Page 1

Festool Group GmbH & Co. KG

Wertstraße 20

D-73240 Wendlingen

Tel.: +49 (0)7024/804-0

Telefax: +49 (0)7024/804-20608

www.festool.com

Originalbetriebsanleitung - Renovierungsfräse 3

Original operating manual - Renovation Cutter 11

Notice d’utilisation d’origine - Freiseuse d’assainissement 18

Manual de instrucciones original - Fresadora de saneamiento 27

Istruzioni per l’uso originali - Fresatrice di risanamento 35

Originele gebruiksaanwijzing - Saneringsfrees 43

Originalbruksanvisning - Renoverings fräs 51

Alkuperäiset käyttöohjeet - Saneerausjyrsin 58

Original brugsanvisning - Sanerings fræser 66

Originalbruksanvisning - Fresemaskin for renovering 74

Manual de instruções original - Fresa de renovação 82

Оригинал Руководства по эксплуатации - Санационная фреза 91

Originál návodu k obsluze - Renovační frézka 100

Oryginalna instrukcja eksploatacji - Szlifi erka renowacyjna 108

768839_002

R E N O F I X

RG 80 E

Page 2

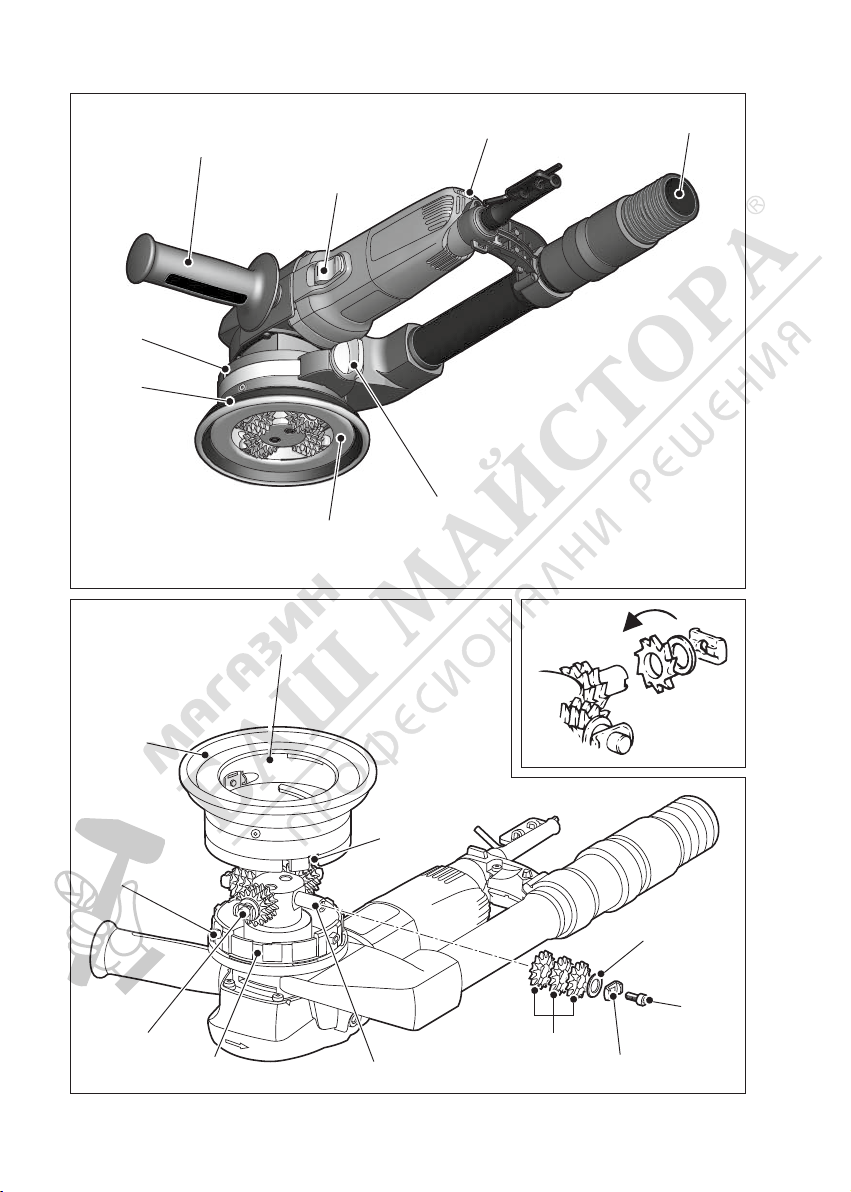

1

1-8

1-7

1-1

1-2

1-6

1-5

1-3

1-4

2

2-10

2-8

2-7

2-6

2-11

2-5

3

2-9

2-3

2-1

2-4

2-2

Page 3

GB

Renovation Cutter RG 80 E

1 Symbols

Double insulation

Warning of general danger

Risk of electric shock

Use protective goggles!

Wear ear protection!

Use protective gloves!

Read the instructions

Not to be included in municipal refuse

Advice or tip

2 Technical data

Nominal voltage 220-240 V ~

Mains frequency 50 / 60 Hz

Power input 1100 W

Adjustable revolutions 2000 – 5900 min

Tool diameter 80 mm

Weight 3.2 kg

Protection class II /

–1

3 Prescribed usage

The machine works on the principle of an angle

grinder but uses also special tools for milling and

grinding, e.g. of concrete and plaster.

The machine is intended for removal of paint

coats, plasters, residues of wall tile and carpet

adhesives mainly from rigid surfaces. In addition, the machine can be used for roughing of fl at

concrete surfaces and for milling of lining work

transitions.

The user proper is responsible for improper usage.

4 Control Elements

[1-1] Additional handle

[1-2] Switch lever

[1-3] Adjusting wheel

[1-4] Handle

[1-5] Knob

[1-6] Backstop bar

[1-7] Suction fl ange

[1-8] Scale

[2-1] Bolt

[2-2] Retainer

[2-3] Washer

[2-4] Milling rings

[2-5] Tool carrier

[2-6] Guide surface

[2-7] Bolt

[2-8] Sliding part

[2-9] Slot

[2-10] Suction fl ange

[2-11] Guide surface

Accessories that are illustrated or described here

are not always included in the scope of delivery.

The specifi ed illustrations can be found at the beginning of the operating instructions.

5 Notes on Safety Prevention

5.1 General safety instructions

WARNING! Read all safety warnings and

all instructions. Failure to follow the warn-

ings and instructions may result in electric

shock, fi re and/or serious injury.

Save all warnings and instructions for future

reference.

The term „power tool“ in the warnings refers to

your mains-operated (corded) power tool or battery-operated (cordless) power tool.

5.2 Safety instructions for all operations

Safety Warnings Common for grinding, surface

grinding, grinding with wire brush or ABRASIV

cutting:

a) This power tool is intended to function as

a surface grinder or a cutter with a cutter

head. Read all safety warnings, instructions,

illustrations and specifications provided with

this power tool. Failure to follow all instruc-

tions listed below may result in electric shock,

fi re and/or serious injury.

b) Operations such as polishing or cutting are

not recommended to be performed with this

power tool. Operations for which the power

tool was not designed may create a hazard and

cause personal injury.

c) Do not use accessories which are not specifi -

cally designed and recommended by the tool

11

Page 4

manufacturer. Just because the accessory can

be attached to your power tool, it does not assure safe operation.

d) The rated speed of the accessory must be at

least equal to the maximum speed marked

on the power tool. Accessories running faster

than their rated speed can break and fl y apart.

e) The outside diameter and the thickness of

your accessory must be within the capacity

rating of your power tool. Incorrectly sized

accessories cannot be adequately guarded or

controlled.

f) The arbour size of wheels, fl anges, backing

pads or any other accessory must properly fi t

the spindle of the power tool. Accessories with

arbour holes that do not match the mounting

hardware of the power tool will run out of balance, vibrate excessively and may cause loss

of control.

g) Do not use a damaged accessory. Before each

use inspect the accessory such as ABRASIV

wheels for chips and cracks, backing pad for

cracks, tear or excess wear, wire brush for

loose or cracked wires. If power tool or accessory is dropped, inspect for damage or

install an undamaged accessory. After inspecting and installing an accessory, position yourself and bystanders away from the

plane of the rotating accessory and run the

power tool at maximum no-load speed for one

minute. Damaged accessories will normally

break apart during this test time.

h) Wear personal protective equipment. Depend-

ing on application, use face shield, safety goggles or safety glasses. As appropriate, wear

dust mask, hearing protectors, gloves and

workshop apron capable of stopping small

ABRASIV or workpiece fragments. The eye

protection must be capable of stopping fl ying

debris generated by various operations. The

dust mask or respirator must be capable of

fi ltrating particles generated by your operation.

Prolonged exposure to high intensity noise may

cause hearing loss.

i) Keep bystanders a safe distance away from

work area. Anyone entering the work area

must wear personal protective equipment.

Fragments of workpiece or of a broken accessory may fl y away and cause injury beyond immediate area of operation.

j) Hold power tool by insulated gripping surfaces

only, when performing an operation where the

cutting accessory may contact hidden wiring

12

or its own cord. Cutting accessory contacting a

“live” wire may make exposed metal parts of

the power tool “live” and shock the operator.

k) Position the cord clear of the spinning acces-

sory. If you lose control, the cord may be cut or

snagged and your hand or arm may be pulled

into the spinning accessory.

l) Never lay the power tool down until the acces-

sory has come to a complete stop. The spin-

ning accessory may grab the surface and pull

the power tool out of your control.

m

) Do not run the power tool while carrying it at

your side. Accidental contact with the spinning

accessory could snag your clothing, pulling the

accessory into your body.

n) Regularly clean the power tool’s air vents. The

motor’s fan will draw the dust inside the housing and excessive accumulation of powdered

metal may cause electrical hazards.

o) Do not operate the power tool near fl ammable

materials. Sparks could ignite these materials.

p) Do not use accessories that require liquid

coolants. Using water or other liquid coolants

may result in electrocution or shock.

Further safety instructions for all operations

Kickback and Related Warnings

Kickback is a sudden reaction to a pinched or

snagged rotating wheel, backing pad, brush or

any other accessory. Pinching or snagging causes

rapid stalling of the rotating accessory which in

turn causes the uncontrolled power tool to be

forced in the direction opposite of the accessory’s

rotation at the point of the binding.

For example, if an ABRASIV wheel is snagged or

pinched by the workpiece, the edge of the wheel

that is entering into the pinch point can dig into

the surface of the material causing the wheel to

climb out or kick out. The wheel may either jump

toward or away from the operator, depending on

direction of the wheel’s movement at the point of

pinching. ABRASIV wheels may also break under

these conditions.

Kickback is the result of power tool misuse and/

or incorrect operating procedures or conditions

and can be avoided by taking proper precautions

as given below.

a) Maintain a firm grip on the power tool and

position your body and arm to allow you to

resist kickback forces. Always use auxiliary

handle, if provided, for maximum control over

kickback or torque reaction during start-up.

The operator can control torque reactions or

Page 5

kickback forces, if proper precautions are taken.

b) Never place your hand near the rotating ac-

cessory. Accessory may kickback over your

hand.

c) Do not position your body in the area where

power tool will move if kickback occurs. Kickback will propel the tool in direction opposite to

the wheel’s movement at the point of snagging.

d) Use special care when working corners, sharp

edges etc. Avoid bouncing and snagging the

accessory. Corners, sharp edges or bouncing

have a tendency to snag the rotating accessory

and cause loss of control or kickback.

e) Do not attach a saw chain woodcarving blade

or toothed saw blade. Such blades create frequent kickback and loss of control.

Additional safety instructions for grinding and

cutting

Safety Warnings Specifi c for Grinding and

ABRASIV Cutting-Off Operations:

a) Use only wheel types that are recommended

for your power tool and the specifi c guard

designed for the selected wheel. Wheels for

which the power tool was not designed cannot

be adequately guarded and are unsafe.

b) The guard must be securely attached to the

power tool and positioned for maximum safety, so the least amount of wheel is exposed

towards the operator. The guard helps to pro-

tect operator from broken wheel fragments

and accidental contact with wheel.

c) Wheels must be used only for recommended

applications. For example: do not grind with

the side of cut-off wheel. ABRASIV cut-off

wheels are intended for peripheral grinding,

side forces applied to these wheels may cause

them to shatter.

d) Always use undamaged wheel fl anges that

are of correct size and shape for your selected

wheel. Proper wheel fl anges support the wheel

thus reducing the possibility of wheel breakage. Flanges for cut-off wheels may be different from grinding wheel fl anges.

e) Do not use worn down wheels from larger

power tools. Wheel intended for larger power

tool is not suitable for the higher speed of a

smaller tool and may burst.

Additional safety instructions for wire brushing

operations

Safety Warnings Specifi c for Wire Brushing

Operations:

a) Be aware that wire bristles are thrown by the

brush even during ordinary operation. Do not

overstress the wires by applying excessive

load to the brush. The wire bristles can easily

penetrate light clothing and/or skin.

b) If the use of a guard is recommended for wire

brushing, do not allow any interference of the

wire wheel or brush with the guard. Wire wheel

or brush may expand in diameter due to work

load and centrifugal forces.

Further safety instructions

- The machine may not be used in damp and wet

spaces, outdoor when it is rainy, foggy or snowy

or in the explosive environment.

- Before use always inspect the fl exible lead and

the plug. Have the defects repaired by a specialist repair shop.

- Outside the premise use only approved exten-

sion leads and cable connections.

- Apply the machine to the material only when

switched on.

- Do not carry the machine by the lead.

- Do not work on a ladder.

- When operating the tool, use protective gloves

and tough footwear.

- When operating the tool, use goggles and ear

protectors.

- The dust generated during work is harmful to

health. When operating the tool, use the dust

extraction system and the respirator.

- Materials containing asbestos can only be pro-

cessed by qualifi ed individuals. Comply with the

safety regulations that apply in your country.

- Flexible power supply cable always route from

the tool backwards.

- Only use milling rings recommended by the

manufacturer.

- The machine is only allowed be used when pro-

tective guard is in place and additional handle

is fastened.

- Plug in the fl exible power supply cable’s plug

into the wall socket when the machine is off.

- Make yourself sure whether the material that is

going to be machined does not contain electric,

water or gas lines – an injury could occur.

- Do not mill over metal objects, nails or screws.

13

Page 6

- The machine is not allowed to be operated by a

person under 16 years of age.

- Only for AS/NZS: The tool shall always be sup-

plied via residual current device with a rated residual current of 30 mA or less.

5.3 Emission levels

Measured values determined according to EN 60 745.

Typically the A-weighted noise level of the tool are:

Sound pressure level: 86 dB (A)

Sound power level: 97 dB (A)

Inaccuracy of measurement K = 1.5dB (A)

CAUTION

Operating noise

Damage to hearing

Use ear protection!

Measured values determined according to EN 60 745.

Grinding with grinding wheel ah = 5.3 m/s2

Inaccuracy of measurement K = 1.5 m/s²

The specifi ed emissions values (vibration, noise)

– are used to compare machines.

– They are also used for making preliminary estimates regarding vibration and noise loads during

operation.

– They represent the primary applications of the

power tool.

Increase possible for other applications, with other insertion tools or if not maintained adequately.

Take note of idling and downtimes of machine!

6 Activation

WARNING

Risk of accident if the machine is operated using unauthorised voltages or frequencies.

The mains voltage and the frequency of the

power source must correspond with the

specifi cations on the machine’s name plate.

In North America, only Festool machines with

the voltage specifi cations 120 V/60 Hz may

be used.

61 Switching on – off

Switching on

Move the switch button [1-2] forward and the device will switch on. If you press the front part of the

button, it will arrest and start continual operation.

14

Switching off

Press the rear part of the button [1-2] to relax ar-

rest. The button returns to switched-off position.

6.2 Motor electronics

Starting current limitation

Electronically controlled continual running secures device acceleration without back thrust.

Due to starting current limitation in the device,

15A protection is suffi cient.

WARNING

Devices without starting current limitation

need higher protection – at least 16A circuit

breaker.

Switching off during back thrust

During sudden drop of revolutions, for example

blocking in dividing cut, the current input in motor stops. For re-starting, the device must be fi rst

switched off and again switched on.

Protection against re-starting

Prevent uncontrolled starting of the device after

current supply cut off. For re-starting, the device

must be fi rst switched off and again switched on.

Revolutions pre-setting

Use the revolutions regulator [1-3] for smooth

revolutions pre-setting.

Degree 1: 2000 min–1 Degree 4: 4500 min

Degree 2: 2950 min–1 Degree 5: 5300 min

Degree 3: 3750 min–1 Degree 6: 5900 min

Required number of revolutions depends on applied grinding wheel and worked material.

Constant electronics

Constant electronics maintains revolutions during

operation and idle run near the constant. Regular

operating shift is achieved.

Protection from overloading dependant on

temperature

The safety electronics switches to cooling regime

when the critical temperature is reached. Motor

continues running at approximately 2500 min

revolutions, constant electronics is deactivated.

After cooling to approximately 10 – 20 s, the device

is fully operational.

Heat protection for devices heated during operation, reacts adequately sooner.

–1

–1

–1

–1

Page 7

7 Milling tools

7.1 Choice of cutter and grinding head

According to use and type of application, there are

various types of cutter heads. To achieve optimal

work results, use suitable grinding heads.

Data in the Chart showing speed pre-selection

options are recommended values only; practice

testing should be always performed – see page

19!

7.2 Cutter / Grinding head change

Before putting into operation, check perfect run

of the cutter tool: turn it manually.

Make sure that all screws are tightened up well.

Four screws connecting the fl ange and the head

tool should be well-tightened up: use torque 5

Nm.

Two screws fi xing the position of the head on the

machine should be well-tightened up: use torque

8 Nm.

Do not leave any tools inserted in.

7.3 Replacing Grinding Wheels

WARNING

Risk of accident, electric shock

Always pull the plug out of the socket before

performing any type of work on the machine.

If teeth of milling rings that are made of hard alloy

are worn, it is possible to replace them.

By means of turning the knob [1-5] release the

clamping belt to such extent so as it is possible

to move the suction fl ange [1-7].

Turn the suction fl ange fully counter-clockwise

and pull it downwards.

Release two bolts [2-1], [2-7] on four axes of

tool carrier using the hexagonal spanner S4.

Now, the milling cutters are easily accessible.

When replacing milling rings replace also bolts

[2-1], [2-7] and excessive turn retainers [22]. The bolts have been fi xed by light adhesive

agent so as they cannot be loosened by vibrations. Only use originally supplied bolts.

Firstly, put three milling rings [2-4] onto each

axis, then the washer [2-3]; fasten everything

with the help of excessive turn retainer [2-2]

and bolts [2-1], [2-7]. It is extremely important

that you insert the excessive turn retainer into

corresponding slot [2-5] located in tool carrier

axis. If the excessive turn retainers are not installed, bolts could be loosened during operation; this may cause major losses.

Put on the suction fl ange [2-10] so as sliding

parts [2-8] snap into corresponding slots [2-9]

located on suction fl ange.

Set the milling depth required and tighten the

clamping belt using the turning knob.

When installing the model with fl at teeth, it is important that milling rings are installed as shown

in the Fig. [3]; it means that tips must be oriented

in the direction of milling head rotation.

The model with spiked teeth (HW-SZ 12) is used

to remove old layers of paint from concrete or

plasters. The version with fl at teeth (HW-FZ 12)

is used for smoothening of timbering gaps and

for machining of concrete edges.

8 Operation

When operating with renovation cutter, you

must use goggles so as you protect your eyes

from fl ying material particles!

Adjustable height of suction fl ange is necessary

to be adapted to mode of use. When removing old

layers of paints, tips of teeth would not overlap

the suction fl ange by more than 1 mm. In the contrary, when milling plasters, the milling rings can

overlap by 2 to 4 mm. To adjust the height, slightly

release the clamping belt using the turning knob

[1-5] and turn the suction fl ange [1-7] counter-

clockwise or clockwise. Adjustable range is up to

5.5 mm. The milling depth adjusted can be roughly

read on the scale [1-8]. If height adjustment does

not operate smoothly, we recommend cleaning

the guide surfaces [2-6] and [2-11]. Once the

height is adjusted, fasten tight the clamping belt.

Do not ever operate the machine without suction fl ange! Only remove it when cleaning the

guide surfaces or when replacing milling rings.

When carrying out these operations, always

remove the plug from wall socket!

The suction fl ange can be also used on machined

area as a holder [1-6]. On principle, the renovation cutter should be applied fl atwise onto the

work piece. In case of fl at surfaces, optimum adjustment is 6

WARNING

CAUTION

th

step of the Electronic.

15

Page 8

CAUTION

During work, inspect whether milling rings

still freely rotate on axes. If it is not the case,

e.g. due to accumulated dust; it is necessary

to remove it from the milling head. For this

reason the machine should not be operated

without suction system connected!

8.1 Suction system

To ensure the operability of suction system, put

the hose (36 mm diameter) of some Festool brand

vacuum cleaner onto the handle adaptor [1-4].

Keep in mind that as fi ltration sack is being fi lled,

the suction effectiveness signifi cantly reduces.

Also clean vacuum cleaner’s fi lter time to time.

CAUTION

Always operate the machine with the suction

system connected; otherwise, the milling rings

as well as suction fl ange height adjustment

system will be clogged with dust!

To prevent discharges of static electricity in dusty

environment, use vacuum cleaners of antistatic

models only.

8.2 Additional handle

To operate the grinder with both hands, it is possible to fasten an additional handle [1-1] to the

left-hand side of gearbox cover’s front part.

The special “VIBRASTOP” design reduces vibrations in the additional handle.

9 Service and maintenance

Risk of accident, electric shock

Always pull the plug out of the socket before

performing any type of work on the machine.

All maintenance and repair work which re-

quires the motor housing to be opened, must

only be carried out by an authorised service

workshop.

WARNING

- To ensure the airfl ow is suffi cient, cooling open-

ings of the motor must be always clean and free.

- The machine is equipped with special self-

disconnecting brushes. When the brushes are

worn, the power supply is automatically disconnected, and the machine is stopped.

- If the suction fl ange height adjustment system

does not operate smoothly, the fl ange must be

removed and cleaned.

Customer service and repair. Only

through manufacturer or service

workshops: Please find the nearest

address at: www.festool.net/service

EKAT

4

Use only original Festool spare parts!

5

3

2

Order No. at: www.festool.net/service

1

10 Environment

Do not throw the power tool in your household

waste! Dispose of the machine, accessories and

packaging at an environmentally-responsible recycling centre! Observe the valid national regulations.

EU only: In accordance with European Directive on

waste electrical and electronic equipment and implementation in national law, used electric power

tools must be collected separately and handed in

for environmentally friendly recycling.

Information on REACh:

www.festool.com/reach

11 EU Declaration of Conformity

Renovation Cutter Serial no.

RG 80 E 769231, 768829,

Year of CE mark: 2013

We declare under sole responsibility that this

product comply with all relevant requirements

of the following directives, norms or normative

documents:

2006/42/EC, 2004/108/EC, 2011/65/EU, EN 55

014-1, EN 55 014-2, EN 60 745-1, EN 60 745-2-3,

EN 61 000-3-2, EN 61 000-3-3.

Festool Group GmbH & Co. KG

Wertstr. 20, D-73240 Wendlingen

768798

- Wrapped electric tools can be stored in a dry

place without heating, with temperatures not

lower than –5°C. Unwrapped electric tools can

only be stored in dry places with temperatures

not lower than +5°C, without sudden changes

in the temperature.

16

Dr. Martin Zimmer 2013-04-15

Head of Research, Development and Technical

Documentation

Page 9

Cutter head Installation Application

Cutter head “Flat Shape” with

12 hard-metal cutter wheels

FZ-RG 80

Cutter head “Pointed Shape”

with 12 hard-metal cutter

wheels SZ-RG 80

Grinding head Installation Application

Diamond grinding head:

grinding wheel with 8

segments provided with

diamond grits DIA HARD-RG

80

Diamond grinding head:

grinding wheel with 8

segments provided with

diamond grits DIA ABRASIVRG 80

Diamond grinding head

DIA THERMO-RG 80

- Plaster removal

- Removing of elastic protective coats on walls

and fl ooring

- Removing of foam base and glue remnants

(carpet remnants)

- Removing of fl oor tile glue remnants

- Removing of bitumen and concrete protective

coats

- Removing of latex paints or oil paints on

gypsum surface

- Plaster removal

- Removing of bumps and excessive material

after boarding – fresh concrete work

- Removing of foam base and glue remnants (and

carpet remnants)

- Removing of fl oor tile glue remnants

- Removing of plaster made of synthetic resin

(made on thermal insulation)

- Removing of bumps and excessive material –

screed fl oor cover

- Grinding and cleaning weather-worn parts of

concrete constructions

- Removing of bumps – old concrete

- Removing of bumps and excessive material –

screed fl oor cover

- Grinding and cleaning – fresh concrete

- Grinding – ABRASIV materials

- Tenacious and thermo-elastic materials, such as

paints, protective paints, elastic glue

Electronic

adjusting

wheel

4 – 6

4 – 6

Electronic

adjusting

wheel

6

6

5 – 6

Hard-metal grinding head:

grinding wheel provided with

hard-metal grits HW Grob-RG

80

Diamond grinding head,

ABRASIV disk with soldered

diamond grains DIA UNI-RG 80

Hard-metal grinding head:

grinding wheel provided with

hard-metal grits HW Fein-RG

80

- Removing of elastic protective coats on walls

and fl ooring

- Reduction of gypsum and cellular concrete

- Removing of impurities – concrete fl oors

- Removing of latex or oil paints – gypsum

surface

- Rough working

- Universal use, removal of paint from concrete,

hard plasters, wood, removal of elastic glues,

hard plasters, soft concrete

- Removing of elastic protective coats on walls

and fl ooring

- Reduction of gypsum and cellular concrete

- Removing of impurities – concrete surface

- Removing of latex or oil paints on gypsum

surface

- Fein working

3 – 5

5 – 6

3 – 5

17

Loading...

Loading...