Page 1

767810_002

Festool Group GmbH & Co. KG

Wertstraße 20

D-73240 Wendlingen

Tel.: +49 (0)7024/804-0

Telefax: +49 (0)7024/804-20608

www.festool.com

Originalbetriebsanleitung 6

Original operating manual

11

Notice d’utilisation d’origine 16

Manual de instrucciones original

21

Istruzioni per l'uso originali

26

Originele gebruiksaanwijzing 31

Originalbruksanvisning 36

Alkuperäiset käyttöohjeet 41

Original brugsanvisning 46

Originalbruksanvisning 51

Manual de instruções original 56

Оригинал Руководства по эксплуатации 61

Originál návodu k obsluze 66

Oryginalna instrukcja eksploatacji 71

Q U A D R I L L

DR 18/4 E

PD 20/4 E

Page 2

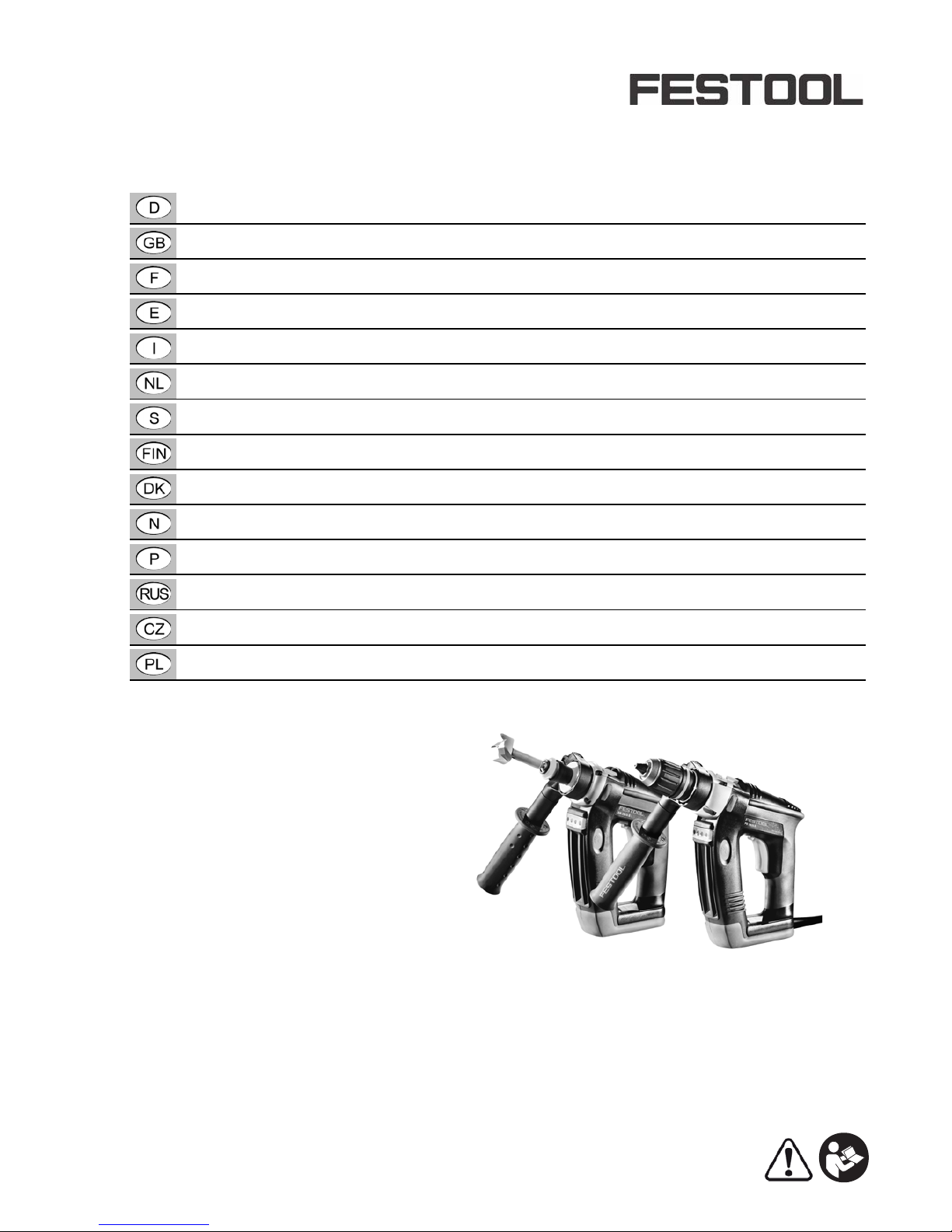

DR 18/4 E

PD 20/4 E

1-2

1-1

1-3

1-4

1-2

1-1

1-3

1-4

1-6

1-6

1-5

1-7

1-8

1-9

1-10

1-7

1-8

1-9

1-10

1-11

1

Page 3

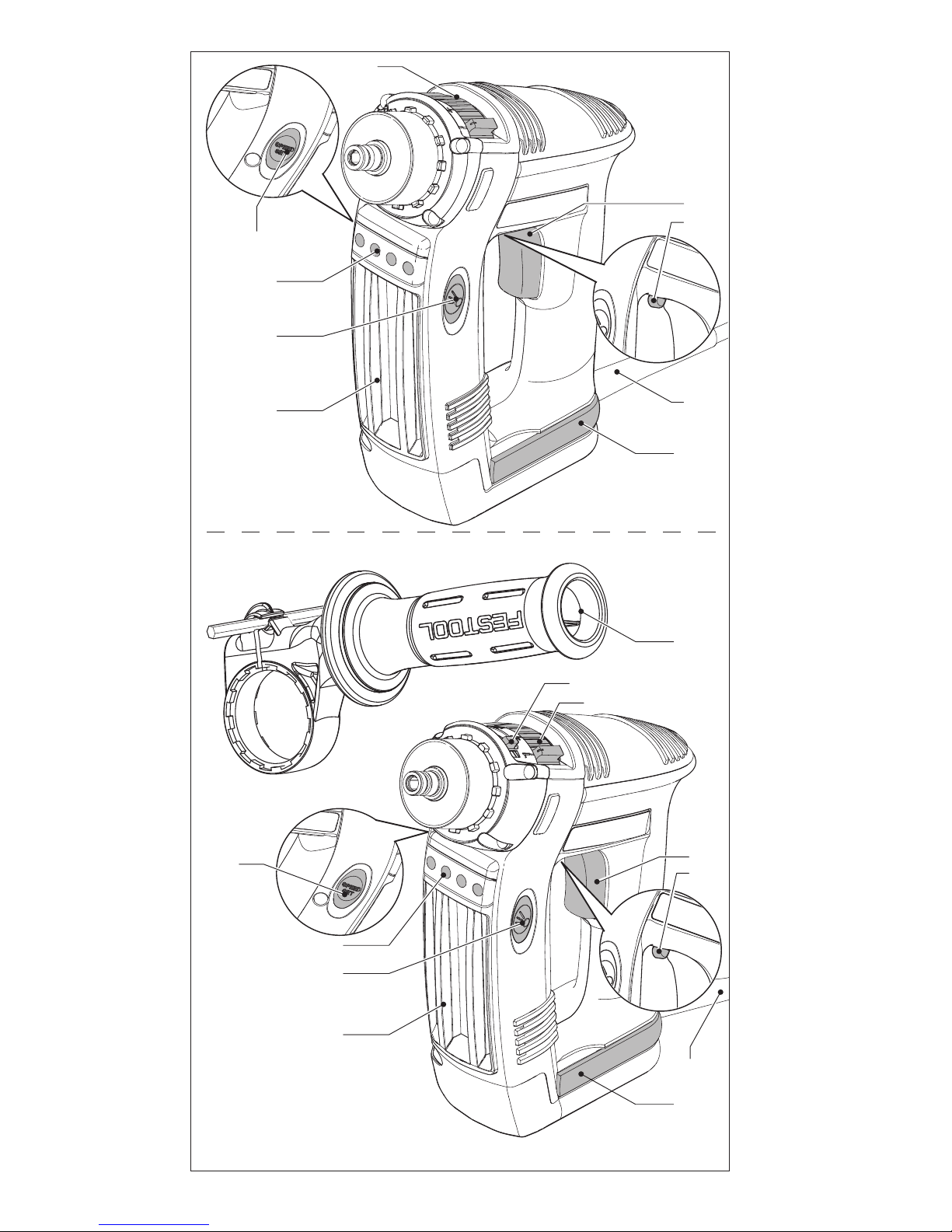

2-2

2-1

2

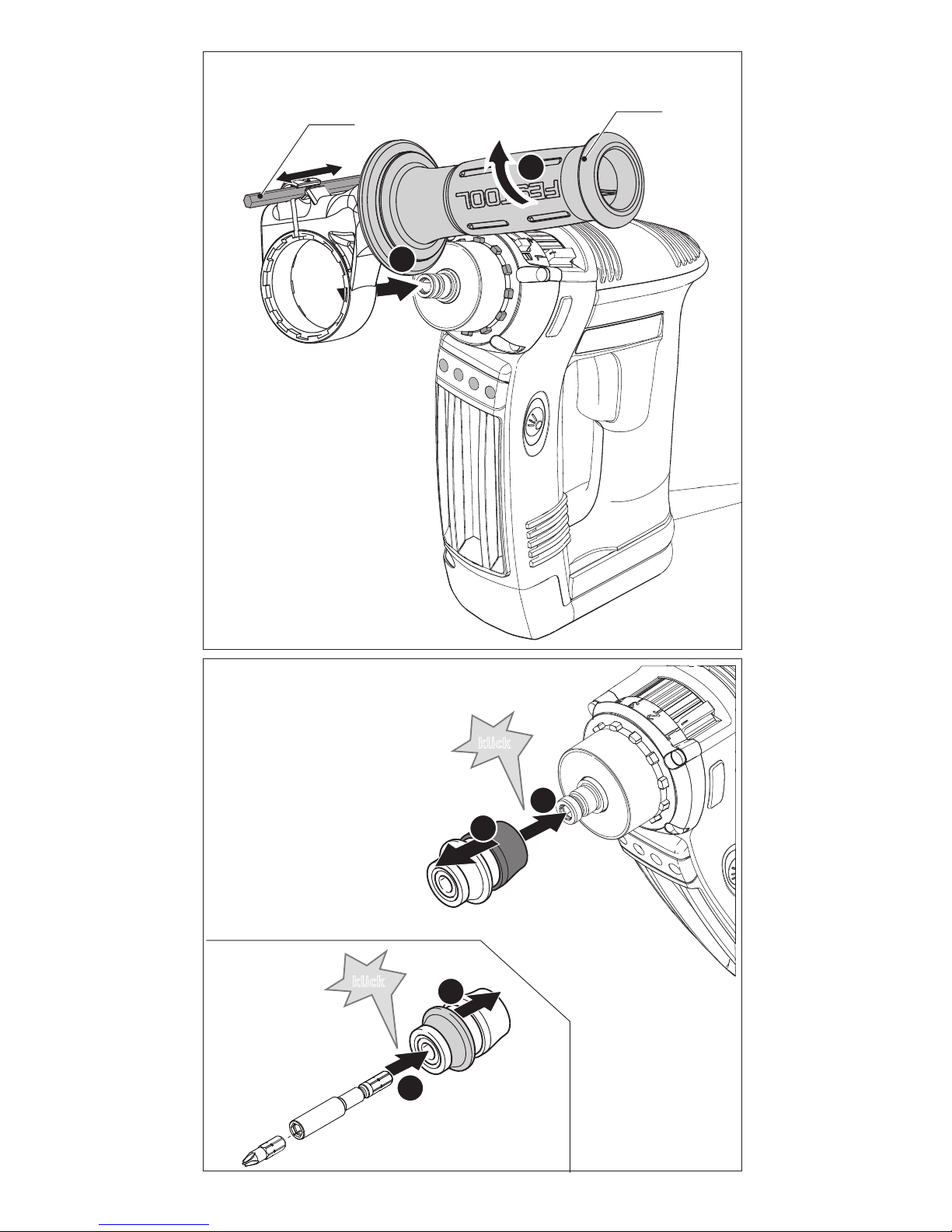

klick

klick

1

3

4

2

1

3

2

Page 4

1

2

2

3

6

4

5

klick

1

5

4

klick

Page 5

6-1

7

6

2

3

4

klick

1

Page 6

Q U A D R I L L

11

GB

Original operating manual

1Technical data

Noise/vibration information

Levels determined in accordance with EN 60745 are

typically:

Vibration emission value a

h

(vector sum for three

directions) and uncertainty K measured in accordance with EN 60745:

The specified emissions values (vibration, noise)

– are used to compare machines.

– They are also used for making preliminary esti-

mates regarding vibration and noise loads during

operation.

– They represent the primary applications of the

power tool.

Drill / Impact drill DR 18/4 E PD 20/4 E

Power 705 W

No-load speed 1st gear 0 - 400

rpm

0 - 400

rpm

2nd gear 0 - 850

rpm

0 - 850

rpm

3rd gear 0 - 1900

rpm

0 - 1900

rpm

4th gear 0 - 4000

rpm

0 - 4000

rpm

Impact count 1st gear - 0 - 8200

rpm

2nd gear - 0 - 17000

rpm

3rd gear - 0 - 38000

rpm

4th gear - 0 - 79000

rpm

Chuck clamping range 1,5 - 13 mm

Max. drilling diameter Wood 50 mm

Metal 18 mm

Concrete 20 mm

Fastening into wood 10 mm

Tool holder in drill spindle 1/4 ’’

Collar 43 mm

Weight 1,7 kg

Safety class /II

DR 18/4 E PD 20/4 E

Sound pressure level L

PA

86 dB(A) 105 dB(A)

Noise level L

WA

97 dB(A) 116 dB(A)

Uncertainty K 3 dB 3 dB

DR 18/4 E PD 20/4 E

Drilling into metal ah = 5.0 m/s

2

ah = 5.0 m/s

2

Impact drilling into concrete - ah = 15.0 m/s

2

Fastening ah < 2.5 m/s

2

ah < 2.5 m/s

2

Uncertainty K = 1,5 m/s

2

K = 1,5 m/s

2

CAUTION

When working with noise

Damage to hearing

Always use ear protection.

Page 7

12

Q U A D R I L L

GB

Increase possible for other applications, with other

insertion tools or if not maintained adequately. Take

note of idling and downtimes of machine!

2Symbols

3 Machine features

The specified illustrations appear at the beginning

of the Operating Instructions.

4 Intended use

The machine

DR 18/4 E

– was designed for drilling into wood, metal, ce-

ramic and plastic.

PD 20/4 E

– was designed for impact drilling into tiles, con-

crete and masonry as well as

– drilling into wood, metal, ceramic and plastic.

Machines with forward/reverse setting are also

suitable for fastening screws and tapping threads.

The user is liable for improper or non-intended use.

5 Safety instructions

5.1 General safety instructions

WARNING! Read all safety warnings and all

instructions.

Failure to follow the warnings

and instructions may result in electric shock, fire

and/or serious injury.

Save all warnings and instructions for future reference.

The term "power tool" in the warnings refers to

your mains-operated (corded) power tool or battery-operated (cordless) power tool.

5.2 Machine-related safety instructions

–

Wear ear protectors when impact drilling.

Expo-

sure to noise can cause hearing loss.

–

Use auxiliary handle(s), if supplied with the

tool.

Loss of control can cause personal injury.

–

Hold power tool by insulated gripping surface,

when performing an operation where the cutting accessory or fastener may contact hidden

wiring or its own cord.

Cutting accessory or fasteners contacting a "live" wire may make exposed

metal parts of the power tool "live" and could give

the operator an electric shock.

–

The machine must never be operated when wet

or located in a damp environment.

Connect devices that you intend to use outdoors via an earth

leakage circuit breaker (FI) with a maximum release current of 30mA. Always use a cable approved for outdoor use.

–

Wear suitable protection:

such as ear protection, safety goggles, a dust mask for work which

generates dust, and protective gloves when

working with raw materials and when changing

tools.

CAUTION! Rebound!

Rotation: Switch off device immediately!

– Do not lock the on/off switch permanently!

– Secure the workpiece using clamping devices.

– Check the plug and the cable regularly and

should either become damaged, in order to avoid

Warning of general danger

Risk of electric shock

Read the Operating Instructions/Notes!

Wear ear protection.

Wear a dust mask.

Wear protective goggles.

Do not throw in the household waste.

Fastening / Drilling mode

Impact drilling mode

[1-1]

Bit store

[1-2]

LED light switch

[1-3]

LED lamp

[1-4]

Speed set button

[1-5]

Switch for selecting drilling/fastening or

impact drilling mode (only PD 20/4 E)

[1-6]

Gear switch

[1-7]

On/Off switch

[1-8]

Right/left switch

[1-9]

Mains power cable

[1-10]

Belt clip

[1-11]

Additional handle

Page 8

Q U A D R I L L

13

GB

a hazard, have them replaced by an authorised

after-sales service workshop.

– Always guide the cable backwards away from the

machine.

– Take care when drilling into walls as there is a

danger of rupturing concealed gas/water pipes

or cutting through power cables.

–

Only for AS/NZS:

The tool shall always be supplied via residual current device with a rated residual current of 30 mA or less.

6Operation

6.1 Switch on/off

On/off switch [1-7]

Press = ON, release = OFF

The speed of the machine depends on how far

the on/off switch is pressed in.

Speed set button[1-4]

Press once = ON, press twice or press on/off switch

= OFF

6.2 Attaching the additional handle[2]

Always use the additional handle.

Position the additional handle

[2-2]

on the extension of the gearbox housing and engage the

recesses on the additional handle in the lugs on

the housing.

Turn the handle until secured in position.

Turn the handle to adjust the position in 30° increments.

The drilling depth can be adjusted using the

depth stop

[2-1]

.

7 Settings

7.1 Changing the rotational direction[1-8]

• Switch to the left = clockwise

• Switch to the right = anticlockwise

7.2 Changing gear[1-6]

Only press the speed switch when the machine is off. Otherwise there is a danger of

damaging the gearbox.

7.3 Selecting the operating mode (only PD

20/4 E)

Fastening / Drilling

Set the selector switch

[1-5]

to the drill bit

symbol.

When fastening

, always remember to work

in 1st gear and at low speeds.

Impact drilling

Set the selector switch

[1-5]

to the hammer

symbol.

The machine was designed for impact drilling

into tiles, masonry and stone.

8 Tool holder, attachments

8.1 CENTROTEC tool chuck [3]

Quick change of tools with CENTROTEC shaft

Only clamp CENTROTEC tools in CENTROTEC tool chucks.

Wear gloves when replacing!

8.2 Chuck [4]

The drill chuck retains the drill or screwdriver bit.

Before initial use:

apply a coat of multi-purpose

grease to the drill spindle.

WARNING

Unauthorised voltage or frequency!

Risk of accident

The mains voltage and the frequency of the power source must correspond with the specifications on the machine's name plate.

WARNING

Risk of injury, electric shock

Always pull the mains plug out of the socket before performing any type of work on the machine!

WARNING

Risk of injury, electric shock

Always pull the mains plug out of the socket before performing any type of work on the machine!

CAUTION

Risk of injury

Clamp the tool centrally in the drill chuck!

Page 9

14

Q U A D R I L L

GB

8.3 Angle attachment [5]

The angle attachment (partly as an accessory) allows the user to drill and fasten at right angles to

the machine.

Prior to initial use:

apply some multi-purpose

grease to the drill spindle and the gearbox neck.

8.4 Depth stop [6]

The depth stop (partly as an accessory) allows the

user to insert screws to a predefined depth. You can

set the dimension by which the screw head protrudes above or is recessed below the surface of the

workpiece.

Depth setting

Turn the housing

[6-1]

to set the

desired fastening depth. Each

detent position changes the fastening depth by 0.1 mm.

Sleeve A/B must be removed before a screw can be

unscrewed.

8.5 Tool holder in the drill spindle [7]

Bits can be inserted directly into the hexagon socket holder of the drill spindle.

9 Working with the machine

Please observe all mentioned safety informations and the following rules when working:

– Only use tools designed for the specified maxi-

mum speed.

– Only sharp tools ensure efficient drilling and pre-

vent machine overload.

– Always use faultless, sharpened HSS drill bits

(HSS: High Speed Steel) when drilling into metal.

– Do not cause the machine to seize through over-

loading.

– Always switch off the machine before placing on

the nut/screw.

– Caution: when inserting long screws, there is a

risk the bit may slip from the screw head and

cause injury.

– Machine vice: clamp the workpiece securely in a

machine vice, for example, before drilling to prevent the workpiece from turning and causing accidents.

9.1 Bit depot [1-1]

Magnetic, for storing bits and bit holders.

9.2 Belt clip [1-9]

The belt clip (right/left) allows the user to attach

the machine briefly to work clothing.

9.3 Lighting

ON: Press the LED light switch

[1-3]

.

OFF: Press the LED light switch

[1-3]

again.

The light remains switched on for approx. 20 s

after the machine is disconnected from the

mains power.

9.4 Warning signals

Acoustic warning signal

An acoustic warning signal sounds and the machine switches off in the following operating states:

Visual warning signal

A visual warning signal is issued and the machine

switches off in the following operating states:

10 Service and maintenance

Customer service and repair

only

through manufacturer or service

workshops: Please find the nearest

address at:

www.festool.com/Service

Use only original Festool spare parts!

Order No. at:

www.festool.com/Service

To ensure constant air circulation, always keep the cooling air openings in

the motor housing clean and free of blockages.

Machine overloaded.

LED

[1-3]

Red - flashing

Machine has overheated.

Press the Speed set button

[1-

4]

to switch the machine to

recovery mode.

Do not place

under load

! The machine

reverts to normal operating

mode once the machine has

cooled, if the Speed set button

or on/off switch are pressed or

the machine is placed under

load.

WARNING

Risk of injury, electric shock

Always disconnect the mains plug from the

socket before performing maintenance work on

the machine!

All maintenance and repair work which requires

the motor housing to be opened must only be

carried out by an authorised service workshop.

peep peep peep

EKAT

1

2

3

5

4

Page 10

Q U A D R I L L

15

GB

11 Environment

Do not dispose of the device in household waste!

Recycle devices, accessories and packaging. Observe applicable country-specific regulations.

EU only:

European Directive 2002/96/

EC stipulates that used electric power tools must

be collected separately and disposed of at an environmentally responsible recycling centre.

Information on REACh:

www.festool.com/reach

12 EU Declaration of Conformity

We declare under sole responsibility that this product complies with all the relevant requirements in

the following Directives, standards and normative

documents:

2006/42/EC, 2004/108/EC, 2011/65/EU, EN 607451, EN 60745-2-1, EN 60745-2-2, EN 55014-1, EN

55014-2, EN 61000-3-2, EN 61000-3-3.

Festool Group GmbH & Co. KG

Wertstr. 20, D-73240 Wendlingen, Germany

Dr. Martin Zimmer

Head of Research, Development and Technical

Documentation

2013-04-20

Drill / Impact drill Serial no.

DR 18/4 E 767832, 767839,

769218, 499928

PD 20/4 E 767833, 467840,

769222, 499926

Year of CE mark: 2013

Loading...

Loading...