Festool TDK 12, TDK 15.6 User Manual

TDK 12

TDK 15.6

Instruction manual |

Cordless Drill / |

Page 2 - 7 |

Screwdriver |

IMPORTANT: Read and understand |

|

all instructions before using. |

|

465 297_002

Guide d’utilisation |

Perceuse visseuse á |

Page 8 - 13 |

accumulateur |

IMPORTANT: Lire et comprendre toutes les |

|

instructions avant de démarrer les travaux. |

|

Manual de instrucciones |

Taladradora-atornilladora |

Página 14 - 19 |

con acumuladores |

IMPORTANTE: Lea y comprende todas |

|

las instrucciones antes de usar. |

|

1

GENERAL SAFETY RULES

Read and understand all instructions. Failure to follow all instructions

listed below, may result in electric shock, fire and/or serious personal injury.

SAVE THESE INSTRUCTIONS Work area

1Keep your work area clean and well lit.

Cluttered benches and dark areas invite accidents.

2Do not operate tools in explosive atmospheres, such as in the presence of flammable liquids, gases, or dust. Tools create sparks which may ignite the dust or fumes.

3Keep bystanders, children, and visitors away while operating a tool. Distractions can cause you to lose control.

Electrical safety

4 A battery operated tool with integral batteries or a separate battery pack must be recharged only with the specified charger for the battery. A charger that may be suitable for one type of battery may create a risk of fire or electric shock when used with another battery.

5 Use battery operated tool only with specifically designated battery pack. Use of any other batteries may create a risk of fire.

Personal safety

6 Stay alert, watch what you are doing and use common sense when operating a tool. Do not use while tired or under the influence of drugs, alcohol, or medication. A moment of inattention while operating tools may result in serious personal injury.

7 Dress properly. Do not wear loose clothing or jewellery. Contain long hair. Keep your hair, clothing, and gloves away from moving parts. Loose clothes, jewellery, or long hair can be caught in moving parts.

8 Avoid accidental starting. Ensure switch is in the off position before plugging in or inserting battery pack. Carrying tools with your finger on the switch or energising tools that have the switch on invites accidents.

9 Remove adjusting keys or wrenches before turning the tool on. A wrench or key that is left attached to a rotating part of the tool may result in personal injury.

10Do not overreach. Stand on both feet an keep proper footing and balance at all times. Proper footing and balance enables better control of the tool in unexpected situations.

11Use safety equipment. Always wear eye protection. Dust mask, non-skid safety shoes, hard hat, or hearing protection must be used for appropriate conditions.

12 If devices are provided for the connection of dust extraction and collection facilities ensure these are connected and properly used. Use of these devices can reduce dust related hazards.

Tool use and care

13 Use clamps or other practical way to secure and support the workpiece to a stable platform. Holding the work by hand or against your body is unstable and may lead to loss of control.

14 Do not force tool. Use the correct tool for your application. The correct tool will do the job better and safer at the rate for which it is designed.

15 Do not use tool if switch does not turn it on or off. Any tool that cannot be controlled with the switch is dangerous and must be repaired.

16 Disconnect battery pack from tool before making any adjustments, changing accessories, or storing the tool. Such preventive safety measures reduce the risk of starting the tool accidentally.

17 Store idle tools out of reach of children and other untrained persons. Tools are dangerous in the hands of untrained users.

18 When battery pack is not in use, keep it away from other metal objects like: paper clips, coins, keys, nails, screws, or other small metal objects that can make a connection from one terminal to another.

Shorting the battery terminals together may cause sparks, burns, or a fire.

19 Maintain tools with care. Keep cutting tools sharp and clean. Properly maintained tools, with sharp cutting edges are less likely to bind and are easier to control.

20 Check for misalignment or binding of moving parts, breakage of parts, and any other condition that may affect the tools operation. If damaged, have the tool serviced before using. Many accidents are caused by poorly maintained tools.

21 Use only accessories that are recommended by the manufacturer for your model. Accessories that may be suitable for one tool, may become hazardous when used on another tool.

Service

22 Tool service must be performed only by qualified repair personnel. Service or maintenance performed by unqualified personnel could result in a risk of injury.

23 When servicing a tool, use only identical replacement parts. Follow instructions in the Maintenance section of this manual. Use of unauthorised parts or failure to follow Maintenance instructions may create a risk of electric shock or injury.

2

Various dust created by power sanding, sawing, grinding, drilling and other construction activities contains chemicals known (to the State of California) to cause cancer,

birth defects or other reproductive harm. Some examples of these chemicals are:

•lead from lead-based paints,

•crystalline silica from bricks and cement and other masonry products, and

•arsenic and chromium from chemically-treated lumber.

The risk from these exposures varies, depending on how often you do this type of work.

To reduce your exposure to these chemicals: work in a well ventilated area, and work with approved safety equipment, such as dust masks that are specially designed to filter out microscopic particles.

Technical data

Cordless drill/screwdriver |

TDK 12 |

TDK 15.6 |

|

Motor voltage |

|

12 V |

15.6 V |

Idle-running speed |

• 1. speed |

0 – 430 rpm |

0 - 450 rpm |

|

• 2. speed |

0 – 1400 rpm |

0 - 1500 rpm |

Max torque |

• Soft case |

20 Nm |

25 Nm |

|

• Hard case |

28 Nm |

36 Nm |

Adjustable torque |

• 1. speed |

2 – 7 Nm |

2 - 7 Nm |

|

• 2. speed |

0.5 – 2.5 Nm |

0.5 - 2.5 Nm |

Chuck capacity |

|

1.5 – 13 mm |

1.5 - 13 mm |

Max. drill diameter for metal / wood |

14 mm / 25 mm |

16 mm / 35 mm |

|

Tool fitting in chuck |

|

1/4 " |

1/4 " |

Weight with battery pack |

2.0 kg (4.4 lbs) |

2.3 kg (5.1 lbs) |

|

Charger |

|

LC 45 |

Supply voltage (input) / line frequency |

120 V ~ / 60 Hz |

|

Charging voltage (output) |

7.2 - 18 V (DC) |

|

Charging current |

|

|

• Quick charge |

|

max. 3 A |

• Compensation charge, pulsating |

app. 0.06 A |

|

Charging time for |

• NiCd 2.0 Ah |

app. 45 min |

|

• NiCd 2.4 Ah |

app. 50 min |

|

• NiMH 3.0 Ah |

app. 70 min |

Battery pack |

BPS 12 |

BPS 12 |

BPS 15.6 |

BPS 15.6 |

|

NiCd 2.4 |

NiMH 3.0 |

NiCd 2.4 |

NiMH 3.0 |

Order number |

492 268 |

491 821 |

492 269 |

491 823 |

Voltage |

12 V |

12 V |

15.6 V |

15.6 V |

Capacity |

2.4 Ah |

3.0 Ah |

2.4 Ah |

3.0 Ah |

Temp. range for charging |

|

5 - 45 °C |

|

|

Monitoring of charge |

|

by means of NTC thermistor |

|

|

Weight |

0.73 kg (1.6 lbs) |

0.75 kg (1.7 lbs) |

0.90 kg (2.0 lbs) |

0.92 kg (2.0 lbs) |

Symbols

V |

volts |

A |

amperes |

Hz |

hertz |

W |

watt |

~alternating current

n0 |

no load speed |

|

Class II Construction |

rpm |

revolutions per minute |

Intended use

Cordless drills are suitable for drilling metal, wood, plastics and similar materials, as well as tightening and screwing in screws (into wood, up to a diameter of 6 mm).

The LC 45 battery charger is designed for recharging the battery pack listed.

The user will be liable for damage due to improper use.

3

Wall mounting LC 45

The charger LC 45 has two longitudinal slots on its rear by which it can be suspended on walls using two screws (e.g. button-headed or flat head screw with a shaft diameter of 5 mm). Screw both screws into the wall 96 mm apart until the screwhead is protruding from the wall by approx. 4 mm.

Machine settings

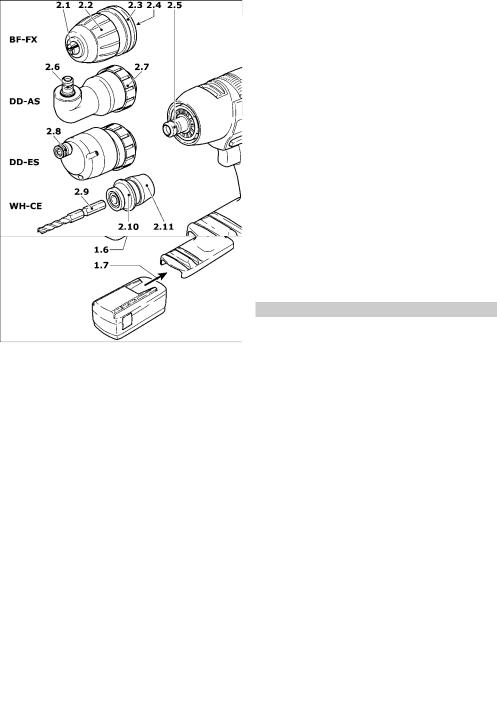

Exchanging the battery pack

-Removing battery pack: Press the two buttons (1.6) and slide the battery pack forwards to remove.

-Inserting battery pack: Slide the battery pack into the holder on the underside of the handle until it latches into place (1.7).

To change the direction of rotation

The selector button (1.2) determines the direction of rotation.

•Turn button from right to left = clockwise rotation.

•Turn button from left to right = anticlockwise rotation.

•Selector button in central position = circuit interlock.

Shifting speeds

Change only when completely

stopped!

Using the shift lever (1.3), the speed can be changed.

•1. Speed: Lever forward - Figure 1 is visible.

•2. Speed: Lever backwards - Figure 2 is visible.

Torque adjustment

By turning the adjustment ring (1.4) the required torque can be adjusted. The arrow (1.5) aligns with the adjusted state.

Drilling:

Drilling symbol on adjustment ring aligns with the arrow = maximum torque.

Screwing:

Torque corresponding to setting:

•Position 1 = low torque

•Position 20 = high torque

Operation

Turn on by pressing button (1.1). Depending on the pressure exerted on the button, the adjustment of running speed can be varied infinitely.

Turn off by releasing the button (1.1). After releasing the button, the chuck is stopped and therefore, after-running of the equipment is prevented.

Tool holding fixture, attachments

Make sure that the machine is switched of and the battery block has been

removed before changing the tool holding fixture, attachments and tools.

Chuck BF-FX

The chuck is used to clamp drills and bits. Fitting:

-Place the chuck on the drill spindle (2.5) and twist until the hexagon key (2.4) of the chuck latches into the hexagon socket of the drill spindle.

4

-Pull the unlocking ring (2.3) forwards, press the chuck onto the drill spindle up to the stop and release the unlocking ring.

Removal:

-Pull the unlocking ring forwards and remove the chuck.

Changing tools:

-Turn the clamping sleeve (2.2) anti-clockwise to open the clamping jaws (2.1)

(Note: the spindle is automatically locked when the machine is switched off).

-Insert the tool into the chuck.

-Clamp the tool by turning the clamping sleeve clockwise. Always make sure that the tool is clamped centrally in the chuck.

Angle attachment DD-AS

The angle attachment permits work (drilling, screwing) vertical to the machine’s longitudinal axis.

Fitting:

-Place the angle attachment on the drill spindle and turn until it catches in the desired position (Note: The angle attachment can be fitted in 16 different angle settings).

-Lock the angle attachment by turning the fastening ring (2.7) tightly clockwise.

Removal:

-Turn the fastening ring anti-clockwise up to the stop and remove the angel attachment.

Fitting / removal of chuck on angle attachment:

The chuck is fitted on the shaft (2.6) of the angle attachment in the same way as on the drill spindle of the machine.

Eccentric attachment DD-ES

The eccentric attachment is used to hold bits. It allows screwing close to edges.

Fitting / removing the eccentric attachment:

The eccentric attachment is fitted / removed in the same was as the angle attachment (see DDAS).

Changing tools:

Pull the unlocking ring (2.8) back and remove the tool and/or insert the new tool.

CENTROTEC WH-CE toolholder

The CENTROTEC toolholder enables rapid changes of tools with CENTROTEC shafts.

Danger of injury! When changing tools, handle the tool and its sharp cutters with

special care and wear protective gloves, if necessary.

Do not fit CENTROTEC tools at the round shaft section in a conventional chuck to

prevent damage to the shaft.

Fitting

-Pull the release ring (2.11) forwards, place the toolholder as far as it will go on the drill spindle (2.5) and let go of the release ring.

Removal

-Pull the release ring forwards and take off the toolholder.

Changing tools

-To insert or remove a tool with CENTROTEC shaft, pull the green release ring (2.10) back. On inserting the tool, turn it until its hex shank arbour (2.9) locks in place in the hexagonal shank of the drill spindle, and push the tool into the toolholder as far as it will go.

Tool holding fixture in the drill spindle

Bits can be fitted directly in the hexagon socket holder of the drill spindle (2.5) to make the machine lighter and shorter.

Charge battery pack

To load the battery pack, push it into the holder (3.1) on the charger up to the stop. Perform this in reverse to remove the battery pack from the charger.

The battery type used (NiCd or NiMH) is detected automatically. Charging is controlled by a microprocessor.

If a warm NiMH battery pack (>37° C) is inserted, charging will only be carried out at a lower charge current. In this case, the charging time is extended.

The LED (3.2) indicates the respective charging state of the charger.

LED yellow – steady: charger is ready for use.

LED green – flashing:

battery pack being charged. LED green – steady:

battery pack fully charged, conservation charge on.

LED red – flashing:

general malfunction, e. g. full contact not being made, short-circuit, battery pack faulty.

5

LED red – steady:

temperature of battery pack is outside permissible limit.

It is essential that you read the instructions in the Chapter „Maintenance - Care“.

Bit storage well

You can insert several bits or bit extensions into the bit magazine (4.1) from the side.

The magnetic attachment allows you to pick up screws and similar objects.

Maintenance and care

Pay attention to the following instructions. Otherwise there is a risk of damage

to the tool, charger or battery pack.

•Repairs may only be performed by authorised technicians. LC 45 charging device: Even after disconnection from the mains, there is still a high capacitor voltage on the power output component on the inside of the device.

•Keep the air vents of the electronic equipment and the charger clean to guarantee the air circulation for cooling.

•No metal objects (metal chips) should enter the charger at the contact points as well as through the cooling slits into the equipment (danger of short circuit).

•Only use original Festool battery packs. Do not use spent and recycled battery packs. The user shall be liable for damages if Festool original battery packs are not used.

•Keep the connection contacts of electronic equipment, charger and battery pack clean.

•By keeping the battery pack in a ready for use charger, the battery pack will be kept in a state of readiness by float charging conservation.

•Do not keep discharged battery pack (maximum one month) attached to charger whenever charger is detached from the power supply (danger of deep discharging).

•A new battery pack or a battery pack not used for a longer period of time reaches it full capacity after about 5 charging and discharging cycles.

•Battery packs should, before charging, be fully discharged if possible.

Continuous starting of the charging process shortens the lifespan of the batteries.

•A considerably reduced time of operation per charging shows that the battery pack is used up an should be replaced by a new one.

•NiCd battery packs that are not used for longer periods should be stored in a discharged state.

Special instructions for NiMH battery packs:

•The output of NiMH battery packs drops noticeably at ambient temperatures below 0° C or above 45° C.

•Do not overload the tool (do not load the tool excessively so that it comes to a standstill).

•Even if NiMH battery packs are not used, recharge them approx. every 4 months so that they retain their full capacity.

•NiMH battery packs should be left for 60 min. in the charger after every 10th fast charge to compensate any differences in capacity between the cells.

•Because NiMH battery packs discharge automatically, store them preferably at ambient temperatures of between 0° C and 25° C.

Changing carbon brushes

If the carbon brushes have worn to a length of less than 6 mm, this may reduce the performance of the machine or cause the machine to stop. In this case, the brushes (5.2) should be replaced.

-Unscrew the cover (5.4) and remove the worn brushes.

-Push in the retaining plate (5.3) on the new carbon brushes until it latches into the notches (5.1) and screw the covers back on.

-Operate the machine in idling state for a few minutes so that the carbon brushes attain optimal contact.

Recycling battery packs

Never throw spent battery packs into domestic waste containers! Return spent or defective battery packs to dealers, the Festool after-sales service department or approved waste disposal facilities. This ensures that they are correctly recycled.

Accessories, tools

For safety reasons, only use original Festool accessories and tools!

The accessory and tool order number can be found in your Festool catalog or on the Internet at www.festool-usa.com.

6

Loading...

Loading...