Page 1

Getting the Most From the Festool

Domino Machine

Text and Photos by Jerry Work

For many woodworkers the construction of a butterfly leaf dining table like the small one

shown here is considered a rite of passage because it is very difficult to do correctly.

The table tops slide apart to reveal a self storing leaf that folds in the middle. By pulling

up on one half of the leaf both halves rise up to perfectly align with the table top both on

the flat top surface as well as along each edge. Then the two halves of the top slide together to engage the butterfly leaf in its deployed position.

Properly executed,

this operation is a

thing of beauty in

and of itself. Most

people watching a

butterfly leaf table

open for the first

time seem to be

transfixed as they

watch everything

side so effortlessly

into perfect alignment. And, watching

the leaf fold down

and store below the

table top is no less

captivating.

I often caution my

customers to be

prepared for the first

dinner party on their

new table. If the

guests see the butterfly leaf deploy, they

usually will stand around opening and

closing it time after

time just because it

is fun and interesting

to do.

Using conventional

tools and techniques

it is very difficult to

get all the pivot

points in exactly the

right places so designing and building

such a table can be

quite complex and

intimidating. But, as

we will see while we

follow the construction of the table

shown here from

start to finish, using

the innovative Festool Domino ma-

chine and the self

aligning, self squaring and self locking

features of the sliding dovetail joint, build-

Page 2

ing tables such as this one are well within

your grasp whether you are a hobbyist

just starting out or a seasoned furniture

maker with years of experience under

your belt.

The Domino machine is the key.

Also in this manual we will follow the construction of a conventional four leg with

side skirt style of table, an upright chest

with gracefully flaring legs and sliding

doors, and a unique “convertible” coffee

table that can quickly change look and

function.

All of these are easy to build by using

the Domino machine and are all within

your reach as well.

How should we describe this innovative tool?

to precisely aligning two or more components during assembly operations, to

making hidden latches, stops and door

slides, and much more.

As you progress through this manual I

think you will enjoy seeing examples of all

of these uses and the opportunity to learn

more about this truly remarkable and

unique woodworking tool.

Early in the U.S. introduction planning I

was asked by Festool USA how I

thought the machine should be described. Because I had lots of experience with loose tenon joinery using the

three dimensional sliding table on my

industrial slot mortising machine, I first

described it in those terms. At that time I

wrote that I would describe the Domino

machine as, “a portable loose tenon

jointer with great positional accuracy.”

And, as we will discover moving through

this manual, it certainly is that.

However, as I used the Domino machine

on more and different projects, it evolved

in my head to something much more than

those words could capture. The Domino

machine solves a whole range of woodworking issues from joining two pieces of

wood in all six ways one can joint two

pieces together, to handling a myriad of

wood movement problems that are always a part of building with solid woods,

The author, Jerry Work, designs

and hand crafts fine furniture in

the 1907 Masonic Temple building in historic Kerby, OR, where

visitors are always welcome.

glwork@mac.com

www.jerrywork.com

Page 3

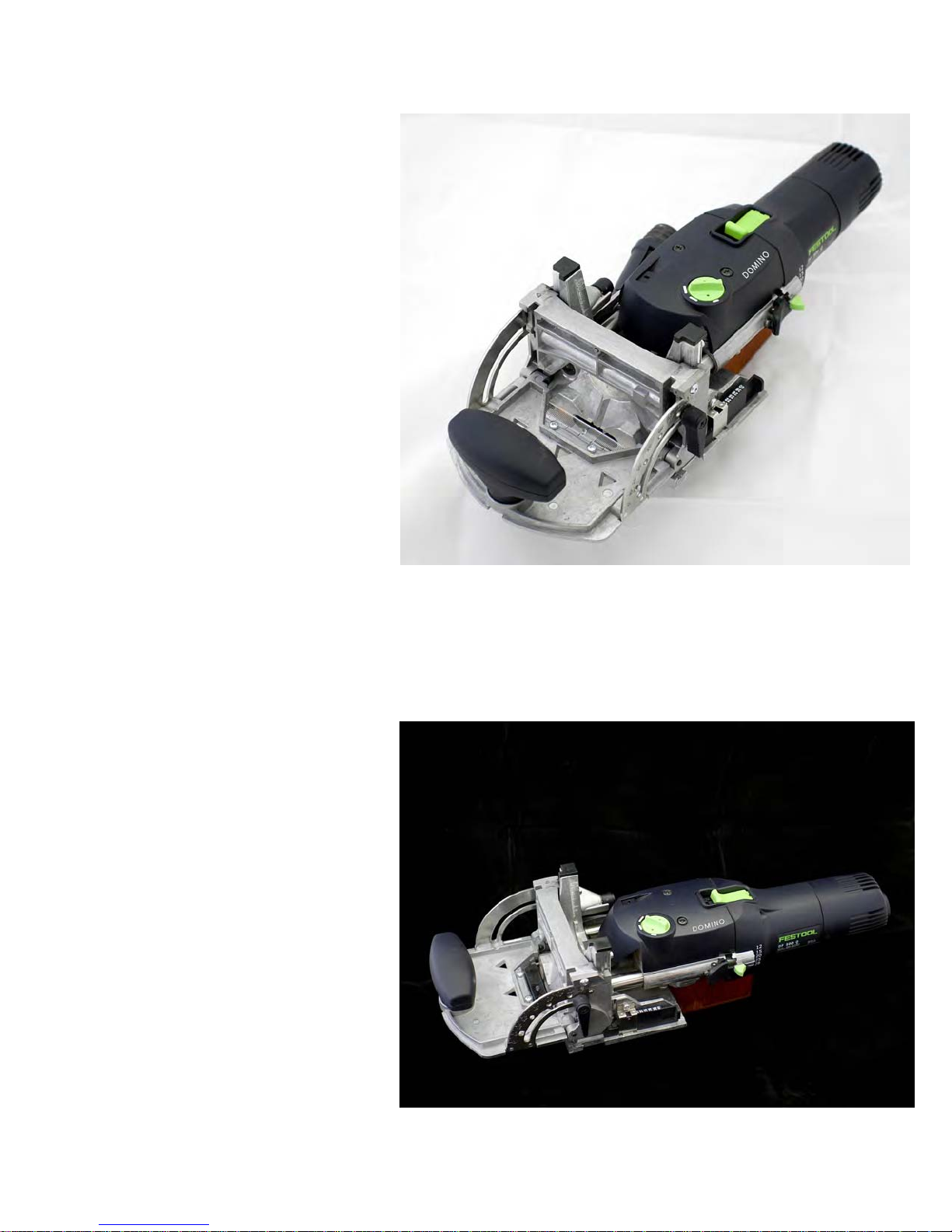

What is a Domino Machine?

Let’s begin by exploring the tool

itself. It is made up of a body

with a unique mechanism that

both rotates and oscillates a

drill-like cutter bit. The body

slides nearly effortlessly on two

hardened steel shafts built into

the fence section of the tool.

Once aligned where you want

the cut to be made, you push

the body towards the work piece

to produce an elongated slot,

most commonly called a “mortise.”

The Domino machine fence and

positioning systems allow you to

center that slot both horizontally

and vertically very accurately.

Built into the machine are adjustments for the width and the depth of the

slot. The cutters can be interchanged

easily and quickly and come in 5mm,

6mm, 8mm and 10mm diameters producing slots of those widths.

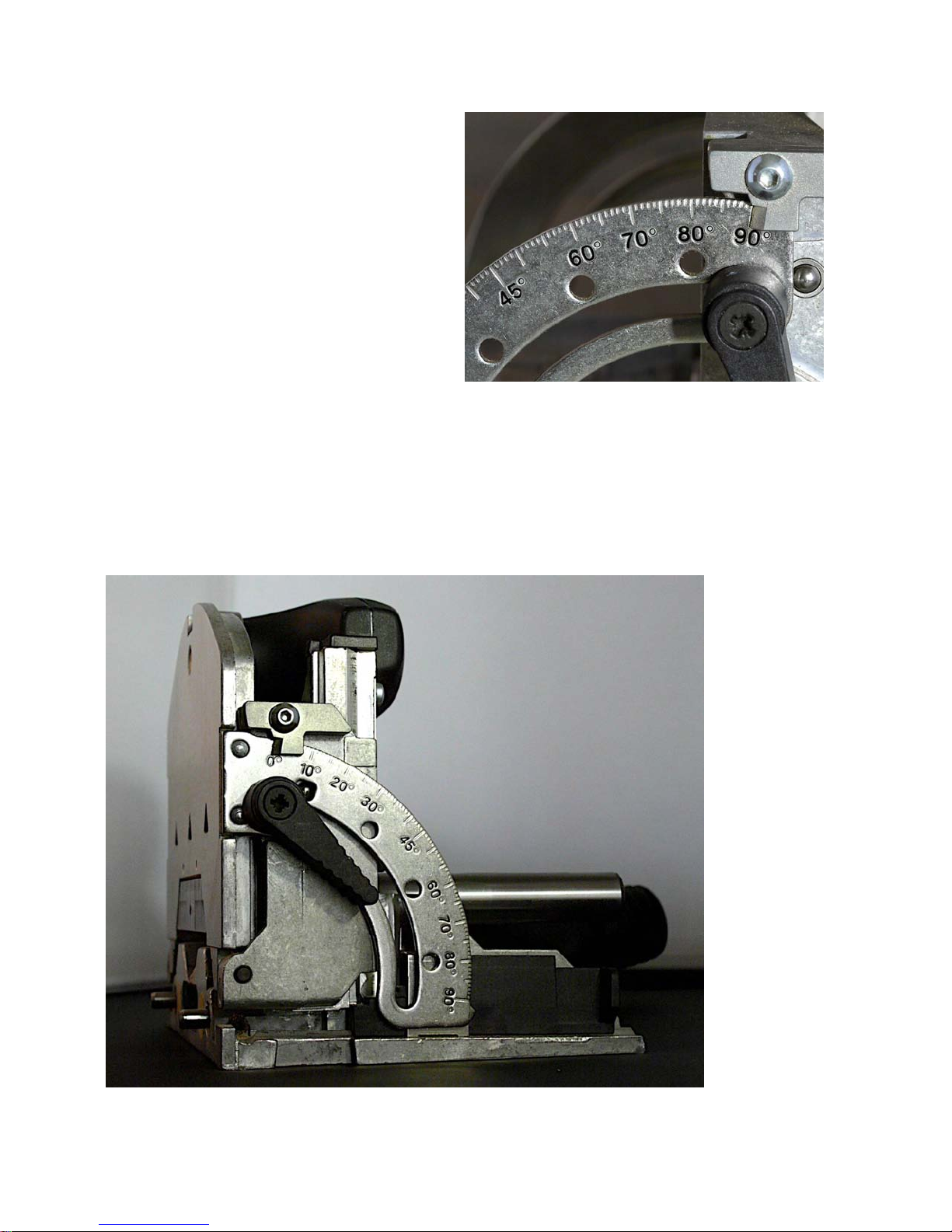

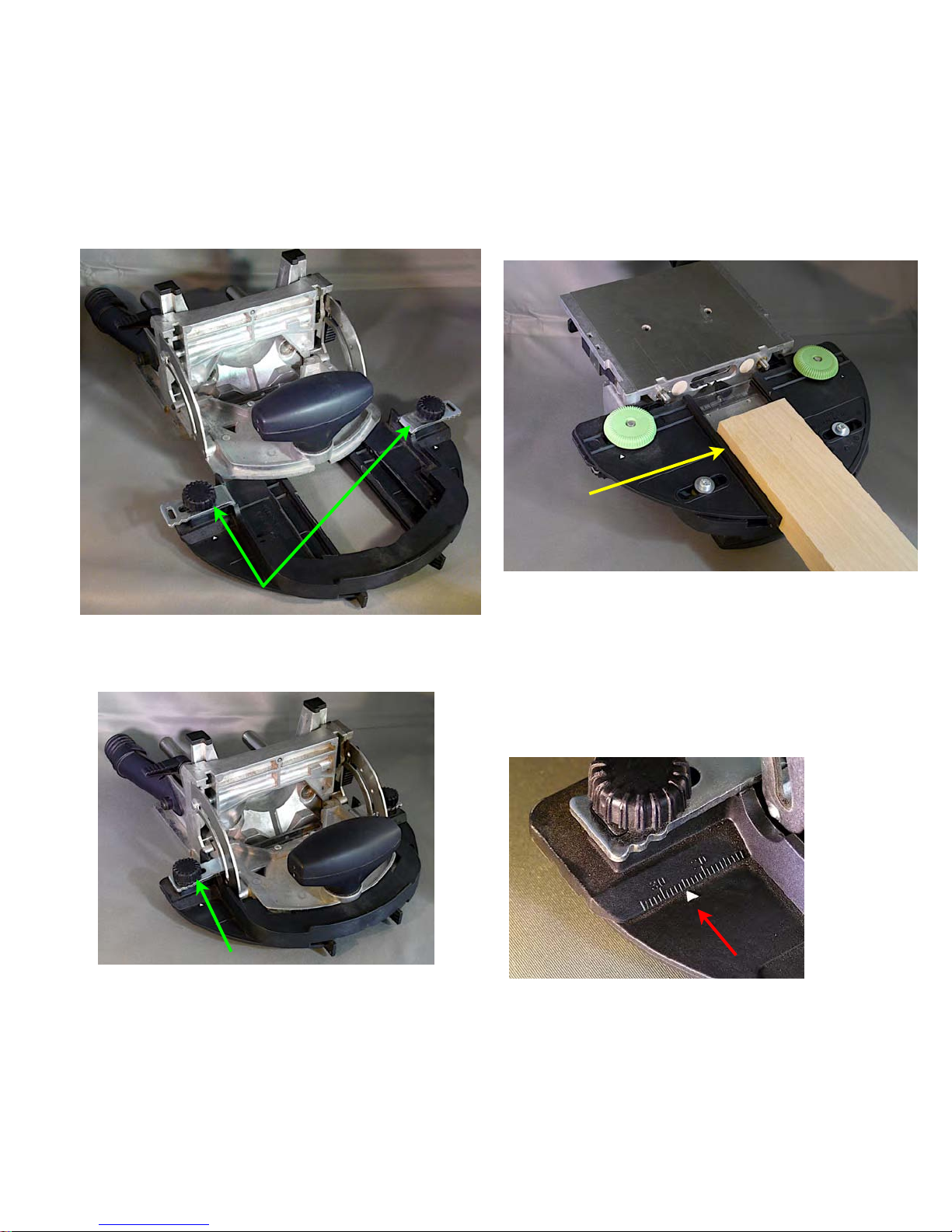

The pictures on this page show the Domino in broad view. As we come in closer

with the detailed photos on the next few

pages we will see the many precise adjustments and alignment aids.

The idea is to cut a mortise slot

into which you can insert a premade wooden tenon which Festool calls a “domino,” hence the

name of the machine.

You can make your own if you

want to, but the pre-made Festool tenons are extremely

strong, very precisely dimensioned to fit perfectly into the

mortise slot cut by the Domino

machine and they are quite

economical to buy. My recommendation is to simply use the

Festool dominos and not try to

reinvent that wheel on your own.

Page 4

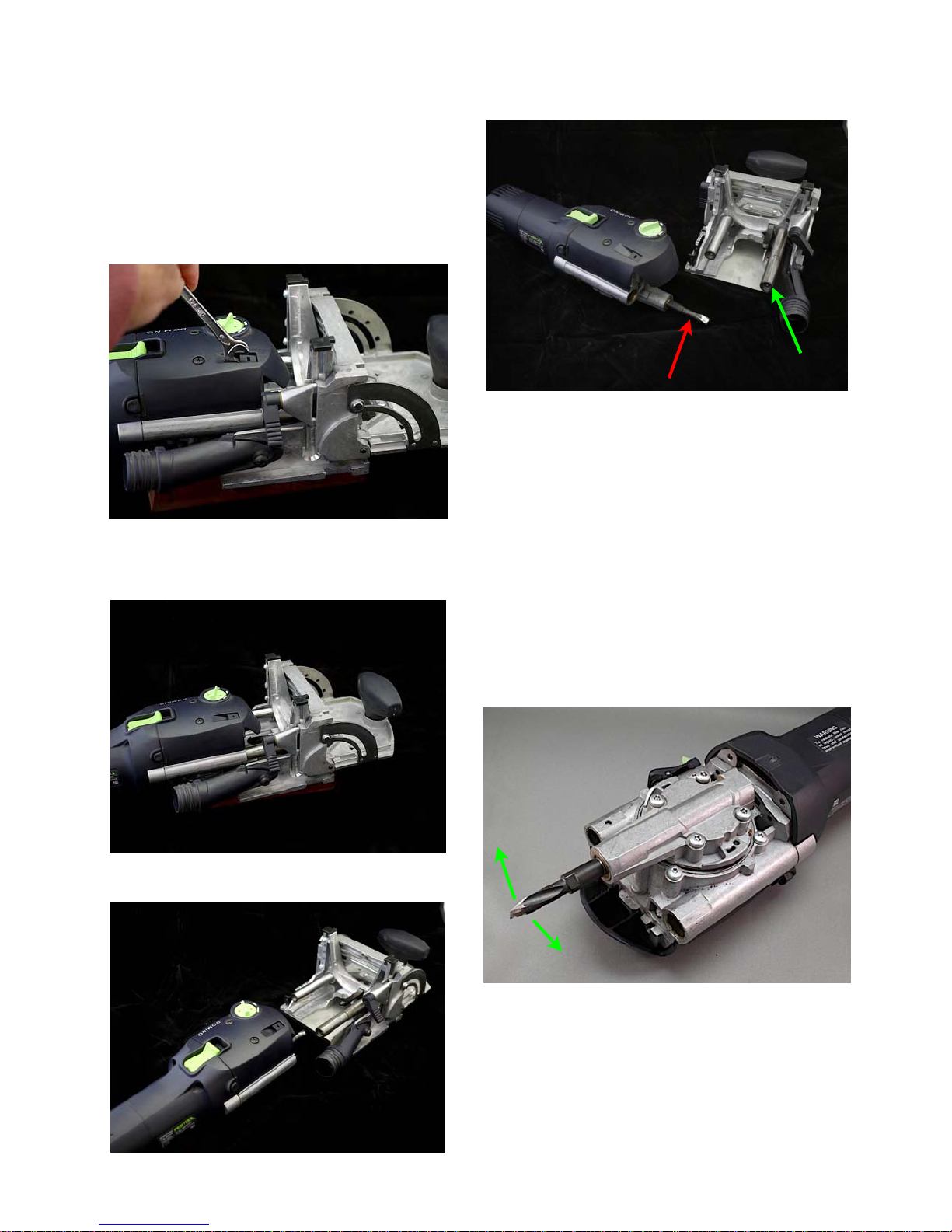

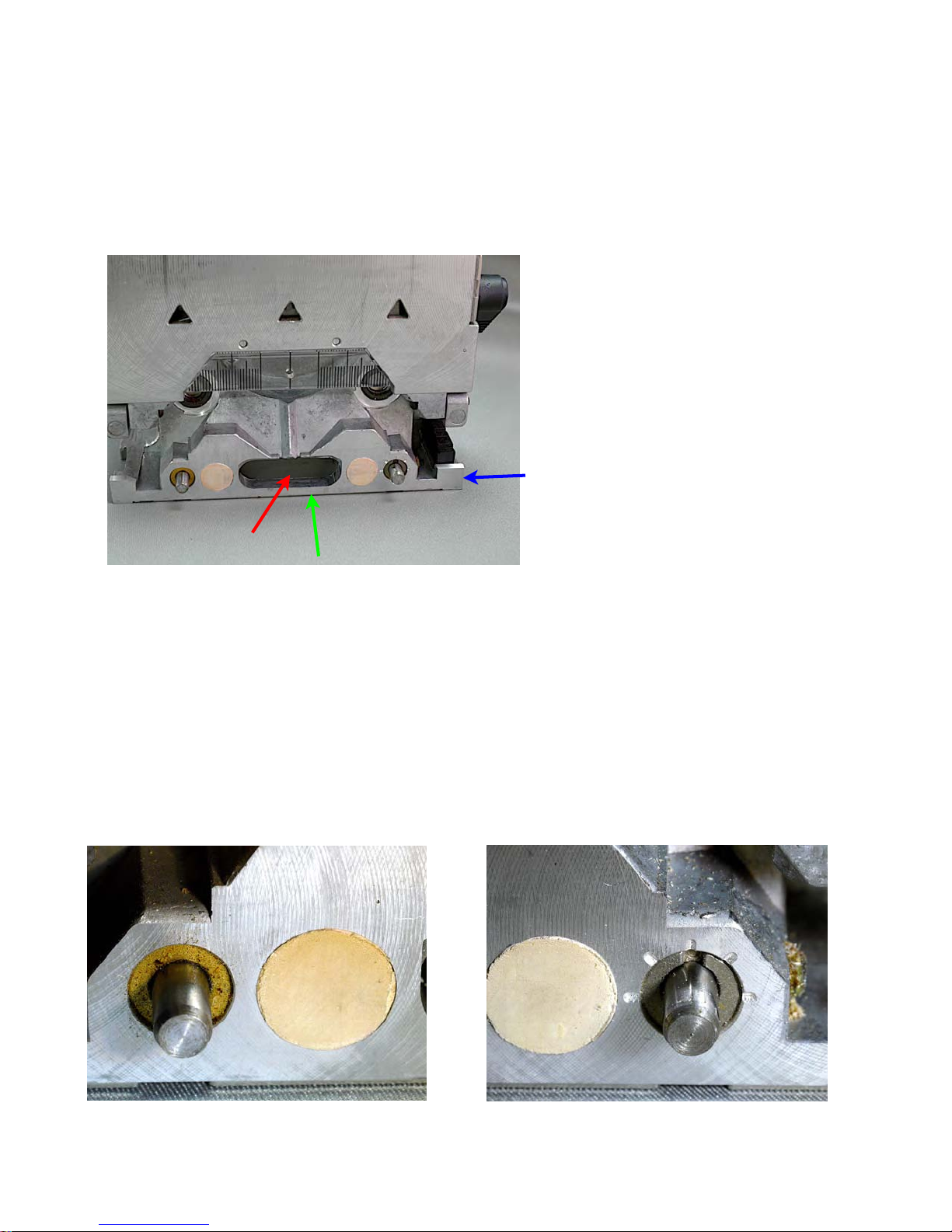

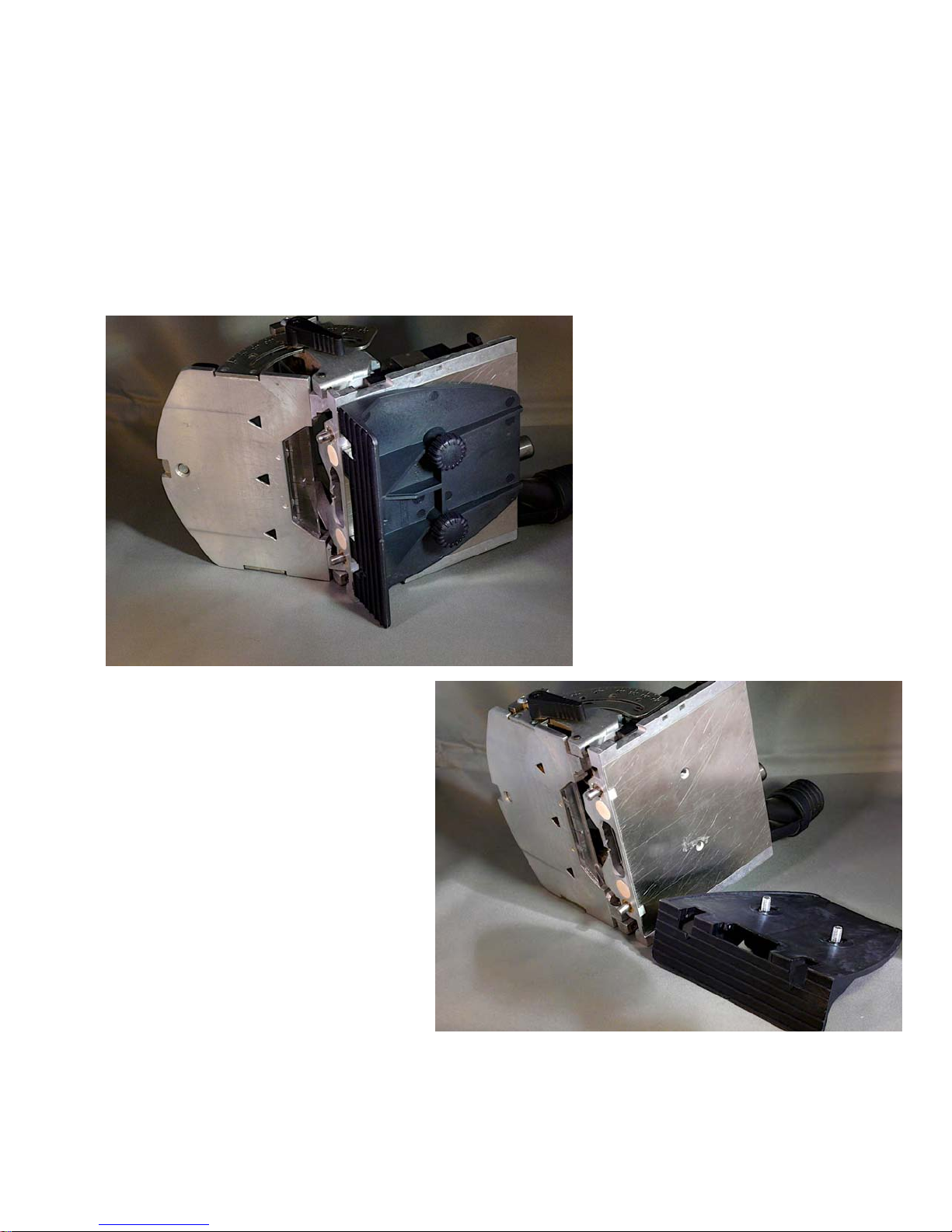

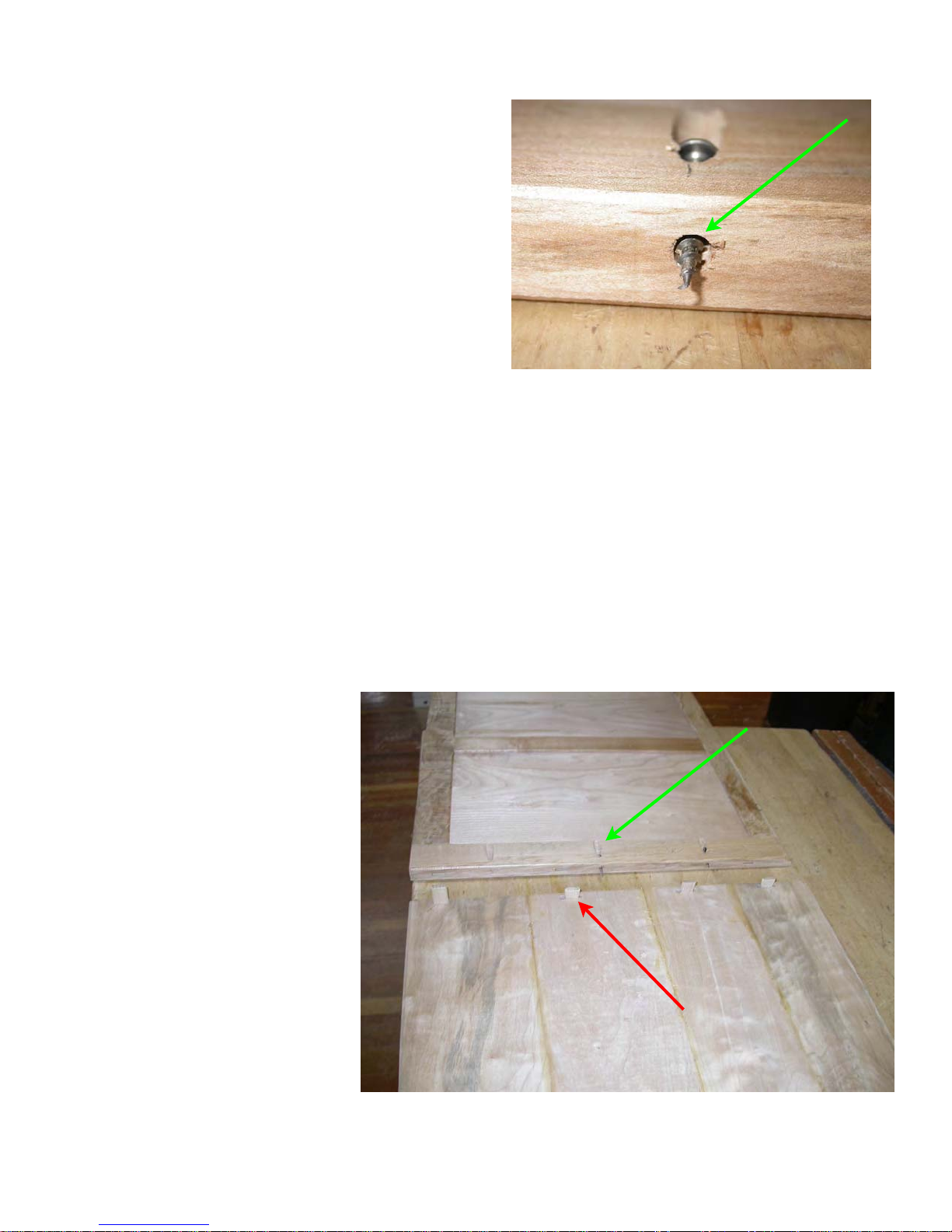

The Domino Body

This sequence of photos shows how the

body and fence can easily be separated

by simply raising the lock tab as shown

here. The wrench used to change cutters

is ideal for this. Hook the edge of the

wrench beneath the lock tab and lift it up.

The fence will start to slide off the body

as shown in the photos left and above

exposing the rotating and oscillating cutter (red arrow).

In the photo above you can see the two

hardened shafts (green arrow pointing to

the right shaft) that the body slides on as

you push the body in to cut the mortise

slot. They ensure the mortise slot will be

exactly parallel to the base of the Domino

machine, one of the keys to Domino’s

impressive accuracy.

Here is a view of the under side of the

body. The round housing held by the four

screws is gear driven to move the cutter

tip back and forth in a horizontal arc while

the cutter is also rotated to make the cut.

Page 5

The cutters can be easily changed as

they just screw onto the threaded end of

the gear-driven shaft as shown by these

photos.

comes with the set of domino tenons.

Above, the wrench is positioned on the

flats of the cutter tip. The shaft lock button is on the side of the Domino body

right where the thumb on one hand can

easily press it while you loosen or tighten

the cutter with the wrench held in the

The photo below shows the cutters with

other hand. In the photo above I moved

my thumb down so you can see the shaft

lock lever (red arrow).

The cutters are available in four different

diameters, 5, 6, 8 and 10mm. The 5mm

cutter comes standard with the machine

itself and the four cutter set shown above

their respective Domino tenons for size

comparison.

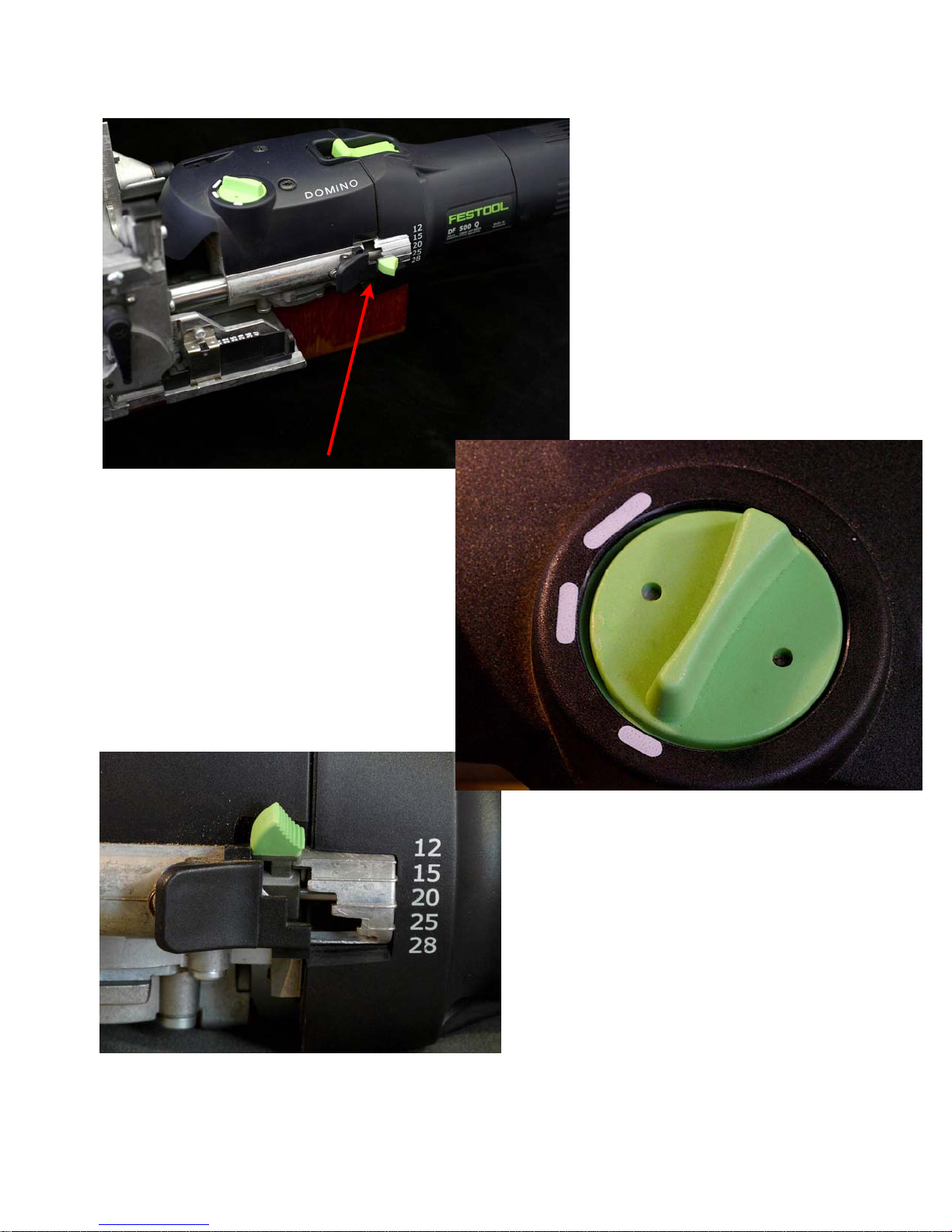

Page 6

Depth of cut is controlled by a lever on

the side of the Domino body (red arrow

above and in detail below). Settings

are for depths of cut of 12, 15, 20, 25

and 28mm. This is the depth measured from the front of the fence to the

bottom of the mortise. Lift the black

safety catch and move the green depth

lever to align with the desired depth of

cut. To allow for some glue build up in

the bottom of the mortise as the tenon

shorter than the depth of the

corresponding mortise.

The top green knob turns to

set the desired width of cut.

Three settings are provided.

The narrowest width (the setting shown below) matches

the supplied domino tenon for

each domino (tenon) thickness. The 5mm thick domions are just under 19mm wide

scaling up to the just under

23mm width of the 10mm

is inserted, the actual length of the Festool supplied tenons is about 1.5mm

thick dominos.

At the minimum width of cut setting

(the way the width knob is set in this

photo) the cutter bit oscillation is

13.7mm. With a 5mm cutter bit the

overall cut mortise slot will be 13.7 + 5

= 18.7mm wide, nominally 19mm.

Move the knob to the intermediate

width of cut setting and the oscillation

increases from 13.7mm to 19.2mm

resulting in a slot 24.5mm wide for the

5mm cutter bit. The tenon still fits tightly

Page 7

into the sides of the

mortise slot, but the

slot is longer than the

width of the tenon allowing some assembly

adjustment room side

to side. The third width

setting increases the

oscillation to 23.2mm

resulting in a 28.2mm

mortise slot which provides close to 10mm

side to side adjustment

room.

The ability to vary the

slot width is key to

many of the Domino

machine attributes. As

indicated, at the narrow

setting the domino tenon fits tightly into

the slot. At the wider settings the thickness of the domino tenon fits tightly into

the mortise slot front to back, but the

domino tenon is free to shift side to side.

We will see numerous examples of when

and where you want to use tight fitting or

over-width mortise slots as we progress

through the manual and show actual projects in process.

When you cut a tight mortise (width knob

at the narrowest setting) at the same location on two different boards, that one

M&T joint will keep the two boards

aligned as desired. Placing wider mortise

slots along the same face of one of the

two boards means the remaining domino

mortise slots can be cut with some margin for positional error while still allowing

the joint to close properly, a great advantage over dowel joints where the positional accuracy must be dead on or the

joint simply will not close up at all.

Since the majority of the strength of a

loose tenon joint is derived from the fit

and glue surface on the faces of the mortise slot and the faces of the tenon, little

strength is lost when the width of the mortise is greater than the width of the tenon.

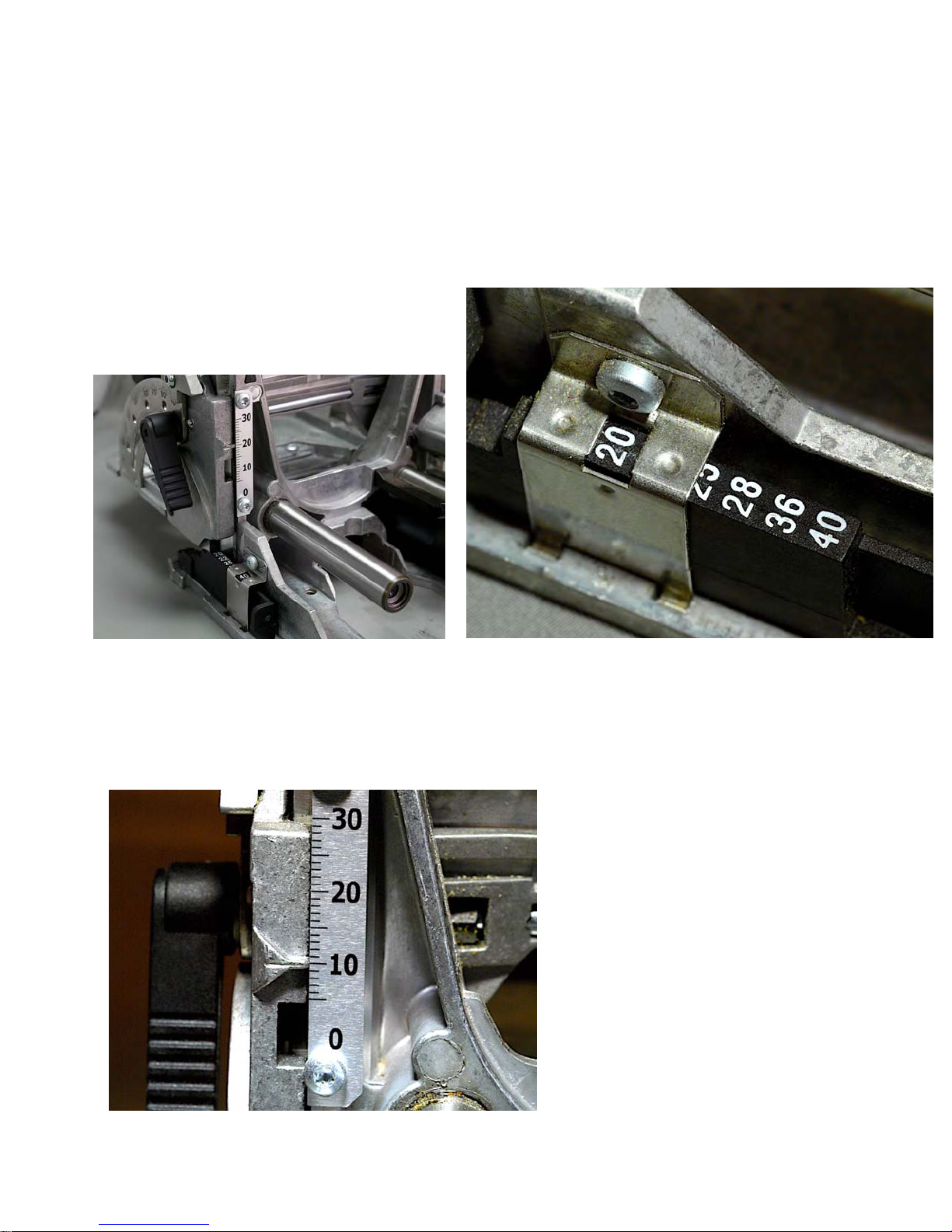

Page 8

The Domino Fence

Now let’s look at the adjustments on the

fence part of the Domino machine. In this

photo we are looking at the back side of

the fence with the body removed. You

can see one of the two hardened steel

rods that the body slides on as it moves

the cutter in and out of the work piece

keeping the mortise slot parallel with the

base of the fence.

10mm above the centerline of the cutter.

A lock lever secures the fence at the desired height. The fence moves up and

down on machined ways so it remains

exactly parallel with the cutter at all

heights.

The first adjustment to consider is the

height the fence is above the horizontal

centerline of the cutter. That is shown

by a scale and pointer. In the close up

photo below the fence is set to be exactly

For rapidly setting the fence to common

heights above the horizontal centerline of

the bit, a stop block (shown in detail

above) is provided that slides back and

forth to reveal different step heights. The

fence sits on the top of a stop

block step, positioning it exactly

an indicated distance above the

horizontal centerline of the cutter.

The stop block (shown here at a

setting of 20mm) is marked in

units corresponding to the overall

thickness of the work piece for

which the cutter will be exactly

centered. In this case the stop

block is set for a 20mm thick work

piece resulting in the pointer

(photo left) indicating that the centerline of the cutter will be at

10mm.

Page 9

The stop block is marked to center the

bit on work pieces 16, 20, 22, 25, 28, 36

and 40mm thick.

You can also simply use the height

scale to set the fence any distance you

want it to be above the horizontal centerline of the bit within the range of 7mm

to 30mm.

The minimum height of 7mm ensures

that a 10mm cutter will leave a minimum

of 2mm of wall between the upper side

of the mortise slot and the upper side of

the work piece so you don’t inadvertently

drive the cutter into the bottom side of the

fence.

The fence also rotates from 90 degrees

angle relative to the edge of the work

piece (meaning the fence is parallel with

the cutter) to zero degrees relative to the

edge of the work piece (meaning the cutter is moving perpendicular to the fence

the way it is shown in the photo left).

Ball detent stops are also provided for

common intermediate

settings, or

you can simply set the

angle with the

protractor

scale and

pointer. The

pointer is adjustable so

you can calibrate the angles to be

dead on.

Now let’s look

at the variety

of alignment

marks to help

you place the

mortise slots

exactly where

you want

them.

Page 10

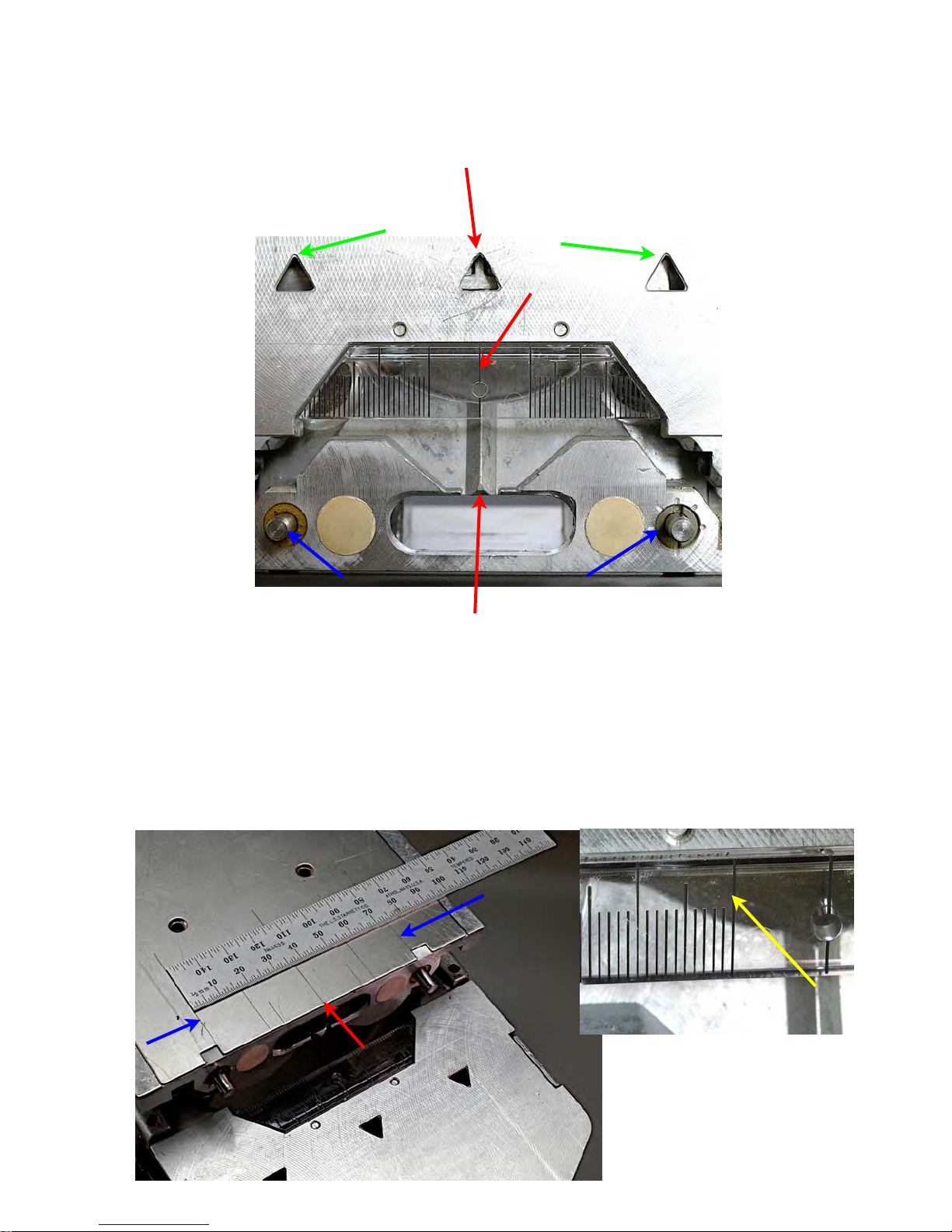

This first photo is looking at the front of

the Domino fence with the fence piece

raised to the zero degree angle for clarity

of view. The slot in the center towards

the bottom (red arrow) is where the cutter

emerges when the body is pushed towards the work piece to make the mortise

cut. The cutter centerline is 10mm up

from the base of the fence assembly

(green arrow above).

Two alignment pins are spring loaded and

are set 74mm apart so each is 37mm

from the centerline of the cutter.

The right and left spring loaded alignment

pins are shown in detail below. The right

pin is mounted in an eccentric with a

screwdriver slot by which you can turn

the eccentric to bring the two pins into

exact alignment the same distance

from the vertical centerline of the

cutter. The left pin is fixed in position 37mm from the vertical centerline of the cutter and 24mm from the

outside of the pin to the outside

edge of the fixed portion (base) of

the fence (blue arrow).

The pins are 5mm in diameter so

the base is machined to be 132mm

wide or 66mm from outside edge to

vertical center of cutter. All of these

measurements are very useful to

keep in mind as they each can play

a role in helping you precisely position the center of the Domino mor-

tise slots.

When you first get your machine, make

sure the adjustable fence height pointer is

exactly on 10mm when the fence is on

the stop block marked 20mm, the angle

pointer is exactly on mark, and the distance between the two spring loaded pins

is 74mm. Adjust the right pin shown below if necessary.

Page 11

The vertical centerline of the cutter is also

marked in several other ways (red arrows) as well: by the “V” cast into the

fence base, by the line scribed on the

clear plastic

reference

scale attached

to the moving

portion of the

fence (note

the hole in the

plastic denoting center),

and the point

of the triangle

cast into the

moving portion

of the fence.

The outer two

triangles

(green arrows)

cast into the

moving portion of the fence have points

that are exactly 74mm apart, the same

as, and aligned with, the inside edges of

the spring loaded alignment pins (blue

arrows).

There is yet one further set of marks denoting the vertical centerline of the cutter.

These are scribed on the bottom of the

base of the fence (the fixed portion). I

placed a rule on the inverted base of the

fence for the bottom left photo so you can

see the centerline of the cutter lined up

with 37mm

on the rule.

The left end

lines up

with the

mark for

the inside

of the left

spring

loaded

alignment

pin while

the mark

denoting

the inside

of the right

alignment

pin is at

74mm.

5mm beyond the left end of the rule and

the 74mm mark are lines denoting the

outside edges of the alignment pins.

Two additional sets of scribe lines are set

15mm from the vertical centerline of the

bit (the shorter lines) and 20mm from the

bit center (the longer lines).

The photos above show

the clear plastic alignment

scale that tilts with the

Page 12

moving portion of the fence. As we saw

earlier, the center scribe line with the circle cut through it is the horizontal center

of the bit oscillation movement and hence

is the side to side center of any mortise

slot cut with any bit. Long scribe lines are

10mm increments (yellow arrow) while

the shorter lines are 1mm and 5mm increments on this clear plastic guide.

Here is a picture of the guide taken from

above the fence when it is lowered to the

horizontal position parallel with the bit oscillation. In use, it is quite visible and I

am constantly impressed by just how

close I can set the Domino mortise slot

with just this visual reference.

Once you start using the Domino you will

quickly learn to trust the marks and, so

long as you lay out your mortise slots

around centerline measurements, you

can achieve great accuracy and also do

all kinds of offsets using just your layout

mark and these several methods of aligning the Domino.

The spring loaded pins are especially fast

and accurate. By hooking one of the pins

over an end or edge of your work piece,

you will place a mortise slot centered ex-

actly 37mm from that edge no matter

what size cutter you use or what slot

width setting you choose.

Take the case of an end to edge joint

such as creating a 90 degree joint which

properly lines up the outside

edge of both pieces. Set

the fence height to place

the mortise slot where you

want it on the edge and end

of the work pieces, set the

depth of cut you want and

set the slot width to the narrowest mark (shortest white

icon of the three surrounding the green round width

adjustment knob). Hook the

alignment pin over the end

of one piece and make the

mortise cut in that edge.

Next hook the pin over the

edge of the mating piece

and make the cut into that

end. Put the Domino tenon

in place and the edges of the joint will be

perfectly aligned with no layout marking

on your part at all.

It is that easy!

Before we move on to look at all six ways

that two boards can be joined and see

how these various alignment marks and

pins are used to precisely position your

M&T Domino joints, there are three more

positioning aids we need to examine. All

come standard with the Domino Set (574-

283). If you want just the machine itself

with only a 5mm bit, that is item number

574-258.

Page 13

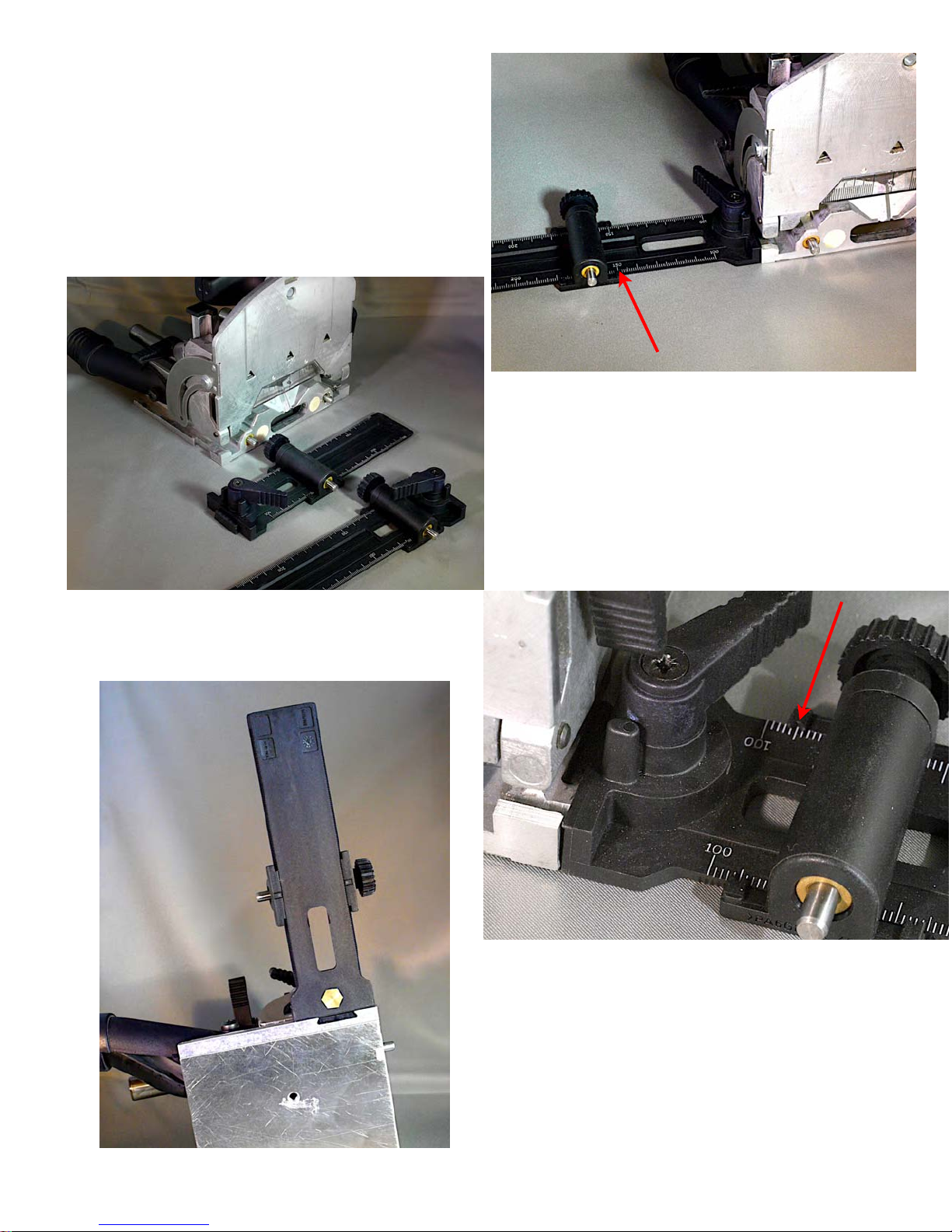

The first is a two part fence extender.

One part attaches to each side of the

Domino fence and each features a movable spring loaded reference pin and numeric scale. They attach by a clever

dovetail machined into each side of the

In the photo above the inside edge of

the spring loaded pin is set to be 150mm

away from the horizontal center of the

mortise slot. The red arrows show the

alignment scale and pointer.

In the close-up below the pin is set so it

would register the work piece to position

Domino base as shown in the photo below taken from the bottom of the base.

the mortise slot 105mm away from the

edge of the work piece that rests against

the stop pin.

Page 14

The second very useful positioning ac-

cessory is a saddle fence that attaches

to the bottom of the moving portion of the

fence. Here the Domino body is removed

from the fence to make it easier to see.

the in-out motion of the cutter (yellow arrow). They capture and hold the edges of

the work piece making it easy to cut mortises in the end grain. The green knobs

secure the fences in the desired position,

The saddle fence slides onto the fence

and locks in place via the two black

knobs and metal fingers (green arrow).

The photo above right shows the bottom

of the saddle fence. It features two movable fence elements that run parallel with

and on top (detail below), is a scale that

indicates how far away those fence sides

are from the vertical center of the mortise

slot.

Want to cut a 10mm mortise in the center

of the end of a 20mm x 50mm work

piece? Set the fence to 10mm high and

set the two sides of the saddle fence to

25mm as shown above. The resulting

mortise will be exactly centered in the

Page 15

end grain no matter which cutter you use

or which width setting you select. Neat!

The third accessory is for stabilizing the

Domino machine when used upright cutting into the face of a work piece registered off of an edge. It is an auxiliary

fence that screws to the bottom of the

Now that we are familiar with the

Domino machine and the variety

of ways to accurately register the

location of the mortise slot, let’s

take a look at the six ways you

can join two pieces of wood together.

Then we will move on

to several build-along

projects that show the

amazing versatility of

this innovative wood

working tool.

moving portion of the Domino fence.

This photo shows it installed with the

fence set to 45 degrees. Right is a

photo showing the auxiliary fence

before it is mounted to the bottom of

the moving portion of the Domino

fence, shown here set at zero degrees (perpendicular to the movement of the cutter.)

Page 16

There are only six ways you

can join two pieces of wood

together.

I will refer to the surfaces of a board

as the faces (the wide flat top and

bottom of the board), the edges (the

sides of the board) and the ends.

Boards can be joined:

1) edge-to-edge

2) face-to-face

3) end-to-end

4) edge-to-face

5) end-to-face

6) end-to-edge

Do that on both boards. Since the spring

loaded pins set the horizontal mortise

center and the fence sets the vertical

mortise slot center, the ends and the

faces of the two boards will be perfectly

aligned. In the photo above you can see

that I mark the end aligned with the

spring loaded pin with an “X” mark. That

mortise is centered 34mm in from the

edge.

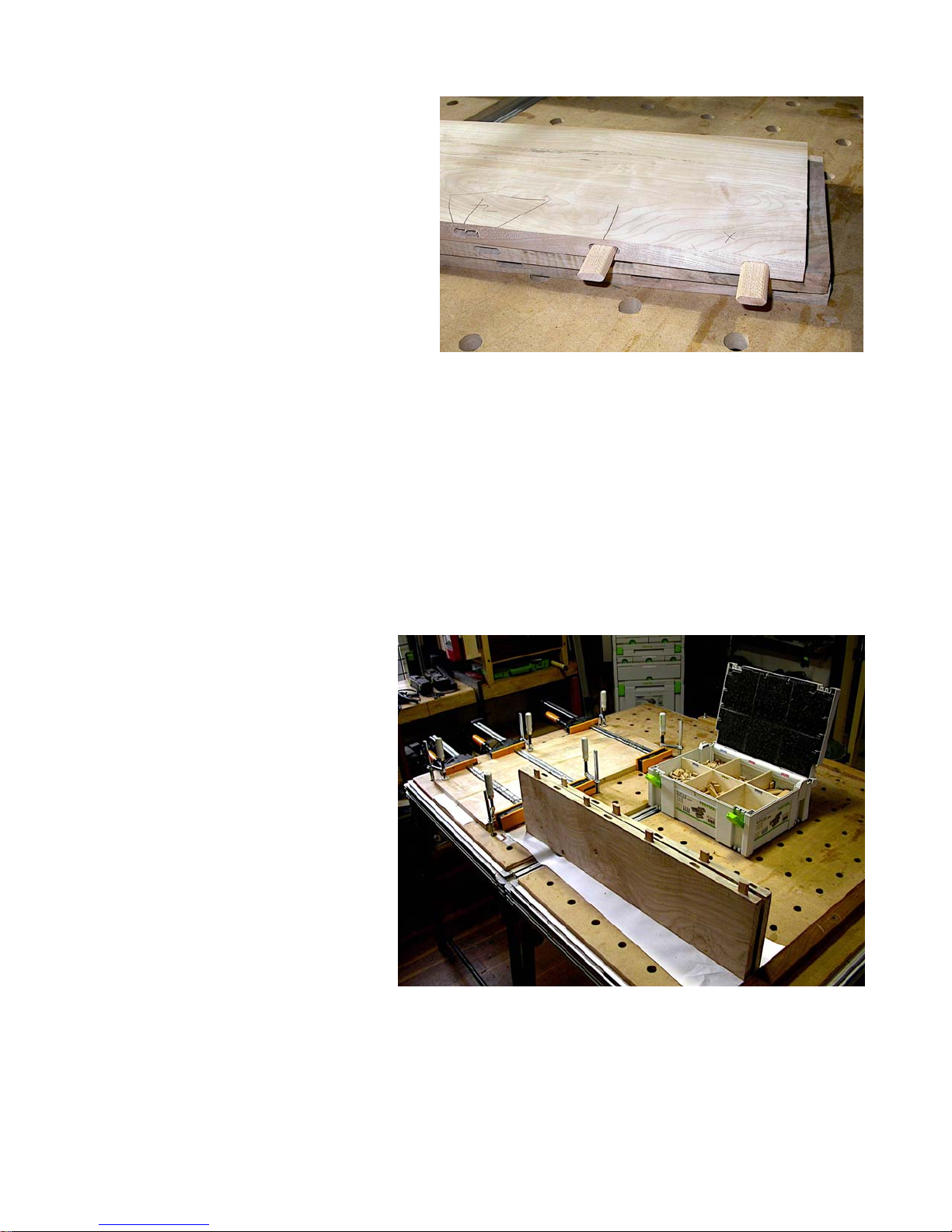

Edge-to-edge is a common op-

eration any time you need a

board wider than the stock you

have on hand. We usually call

that a “glue up” or a “panel

joint.”

Reinforcing and properly aligning this edge-to-edge joint is

easy, very fast and very precise

with the Domino machine. Set

the slot width to narrow, the

fence to 90 degrees and the

fence height to half the work

piece edge thickness. Hook the

pin over one end of each piece

to be joined while pressing the

fence down on the face of what

is to be the top or good surface

of the glue up. Turn on the Domino machine and push the body towards the

work piece until it bottoms out at the desired depth of cut to machine the mortise

slot.

I suggest you always work with the

fence on the top or “good” surface of

your work pieces so those faces will

align even if the two work pieces are

not exactly the same thickness.

Page 17

Add additional Domino mortises along the

edges of each board using either of two

methods. First you can use the excellent

two part fence extender (called a “side

stop” in Festool literature) we saw earlier.

Set the pin spacing to match the desired

mortise to mortise spacing. By hooking

the alignment pin in the edge of the mortise you just cut, the next mortise will be

spaced over by that amount. Progress

across both board with the same settings

and the mortises will all align perfectly.

You also can align by just marking the

desired locations with a pencil line across

both boards. Leave the slot width set to

narrow and cut mortises with the bit center mark aligned with each of your pencil

lines on one of the two boards to be

joined. Reset the slot width to the wider

slot setting and cut the remaining mortise

slots in the second board (shown in the

photo at the top of the previous page).

Since the first mortise slot in each board

is the same width as the Domino tenon,

that one M&T joint will align the two

boards end to end. The slightly wider

mortise slots you cut for the remaining

mortises in the second board will offset

any minor misalignment that might be

present, allowing the two edges of the

boards to come tightly together with the

faces perfectly aligned.

The Domino mortise slot to Domino tenon

fit is much tighter than is the case with a

biscuit jointer so the face to face alignment is much better. The Domino tenons

are also a lot stronger, set deeper and

provide more glue surface area than a

biscuit so a Domino reinforced edge-toedge joint is superior in every way to an

equivalent biscuit edge-to-edge joint in

my experience.

While you can cut these Domino mortise

slots at any height down the edge from

the face of the boards, conventional “wisdom” would have you place them in the

middle of the two work pieces to be

joined. Usually the recommendation is

to use a tenon one third the thickness of

the work pieces to be joined thereby leaving an edge to slot width the same as the

tenon width.

In working with Dominos I find I prefer to

use a Domino that is half, rather than one

third, the thickness of the work pieces to

be joined. The Domino tenons do not

swell up the way biscuits can and the

grain runs the length of the Domino tenon. Since the Domino penetrates into

the edge of the work piece a relatively

long way (anywhere from 15 to 25mm

depending on the tenon length you use,)

the bending moment is spread over

enough distance that even on a stressed

joint the relatively thinner wall provides

plenty of support.

Now let’s look at the case of a common

end-to-edge joint, such as you find in rail

and stile work.

Because it is so easy to calculate dimensions in my head this way, I commonly

use rail and stile components that are

50mm wide by 20mm thick and panel

slots are 10mm wide by 10mm deep and

centered on the 20mm thick work piece

edges or ends.

A Domino mortise and tenon centered on

the 20mm thickness of my work pieces

matches these standards perfectly. And,

I can reinforce the glued up 10mm thick

panels by using a 5mm centered Domino

mortise and tenon.

Page 18

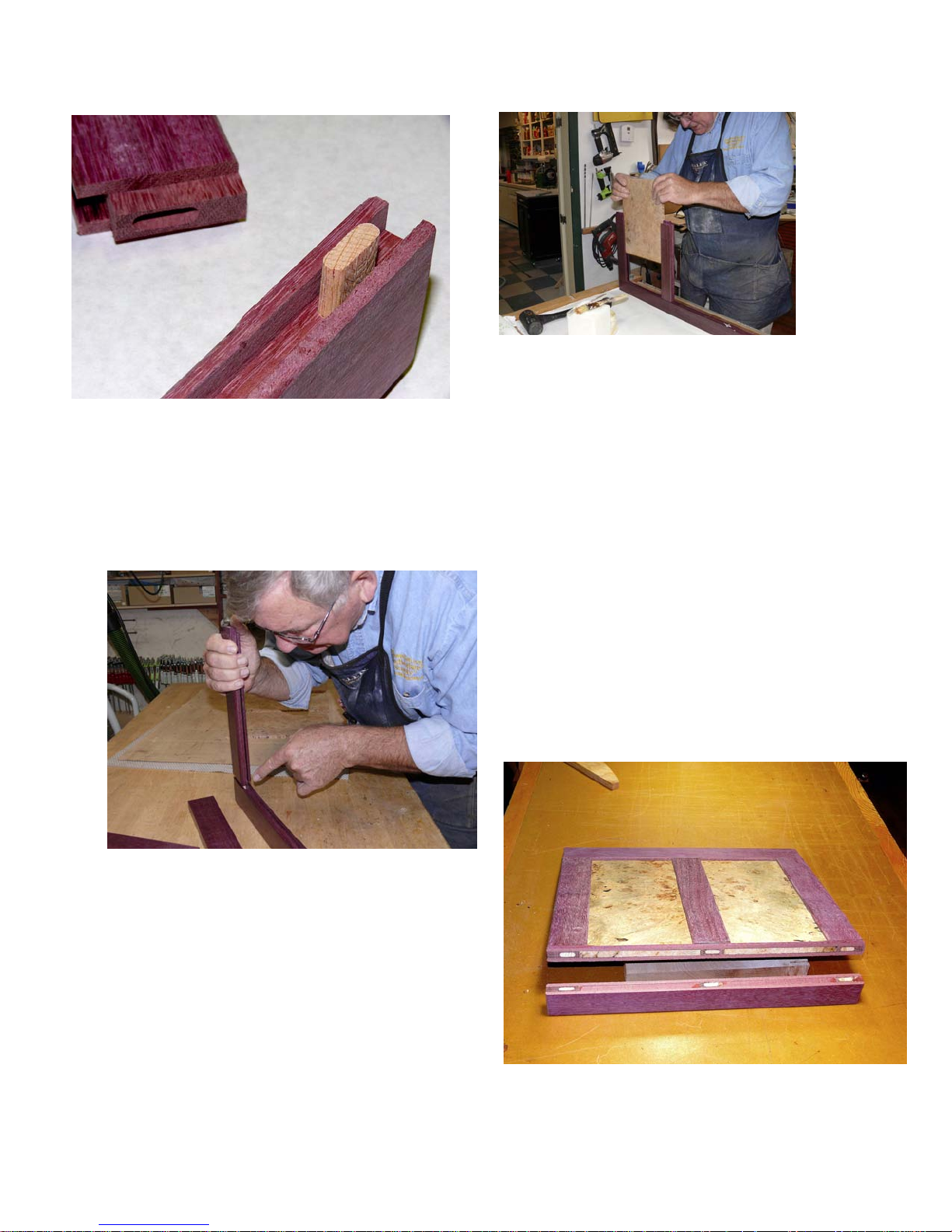

In the example shown on this page the

R&S components are Purple Heart while

the panels are Maple Burl.

If the joint is a stressed joint, such as the

corners of a door, then I like to put an

well. And, by having glue on both sides

of the trapped narrow 1mm tongue wall,

the joint is incredibly strong.

In the photo left my finger points to the

joint going together and above is a photo

of a panel being inserted into a three

panel R&S assembly that was made this

way.

Below is a cut away of a door done

this way to show how the precise positioning the Domino machine provides can quickly and easily cut what

many would consider a most difficult

joint - three 8mm M&Ts cut inside

three 10mm tongue and groove joints,

all perfectly aligned!

8mm Domino M&T inside the 10 x 10mm

tongue and groove cut into the rail and

stile pieces as shown above. The 10mm

tongue is cut into the rail piece and the 10

x 10mm groove cut into the stile piece.

The 8mm Domino mortise is cut into the

middle of the groove and the middle of

the tongue (top photo).

The Domino M&T not only strengthens

this joint, it also automatically aligns it as

Page 19

Just for fun here is an edge-to-edge joint

used to join two thick pieces of maple

together to make a fancy countertop

chopping block.

Waterproof glue and four 10mm x 50mm

Domino tenons make sure this chopping

The Domino machine makes a

fast, secure & hidden joint without that fuss.

block will never separate. The waney

edges add interest while the large

breadboard end dovetailed to the body

prevents any bowing or warping.

The dovetailed feet keep the bottom off

the countertop.

I would not consider making this piece

using biscuits as I would be concerned

about joint strength. Over the life of this

piece it will be hit with everything from a

meat cleaver to a tenderizing hammer

and it will be in and out of cleaning water

constantly.

BD (before Domino, grin) the only way I

could do this was to either use a spline or

a sliding dovetail to hold the two pieces

together.

Now back to the edge-to-edge joints....

One tenon centered on the edge of each

work piece is usually more than strong

enough given the strength of modern

Page 20

glues. If your application demands exceptional strength and the work pieces

are more than 3.5 x the thickness of the

tenon you intend to use, I suggest setting

two tenons, each centered the tenon

thickness down from each face if the two

work pieces are exactly the same thickness. (For exceptionally stressed joints

in thick material that is at least 5x the

thickness of the tenon, set two tenons

centered 1.5x the tenon thickness down

from each face).

If the work pieces are not the same thickness, put the first tenon centered the tenon thickness down from the top or

“good” face and the other tenon down far

enough to be centered about the tenon

thickness above the bottom of the thinnest of the two work pieces.

auxiliary spring loaded pins to position

the Domino mortise slot(s).

If your work pieces are exactly the same

width, you can work from both edges. If

they are not, register all cuts from the

same edge so that one edge will be

properly aligned even if the other edge is

not.

A variation on an end-to-end joint is

strengthening a mitered end joint like the

one shown here cut in African Blood

Wood (sometimes called

“Sealing Wax

Wood” because of the

rich, red natural color).

Make all of the Domino mortise cuts with

the fence held firmly to the top or “good”

face of each work piece. That way the

good faces will be properly aligned and

the tenons will fit together nicely to produce superior joint strength to what you

would have if you used just one tenon

centered on the edges.

End-to-end joints.

For these, mount the saddle

fence if your work pieces are

each less than 70mm wide.

Each saddle fence can be positioned 35mm away from the

horizontal mortise center thus

accommodating up to 70mm

material.

If the work pieces are more

than 70mm wide then use either

the built in spring loaded alignment pins hooked over one

edge to align the two ends and/

or mount the two wings with the

The ability to

swing the

fence over a

90 degree arc range is really handy for

this cut.

Match the angle to the mortise angle, in

this case 45 degrees. Set the depth of

cut and the height of the fence to be sure

you do not cut the Domino mortise

Page 21

through to the good side of your work

pieces. Usually that will mean placing the

mortise below the joint center as shown

on the previous page and using a short

tenon. This is where the 12mm cut depth

setting is really handy.

Edge-to-face joints are common when

you want to mount one piece of wood

perpendicular to another like putting a

fixed shelf between two sides of a chest.

This is simple and easy to do remembering that the bit center is 10mm above the

base of the Domino machine. A board

clamped across the side pieces 10mm

back from your desired centerline will position the bit to cut the mortise on the

sides to wind up centered on a 20mm

shelf.

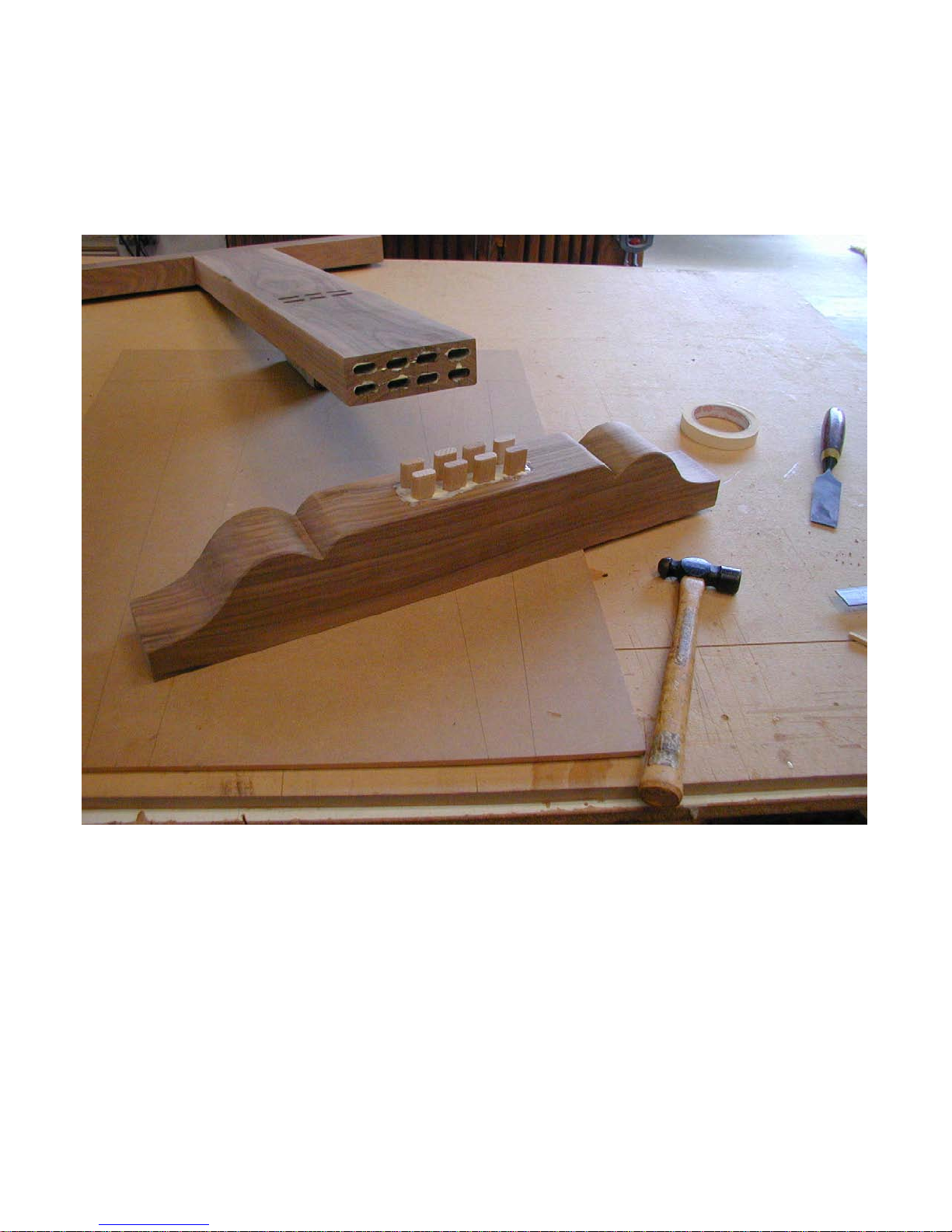

Here I am getting ready to do something

similar, but with a significant twist.

You may need even more pocket

hole clearance for some woods.

one piece aligned with the face of the

other, I am using four Domino M&Ts

without glue to hold the alignment (red

arrow), and pocket hole screws with

elongated screw holes (green arrow) to

actually hold the two pieces tightly together while still allowing one to slide

enough relative to the other....a very

handy trick to keep in mind.

While it may be hard to see in these small

photos, one of these work pieces is a

solid wood glue up (the bottom piece in

the lower photo) with grain

running up and down while

the other is a rail and stile

with the stile grain running

across the wide grain of the

glued up panel. We will

see why this configuration

is needed when we get to

the pedestal desk buildalong project a bit later.

But, given the long grain to

cross grain construction,

we certainly cannot glue

this joint or the expansion/

contraction of the glued up

panel would fracture the

glue joint in a year or less.

One final note on joining two pieces of

wood. Where even more strength is

needed than you think would be supplied

To avoid this problem while

still keeping the edge of

Page 22

by one or two Domino placed along the

thickness of the edge, it is good practice

to stack Dominos using multiple sets in

the same joint.

to side the joint edge closest to the point

of force is placed in tension while the side

of the joint furthest from the point of force

is placed in tension. The shorter the dis-

This photo (supplied by Festool) shows

one example. The leg to base joint uses

eight Dominos stacked in a 2 x 4 array

while the leg to stretcher joint uses six

Dominos stacked in a 2 x 3 array.

The more Dominos you use the greater

the glue surface area, the greater the

Domino surface area, and the greater the

strength.

Joints like this try to fail by the racking

load applied. As the table is pushed side

tance between the edge of the leg (in this

example) and the edge of the Domino,

the less bending stress there is and the

more pull out stress is applied to the

Domino joints on the other side of the leg.

With this many Dominos and this much

glue surface it would take a lot more rack

pressure to fracture this joint than would

ever be applied to a table in normal use.

The same technique also allows the

construction of very strong doors.

Page 23

Domino Machine In Action

Now let’s turn our attention to how the

Domino machine simplifies and improves

the construction of several different furniture projects.

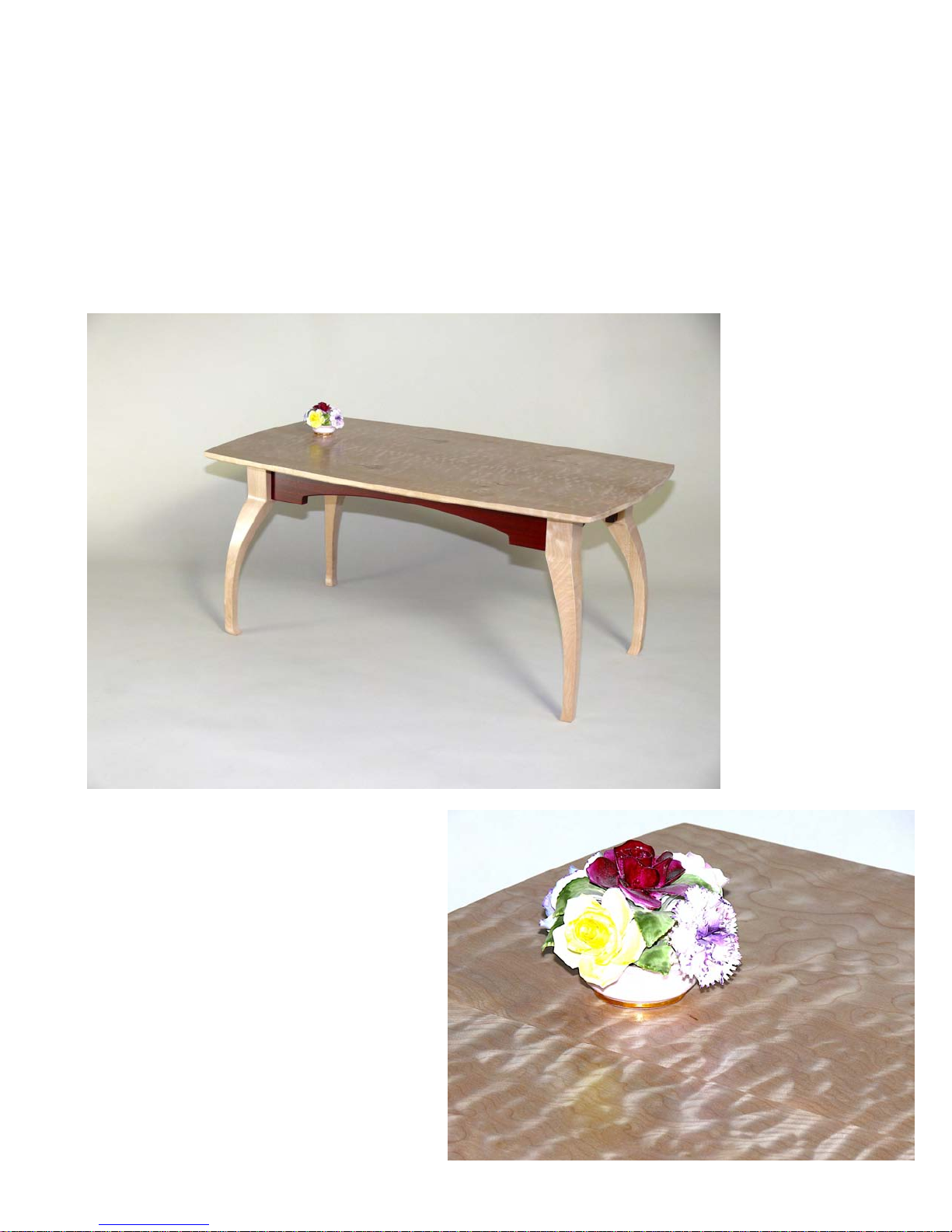

Small Conventional Coffee Table

The legs are cabrio style cut from glued

up blocks of Maple. The Blood Wood

skirts are attached to the legs with one

Domino loose tenon which is more than

strong enough given the small size of this

particular table. The top is attached via

“L” shaped tongue pieces screwed to the

underside of the top with the tongue in-

serted into

Domino

mortises

cut into the

inner face

of the

skirts.

We start by

gluing up

blocks

which will

form the

legs. Determine the

distance

you want

your cabrio

legs to

curve out

from the

inside of

the top of

This lovely small coffee table is constructed from highly figured Oregon

Big Leaf Maple with Blood Wood

skirts. The quilting in the top is so

pronounced that you have to touch it

to convince yourself that the top is

really flat. As this photo shows, your

eye is convinced the top is three dimensional with peaks and valleys.

The finish is a water based, environmentally benign pre-catalyzed conversion varnish that has been polished to a mirror like piano finish.

Page 24

the leg where in mates with the skirt to

the outer most portion of the curve.

Make the block that size square and a bit

longer than the leg will be high. Do not

use Dominos to join these pieces to form

your blocks as the leg curve is likely to go

right through wherever you put the Domino tenon causing it to show once the

legs are cut out. Next, square up and

dimension the leg blocks. You can see

the template I used to draw the cabrio leg

outline on two adjoining faces of each

block lying on the Festool MFT just behind the leg block in the bottom picture.

Next, place the four blocks together so

the outline of the square top of the leg on

each block and draw an arrow pointing

diagnonally out to what will be the outside

of the cabrio curved leg.

Behind the stack of four leg blocks you

can see the glue up for the top. That was

done using Domino M&T as described in

the previous section under “edge-toedge” joints.

Now set up the Domino machine to cut

the leg-to-apron mortises in each face of

each leg blank as shown. I wanted the

skirts to be inset from the legs by 15mm

and the skirts to be 20mm thick. So I set

the fence on the Domino machine to be

25mm up from the cutter centerline as

the corner where the top of the cabrio leg

outlines are common are all placed to the

center of the stack. Now roughly draw

Page 25

we discussed earlier. Simple to do, just

set the height pointer to 25mm and lock

the fence as shown in this photo (the

Domino body has been removed from the

fence so you can more easily see the

height setting).

Place the Domino fence on the leg surface where you want the mortise and

slide it to where the centerline mark

aligns with the mark you made on the leg

blank, turn on the Domino machine and

make the cut.

You will be amazed at how

accurately you can position

these mortises with “just” the

visual reference marks. Using an adjustable square or

other “story stick” and a sharp

pencil or knife to make the

mark, both mortises in each of

the four legs will be very close

to being in exactly the same

place. And, it will only take a

few minutes to cut all eight

mortises.

Thank you Domino machine!

Now make a mark on each leg about half

the maximum height of the skirt down

from the top of each leg on the two faces

which will form the inside top of the leg.

Make this mark with an adjustable square

set to the desired length so it is the same

on all four legs. Set the square aside and

don’t move the setting as we will need it

to align the Domino mortise we will cut in

the ends of each skirt piece. The mark

indicates the centerline for the mortise

relative to the top of each leg and the

fence height setting establishes the centerline for the mortise relative to the outside of each leg. Put on the cutter you

need, set the mortise width to minimum,

and set the depth of cut to be half the

nominal length of the Domino tenon you

intend to use. As I recall I used a 10mm

x 50mm for these legs so the mortise

depth was set to 25mm.

(Note: you can also just hook

the spring loaded pins over

the ends of the leg and skirt to align them

for this cut as well, if you want to.)

Take each leg blank to the band saw and

follow the leg shape you drew on one

side of the cabrio leg with the template.

Save the off cut piece and tape it back in

place with clear package wrap tape. If

you look carefully at the photo on the bottom of the last page you can see the saw

kerf and the glare of the package tape

holding the off cut piece on the leg blank

shown.

The taped-on off cut piece reestablishes

a flat surface for making the second leg

profile cut on the band saw. When you

get finished with all four legs, you will

have quite a stack of scrap as shown in

the photo on the next page.

Page 26

machine to be plenty good enough for

you to cut all the mortises on the minimum width setting allowing the tenon to

do the leg top to skirt top alignment for

you. However, if you prefer to cut a wider

mortise slot and do your own alignment,

there will be very little difference in the

leg-to-skirt joint strength as most of the

strength of a M&T joint is derived from

the glue on the faces of the tenon, not on

the edges of the tenon.

Sand all the legs to final shape and dimension and cut the profile for the skirts.

I like to break the edges on things like

skirts with a 45 degree chamfer router bit

so the hand feels a smooth, rather than a

sharp edge.

Once the skirts are finished, use the adjustable square set as before to mark the

centerline of the mortise to be cut in each

skirt. Mark each from what will be the top

of the skirt so you are always using the

same reference and to make sure the top

of the skirt and the top of the leg line up.

Reset the Domino fence height to be half

the skirt height, keep the width set to

minimum and the depth to the same setting you used for the legs. Place the

fence on the outside face of each skirt

piece, slide the Domino until the center

mark lines up with your mark, and make

the cut.

Next, shape and sand the top. I like to go

up to 800 grit before the first seal coat

when I want such a high gloss glass-like

finish such as on the top of this piece.

Seal it on all surfaces, sand again to 800

grit and do the build coats. Sand the final

build coat to 800 and do one light top

coat. Set the top aside to cure for a couple of days before polishing.

A bit of a confession here - I have done

the polishing long enough to be comfortable polishing a piece after just a few

hours of curing, but I don’t recommend

that to you until you gain a lot of experience as it is easy to burn the finish when

it is so young. Once it fully cross-links, it

will polish without burning.

For more detail on water based finishes,

buffing and polishing take a look at the

manual available on the

targetcoatings.com home page.

If you are nervous about your ability to

cut all the skirt mortises to the same centerline you used for the leg mortises, then

reset the slot width to the middle setting

before you make the skirt mortise cuts.

The resulting skirt mortise will be wider

than the leg mortise providing some adjustment room at assembly time.

That said, I think you will find the visual

reference accuracy built into the Domino

While the top is being finished, assemble

the legs to the skirts with glue, legs

pointed up. Clamp the skirts down to the

top of a flat surface like the MFT to register the top of the skirt and the top of the

legs to the same plane and square that

assembly while the glue dries.

Finish the leg and skirt assembly and you

are ready to mate the top to the legs by

Page 27

machining Domino mortises on the

inside of the skirts as shown in this

photos.

It is easy to make a tongue

block with the base of the

tongue up slightly less than

7mm from stock that is

12mm thick. That will present a 5mm tongue to insert

into the 6mm slot cut on the

inside of the skirts. By keeping the bottom of the tongue

a bit less than 7mm, when

you screw that block to the

underside of the table top the

tongue will press the skirt

firmly to the top while still allowing it to move with normal

seasonal changes in humidity.

Invert the now finished top on a soft,

flat surface. I use a rubber sanding

pad but an old blanket will work as

well. You do not want to scratch the

top you worked so hard to polish.

Don’t worry though, if you do

scratch it, you can remove the

scratch by repolishing.

The easiest way to cut the Domino

mortises into the inside of the skirts

is to cut them while the skirt and leg

assembly is clamped to the flat reference surface. Remember that the

distance from the base of the Domino fence to the centerline of the cutter is

10mm. If you use a 6mm cutter with the

base on the reference surface a 6mm slot

will be centered up 10mm leaving a 7mm

distance from the bottom of the slot to the

reference surface which is on the same

plane that the bottom of the top will be on

when you mate the two components together.

You can also cut these mortises from the

top side if you want more bottom of slot to

underside of top dimension. Set the

Domino fence height to wherever you

want the center of the slot. Add on the

auxiliary base for stability. Place the

fence on the top edge of the skirt with the

auxiliary fence held to the inside face of

the skirt and make the cuts. Machine

tongue blocks to match, screw them

Page 28

down as shown and you are done. Al-

most.....

Be sure to sign and date your work before delivering it to family, friends or cus-

tomers. Generations from now that

owner will want to know who built your

beautiful piece of art furniture and when.

Page 29

Next let’s move to another more challenging coffee table that will help illustrate

even more and different ways the Domino

machine will speed up and improve the

quality of

your work.

two hands to do a one handed operation not good.

I hit on the idea of the “convertible” coffee

table shown

here.

This is a

unique design for a

special application.

The customer

wanted a

coffee table

with casters, a

drawer, and

an intermediate shelf

for her

downtown

condo. She

is an artist of repute and has decorated

the condo in a tasteful blend of contemporary and traditional styles, but with a

definite artist’s flair.

She also likes to

change things

around as she rotates her own art

into and out of the

space.

It was important for

the coffee table to

both blend in and

still be a functional

art piece.

Usually wheels

and drawers do not

work well in the same piece: go to open

the drawer and the piece moves requiring

The upper

photo

shows the

table in the

“contemporary” position while

the lower

photo

shows the

“traditional”

position.

Converting

from one

look to the

other is

simply a matter of lifting off the top, slipping out the casters, inverting the base

and leg unit, turning the drawer upright

and replacing the top. In either configura-

tion the top is indexed to either the

legs or the base

via hidden Domino

tenons.

The base contains

hidden casters and

the drawer. When

in the contemporary mode it rolls

easily from place to

place without the

awkward look of

exposed wheels.

With the drawer down low there is less

tendency for the table to roll while opening the drawer for access.

Page 30

Inverted into the traditional

mode the table looks more

fixed in the environment and

the drawer opens easily in the

traditional way.

The book matched intermediate shelf and legs in Oregon

Big Leaf Maple compliment the

Black Walnut of the top and

side skirts. The top is made up

create a maple frame

around the

walnut skirts

and drawer

fronts when

the table was

in either

mode. That

meant that

the skirts

could not

simply be attached to the upper

and lower platform pieces or one

would not be able to assemble it

as the last edge would either not

fit or would have to be attached

without positive location by

something like pocket hole

screws.

of four book matched panels floating inside a picture frame with intermediate cross members and is a real

knock out when seen in person.

The trick is to make it all work and

that is where the Domino machine

comes in. What is a bit tricky here

is the need for both an upper and a

lower platform made from maple

that separates the walnut side

skirts and the need for the drawer

box to be able to support both a

drawer that pulls from both directions and the hidden casters.

The solution came in the form of

a unique platform frame to leg

joint that, as we will see in a

moment, involves a dado in the

upper and lower frame members

which holds the walnut skirts in

proper registration, a skirt-to-leg

Domino M&T joint to keep the

short skirts that flank the drawer openings

I wanted the upper and lower platforms to be mated to the legs to

Page 31

registered to the legs, and a Domino mortise and tenon frame-to-leg connection on

both the upper and lower frames to provide the strength necessary to offset the

leg stress imposed by rolling the unit

around and/or converting it from one

mode to the other.

Let’s see if I can describe and show the

construction details well enough for you

to follow.

We will start with the legs. Like the previous coffee table, this unit features a

simple cabrio leg that is cut the same way

as the more complicated curved cabrio

leg we saw before. In this case the legs

just flair out in both dimensions so they

look right in either mode. In this photo

the leg blanks were glued up, a template

used to mark the flair, and a band saw

used to cut the rough shapes shown

here.

This is the same process we used before

except this time I waited to cut the mortises until after the legs were formed because you can see from the photo that

we need three Domino mortises on each of two sides

of each of four legs. The

upper and lower horizontal

mortises will attach the legs

to the platform frames while

the vertical mortise will attach the skirts to the legs.

By using the saddle fence

shown in detail above, the

Domino machine can strad-

dle the square part of the leg

to cut the upper mortise from a penciled

reference mark using the same technique

of an adjustable square or story stick to

mark exactly the same distance up from

the end of the legs on both sides of all

four legs.

The lower horizontal mortise is cut with

the leg standing upright on a flat reference surface and with the Domino base

also sitting on that same flat reference

Page 32

surface. We know that the Domino baseto-cutter centerline is 10mm. Our platform frame is made from 20mm stock so

the resulting mortise will be exactly centered on the frame and hold the frame

flush with the end of the leg once the

mortise is cut in the center of the frame

members.

fence to one-half the leg

thickness so the leg will

snugly fit inside the saddle

fence. Then I slide the Domino machine up until my mark

is aligned with the mortise

centerline on the Domino machine fence. Then the clamp

As you can see in this photo the saddle

fence keeps the leg standing upright and

centered over the cutter laterally while the

reference base puts the center of the

mortise 10mm up from the end of the leg.

While you can hand hold the pieces for

the bottom-most horizontal mortises (the

saddle fence & flat reference surface secure the work piece and all you need to

do is hold it tight against the Domino machine during the plunge cut), it is not easy

to hand hold for the upper horizontal mortise cuts.

Since these mortise slots are being cut

after the legs have been roughed to

shape, I clamp the Domino to the leg so

neither the Domino machine nor the leg

can move during the plunge cut. As we

did before, I set each side of the saddle

Page 33

holds it in that position while the cut is

made.

To check to make sure both mortises in

both sides of all four legs line up correctly, I put a dry (no glue yet) Domino

tenon into each joint and push the legs

together as shown in the top photo on the

previous page. If the mortises are all

perfectly aligned, the legs will go together

easily. If they are not, the legs won’t go

together at all.

As before, all 8 mortises wound up in exactly the right places by indexing one off

of the leg end and the other off of a visual

reference mark. That would only work if

all the Domino measurements, machining

and markings are all spot on - and they

are.

Now we need to cut the vertical mortises

which will index the side skirts and the

skirt pieces beyond the drawer openings

to the legs. To cut these I needed to set

I keep a set of metric gauge blocks

around just for such purposes. Remember the step block built into the base of

the Domino machine? That slides back

and forth to establish a step that will position the Domino fence up half that

amount from the centerline of the cutter.

One of those stop block settings is for

40mm thick material and it will position

the cutter right in the center, or 20mm up.

We need 22.5mm up to center on our

45mm legs, so I placed a 5mm gauge

block between the step and the fence to

register the fence for a 45mm stock

thickness to put the cutter centerline up

22.5mm.

the Domino fence to be exactly 22.5mm

to center those on the 45mm thickness of

the legs. They must be spot on because

those skirts will sit in a dado we will cut in

the platform frames and they have to also

index into the legs via these Domino M&T

joints.

I could have just eyeballed 22.5mm on

the height scale and pointer, but the

gauge block method is much more precise.

To establish the reference to center the

mortise between the other two mortises I

used the auxiliary spring pin wings that

attach to the dovetail in the base of the

Domino fence. You can see that in the

photo to the left. By hooking that spring

pin over the end of the leg and placing

Page 34

the fence firmly on the flat part of the leg,

I could cut the vertical mortises just as

accurately as the horizontal ones....great

fun and it takes only minutes to do.

I know it looks a bit complicated in these

pictures, but when you have a Domino

machine in your hands and start using it

you will see just how fast and accurate

these cuts can be.

The next step was to machine the

upper and lower platform pieces to

size and then machine the dado that

will hold the side skirts. Here I have

clamped one of the platform pieces

down to the top of a Festool 1080

MFT. I have five MFTs in my studio

and they all are in use constantly as I

just do not know of any better way to

hold work pieces steady while you

machine them.

In these photos you can see the Domino

machine with the saddle fences set for

the 50mm width of the platform frame

members and the fence set to center the

Domino mortise on the 20mm thickness

of those pieces.

Drop the Domino machine onto the end

of the work piece, slide it forward until the

face of the Domino machine registers

Page 35

with the end of the work piece and plunge

to make the cut. The result is shown on

the bottom of the previous page along

with one of the legs that it will mate to.

The photos on this page show how the

ends of the 10 x 10mm tongues on the

side skirts are cut back to clear the Dom-

how the vertical M&T joint between

the leg and the side skirt will make

up as the skirt slides in the dado

and onto the leg tenon.

The photo above is after all the

parts have been through final

sanding, ready for finish and actual

assembly.

ino tenon since the centerline of the tenon and the bottom of the dado are both

10mm. (Suppose we should invent a

term and call this a “Dominoed dado”

joint? grin.)

The views here are of the platform

frame member that will index to the

ends of the legs. The photo above is

from the end of the leg view and the

photo below right is taken looking

down on the platform frame with both

the leg and frame members flat on

the reference surface.

Notice that the side skirt 10 x 10mm

tongue is cut back to clear the upper

Domino M&T joint just as was done

to clear the bottom frame-to-leg joint.

It all works like a big puzzle and is

much easier to do than to visualize

beforehand or to see in small photos.

In the photo right you can also see

Page 36

More work was required to cut the

dado in the inside of the top most

frame member to accept the maple

book matched panels you saw in the

opening photos. There also was

machining to do to hold the drawer

slides and the bases for the hidden

casters.

make the four square openings for

the book matched top panels.

Mitered corners are not strong

enough for such an application so

Domino M&T joints were used to reinforce them as shown below left

and in detail below.

The Domino fence was set to center

the bit on the 20mm thickness of

these pieces. I used an adjustable

Now we will look at how the top was

constructed and how the whole project came together.

The top is a picture frame with mitered

corners and interior cross members to

square to establish the length I wanted

each mortise to be down from the outside edge of the 45 degree frame corner and used that to make a mark on

both ends of the four frame members.

Pressing the Domino fence down on

the top face of each frame member

and the Domino face snugly against

the 45 degree miter cut on the end of

the frame pieces, I slid the Domino to

the point where the bit centerline was

aligned with my mark and made the

cut. As was discussed in the earlier

section on miter corners, look carefully to

make sure your mortises do not go

Page 37

through to the outside of the frame.

Shorten the tenons by cutting them if you

have to.

In the upper left photo the top is registered into the end-of-leg to underside of

top Domino M&T joints to make sure the

legs and top will properly

mate in the final assembly.

With everything square and

accurate I could invert the

piece and do the top of

frame to underside of top

Domino M&T joints since

those are in a different place

than the end-of-leg to underside of top joints.

Once all the components fit

together correctly, it was off

to final sanding and then to

the finish room.

Notice also how the frame center cross

members are held in Domino M&T joints

in both directions to make for a very

strong outer frame for the walnut top.

The final steps are test assembly of all of

these components. When these pictures

were taken I had already finished the top.

The photo above shows clamps holding

the leg-to-panel frame joints tightly,

clamps holding the whole assembly into a

known square corner, and clamps holding

the skirt pieces on each side of the

drawer openings tightly to the leg-to-skirt

M&T joints. I removed the clamps holding the unit to the known square corner

front to back so you could see the details

more clearly.

For more info on clamping into a known

square corner, look at the manual I wrote

about the Festool MFT which is available

for download from the festoolusa.com

web site.

Page 38

The following photos show how I like to

finish all components in the flat, before

final assembly.

With no top in the way it is easy to

polish the book-matched maple panels that form the intermediate shelf

and to spruce up the skirts, legs and

frame members.

The last step was the signature block

and then notifying the customer that

the piece was ready for pick up.

They were thrilled, and so was I!

Page 39

Let’s switch gears a bit from how the

Domino machine does all sorts of very

precise M&T joints to how it can do many

other things with ease as well.

Wine Service Center

First, let’s look at an interesting wine

service center, this one made from Purple

Heart and Maple Burl. The sides and

back are done as R&S with 10mm thick

slabs of maple burl as the panels. The

the legs and upper

frame by tongued

splines screwed to

the underside of

the top. The bottom shelf is held to

the leg stretchers

by wide Domino

mortise slots and

tenons inserted

without glue to allow for seasonal

expansion and

contraction of the

shelf.

doors slide in machined grooves cut in

the top and bottom front frame members.

They have to fit the opening tightly to

look right and feature a very unique

Domino enabled moving pin mechanism

that we will see in detail later.

A curved maple drop fits into a sliding

dovetail groove to soften the opening below the base of the upper cabinet on the

front, back and sides. The top is held to

Let’s build it.....

Page 40

As before, let’s start with the legs. Glue

up stock to make four blanks. In this

case the legs flair out side to side, but not

front to back. Construction is the same,

but we only need to scribe our template

on one face, not both faces as is the case

with cabrio legs.

and lower side frame members

and to hold the leg stretchers.

Since those frame members are

oriented with their wide face up

and down (where the front and

rear frame members are oriented with their narrow edge up

and down) we need to cut those

mortises in a vertical, rather

than horizontal orientation as

shown below.

While they can be cut before the

legs are profiled, I find it easier

Dimension all four leg blanks to be exactly the same size and perfectly rectangular so we can reference from both

sides.

We will need Domino mortises cut horizontally (red arrows) on the faces of the

legs that will be in towards the center of

the completed piece. One will be set

10mm down from the top of the legs to

hold the front and rear upper frame

members. The other will be set down

near where the leg flair begins to hold the

lower front and rear frame members. The

position of that mortise determines the

overall depth of the cabinet portion of the

piece.

We also need Domino mortises cut in the

sides of the legs that will face front to

back (green arrows) to hold the upper

to do so after profiling because the bottom frame is made up of pieces in different orientations (front and back narrow

edge visible, sides wide face visible) and

it is easier to see the relationship between these two locations after the leg is

cut than before.

To do the locating I tape the cut off piece

back onto the leg to provide a reference

surface and more flat space to support

the Domino base. You can see this in the

Page 41

photos below. Here is the locating of the

leg stretcher mortises. With both sides of

the leg curved you need the cut off piece

to get a reference. Be sure to align the

cut off pieces in the same place up and

down on the leg so the relative saw kerf

is the same on all four legs.

While I did not need it here, use

of the auxiliary fence would provide more stability for the Domino machine for cuts such as

these.

Next comes the cutting of the

Domino mortises in the ends of

the frame members. The front

and back members are cut horizontally by use of the saddle

fence shown here and on the next

page.

The mortises cut in the front and back

upper and lower members are not cut

in the center of the 50mm dimension.

Instead they are offset a bit so their

edges will line up properly with the side

Page 42

frame members. In the photo above you

can see how one side of the fence is further away from the bit center than the

other. In the lower photo on the previous

page you can see how this results

in a different centerline for the mortise than for the dovetail groove

which will hold one of the curved

maple pieces.

such as cutting the tracks for the

door slides, cutting the dados to

hold the bottom of the cabinet,

cutting the dados that hold the

side burl panels, etc.

Meanwhile, let’s see what the

skeleton looks like. The shelf is

not in place for these photos. We

will get there a bit further on.

Even seemingly difficult alignments

like this one are easy to do by using the lines scribed on the clear

plastic window and the scales on

the upper portion of the saddle

fence.

To make the cut, clamp the work

piece to the top of the MFT, drop

the saddle fence over it and push

the Domino up snugly to the end.

Set the depth and the width of cut

and plunge to make the cut....fast,

easy and very accurate.

The next several photos will show a mock

assembly of the main structural members

so you can see how they go together.

Before we actually assemble the piece,

however, there is more machining to do

Page 43

These are the main pieces of the skeleton. Note that the top edge of the front,

back and side frame members all align

with the top of the legs. The lower edge

of the front, back and side frame members align together.

Now that we see what the structure is

going to look like, let’s go back and

show some really innovative uses of

the Domino machine.

Page 44

The first thing to do is assemble the two

sides after cutting the groove for the burl

side panels. These photos show this sequence.

Once the sides are glued up and squared

with the leg stretchers in place, we can

turn our attention to building the back rail,

stile and burl panel and the two front

doors.

In the photo above

notice how handy the

Festool DX 93 E detail sander is for

reaching into tight

spots such as where

the leg stretchers

meet the legs. Any

glue squeeze out on

purple heart really

shows once the finish

goes on so be sure to

sand very throughly.

The photo above

shows a booboo.

When I first started this

piece I thought it would

look good with a book

matched maple top.

You can see the glue

up here. But, once the

piece was completed it

became clear that a

maple top was “over

the top” so I crafted the

purple heart top you

see in the final piece.

Page 45

Now let’s construct the rail, stile and maple burl back panel. The doors will be

done the same way. We saw earlier how

I now use Domino M&T joints cut inside

the tongue and groove joints of the rail

and stile components to both reinforce

these joints and to make them selfaligning.

With normal rail and stile construction

when you clamp up the assembly the rail

pieces with the tongues cut in their ends

can slide down the groove cut in the stile

pieces leaving the assembly either out of

square or with an unsightly gap between

the edge of the rail and the end of the

stile.

The Domino M&T eliminates that misalignment by holding the edge of the rail

flush with the end of the stile speeding up

the whole process by much more than

the time required to cut the Domino mortises in the first place. That is what I call

a real win-win.

The same is true with respect to placement of intermediate stiles as we will see

shortly on the back assembly for this

piece. Normally you have to measure

and mark the location for those and make

sure the intermediate stile stays in the

right place while you glue up and clamp

up. On many occasions that turns out to

be quite a time consuming process.

Well, watch here while the back rail, stile

and panel components go together. The

Domino M&Ts keep it all aligned without

me having to do anything.

While this would not necessarily be

true for everyone, I can justify the cost

of the Domino machine for this one

reason alone!

Page 46

Page 47

The self-aligning feature of a Domino

M&T joint cut inside a normal R&S

tongue and groove joint really speeds up

the process of assembling a multi-panel

component like the back on this piece.

grain component that will attach to the

long grain of the back lower stile, we can

screw these two together with the screws

placed inside the sliding dovetail slot.

As we assemble we can slide

the lower maple curved

pieces into the sliding dovetail

slot while we insert the Domino tenons to affix the back

and the front frame members

to the sides we completed

earlier.

Next we suspend the shelf

With the back now finished it is time to

mate the dovetailed and end mortised

rear lower frame rails (which also have

the groove that will hold the bottom of the

cabinet in place) to the bottom of the

back component. Since this is a long

between the two leg

stretchers using Domino

tenons inserted dry (no

glue) into wide mortises cut

on the inside of the stretchers and the ends of the

shelf. From previous descriptions, aligning these

Page 48

mortises should be easy for you to

visualize. Here is the piece assembled (minus top and doors), squared

up and waiting for the glue to dry. All

of the major joints are Domino M&T

joints so assembly is fast and self

aligning.

mum depth) is cut parallel

with and centered on the

bottom and top surfaces of

the door.

Then I turned the Domino

machine sideways and cut

a 5mm mortise centered

on the 10mm mortise both

side to side and top to bottom.

A 10mm tenon was drilled

to accept a metal pin a bit

Now let’s revisit the sliding doors.

Earlier I said that the doors had to fit

snugly into the door openings to look

right. The problem with most sliding

doors is they have to fit loosely

enough to lift up into a top track to let

the bottom free of the bottom track to

get the doors in and out. That simply

looks bad and is not pleasing to use.

So, let’s use the Domino machine to

do something far more satisfying and

sophisticated, a sliding pin assembly

that can be withdrawn up into the

door itself and then lowered into the

door tracks once the snugly fitting

door is in place.

In the lower close-up photo you can

see that I cut two overlapping mortises. One (10mm wide and maxi-

Page 49

smaller in diameter than the width of the

sliding door tracks machined in the front

upper and lower frame members. I cut

the length of the tenon so the end of the

pin would be flush with the bottom or top

surface of the door when it was fully inserted into the 10mm mortise. A hole

was then drilled into the face of the

10mm tenon through the center of the

5mm mortise so a small screw can secure the 10mm tenon/pin unit either

withdrawn up into the door or with it low-

ered down into the track.

Slick as can be we have a snugly fitting door with hidden sliding pins yet

the doors can be easily removed and

replaced any time.

This same double overlapping mortise idea can be used for making nice

hidden latches as well. For a latch

cut the 5mm mortise in the front of the

door and replace the screw with a

nice small dowel or decorative rod.

Slide the rod or dowel back to retract

the Domino tenon to release the door.

It doesn’t matter whether you put the

latch at the top, side or bottom of the

door. It will work just the same way.

Get creative with the dowel or rod

component and you can create all

kinds of neat looks.

Page 50

Now that we have seen how the Domino

M&T can be used for joining pieces,

aligning pieces to be joined by other

means, and used for things like hidden

door slide pins and latches, let’s move to

still two more projects to find even more

innovative uses for the Domino machine.

Double Pedestal Desk with a

Twist

Double pedestal desks are very common

and many woodworkers eventually get

around to building

one either for

themselves, some

other family

member or a

friend. They

mostly all look a

lot a like as the

top sits on two

pedestals, usually

with drawers both

in the pedestals

and in the bridge

between the pedestals.

The “finished product” pictures were

taken in a show context in one corner of

my booth space along with a couple of

the other “Domino inspired” pieces we

have already covered so excuse the

background clutter.

In this case the client is an active, energetic person who spends a lot of time at

her desk. She is slender and tall with

long legs and her most comfortable working position is sitting in her chair with her

legs folded. That meant the space between the pedestals and from the floor to

Some of these

designs can be

quite handsome.

Sometimes the

requirements and/

or the aesthetics

call for something quite different while still

maintaining the double pedestal look and

function. Here is an example we will follow because it holds a number of hidden

Domino “tricks” that greatly simplify construction and speed up what otherwise

would be a long and involved build process.

the underside of the desk top had to be

maximized.