................................... 2-*

Suspension General Diagnosis...............................2A-*

Front Suspension....................................................2B-*

Rear Suspension.................................................... 2C-*

Wheels and Tires ................................................... 2D-*

Driveline / Axle ........................................................... 3-i

Precautions ............................................................... 3-*

Drive Shaft / Axle ................................................... 3A-1

Differential.............................................................. 3B-1

Transfer.................................................................. 3C-*

Propeller Shafts...................................................... 3D-*

Brakes .........................................................................4-*

Precautions ............................................................... 4-*

Brake Control System and Diagnosis .....................4A-*

Front Brakes............................................................4B-*

Rear Brakes ........................................................... 4C-*

Parking Brake......................................................... 4D-*

ABS.........................................................................4E-*

Transmission / Transaxle .......................................... 5-i

Precautions ............................................................... 5-*

Manual Transmission/Transaxle ............................5B-1

Clutch .....................................................................5C-1

Steering....................................................................... 6-i

Precautions ............................................................... 6-*

Steering General Diagnosis ................................... 6A-*

Steering Wheel and Column .................................. 6B-*

Power Assisted Steering System ...........................6C-1

HVAC ........................................................................... 7-i

Precautions ............................................................... 7-*

Heater and Ventilation............................................ 7A-1

Air Conditioning System.........................................7B-1

Restraint...................................................................... 8-*

Precautions ............................................................... 8-*

Seat Belts............................................................... 8A-*

Air Bag System ...................................................... 8B-*

Body, Cab and Accessories ...................................... 9-i

Precautions ............................................................... 9-*

Wiring Systems ......................................................9A-1

Lighting Systems.................................................... 9B-*

Instrumentation / Driver Info. / Horn .......................9C-1

Wipers / Washers................................................... 9D-*

Glass / Windows / Mirrors ...................................... 9E-*

Security and Locks..................................................9F-*

Seats ..................................................................... 9G-1

Interior Trim............................................................ 9H-*

Hood / Fenders / Doors........................................... 9J-*

Body Structure ....................................................... 9K-*

Paint / Coatings....................................................... 9L-*

Exterior Trim...........................................................9M-*

Control systems ....................................................... 10-i

Precautions ............................................................ 10-1

Body Electrical Control System............................10B-1

Immobilizer Control System .................................10C-1

Keyless Start System ........................................... 10E-1

1

2

3

4

5

6

7

8

9

10

11

Table of Contents 00- i

Section 00

Precautions

CONTENTS

NOTE

For the items with asterisk (*) in the “CONTENTS” below, refer to the same section of the service manual

mentioned in the “FOREWORD” of this manual.

00

Precautions ...............................................00-1

Precautions........................................................... 00-1

Precautions for Vehicles Equipped with a

Supplemental Restraint (Air Bag) System .........00-*

General Precautions ........................................... 00-1

Warning for Wheel (with tire) Removal ................00-*

Precautions in Servicing 4WD Vehicle................. 00-*

Precautions for Catalytic Converter and

Diesel Particulate Filter ..................................... 00-3

Precautions for Installing Mobile

Communication Equipment................................00-*

Precaution for CAN Communication System....... 00-*

Precautions for Electrical Circuit Service .............00-*

Air Bag Warning ...................................................00-*

Air Bag System Service Warning .........................00-*

Fastener Caution..................................................00-*

Suspension Caution .............................................00-*

Wheels and Tires Caution....................................00-*

Brake Caution ......................................................00-*

Repair Instructions ...............................................00-*

Electrical Circuit Inspection Procedure ................00-*

Intermittent and Poor Connection Inspection .......00-*

00-1 Precautions:

Precautions

Precautions

General Precautions

S5RW0D0000002

The WARNING and CAUTION describe some general

precautions that you should observe when servicing a

vehicle. These general precautions apply to many of the

service procedures, and they will not necessarily be

repeated with each procedure to which they apply.

!

WARNING

• Whenever raising a vehicle for service, be

sure to follow the instructions under

“Vehicle Lifting Points in Section 0A in

related manual”.

• When it is necessary to do service work

with the engine running, make sure that

the parking brake is set fully and the

transmission is in Neutral (for manual

transmission vehicles) or Park (for

automatic transmission vehicles), Keep

hands, hair, clothing, tools, etc. away from

the fan and belts when the engine is

running.

• When it is necessary to run the engine

indoors, make sure that the exhaust gas is

forced outdoors.

• Do not perform service work in areas

where combustible materials can come in

contact with a hot exhaust system. When

working with toxic or flammable materials

(such as gasoline and refrigerant), make

sure that the area you work in is wellventilated.

• To avoid getting burned, keep away from

hot metal parts such as the radiator,

exhaust manifold, tail pipe, muffler, etc.

• New and used engine oil can be

hazardous. Children and pets may be

harmed by swallowing new or used oil.

Keep new and used oil and used engine oil

filters away from children and pets.

Continuous contact with used engine oil

has been found to cause [skin] cancer in

laboratory animals. Brief contact with used

oil may irritate skin. To minimize your

exposure to used engine oil, wear a longsleeve shirt and moisture-proof gloves

(such as dish washing gloves) when

changing engine oil. If engine oil contacts

your skin, wash thoroughly with soap and

water. Launder any clothing or rags if wet

with oil, recycle or properly dispose of

used oil and filters.

• Be sure to observe following instructions

when handling service materials such as

fuel, oil, fluid, coolant, grease, sealant,

thread lock cement, etc. Otherwise, your

health may be ruined.

– Whenever handling any of these service

materials, wear safety glasses to protect

your eyes. If it gets into your eye, it may

cause inflammation.

– Whenever handling any of these service

materials, wear moisture-proof gloves to

protect your skin. If it adheres to your

skin, it may cause inflammation.

– Do not swallow any of these service

materials. It would cause diarrhea or

nausea.

– Keep all these materials out of children’s

reach.

• Make sure the bonnet is fully closed and

latched before driving. If it is not, it can fly

up unexpectedly during driving,

obstructing your view and resulting in an

accident.

• Before starting any service work, cover fenders, seats

and any other parts that are likely to get scratched or

stained during servicing. Also, be aware that what you

wear (e.g., buttons) may cause damage to the

vehicle’s finish.

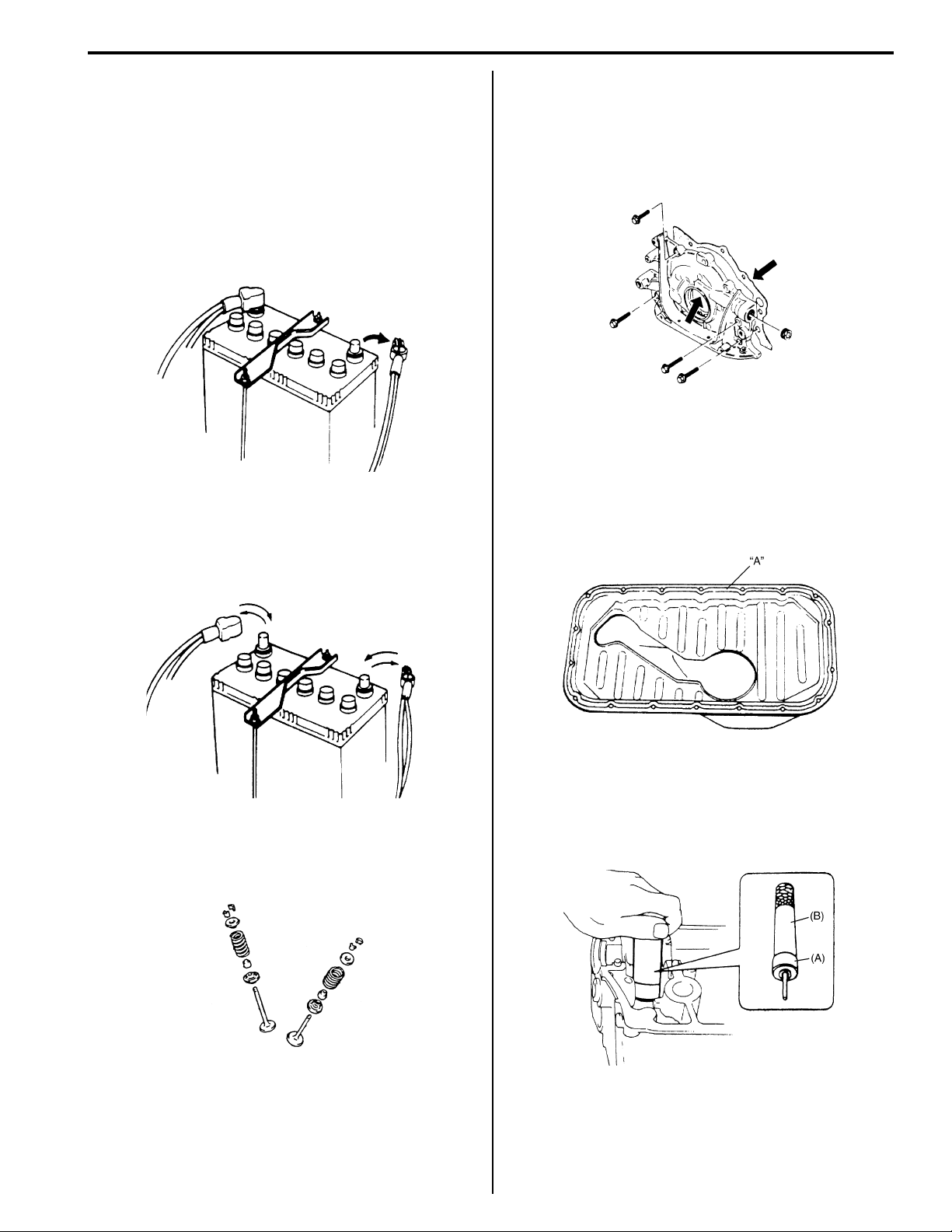

I2RH01010025-01

Precautions: 00-2

• When performing service to electrical parts that does

not require use of battery power, disconnect the

negative cable of the battery.

• When disconnecting the negative cable from the

battery, be careful to the following.

– Check and record DTCs in ECM and/or PS control

module if necessary before disconnecting.

– Record displayed contents of the clock and/or

audio system, etc. before disconnecting and reset it

as before after connecting.

I2RH01010026-01

• When removing the battery, be sure to disconnect the

negative cable first and then the positive cable. When

reconnecting the battery, connect the positive cable

first and then the negative cable, and replace the

terminal cover.

• Whenever you use oil seals, gaskets, packing, Orings, locking washers, split pins, self-locking nuts,

and certain other parts as specified, be sure to use

new ones. Also, before installing new gaskets,

packing, etc., be sure to remove any residual material

from the mating surfaces.

I2RH01010029-01

• Make sure that all parts used in reassembly are

perfectly clean.

When use of a certain type of lubricant, bond or

sealant is specified, be sure to use the specified type.

“A”: Water tight sealant 99000–31250 (SUZUKI

Bond No.1207F)

I2RH01010027-01

• When removing parts that are to be reused, be sure to

keep them arranged in an orderly manner so that they

may be reinstalled in the proper order and position.

I5RW0A000002-01

I2RH01010030-01

• Be sure to use special tools when instructed.

Special tool

(A): 09917–98221

(B): 09916–58210

I2RH01010031-01

00-3 Precautions:

• When disconnecting vacuum hoses, attach a tag

describing the correct installation positions so that the

hoses can be reinstalled correctly.

I2RH01010032-01

• After servicing fuel, oil, coolant, vacuum, exhaust or

brake systems, check all lines related to the system

for leaks.

• Use care not to expose connectors and electrical

parts to water which will be a cause of a trouble.

I2RH01010035-01

• Always be careful not to handle electrical parts

(computer, relay, etc.) in a rough manner or drop

them.

I2RH01010033-01

• For vehicles equipped with fuel injection systems,

never disconnect the fuel line between the fuel pump

and injector without first releasing the fuel pressure, or

fuel can be sprayed out under pressure.

• When performing a work that produces a heat

exceeding 80 °C (176 °F) in the vicinity of the

electrical parts, remove the heat sensitive electrical

part(s) beforehand.

I2RH01010034-01

I2RH01010036-01

Precautions for Catalytic Converter and Diesel Particulate Filter

S5RW0D0000004

• Use only specified fuel and be careful not to let a large

amount of unburned fuel enter the converter and filter

or they can be damaged.

• Be careful not to expose catalytic converter and diesel

particulate filter to excessive shock to avoid an

damage to them.

Table of Contents 0- i

Section 0

General Information

CONTENTS

NOTE

For the items with asterisk (*) in the “CONTENTS” below, refer to the same section of the service manual

mentioned in the “FOREWORD” of this manual.

0

General Information ................................ 0A-1

General Description .............................................0A-1

Abbreviations .......................................................0A-*

Symbols ...............................................................0A-*

Wire Color Symbols .............................................0A-*

Fasteners Information ..........................................0A-*

Vehicle Lifting Points............................................0A-*

Vehicle Identification Number ..............................0A-*

Engine Identification Number.............................. 0A-1

Component Location ...........................................0A-2

Warning, Caution and Information Labels

Location ............................................................ 0A-2

Maintenance and Lubrication................. 0B-1

Precautions........................................................... 0B-*

Precautions for Maintenance and Lubrication......0B-*

Scheduled Maintenance ......................................0B-1

Maintenance Schedule under Normal Driving

Conditions ......................................................... 0B-1

Maintenance Recommended under Severe

Driving Conditions............................................. 0B-2

Repair Instructions ..............................................0B-3

Accessory Drive Belt Inspection.......................... 0B-3

Accessory Drive Belt Replacement..................... 0B-3

Camshaft Timing Belt Replacement.................... 0B-3

Valve Lash (Clearance) Inspection .....................0B-3

Engine Oil and Filter Change..............................0B-3

Engine Coolant Change...................................... 0B-5

Exhaust System Inspection..................................0B-*

Air Cleaner Filter Inspection................................ 0B-5

Air Cleaner Filter Replacement ...........................0B-5

Fuel Lines and Connections Inspection ...............0B-*

Fuel Filter Replacement ......................................0B-5

Fuel Tank Inspection........................................... 0B-*

Brake Discs and Pads (Front) Inspection............ 0B-*

Brake Drums and Shoes (Rear) Inspection ........ 0B-*

Brake Hoses and Pipes Inspection ..................... 0B-*

Brake Fluid Replacement.................................... 0B-*

Brake Lever and Cable Inspection ...................... 0B-*

Clutch Fluid Inspection........................................ 0B-*

Tires Inspection................................................... 0B-*

Wheel Discs Inspection....................................... 0B-*

Wheel Bearing Inspection ................................... 0B-*

Suspension System Inspection ........................... 0B-*

Steering System Inspection ................................ 0B-*

Drive Shaft (Axle) Boots Inspection .................... 0B-*

Propeller Shaft (4WD) Inspection........................ 0B-*

Manual Transaxle Oil Inspection......................... 0B-*

Manual Transaxle Oil Replacement .................... 0B-*

Transfer Oil Inspection (4WD)............................. 0B-*

Transfer Oil Replacement (4WD)........................ 0B-*

Rear Deferential Oil Inspection (4WD)................ 0B-*

Rear Deferential Oil Replacement (4WD) ........... 0B-*

All Latches, Hinges and Locks Inspection........... 0B-*

HVAC Air Filter (If Equipped) Inspection............. 0B-*

HVAC Air Filter (If Equipped) Replacement ........ 0B-*

Final Inspection for Maintenance Service ........... 0B-*

Specifications.......................................................0B-5

Tightening Torque Specifications........................ 0B-5

Special Tools and Equipment .............................0B-6

Recommended Fluids and Lubricants.................0B-6

Special Tool ........................................................ 0B-6

0A-1 General Information:

General Information

General Description

Engine Identification Number

The number is punched on cylinder block.

S5RW0D0101007

I5RW0B010001-01

Component Location

General Information: 0A-2

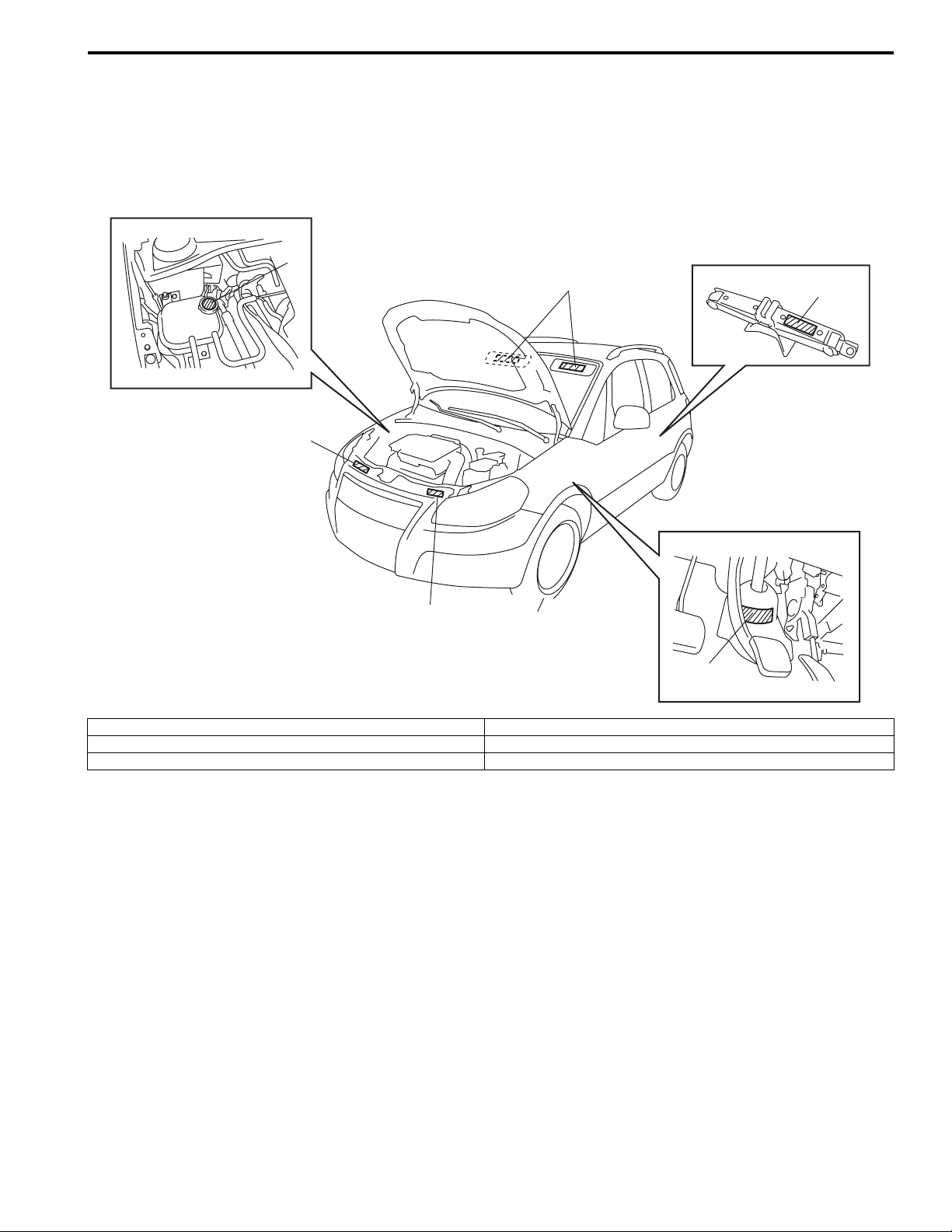

Warning, Caution and Information Labels Location

The figure shows main labels among others that are attached to vehicle component parts.

When servicing and handling parts, refer to WARNING / CAUTION instructions printed on labels.

If any WARNING / CAUTION label is found stained or damaged, clean or replace it as necessary.

2

1

6

S5RW0D0103001

5

3

4

1. Air bag label on sun visor (if equipped) 4. Steering shaft joint cover label (if equipped)

2. Degassing tank cap label 5. Jack label

3. Engine cooling fan label 6. Smoke level label

I5RW0B010002-04

0A-3 General Information:

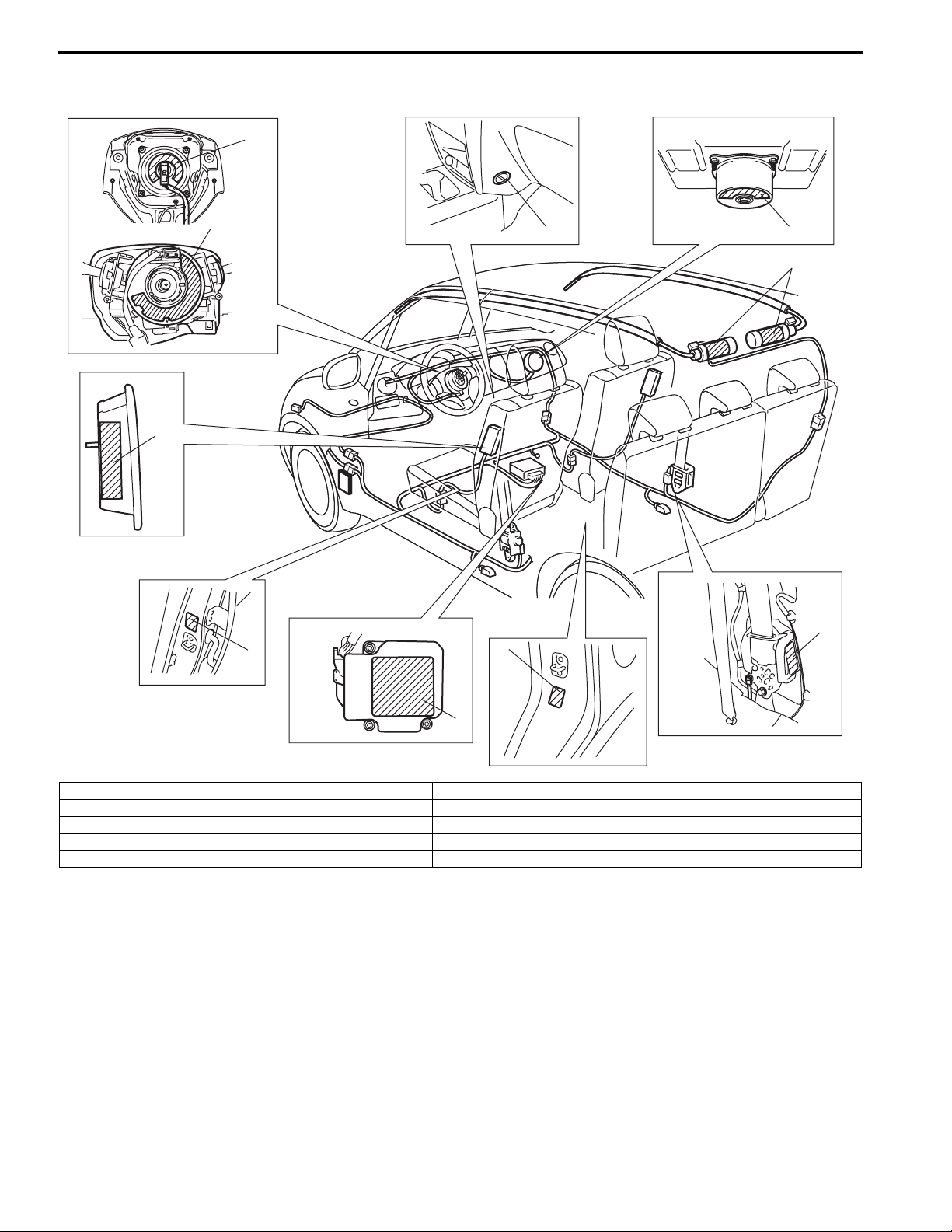

[A]

1

2

4

9

9

8

3

5

7

6

I5RW0A010006-05

1. Air bag label on driver air bag (inflator) module 6. Air bag label on SDM

2. Air bag label on contact coil assembly 7. Pretensioner label on seat belt retractor

3. Air bag label on passenger air bag (inflator) module 8. Child seat label (if equipped)

4. Air bag label on side air bag (inflator) module 9. Side/Curtain air bag label on pillar (both right and left sides) (if equipped)

5. Air bag label on curtain air bag (inflator) module [A]: These labels are attached on vehicle equipped with air bag system only.

Maintenance and Lubrication

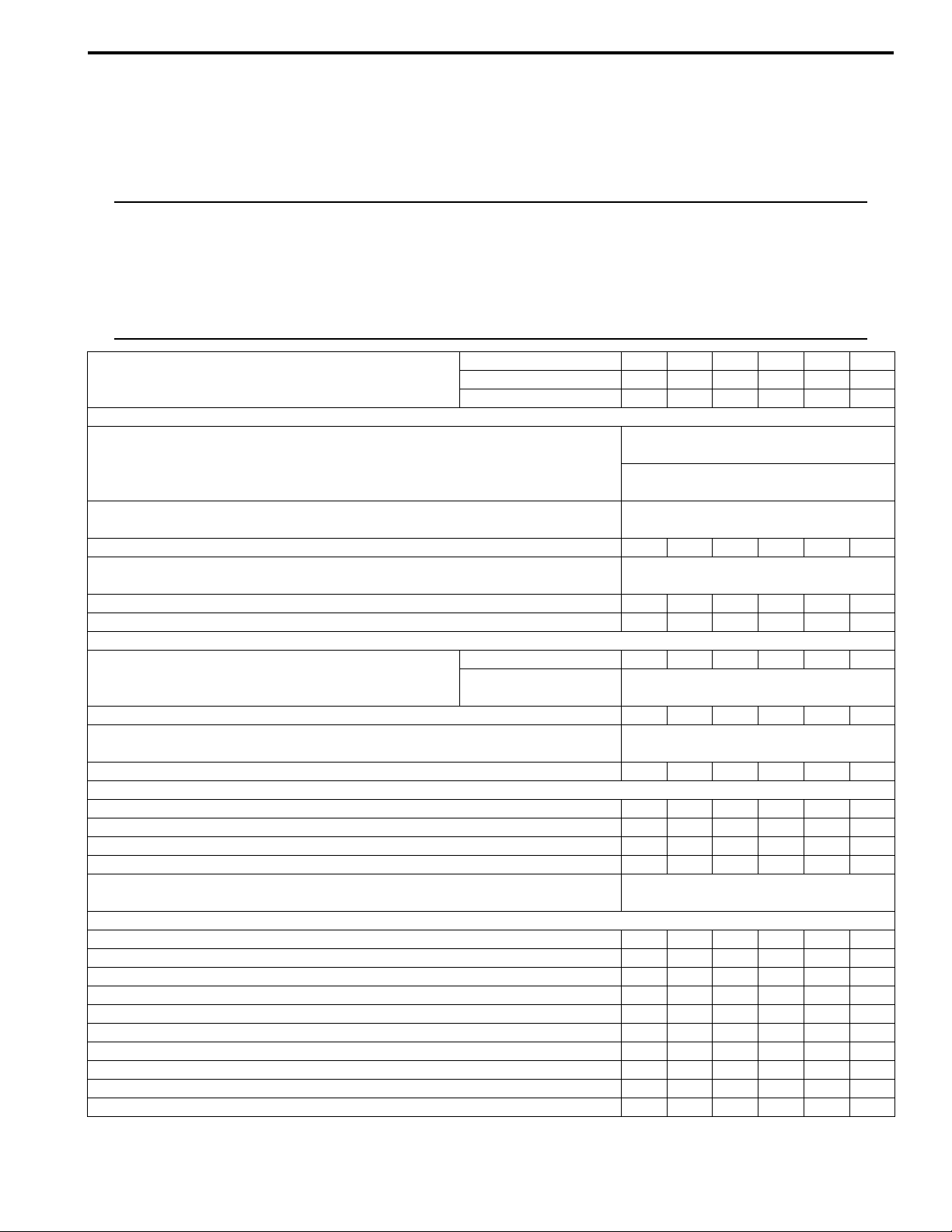

Scheduled Maintenance

Maintenance and Lubrication: 0B-1

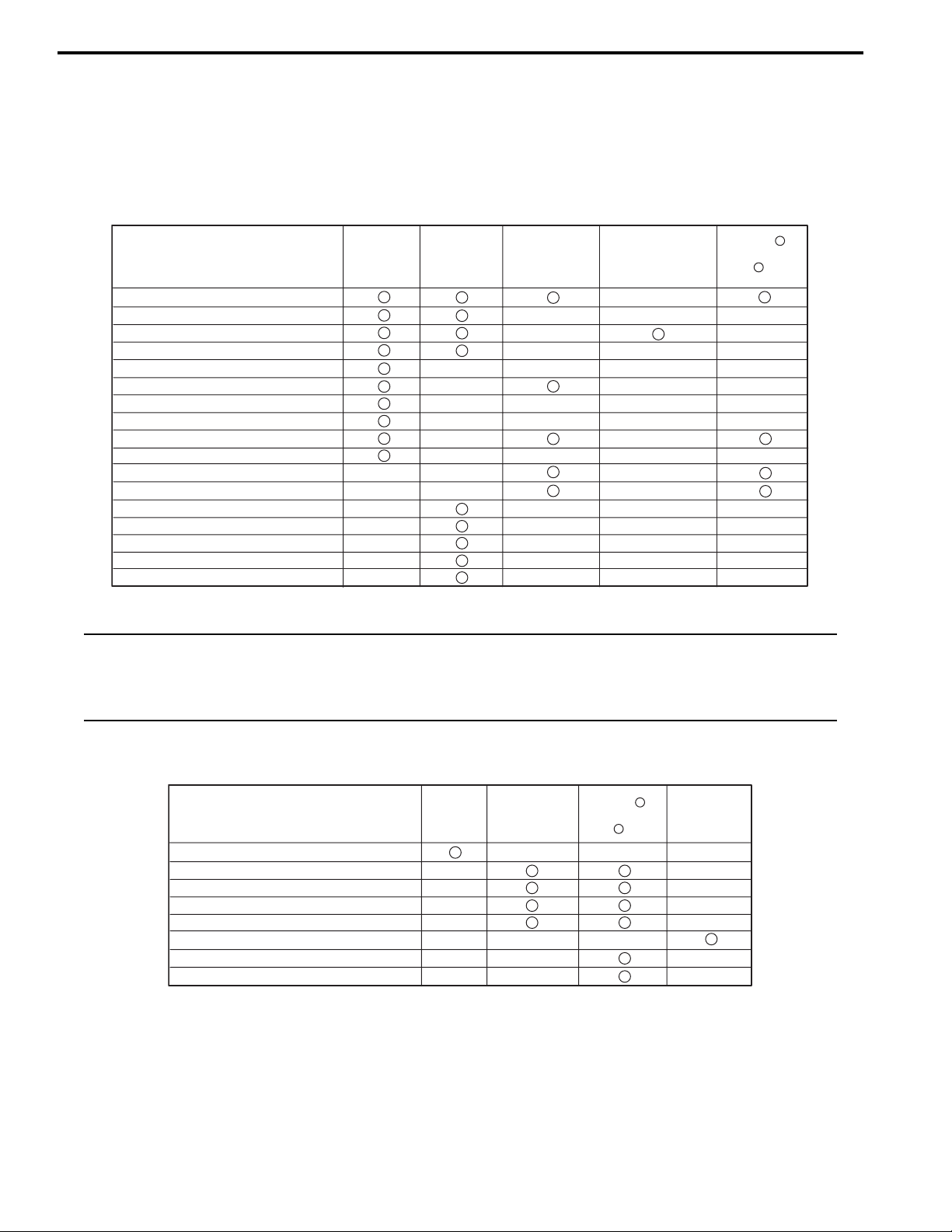

Maintenance Schedule under Normal Driving Conditions

S5RW0D0205001

NOTE

• This vehicle is equipped with oil life monitoring system.

Be sure to replace engine oil and oil filter if oil pressure warning light is blinking.

For details of system description, refer to “Oil Life Monitoring System in Section 1A”.

• This interval should be judged by odometer reading or months, whichever comes first.

• This table includes service as scheduled up to 90,000 km (54,000 miles) mileage. Beyond 90,000 km

(54,000 miles), carry out the same services at the same intervals respectively.

Km (x 1,000) 15 30 45 60 75 90

Interval

Engine

Accessory drive belt (I: ), R: ))

Camshaft timing belt (R: ))

Valve lash (clearance) (I: ))———I——

Engine oil and oil filter (R: )) (Synthetic oil)

Engine coolant (R: ))——R——R

Exhaust system (I: )) —I—I—I

Fuel system

Air cleaner filter (R: ), I: ))

Fuel lines and connections (I: )) —I—I—I

Fuel filter (R: ))

Fuel tank (I: ))——I——I

Brake

Brake discs and pads (thickness, wear, damage) (I: )) IIIIII

Brake drums and shoes (wear, damage) (I: )) —I—I—I

Brake hoses and pipes (leakage, damage, clamp) (I: )) —I—I—I

Brake fluid (R: )) —R—R—R

Brake lever and cable (damage, stroke, operation) (I: ))

Chassis and body

Clutch (fluid leakage, level) (I: )) —I—I—I

Tires (wear, damage, rotation) / wheels (damage) (I: ) / )) IIIIII

Suspension system (tightness, damage, rattle, breakage) (I: )) —I—I—I

Steering system (tightness, damage, breakage, rattle) (I: )) —I—I—I

Drive shaft (axle) boots / Propeller shaft (4WD) (I: )) (I: ))——I——I

Manual transaxle oil (leakage, level) (I: ) 1st 15,000 km only) (R: ))I—R——R

Transfer oil (4WD) (leakage, level) (I: )) I—I—I—

Rear differential oil (4WD) (leakage, level) (I: )) (R: ) 1st 15,000 km only) R or I — I — I —

All latches, hinges and locks (I: )) —I—I—I

HVAC air filter (if equipped) (I: )) (R: ))—IR—IR

Miles (x 1,000) 9 18 27 36 45 54

Months 12 24 36 48 60 72

Inspect every 30,000 km (18,000

miles) or 24 months

Replace every 120,000 km (72,000

miles) or 96 months

Replace every 150,000 km (90,000

miles) or 60 months

Replace when oil pressure warning

light blinks or every 24 months

Paved-road I I R I I R

Dusty conditions

Refer to “Maintenance Recommended

under Severe Driving Conditions”.

Replace every 60,000 km (36,000

miles) or 48 months

Inspect at first 15,000 km (9,000 miles

only)

0B-2 Maintenance and Lubrication:

NOTE

• “R”: Replace or change

• “I”: Inspect and correct, replace or lubricate if necessary

Maintenance Recommended under Severe Driving Conditions

S5RW0D0205002

If the vehicle is usually used under the conditions corresponding to any severe condition code given below, IT IS

RECOMMENDED that applicable maintenance operation be performed at the particular interval as shown in the

following table.

Severe condition code:

A: Repeated short trips

B: Driving on rough and/or muddy roads

C: Driving on dusty roads

D: Driving in extremely cold weather and/or salted roads

E: Repeated short trips in extremely cold weather

F: Leaded fuel use

G: Low quality fuel use (Diesel engine only)

H: Towing a trailer (if admitted)

Severe

condition code

Maintenance

– B C D – – – – Accessory drive belt

A – – D E – – – Camshaft timing belt ) R Every 36 months

A – C D E – – H Engine oil and oil filter ) R

– – C – – – – – Air cleaner filter *1

– B C D – – – H Wheel bearings ) I

– B – D E – – H

Drive shaft boots / Propeller shaft

(4WD)

Manual transaxle oil

– B – – E – – H

Transfer oil (4WD)

Differential oil (4WD)

– – C D – – – – HVAC air filter (if equipped) *2

Maintenance

operation

) I

) R

) I

) R

) / ) I

) / ) / ) R

) I

) R

Maintenance interval

Every 15,000 km

(9,000 miles) or 12 months

Every 45,000 km

(27,000 miles) or 36 months

Every 7,500 km

(4,500 miles) or 6 months

Every 2,500 km

(1,500 miles)

Every 30,000 km

(18,000 miles) or 24 months

Every 15,000 km

(9,000 miles) or 12 months

Every 15,000 km

(9,000 miles) or 12 months

First time only:

15,000 km (9,000 miles) or 12

months

Second time and after:

Every 30,000 km (18,000 miles) or

24 months reckoning from 0 km (0

mile) or 0 month

Every 15,000 km (9,000 miles) or

12 months

Every 45,000 km (27,000 miles) or

36 months

NOTE

• “I”: Inspect and correct or replace if necessary

• “R”: Replace or change

• *1: Inspect or replace more frequently if the vehicle is used under dusty conditions.

• *2: Clean or replace more frequently if the air from the air conditioning decreases.

Repair Instructions

Maintenance and Lubrication: 0B-3

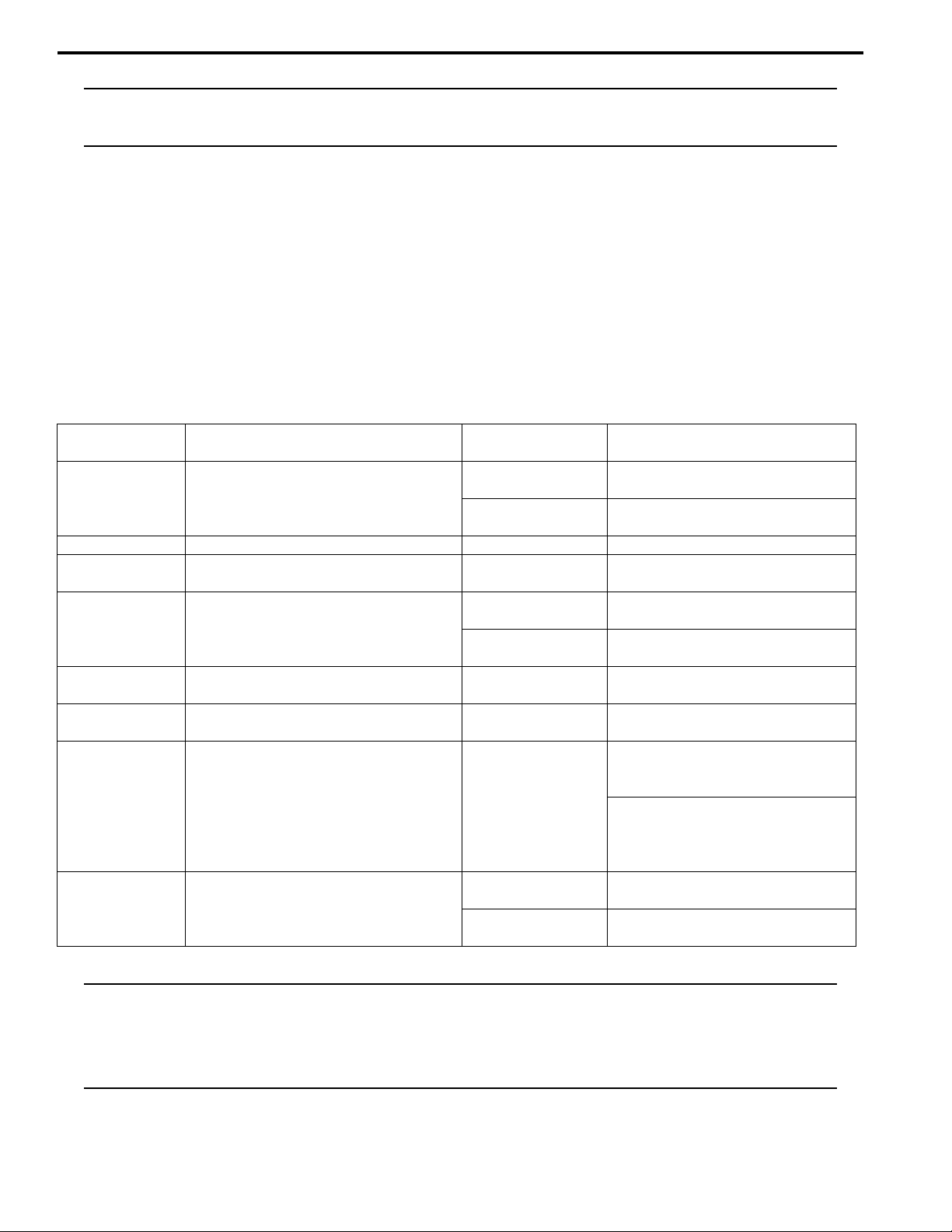

Accessory Drive Belt Inspection

!

WARNING

All inspection and replacement are to be

performed with ENGINE NOT RUNNING.

Generator Drive Belt

Inspect belt for cracks, cuts, deformation, wear and

cleanliness.

If any defect exists, replace.

S5RW0D0206001

I5RW0B020001-03

Accessory Drive Belt Replacement

S5RW0D0206002

Generator Drive Belt

Replace belt with new one referring to “Generator Drive

Belt, Tensioner and Idler Pulley Removal and Installation

in Section 1J”.

Camshaft Timing Belt Replacement

S5RW0D0206037

Replace camshaft timing belt (1) with new ones referring

to “Timing Belt, Belt tensioner and Idler Removal and

Installation in Section 1D”.

Valve Lash (Clearance) Inspection

S5RW0D0206003

Inspect intake and exhaust valve lash and adjust as

necessary.

Refer to “Valve Lash (Clearance) Inspection in Section

1D” for valve lash inspection and adjustment procedure.

I5RW0B020003-02

Engine Oil and Filter Change

!

WARNING

• New and used engine oil can be

hazardous.

Be sure to read “WARNING” in “General

Precautions in Section 00” and observe

what is written there.

• Step 1) – 14) outlined below must be

performed with ENGINE NOT RUNNING.

For Step 15), be sure to have adequate

ventilation while engine is running.

!

CAUTION

S5RW0D0206004

I5RW0B020002-03

After replacing engine oil and filter, be sure to

reset blinking of oil pressure light and engine

oil parameter by using SUZUKI scan tool.

If not, engine will be destroyed by degraded

engine oil.

Before draining engine oil, check engine for oil leakage.

If any evidence of leakage is found, make sure to correct

defective part before proceeding to the following work.

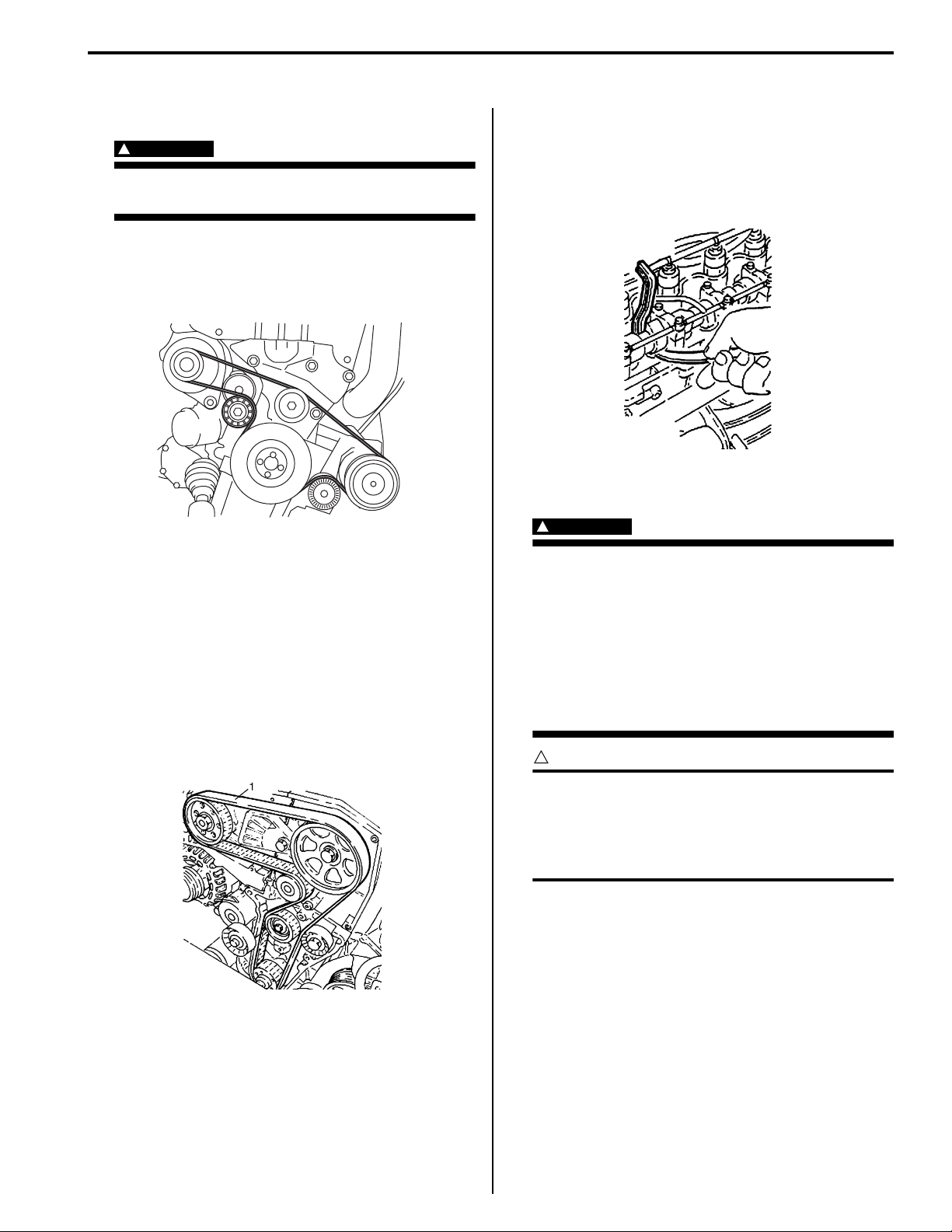

1) Remove oil filler cap and dipstick from engine.

2) Remove engine under cover.

3) Drain engine oil by removing drain plug.

0B-4 Maintenance and Lubrication:

(a)

4) After draining oil, wipe drain plug clean. Reinstall

drain plug with new gasket.

Tightening torque

Engine oil drain plug (a): 20 N·m (2.0 kgf-m, 14.5

lb-ft)

I5RW0B020004-01

5) Drain engine oil in filter as follows.

a) Connect a suitable hose (1) to bleeder pipe (2)

and put hose end into a suitable container.

b) Loosen filter cover (3) slowly up to the position

where oil comes out from hose.

Special tool

(A): 09915–47910

(A)

3

2

1

I5RW0B020005-03

6) Remove oil filter cover (1) and oil filter (2) from oil

filter stand.

7) Install new oil filter (1) to oil filter stand.

8) Install new O-ring (2) to oil filter cover (3).

9) Tighten oil filter cover (3) to specified torque

embossed on oil filter cover, using special tool.

10) Remove suitable hose (4) from bleeder pipe (5).

4

3 2

1 5

I5RW0B020007-02

11) Install engine under cover.

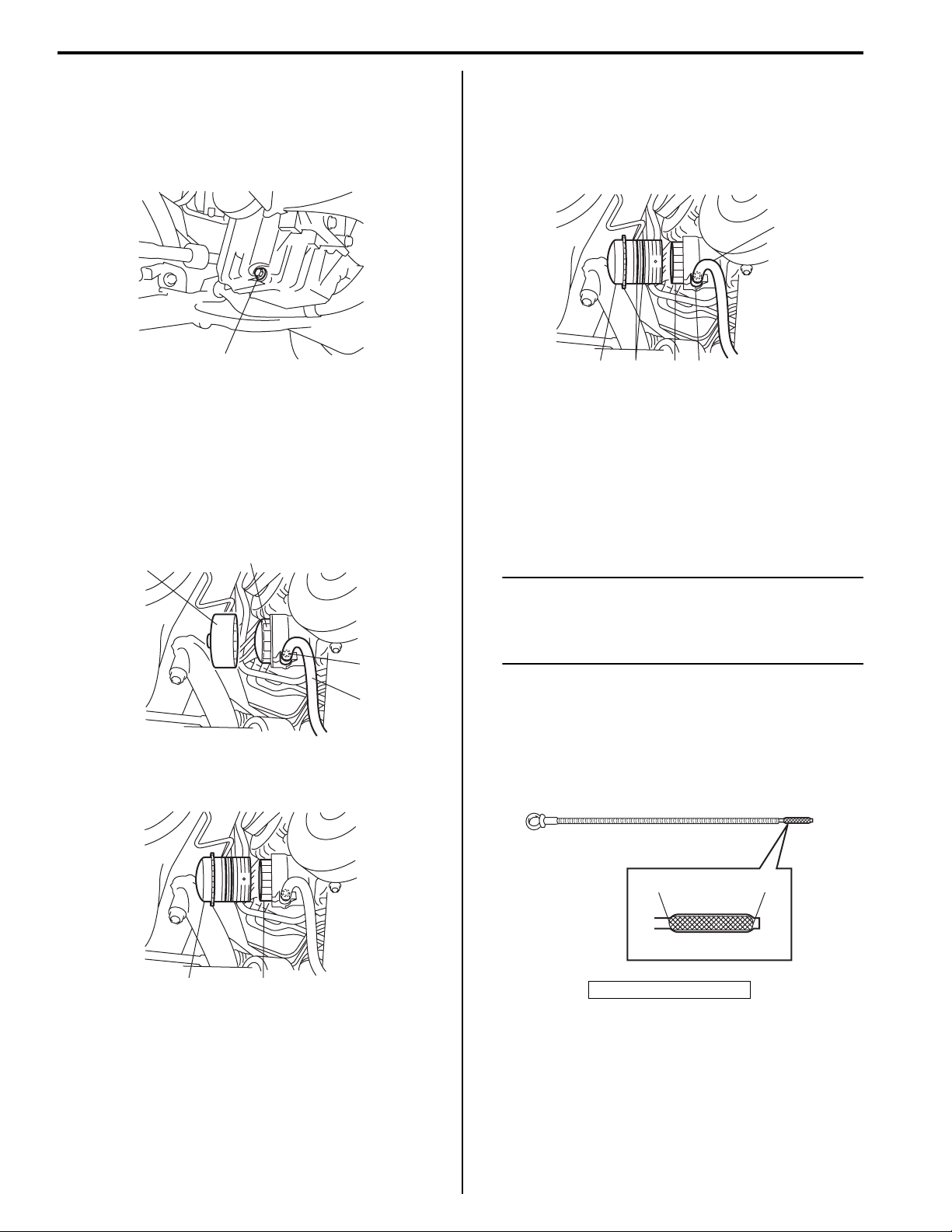

12) Replenish oil until oil level is brought to FULL level

mark on dipstick (oil pan and oil filter capacity about

4.5 liters (9.5/7.9 US/lmp pt.)). The filler inlet is at the

top of the cylinder head cover.

Use specified synthetic engine oil.

Engine oil grade: ACEA B3 or B4

Engine oil viscosity: SAE 5W-40

NOTE

Note that the amount of oil required when

actually changing oil may somewhat differ

from the data depending on various

conditions (temperature, viscosity, etc.).

13) Check oil filter and drain plug for oil leakage.

14) Install oil filler cap and dipstick to engine.

15) Start engine and run it for 2 minutes. Stop it and wait

several minutes before checking oil level. Add oil, as

necessary, to bring oil level to FULL level mark (1)

on dipstick.

1 2

I5RW0B020006-02

12

I3RM0B020008-01

2. Low level mark

Maintenance and Lubrication: 0B-5

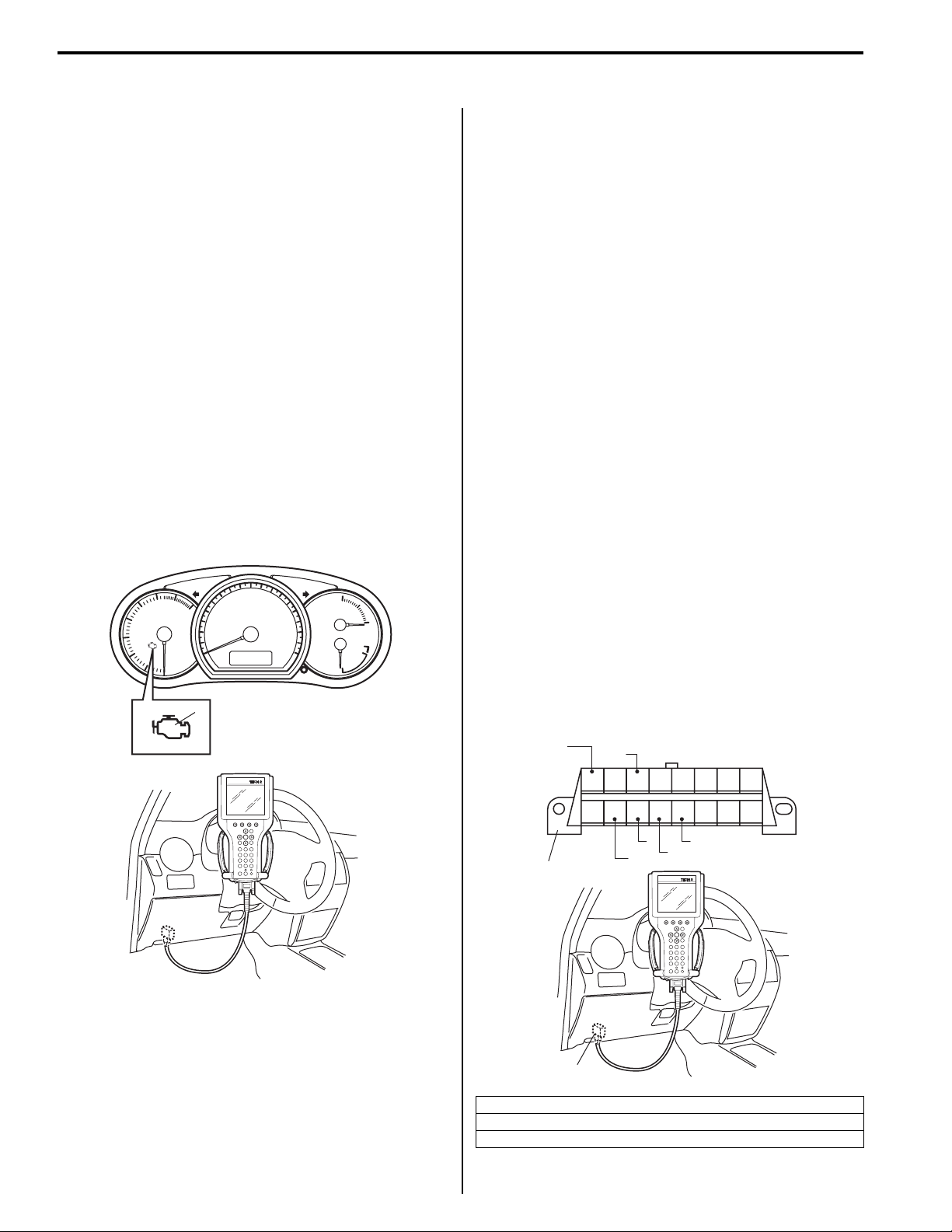

16) Reset blinking of oil pressure light and engine oil

parameter as follows.

NOTE

For further details of SUZUKI scan tool, refer

to its operator’s manual.

a) Connect SUZUKI scan tool to DLC with IG

switch OFF.

b) Turn IG switch to ON position.

c) Select “Reset Oil Pressure warning Light” under

“Miscellaneous test” (“Misc test”) mode of

SUZUKI scan tool.

d) Turn ignition switch to OFF position, and wait 30

seconds or more.

Engine Coolant Change

S5RW0D0206005

Change engine coolant with new one referring to

“Cooling System Flushing in Section 1F”.

Air Cleaner Filter Inspection

S5RW0D0206008

1) Remove air cleaner case screw.

2) Take air cleaner filter out of case.

3) Check that filter is not excessively dirty, damaged or

oily, clean filter with compressed air from air outlet

side of filter.

4) Install air cleaner filter and screw securely.

I5RW0B020008-02

Air Cleaner Filter Replacement

S5RW0D0206009

Replace air cleaner filter with new one according to

Steps 1), 2) and 4) of “Air Cleaner Filter Inspection”.

Fuel Filter Replacement

S5RW0D0206039

Replace fuel filter element in fuel filter assembly (1) with

new one referring to “Fuel Filter Element Replacement in

Section 1G”.

1

I5RW0B020009-01

I2RH01140007-01

Specifications

Tightening Torque Specifications

Fastening part

N⋅mkgf-mlb-ft

Engine oil drain plug 20 2.0 14.5 )

Reference:

For the tightening torque of fastener not specified in this section, refer to “Fasteners Information in Section 0A in

related manual”.

Tightening torque

S5RW0D0207001

Note

0B-6 Maintenance and Lubrication:

Special Tools and Equipment

Recommended Fluids and Lubricants

S5RW0D0208001

Engine oil Refer to “Engine Oil and Filter Change”.

Engine coolant

(Ethylene glycol base coolant)

Brake fluid Refer to reservoir cap of brake master cylinder.

Manual transaxle oil Refer to “Manual Transaxle Oil Change in Section 5B”.

Transfer oil (4WD) Refer to “Transfer Oil Change in Section 3C in related manual”.

Rear differential (4WD) Refer to “Rear Differential Oil Change in Section 3B in related manual”.

Door hinges Engine oil or water resistance chassis grease

Hood latch assembly Engine oil or water resistance chassis grease

Key lock cylinder Spray lubricant

“Antifreeze/Anticorrosion coolant”

Special Tool

S5RW0D0208002

09915–47910

Oil filter wrench

)

Section 1

Engine

CONTENTS

Table of Contents 1- i

NOTE

For the items with asterisk (*) in the “CONTENTS” below, refer to the same section of the service manual

mentioned in the “FOREWORD” of this manual.

Precautions .................................................1-1

Precautions............................................................. 1-1

Precautions for Engine.......................................... 1-1

Engine General Information and

Diagnosis ................................................. 1A-1

Precautions...........................................................1A-1

Precautions on Engine Service...........................1A-1

Precautions in Diagnosing Trouble .....................1A-1

Statement on Cleanliness and Care ...................1A-1

General Description .............................................1A-2

Engine Diagnosis General Description ...............1A-2

OBD System Description ....................................1A-2

CAN Communication System Description........... 1A-3

Electronic Control System Description................ 1A-5

Diesel Particulate Filter Description .................. 1A-10

Diesel Particulate Filter Regeneration

Description ......................................................1A-10

Oil Life Monitoring System ................................ 1A-11

Component Location .........................................1A-12

Electronic Control System Components

Location ..........................................................1A-12

Diagnostic Information and Procedures..........1A-13

MIL Check.........................................................1A-13

Engine and Emission Control System Check....1A-14

DTC Check ....................................................... 1A-16

DTC Clearance ................................................. 1A-16

DTC Table......................................................... 1A-17

Fail-safe Table .................................................. 1A-21

Scan Tool Data ................................................. 1A-24

Visual Inspection............................................... 1A-28

Engine Basic Inspection.................................... 1A-28

Engine Symptom Diagnosis..............................1A-29

DTC P0016: Crankshaft Position – Camshaft

Position Correlation......................................... 1A-50

DTC P0045: Turbo Boost Control Solenoid

Circuit / Open .................................................. 1A-51

DTC P0087 / P0088: Fuel Rail Pressure –

Too Low / Too High......................................... 1A-52

DTC P0090: Fuel Pressure Regulator Control

Circuit.............................................................. 1A-53

DTC P0091: Fuel Pressure Regulator Control

Circuit Low ...................................................... 1A-54

DTC P0092: Fuel Pressure Regulator Control

Circuit High......................................................1A-54

DTC P0093: Fuel System Leak Detected –

Large Leak ......................................................1A-55

DTC P0094: Fuel System Leak Detected –

Small Leak ......................................................1A-56

DTC P0095: Intake Air Temperature Sensor 2

Circuit..............................................................1A-56

DTC P0100 / P0101: Mass Air Flow Circuit /

Mass Air Flow Circuit Range / Performance ...1A-57

DTC P010F: Mass Air Flow Sensitivity Drift......1A-57

DTC P0110 / P0111: Intake Air Temperature

Sensor 1 Circuit / Intake Air Temperature

Sensor 1 Circuit Range / Performance ...........1A-58

DTC P0115: Engine Coolant Temperature

Circuit..............................................................1A-59

DTC P0116: Engine Coolant Temperature

Circuit Range / Performance...........................1A-59

DTC P0120: Throttle Position Sensor Circuit....1A-60

DTC P0122: Throttle Position Sensor Circuit

Low.................................................................. 1A-60

DTC P0168: Fuel Temperature Too High .........1A-61

DTC P0180: Fuel Temperature Sensor Circuit ..1A-62

DTC P0190: Fuel Rail Pressure Sensor

Circuit..............................................................1A-62

DTC P0201 / P0202 / P0203 / P0204: Injector

Circuit/Open – Cylinder 1 / Cylinder 2 /

Cylinder 3 / Cylinder 4..................................... 1A-62

DTC P0216: Injector / Injection Timing Control

Circuit..............................................................1A-63

DTC P0219: Engine Overspeed Condition .......1A-63

DTC P0220: Pedal Position Sensor Circuit.......1A-63

DTC P0230: Fuel Pump Primary Circuit ...........1A-64

DTC P0235: Turbo Boost Sensor Circuit ..........1A-64

DTC P0237 / P0238: Turbo Boost Sensor

Circuit Low / High............................................1A-65

DTC P0262 / P0265 / P0268 / P0271:

Cylinder 1 / 2 / 3 / 4 Injector Circuit High.........1A-67

DTC P0335: Crankshaft Position Sensor

Circuit..............................................................1A-67

DTC P0340: Camshaft Position Sensor

Circuit..............................................................1A-67

DTC P0380: Glow Plug Circuit.......................... 1A-68

DTC P0401: Exhaust Gas Recirculation Flow

Insufficient Detected........................................1A-68

1

1-ii Table of Contents

DTC P0402: Exhaust Gas Recirculation Flow

Excessive Detected ........................................1A-69

DTC P0403: Exhaust Gas Recirculation

Control Circuit ................................................. 1A-70

DTC P0480: Fan 1 Control Circuit ....................1A-70

DTC P0481: Fan 2 Control Circuit ....................1A-71

DTC P0482: Fan 3 Control Circuit ....................1A-72

DTC P0500: Vehicle Speed Sensor.................. 1A-73

DTC P0503: Vehicle Speed Sensor

Intermittent / Erratic / High ..............................1A-74

DTC P0504: Brake Switch 1 / 2 Correlation...... 1A-74

DTC P0520: Engine Oil Pressure Switch

Circuit..............................................................1A-75

DTC P0530: A/C Refrigerant Pressure

Sensor Circuit .................................................1A-76

DTC P0560: System Voltage ............................ 1A-76

DTC P0601: Internal Control Module Memory

Check Sum Error ............................................1A-76

DTC P0606: ECM Processor ............................ 1A-77

DTC P060A: Shut Off Monitoring During

Initialization .....................................................1A-77

DTC P060B: ADC Monitoring............................ 1A-77

DTC P0611: ECM Performance........................ 1A-78

DTC P061B: FMTC Map Non Strictly

Monotonus ......................................................1A-78

DTC P061C: Engine Speed Calculation in

Overrun ...........................................................1A-78

DTC P062D: Injectors Specific Chip 1 ..............1A-78

DTC P062E: Injectors Specific Chip 2 ..............1A-79

DTC P0638: Throttle Actuator Control Range

/ Performance .................................................1A-79

DTC P0641: Sensor Reference Voltage 1

Circuit / Open .................................................. 1A-80

DTC P0645: A/C Clutch Relay Control Circuit ..1A-80

DTC P0651: Sensor Reference Voltage 2

Circuit / Open .................................................. 1A-81

DTC P0683: Glow Plug Control Module to

ECM Communication Circuit...........................1A-81

DTC P0685: ECM Power Relay Control

Circuit / Open .................................................. 1A-82

DTC P0697: Sensor Reference Voltage 3

Circuit / Open .................................................. 1A-82

DTC P0704: Clutch Switch Input Circuit

Malfunction......................................................1A-82

DTC P0748: Fuel Flow Actuator Circuit ............1A-83

DTC P0778: Fuel Pressure Regulator Circuit ... 1A-84

DTC P1205: Diesel Particulate Filter Flow

Resistance Monitoring Too Low......................1A-84

DTC P1206: Diesel Particulate Filter Flow

Resistance Monitoring Too High.....................1A-85

DTC P1218: Hard Ware Recovery.................... 1A-85

DTC P1219: Diesel Particulate Filter

Regeneration Not Ended ................................ 1A-86

DTC P1301: Fuel Injector Calibration Code

Classification...................................................1A-86

DTC P1605: Communication between CY310

and µP.............................................................1A-86

DTC P1606: Hard Ware Module

Communication ...............................................1A-87

DTC P1618: Supply Voltage of CJ940 above

Limit.................................................................1A-87

DTC P1619: Supply Voltage of CJ940 below

Limit.................................................................1A-87

DTC P1623: SPI Communication......................1A-88

DTC P1667: Fuel Filter Heating ........................1A-88

DTC P2080 / P2081: Exhaust Gas

Temperature Sensor Circuit Range /

Performance / Intermittent...............................1A-88

DTC P2084 / P2085: Exhaust Gas

Temperature Sensor-2 Circuit Range /

Performance / Intermittent...............................1A-89

DTC P2100 / P2101: Throttle Actuator Control

Motor Circuit / Open / Range / Performance...1A-89

DTC P2107 / P2108: Throttle Actuator Control

Module Processor / Performance....................1A-90

DTC P2111 / P2112: Throttle Actuator Control

System – Stuck Open / Stuck Closed .............1A-90

DTC P2135: Throttle / Pedal Position Sensor

Voltage Correlation .........................................1A-90

DTC P2146 / P2148: Fuel Injector Group 1

Supply Voltage Circuit / Open / High...............1A-91

DTC P2149 / P2151: Fuel Injector Group 2

Supply Voltage Circuit / Open / High...............1A-91

DTC P2226: Barometric Pressure Circuit .........1A-91

DTC P2264: Water in Fuel Sensor Circuit ........1A-91

DTC P2293: Fuel Pressure Regulator

Performance....................................................1A-92

DTC P2294: Fuel Pressure Regulator Control

Circuit..............................................................1A-93

DTC P2295: Fuel Pressure Regulator Control

Circuit Low ...................................................... 1A-93

DTC P2296: Fuel Pressure Regulator Control

Circuit High......................................................1A-94

DTC P2299: Brake Pedal Position /

Accelerator Pedal Position Incompatible.........1A-95

DTC P2452: Differential Pressure Sensor

Electrical Failure..............................................1A-95

DTC P2453 / P2455: Differential Pressure

Sensor Hose Line Monitoring / Plausibility......1A-96

DTC P2505: ECM Power Input Signal ..............1A-96

DTC P2620: Throttle Position Output Circuit /

Open ...............................................................1A-96

DTC U1601: Control Module Communication

Bus Off ............................................................1A-97

DTC U1700: Lost Communication with Body

Control Module................................................1A-98

DTC U1706: Lost Communication with ABS

or ESP® Control Module.................................1A-99

DTC U1711: Lost Communication with 4WD

Control Module..............................................1A-100

Table – 1040AA: Check on Supply Voltage

and Current Uptake.......................................1A-102

Table – 1040OA: Fuel Supply System Check. 1A-102

Table – 1048OA: Air Intake / Vacuum Circuit

Check............................................................1A-104

Table – 1060EA: Fuel Temperature Sensor

Check............................................................1A-105

Table – 1060FA: Injector Operation Check.....1A-106

Table of Contents 1-iii

Table – 1060FB: Injector Circuit Operation

Check............................................................ 1A-108

Table – 1060GD: Barometric Pressure Check 1A-111

Table – 1060GF: Boost Pressure Check ........1A-111

Table – 1060GG: Check Measured Air Mass .1A-112

Table – 1060GH: Diesel Fuel Pressure Check 1A-113

Table – 1060GI: Engine Speed Check ...........1A-114

Table – 1060GL: Main Relay Operation

Check............................................................ 1A-115

Table – 1060GM: Sensor Power Supply 1

Circuit Check................................................. 1A-116

Table – 1060GN: Sensor Power Supply 2

Circuit Check................................................. 1A-117

Table – 1060GO: Inlet Throttle Valve

Operation Check ........................................... 1A-119

Table – 1060GP: Sensor Power Supply 3

Circuit Check................................................. 1A-120

Table – 1060GQ: Fuel Filter Water Detection

Sensor Operation Check............................... 1A-121

Table – 1060GR: Fuel Pressure Regulator

Operation Check ........................................... 1A-122

Table – 1060GS: MAF Sensor Operation

Check............................................................ 1A-122

Table – 1060OE: ECT Sensor Operation

Check............................................................ 1A-123

Table – 1064BB: Boost Pressure Control

Solenoid Valve Operation Check ..................1A-124

Table – 1064BD: IAT Sensor 2 Check............ 1A-124

Table – 1068AC: Accelerator Pedal Check.....1A-125

Table – 1080BE: Particulate Filter Saturation

Check............................................................ 1A-127

Table – 1080BF: Differential Pressure Sensor

Operation Check ........................................... 1A-128

Table – 1080BG: Exhaust Gas Temperature

Sensor-1 Operation Check ........................... 1A-129

Table – 1080BH: Exhaust Gas Temperature

Sensor-2 Operation Check ........................... 1A-129

Table – 1080CB: EGR Valve Operation

Check............................................................ 1A-130

Table – 3340AB: Speed Signal Check............1A-131

Table – 5505AC: Fuel Heater Operation

Check............................................................ 1A-131

Table – 5510CG: CMP Sensor Operation

Check............................................................ 1A-132

Table – 5520CA: Glow Plugs Operation

Check............................................................ 1A-133

Table – 5530BB: Battery Voltage Check ........ 1A-134

Low Fuel Pressure Circuit Check.................... 1A-135

High Fuel Pressure Circuit Check...................1A-137

Special Tools and Equipment ......................... 1A-138

Special Tool .................................................... 1A-138

Aux. Emission Control Devices ............. 1B-1

Repair Instructions ..............................................1B-1

EGR Valve Inspection......................................... 1B-1

Exhaust Gas Temperature Sensor 1 and 2

Removal and Installation................................... 1B-1

Exhaust Gas Temperature Sensor 1 and 2

Inspection..........................................................1B-1

Differential Pressure Sensor Removal and

Installation......................................................... 1B-1

Engine Electrical Devices ....................... 1C-1

Precautions...........................................................1C-1

Precaution in Replacing ECM .............................1C-1

General Description .............................................1C-1

ECM Registration ................................................1C-1

Repair Instructions ..............................................1C-2

Idle Speed Inspection..........................................1C-2

Engine Control Module (ECM) Removal and

Installation.........................................................1C-2

Registration for ECM Replacement.....................1C-2

Fuel Injector Registration ....................................1C-3

Fuel Pressure Sensor Data Initialization .............1C-3

Diesel Particulate Filter Data Initialization...........1C-3

Differential Pressure Sensor Data

Initialization .......................................................1C-3

Pre-catalytic Converter Data Initialization ...........1C-3

Diesel Particulate Filter After-sales

Regeneration.....................................................1C-3

After-sales Regeneration Failure ........................1C-4

Glow Plug Removal and Installation ...................1C-5

Glow Plug Inspection ..........................................1C-5

Accelerator Pedal Position (APP) Sensor

Assembly On-Vehicle Inspection ......................1C-6

Accelerator Pedal Position (APP) Sensor

Assembly Removal and Installation ..................1C-6

Accelerator Pedal Position (APP) Sensor

Assembly Inspection .........................................1C-6

Engine Coolant Temperature (ECT) Sensor

Removal and Installation...................................1C-7

Camshaft Position (CMP) Sensor Removal

and Installation..................................................1C-8

CKP Sensor Removal and Installation ................1C-8

CKP Sensor Inspection .......................................1C-9

Boost Pressure Sensor with IAT Sensor-2

Removal and Installation...................................1C-9

Fuel Pump Relay, Starting Motor Control

Relay, Main Relay and Fuel Heating Relay

Inspection..........................................................1C-9

Glow Plug Control Module Removal and

Installation.......................................................1C-10

Boost Pressure Control Solenoid Valve

Removal and Installation.................................1C-10

Boost Pressure Control Solenoid Valve

Inspection........................................................1C-10

MAF Sensor with IAT Sensor-1 Removal and

Installation.......................................................1C-10

Inlet Throttle Valve Removal and Installation....1C-10

Inlet Throttle Valve On-Vehicle Inspection ........1C-10

Specifications.....................................................1C-11

Tightening Torque Specifications......................1C-11

Engine Mechanical .................................. 1D-1

Diagnostic Information and Procedures............1D-1

Compression Check............................................1D-1

Vacuum Pump Inspection ...................................1D-2

Valve Lash (Clearance) Inspection .....................1D-2

1-iv Table of Contents

Valve Lash (Clearance) Adjustment....................1D-2

Repair Instructions ..............................................1D-4

Air Cleaner Components.....................................1D-4

Air Cleaner Filter Removal and Installation.........1D-5

Air Cleaner Filter Inspection and Cleaning..........1D-5

Intercooler Components......................................1D-6

Intercooler Removal and Installation...................1D-7

Cylinder Head Cover Components .....................1D-7

Cylinder Head Cover Removal and

Installation.........................................................1D-8

Inlet Throttle Valve Removal and Installation......1D-9

Vacuum Pump Removal and Installation ..........1D-10

EGR Valve Components ...................................1D-11

EGR Valve Removal and Installation................1D-12

EGR Pipe and EGR Cooler Removal and

Installation.......................................................1D-12

Turbocharger Included in Exhaust Manifold

Components....................................................1D-14

Turbocharger Included in Exhaust Manifold

Removal and Installation.................................1D-14

Turbocharger Included in Exhaust Manifold

Inspection........................................................1D-17

Timing Belt and Belt Tensioner Components....1D-18

Timing Belt, Belt tensioner and Idler Removal

and Installation................................................1D-18

Timing Belt Inspection.......................................1D-22

Intake Manifold Components ............................1D-23

Intake Manifold Removal and Installation .........1D-24

Camshaft and Tappet Components ..................1D-25

Camshaft and Tappet Removal and

Installation.......................................................1D-25

Camshaft and Tappet Inspection ......................1D-28

Valve and Cylinder Head Assembly

Components....................................................1D-31

Valve and Cylinder Head Assembly Removal

and Installation................................................1D-32

Valve and Cylinder Head Assembly

Inspection........................................................1D-34

Valve and Cylinder Head Disassembly and

Reassembly ....................................................1D-34

Valves and Valve Guides Inspection.................1D-36

Cylinder Head Inspection..................................1D-37

Valve Spring Inspection ....................................1D-38

Engine Mounting Components..........................1D-39

Engine Assembly Removal and Installation ......1D-40

Piston, Piston Ring, Connecting Rod and

Cylinder Components .....................................1D-43

Piston, Piston Ring and Connecting Rod

Removal and Installation.................................1D-44

Cylinders, Pistons and Piston Rings

Inspection........................................................1D-46

Piston Pins and Connecting Rods Inspection ...1D-48

Crank Pin and Connecting Rod Bearings

Inspection........................................................1D-48

Main Bearing, Crankshaft and Cylinder Block

Components....................................................1D-51

Main Bearing, Crankshaft and Cylinder Block

Removal and Installation.................................1D-52

Crankshaft Inspection .......................................1D-55

Main Bearings Inspection..................................1D-55

Cylinder Block Inspection..................................1D-57

Specifications.....................................................1D-58

Tightening Torque Specifications......................1D-58

Special Tools and Equipment ...........................1D-60

Recommended Service Material .......................1D-60

Special Tool ......................................................1D-60

Engine Lubrication System .................... 1E-1

General Description ............................................. 1E-1

Engine Lubrication Description ...........................1E-1

Diagnostic Information and Procedures............ 1E-1

Oil Pressure Check .............................................1E-1

Repair Instructions ..............................................1E-2

Oil Pan and Oil Pump Strainer Components.......1E-2

Oil Pan and Oil Pump Strainer Removal and

Installation .........................................................1E-3

Oil Pump Component..........................................1E-5

Oil Pump Removal and Installation .....................1E-6

Oil Pump Disassembly and Reassembly ............1E-8

Oil Pump Inspection ............................................1E-8

Heat Exchanger Removal and Installation..........1E-9

Heat Exchanger Disassembly and

Reassembly ......................................................1E-9

Specifications..................................................... 1E-10

Tightening Torque Specifications...................... 1E-10

Special Tools and Equipment ...........................1E-11

Recommended Service Material .......................1E-11

Special Tool ......................................................1E-11

Engine Cooling System ...........................1F-1

General Description ............................................. 1F-1

Cooling System Description ................................ 1F-1

Coolant Description............................................. 1F-1

Schematic and Routing Diagram ........................ 1F-2

Coolant Circulation.............................................. 1F-2

Diagnostic Information and Procedures............ 1F-2

Engine Cooling Symptom Diagnosis...................1F-2

Repair Instructions .............................................. 1F-3

Cooling System Components.............................. 1F-3

Coolant Level Check ........................................... 1F-4

Engine Cooling System Inspection and

Cleaning............................................................ 1F-4

Cooling System Draining..................................... 1F-5

Cooling System Refilling ..................................... 1F-5

Cooling System Flushing .................................... 1F-6

Cooling Water Pipe or Hose Removal and

Installation ......................................................... 1F-6

Radiator Cooling Fan Motor On-Vehicle

Inspection.......................................................... 1F-6

Radiator Cooling Fan Relay Inspection............... 1F-7

Radiator Cooling Fan Assembly Removal and

Installation ......................................................... 1F-7

Radiator Cooling Fan Disassembly and

Reassembly ...................................................... 1F-7

Radiator Cooling Sub Fan Removal and

Installation ......................................................... 1F-8

Radiator Cooling Sub Fan Inspection ................. 1F-8

Radiator On-Vehicle Inspection and Cleaning ....1F-8

Radiator Removal and Installation ......................1F-9

Table of Contents 1-v

Water Pump Removal and Installation................ 1F-9

Water Pump Inspection....................................... 1F-9

Thermostat Removal and Installation................ 1F-10

Specifications..................................................... 1F-10

Tightening Torque Specifications...................... 1F-10

Fuel System .............................................1G-1

Precautions...........................................................1G-1

Precautions on Fuel System Service ..................1G-1

Fuel System Description .....................................1G-4

Repair Instructions ..............................................1G-5

Fuel System Components...................................1G-5

Fuel Pressure Relief Procedure..........................1G-7

Fuel Leakage Check Procedure .........................1G-7

Water Draining of Fuel Filter ...............................1G-7

Air Bleeding of Fuel System................................1G-7

Fuel Filter Assembly Removal and Installation ....1G-8

Fuel Heater and Fuel Temperature Sensor

Inspection..........................................................1G-8

Fuel Filter Element Replacement........................1G-9

Fuel Hose Disconnecting and Reconnecting....1G-10

Fuel Lines Inspection ........................................1G-12

Fuel Pipe Removal and Installation ..................1G-12

High Pressure Pipe Removal and Installation...1G-13

Fuel Injector On-Vehicle Inspection ..................1G-14

Fuel Injector Removal and Installation..............1G-14

High Pressure Pump Removal and

Installation.......................................................1G-16

Fuel Flow Actuator Inspection...........................1G-19

Common Rail, Fuel Pressure Sensor and

Fuel Pressure Regulator Valve Removal

and Installation................................................1G-19

Fuel Pressure Regulator Valve Inspection........1G-20

Fuel Pressure Sensor Inspection......................1G-20

Fuel Damper Removal and Installation.............1G-20

Fuel Filler Cap Inspection .................................1G-21

Fuel Tank Removal and Installation..................1G-21

Fuel Tank Inspection.........................................1G-23

Fuel Tank Purging Procedure ...........................1G-23

Fuel Pump Assembly Removal and

Installation.......................................................1G-23

Fuel Pump Inspection .......................................1G-24

Specifications.....................................................1G-25

Tightening Torque Specifications......................1G-25

Special Tools and Equipment ...........................1G-26

Special Tool ......................................................1G-26

Starting System .........................................1I-1

Schematic and Routing Diagram..........................1I-*

Cranking System Circuit Diagram .........................1I-*

Diagnostic Information and Procedures............. 1I-1

Cranking System Symptom Diagnosis..................1I-*

Cranking System Test.......................................... 1I-1

Repair Instructions ............................................... 1I-2

Starting Motor Unit Components.......................... 1I-2

Starting Motor Dismounting and Remounting ...... 1I-2

Specifications........................................................ 1I-3

Tightening Torque Specifications......................... 1I-3

Charging System ......................................1J-1

General Description .............................................. 1J-*

Battery Description............................................... 1J-*

Generator Description .......................................... 1J-*

Diagnostic Information and Procedures............ 1J-1

Battery Inspection ................................................ 1J-*

Generator Symptom Diagnosis ........................... 1J-1

Generator Test (Undercharged Battery

Check)............................................................... 1J-1

Generator Test (Overcharged Battery Check) .... 1J-2

Repair Instructions .............................................. 1J-2

Jump Starting in Case of Emergency................... 1J-*

Battery Dismounting and Remounting ................. 1J-*

Generator Unit Components ............................... 1J-2

Generator Dismounting and Remounting............. 1J-*

Generator Drive Belt, Tensioner and Idler

Pulley Removal and Installation ........................ 1J-3

Generator Drive Belt Inspection .......................... 1J-3

Specifications....................................................... 1J-3

Tightening Torque Specifications........................ 1J-3

Exhaust System....................................... 1K-1

General Description .............................................1K-1

Exhaust System Description ............................... 1K-1

Diesel Particulate Filter ....................................... 1K-1

Diagnostic Information and Procedures............1K-1

Exhaust System Check .......................................1K-1

Repair Instructions ..............................................1K-2

Exhaust System Components............................. 1K-2

Exhaust Manifold Removal and Installation ........1K-2

Pre-Catalytic Converter Removal and

Installation......................................................... 1K-3

Diesel Particulate Filter (with Main Catalytic

Converter) Removal and Installation.................1K-3

Specifications.......................................................1K-4

Tightening Torque Specifications........................ 1K-4

1-1 Precautions:

Precautions

Precautions

Precautions for Engine

Air Bag Warning

Refer to “Air Bag Warning in Section 00 in related manual”.

Precautions on Engine Service

Refer to “Precautions on Engine Service in Section 1A”.

Precautions in Diagnosing Trouble

Refer to “Precautions in Diagnosing Trouble in Section 1A”.

Statement on Cleanliness and Care

Refer to “Statement on Cleanliness and Care in Section 1A”.

Precautions on Fuel System Service

Refer to “Precautions on Fuel System Service in Section 1G”.

Engine Cooling System Warning

Refer to “Coolant Description in Section 1F”.

Exhaust System Caution

Refer to “Exhaust System Check in Section 1K”.

Precaution for CAN Communication System

Refer to “Precaution for CAN Communication System in Section 00 in related manual”.

S5RW0D1000001

Precautions for Catalytic Converter and Diesel Particulate Filter

Refer to “Precautions for Catalytic Converter and Diesel Particulate Filter in Section 00”.

Precautions for Electrical Circuit Service

Refer to “Precautions for Electrical Circuit Service in Section 00 in related manual”.

Precaution in Replacing ECM

Refer to “Precaution in Replacing ECM in Section 1C”.

Engine General Information and Diagnosis: 1A-1

Engine General Information and Diagnosis

Precautions

Precautions on Engine Service

!

CAUTION

The following information on engine service

should be noted carefully, as it is important in

preventing damage, and in contributing to

reliable engine performance.

• When raising or supporting engine for any reason, do

not use a jack under oil pan. Due to small clearance

between oil pan and oil pump strainer, jacking against

oil pan may cause it to be bent against strainer

resulting in damaged oil pick-up unit.

• It should be kept in mind, while working on engine,

that 12-volt electrical system is capable of violent and

damaging short circuits.

When performing any work where electrical terminals

could possibly be grounded, ground cable of the

battery should be disconnected at battery.

• Any time the air cleaner, air cleaner outlet hose,

turbocharger, intercooler, intercooler outlet hose or

intake manifold is removed, the intake opening should

be covered. This will protect against accidental

entrance of foreign material which could follow intake

passage into cylinder and cause extensive damage

when engine is started.

S5RW0D1100001

Precautions in Diagnosing Trouble

S5RW0D1100002

• Don’t disconnect couplers from ECM, battery cable

from battery, ECM ground wire harness from engine

or main fuse before confirming diagnostic information

(DTC) stored in ECM memory.

• Diagnostic information stored in ECM memory can be

cleared as well as checked by using SUZUKI scan

tool or OBD generic scan tool. Before using scan tool,

read its Operator’s (Instruction) Manual carefully to

have good understanding as to what functions are

available and how to use it.

• Be sure to read “Precautions for Electrical Circuit

Service in Section 00 in related manual” before

inspection and observe what is written there.

• Replacement of the ECM

Before replacement of the ECM, save the data of

vehicle information (injector calibration code and

diesel particulate filter data) into SUZUKI scan tool

from ECM according to procedure described in “ECM

Registration in Section 1C”.

• ECM registration:

If ECM is replaced with new one or with another one,

register vehicle information (fuel injector calibration

code, diesel particulate filter data) and immobilizer

system data (password and secret key code) into

ECM referring to “ECM Registration in Section 1C”.

• Communication of ECM, BCM, combination meter,

ABS or ESP® control module (ESP® model), steering

angle sensor (ESP® model), keyless start control

module (keyless start model) and 4WD control

module (4WD model), is established by CAN. (For

more detail of CAN communication for ECM, refer to

“CAN Communication System Description”).

Therefore, handle CAN communication line with care

referring to “Precaution for CAN Communication

System in Section 00 in related manual”.

Statement on Cleanliness and Care

S5RW0D1100003

An automobile engine is a combination of many

machined, honed, polished and lapped surfaces with

tolerances that are measured in the thousands of an

millimeter (ten thousands of inch).

Accordingly, when any internal engine parts are

serviced, care and cleanliness are important.

It should be understood that proper cleaning and

protection of machined surfaces and friction areas is part

of the repair procedure. This is considered standard

shop practice even if not specifically stated.

• A liberal coating of engine oil should be applied to

friction areas during assembly to protect and lubricate

the surfaces on initial operation.

• Whenever valve train components, pistons, piston

rings, connecting rods, rod bearings, and crankshaft

journal bearings are removed for service, they should

be retained in order.

At the time of installation, they should be installed in

the same locations and with the same mating

surfaces as when removed.

• Battery cables should be disconnected before any

major work is performed on the engine.

Failure to disconnect cables may result in damage to

wire harness or other electrical parts.

• The four cylinders of the engine are identified by

numbers; No.1 (1), No.2 (2), No.3 (3) and No.4 (4) as

counted from crankshaft pulley side to flywheel side.

1 2 3 4

I5RW0D110001-01

1A-2 Engine General Information and Diagnosis:

General Description

Engine Diagnosis General Description

S5RW0D1101002

The engine and emission control system in this vehicle

are controlled by ECM. ECM has an OBD system which

detects a malfunction in this system and abnormality of

those parts that influence the engine exhaust emission.

When diagnosing engine troubles, be sure to have full

understanding of the outline of “OBD System

Description” and each item in “Precautions in

Diagnosing Trouble” and execute diagnosis according to

“Engine and Emission Control System Check”.

There is a close relationship between the engine

mechanical, engine cooling system, exhaust system,

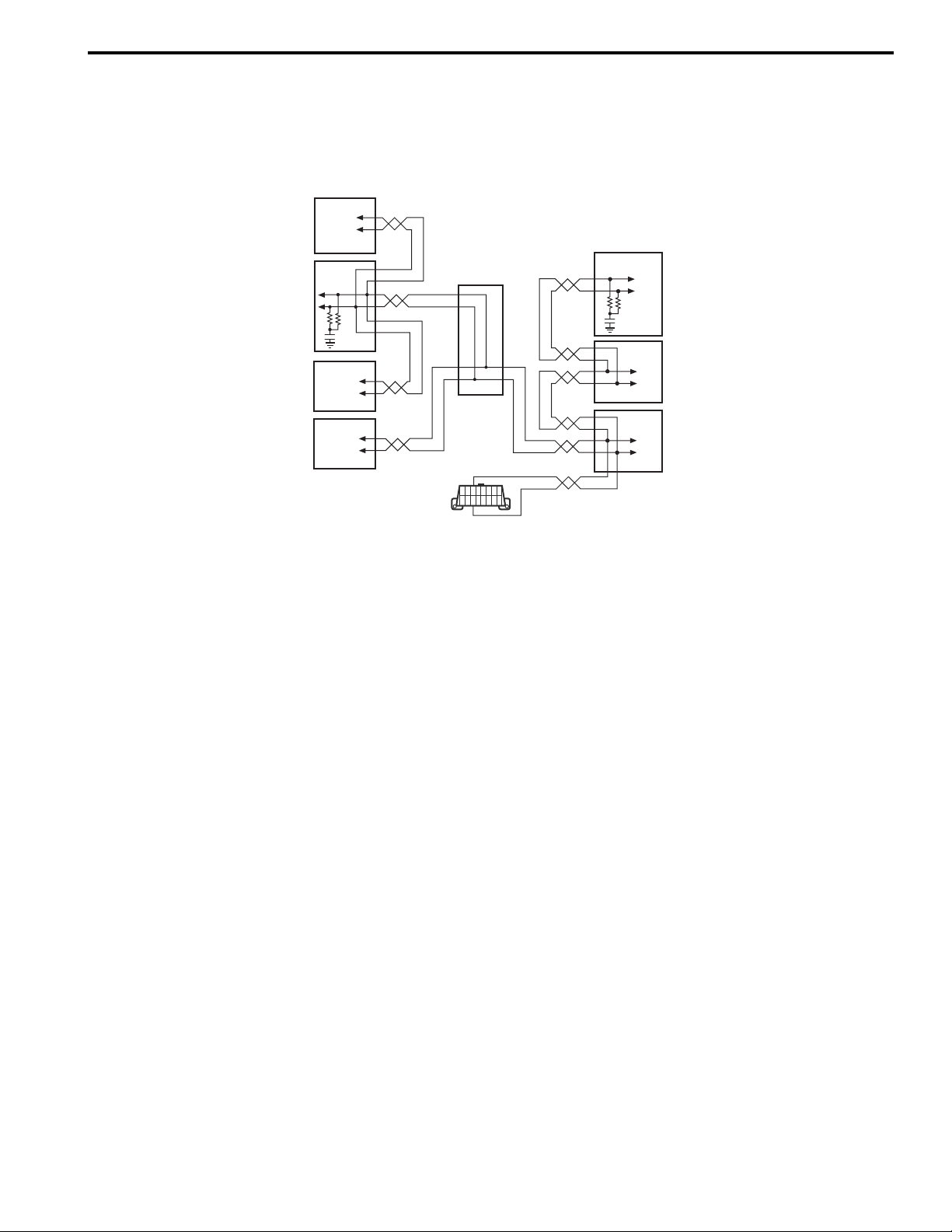

etc. and the engine and emission control system in their