Page 1

Festool GmbH

Wertstraße 20

73240 Wendlingen

Germany

www.festoolusa.com

Instruction manual

Page 6

IMPORTANT: Read all instructions before using.

Guide d’utilisation

Page 14

IMPORTANT: Lire toutes les instructions avant de démarrer les travaux.

Manual de instrucciones

Página 24

IMPORTANTE: Lea todas las instrucciones antes de usar.

707511 _001

Instruction manual

Guide d’utilisation

Manual de instrucciones

S H I N E X

RAP 150-14 FE

RAP 150-21 FE

Page 2

Page 3

Page 4

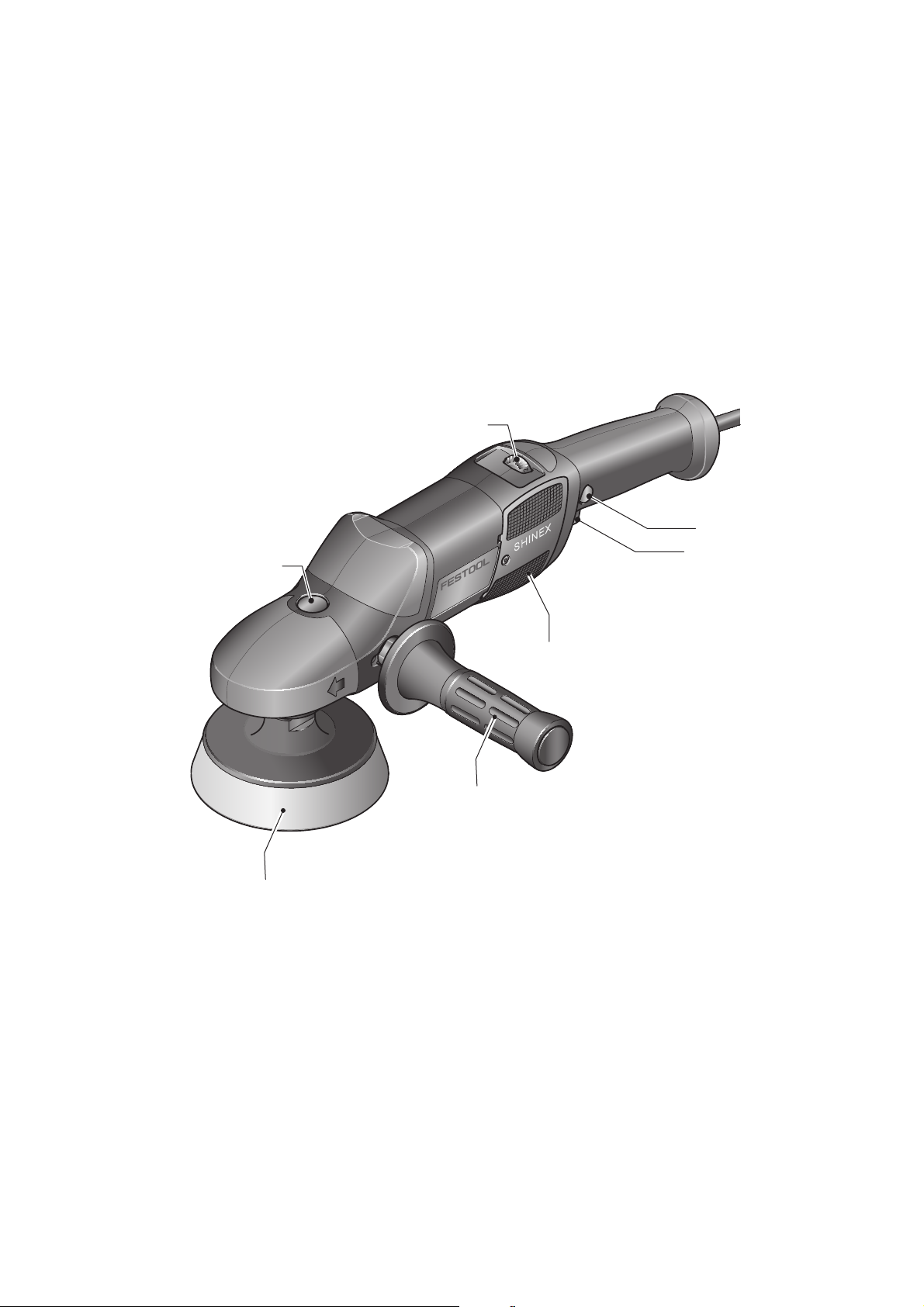

1-1

1-2

1-3

1-4

1

1-5

1-6

1-7

Page 5

Page 6

Contents

Symbols................................................ 6

About this manual................................ 6

Safety instructions............................... 7

Technical data...................................... 10

Functional description......................... 10

Intended use ........................................ 10

n

no load speed

0

Class II construction

rpm

min

revolutions per minute

-1

’’ inch

lb. pound

diameter

Operation ............................................. 10

Electronics........................................... 11

Settings ................................................ 11

Working with the machine................... 12

Service and maintenance .................... 13

Accessories.......................................... 13

Environment......................................... 13

Symbols

Vvolts

A amperes

Hz hertz

~ a.c. alternating current

direct current

d.c.

handling instruction

hint, tipp

Warning of general danger

Risk of electric shock

Read the Operating Instructions/Notes!

Wear protective goggles.

Wear ear protection.

Wear breathing mask.

About this manual

Save these instructions

It is important for you to read and understand this manual. The information it contains relates to protecting

your safety

and

preventing problems

. The symbols below are used to help you recognize this information.

DANGER Description of imminent haz-

ard and failure to avoid hazard

will result in death.

WARNING Description of hazard and

possible resulting injures or

death.

CAUTION Description of hazard and

possible resulting injuries.

NOTICE Statement including nature of

hazard and possible result.

HINT Indicates information, notes,

or tips for improving your success using the tool.

6

Page 7

Safety instructions

General safety instructions

WARNING! Read all safety warnings, instructions, illustrations and specifications

provided with this power tool.

instructions listed below may result in electric

shock, fire and/or serious injury.

Save all warnings and instructions for future reference.

The term “power tool” in the warnings refers to

your mains-operated (corded) power tool or battery-operated (cordless) power tool.

1 WORK AREA SAFETY

a.

Keep work area clean and well lit.

dark areas invite accidents.

b.

Do not operate power tools in explosive atmospheres, such as in the presence of flammable

liquids, gases or dust.

which may ignite the dust or fumes.

c.

Keep children and bystanders away while operating a power tool.

lose control.

2 ELECTRICAL SAFETY

a.

Power tool plugs must match the outlet. Never

modify the plug in any way. Do not use any

adapter plugs with earthed (grounded) power

tools.

will reduce risk of electric shock.

b.

Avoid body contact with earthed or grounded

surfaces, such as pipes, radiators, ranges and

refrigerators.

tric shock if your body is earthed or grounded.

c.

Do not expose power tools to rain or wet conditions.

the risk of electric shock.

d.

Do not abuse the cord. Never use the cord for

carrying, pulling or unplugging the power tool.

Keep cord away from heat, oil, sharp edges or

moving parts.

crease the risk of electric shock.

e.

When operating a power tool outdoors, use an

extension cord suitable for outdoor use.

a cord suitable for outdoor use reduces the risk of

electric shock.

f.

If operating a power tool in a damp location is

unavoidable, use a residual current device

(RCD) protected supply.

the risk of electric shock.

Unmodified plugs and matching outlets

There is an increased risk of elec-

Water entering a power tool will increase

Damaged or entangled cords in-

Power tools create sparks

Distractions can cause you to

Failure to follow all

Cluttered and

Use of

Use of an RCD reduces

3 PERSONAL SAFETY

a.

Stay alert, watch what you are doing and use

common sense when operating a power tool. Do

not use a power tool while you are tired or under

the influence of drugs, alcohol or medication.

moment of inattention while operating power

tools may result in serious personal injury.

b.

Use personal protective equipment. Always

wear eye protection.

as dust mask, non skid safety shoes, hard hat, or

hearing protection used for appropriate conditions will reduce personal injuries.

c.

Prevent unintentional starting. Ensure the

switch is in the off-position before connecting to

power source and/or battery pack, picking up or

carrying the tool.

finger on the switch or energising power tools

that have the switch on invites accidents.

d.

Remove any adjusting key or wrench before

turning the power tool on.

attached to a rotating part of the power tool may

result in personal injury.

e.

Do not overreach. Keep proper footing and balance at all times.

the power tool in unexpected situations.

f.

Dress properly. Do not wear loose clothing or

jewellery. Keep your hair, clothing and gloves

away from moving parts.

lery or long hair can be caught in moving parts.

g.

If devices are provided for the connection of

dust extraction and collection facilities, ensure

these are connected and properly used.

dust collection can reduce dust-related hazards.

h.

Do not let familiarity gained from freuquent use

of tools allow you to become complacent and ignore, tool safety principles.

can cause severe injury within a fraction of a second.

4 POWER TOOL USE AND CARE

a.

Do not force the power tool. Use the correct

power tool for your application.

power tool will do the job better and safer at the

rate for which it was designed.

b.

Do not use the power tool if the switch does not

turn it on and off.

controlled with the switch is dangerous and must

be repaired.

c.

Disconnect the plug from the power source and/

or battery pack from the power tool before

Protective equipment such

Carrying power tools with your

A wrench or a key left

This enables better control of

Loose clothes, jewel-

Use of

A careless action

The correct

Any power tool that cannot be

A

7

Page 8

making any adjustments, changing accessories,

or storing power tools.

Such preventive safety

measures reduce the risk of starting the power

tool accidentally.

d.

Store idle power tools out of the reach of children and do not allow persons unfamiliar with

the power tool or these instructions to operate

the power tool.

Power tools are dangerous in the

hands of untrained users.

e.

Maintain power tools. Check for misalignment

or binding of moving parts, breakage of parts

and any other condition that may affect the power tool‘s operation. If damaged, have the power

tool repaired before use.

Many accidents are

caused by poorly maintained power tools.

f.

Keep cutting tools sharp and clean.

Properly

maintained cutting tools with sharp cutting edges

are less likely to bind and are easier to control.

g.

Use the power tool, accessories and tool bits

etc. in accordance with these instructions taking into account the working conditions and the

work to be performed.

Use of the power tool for

operations different from those intended could

result in a hazardous situation.

h.

Keep handles dry, clean and free from oil and

grease.

Slippery handles do not allow for safe

handling and control of the tool in unexpected

situations.

5 SERVICE

a.

Have your power tool serviced by a qualified repair person using only identical replacement

parts.

This will ensure that the safety of the pow-

er tool is maintained.

Machine-related safety instructions

Special safety instructions for polishing

a.

This machine is designed for polishing. Please

read all of the safety information, instructions,

illustrations and descriptions supplied with the

machine.

structions may result in an electric shock, fire

and/or serious injury.

b.

Do not use this machine to perform work such

as roughing, fine sanding, brushing or abrasive

cutting.

tool is not designed can create hazards and lead

to injury.

Never use accessories that were not specially

c.

developed and designed for this machine.

because an accessory part can be fitted on your

machine does not guarantee safe operation.

d.

The permissible speed of the accessory must be

at least as high as the maximum speed specified

Failure to observe the following in-

Performing tasks for which the power

Just

on the machine

. Accessories that rotate faster

than the permissible level can rupture and the

shattered pieces may fly around.

e.

The outside diameter and the thickness of the

accessory must be within the specified size

range of the machine.

Accessories with incorrect

dimensions cannot be sufficiently protected or

controlled.

The bore diameter of discs, flanges, backing

f.

pads and all other accessories must fit the spindle of the power tool exactly.

Accessories with

an unsuitable bore diameter do not run smoothly,

vibrate excessively and lead to loss of control.

g.

Do not use damaged accessories. Before use,

always check accessories such as polishing

pads for nicks or cracks and check backing pads

for cracks and excessive wear. Every time the

machine is dropped, check both the machine

and accessories for damage, or install undamaged accessories. Following the check and assembly of accessories, ensure that all persons

are beyond the rotating range of the tool and

run the machine for one minute at maximum

speed.

Damaged accessories usually break com-

pletely during this test time.

Wear personal protective equipment. Depend-

h.

ing on the application, use a shield, full-face

mask or protective goggles. If practical, wear a

dust mask, ear protection, safety gloves and a

work apron suitable to protect against impact or

small sanding or workpiece parts.

The eyes

should be protected against foreign objects flying

around, which are generated during various applications. The dust or respiratory mask must be

suitable to filter dust arising from the application. If you are exposed to prolonged periods of

loud noise, you may suffer a loss of hearing.

i.

Ensure that persons standing near the machine

maintain a safe distance to the work area. Everyone who enters the work area must wear

personal protective equipment.

Parts of the

workpiece or tool can fly off and cause injury outside the immediate work area.

j.

Keep the power cable away from rotating

parts.

If you lose control, the power cable could

be cut or become stuck and your hand or arm

could be drawn into the rotating parts.

k.

Never set the power tool down until the tool has

stopped completely.

Rotating tools may come

into contact with the storage area, whereby you

may lose control of the power tool.

Do not allow the power tool to continue running

l.

while you are carrying it.

Your clothing may acci-

8

Page 9

dentally get caught in the rotating power tool and

the tool may drill into your body.

m.

Clean the ventilation slots of your power tool on

a regular basis.

dust into the housing, heavy deposits of swarf can

cause electrical hazards.

n.

Never operate the machine near combustible

materials.

o.

Never use tools that have to be liquid-cooled.

Water and other liquid coolants can cause potentially fatal electric shocks.

Kickbacks and corresponding safety instructions:

A kickback is a sudden reaction as a result of a

jammed or blocked rotating tool, sanding disc,

sanding pad, wire brush, etc. Jamming or blocking

leads to an abrupt stop of the rotating tool. An uncontrolled power tool is thus accelerated against

the direction of rotation of the tool at the blocking

point.

If, for example, a sanding disc is jammed or blocked

in the workpiece, the edge of the sanding disc,

which is immersed in the workpiece, can get caught

and the sanding disc may crack or cause a kickback. The sanding disc then moves away from or towards the operator, depending on the direction of

rotation of the disc at the blocking point. This can

also cause sanding discs to break.

A kickback is the consequence of incorrect use or

misuse of the power tool and can be prevented by

taking appropriate precautionary measures, as described below.

Hold the power tool firmly in your hands and

a.

move your body and arms into a position where

you can absorb the kickback forces of a rebounding tool. Always use the additional hand

grip, if available, in order to have the greatest

possible control over kickback forces or reaction moments upon start-up.

control the kickback and reaction forces with

suitable precautionary measures.

Never place your hands near rotating tools.

b.

power tool can move over your hand in the event

of a kickback.

Avoid the area in which the power tool is moved

c.

in the event of a kickback.

the power tool in the opposite direction to the

The motor-driven blower draws

Sparks can ignite these materials.

The operator can

The

The kickback drives

movement of the sanding disc at the blocking

point.

d.

Exercise extreme caution when working in the

area of corners, sharp edges, etc. Prevent power tools rebounding from the workpiece and

getting stuck.

get stuck at corners, sharp edges, etc., or if it rebounds. This causes a loss of control or a kickback.

e.

Do not use a chainsaw or toothed saw blade.

Such tools often cause a kickback or the loss of

control over the power tool.

Special safety instructions for polishing

a.

Ensure there are no loose parts of the polisher

hood, in particular cords. Stow or shorten the

cords.

fingers or get stuck at the workpiece.

Further safety information

–

Prevent liquid polish from seeping into the machine.

power tool increases the risk of electric shock.

Loose and rotating strings can catch your

The penetration of liquid polish into the

The rotating power tool tends to

Health hazard by dust

WARNING!

sanding, sawing, grinding, drilling and other

construction activities contains chemicals

known (to the State of California) to cause cancer,

birth defects or other reproductive harm. Some examples of these chemicals are:

• lead from lead-based paints,

• crystalline silica from bricks and cement and

other masonry products, and

• arsenic and chromium from chemically treated

lumber.

proved safety equipment, such as dust masks that

are specially designed to filter out microscopic particles. Wash hands after handling.

Various dust created by power

The risk from these exposures

varies, depending on how often

you do this type of work. To reduce your exposure to these

chemicals: work in a well ventilated area, and work with ap-

WARNING

TO REDUCE THE RISK OF INJURY, USER MUST

READ INSTRUCTION MANUAL.

9

Page 10

Technical data

SHINEX rotary polisher RAP 150-14 FE RAP 150 -21 FE

Power 10 A 10 A

Tens io n ~120 V, 60Hz ~120 V, 60Hz

Speed 600 - 1400 min

Max. speed

1

2100 min

-1

-1

900 - 2100 min

3000 min

Polishing pads up to dia.150 mm (5.9 in.) dia. 150 mm (5.9 in.)

Weight (without mains cable/polishing pad) 2,1 kg (4.6 lbs.) 2.1 kg (4.6 lbs.)

Safety class /II /II

1.

Max. speed in the event of faulty electronics.

Functional description

-1

-1

The pictures for the functional description are on a

fold-out page at the beginning of the instruction

manual. While reading the manual you can fold out

the page for comparison and quick reference.

[1-1]

[1-2]

Spindle stop

Speed control

Intended use

This machine is designed for polishing painted surfaces. To guarantee electrical safety, the machine

may not be operated while moist or in a damp environment.

Operation

[1-3]

[1-4]

[1-5]

[1-6]

[1-7]

Locking button

On/Off switch

Lint filter

Additional handle

Polishing pads

WARNING

The user will be liable for damage due to improper use.

WARNING

Unauthorised voltage or frequency!

Risk of accident

The mains voltage and the frequency of the power source must correspond with the specifications on the machine's name plate.

In North America, only Festool machines with

the voltage specifications 120 V/60 Hz may be

used.

10

Switch on/off

The switch

lease = OFF).

The locking button

in continuous mode. Press the switch again to release the knob.

[1-4]

is an on/off switch (press = ON, re-

[1-3]

can be engaged to operate

Page 11

Extension Cord

If an extension cord is required, it must have sufficient cross-section to prevent overheating or an excessive drop in voltage. An excessive drop in voltage

reduces the output and can lead to failure of the

motor. The table below shows you the correct cord

Electronics

diameter as a function of the cord length for this

power tool.

Total extension cord

length (feet)

Cable size (AWG) 18 16 16 14

Use only U.L. and CSA listed extension cords.

Never use two extension cords together. Instead,

use one long one.

The lower the AWG number, the stronger the

cord.

25 50 100 150

Consider the pictures on the fold-out page.

The machine features full-wave phase control electronics with the following features:

Smooth start-up

The electronically controlled smooth start-up ensures that the machine starts up jolt-free.

Speed control

The available speed when the ON/OFF switch

is pressed down fully can be set

and 1400 rpm (RAP 150-14) or 900 and 2100 rpm

(RAP 150-21) using the adjusting wheel. This enables you to optimise the cutting speed to suit the

surface (see table).

The power tool is fitted with a variable speed

trigger: Pressing the ON/OFF switch harder increases the speed.

Application Adjusting wheel

[1-3]

between 600

setting

[1-4]

Constant speed

The preselected motor speed is maintained on a

constant level. Electronic controls ensure a steady

cutting speed even when operating under different

loads.

Temperature cut-out

The machine power supply is limited and the speed

reduced if the motor exceeds a certain temperature. The machine continues operating at reduced

power to allow the ventilator to cool the motor rapidly. The machine starts up again automatically

once the motor is cooled down sufficiently.

Electric current limit

AC limiting prevents excessive current consumption under extreme overload, which can lead to a

decrease in the motor speed. The motor immediately restarts after the load is removed.

Working in polish 1 - 2

Polishing sensitive surfaces 3 - 4

High-gloss polishing 5 - 6

WARNING

Risk of injury, electric shock

Always pull the mains plug out of the socket before performing any type of maintenance on the

machine!

Settings

Attaching polishing pads

Only use polishing pads that are suitable for the

maximum speed specified.

The polishing pads M 14 are fitted with a thread M

11

Page 12

14 and are screwed directly onto the spindle.

2-1

2-2

2

2-3

1

2

3

4-1

4

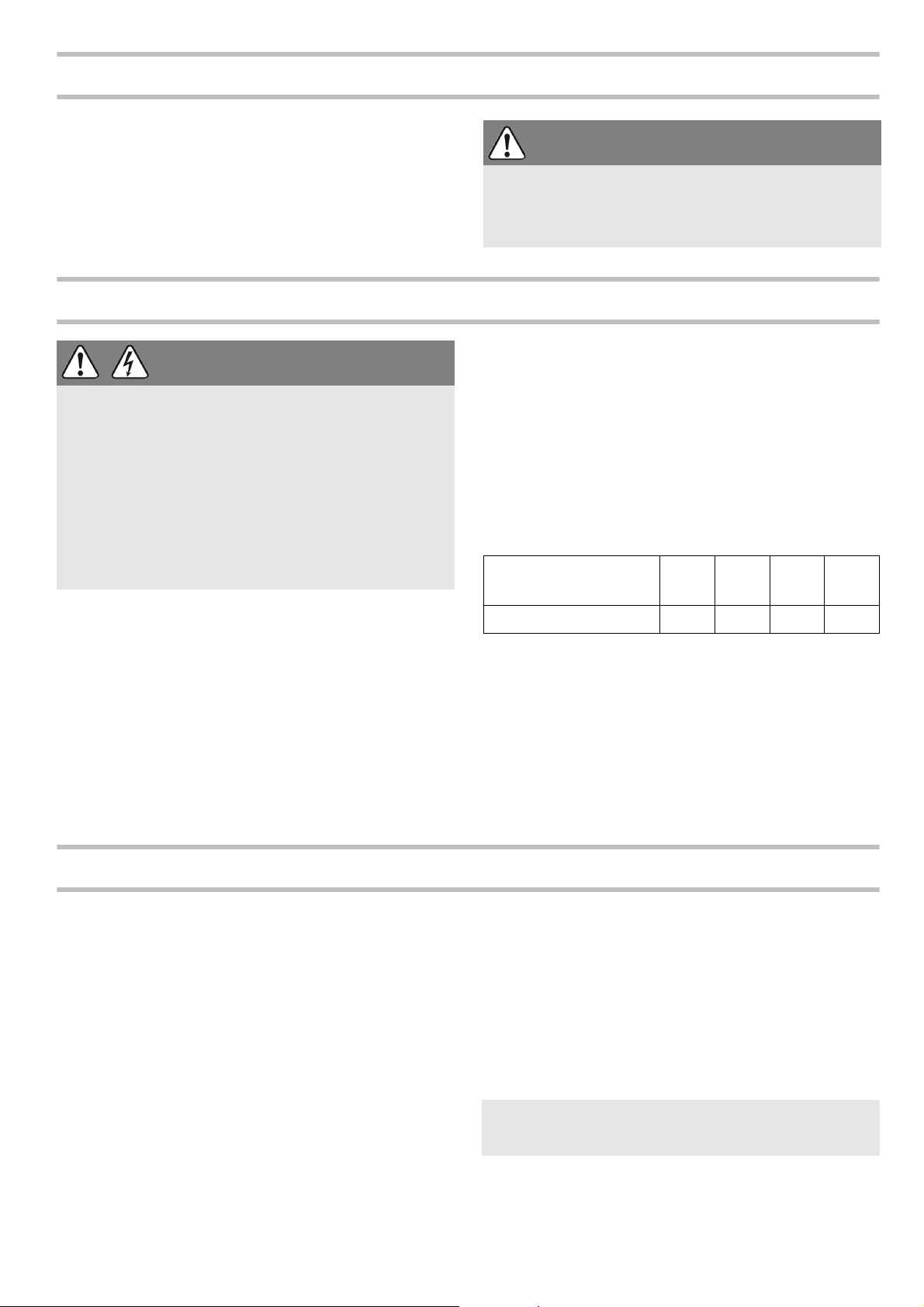

Attaching polishing accessories

Procedure

Rotate the polishing pad

tool spindle.

Press and hold the spindle stop

Turn the tool spindle

firmly screw the polishing pad.

[2-3]

[2-2]

loosely on the

[2-1]

.

until it stops and

StickFix is a system that simplifies the attachment

of polishing accessories (felt, sponge, sheepskin) to

the polishing pad

an adhesive coating.

[2-2]

where they are retained by

Attaching the additional handle

The additional handle

ther the right or left of the gear head.

[3-1]

can be screwed onto ei-

3

1

3-1

2

Working with the machine

Observe the following instructions:

– Do not use the machine when the electronics are

faulty because the machine may operate at excessive speeds. An absence of the smooth startup function or speed control indicates that the

electronics are faulty.

– Do not overload the machine by pressing with ex-

cessive force! The best polishing results are

achieved with moderate application pressure.

The polishing capacity and quality are mainly dependent on the selection of the correct polish.

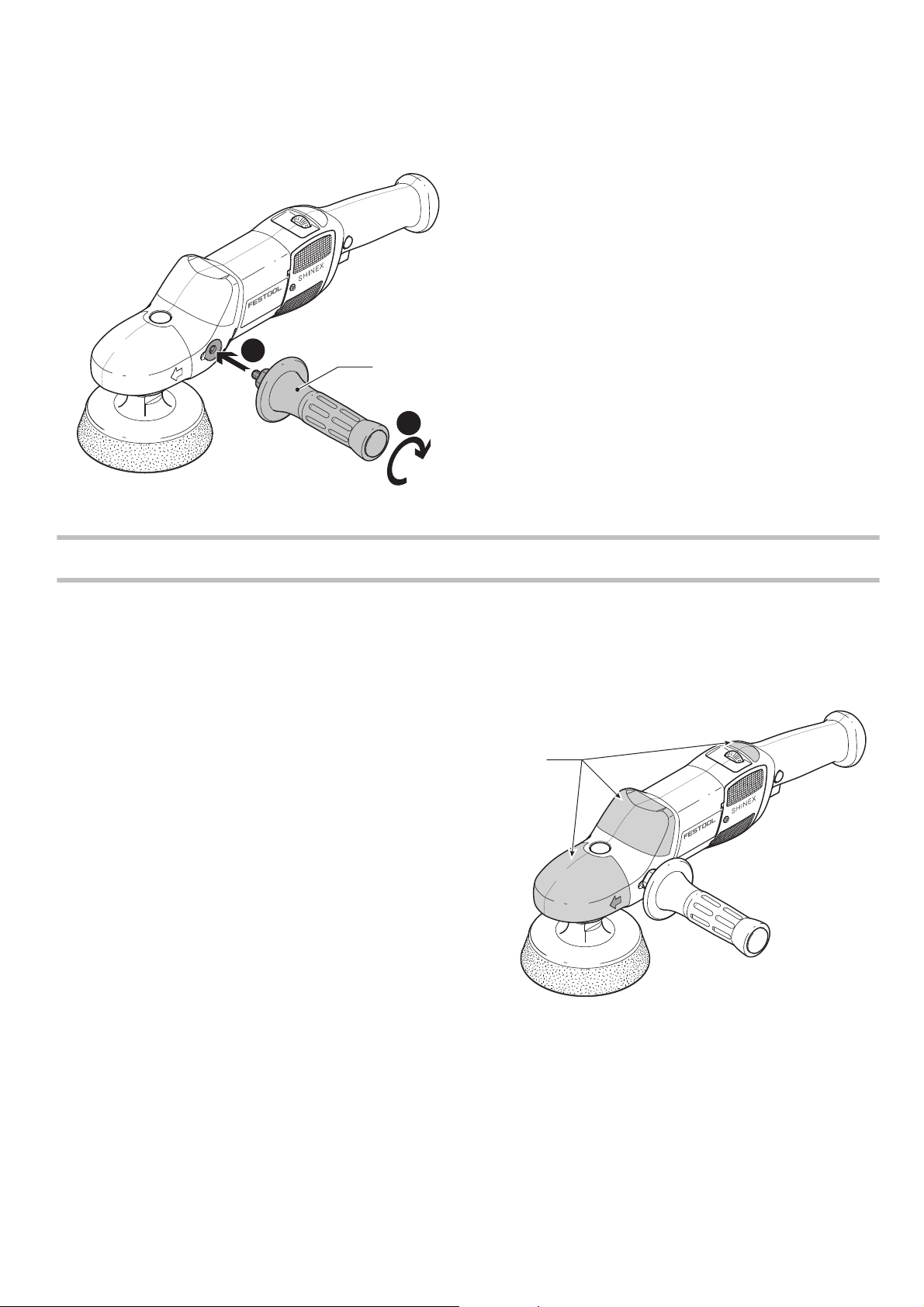

– Hold the machine with two hands, one on the mo-

tor housing and one on the gear head or additional handle

[1-6]

to ensure safe guidance.

The rubber support points

stability when the machine is set down.

[4-1]

provide extra

12

Page 13

Service and maintenance

WARNING

Any maintenance or repair work that requires

opening the motor or gear housing may only be

carried out by an authorised Customer Service

Centre (name supplied by your dealer)!

Maintenance or repair work carried out by an unauthorised person can lead to the wrong connection of the power cord or other components, which

in turn can lead to accidents with serious consequences.

of the machine.

If the lint filter is heavily soiled, loosen the

[5-2]

screw

an extractor.

The machine is equipped with special carbon

brushes. If they are worn out, the power is interrupted automatically and the machine comes to a

standstill.

, remove the filter and clean using

5-2

WARNING

To prevent accidents, always remove the plug

from the power supply socket before carrying out

any changes or maintenance work on the tool!

Do not use compressed air to clean the electrical

tool! Do not try to clean parts inside the tool in

this way, as you could let foreign objects in

through the openings of the tool housing.

To ensure constant air circulation, always keep the

cooling air openings in the motor housing clean and

free of any obstruction.

Cleaning the lint filter

Clean the lint filter

[5-1]

regularly on both sides

Accessories

5-1

5

Use only original Festool accessories and Festool

consumable material intended for this machine.

These components are designed specifically for

this machine. Using accessories and consumable

material from other suppliers will most likely affect

the quality of your results and limit warranty

claims. Machine wear or your own personal workload may increase depending on the application.

Protect yourself and your machine, and preserve

Environment

Do not dispose of the device as domestic waste!

Dispose of machines, accessories and packaging at

your warranty claims by always using original Festool accessories and Festool consumable material!

Use only genuine Festool polishing pads. Lowquality polishing pads may cause serious machine

imbalance and decreases the quality of the working

results as well as increase machine wear.

The order numbers of the accessories and tools can

be accessed via the Festool catalogue or on the Internet at "www.festoolusa.com".

an environmentally responsible recycling centre.

Observe the respective national regulations.

13

Page 14

Sommaire

d.c.courant continu

Symboles.............................................. 14

À propos de ce manuel ........................ 14

Consignes de sécurité ......................... 15

Caractéristiques techniques................ 18

Description fonctionnelle..................... 19

Utilisation en conformité avec les ins-

tructions............................................... 19

Mise en service .................................... 19

Électronique......................................... 20

Réglages .............................................. 20

Travail avec la machine........................ 21

Entretien et maintenance .................... 22

Accessoires .......................................... 22

Environnement..................................... 23

Symboles

n

0

Vitesse de rotation à vide

Classe II conception

.../min

min

tours ou course par minute

-1

’’ pouce

lb. livre

Diamètre

Information, astuce

Consignes operatoires

Avertissement de danger général

Risque d'électrocution

Lire les instructions / les remarques !

Portez des lunettes de protection !

Portez une protection auditive !

VVolt

AAmpère

Porter une protection respiratoire !

Hz Hertz

~

Tension alternative

a.c.

À propos de ce manuel

Conservez ces instructions

Il est important pour vous de lire et de comprendre ce manuel. Les informations qu'il contient, se rapporte

à la protection

vous aider à reconnaître cette information.

DANGER Description du risque immi-

AVERTISSEMENT

de votre sécurité

et

de prévention des problèmes

nent et l'incapacité à éviter

tout risque qui peut entraîner

la mort.

Description des dangers possibles et des blessures qui en

résultent ou la mort.

. Les symboles suivants sont utilisés pour

AVIS Déclaration incluant le type de

danger et conséquences possibles.

CONSEIL Indique des informations, des

notes ou des conseils pour

améliorer votre succès en utilisant l'outil.

14

ATTENTION

Description des dangers et

des éventuelles blessures qui

en résultent.

Page 15

Consignes de sécurité

Consignes de sécurité d'ordre général

ATTENTION ! Lire toutes les consignes de

sécurité, des instructions, des illustrations

et des indications fournies avec cet outil électrique.

ci-après peut entraîner un choc électrique, un incendie et/ou de graves blessures.

Conserver tous les avertissements et toutes les

instructions pour pouvoir s'y reporter ultérieurement.

Le terme " outil " dans les avertissements fait reference à votre outil électrique alimenté par le secteur (avec cordon d'alimentation) ou votre outil

fonctionnant sur batterie (sans cordon d'alimentation).

1 PLACE DE TRAVAIL

a.

b.

c.

2 SECURITE RELATIVE AU SYSTEME ELECTRIQUE

a.

b.

c.

d.

Le non-respect des instructions indiqués

Maintenez l'endroit de travail propre et bien

éclairé.

éclairé augmente le risque d'accidents.

N'utilisez pas l'appareil dans un environnement

présentant des risques d'explosion et où se

trouvent des liquides, des gaz ou poussières inflammables.

des étincelles risquant d'enflammer les poussières ou les vapeurs.

Tenez les enfants et autres personnes éloignés

durant l'utilisation de l'outil électroportatif.

cas d'inattention vous risquez de perdre le

contrôle sur l'appareil.

La fiche de secteur de l'outil électroportatif doit

être appropriée à la prise de courant. Ne modifiez en aucun cas la fiche. N'utilisez pas de

fiches d'adaptateur avec des appareils avec

mise à la terre.

prises de courant appropriées réduisent le risque

de choc électrique.

Evitez le contact physique avec des surfaces

mises à la terre tels que tuyaux, radiateurs,

fours et réfrigérateurs.

choc électrique au cas où votre corps serait relié

à la terre.

N'exposez pas l'outil électroportatif à la pluie

ou à l'humidité.

til électroportatif augmente le risque d'un choc

électrique.

N'utilisez pas le câble à d'autres fins que celles

prévues, n'utilisez pas le câble pour porter l'ap-

Un lieu de travail en désordre ou mal

Les outils électroportatifs génèrent

En

Les fiches non modifiées et les

Il y a un risque élevé de

La pénétration d'eau dans un ou-

pareil ou pour l'accrocher ou encore pour le débrancher de la prise de courant. Maintenez le

câble éloigné des sources de chaleur, des parties grasses, des bords tranchants ou des parties de l'appareil en rotation.

endommagé ou torsadé augmente le risque d'un

choc électrique.

e.

Au cas où vous utiliseriez l'outil électroportatif

à l'extérieur, utilisez une rallonge autorisée homologuée pour les applications extérieures.

L'utilisation d'une rallonge électrique homologuée pour les applications extérieures réduit le

risque d'un choc électrique.

f.

Si l'usage d'un outil dans un emplacement humide est inévitable, utiliser une alimentation

protégée par un dispositif à courant différentiel

résiduel (RCD).

risque de choc électrique.

3 SECURITE DES PERSONNES

a.

Restez vigilant, surveillez ce que vous faites.

Faites preuve de bon en utilisant l'outil électroportatif. N'utilisez pas l'appareil lorsque vous

êtes fatigué ou après avoir consommé de l'alcool, des drogues ou avoir pris des médicaments.

l'utilisation de l'appareil peut entraîner de graves

blessures sur les personnes.

b.

Portez des équipements de protection. Portez

toujours des lunettes de protection.

porter des équipements de protection personnels

tels que masque anti-poussières, chaussures de

sécurité antidérapantes, casque de protection ou

protection acoustique suivant le travail à effectuer, réduit le risque de blessures.

c.

Evitez une mise en service par mégarde. Assurez-vous que l'interrupteur est effectivement

en position d'arrêt avant de retirer la fiche de la

prise de courant.

le doigt sur l'interrupteur ou de brancher l'appareil sur la source de courant lorsque l'interrupteur est en position de fonctionnement, peut

entraîner des accidents.

d.

Enlevez tout outil de réglage ou toute clé avant

de mettre l'appareil en fonctionnement.

ou un outil se trouvant sur une partie en rotation

peut causer des blessures.

e.

Ne surestimez pas vos capacités. Veillez à garder toujours une position stable et équilibrée.

Un moment d'inattention lors de

L'usage d'un RCD réduit le

Le fait de porter l'appareil avec

Un câble

Le fait de

Une clé

15

Page 16

Ceci vous permet de mieux contrôler l'appareil

dans des situations inattendues.

f.

Portez des vêtements appropriés. Ne portez

pas de vêtements amples, ni de bijoux. Gardez

les cheveux et les vêtements à distance des

pièces mobiles.

joux ou des cheveux longs peuvent être happés

par les pièces en mouvement.

g.

Si des dispositifs servant à aspirer ou à recueillir les poussières doivent être utilisés, vérifiez

que ceux-ci soient effectivement raccordés et

qu'ils sont correctement utilisés.

tels dispositifs réduit les dangers dus aux poussières.

h.

Ne devenez pas trop sûr de vous, par habitude

suite à une utilisation fréquente de l’appareil,

de manière à ne pas respecter les principes de

sécurité de base de l’appareil.

prudente peut occasionner de graves blessures

en l’espace d’une fraction de seconde.

Des vêtements amples, des bi-

L'utilisation de

Une action im-

ser l'appareil.

des outils électroportatifs mal entretenus.

f.

Maintenez les outils de coupe aiguisés et

propres.

avec des bords tranchants bien aiguisés se

coincent moins souvent et peuvent être guidés

plus facilement.

g.

Utilisez les outils électroportatifs, les accessoires, les outils à monter etc. conformément à

ces instructions et aux prescriptions en vigueur

pour ce type d'appareil. Tenez compte également des conditions de travail et du travail à effectuer.

d'autres fins que celles prévues peut entraîner

des situations dangereuses.

h.

Gardez les poignées dans un état sec, propre et

exempt d’huile et de graisse.

santes ne permettent pas une prise en main sûre

et le contrôle de l’outil électrique dans des situations inattendues.

L'utilisation des outils électroportatifs à

De nombreux accidents sont dus à

Des outils soigneusement entretenus

Des poignées glis-

4 UTILISATION ET EMPLOI SOIGNEUX DE L'OUTIL

ELECTROPORTATIF

a.

Ne surchargez pas l'appareil. Utilisez l'outil

électroportatif approprié au travail à effectuer.

Avec l'outil électroportatif approprié, vous travaillerez mieux et avec plus de sécurité à la vitesse

pour laquelle il est prévu.

b.

N'utilisez pas un outil électroportatif dont l'interrupteur est défectueux.

tatif qui ne peut plus être mis en ou hors

fonctionnement est dangereux et doit être réparé.

c.

Retirer la fiche de la prise de courant avant d'effectuer des réglages sur l'appareil, de changer

les accessoires, ou de ranger l'appareil.

mesure de précaution empêche une mise en

fonctionnement par mégarde.

d.

Gardez les outils électroportatifs non utilisés

hors de portée des enfants. Ne permettez pas

l'utilisation de l'appareil à des personnes qui ne

se sont pas familiarisées avec celui-ci ou qui

n'ont pas lu ces instructions.

portatifs sont dangereux lorsqu'ils sont utilisés

par des personnes non initiées.

e.

Prenez soin des outils électroportatifs. Vérifiez

que les parties en mouvement fonctionnent correctement et qu'elles ne soient pas coincées, et

contrôlez si des parties sont cassées ou endommagées de telle sorte que le bon fonctionnement de l'appareil s'en trouve entravé. Faites

réparer les parties endommagées avant d'utili-

Un outil électropor-

Cette

Les outils électro-

5 SERVICE

a.

Ne faites réparer votre outil électroportatif que

par un personnel qualifié et seulement avec des

pièces de rechange d'origine.

surer la sécurité de l'appareil.

Ceci permet d'as-

Consignes de sécurité spécifiques à la ma-

chine

–

Cette machine est conçue de façon conforme aux

prescriptions pour le polissage. Lisez toutes les

consignes de sécurité, modes d'emploi, figures et

descriptions livrées avec la machine.

non-respect des consignes de sécurité, vous risquez une décharge électrique, un incendie ou de

graves blessures.

–

Les travaux tels que le ponçage de dégrossissage, le ponçage de finition, le brossage ou le

tronçonnage ne doivent pas être exécutés à l'aide

de cette machine.

machine n'a pas été conçue peuvent faire courir

des risques aux personnes et entraîner des dommages corporels.

–

N'utilisez pour cet outil aucun accessoire qui n'a

pas été spécialement conçu et développé par

Festool.

être monté sur un outil qu'un fonctionnement sans

danger peut être garanti.

La vitesse admissible de l'accessoire doit être au

–

moins aussi élevée que la vitesse maximale indiquée sur la machine.

la vitesse admise peuvent se briser.

–

Le diamètre extérieur et l'épaisseur de l'accessoire doivent se trouver dans l'ordre de grandeur

Ce n'est pas parce qu'un accessoire peut

Les travaux pour lesquels la

Les accessoires dépassant

En cas de

16

Page 17

indiqué de la machine.

Un accessoire de dimensions inadaptées ne peut être ni suffisamment

protégé, ni suffisamment maîtrisé.

–

Le diamètre d'alésage des disques, des brides,

des plateaux de support et des autres accessoires doit être adapté avec précision à l'arbre de

la machine.

Un accessoire dont le diamètre est

inadapté ne tourne pas rond, vibre excessivement

et peut entraîner une perte de contrôle.

–

N'utilisez pas des accessoires défectueux. Avant

chaque utilisation, contrôlez si le disque de polissage ne présente pas de ruptures ou de fissures

et si le plateau de support ne présente pas de fissures et d'usure excessive. Après une chute, vérifiez que l'outil et l'accessoire n'ont pas été

endommagés ou montez un accessoire non endommagé. Après vérification et montage des accessoires, placez-vous hors du plan de rotation

des accessoires, faites éloigner les personnes

qui vous entourent puis laissez tourner l'accessoire pendant une minute à sa vitesse maximale.

Habituellement, un accessoire endommagé se

brise au cours de ce test.

–

Portez un équipement de protection individuelle.

Selon l'utilisation, employez un écran de protection ou des lunettes de protection. Si nécessaire,

portez un masque respiratoire, une protection

auditive, des gants de sécurité et un tablier de

travail, permettant de se protéger des projections provoquées par le polissage de petites

pièces.

Les lunettes de protection permettent

d'intercepter les débris volants dus à différents

travaux. Le masque respiratoire ou l'appareil respiratoire doivent être en mesure de filtrer les particules générées par vos travaux. Une pollution

sonore durable peut entraîner la surdité.

Maintenez les personnes environnantes à dis-

–

tance de sécurité de la zone de travail. Toute personne présente dans la zone de travail doit porter

une protection personnelle.

Des parties de la

pièce à travailler ou de l'accessoire brisé peuvent

être éjectées et provoquer des blessures en dehors de l'entourage immédiat du lieu de travail.

–

Maintenez le câble électrique à l'écart des éléments en rotation.

Si vous perdez le contrôle, le

câble électrique pourrait être sectionné ou rester

accroché ; votre main ou votre bras pourrait également être happé par les parties en rotation.

–

Ne posez jamais la machine tant que l'outil n'est

pas complètement à l'arrêt.

Les outils en rotation

peuvent s'enfoncer dans la surface sur laquelle

vous les avez déposés et échapper ainsi à votre

contrôle.

–

Ne laissez pas la machine tourner pendant que

vous la portez sur le côté.

En cas de contact fortuit, l'outil en rotation peut agripper votre vêtement, ce qui l'entraînera dans votre corps.

Nettoyez régulièrement les ouvertures d'air de

–

refroidissement de votre machine.

Le ventilateur

aspire la poussière dans le carter de l'outil, et des

dépôts excessifs de poussière métallique peuvent

être source de risques électriques.

–

N'utilisez pas l'outil à proximité de matières inflammables.

Des étincelles pourraient enflammer

ces matières.

N'utilisez aucun outil à refroidissement liquide.

–

L'eau ou d'autres réfrigérants liquides peuvent

provoquer des décharges électriques (mortelles).

Origine et prévention des reculs:

Un recul est une réaction soudaine au serrage ou à

l'enclenchement d'un disque, d'un bord d'appui,

d'une brosse ou d'un autre accessoire en rotation.

Le blocage ou l'accrochage provoque un arrêt très

rapide de l'accessoire en rotation, ce qui entraîne

par contre-réaction l'accélération incontrôlée de la

machine au niveau du point de blocage dans le sens

inverse de la rotation de l'accessoire.

Si par exemple on enclenche ou on coince un plateau de ponçage par la pièce à travailler, le bord du

disque peut s'enfoncer au niveau du point de blocage dans la surface de la pièce à travailler et ainsi

éjecter le disque. Le disque peut être éjecté soit en

direction de l'utilisateur soit en sens opposé, selon

le sens de rotation au niveau du point de blocage.

Les plateaux de ponçage peuvent se briser à cette

occasion. Un recul résulte d'une mauvaise utilisation de l'outil et/ou d'une manière fautive de travailler et peut être évité en respectant les mesures

de sécurité suivantes.

a.

Tenez toujours fermement la machine et placez

votre corps et vos bras de façon à pouvoir

contrôler un recul. Pour un contrôle optimal des

reculs ou des temps de réaction au démarrage,

utilisez la poignée additionnelle si elle faisait

partie de la livraison.

L'utilisateur peut contrôler

des temps de réaction ou des forces engendrées

par le recul, dans la mesure où les mesures de

sécurité adéquates sont prises.

b.

Ne placez jamais votre main à proximité d'outils

en rotation.

Les outils peuvent reculer sur votre

main.

Ne placez jamais votre corps dans la zone où

c.

l'outil peut effectuer un recul.

Un recul accélé-

17

Page 18

rera l'outil dans le sens opposé à la rotation au

niveau du point de blocage.

d.

Soyez particulièrement prudent lorsque vous

travaillez dans des coins, au niveau d'arêtes

vives etc. Evitez un recul et un accrochage de

l'outil.

Les coins, les arêtes vives ou un saut en

arrière ont tendance à accrocher l'outil et à entraîner la perte de contrôle ou un recul.

e.

Ne montez pas de scie à chaîne pour travailler

le bois ou de lames de scie dentées.

Des lames

de scie de ce type provoquent souvent des reculs

et la perte de contrôle.

Consignes de sécurité particulières pour le polissage

a.

Éliminez les morceaux détachés du plateau de

polissage, en particulier les fils de fixation.

Rangez ou raccourcissez les fils de fixation.

Les

fils de fixation détachés ou en rotation peuvent

s'enrouler autour de vos doigts ou rester coincés

dans la pièce.

–

Évitez l'infiltration de produit de polissage liquide dans l'appareil.

L'infiltration de produit de

polissage liquide dans un outil électrique augmente le risque de décharge électrique.

meulage, le perçage et autres activités reliées à la

construction contiennent des substances chimiques

connues (dans l’État de la Californie) comme pouvant

causer le cancer, des anomalies congénitales ou représenter d’autres dangers pour la reproduction.

Voici quelques exemples de telles substances:

• plomb provenant de peintures à base de plomb,

• silice cristallisée utilisée dans les briques, le ciment et autres matériaux de maçonnerie, et

• arsenic et chrome du bois d’oeuvre traité avec un

produit chimique.

Le risque d’exposition à de tels

produits varie selon la fréquence à laquelle vous faites ce

genre de travail. Pour réduire

les risques d’exposition à ces

substances chimiques : travaillez dans un endroit adéquatement ventilé et utilisez

un équipement de sécurité approuvé, tel que

masques antipoussières spécialement conçus pour

filtrer les particules microscopiques.

AVERTISSEMENT

La poussière, un risque pour la santé

POUR RÉDUIRE LE RISQUE DE DOMMAGES, L'UTILISATEUR DOIT LIRE LE MANUEL D'INSTRUCTION.

AVERTISSEMENT!

Certaines poussières

créées par le ponçage mécanique, le sciage, le

Caractéristiques techniques

SHINEX RAP 150 FE RAP 150-14 FE RAP 150 -21 FE

Intensité nominale 10 A 10 A

Tens io n ~120 V, 60Hz ~120 V, 60Hz

Vitesse de rotation 600 - 1400 min

Vitesse de rotation max.

1

2100 min

Plateau de polissage jusqu'à dia.150 mm (5.9 in.) dia. 150 mm (5.9 in.)

Poids (sans câble d'alimentation / sans plateau

2,1 kg (4.6 lbs.) 2,1 kg (4.6 lbs.)

de polissage)

Classe de protection /II /II

1.

Vitesse de rotation max. en cas d'électronique défectueuse.

-1

-1

900 - 2100 min

3000 min

-1

-1

18

Page 19

Description fonctionnelle

Des eléments fournis sont disponibles sur le volet

qui se trouve au début de cette notice d'utilisation.

Vous pouvez ainsi déplier cette page et visualiser

en permanence les différentes parties de l'outil

lorsque vous lisez la notice.

[1-1]

[1-2]

[1-3]

[1-4]

Blocage d'arbre

Régulation de la vitesse

Bouton de blocage

Interrupteur de marche/arrêt

Utilisation en conformité avec les instructions

La machine est destinée au polissage de surfaces

peintes. Afin de garantir la sécurité électrique, elle

ne doit pas être mouillée ou utilisée en environnement humide.

Mise en service

AVERTISSEMENT

Tension ou fréquence non admissible !

Risque d'accident

La tension et la fréquence d'alimentation électrique doivent être conformes aux indications de

la plaque signalétique.

En Amérique du nord, utilisez uniquement les

outils Festool fonctionnant sous une tension de

120 V/60 Hz.

[1-5]

[1-6]

[1-7]

Filtre anti-peluche

Poignée additionnelle

Plateau de polissage

AVERTISSEMENT

Seul l’utilisateur est tenu responsable des dommages qui résulteraient d’une utilisation non

conforme aux prescriptions.

Câble de rallonge

Si une rallonge électrique est nécessaire, elle doit

présenter une section suffi sante pour éviter une

chute de tension excessive ou une surchauffe. Une

chute de tension excessive réduit la puissance et

peut entraîner une défaillance du moteur. Le tableau suivant vous présente la section correcte du

câble en fonction de sa longueur pour la norme du

cette machine.

Longueur totale rallonge (pieds)

25 50 100 150

Marche/Arrêt

L'interrupteur

marche/arrêt (pression = MARCHE, relâchement =

ARRET).

Pour le fonctionnement continu, il peut être bloqué

au moyen du bouton de blocage

pression sur l'interrupteur libère le blocage.

[1-4]

fait office d'interrupteur de

[1-3]

. Une nouvelle

Section du câble 18161614

Utilisez exclusivement des rallonges recommandées par les organismes U.L. et CSA.

N'utilisez jamais deux rallonges branchées l'une

après l'autre, mais remplacez-les par une rallonge

plus longue.

Plus le numéro AWG est petit, plus la section du

câble est grande.

19

Page 20

Électronique

Attention aux illustrations au début de la présente

notice d’utilisation.

La machine dispose d'un système électronique à

ondes pleines avec les propriétés suivantes :

Démarrage progressif

Le démarrage progressif assure un fonctionnement sans à-coups de la machine.

Régulation de la vitesse

La vitesse de rotation disponible, lorsque l'inter-

[1-4]

rupteur de marche/arrêt

peut être réglée

[1-2]

entre 600 et 2100 tr/mn au

est pressé à fond,

moyen de la molette. Vous pouvez ainsi adapter de

façon optimale la vitesse de coupe à chaque surface

(voir tableau).

La machine possède une gâchette d’accélération

: la vitesse augmente avec une pression croissante sur l'interrupteur de marche/arrêt. Cela

permet de varier la vitesse en continu entre 400

tr/mn et la vitesse réglée sur la molette.

Cas d'application Position de la

molette

Répartition du polissage 1 - 2

Polissage de surfaces sensibles 3 - 4

Polissage miroir 5 - 6

Vitesse de rotation constante

La vitesse sélectionnée est maintenue constante de

manière électronique. Elle reste donc homogène,

même lorsque l'outil est fortement sollicité.

Sécurité thermique

L'alimentation électrique et la vitesse de rotation

sont réduites en cas de température trop élevée du

moteur. La machine ne fonctionne plus qu'à une

puissance réduite, afin de permettre un refroidissement rapide du moteur. Après le refroidissement,

la machine remonte automatiquement en puissance.

AVERTISSEMENT

Risques de blessures, choc électrique

Débranchez prise de courant avant toute intervention sur la machine !

Limitation de courant

La limitation de courant empêche une absorption

élevée de courant en cas de charge extrême, ce qui

entraînerait une baisse de la rotation du moteur.

Après la décharge, le moteur se remet en route.

Réglages

Utilisez exclusivement des plateaux de polissage,

qui sont autorisés pour la vitesse de rotation maximale indiquée.

Les plateaux de polissage sont munis d'un taraudage M 14 et sont vissés directement sur l'arbre.

Manière de procéder

Montage du plateau de polissage

Desserrez le plateau de polissage

l'arbre porte-outil.

[2-2]

sur

20

Maintenez la commande de blocage d'arbre

enfoncée.

1]

Tournez l'arbre porte-outil

[2-3]

jusqu'à ce qu'il

soit bloqué et vissez le plateau de polissage en

[2-

Page 21

butée.

2-1

2-2

2

2-3

1

2

3

1

2

3-1

3

4-1

4

maintenus par le revêtement auto-agrippant du

plateau de polissage.

Montage de la poignée

additionnelle

Fixer l'accessoire de polissage

Grâce au système Stickfix, les accessoires de polissage (feutre, éponge, peau d'agneau) sont pressés

simplement sur le plateau de polissage

[2-2]

et

La poignée additionnelle

choix, à gauche ou à droite sur la tête de carter.

[3-1]

peut être vissée, au

Travail avec la machine

Observez les consignes suivantes :

– Ne travaillez pas avec la machine lorsque l'élec-

tronique est défectueuse, sous peine d'occasionner des vitesses excessives. Vous reconnaissez

une électronique défectueuse à l'absence de démarrage progressif ou lorsqu'aucune régulation

de vitesse n'est possible.

– Ne surchargez pas la machine : n'exercez pas de

pression trop importante ! Pour obtenir le meilleur résultat de polissage, exercez une pression

d'appui modérée. Les performances de polissage et la qualité du polissage dépendent essentiellement du choix du produit de polissage.

– Pour guider la machine de façon sûre, mainte-

nez-la avec les deux mains au niveau du carter

du moteur et de la tête de carter ou de la poignée

additionnelle

[1-6]

.

Les points d'appui caoutchoutés de la machine

[4-1]

permettent une dépose confortable de la

machine.

21

Page 22

Entretien et maintenance

AVERTISSEMENT

Tout travail de maintenance ou de réparation, qui

nécessite l'ouverture du moteur ou du carter

d'engrenages doit uniquement être effectué par

un centre service-client autorisé (nom fourni par

votre revendeur) !

Les travaux de maintenance ou de réparation effectués par un personnel non autorisé peuvent

conduire à la mauvaise connexion de câbles

d'alimentation ou d'autres composants, ce qui

peut entraîner à son tour des accidents avec des

conséquences graves.

Pour assurer la circulation de l'air, il est impératif

que les ouïes de ventilation du carter moteur soient

maintenues dégagées et propres.

Nettoyer les filtres anti-peluche

Nettoyez régulièrement les filtres anti-peluche

[5-1]

des deux côtés de la machine.

En cas d'encrassement prononcé, détachez le

filtre anti-peluche au moyen de la vis

passez le filtre anti-peluche à l'aspirateur.

[5-2]

et

5-2

AVERTISSEMENT

Pour éviter les accidents, retirez toujours la fiche

mâle de la prise d'alimentation électrique avant

d'effectuer tout travail de maintenance ou de réparation sur la machine !

N'utilisez pas d'air comprimé pour nettoyer l'outil électrique ! N'essayez pas de nettoyer des

parties à l'intérieur de la machine de cette façon,

étant donné que des corps étrangers pourraient

pénétrer dans les ouvertures du carter de la machine.

Accessoires

5-1

5

L'appareil est équipé de charbons spéciaux à coupure automatique. Lorsque ceux-ci sont usés, l'alimentation est coupée et l'appareil s'arrête.

Utilisez uniquement les accessoires Festool et

consommables Festool d'origine prévus pour cette

machine, car ces composants systèmes sont parfaitement adaptés les uns par rapport aux autres.

Si vous utilisez des accessoires et consommables

d'autres marques, la qualité du résultat peut être

dégradée et les recours en garantie peuvent être

soumis à des restrictions. L'usure de la machine ou

votre charge personnelle peuvent augmenter selon

22

chaque application. Pour cette raison, protégezvous, votre machine et vos droits à la garantie en

utilisant exclusivement des accessoires Festool et

des consommables Festool d'origine !

Utilisez uniquement des plateaux de polissage

d'origine (de marque Festool). L'utilisation de plateaux de polissage de moindre qualité peut provoquer un balourd considérable, entraînant une dé-

Page 23

gradation de la qualité du résultat ainsi que l'usure

de l'outil.

Les références des accessoires et des outils figurent dans le catalogue Festool ou sur Internet

sous "www.festoolusa.com".

Environnement

Ne jetez pas l'appareil avec les ordures ménagères !

Eliminez l'appareil, les accessoires et les

emballages de façon compatible avec l'environne-

ment. Respectez les prescriptions nationales en vigueur.

23

Page 24

Índice

Símbolos............................................... 24

Sobre este manual............................... 24

Indicaciones de seguridad ................... 25

Datos técnicos...................................... 28

Descripción de las funciónes............... 28

Uso conforme a lo previsto.................. 29

Puesta en servicio................................ 29

Sistema electrónico ............................. 29

Ajustes.................................................. 30

Trabajo con la máquina........................ 31

tensión continua

d.c.

n

revoluciones por minuto en vacío

0

Clase II Construcción

rpm

min

revoluciones por minuto

-1

’’ pulgada

lb. libras

Diámetro

Indicación, consejo

Guía de procedimiento

Mantenimiento y cuidado..................... 32

Accesorios............................................ 32

Medio ambiente.................................... 33

Símbolos

V voltios

Aamperios

Hz hertzios

~

a.c.

tensión alterna

Aviso ante un peligro general

Peligro de electrocución

¡Leer las instrucciones e indicaciones!

¡Utilizar gafas de protección!

¡Usar protección para los oídos!

Utilizar protección respiratoria!

Sobre este manual

Guarde estas instrucciones

Es importante que usted lea y entienda este manual. La información que contiene se relaciona con la protección de

su seguridad

y

la prevención de problemas

. Los símbolos que siguen se utilizan para ayudarlo

a reconocer esta información.

PELIGRO Descripción de peligro inmi-

nente y fracaso para evitar

riesgos que podran causar la

muerte.

ADVERTENCIA

Descripción de peligro y posibles lesiones resultantes o la

AVISO Declaración incluyendo el tipo

de riesgo y posible resultados.

CONSEJO Indica informaciónes, notas, o

consejos para mejorar su

éxito con la herramienta.

muerte.

PRECAUCIÓN

Descripción de peligro y posibles lesiones resultantes.

24

Page 25

Indicaciones de seguridad

Indicaciones de seguridad generales

¡ATENCIÓN! Lea todas las advertencias de

seguridad, instrucciones, ilustraciones y

especificaciones que acompañan a esta herramienta eléctrica.

trucciones puede dar lugar a descargas eléctricas,

incendios o lesiones graves.

Guardar todas las advertencias de peligro e instrucciones para futuras consultas.

El término herramienta eléctrica empleado en las

siguientes advertencias de peligro se refiere a herramientas eléctricas de conexión a la red (con cable de red) y a herramientas eléctricas accionadas

por acumulador (o sea, sin cable de red).

1 PUESTO DE TRABAJO

a.

Mantenga limpio y bien iluminado su puesto de

trabajo.

en las áreas de trabajo pueden provocar accidentes.

b.

No utilice la herramienta eléctrica en un entorno con peligro de explosión, en el que se encuentren combustibles líquidos, gases o

material en polvo.

producen chispas que pueden llegar a inflamar

los materiales en polvo o vapores.

c.

Mantenga alejados a los niños y otras personas

de su puesto de trabajo al emplear la herramienta eléctrica.

perder el control sobre el aparato.

2 SEGURIDAD ELÉCTRICA

a.

El enchufe del aparato debe corresponder a la

toma de corriente utilizada. No es admisible

modificar el enchufe en forma alguna. No emplear adaptadores en aparatos dotados con una

toma de tierra.

cuados a las respectivas tomas de corriente reducen el riesgo de una descarga eléctrica.

b.

Evite que su cuerpo toque partes conectadas a

tierra como tuberías, radiadores, cocinas y refrigeradores.

sacudida eléctrica es mayor si su cuerpo tiene

contacto con tierra.

c.

No exponga las herramientas eléctricas a la lluvia y evite que penetren líquidos en su interior.

Existe el peligro de recibir una descarga eléctrica

El desorden y una iluminación deficiente

El incumplimiento de dichas ins-

Las herramientas eléctricas

Una distracción le puede hacer

Los enchufes sin modificar ade-

El riesgo a quedar expuesto a una

si penetran ciertos líquidos en la herramienta

eléctrica.

d.

No utilice el cable de red para transportar o colgar el aparato, ni tire de él para sacar el enchufe de la toma de corriente. Mantenga el cable de

red alejado del calor, aceite, esquinas cortantes

o piezas móviles.

enredados pueden provocar una descarga eléctrica.

e.

Al trabajar con la herramienta eléctrica en la intemperie utilice solamente cables de prolongación homologados para su uso en exteriores.

utilización de un cable de prolongación adecuado

para su uso en exteriores reduce el riesgo de una

descarga eléctrica.

f.

Si fuese imprescindible utilizar la herramienta

eléctrica en un entorno húmedo, es necesario

conectarla a través de un fusible diferencial.

aplicación de un fusible diferencial reduce el riesgo a exponerse a una descarga eléctrica.

3 SEGURIDAD DE PERSONAS

a.

Esté atento a lo que hace y emplee la herramienta eléctrica con prudencia. No utilice la herramienta eléctrica si estuviese cansado, ni

tampoco después de haber consumido alcohol,

drogas o medicamentos.

rante el uso de una herramienta eléctrica puede

provocarle serias lesiones.

b.

Utilice un equipo de protección y en todo caso

unas gafas de protección.

se reduce considerablemente si, dependiendo del

tipo y la aplicación de la herramienta eléctrica

empleada, se utiliza un equipo de protección adecuado como una mascarilla antipolvo, zapatos de

seguridad con suela antideslizante, casco, o protectores auditivos.

c.

Evite una puesta en marcha fortuita del aparato.

Cerciorarse de que el aparato esté desconectado antes conectarlo a la toma de corriente.

transporta el aparato sujetándolo por el interruptor de conexión/desconexión, o si introduce el enchufe en la toma de corriente con el aparato

conectado, ello puede dar lugar a un accidente.

d.

Retire las herramientas de ajuste o llaves fijas

antes de conectar la herramienta eléctrica.

herramienta o llave colocada en una pieza rotante

puede producir lesiones al ponerse a funcionar.

e.

Sea precavido. Trabaje sobre una base firme y

mantenga el equilibrio en todo momento.

permitirá controlar mejor la herramienta eléctri-

Los cables de red dañados o

El no estar atento du-

El riesgo a lesionarse

Ello le

La

La

Si

Una

25

Page 26

ca en caso de presentarse una situación inesperada.

f.

Utilice ropa adecuada. No utilice ropa ancha ni

objetos de joyería o bisutería. Mantenga el pelo

y la ropa alejada de las piezas en movimiento.

La ropa suelta o el pelo largo pueden quedar

atrapados por piezas en movimiento.

g.

Siempre que sea posible utilizar unos equipos

de aspiración o captación de polvo, asegúrese

que éstos estén montados y que sean utilizados

correctamente.

duce los riesgos derivados del polvo.

h.

No debe jamás confiarse por el uso frecuente de

las máquinas e ignorar los principios de seguridad de la herramienta.

puede ocasionar lesiones graves en fracciones

de segundo.

El empleo de estos equipos re-

Un manejo imprudente

mientas eléctricas para trabajos diferentes de

aquellos para los que han sido concebidas puede

resultar peligroso.

h.

Mantenga las empuñaduras secas, limpias y libres de aceite y grasa.

ladizas no permiten una manipulación y un

control seguros de la herramienta eléctrica en

situaciones inesperadas.

5 SERVICIO

a.

Únicamente haga reparar su herramienta eléctrica por un profesional, empleando exclusivamente piezas de repuesto originales.

así se mantiene la seguridad de la herramienta

eléctrica.

Las empuñaduras resba-

Solamente

Indicaciones de seguridad

específicas

4 TRATO Y USO CUIDADOSO DE HERRAMIENTAS

ELÉCTRICAS

a.

No sobrecargue el aparato. Use la herramienta

prevista para el trabajo a realizar.

mienta adecuada podrá trabajar mejor y más seguro dentro del margen de potencia indicado.

b.

No utilice herramientas con un interruptor defectuoso.

conectar o desconectar son peligrosas y deben

hacerse reparar.

c.

Saque el enchufe de la red antes de realizar un

ajuste en el aparato, cambiar de accesorio o al

guardar el aparato.

duce el riesgo a conectar accidentalmente el

aparato.

d.

Guarde las herramientas fuera del alcance de

los niños y de las personas que no estén familiarizadas con su uso.

das por personas inexpertas son peligrosas.

e.

Cuide sus aparatos con esmero. Controle si funcionan correctamente, sin atascarse, las partes

móviles del aparato, y si existen partes rotas o

deterioradas que pudieran afectar al funcionamiento de la herramienta. Si la herramienta

eléctrica estuviese defectuosa haga repararla

antes de volver a utilizarla.

dentes se deben a aparatos con un mantenimiento deficiente.

f.

Mantenga los útiles limpios y afilados.

mantenidos correctamente se dejan guiar y controlar mejor.

g.

Utilice herramientas eléctricas, accesorios, útiles, etc. de acuerdo a estas instrucciones y en la

manera indicada específicamente para este

aparato. Considere en ello las condiciones de

trabajo y la tarea a realizar.

Las herramientas que no se puedan

Esta medida preventiva re-

Las herramientas utiliza-

Muchos de los acci-

Con la herra-

Los útiles

El uso de herra-

–

Esta máquina se destina a trabajos de pulido conforme a lo prescrito. Lea todas las indicaciones

de seguridad, instrucciones, imágenes y descripciones que se suministraron junto con esta máquina.

instrucciones, puede producirse una descarga

eléctrica, fuego o lesiones graves.

Con esta máquina no deben realizarse trabajos

–

de lijado desbastador, lijado fino, cepillado o

tronzamiento con muela.

trabajos para los cuales no ha sido diseñada puede

resultar peligroso o causar daños personales.

–

Utilice únicamente accesorios de Festool diseñados especialmente para esta máquina.

de que un accesorio pueda colocarse en su máquina no presupone una garantía de un funcionamiento sin riesgos.

El número de revoluciones admisible del acceso-

–

rio debe ser mínimo igual al número de revoluciones máximo indicado en la máquina.

piezas que sobrepasen la velocidad permitida pueden reventar.

El diámetro exterior y el grosor del accesorio de-

–

ben hallarse dentro del ámbito de dimensiones

indicado de la máquina.

nes incorrectas no se puede proteger ni controlar

con garantías.

–

El diámetro del taladro de discos, bridas, platos

de apoyo y otros accesorios debe corresponderse

exactamente con el husillo de la máquina.

cesorios que no tienen un diámetro de taladro adecuado giran descentrados, vibran con exceso y

provocan la pérdida del control.

No utilice accesorios dañados. Antes de cada

–

aplicación, compruebe que accesorios como los

discos de lijar no presentan roturas ni fisuras,

Si no se cumplen las siguientes

Realizar con la máquina

El hecho

Las

Un accesorio de dimensio-

Los ac-

26

Page 27

que los platos de apoyo no presentan grietas y

que no existe un desgaste excesivo. Compruebe

en cada caso que la máquina y el accesorio no

presentan daños o monte únicamente accesorios

en buen estado. Tras la comprobación y el montaje del accesorio, colóquense usted y las personas

que se encuentren a su lado fuera del plano de

rotación de la herramienta y deje que la máquina

funcione durante un minuto al número de revoluciones máximo.

Normalmente los accesorios de-

fectuosos se rompen durante esta fase de prueba.

–

Utilice equipamiento de protección. Use pantalla

protectora o gafas protectoras en función de la

aplicación. Cuando sea necesario, utilice mascarilla de respiración, protección para los oídos,

guantes de seguridad y delantal de trabajo adecuados para la protección contra los impactos de

pequeños trozos del lijado y de las piezas de trabajo.

Las gafas de protección deben ser apropiadas para detener los fragmentos despedidos que

se generan con los diferentes trabajos. Las mascarillas de respiración o los respiradores deben

ser adecuados para filtrar los fragmentos generados con los trabajos. Una carga acústica prolongada e intensa puede provocar sordera.

–

Asegúrese de que las personas presentes mantienen una distancia de seguridad con respecto a

la zona de trabajo. Toda persona en el ámbito de

trabajo debe utilizar un equipamiento de protección personal.

Los trozos de la pieza de trabajo o

de un accesorio roto pueden salir despedidos y

causar daños fuera de la zona de trabajo más

próxima.

–

Mantenga el cable de la corriente alejado de las

piezas giratorias.

Si pierde el control, el cable de

corriente podría separarse o quedar suspendido y

su mano o su brazo podrían verse arrastrados hacia dichas piezas.

–

No suelte nunca la máquina hasta que la herramienta esté totalmente parada.

Las herramientas

giratorias se pueden enganchar en la superficie de

depósito y sacudir la máquina fuera de su control.

–

No deje la máquina en funcionamiento mientras

la lleve consigo.

En caso de contacto accidental, la

herramienta giratoria podría engancharse en su

ropa y entrar en contacto con su cuerpo.

–

Limpie regularmente los orificios del aire de refrigeración de la máquina.

El ventilador de refrigeración aspira el polvo en la carcasa de la

máquina y una sedimentación excesiva de polvo

metálico puede provocar peligros eléctricos.

No utilice la máquina cerca de sustancias infla-

–

mables.

Las chispas podrían prender estas sus-

tancias.

–

No utilice herramientas que deban refrigerarse

por líquido.

El agua u otros refrigerantes líquidos

pueden causar descargas eléctricas mortales.

Causas y prevención de contragolpes:

Un contragolpe es la reacción repentina ante un

atasco o enganche de un disco giratorio, un plato de

apoyo, un cepillo u otros accesorios. El atasco o el

enganche provoca una detención muy rápida del

accesorio giratorio, a causa de la cual, como contrarreacción, se acelera la máquina sin control en

contra del sentido de giro del accesorio en el punto

de sujeción.

Si, por ejemplo, la pieza de trabajo atasca o engancha un disco de lijar, el disco con el perímetro en el

punto de sujeción puede introducirse en la superficie de la pieza de trabajo y provocar que el disco sea

expulsado o despedido hacia fuera. El disco puede

salir despedido bien hacia el usuario o en el sentido

contrario, dependiendo de su sentido de giro en el

punto de sujeción. Esto también puede provocar la

rotura de los discos de lijar. Un contragolpe es el

resultado de un uso erróneo de la máquina o de una

forma de trabajo o unas condiciones de funcionamiento inadecuadas y puede evitarse prestando

atención a las siguientes medidas de precaución.

a.

Sujete siempre la máquina con firmeza y coloque su cuerpo y su brazo de forma que siempre

pueda controlar la fuerza de un contragolpe.

Durante la puesta en marcha utilice siempre el

mango adicional (si viene suministrado) para

lograr un control óptimo de los contragolpes o

de los momentos de reacción.

El usuario puede

controlar los momentos de reacción o la fuerza

de los contragolpes si se aplican las medidas de

precaución adecuadas.

b.

No coloque nunca su mano cerca de las herramientas giratorias.

Las herramientas pueden

rebotar hacia su mano.

c.

No se sitúe en la zona hacia la que se moverá la

máquina en caso de un contragolpe.

Un contragolpe acelerará la máquina en contra del sentido

de giro del disco en el punto de sujeción.

d.

Preste especial atención cuando trabaje en esquinas, cantos afilados, etc. Evite un retorno y

enganche de la herramienta.

Las esquinas, los

cantos afilados o los retornos suelen provocar el

enganche de la herramienta y la pérdida del control, así como los contragolpes.

No monte sierras de cadena para los recortes

e.

de madera ni hojas de sierra dentadas.

Estas

hojas provocan a menudo contragolpes y la pérdida del control.

27

Page 28

Indicaciones de seguridad especiales para el pulido

a.

No permita que quede ninguna pieza suelta de

la caperuza de pulido, en especial los cordones

de fijación. Oculte o acorte los cordones de fijación.

Las hebras de fijación sueltas y que giran

pueden capturar sus dedos o quedar colgadas de

la pieza de trabajo.

–

Evite la entrada de agentes pulidores (pulimentos) líquidos en la herramienta.

La penetración

de agentes pulidores (pulimentos) líquidos en la

herramienta eléctrica aumenta el riesgo de descarga eléctrica.

Riesgos para la salud producidos por el pol-

vo

ADVERTENCIA!

lijadoras motorizadas, aserraderos, triturado-

res, perforadoras y otras actividades de construcción contienen sustancias químicas que se sabe

(en el Estado de California) causan cáncer, defectos

Algunos polvos creados por

de nacimiento u otros daños al sistema reproductivo.

Algunos ejemplos de estas sustancias químicas son:

• Plomo de las pinturas con base de plomo

• Sílice cristalino de los ladrillos y cemento y otros

productos de mampostería, y

• Arsénico y cromo de madera tratada con sustancias químicas

El riesgo de exposición a estas

sustancias varía, dependiendo

de cuantas veces se hace este

tipo de trabajo. Para reducir el

contacto con estas sustancias

químicas: trabaje en un área con

buena ventilación y trabaje con equipo de seguridad

aprobado, como mascarillas para el polvo diseñadas

específicamente para filtrar partículas microscópicas.

ADVERTENCIA

PARA REDUCIR EL RIESGO DE LESIÓN, EL USUARIO DEBE LEER EL MANUAL DE INSTRUCCIÓN.

Datos técnicos

SHINEX Pulidora RAP 150-14 FE RAP 150 -21 FE

Potencia 10 A 10 A

Tens ió n ~120 V, 60Hz ~120 V, 60Hz

Número de revoluciones 600 - 1400 min

Número de revoluciones máx

1

3000 min

-1

-1

900 - 2100 min

3000 min

Plato pulidor hasta dia.150 mm (5.9 in.) dia. 150 mm (5.9 in.)

Peso (sin cable de red/sin plato pulidor) 2,1 kg (4.6 lbs.) 2,1 kg (4.6 lbs.)

Clase de protección /II /II

1.

Número de revoluciones máx. que puede aparecer con la electrónica defectuosa.

Descripción de las funciónes

Las imágenes con la dotación de suministro se encuentran en una hoja desplegable al comienzo de

este manual de instrucciones. Cuando lea este manual, le recomendamos que despliegue esta página

para disponer fácilmente de una vista general de la

máquina.

[1-1]

[1-2]

[1-3]

[1-4]

[1-5]

Bloqueo del husillo

Regulación del número de revoluciones

Botón de bloqueo

Interruptor de conexión y desconexión

Filtro de pelusas

-1

-1

28

[1-6]

[1-7]

Mango adicional

Plato pulidor

Page 29

Uso conforme a lo previsto

Esta máquina ha sido diseñada para pulir superficies barnizadas conforme a lo prescrito. Por motivos de seguridad eléctrica, la máquina no debe mojarse ni utilizarse en entornos húmedos.

Puesta en servicio

ADVERTENCIA

Tensión o frecuencia no permitida

Peligro de caída

La tensión de red y la frecuencia de la red eléctrica deben coincidir con los datos que figuran

en la placa de tipo.

En Norteamérica sólo las máquinas Festool

pueden utilizarse con una tensión de 120 V/60

Hz.

ADVERTENCIA

El usuario responde de los daños y accidentes

que puedan derivarse de un uso no conforme a lo

previsto.

Cable de extensión

Cuando se necesite un cable de extensión, éste tiene que disponer de una sección suficiente a fin de

evitar una excesiva caída de voltaje o un sobrecalentamiento. Una caída excesiva del voltaje reduce

la potencia y puede conducir a falla del motor. En la

tabla de abajo indica el diámetro correcto del cable

para su máquina, a saber, en función de la longitud

de cable.

Longitud total del

cable (pies)

25 50 100 150

Conexión y desconexión

El interruptor