Page 1

FIATPANDA

PANDA CROSS

Page 2

FIAT PANDA PANDA CROSS

The Fiat Panda Panda Cross PetrolMethane version is dealt with in this appendix.

For anything not included in this supplement, refer to the Fiat Panda Owner Manual.

CONTENTS

INTRODUCTION ............................................................................................................ 3

FUNCTIONAL SYSTEM DIAGRAM ............................................................................ 5

CANISTERS ....................................................................................................................... 6

SOLENOID VALVE/SAFETY DEVICES ........................................................................ 7

PIPING ................................................................................................................................. 8

PRESSURE REGULATOR/REDUCTION UNIT ....................................................... 8

METHANE INJECTORS ................................................................................................. 8

METHANE ELECTRONIC CONTROL UNIT ......................................................... 8

PETROL/METHANE SWITCH ...................................................................................... 9

FUEL CUT OFF SWITCH ............................................................................................. 10

STARTING THE ENGINE ............................................................................................. 10

AT THE PETROL STATION ......................................................................................... 11

WHEN NEEDING TO CHANGE AN EXTERNAL BULB ..................................... 12

CANISTER IDENTIFICATION DATA ....................................................................... 15

MAINTENANCE SCHEDULE ...................................................................................... 16

WHEELS ............................................................................................................................. 17

ENGINE ............................................................................................................................... 18

WEIGHTS ........................................................................................................................... 20

LOAD COMPARTMENT VOLUME ............................................................................. 20

TYRES .................................................................................................................................. 21

DIMENSIONS .................................................................................................................... 22

CAPACITIES ....................................................................................................................... 23

2

Page 3

INTRODUCTION

The Fiat Panda Natural Power version features two fuel systems, one for petrol and

one for natural gas (methane).

The two systems are independent of one

another and the methane one is the

phased, sequential, multipoint type.

The starting system runs on petrol and is

the only one.

What is natural gas?

Natural gas is a mixture of gas used as a

main source of energy.

Its main component is methane so for this

reason it is usually known as methane in

Italy but it contains small amounts of other hydrocarbons and inert gases.

It is extracted in a gaseous stage and transported to where it is used via gas pipelines;

world reserves are plentiful and evenly distributed. Methane is fuel with a low impact

on the environment because it significantly

reduces the contribution of the exhaust

gases to the greenhouse effect and creating pollution.

The methane multipoint injection

system

This is an original product from Fiat’s research in the field of alternative fuels that

comes from close co-operation with important suppliers in the methane sector.

By adapting the sophisticated electronic

control technology of petrol engines to

meet the specifications of methane, it has

been possible to achieve important results

in terms of driveability, exhaust emissions

and consumption.

Using the methane multipoint injection

system the engine offers the same driving

conditions as running on petrol.

It should be borne in mind that, in all driving conditions, methane operation gives

engine power and torque specifications

that are 10% lower than petrol operation.

Petrol operation is therefore recommended if a lot of power is required (e.g. driving uphill with a

laden car, setting off on a steep incline).

Selecting the type of fuel supply

The Fiat Panda Panda Cross version is

configured to normally run on methane.

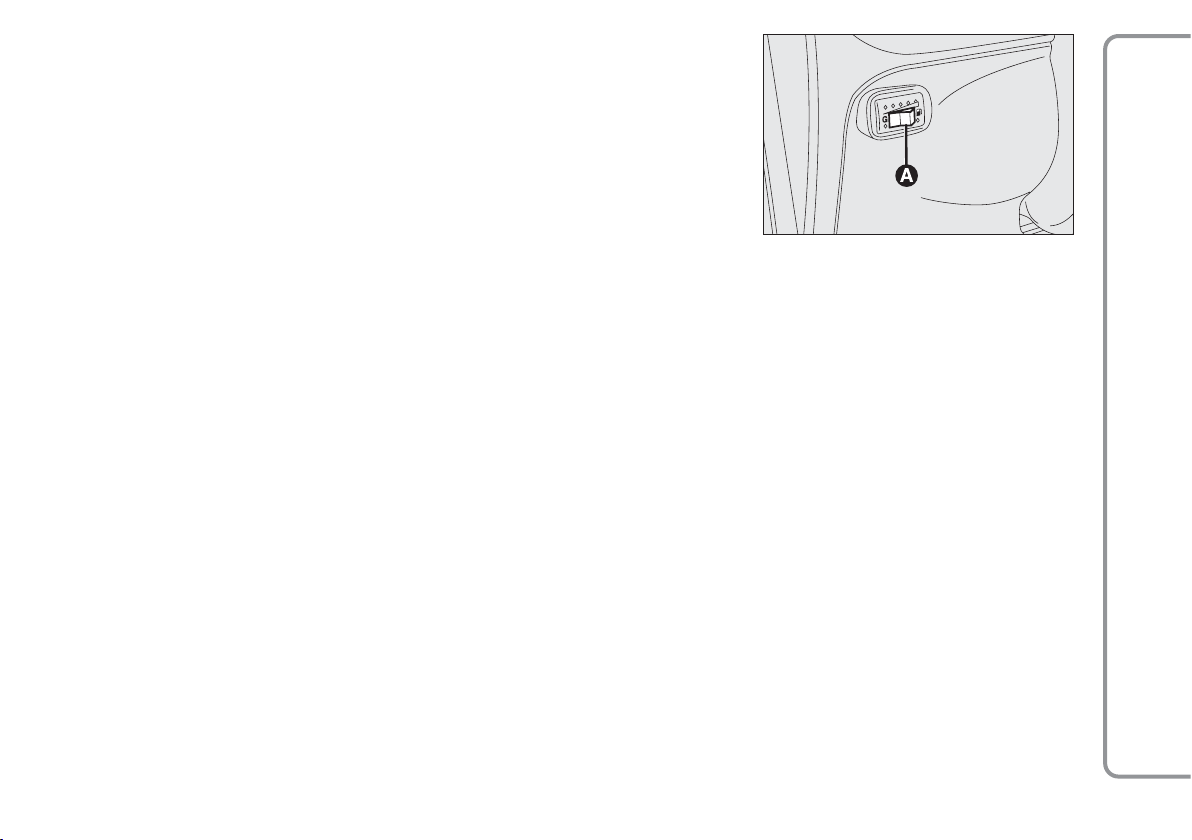

fig. 1

F0G0654m

When the methane is running out and the

pressure in the canister is close to the correct operating limit, the system automatically switches to petrol operation.

The engine is always started up using

petrol (to keep this fuel supply system efficient) with an automatic switch to

methane after a few seconds.

For this reason there always needs

to be petrol in the tank.

The petrol/methane switch A - Fig. 1, on

the hatch for the fuse box unit (left dashboard), makes it possible to select petrol

operation. The system does not switch automatically to methane operation if the

petrol runs out.

FIAT PANDA PANDA CROSS

3

Page 4

FIAT PANDA PANDA CROSS

Passive safety

The Fiat Panda Panda Cross version has

the same passive safety features as the

other versions.

In particular, the location and mountings

of the canisters have been designed to

pass the impact tests in accordance with

Fiat safety standards. The flow of methane

coming out of the canisters is governed by

a solenoid valve that is only open during

methane operation.

The solenoid valve unit includes protection against excess flows (if the high pressure system breaks, the flow of methane

is restricted to values that are not dangerous), overheating (fuse pad that allows

the methane to drain off if the temperature exceeds 110 °C) and a pressure calibration device that intervenes if the pressure goes above 300 bar ensuring the

methane escapes in a controlled manner

and as quickly as possible.

The solenoid valve is connected to the

Fire Protection System (inertia switch or

fuel cut off switch).

Active safety

The Fiat Panda Panda Cross version has

the same active safety features as the other versions.

WARNING

The Fiat Panda Panda Cross

version is equipped with a

high pressure methane system designed to run at 200 bar.

It is dangerous to force the system

with higher pressures. When towing

or lifting the vehicle, the instructions

in this booklet at the end of the chapter should be followed in order to prevent damage to the methane system

parts: ‘Towing the vehicle’.

If there is a problem with the methane

system, only go to an authorised Fiat

Dealer.

Do not alter the methane system configuration or components; they are designed exclusively for the Fiat Panda

Panda Cross. The use of other components or materials may lead to malfunctioning and compromise safety.

WARNING

When oven painting, the

canisters should be removed

from the vehicle and later carefully

refitted by a Fiat Dealer. Although the

methane system has numerous safety features, it is advisable to close the

manual taps for the canisters every

time the car is not in use for a long

period, transported on other vehicles

or moved in an emergency as a result

of a breakdown or accident.

4

Page 5

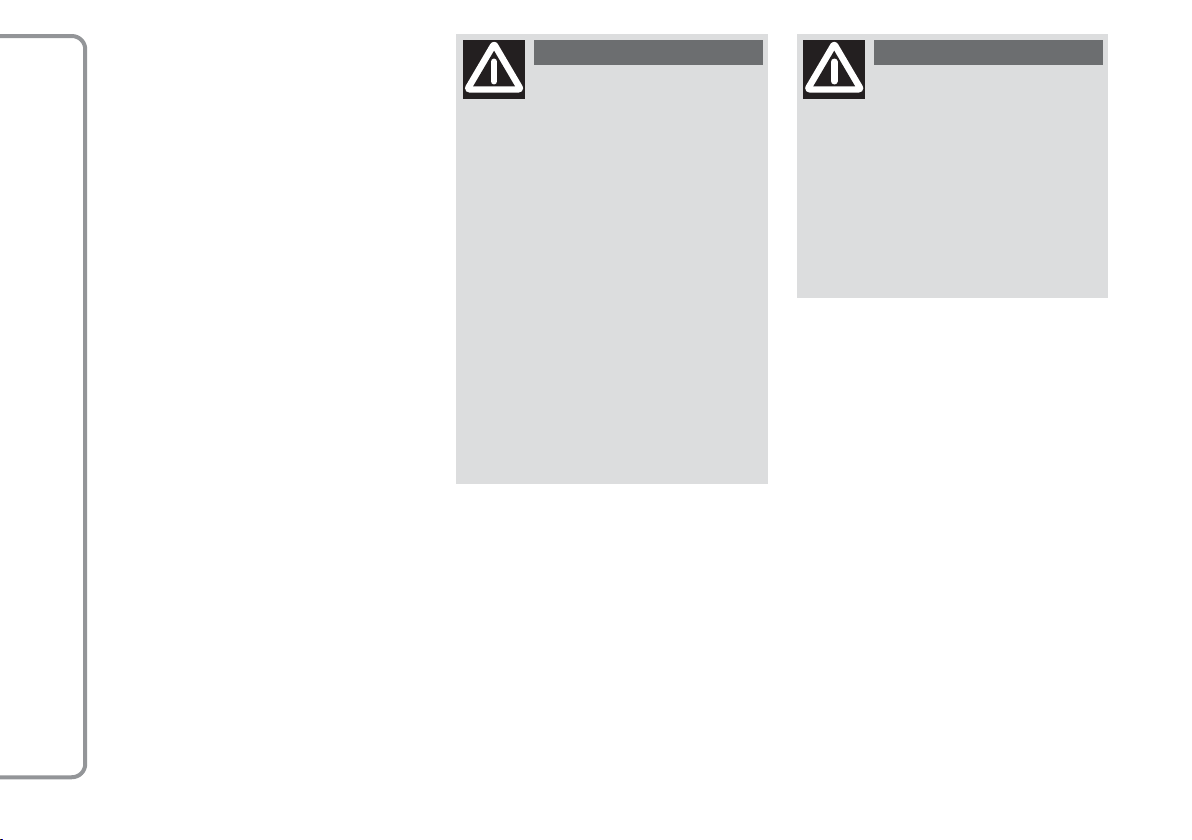

FUNCTIONAL SYSTEM DIAGRAM

Description of the functional system diagram Fig. 2

1 Methane canisters - 2 Methane repressurising filler - 3 Methane-Petrol switch - 4 Methane piping - 5 Pressure regulator/reduction

unit - 6 Methane injection system electronic control panel - 7 Methane injector carrier manifold - 8 Petrol tank

FIAT PANDA PANDA CROSS

fig. 2

F0G0811m

5

Page 6

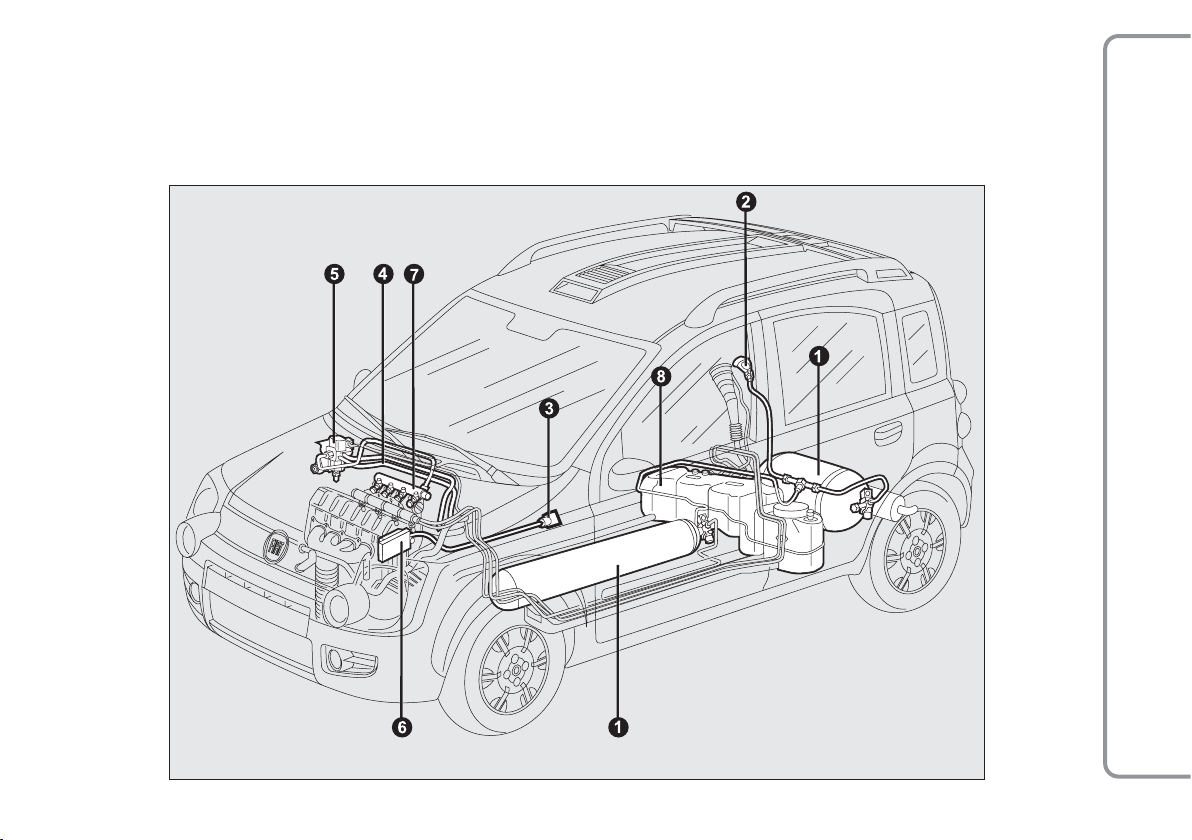

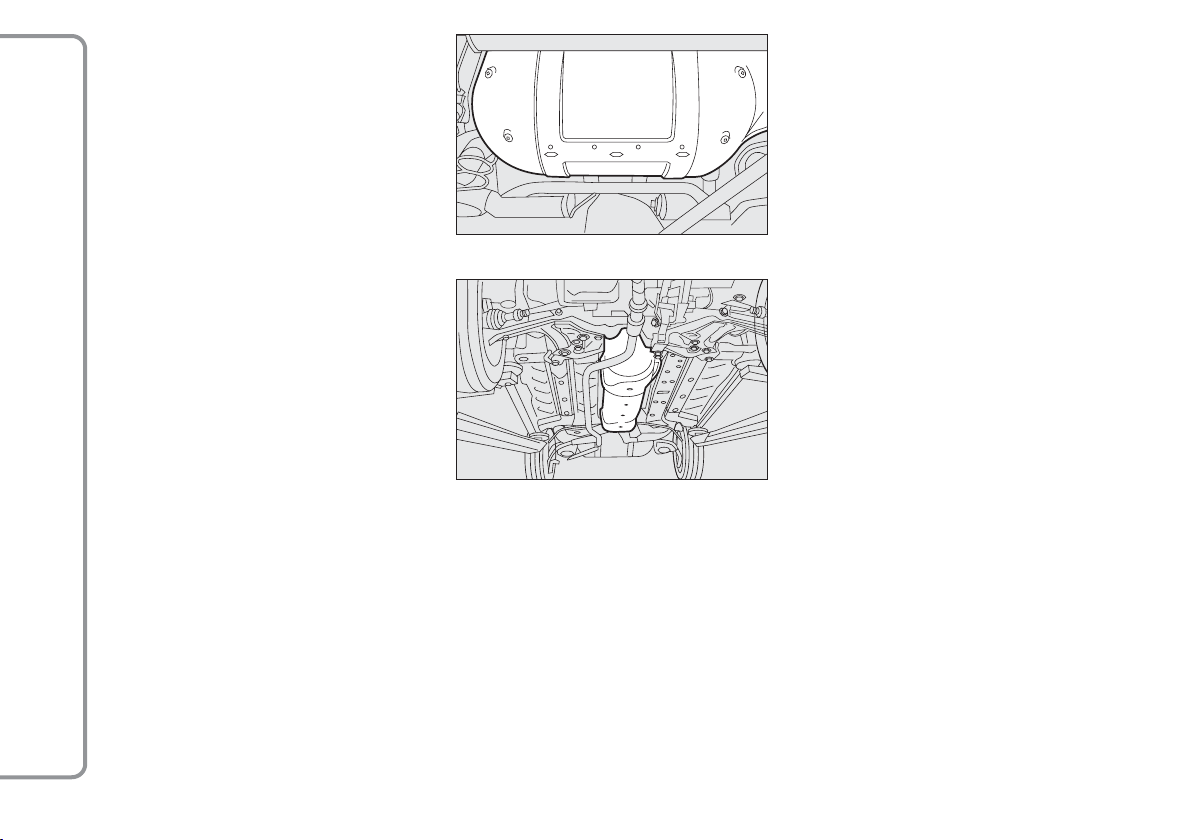

CANISTERS

The car has two canisters (total capacity

about 72 litres) located under the floor of

the car and protected by two special

guards. The canisters Fig. 3 and Fig. 4 are

the tank that contains the methane in the

compressed gaseous state (pressure 200

bar at 15 °C). The methane, stored in the

canisters at high pressure, flows through

a dedicated pipe to reach the pressure

regulator/reduction unit which supplies

the 4 methane injectors at low pressure

(about 9 bar).

fig. 3

F0G0656m

The plates handed over by the Dealership

with the documentation contain the date

for the first inspection of the canisters.

Those responsible for the

methane supply are not authorized to refill the canisters when

the inspection date has expired.

IMPORTANT If the vehicle has

been registered in a country other than Italy, the certification data, identification and inspection

procedures for the methane canisters should conform to the legislation in that country. In any

case, it should be remembered

that the life of the canisters is 20

years from the production date

as set out in Regulation (ECE) no.

110.

FIAT PANDA PANDA CROSS

6

fig. 4

Canister certification

The methane canisters are certified in accordance with ECE Regulation no. 110

F0G0657m

The canisters should be inspected, in accordance with ECE Regulation Procedure no. 110, every

4 years from the vehicle registration date or in accordance

with specific regulations in individual countries (see ‘Identification data’ chapter).

Page 7

SOLENOID VALVES/

D

1

2

SAFETY DEVICES

The solenoid valves Fig. 5 and Fig. 6 are

bolted directly onto the methane canisters with the main function on interrupting the flow of methane to the supply circuit.

The solenoid valves are open when:

❒

the switching button is in the methane

position;

❒ t

he pressure in the canister is sufficient

for operation;

❒

the engine is running;

❒

the inertia switch has not been triggered.

The solenoid valve assembly is equipped

with the following safety devices:

1) Fuse pad, in the case of overheating

(temperature above 110 °C), it totally

eliminates the danger of excess pressure

making the methane in the canister flow

out as quickly as possible in a controlled

manner.

2) Mechanical excess pressure device

(Burt Disk), in the case of excess pres-

sure (above 300 bar), it ensures that the

methane escapes as quickly as possible in

a controlled manner.

fig. 5

fig. 6

F0G0658m

F0G0659m

3) Excess flow, it intervenes if the piping

is broken limiting the flow of methane to

values that are not dangerous.

The flow restrictor valve is located to allow it to operate even if the solenoid valve

casing is broken due to an impact.

4) Manual tap, it is located upstream of

the solenoid valve.

fig. 7

F0G0660m

This separates the canister from the

methane system to allow maintenance operations.

The taps are accessible from outside the

car and are located, in the case of the

lengthwise centre canister, at the rear of

the canister and, in the case of the transverse rear canister, towards the left wheel

side.

To close the taps D - Fig. 7: turn the

knob in the direction (1) shown by the arrow (clockwise

OFF)

To open the taps D - Fig. 7: turn the knob

in the direction (2) shown by the arrow

(anti-clockwise

ON)

5) Single-acting valve, positioned on

the piping that comes from the filler, to

prevent the methane from flowing back.

FIAT PANDA PANDA CROSS

7

Page 8

PIPING

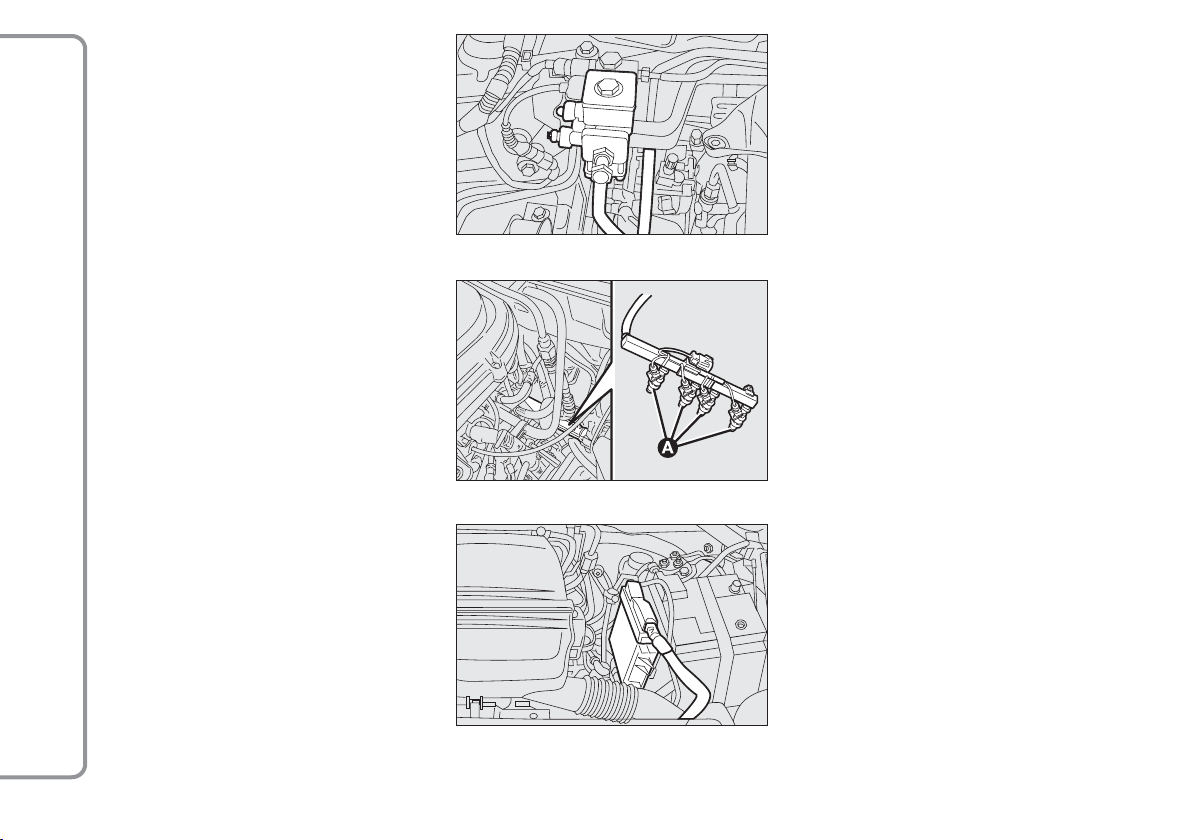

METHANE INJECTORS

FIAT PANDA PANDA CROSS

The methane piping from the filler to the

pressure regulator/reduction unit is made

from galvanized steel and covered in plastic (high pressure) and is located outside

the passenger compartment; the piping

from the pressure regulator/reduction

unit to the methane injectors is in galvanised steel (rigid pipe) and stainless steel

(flexible hose).

PRESSURE

REGULATOR/

REDUCTION UNIT

The pressure reduction unit Fig. 8 is installed in the engine compartment.

It has the function of reducing the pressure of the methane from the value in the

canister to the supply value for the

methane injectors (about 9 bar) and keeping it constant in all operating conditions.

fig. 8

fig. 9

F0G0661m

F0G0662m

There are 4 dedicated injectors for the

methane gas A - Fig. 9, fitted on the intake manifold near the cylinder head, one

for each intake duct; they are supplied at

a constant pressure (about 9 bar) and operated by the specific electronic control

unit.

ELECTRONIC CONTROL

PANEL FOR

METHANE SYSTEM

Specific electronic control panel for

methane supply and advance ignition.

If the methane has run out, the control

unit fig. 10 automatically handles the

switch to running on petrol.

fig. 10

F0G0663m

8

Page 9

PETROL/METHANE

D

A

C

B

SWITCH

❒

A Methane/Petrol switch.

❒

B Methane quantity indicator; 5 LEDs

of which four green and one amber to

indicate reserve. The amber LED is

turned on when only one green LED

is on; as the green LED turns off, the

amber LED remains on alone, meaning

that you are running on reserve.

❒

C Petrol operating mode indicator: amber LED next to switch A. This function is controlled directly by the

Methane control unit.

❒

D Methane operating mode indicator:

green LED next to switch

tion is controlled directly by the

Methane control unit.

WARNING By taking the ignition key to

MAR, all the device LEDs will stay on for

approximately 4 seconds (check function).

WARNING By taking the ignition key to

STOP, the LED for the operating mode

selected will stay on for approximately 2

seconds (LED C or D).

A. This func-

fig. 11

Normal engine function is Methane (except for start-up which is always petrol):

❒

the switch A pressed on the right side

(identified by the symbol K indicates

petrol functioning with switching on of

the relative amber LED C;

❒

the switch A pressed on the left side

(identified by the symbol G) indicates

methane functioning with switching on

of the relative green LED D.

There are 5 LEDs B (1 amber and 4

green) on the top part of the switch that

display the amount of methane in the canisters.

When the amount of methane remaining

falls below 1/5 of the capacity of the canisters, only the amber LED above the

switch (reserve) remains on, signalling the

need to refuel.

F0G0664m

If the methane has run out, switching to

petrol takes place automatically: the amber LED C next to the switch turns on and

the green one turns off D relative to

methane operation.

By refuelling with methane, after normal

start-up with petrol, the supply automatically returns to methane: the amber LED

C next to the switch turns on and the

green one D relative to methane operation, turns on.

If you specifically wish to run on petrol

(for greater power, not to use methane,

etc.), press the switch A on the right-hand

side.

The amber LED C next to the switch will

turn on to indicate that the switch has taken place (the methane power system has

been entirely disabled).

You can only return to running on

methane by acting on the switch once

A, the green LED D next to the

again

switch, will turn on to indicate that the

switch has taken place.

The manual selection of the operating mode from petrol to

methane and vice versa is only activated if the engine speed is below 2000 rpm.

FIAT PANDA PANDA CROSS

9

Page 10

FIAT PANDA PANDA CROSS

In addition, in the case of starting at outside temperatures of below around -10°C,

the switching times from Petrol to

Methane increase to allow the pressure

regulator/reduction unit to become warm

enough.

IMPORTANT If the switching takes place

during acceleration or pick-up, there may

be a brief flat spot (fall in power).

WARNING

Do not switch between the

two operating modes whilst

starting the engine

FUEL CUT OFF SWITCH

The safety switch is triggered in the case

of an impact, cutting off the methane supply and causing the engine to cut out.

For further information, see the “Fuel cut

off switch” paragraph in the “Controls”

chapter in the Owner Handbook.

STARTING THE ENGINE

To carry out the starting manoeuvre, see

the warnings and advice in the Owner

Handbook under the chapter “Starting the

engine”.

WARNING

Start-up of the Fiat Panda

Panda Cross engine always

takes place with petrol, even when

the switch is set to ‘methane’. In this

case, the amber LED is on, indicating petrol supply, and will remain

such until the automatic switch to

methane, at which the amber LED

goes off, and the green one comes on.

There must, therefore, always be

some petrol in the tank.

10

Page 11

AT THE FILLING

B

A

STATION

METHANE GAS FILLER

The methane gas filler is on the right-hand

side of the vehicle.

It is comes complete with a double ‘single-acting’ valve: one in the filler itself, and

the other near the rear canister under the

floor.

To access the filler, undo the cap B-fig.

13 unscrew the cap A-fig. 12, turning it

anticlockwise.

The profile of the filler

universal type compatible with Italia and

NGV1 standards.

B for refilling is the

fig. 12

The other plates (handed over with the

car documentation) contain the date for

the first inspection of the canisters.

Those responsible for the methane supply

are not authorized to refill the canisters

when the inspection date has expired.

F0G0666m

fig. 13

F0G0665m

FIAT PANDA PANDA CROSS

In some European countries adaptors are

considered ILLEGAL (e.g. in Germany).

In the case of service stations with m

3

(different pressure) nozzles, to measure the

residual pressure in the canister, the single-acting valves must be undone supplying a small amount of methane.

11

Page 12

WHEN NEEDING TO

CHANGE AN

EXTERNAL BULB

For the type of bulb and relative power,

please see the paragraph ‘Bulb replacement’ at chapter ‘In an emergency’ of the

attached Use and Maintenance manual.

FIAT PANDA PANDA CROSS

12

FRONT LIGHT CLUSTER

To change the low beam bulb, proceed

as follows:

❒

remove the cover A-fig. 14;

❒

disconnect the connector C-fig. 15;

❒

release the bulb holder fixing clip A;

❒

remove the bulb B and insert the new

bulb.

fig. 14

fig. 15

F0G0617m

F0G0618m

To change the side light bulb, proceed as

follows:

❒

remove the cover A-fig.: 14;

❒

remove the bulb-holder A-fig.: 16

❒

remove the bulb B;

❒

insert the new bulb.

fig. 16

fig. 17

F0G0619m

F0G0628m

To replace the fog light bulb, proceed as

follows:

❒

remove the cover A-fig. 14;

❒

disconnect the connector D-fig. 17;

❒

turn the bulb holder slightly B and pull

it out;

❒

remove the bulb C and insert the new

bulb.

Page 13

fig. 18

F0G0620m

fig. 20

F0G0622m

fig. 22

F0G0624m

fig. 19

F0G0621m

To replace the full beam light bulb, proceed as follows:

❒

remove the head light mask by unscrewing the three fixing screws A-fig.

18;

❒

remove the mask, freeing it from the

fixing devices B;

❒

remove the light fig. 19 by unscrewing the three fixing screws A;

❒

turn the connector anticlockwise A-fig.

20 and pull it out;

fig. 21

❒

remove the bulb B-fig. 20 and insert

F0G0623m

the new bulb.

To change a direction indicator bulb, proceed as follows:

❒

undo both fastening bolts A-fig 21 and

remove the mask B;

❒

undo the fastening screws A-fig 22 and

remove the lamp B;

❒

remove the boot A-fig. 23 from the lens

B and pull out the bulb-holder C;

fig. 23

❒

remove the bulb D by pushing it

F0G0631m

slightly and turning it in an anticlockwise direction, now insert the new

bulb.

To replace the direction indicator light

bulbs, the third brake light bulbs and the

number plate bulbs, follow the descriptions and explanations given in the paragraph ‘Bulb replacement’ in the chapter ‘In

an emergency’ of the Use and Maintenance

Manual to which this supplement is attached.

FIAT PANDA PANDA CROSS

13

Page 14

fig. 24

F0G0627m

fig. 25

F0G0625m

fig. 26

F0G0626m

FIAT PANDA PANDA CROSS

14

REAR LIGHT UNIT

The bulbs are arranged inside the rear light

unit as follows fig. 24:

A dual filament bulb 12V-W5W for

brake/side lights.

B 12V-P21W bulb for direction indicator lights.

C 12V-P21W bulb for rear fog lights (left

head light) or reverse lights (right head

light).

To change the bulb proceed as follows:

❒

unscrew the three screws A-fig. 25

then pull the complete head light gently outwards, until complete release of

the three fixing clamps;

❒

unscrew the four screws A-fig. 26 and

disconnect the two connectors;

❒

remove the bulb-holder rotating it anticlockwise;

❒

remove the desired bulb (A, B or C-

fig. 24), by pushing it slightly and turn-

ing it in an anticlockwise direction

(bayonet fastening), now insert the

new bulb.

Page 15

IDENTIFICATION DATA

IMPORTANT If the car has been

registered in a country other than

Italy, the certification data, identification and inspection procedures for

the methane canisters should conform to the legislation in that country. In any case, it should be remembered that the life of the canisters is 20 years from the production date as set out in ECE Regulation no. 110.

Canister marking

Each methane canister is identified in the

factory with a stamp on the nose of the

actual canister.

The stamp includes:

❒

type of gas it is designed for (methane);

❒

twenty-year canister expiry date

(month/year);

❒

name of canister manufacturer;

❒

canister serial number;

❒

nominal canister capacity in litres;

❒

canister weight in kg (specific for each

canister);

❒

operating pressure (200 bar at 15°C);

❒

canister test pressure (300 bar);

❒

identification stamp for homologating

country;

❒

ECE homologation number;

❒

inspection stamp;

❒

ENI stamp;

❒

canister manufacture test date

(month/year).

The other plates (handed over with the

car documentation) contain the date for

the first inspection of the canisters.

SYSTEM INSPECTION

The canisters should be inspected, in accordance with ECE Regulation Procedure

no. 110, every 4 years from the vehicle

registration date or in accordance with

specific regulations in individual countries.

FIAT PANDA PANDA CROSS

15

Page 16

MAINTENANCE SCHEDULE

Additional operations to the Maintenance Schedule in the Owner’s Handbook.

FIAT PANDA PANDA CROSS

Thousands of kilometres

Cold cylinder compression check

Visually inspect the condition of: methane pipes and connectors,

fastening of methane tank, renew if necessary (*)

Check pressure regulator and, if necessary, replace

internal filter (*)

Check operation and parameters of fuel supply system

using self-diagnostic socket

Check correct assembly of injectors

(positioning clip holding)

Check mechanical tappet clearance and restore if necessary

Check tightening torque of canister fastening

bands

(*) or every 12 months

20 40 60 80 100 120 140 160 180

●●●●● ●● ●●

●●●●● ●● ●●

●●●●● ●● ●●

●●●●● ●● ●●

●●●●● ●● ●●

●●●●● ●● ●●

●●●●●

16

Page 17

WHEELS

A

WHEEL REPAIR

The car does not have a spare wheel but

comes with a quick tyre repair kit known

as Fix&Go automatic.

The kit A-fig. 27 is located on the left of

the luggage compartment and is fastened

by Velcro. See the instructions in the

booklet that this supplement comes with.

The tool box Fig. 28 is located under the

driver’s seat and fastened by Velcro.

fig. 27

F0G0668m

fig. 28

F0G0607m

FIAT PANDA PANDA CROSS

17

Page 18

FIAT PANDA PANDA CROSS

ENGINE

ENGINE CODE - BODYWORK VERSIONS

Engine code Bodywork version

1.2 188A4000 169 AXB1A 01T

GENERAL FEATURES 1.2

Engine identification code 188A4.000

Bodywork version code 169 AXB1A 01T

Cycle Otto

Number and layout of cylinders 4 in line

Number of valves per cylinder 2

Piston bore and stroke mm 70.8 x 78.86

Total displacement cm

Compression ratio 9,8:1

Max. EEC power HP

corresponding speed rpm

Max. EEC torque kgm

at a speed of rpm

Spark plugs NGK DCPR7E-N-10

Fuel

kW

Nm

3

Methane Petrol

38

52

5000

88

9,0

3000

Methane

1242

44

60

5000

102

10,4

2500

BOSCH YR7DEU

Green petrol unleaded

95 RON

18

Page 19

FUEL SYSTEM (methane)

Dedicated electronic injection for

methane.

Type: Phased, sequential, multipoint.

Injection pressure; about 9 bar.

Stoichiometric metering of the

air/methane gas mixture.

The methane injection system is controlled by a dedicated control unit using

the sensors already on the car, including

the Lambda sensor for controlling the fuel metering.

IGNITION

Static advance, electronic, integrated with

the injection.

ENGINE COOLING SYSTEM

Engine cooling system with pressure reduction unit heating circuit subject to

strong cooling during operation.

PERFORMANCE

Top speed in km/h.

Running on petrol: 148

Running on methane: 140

WARNING

Modifications or repairs to

the fuel feed system that are

not carried out properly or do not

take the system’s technical specifications into account can cause malfunctions leading to fire risk.

FIAT PANDA PANDA CROSS

19

Page 20

WEIGHTS

Weights (kg) for versions

Unladen weight (with all fluids, fuel tank

filled to 90% and without optional equipment):

1070

FIAT PANDA PANDA CROSS

Payload including the driver (1):

Maximum permitted loads (2)

– front axle:

– rear axle:

– total:

Maximum permitted load on the roof:

(1) In the presence of optional equipment the unladen weight increases and, as a result, the payload decreases in relation to the maximum permitted loads.

(2) Loads not to be exceeded. The user is responsible for arranging goods in the luggage compartment and/on load carrying platform within the maximum permitted loads.

IMPORTANT A trailer cannot be towed so there are no provisions for fitting a tow hook.

380

750

735

1450

50

LOAD COMPARTMENT VOLUME

The volume of the load compartment measured in dm3is as follows:

With rear backrests not folded over:

With rear backrests folded over:

190

840

20

Page 21

TYRES

COLD TYRE INFLATION PRESSURES

Rim

Tyres

1.2 Petrol/Methane

5.5J X14

175/65 R14

Medium load Full load

Engine front rear front rear

1.2 2,2 2,2 2,4 2,4

FIAT PANDA PANDA CROSS

21

Page 22

DIMENSIONS

Dimensions are expressed in mm and refer to the vehicle equipped with its original tyres.

Height is measured with vehicle unladen.

FIAT PANDA PANDA CROSS

22

fig. 29

ABCDEFGH

3581 734 2305 542 1614 / 1576 (*) 1358 1611 1366

(*) Without longitudinal bars

F0G0709m

Page 23

CAPACITIES

Petrol

Petrol . . . . . . . . . . . . . . . . . litres 30

– including a reserve of . . . litres 5÷7

Methane

- Methane (*) . . . . . . . . kg (approx.) 12

(*) The amount of methane depends on

the outside temperature, the supply pressure, the quality of the gas and the type

of refuelling system. The total volume of

the canisters is about 72 litres.

IMPORTANT It should be remembered

that when using a fuel such as methane the

range is very variable because as well as

the driving conditions and car maintenance

it also depends on the temperature of the

gas in the canister.

The methane actually heats up during the

refuelling and cools down whilst driving,

undergoing variations in pressure that reduce the quantity that can be used.

It should also be pointed out that whilst

the vehicle is being run in (up to around

3000 km) the fuel consumption may be

higher than the figures given.

FIAT PANDA PANDA CROSS

23

Page 24

Fiat Group Automobiles S.p.A. - Customer Services - Technical Services -

Service Engineering - Largo Senatore G. Agnelli, 5 - 10040 Volvera - Torino (Italia)

Print no. 603.97.109 - 04/2009 -1 Edition

Loading...

Loading...