Page 1

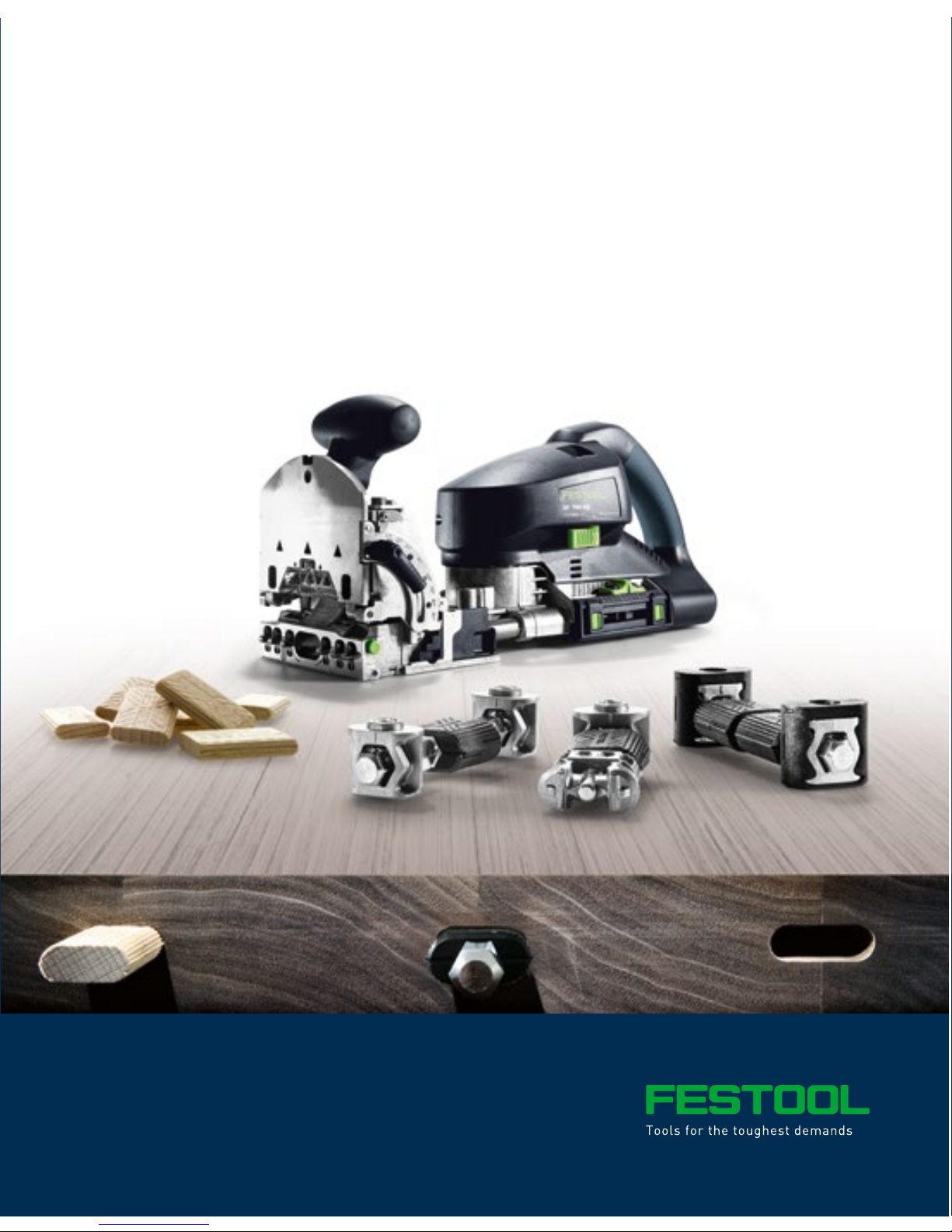

The perfect connection.

The DOMINO system user manual.

Page 2

Page 3

The perfect connection.

The DOMINO system user manual.

Page 4

Two men. One conversation. And the origin of a brilliant idea:

the DOMINO connecting system.

There are numerous draft designs, CAD

drawings, parts lists and documentation

for our DOMINO connecting system. Yet the

conversation and initial drawings where

the idea was formed was on something a lot

less imaginative: a napkin.

But first things first. To be precise, it was

initially only an informal exchange between

two practitioners in our canteen, pondering

what the optimal domino should be capable of.

And because nothing else was readily avail-

able, they sketched a domino on a napkin to

represent the demand for ‘more stability’.

Then a second sketch next to it for a ‘larger

What was missing was the fitting hole –

and thus the real challenge began. That is

to say, the development of a completely

new tool. With the typical southern German

inventiveness, infinite passion and the

concentrated expertise of our engineers,

a mix of traditional vertical bore and

simultaneous horizontal routing movement

was created – the birth of the DOMINO

pendulum router principle as the driving

force for the new DOMINO DF 500.

From its origins on a simple napkin, to

a design that has not only revolutionised

the traditional timber joint, but has been

continuously developed since then with

glue surface’. And finally a third for absolute

‘rotation resistance’ at the first attempt. Using

the simple equation: make one from three,

the foundation was laid for the DOMINO

DF 500 domino system.

further options: the DOMINO XL DF 700

and the newly developed corner and flat

connectors, forming a complete DOMINO

connecting system. For what has always

been extremely stable, is now also flexible,

with separable rack, board and frame joints.

Page 5

Page 6

Contents

PAGE

1 DOMINO joining machine fundamentals

1.1 The DOMINO pendulum router principle 12

1.2 The domino slot principle 13

1.3 The DOMINO joining machines: an overview 14

1.4 Performing basic settings for the DOMINO joining machines

Switching on/off

Selecting hole width

Selecting domino length and thickness

Cutter replacement

Depth adjustment range

Height adjustment range

Angle adjustment range

Working with the stop system

Working with extraction

2 The domino

3 DOMINO system accessories

11

16

16

17

17

18

19

21

23

24

28

31

37

4 Practical application examples

4.1 Overview: making joints with the DOMINO joining machine 42

4.2 Frame joints

Mitred frame joints

Butted frame joints

Stable frame joints with the DOMINO DF 700

4.3 Rack joints and safe positioning of strips 50

4.4 Round profile joints 56

4.5 Stable, separable corner joints 58

4.6 Stable, separable flat joints 66

4.7 Mitred joints 74

4.8 Drawer joints 76

4.9 Butted board joints 79

41

44

44

46

48

Page 7

PAGE

5 Items included, specifications

6 Accessories

85

87

6.1 Cutters 88

6.2 Stops 89

6.3 Domino and connector

Domino and domino rod- Beech

Domino exterior use- Sipo

Domino corner and flat connector

7 Supplementary system accessories

90

92

94

95

97

7.1 Mobile dust extractors 98

7.2 MFT 3 multifunction table

MFT 3 accessories

7.3 VAC SYS vacuum pump and clamping unit

VAC SYS accessories

99

99

100

100

54

Page 8

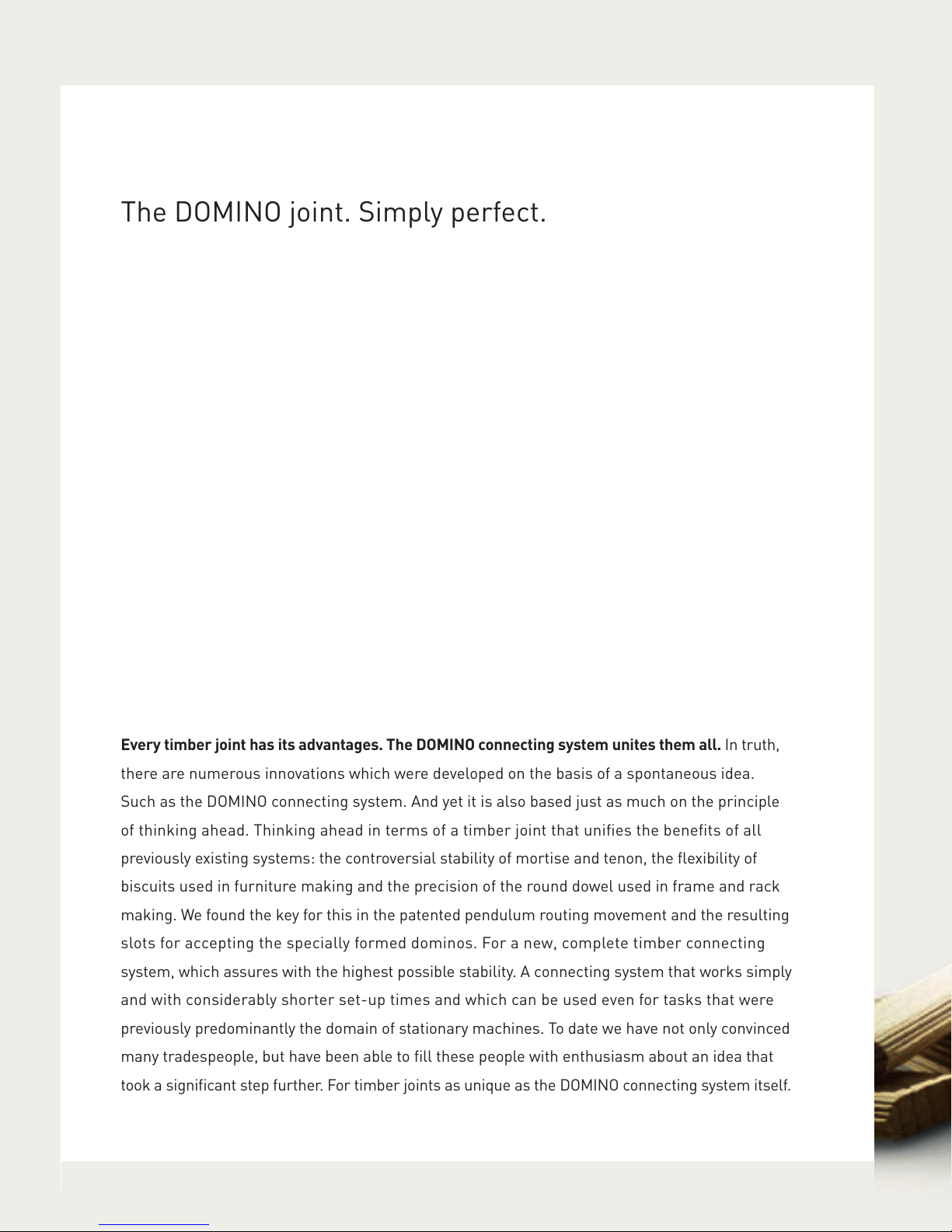

The DOMINO joint. Simply perfect.

Every timber joint has its advantages. The DOMINO connecting system unites them all. In truth,

there are numerous innovations which were developed on the basis of a spontaneous idea.

Such as the DOMINO connecting system. And yet it is also based just as much on the principle

of thinking ahead. Thinking ahead in terms of a timber joint that unifies the benefits of all

previously existing systems: the controversial stability of mortise and tenon, the flexibility of

biscuits used in furniture making and the precision of the round dowel used in frame and rack

making. We found the key for this in the patented pendulum routing movement and the resulting

slots for accepting the specially formed dominos. For a new, complete timber connecting

system, which assures with the highest possible stability. A connecting system that works simply

and with considerably shorter set-up times and which can be used even for tasks that were

previously predominantly the domain of stationary machines. To date we have not only convinced

many tradespeople, but have been able to fill these people with enthusiasm about an idea that

took a significant step further. For timber joints as unique as the DOMINO connecting system itself.

Page 9

76

Page 10

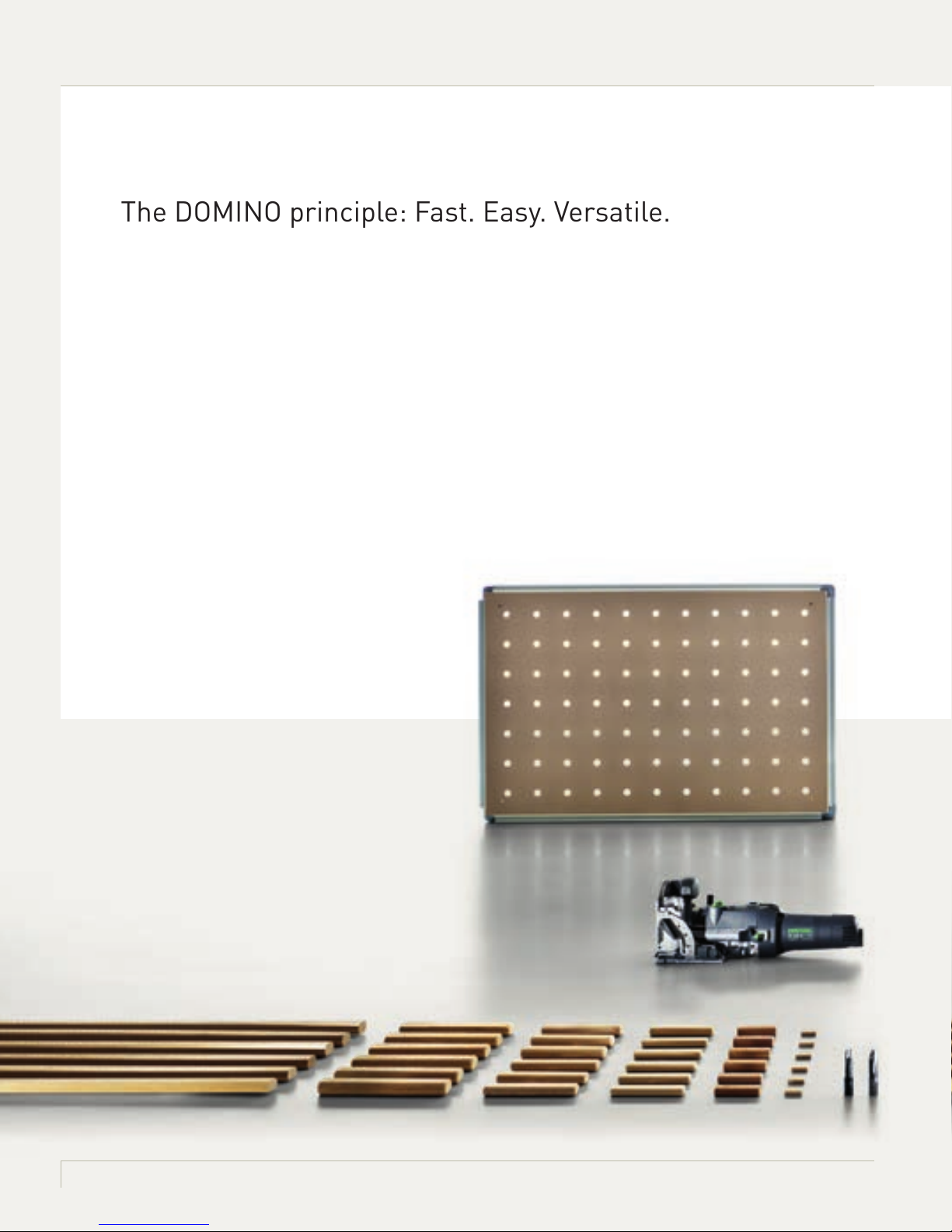

The DOMINO principle: Fast. Easy. Versatile.

Page 11

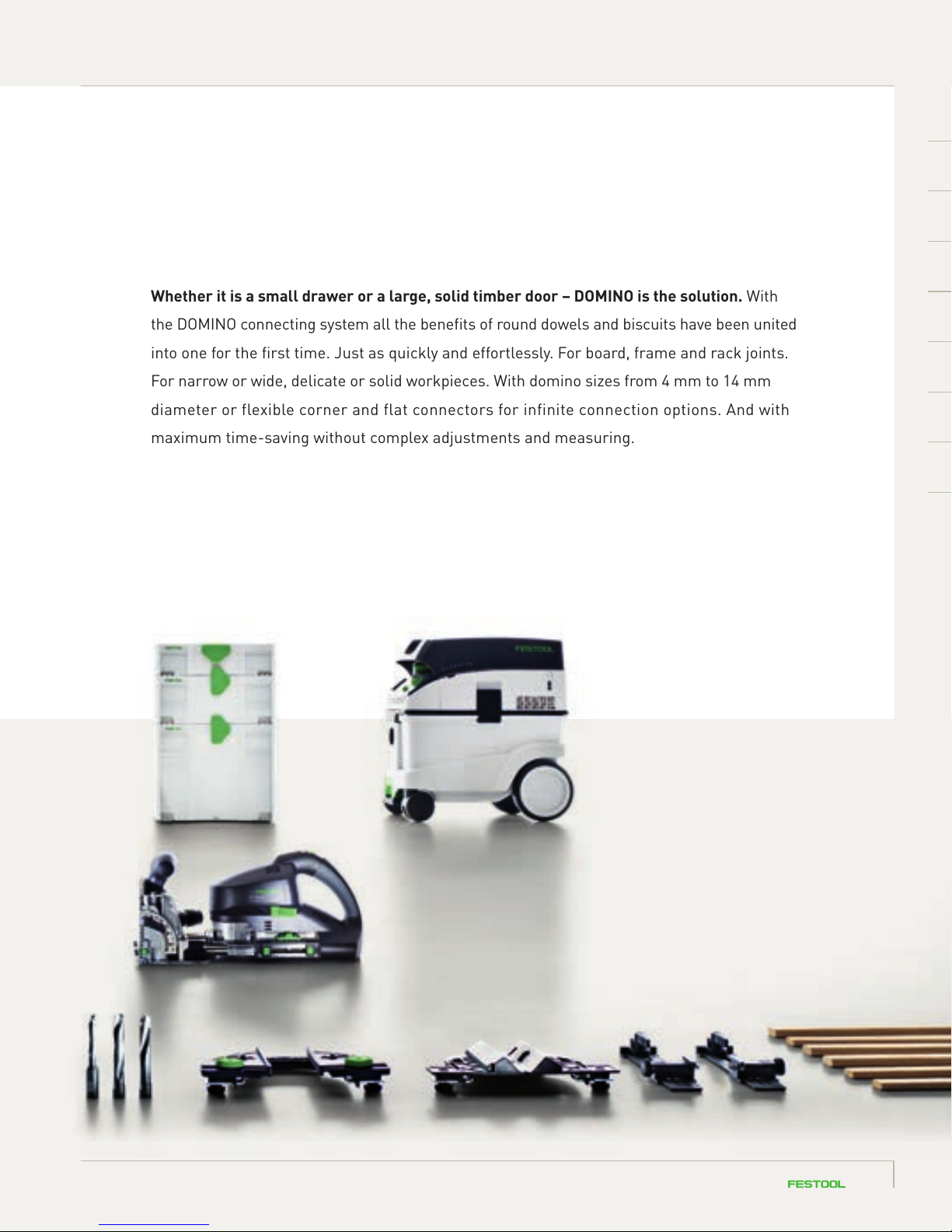

Whether it is a small drawer or a large, solid timber door – DOMINO is the solution. With

the DOMINO connecting system all the benefits of round dowels and biscuits have been united

into one for the first time. Just as quickly and effortlessly. For board, frame and rack joints.

For narrow or wide, delicate or solid workpieces. With domino sizes from 4 mm to 14 mm

diameter or flexible corner and flat connectors for infinite connection options. And with

maximum time-saving without complex adjustments and measuring.

98

Page 12

Page 13

1

DOMINO joining machine fundamentals

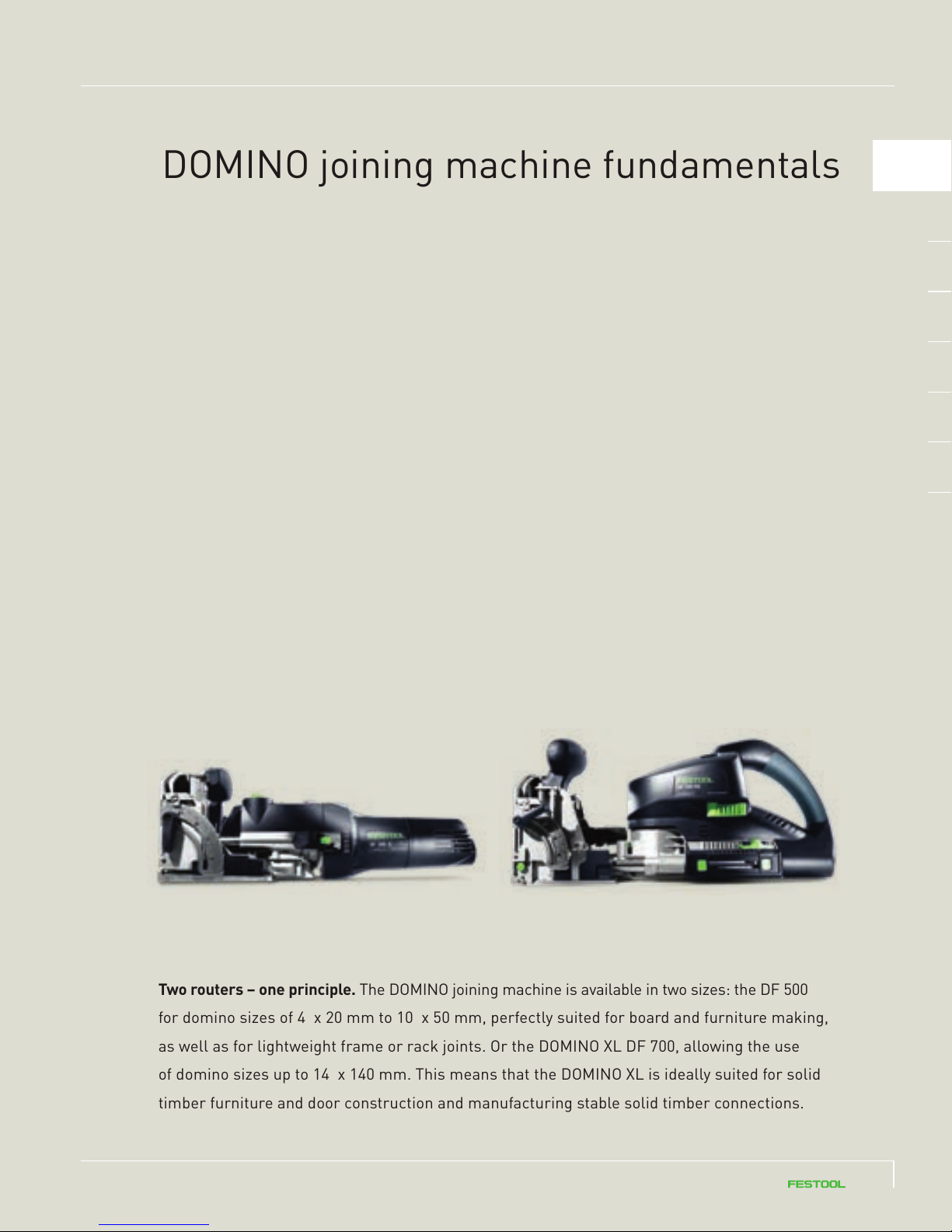

Two routers – one principle. The DOMINO joining machine is available in two sizes: the DF 500

for domino sizes of 4 x 20 mm to 10 x 50 mm, perfectly suited for board and furniture making,

as well as for lightweight frame or rack joints. Or the DOMINO XL DF 700, allowing the use

of domino sizes up to 14 x 140 mm. This means that the DOMINO XL is ideally suited for solid

timber furniture and door construction and manufacturing stable solid timber connections.

1110

Page 14

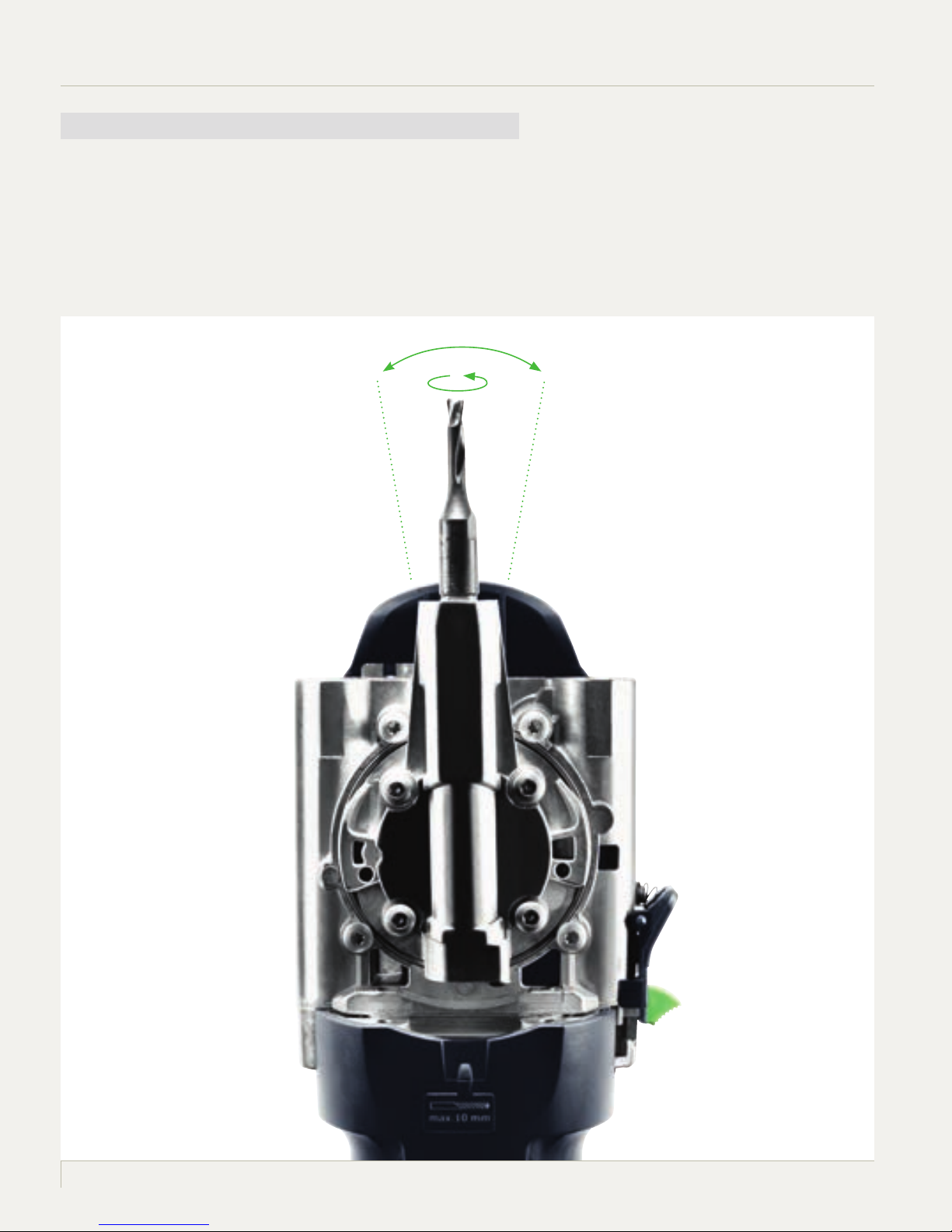

1.1 The DOMINO pendulum router principle

Unique in its manual operation and patent by Festool: the DOMINO joining machine routing movement.

The simultaneous rotating and pendulum movement of the cutter allows smooth working and holes without

scorch marks. Thanks to the pendulum movement the cutters do not overheat, leading to an extremely

high service life.

Page 15

1.2 The domino slot principle

The first domino is positioned via an exact slot, the subsequent dominos inserted in wider

slots with clearance – this allows the joint to be easily aligned. The result is a stable joint,

rotation-resistant from the first domino.

1

Fits exactly.

The slot is precisely routed using

the stop catches (DF 500) or stop

pins (DF 700). The workpiece

is aligned to the edge using this

locating hole and the connection

matches up immediately.

Room to move.

The remaining slots are routed with

clearance. Minor imprecisions in

the remaining domino holes are

compensated for by the DOMINO

connecting system – allowing fast

and efficient progress.

1312

Page 16

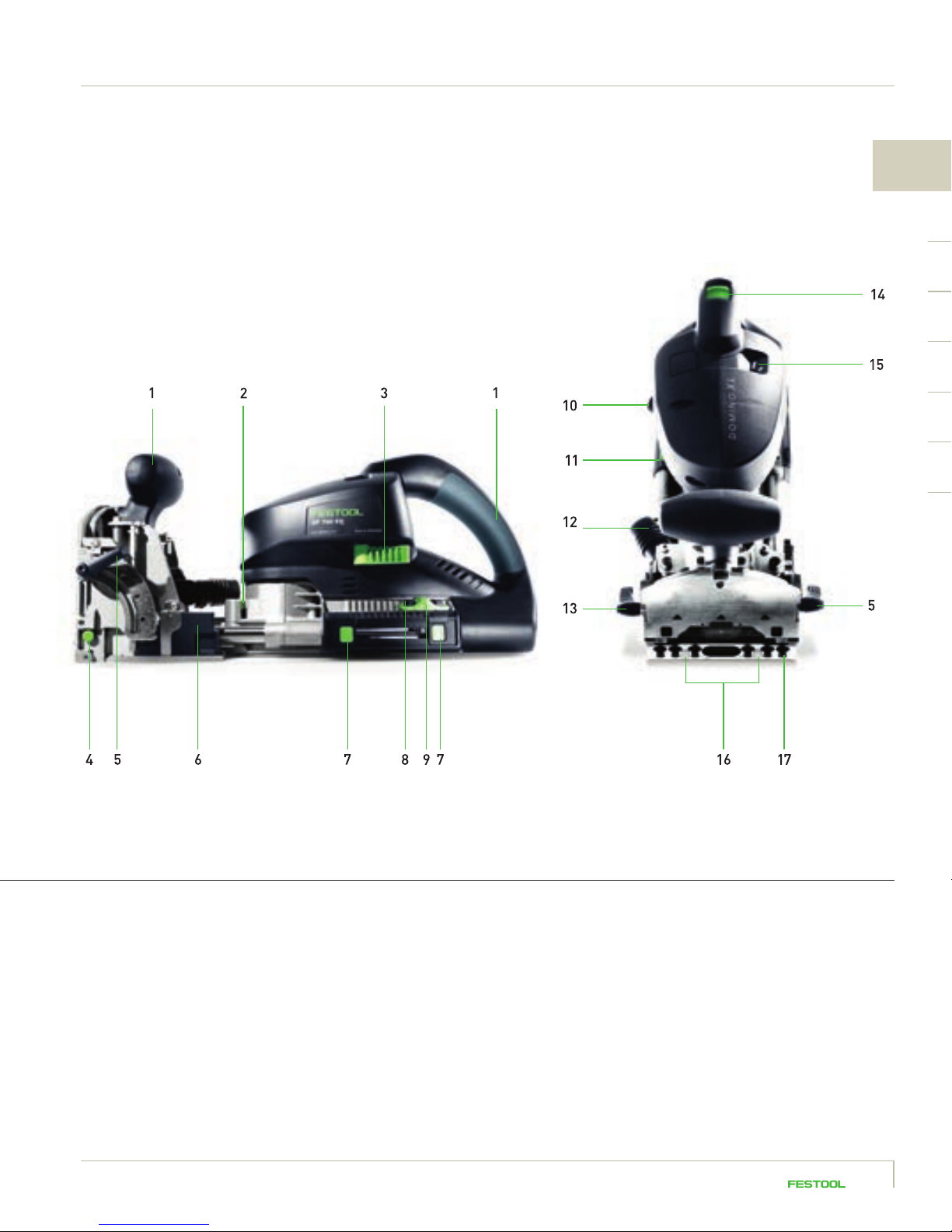

1.3 The DOMINO joining machines: an overview

DOMINO DF 500

1 SECONDARY HANDLE

2 LOCKING LEVER LOCK

3 DOMINO HOLE DEPTH

LOCKING LEVER

4 ANGLE STOP CLAMPING LEVER

5 MATERIAL THICKNESS

PRESELECT SLIDER

6 MAINS CONNECTION

7 SPINDLE LOCK

8 EXTRACTOR STUB

9 MOTOR UNIT/GUIDE FRAME

UNLOCKING

10 ROUTING HEIGHT ADJUSTMENT

CLAMPING LEVER

11 ON/OFF SWITCH

12 DOMINO HOLE WIDTH

ROTARY SWITCH

13 STOP CATCHES

Page 17

1

DOMINO XL DF 700

1 HANDLES

2 MOTOR UNIT/GUIDE FRAME

UNLOCKING

3 DOMINO HOLE WIDTH A

DJUSTMENT LEVER

4 STOP PIN UNLOCKING BUTTON

5 ROUTING ANGLE ADJUSTMENT

CLAMPING LEVER

* The terms stop peg and stop pin are used synonymously on the DOMINO XL DF 700.

6 ROUTING HEIGHT ADJUSTMENT

PRESELECT SLIDER

7 ROUTING DEPTH ADJUSTMENT

MARKER

8 ROUTING DEPTH ADJUSTMENT

LOCKING KNOB

9 ROUTING DEPTH ADJUSTMENT

SLIDER

10 MAINS CONNECTION

11 SPINDLE LOCK

12 EXTRACTOR STUB

13 ROUTING HEIGHT ADJUSTMENT

CLAMPING LEVER

14 ON/OFF SWITCH

15 DOMINO HOLE WIDTH INDICATOR

16 RUBBER BUFFER

17 STOP PINS

*

1514

Page 18

1.4 Performing basic settings for the DOMINO joining machines

The DF 500 and DF 700 DOMINO joining machines are generally similar in handling and setting

options. You should be aware of these in order to fully utilise the machines’ flexibility. All basic

settings are explained step by step below. We refer to these basic settings where appropriate in

the individual application examples.

1.4.1 Switching on/off

To switch on the DOMINO joining machine, connect the plug-it

cable to the tool, attach the extractor hose and then push the

on/off switch on the top of the tool forwards and down until it

locks in position.

To switch off, press the on/off switch at the rear to unlock.

Page 19

1.4.2 Selecting hole width

This is where the unique domino slot principle comes in. The first hole, known as the locating hole, is

routed appropriate to the selected domino diameter. Owing to the domino in the locating hole, the joint

aligns exactly with the front edge – the joint is correctly positioned. The remaining holes are routed with

clearance as slots. This makes aligning and joining effortless; the joint is nevertheless exact, perfect

and stable. On the DF 500, three different hole widths can be selected, and two on the DF 700.

DF 500 DF 700

1

DF 500

1 The standard width, corresponding exactly to the domino

width: 13 mm plus the cutter diameter

2 The average hole width, giving the domino some clearance

(6 mm): 19 mm plus the cutter diameter

3 The largest hole width, providing a lot of clearance (10 mm):

23 mm plus the cutter diameter

NOTE Please only change the hole width by turning

the rotary switch with the motor running, but never while

actually routing.

DF 700

1 The standard width for precise routing is:

13.5 mm plus the cutter diameter

2 The hole width with clearance (3 mm) corresponds to:

16.5 mm plus the cutter diameter

NOTE On the DF 700 the corresponding hole width is set

using the adjusting lever on the left of the machine – the

specified hole width can be seen on the display on the top

of the machine.

1.4.3 Selecting domino length and thickness

Because selection of the domino thickness determines the selection of the cutter used, you first decide on

the domino size and then employ the correct cutter (see section 1.4.4).

1716

Page 20

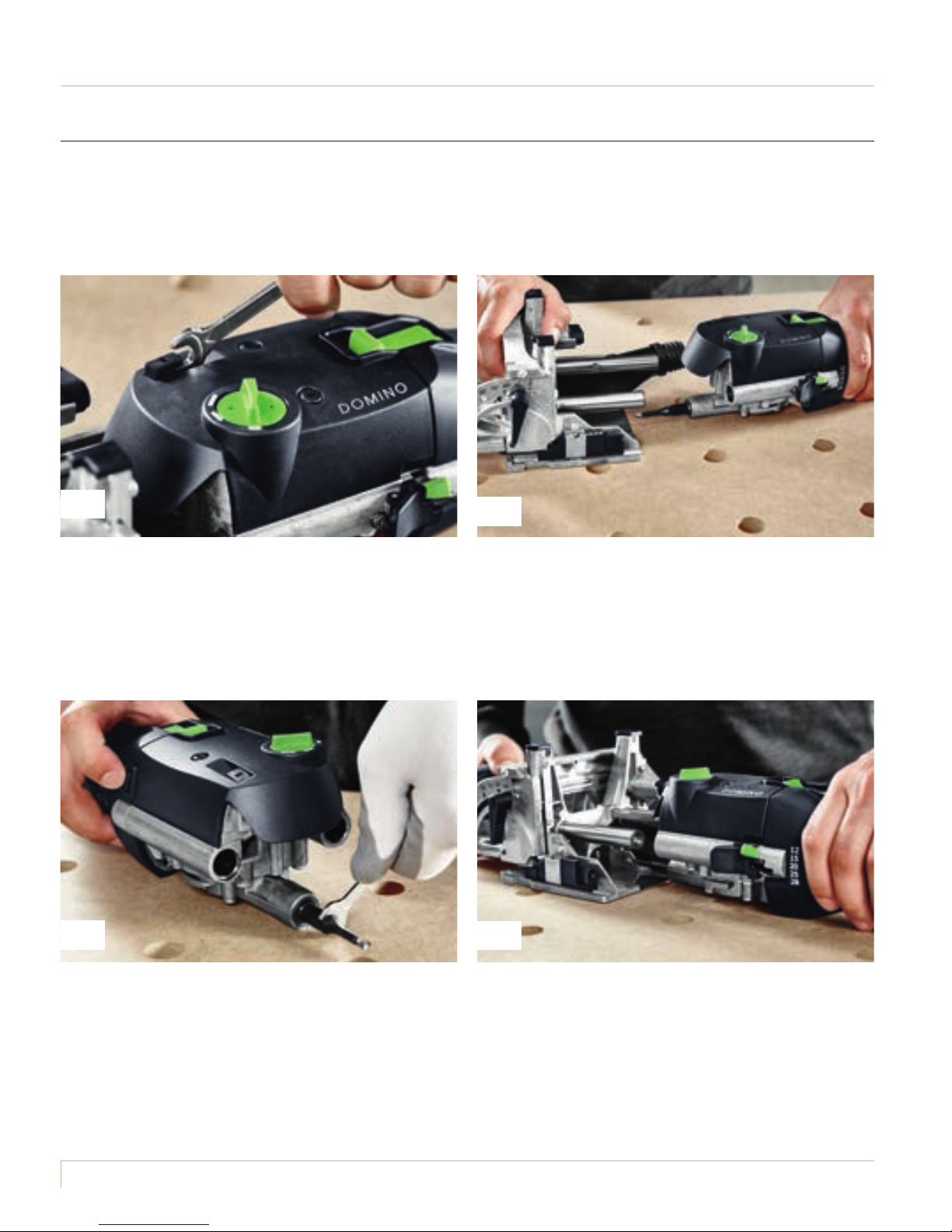

1.4.4 Cutter replacement

After selecting the domino, use the appropriate cutter to make the hole. For example, if you would like

to use an 8 mm diameter domino, you also use the 8 mm cutter.

1

Always disconnect from the mains to change the cutter.

Then raise the unlocking lever using an open ended spanner

(included) until it noticeably locks in place.

3

2

Separate the motor unit and guide frame.

4

Hold the spindle lock on the motor unit, loosen the cutter

using the open ended spanner and screw off. Screw in the

new cutter using the open ended spanner, keeping the spindle

lock pressed. Then release the spindle lock.

Before inserting a new cutter, ensure that the machine, the

guide frame and the guides are clean and free from chippings.

Remove any soiling. Only use sharp, undamaged and clean

cutters. Now push the guide frame onto the motor unit until it

audibly locks in place.

Page 21

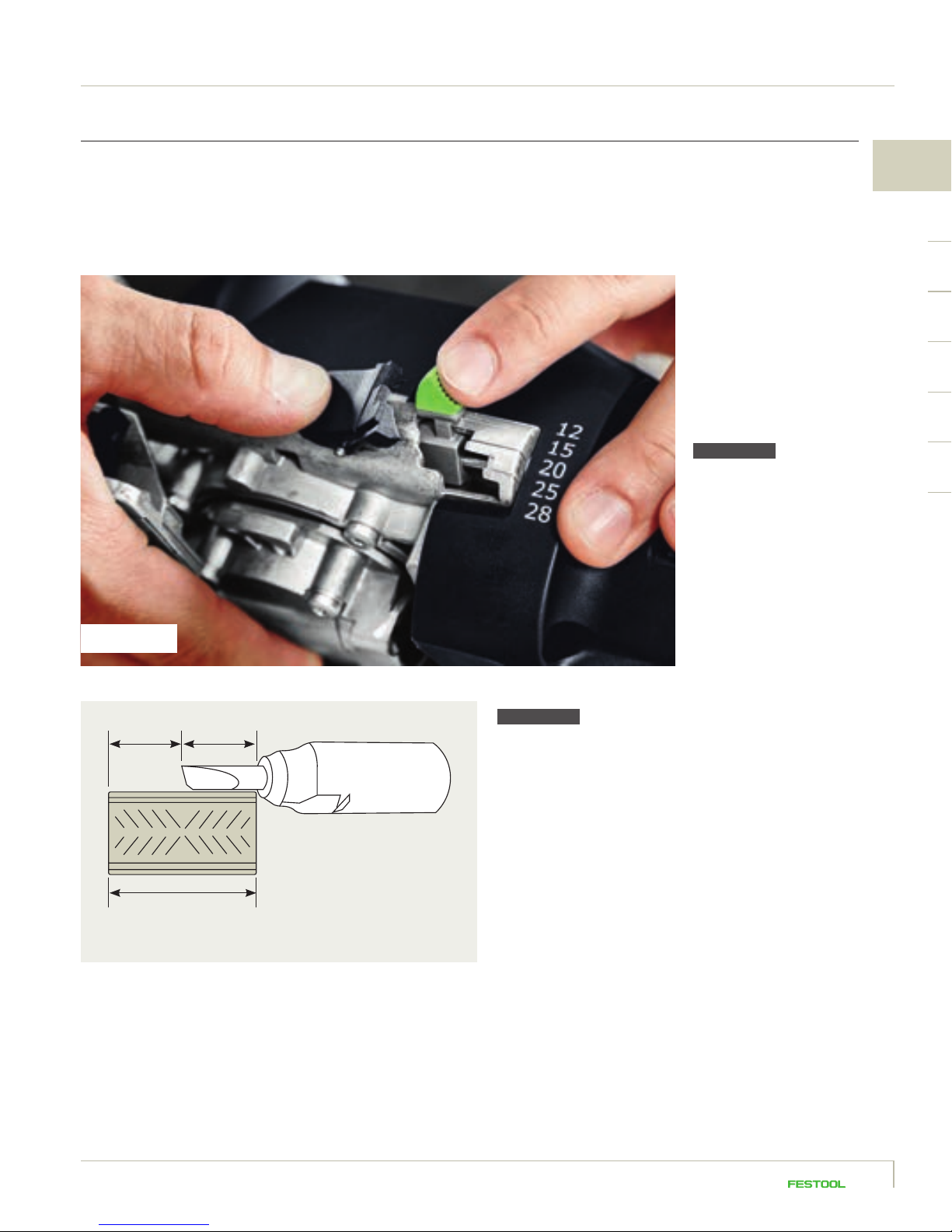

1.4.5 Depth adjustment range

The routing depth determines how deep the cutter cuts into the workpiece. The appropriate routing

depth must be set for the different domino lengths; in most cases half of the domino length. The

routing depth set on the joining machine corresponds to the depth of the domino hole.

DF 500

Open the locking lever lock by

pressing. Now set the required

routing depth using the locking

lever (possible depths ar e 12 mm,

15 mm, 20 mm, 25 mm, 28 mm).

Now release the locking lever

lock again.

ATTENTION

Due to the short shaft length

only the depths 12 mm, 15 mm

and 20 mm are allowed when

using the 5 mm diameter cutter.

1

DF 500

10 mm 10 mm

Domino 4 x 20 mm

20 mm

Festool

D 4-NL 11 HW-DF 500

ATTENTION The D 4-NL 11 HW-DF 500 specialist cutter is

available for the 4 x 20 mm dominos. Please use a routing

depth of 20 mm when working with this domino and cutter.

However, the true routing depth is 10 mm, because the

specialist cutter has been shortened by 10 mm due to the risk

of fracture. This domino can only be positioned centrally.

1918

Page 22

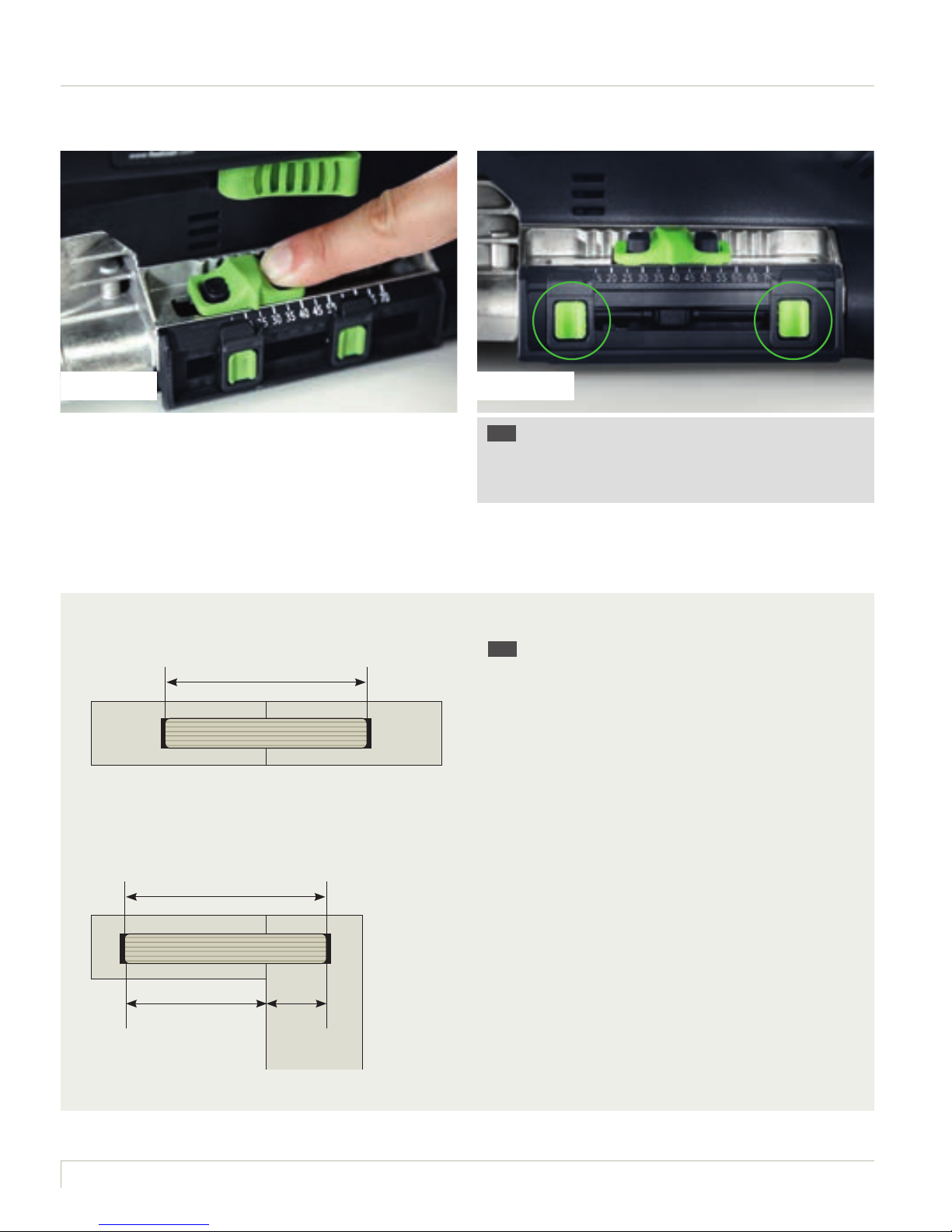

DF 700 DF 700

DF 700 Press one or both locking switch to set the routing

depth. Move the routing depth setting slider to the required

routing depth. On the DF 700, the possible routing depth is

between 15 mm and 70 mm. Now release the locking switch–

briefly check that the slider has locked in to position.

Domino centred

40 mm

Randomly located domino

40 mm

TIP You can mark two routing depths using the two green

markers and easily move between the two using the slider.

For example, this can be helpful when using a domino depth

for spacing as well as for repeated, identical routing depths.

TIP The domino should generally be centred

within the joint; that is, the routing depth should

correspond to half of the domino length. However,

depending on the workpiece or joint type, it may

be necessary to locate the domino randomly. In

this case, both of the holes routed in the workpieces

must together correspond to the length of the

domino being used.

Example: The domino being used is 40 mm long;

the left hole is 28 mm deep, the right hole 12 mm

– that is, together 40 mm.

28 mm 12 mm

Page 23

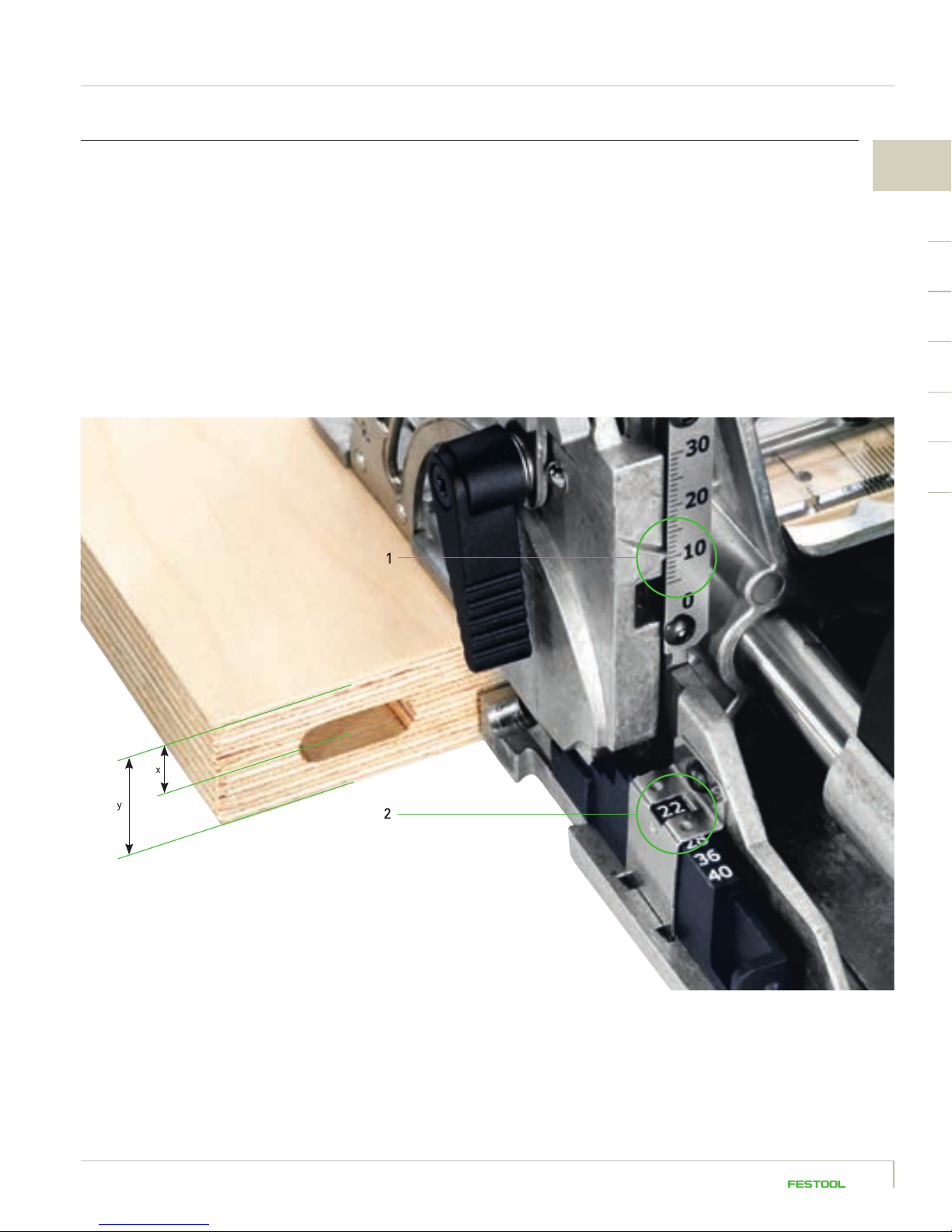

1.4.6 Height adjustment range

The routing height setting on both the DOMINO DF 500 and the DF 700 is performed using the preselect

slider, allowing predefined heights to be used. Alternatively, any individual dimension can be set using

the scale. The routing height defines the distance from the workpiece top from which the hole is routed

into the workpiece. Selection of the correct routing height depends on the material being worked on,

and also on the type of joint to be produced on the other. Here, it is not absolutely necessary for the

routed hole to be in the centre of the material. You can therefore find more information on the topic of

routing height in the description of the individual applications in section 4.

1

y = Material thickness

x = Distance from top of workpiece to centre of routed hole

1 Scale for indiv idual settings (distance from top of

workpiece to centre of routed hole)

2 Pres elect slider (material thickness)

DF 500 – set routing height using the preselect slider.

The dimensions set using the preselect slider determine the material thickness being worked and centre the routed hole exactly

in the middle of the selected disc size – without you having to calculate the distance to the centre. Release the routing height

adjustment clamping lever and lift the front section of the guide frame using the secondary handle. Now select the required disc

size using the slider (16 mm, 20 mm, 22 mm, 25 mm, 28 mm, 36 mm, 40 mm). Then push the front section of the guide frame

downwards until it stops and close the clamping lever.

2120

Page 24

DF 500

DF 500 – set any routing height

The given dimension defines the distance between the

underside of the leaf and the centre of the routed hole. Loosen

the routing height adjustment clamping lever and, using the

secondary handle, raise the front section of the guide frame.

Then push the slider towards the motor unit until it stops.

Set the required routing height on the scale by moving the

front section of the guide frame horizontally. Now close the

clamping lever.

DF 700 DF 700

DF 700 The routing height is adjusted on the DF 700 equivalent

to the DF 500. The only difference to note: here, the preselect

setting does not determine the board thickness, but instead

the true distance from the top of the workpiece to the centre

of the routed hole.

22

NOTE The alignment of the clamping levers can be

adjusted by lifting them. In the tightened state, they

should not overhang past the contact surface.

Page 25

1.4.7 Angle adjustment range

Number of equal sides Cutting angle DOMINO angle

3 Triangle 60 30

4 Square 45 45

5 Pentagon 36 54

6 Hexagon 30 60

7 Heptagon 25.7 64.3

8 Octagon 22.5 67.5

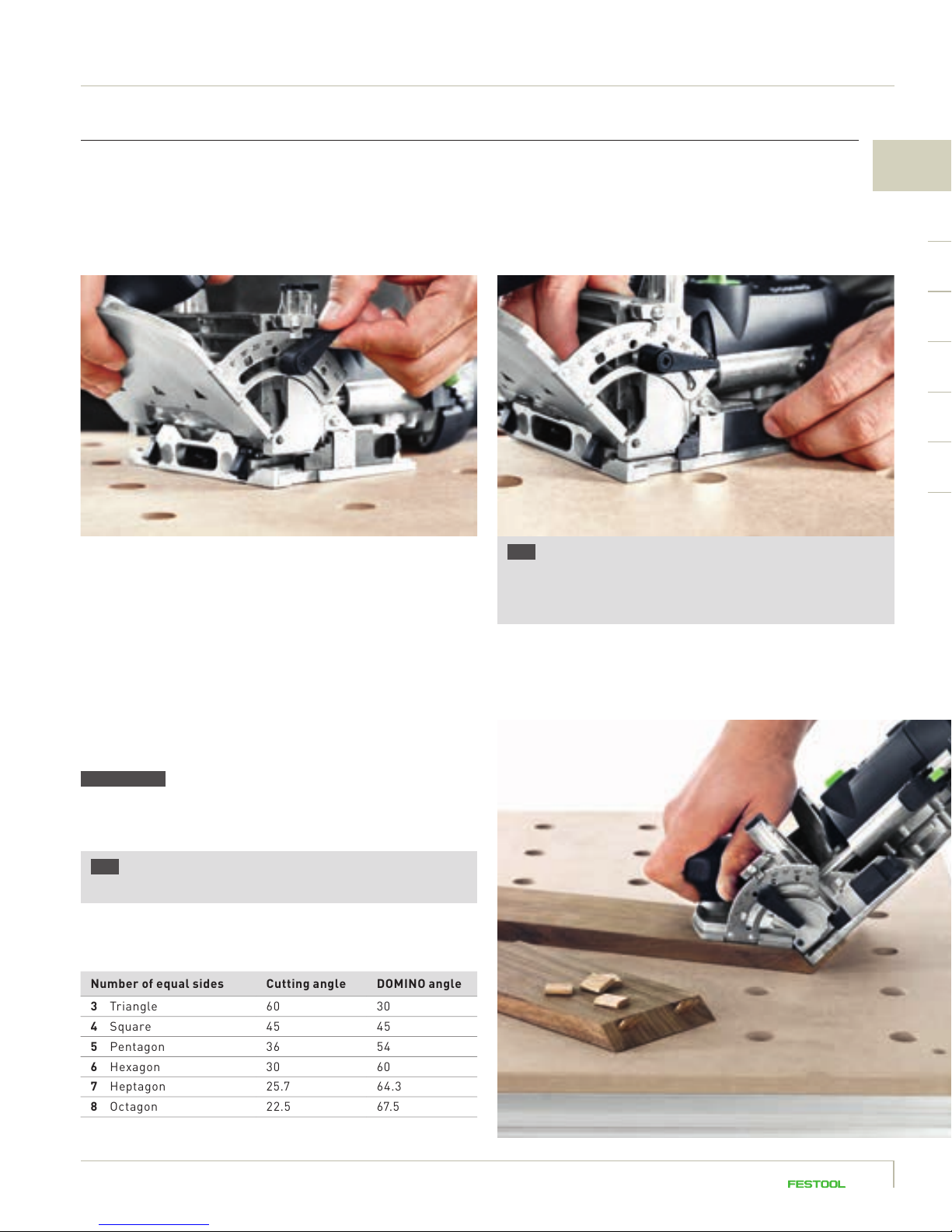

For mitred joints, the joining machine routing angle can be set using stages, predefined angles or any

other degree between 0° and 90°. The precisely machined dominos optimally align the workpiece and

prevent the mitre from slipping when being glued.

DF 500 and DF 700: Loosen the angle stop clamping lever to

adjust the routing angle. Then set the required angle, either

continuously on the scale between 0° and 90° or in stages at

0°, 22.5°, 45°, 67.5°, 90°. Close the clamping lever.

TIP Route thin workpiece with a mitre. Set the required

angle. Loosen routing height adjustment clamping lever, push

the slider towards the motor unit until it stops and then push

the angle stop all the way down. Close the clamping lever.

1

ATTENTION When using mitre routing, set the routing

height and depth as low as possible, otherwise there is a

danger that the cutter will penetrate through the opposite

side of the workpiece.

TIP Material thicknesses from 15 mm can be mitred

using the 4 x 20 mm domino.

The table shows some of the most commonly used mitre angles:

2322

Page 26

1.4.8 Working with the stop system

One of the greatest time advantages of working

with DOMINO joining machines is the result of

working without the need for complex measuring

or marking – the machine can be positioned

quickly and accurately by using stop catches

(DF 500) or stop pins (DF 700).

The edge of the workpiece is visible in the machine’s upper

triangular viewing window. If you do not need the stop

catches, they are automatically pushed aside during the

routing process.

It is easiest to quickly define the positions of repetitive domino

holes by using the integral stop catches for both parts of

the workpiece. The distance between the stop catch and the

router centre is 37 mm. Place the DF 500 at the edge of the

workpiece using a stop catch.

TIP With the aid of the additional stop provided with the

DF 500, the lateral distance to the DOMINO centre can be

reduced from 37 mm to 20 mm.

DF 500 It is possible to define the positions of the DOMINO

routed holes by simply drawing and locating the machine

on the scribe mark looking through the viewing window.

Page 27

1

The DF 700 possesses an innovative stop system, allowing even domino groups to be quickly and precisely positioned in relation

to a reference edge using the integral stop pins.

There are six stop pins on the stop side of the joining machine. Unnecessary stop pins can be pushed aside individually and lock

in place, and can all be released again by pressing the button on the side of the machine (see markings in the figure).

2524

Page 28

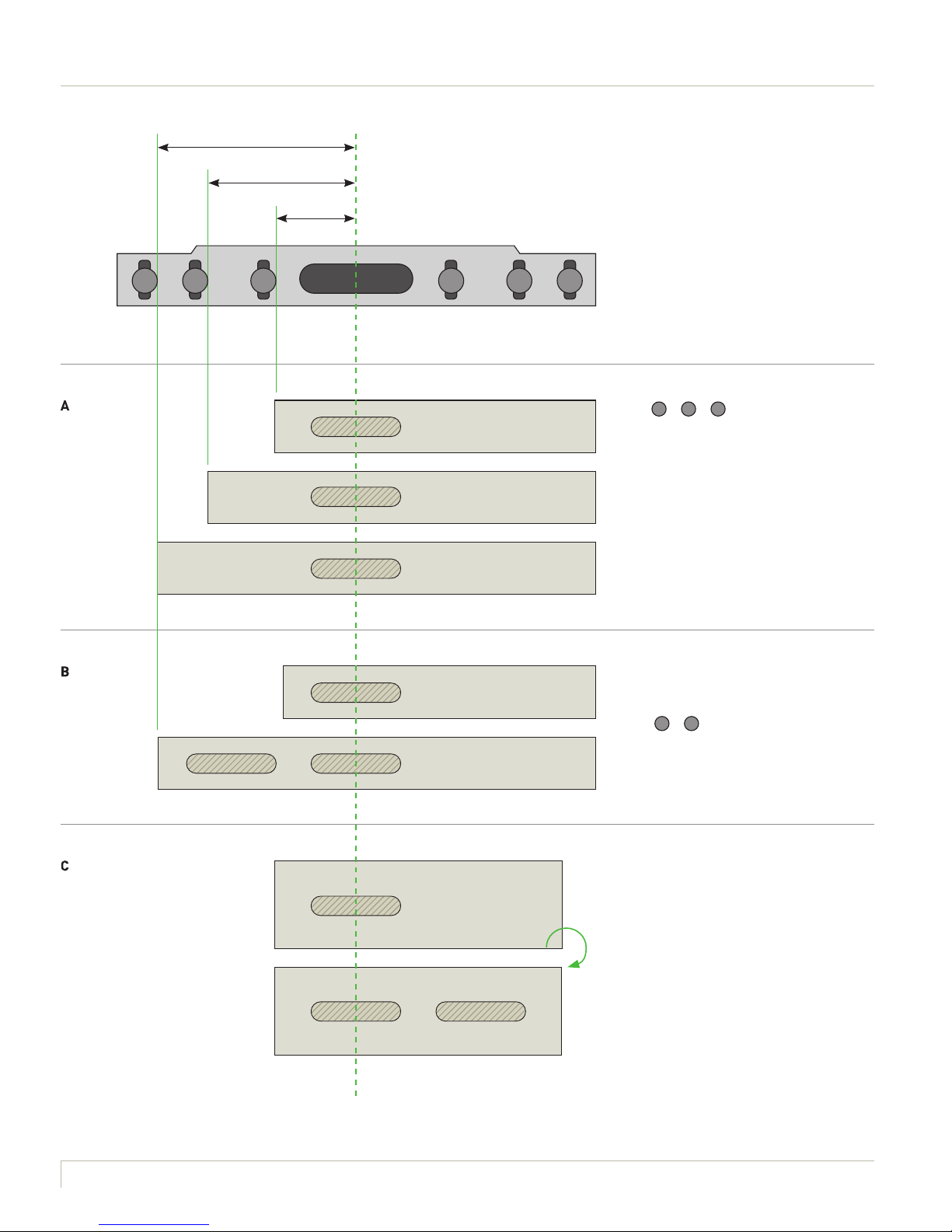

50 mm

37 mm

20 mm

1 2 3 3 2 1

The stop pins serve as distance pieces

to the router centre and can be separately located.

A

Pins (

1

– 2 –

3

) allow three

separate distances to a reference

edge.

B

The pins allow two domino holes to

be placed adjacent to each other

at a defined distance to a reference

1

edge (

–

3

).

C

The pins allow two domino holes to be

placed by rotating the workpiece, e.g.

for the same moulding cross-section.

Page 29

Additionally, it is possible to insert the pin in the previously routed domino hole and to use the edge of the domino

hole as a stop. This means you can define domino holes over larger, uniform distances independent of the edge of the

workpiece and without marking. (In the example using pin 2 in the drawing.)

37 mm 37 mm 37 mm 37 mm

1

2726

Page 30

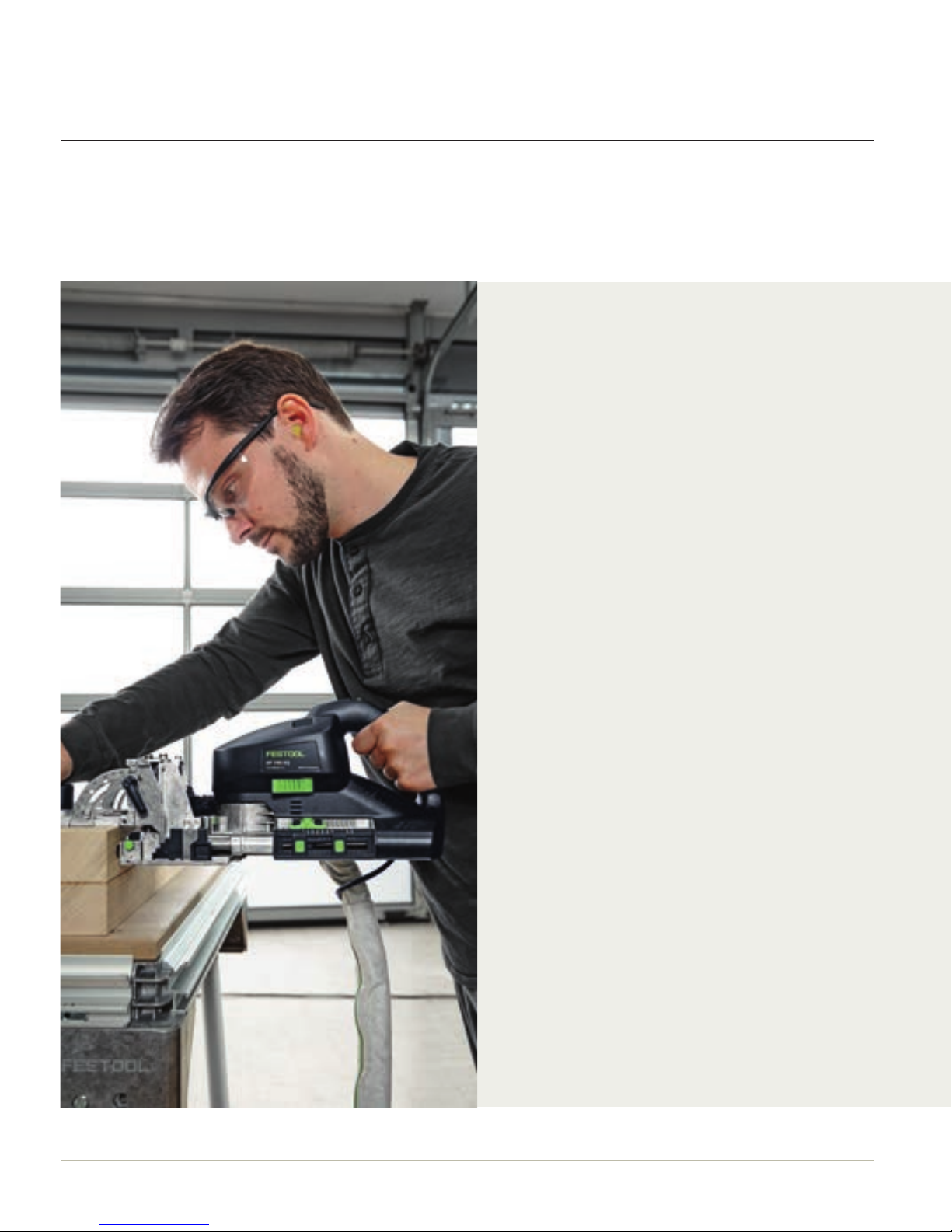

1.4.9 Working with extraction

Large amounts of timber chippings are created when working with the DOMINO joining machines. To improve

chip transfer out of the routed hole during the routing process, and to also protect your own health, we

recommend you always work with dust extraction. However, please examine all domino holes for chips after

routing and empty them if necessary.

Selecting the correct mobile dust extractor:

it all depends on the dust category!

In addition to improving the progress of your

work, the mobile dust extractor also primarily

ensures improved health when working with

the DOMINO joining machines: because when

working in dusty environments, in particular with

materials such as timber, the dust produced

can become a serious health risk. This has been

shown by a recent meta-analysis*, which established that the relative risk of asthma amongst

employees exposed to timber dust is 1.53 times

higher than that of the normal population.

So do yourself a favour and make sure you have

clean air in your workplace – and work with

a tested and approved mobile dust extractor.

You will also be complying with all the statutory

regulations, too.

* Source: Perez-Rios M, Ruano-Ravina A, Etminan M, Takkouche B. A.

Meta-analysis on wood dust exposure and risk of asthma. Allergy

2010;65:467-73.

Page 31

The Festool mobile dust extractors were especially developed for and coordinated with our tools, and

are therefore also ideal in conjunction with the DOMINO joining machines. Whether you choose a mobile

dust extractor with a volume of 26, 32 or 48 litres and with or without automatic AUTOCLEAN cleaning

technology, depends entirely on your personal preferences and other use preferences.

It is important that you work with a mobile dust extractor in dust category M.

This dust category is approved for all timber dusts which are created when

routing with the DOMINO joining machines, but also for dusts produced by putty,

fillers and cement, concrete, tile adhesives and paints such as latex and oil

paints, and also materials containing sand and gravel.

1

2928

Page 32

Page 33

2

The domino

3130

Page 34

2. The domino. The shape makes the difference.

Not flat. Not round. Just domino.

The difference is in the detail. More precisely: in

the shape. Dominos unify all of the benefits of

round dowels and biscuits. And are therefore as

stable as mortise and tenon. They are available

in 14 fixed sizes or as rods – for both inside and

outside, and for delicate and solid workpieces.

Round dowels

The traditional solution for frames and racks.

Round dowels are one of the most important connecting

elements in furniture making, allowing timber connections

to be quickly and reliably aligned. Because round dowels

do not allow offsets, exact drilling is generally performed

on stationary or semi-stationary machines.

Biscuits

The standard for boards for decades.

Biscuits are quick and always used with manually

operated machines, pencil marks are used to position

them. Because the biscuits are shorter than routed

slots, a slight offset during routing is not a problem.

The joint is movable, however this advantage is off set

by the additional position during gluing up.

Page 35

Dominos

Not flat. Not round. Just domino.

The special shape, in combination with swelling glue pockets and longitudinal grooves, gives the dominos

a secure hold. For absolutely rotation-resistant connections and maximum stability. And with substantially

faster working: the first domino hole is very easily positioned and precisely routed with the aid of stop catches

(DF 500) or stop pins (DF 700). It immediately aligns the workpieces, being connected exactly and flush to

a reference edge. However, the DOMINO system even tolerates minor imprecisions in the additional domino

holes, routed with clearance. Compared to traditional connecting elements, you always have the choice of

working precisely or with clearance when working with DOMINO joining machines.

2

NEW The domino corner and flat connectors

As stable as dominos, but can be flexibly released again if necessary.

3332

Page 36

Dominos.

100 % rotation resistant

From the ver y first domino,

the joints are absolutely

rotation resistant without

additional workpiece

alignment.

Highest stability

The unique shape of the

domino in combination with

swelling glue pockets and

longitudinal grooves, gives

the dominos a secure hold.

Fits perfectly

The DOMINO joining machines

route the holes to an exact fit

where needed. The domino’s

special groove geometry

ensures a perfect precision fit.

For inside and out

Dominos are available in two

materials: Beech for interior

applications and weatherproof,

insect- and mould-resistant

Sipo dominos for outside

applications.

Beech dominos are certified by

the Pan European Forest Council

(PEFC) for timber products from

sustainable, caring and responsible

forest management.

Sipo dominos are weatherproof,

and insect- and mould-resistant,

and are therefore ideally suited

for outside applications. They are

manufactured from timber originating in sustainably managed and

controlled forests.

Always a stable connection.

The DOMINO system provides the correct dominos for

every application. With its range of sizes, two timber

types for inside and outside applications and additional,

individually adaptable rods, there are practically no

limits to this system’s options.

The 8 –14 mm diameters are also available as rods and in t wo t ypes of timber for interior and exterior applications.

* Flat connectors – here with the optional enlarging clips around the transverse anchor.

Page 37

Environmentally friendly

All dominos originate from

sustainable forest management.

The Beech dominos are certified

by the Pan European Forest

Council (PEFC).

And now also flexible

Connect even faster. And release

again if needed. The new corner

and flat connectors for the

DOMINO XL DF 700 guarantee

a stable domino connection –

but also add the option of quick

release if required.

2

NEW

Corner

connectors

Flat

connectors*

3534

Page 38

Page 39

3

DOMINO system accessories

3736

Page 40

3. DOMINO system accessories. For even greater application versatility.

The Festool system stands for application versatility and simplifies your work with accessories

thought through to the finest detail: with a variety of stops, compatible with both DOMINO joining

machines, even the most complicated of shapes

can be easily connected.

Handrail fence

Timber rods in diameters from 35 – 60 mm are rotation

resistantly fixed by a single domino: simply push on the

handrail fence, precisely adjust, fit the workpiece and

route.

(For DOMINO DF 500 and DOMINO XL DF 700)

DETAILS on working with the handrail fence can be found

in the example applications on page 56.

Page 41

Trim stop Cross stop

3

Trims of 22 – 70 mm width can be quickly positioned and

fixed centrally using the trim stop – ideal for rack joints.

(For DOMINO DF 500 and DOMINO XL DF 700)

Repetitive hole centres of 100 – 205 mm can be easily

transferred using the cross stop – without scribing the

workpiece.

(For DOMINO DF 500 and DOMINO XL DF 700)

DETAILS on working with the trim stop can be found

in the example applications on page 50.

DETAILS on working with the cross stop can be found

in the example applications on pages 74 and 79.

3938

Page 42

DF 700 support surface extensionDF 500 additional stop

DF 500 DF 700

The additional stop provided with the DF 500 increases

the contact area and reduces the lateral distance of

the stop catches to the DOMINO centre from 37 mm

to 20 mm. This allows precise positioning of narrow

workpieces.

The support surface extension provided with the DF 700

allows the contact area to be extended for routing on

the edge of the workpiece and the machine is thus more

reliably guided.

40

DETAILS on working with the additional stop and the

support surface extension can be found in the example

applications on page 76.

Page 43

4

Practical application examples

41

Page 44

4.1 Overview: connections with DOMINO joining machines

The DOMINO system is ideally suited for board,

frame and rack joints, involving narrow or wide,

delicate or solid workpieces with dominos ranging

from 4 to 14 mm in diameter or flexible, separable

corner and flat connectors. In short, the DOMINO

system is perfect for realising infinite connection

possibilities.

The following chapter showcases examples of

how to work with these various connection types.

Naturally all of these examples are variable in

terms of size, material, and the size and number

of dominos, etc. Nevertheless, these examples

always demonstrate the basic procedure which

can be used as a reference.

Applications

Board connections

Drawers from 4 mm dominos

Furniture making with 5 mm and 6 mm dominos

Solid timber furniture with 8 mm and 10 mm dominos

Solid timber furniture (e.g. beds) with 12 mm and 14 mm dominos

Rack connections

Lightweight rack cons truction (e.g. chairs) up to 10 mm dominos

Stable rack constr uction (e.g. tables) with 10 mm to 14 mm dominos

Frame and stand designs

Frame joints

Furniture fronts in frame design w ith 8 mm and 10 mm dominos

Solid timber furniture in frame de sign

Entrance door s and internal doors

Additional applications

Connection of narrow tr ims from a w idth of 25 mm

Connection of rods w ith handrail fence

Connection of wide rails (e.g. solid timber panels)

Corner connectors from 30 mm material thickness, separable

Flat connectors from 3 0 mm material thickness, separable

Page 45

DOMINO joining machines DF 500 DF 700

4

very suitable suitable

4342

Page 46

4.2 Frame joints

The applications of the DOMINO connecting system are virtually unlimited, as well as uncomplicated.

Just one domino is enough to connect a frame corner securely and ensure it will not twist – so attractive

furniture fronts can be quickly and easily achieved.

With the DF 500, very small dominos can be used even for furniture joints, making it possible to

process very small spindles or narrow frame rails.

With the DF 700 in contrast, stable frame joints can be created in the same way, for example, for

beds, tables or internal doors. Thanks to the larger routing depth, the DF 700 is also suitable for

pinned joints. Some of these connection options are demonstrated in the following examples.

4.2.1 Mitred frame joint

1

In this example, we are processing 5 x 30 mm dominos.

Set the routing depth to 15 mm for this.

Page 47

2 3

4

Select the routing height based on the workpiece; in this

example, the frame is 20 mm thick. Set the routing height

on the DF 500 to 20 mm in this case. The width of the frame

in this example is 60 mm.

We are using two dominos per corner connector for maximum

stability. Place the routing machine on the mitre cross section

and carefully work with the stop catch at the side against the

tip of the mitre. Route the first hole with precision.

4

For the second routed hole, either mark out the position or

run the machine flush along the outside tip of the mitre. This

routed hole can either be precisely routed like the first hole –

which increases the stability of the joint but requires more

precision – or it can be routed with clearance – but then you

must use a sufficient amount of glue for the joint.

Use this method to route the holes in all four frame rails.

5

Insert the dominos, using a sufficient amount of glue, join the

frame rails and brace them with clamps.

4544

Page 48

4.2.2 Butted frame joint

When connecting frame rails without

mitring, i.e. butted joints, proceed

as you normally would. This example

shows another option for using

the DOMINO joining machine on the

workpiece.

1 2

Set the routing height to match the thickness of your

workpiece. For the routing depth, select half the domino

length. Route the holes by either using the right hole width

for both for extreme precision fit or routing the second

hole with clearance, if desired.

The routed holes can be set by marking them out as usual or

using the stop system with the scale in the viewing window –

in this example, 15 mm from the outside edge. For this option,

place the scale with the 15 mm marking at the edge of the

workpiece.

Page 49

3 4

4

The second routed hole is set here using the stop catch.

This method makes it possible to position two dominos next

to each other working from just one reference edge.

TIP When using the stop catches, the edge of the work-

piece can be seen in the triangular viewing window of the

DOMINO joining machine.

Use this method to carry out routing for all four frame rails,

whereby every second frame rail is routed into the workpiece

lengthwise instead of into the front.

51 2

Then glue the frame rail and brace with pads and clamps,

if necessary.

TIP If the frame rail needs to be rebated or grooved, the

rebating depth must be added in advance when routing

the domino holes, so that the domino is centred later despite

the rebate (which then takes up part of the depth of the

domino hole).

4746

Page 50

4.2.3 Stable frame joints with the DF 700

Use the DOMINO DF 700 for stable frame joints such as for doors,

where larger dominos can be processed for even greater stability.

In this example, a panel door is created with a pinned internal rebate

and additional tenon.

The DOMINO joining machines are unique in that you can set the routed

holes even after rebating, which would not be possible with a classic drill

for conventional domino joints, for example, due to the lack of support

surface. This ‘pinned joint’ requires small deviations in the routing

depth setting, which are explained in the following.

TIP Due to the pinned joint, the 14 x 140 mm domino cannot be

processed despite the maximum routing depth of 70 mm for the

DF 700. The maximum possible standard domino is the 14 x 100 mm.

However, if you wish to make full use of the maximum routing depth

and cut the domino itself to the correct maximum size, you can do

so by cutting the domino to the appropriate length and creating the

perfect domino size yourself.

Page 51

1 2

4

Mark out the desired position of the domino and work using

the viewing window. Route into both parts of the workpiece

at the maximum routing depth (70 mm each) with the 14 mm

router.

In the end grain, set both routed holes with the correct hole

width – in this case the dominos are later glued and then fit in

precisely. The routing height is half of the workpiece thickness

(which is 40 mm in this example, so the routing height setting

is 20 mm).

In the lengthwise rail, set the routed holes with a 70 mm

routing depth as well, but route the first hole with precision

and the second as a slot with clearance. Proceed likewise

for the additional lengthwise and crosswise rails.

3 4

Then cut the dominos to fit the ready-made

holes. In this example, the nominal domino

length is 115 mm, which is calculated by

doubling the routing depth of 70 mm = 140 mm

and subtracting the pinned joint of 25 mm =

115 mm. Cut the domino a few millimetres

shorter (so that later the glue has enough

space), down to 112 mm. Chamfer the cut

domino at the edges using a sanding block.

Then drive the dominos all the way into the routed holes

in the end grain, adding glue to the joint.

Join the lengthwise and crosswise rails using fastening

clamps and glue the joint.

4948

Page 52

4.3 Rack joints and secure spindle positioning

Making rack joints with the DOMINO joining machine saves an incredible amount of time. Especially

when relatively narrow spindles are being processed, working with the trim stop (available as an

accessory or included in the DF 500 set) is recommended for safe and precise workpiece routing. This

trim stop fits both the DF 500 and the DF 700 and securely holds spindles with 22 – 70 mm thickness.

Page 53

1 2

4

Mount the trim stop onto the DOMINO joining machine

according to the operating instructions.

Set the width of the trim stop to the thickness of your spindle

by adjusting the guide in the parallel side fence to the correct

dimension using the scale and the green rotary wheels. In

this example, we are working with 30 x 30 mm rectangular

spindles.

3 4

Using the spindle as a guide, ensure that the trim stop dimension

fits perfectly; make further adjustments if necessary.

To process a 6 x 40 mm domino as in this example, use the

6 mm router (6 mm dominos can only be processed with

the DF 500). For details on changing the router, see chapter

1.4.4, page 18.

5150

Page 54

Set the routing height to 15 mm, so that the domino is centred

on the spindle later. Set the routing depth to 20 mm, so that

the 40 mm domino is later positioned evenly between the

spindle and the handrail. Route the hole in the spindles using

the narrow hole setting.

NOTE You can naturally use the DF 700 to apply this

method with a domino diameter of 8 mm or greater.

CAUTION Especially with handrails, it is often not possible

to position the joining machine securely on the side of the

workpiece due to the handrail design; the round shape

prevents the DOMINO joining machine from having a secure

support surface.

6

The trim stop provides additional support in these cases:

mark out the desired position of the spindles on the handrail,

where routing will take place later. From this marking, set

an additional marking 10 mm away (or 15 mm when using the

DF 700) – this is where the joining machine will be placed

later. Then set the routing angle to 90° so that you can route

vertically into the handrail from the top. The routing depth is

20 mm again, as with the spindles, with the 6 x 40 mm router

to be processed.

Page 55

75 8

4

Then set the trim stop to the width of the handrail.

Route the holes in the handrail, positioning the joining

machine on the second marking.

96

Applying a sufficient amount of glue, insert the dominos into

the routed holes and join the handrail to the spindles.

5352

Page 56

TIP Of course, bevelled joints are also possible with

spindles needed especially for going up and down stairs.

In this case, set the cutting angle of the spindle on the

DOMINO joining machine during routing (using the routing

angle adjustment) and route the domino hole.

Set the routed holes in the handrail as described above.

Then join the spindle and handrail together.

TIP For workpieces where a secure support surface is

possible for the joining machine, simply marking out the

domino holes or central axis of the spindles is sufficient

(in this case you do not have to work with the trim stop).

Set the routing height to the centre of the workpiece. Mark

out the axis distance of the spindles on the top side of the

workpiece. In this case (when simply using markings) bring

the scale in the viewing window of the DOMINO over the

scribe mark and set the routed holes. A second scribe mark,

as in the example of the handrail above, is not necessary here.

Page 57

Notes

4

5554

Page 58

4.4 Round profile joints

When connecting round timber profiles, such as those used for handrails, the handrail fence is

available as an accessory to ensure a secure workpiece hold. This part fits both the DF 500 and

the DF 700 for diameters from 35–60 mm. The following example describes how a stop is created

using this handrail.

Before starting, ensure that the correct router is used. In this

example, we are processing an 8 x 40 mm domino, so the 8 mm

router must be used.

Set the routing depth to 20 mm.

Select the routing height so that the domino is offset towards

the inside of the mitre, preventing the routing from going

1

through the workpiece. In our example with a round timber

profile with 40 mm diameter, set the routing height to 20 mm.

Page 59

4

2

Mount the handrail fence onto the DOMINO DF 500 or DF 700

according to the operating instructions.

TIP Before processing your workpiece, it is important

to create a sample piece and make fine adjustments to the

handrail fence according to the operating instructions.

3

The handrail fence holds the workpiece securely and centres

it automatically thanks to the prism-shaped contact surfaces.

4 5

Set the routing angle on the joining machine according to your

sawing angle on the workpiece. In our example, the handrail

was sawed at 15°, which means the routing angle is set to

75°; this is equal to 90° minus 15°. Secure the workpiece, on

the MFT multifunction table. Then route the hole in both

parts of the workpiece.

Insert the 8 x 40 mm domino into the routed hole, applying

glue to the joint. Then join the two workpiece parts together –

the joint is secured from twisting with just one domino!

5756

Page 60

4.5 Stable, separable corner connectors

The separable corner connectors provide

even more flexibility, especially with large,

solid workpieces like tables or beds. These

connectors allow for quick and easy assembly and disassembly of furniture pieces,

making transport a breeze. In terms of how

they are processed, the connectors are very

similar to the securely glued dominos to

a great extent and can be easily mounted

thanks to the large pulling and tightening

distance.

The example provided here demonstrates

how to create a table or bedpost.

Page 61

For corner connectors, you need the following components from the

DOMINO corner and flat connector system:

Dimensions for routing the

DOMINO corner connector

40

1. Anchor bolt

2. Self-drawing expansion bolt – for

a secure hold in the workpiece.

3. Transverse anchor including stud

4. DOMINO connector covers – clipped

around double-headed or anchor

bolts. Items included with

double-headed or anchor bolts.

x + min. 10

min. 2 5

y

min. 2 5

Only suitable for joining timber or timber-like material s in furniture construction (no lightweight

building materials!) The DOMINO connec tor is only a connecting element, not a load-bearing

element. Observe minimum routing depths and edge distances! For indoor use only!

C

x

B A

50 25

Hole width Routing depth Routing height

A

B

C

25 mm ~y/2

50 mm ~y/2

x + min. 10 mm;

min. 25 mm in

total

40 mm

4

Per corner connector:

1 x anchor bolt including DOMINO connector cover

1 x transverse anchor including stud

1 x expansion bolt

Optional: 1 x cover cap in silver, light brown or dark brown

The corner and flat connectors are always processed with

the 14 mm router on the DF 700.

5958

Page 62

1 2

Set the routing depth of the joining machine to 25 mm –

set the markers to 25 mm and 50 mm.

It is a good idea to work with the stop pins in this case. Select

the pins depending on the desired hole distance. Ensure that

the routing for the corner connector has a minimum distance

of 37 mm from the edge of the workpiece. If you work with the

stop pins, use the centre pin at least.

3

Route the domino holes in the table or bedpost (narrow hole

width) with a routing depth of 25 mm. Set one hole for the

expansion bolt of the corner connector, the others for the load

transfer via traditional dominos.

Page 63

4 5

4

Change the routing depth to 50 mm and route the holes

(narrow hole width) in the frame according to the scribe mark

or using the stop pin system. The routing height is determined

by the material thickness, using the usual method you already

know from working with your DOMINO DF 700. In this example,

the frame has a material thickness of 30 mm. Set the routing

height to 15 mm so that the routed hole is centred in the

material.

Then set the routing depth to 25 mm for routing the transverse

hole. (This dimension depends on the workpiece; see dimensional drawing. What is important to note is that the transverse

hole should overlap the longitudinal hole by 3 mm in depth.)

6 7

The flip stop point, i.e. the routing height adjustment, must

always be set to 40 mm. This ensures that the transverse hole

always sits at the right distance to the edge of the workpiece

and that the anchor bolt then catches the transverse anchor.

Then route the transverse hole into the frame, where the

connector will be inserted. Flip the handle down at the front of

the edge of the workpiece and align the machine at the scribe

mark or using the stop pins (depending on how the horizontal

routed hole was set).

TIP For a bigger and therefore safer support surface, it is

possible and would be beneficial during this routing process

to mount the support surface extension onto the DF 700.

6160

Page 64

8

Insert the expansion bolt into the centre routed hole in the post.

9

It is important to ensure that the expansion bolt is flush with

the workpiece surface.

10 11

Then screw the anchor bolt all the way into the expansion bolt.

This expands the expansion bolt, pulling it another approx.

1 mm into the workpiece thanks to the self-drawing property

of the bolt and locking it securely into place. A 10 mm open

ended spanner is used for this.

TIP Alternatively, a 4 mm hexagonal socket can be

inserted through the hole or a ratchet with a 10 mm

socket can be used.

Then unscrew the bolt just enough so that the countersink is

facing the right direction. The expansion bolt is now sitting

securely in the workpiece and cannot fall out of the routed

hole, even if the joint is disassembled for transport purposes.

Page 65

12 13

4

Clip the two DOMINO connector covers around the anchor

bolt. These are used to hold the corner connector flush

against the workpiece.

The transverse anchor is then inserted into the transverse

hole in the side wall, with the screw hole facing upwards.

14 15

Press the transverse anchor all the way into the routed hole

using the spanner.

Then insert the threaded screw. Tighten it only so that the

screw stays in place, but the opening remains open for the

anchor bolt.

6362

Page 66

16

Then join the frame to the post by pushing the connector and dominos into their respective holes.

TIP It is usually a good idea to fit flexible connectors to one

of the sides and securely glue dominos into the other side.

Page 67

17 18

4

Tighten the connection using a 4 mm hexagonal socket.

Optionally, you can cover the routing with a cover cap,

available in one of three colours depending on the material:

silver, light brown or dark brown.

19

This is a quick way to create a stable joint that can be quickly disassembled if necessary, without time-consuming measuring

or marking.

6564

Page 68

4.6 Stable, separable flat joints

The DOMINO flat connector is ideal for creating stable flat joints that are separable. You can connect

plates, kitchen worktops or other surfaces, quickly and flexibly.

This application example demonstrates how to connect a kitchen worktop.

Page 69

For flat joints, you need the following components from the

DOMINO corner and flat connector system:

1. Transverse anchors – here with additional widening. Prevents

the transverse anchor from drawing into sof t materials (e.g. kitchen

worktops).

2. Double-headed bolt – can be used with one or two domino clips.

3. DOMINO connector covers – clipped around double-headed or

anchor bolts. Items included with double-headed or anchor bolts.

Flat connector with enlarging clips around the transverse anchor –

specially designed for materials such as kitchen worktops.

4

x + min. 12

min. 3 0

x

4040

A A

C* C*

5050

Hole width Routing depth Routing height

A

When working without enlarging clips around the transverse anchor:

C

50 mm ~y/2

x + min. 10 mm;

min. 25 mm

in total

y

40 mm

Only suitable for joining timber or timber-like material s in furniture

construction (no lightweight building materials!) The DOMINO connector is

only a connecting element, not a load-bearing element. Observe minimum

routing depths and edge distances! For indoor use only!

When working w ith enlarging clips around the transverse anchor:

C*

x + min. 12 mm;

min. 30 mm

in total

40 mm

6766

Page 70

For this connection, you need at least two flat

connectors and the following components from

the DOMINO corner and flat connector system:

2 x double-headed bolts including DOMINO

connector covers

4 x transverse anchors including studs

Optional: 8 x enlarging clips for the transverse

anchors

Optional: 2 x dominos D14 x 75

Optional: 4 x cover caps in silver, light brown or

dark brown

1 4 5

Mark out the connector position on the surface of the worktop

at the desired point. Also mark the positions for additional

dominos (used to ensure a flush connection).

Page 71

2 3

4

Transfer the markings to the abutting surfaces of the worktop.

It is sufficient to do this where you later want to insert the flat

connectors.

Insert the 14 mm router.

Set the routing height: the distance from the flip stop to the

centre of the router should be half the worktop thickness.

With a worktop thickness of 38 mm, for example, set the

routing height to 20 mm.

Then set the routing depth to 50 mm and set the markers

to 50 mm and 30 mm.

6968

Page 72

Route the 50 mm deep holes with the narrow hole width

into both workpieces at the markings. The joining machine

is placed on the top side of the worktop in this case.

8

Then set a routing depth of 30 mm – this dimension depends on

the material. What is important to note is that the transverse

7 11 12

Switch the machine to the large hole width for the transverse

holes; this gives the transverse anchors enough space when

fitted with the enlarging clips.

hole should overlap the longitudinal hole by 5 mm in depth. If

using the transverse anchors without enlarging clips, an overlap

of 3 mm suffices. The routing height should be set to 40 mm

– this setting is identical for each connector, because it is

based on the length of the connector. Route transverse holes

in both workpieces at the points where the flat connectors will

be inserted.

Page 73

96 10

4

The enlarging clips around the transverse anchors prevent

the anchors from drawing into soft materials (e.g. kitchen

worktops) when tightened. Clip the enlarging clips around

the transverse anchors for this purpose.

Tighten the studs in the transverse anchor only so that the

studs stay in place, but the opening remains open for the

double-headed bolt.

11 12

Insert the transverse anchors into the routed holes. If you have decided to use additional dominos in order

to ensure a flush connection and extra transverse load

transmission, insert these into the other routed holes.

7170

Page 74

13

Clip the domino clips around the double-headed bolt.

TIP The double-headed bolt can be fitted with one or two

domino clips.

With one domino clip, the clip sits flush and neatly between

both workpieces.

With two domino clips, the double-headed bolt has some

clearance later for the alignment, because the clips each

sit in a half of the workpiece.

Page 75

4

14

Then push the double-headed bolt into the workpiece ...

16

Push both workpieces together ...

15

... and tighten the stud in the first transverse anchor.

TIP In general, these connections are located on the

bottom of tabletops and kitchen worktops, i.e. outside

of visible area. Nevertheless it is possible, of course, to

cover the transverse holes with cover caps.

17

... and clamp the connectors by tightening the stud on the

second workpiece side.

7372

Page 76

4.7 Mitred joints

Mitred joints are not just possible for smaller workpieces and frames – naturally they can also be

used for stabler connections of solid workpieces thanks to the DF 700. The following example uses

a bench to show how these types of joints are quickly and easily created using the DOMINO stop

pins of the DF 700.

1

Our workpiece is 30 mm thick. We are processing dominos with

8 x 40 mm thickness. The mitre angle is 45°. This requires the

following settings on the joining machine: adjust the routing

height to the smallest setting, 10 mm. The routing angle is 45°

and the routing depth is half of the domino length, i.e. 20 mm.

Page 77

4

2

Use the stop pin system to select the hole distance based on

the individual workpiece. In this example, we are working with

the two centre pins, to create a hole distance of 37 mm.

3

After routing the first hole (the pin is positioned at the edge of

the workpiece in this case), the pin goes into the routed hole,

thus setting the next stop. Route the first hole with precision,

and all other holes as slots with clearance.

4

Then join the workpiece parts together, gluing the dominos

carefully in the process.

TIP For larger hole distances, you can work with the cross

stop (available as an accessory or included in the DF 500 set)

both with the DF 500 and the DF 700.

7574

Page 78

4.8 Drawer connections

Even thin cross-sections from 12 mm can be joined perfectly with the DF 500, using the small

4 x 20 mm dominos and the appropriate 4 mm router. The 4 x 20 mm domino is suitable for

right-angle connections in thin workpieces or mitred joints from a 15 mm thickness.

Page 79

1 2

4

To process the smallest domino (4 x 20 mm), insert the 4 mm

router into the DOMINO DF 500. This router is unique in that

it is shortened by 10 mm. Therefore, at the maximum routing

depth of 20 mm, the routed hole is only 10 mm deep.

Set the additional stop on the DOMINO DF 500. This uses

the additional stop pins to reduce the lateral distance to the

centre of the DOMINO router from 37 mm to 20 mm.

3 4

Set the routing depth to 20 mm, the routing height to the

minimum and the routing angle to 45°.

Flip the additional stop pin from the additional stop and place

the joining machine on the workpiece – the routed holes

will be further offset from the edge of the workpiece, which

is beneficial with such narrow workpieces.

7776

Page 80

5 6

Insert the dominos into the routed holes, glue them ...

... and join the workpiece together.

NOTE Of course, butted joints are also possible using the

smallest domino. Proceed as described above and route the

domino holes on the front side using the additional stop.

The additional stop also provides a secure support surface

when clamped vertically.

Join the workpiece and glue it together.

Page 81

4.9 Butted panel joint

4

Panel joints like those for cupboard or shelving units can be ideally created with the DOMINO joining

machines. The following example shows how to create a unit with the DF 500.

7978

Page 82

1 52 6

With larger workpiece widths and larger hole distances, the

cross stop can be used to work easily with the stop pin system

instead of marking out holes.

TIP The cross stop can be used both for the DF 500 and

the DF 700 and allows for larger hole distances beyond

the stop pin system. Ensure that the stop is fitted onto the

machine in use.

To fit the cross stop on the machine in question, turn the

clamp jaw on the stop pin so that it is set to the DF 500 or

DF 700 position (each machine is marked accordingly on

the front of the pin).

3 74 8

Mount the cross stop onto the joining machine according to

the operating instructions. In this example, we are processing

6 x 40 mm dominos.

Due to the material thickness of 19 mm, the domino cannot

be inserted into both workpiece parts (front and surface) with

20 mm on each side.

For this reason, a routed hole with a depth of 25 mm is created

(on the front side) for this butted joint. The other routed hole

(on the surface) is 15 mm deep, so that the total domino length

of 40 mm is processed.

Place the joining machine at the front edge of the workpiece

with the stop pin for the first routed hole, and route the hole

with the appropriate hole width.

Page 83

4

For the other routed holes, set the desired hole distance on

the cross stop and position the pin in the first routed hole.

Route the other holes as slots.

Use the same process to create the routed holes for the side

wall of the cabinet. Set the first hole with the stop pin of the

DOMINO joining machine ...

... and create the others using the cross stop pins. Using the

additional stop, along with the cross stop – is beneficial here,

because the joining machine has a sturdy support surface on

the panel.

Then create the routed holes for the shelves (this process is

similar for carcass sides etc).

Place both side parts on top of each other and mark out the

position where the centre shelf will be. Mark the top and

bottom edge of the shelf (material thickness), not the centre.

8180

Page 84

9 1310 14

Place the top side part to one side. Position the centre shelf at

the marked point and fold it over towards the right or left, so

that the top or bottom edge of the centre shelf is aligned with

the corresponding marking. Clamp both workpieces (centre

shelf and side part).

TIP If the centre shelf will be reset at the end, keep this

in mind even when clamping.

In our example, the centre shelf and side part are flush at the

front and are clamped accordingly. Adjust the angle of the

joining machine to 0° and the routing depth to 15 mm. Then

route the first domino hole with the narrow hole width with

the stop pin in the horizontal side part.

11 12

For the other domino holes, switch the hole width to the slot

and mark out the domino positions with a simple scribe mark

on the horizontal centre shelf. Then place the joining machine

on the scribe mark. Use the markings placed on the bottom

of the joining machine by positioning the centre marking on

the machine at the scribe mark on the shelf.

Switch the routing depth to 25 mm and route the domino

holes in the centre shelf, again using the stop pin for the first

routed hole (narrow hole width).

Page 85

4

Set the other holes using the scale in the viewing window,

which you align with the scribe marks. Set all holes here in the

panel edge with the narrow hole width – the domino will be

glued here first and will then fit in precisely.

Proceed likewise for the second side part. Then insert the

domino in the routed holes and join your workpiece together,

applying glue to the joint.

8382

Page 86

Page 87

5

Items included, specifications

8584

Page 88

5. Items included, specifications

DOMINO DF 500 Items included

DF 500 Q-Plus GB 2 40V 574 327

DOMINO D 5 router, support bracket, accessory tool set,

in a SYS 2 T-LOC SYSTAINER

DF 500 Q-Set GB 240V 574 429

DOMINO D 5 router, support bracket, trim stop, cross stop,

accessory tool set, in a SYS 2 T-LOC SYSTAINER

DOMINO DF 700 Items included

DF 700 EQ-Plus GB 240V 574 420

DOMINO D 12 router, support bracket, 2 x domino box,

accessory tool set, in a SYS 5 T-LOC SYSTAINER

Specifications

DOMINO DF 500 DOMINO DF 700

Power consumption (W) 420 720

Idle engine speed (min¹) 25,500 21,000

Depth stop for routing depth (mm) 12, 15, 20, 25, 28 15 – 70

Max. routing depth (mm) 28 70

DOMINO slot cutter (mm) 4, 5, 6, 8, 10 8, 10, 12, 14

Routing height adjustment (mm) 5 – 30 10 – 50

Mitre routing (°) 0 – 90 0 – 90

Dust extractor connection (mm) 27 27

Weight (kg) 3.2 5.2

Page 89

6

Accessories

8786

Page 90

6. Accessories

6.1 Cutters

Cutters for DOMINO DF 500 joining machine

D 4-NL 11 HW-DF 50 0 router

1

D 4 mm, NL 11 mm, in self-ser vice display pack

D 5-NL 20 HW-DF 500 router

2

D 5 mm, NL 20 mm, in self-ser vice display pack

D 6-NL 28 HW-DF 500 router

3

D 6 mm, NL 28 mm, in self-ser vice display pack

D 8-NL 28 HW-DF 500 router

4

D 8 mm, NL 28 mm, in self-ser vice display pack

D 10-NL 28 HW-DF 500 router

5

D 10 mm, NL 28 mm, in self-ser vice display pack

Cutters for DOMINO XL DF 700 joining machine

D 8-NL 50 HW-DF 700 DOMINO router

Cutter with thread inser ts for the DOMINO XL DF 700

1

joining machine, D 8 mm, NL 50 mm, in self-service

display pack

D 10-NL 70 HW-DF 700 DOMINO router

Cutter with thread inser ts for the DOMINO XL DF 700

2

joining machine, D 10 mm, NL 70 mm, in self-ser vice

display pack

D 12-NL 70 HW-DF 700 DOMINO router

Cutter with thread inser ts for the DOMINO XL DF 700

3

joining machine, D 12 mm, NL 70 mm, in self-ser vice

display pack

D 14-NL 70 HW-DF 700 DOMINO router

Cutter with thread inser ts for the DOMINO XL DF 700

4

joining machine, D 14 mm, NL 70 mm, in self-ser vice

display pack

495663

493490

493491

493492

493493

497868

497869

497870

497871

Page 91

6.2 Stops

Stops for DOMINO DF 500 joining machine and DOMINO XL DF 700

QA-DF 500/700 cross stop

for DF 500 and DF 70 0, items included: a left and a right

cross stop, for repeated hole centres of 100 – 205 mm,

for exact positioning of routing with edge distances of

100 – 205 mm, in self-ser vice display pack

LA-DF 500/700 trim stop

for DF 500 and DF 70 0, for 22 – 70 mm wide trims,

qty. in pack 1 pc., in self-ser vice display pack

RA-DF 500/700 handrail fence

for DF 500 and DF 70 0, for wood rods of 35 – 60 mm,

for precisely routing rods Ø 35 – 60 mm, in self-ser vice

display pack

498590

6

493487

494847

ZA-DF 500 additional stop for DF 500 only

Support surface extension and parallel side fence for

reducing the domino centre from 37 mm to 20 mm, for

safely locating the router, in self-ser vice display pack

495666

8988

Page 92

6.3 Dominos and connectors

domino length (mm)

(mm)

Page 93

NEW

6

Corner

connectors

* Flat connectors – here with the optional enlarging clips around the transverse anchor.

Flat connectors

*

9190

Page 94

6.3.1 Dominos and Dominos Beech

Domino, Beech D 4 x 20/450 BU

Dimensions 4 x 20 mm, qty. in pack 45 0 pcs,

in self-service display pack

Domino, Beech D 5 x 30/300 BU

Dimensions 5 x 30 mm, qty. in pack 300 pcs,

in self-service display pack

Domino, Beech D 5 x 30/1800 BU

Dimensions 5 x 30 mm, qty. in pack 1800 pcs, in carton

Domino, Beech D 6 x 40/190 BU

Dimensions 6 x 40 mm, qt y. in pack 190 pcs,

in self-service display pack

Domino, Beech D 6 x 40/1140 BU

Dimensions 6 x 40 mm, qt y. in pack 1140 pcs, in carton

Domino, Beech D 8 x 40/130 BU

Dimensions 8 x 40 mm, qt y. in pack 130 pcs,

in self-service display pack

Domino, Beech D 8 x 40/780 BU

Dimensions 8 x 40 mm, qt y. in pack 78 0 pcs, in carton

Domino, Beech D 8 x 50/100 BU

Dimensions 8 x 50 mm, qty. in pack 100 pcs,

in self-service display pack

Domino, Beech D 8 x 50/600 BU

Dimensions 8 x 50 mm, qty. in pack 600 pcs, in carton

Domino, Beech D 10 x 50/85 BU

Dimensions 10 x 50 mm, qty. in pack 85 pcs,

in self-service display pack

Domino, Beech D 10 x 50/510 BU

Dimensions 10 x 50 mm, qty. in pack 510 pcs, in carton

495661

494938

493296

494939

493297

494940

493298

494941

493299

494942

493300

DOMINO, Beech D 8x80/190 BU

Dimensions 8 x 80 mm, qt y. in pack 190 pcs, in car ton

DOMINO, Beech D 8 x 100/150 BU

Dimensions 8 x 100 mm, qty. in pack 150 pc s, in car ton

DOMINO, Beech D 10 x 80/150 BU

Dimensions 10 x 80 mm, qty. in pack 150 pc s, in car ton

DOMINO, Beech D 10 x 100/120 BU

Dimensions 10 x 100 mm, qty. in pack 120 pcs, in carton

DOMINO, Beech D 12 x 100/100 BU

Dimensions 12 x 100 mm, qty. in pack 100 pc s, in carton

DOMINO, Beech D 12 x 140/90 BU

Dimensions 12 x 140 mm, qty. in pack 90 pc s, in car ton

DOMINO, Beech D 14 x 100/80 BU

Dimensions 14 x 100 mm, qty. in pack 80 pcs, in car ton

DOMINO, Beech D 14 x 140/70 BU

Dimensions 14 x 140 mm, qty. in pack 70 pcs, in car ton

498 212

498213

498214

498 215

498 216

498 217

498218

498 219

T-L OC SOR T-SYS DOMIN O

Empt y SYS 2 T-LOC systainer contains 3 boxes with

flexible compartments for individual filling with dominos,

SYS 2 T-LOC SYSTAINER

498889

Page 95

Domino rod, Beech D 8 x 750/36 BU

Dimensions 10 x 750 mm, qty. in pack 36 pcs, in carton

Domino rod, Beech D 10 x 750/28 BU

Dimensions 10 x 750 mm, qty. in pack 28 pcs, in carton

Domino rod, Beech D 12 x 750/22 BU

Dimensions 12 x 750 mm, qt y. in pack 22 pcs, in carton

Domino rod, Beech D 14 x 750/18 BU

Dimensions 14 x 750 mm, qty. in pack 18 pc s, in car ton

498686

4986 87

4986 88

4986 89

Domino, Beech assortment DS 4/5/6/8/10 1060x BU

Domino assortment 4 x 20, 5 x 30, 6 x 40, 8 x 40, 8 x 50,

10 x 50 mm and DOMINO router for sizes 4, 5, 6, 8 and 10,

dimensions 396 x 296 x 157.5 mm, qty. in pack 1,060 pcs,

in SYS 2 T-LOC SYSTAINER

6

498899

DOMINO XL Beech assortment DS/XL D8/D10 306x BU

for DOMINO XL, domino assortment, dominos 8 x 50,

8 x 80, 8 x 100, 10 x 50, 10 x 80, 10 x 100 mm and DOMINO

XL router for sizes 8 and 10, qty. in pack 306 pcs, in SYS 2

T-LOC SYSTAIN ER

498204 DOMINO XL Beech assortment DS/ XL D12/D14 128x BU

for DOMINO XL, domino assortment, dominos 12 x 100,

12 x 140, 14 x 100, 14 x 140 mm and DOMINO XL router for

size 14, qty. in pack 128 pcs, in SYS 2 T-LOC SYSTAINER

498205

9392

Page 96

6.3.2 Domino and Domino rods SIPO

Domino, Sipo D 5 x 30/300 MAU

Dimensions 5 x 30 mm, qty. in pack 300 pcs,

in self-service display pack

Domino, Sipo D 5 x 30/900 M AU

Dimensions 5 x 30 mm, qty. in pack 900 pcs, in carton

Domino, Sipo D 6 x 40/190 MAU

Dimensions 6 x 40 mm, qt y. in pack 190 pcs,

in self-service display pack

Domino, Sipo D 6 x 40/570 MAU

Dimensions 6 x 40 mm, qt y. in pack 570 pcs, in carton

Domino, Sipo D 8 x 40/130 MAU

Dimensions 8 x 40 mm, qt y. in pack 130 pcs,

in self-service display pack

Domino, Sipo D 8 x 40/390 M AU

Dimensions 8 x 40 mm, qt y. in pack 390 pcs, in carton

Domino, Sipo D 8 x 50/100 MAU

Dimensions 8 x 50 mm, qty. in pack 100 pcs,

in self-service display pack

Domino, Sipo D 8 x 50/300 MAU

Dimensions 8 x 50 mm, qty. in pack 300 pcs, in carton

Domino, Sipo D 10 x 50/85 MAU

Dimensions 10 x 50 mm, qty. in pack 85 pcs,

in self-service display pack

Domino, Sipo D 10 x 50/255 MAU

Dimensions 10 x 50 mm, qty. in pack 255 pcs, in carton

494869

494859

494870

494860

494871

494861

494872

494862

494873

494863

Domino, Sipo D 8 x 750/36 MAU

Dimensions 8 x 750 mm, qty. in pack 36 pcs, in carton

Domino, Sipo D 10 x 750/28 MAU

Dimensions 10 x 750 mm, qty. in pack 28 pcs, in carton

Domino, Sipo D 12 x 750/22 MAU

Dimensions 12 x 750 mm, qt y. in pack 22 pcs, in carton

Domino, Sipo D 14 x 750/18 MAU

Dimensions 14 x 750 mm, qty. in pack 18 pc s, in car ton

498690

498691

498692

498693

Page 97

6.3.3 DOMINO corner and flat connectors

Anchor bolt SV-AB D14/32

32 anchor bolts for corner connections, including 64 domino

connector covers for transferring transverse loads.

201350

Corner

connectors

Flat connectors

Expansion bolt SV-SA D14/32

32 expansion bolts for secure locking.

Transverse anchor SV-QA D14/32

32 transverse anchors including studs for locking anchors

or double-headed bolts.

Enlarger SV-V D14/32

64 domino connector covers for widening 32 transverse anchors.

For widening and pressure distribution when using transverse

anchors in mater ial s such as kitchen worktops.

Double-headed bolt SV-DB D14/16

16 double-headed bolts for flat connections, including 64 domino

connector covers. The double-headed bolts can be clipped using

2 domino connector covers or (as shown) with 4 domino connector

covers – depending on the required alignment and transverse load

transmission.

2013 49

201351

201498

201352

6

(optional)

Connector set EV/32-Set

For 32 corner connectors, 32 S V-AB D14 anchor bolts, 32 SV-Q A D14

transverse anchors, 32 SV-SA D14 expansion bolts.

Connector set FV/16-Set

For 16 flat connectors, 16 SV-DB D14 double-headed bolts,

32 SV-QA D14 transverse anchors, SV-V D14 enlargers for

32 transverse anchors.

201827

201828

9594

Page 98

6.3.3 DOMINO corner and flat connectors

Domino, birch, domino D 14 x 75/104 BU

104 Domino, birch D 14 x 75, exactly matched to the dimensions of the corner

connectors. Ser ves to transfer loads – in addition to the connector s.

Cover cap SV-AK D14 slr/32

32 cover caps, silver. For covering DOMINO milled holes.

Cover cap SV-AK D14 brn1/32

32 cover caps, dark brown. For covering DOMINO milled holes.

Cover cap SV-AK D14 brn2/32

32 cover caps, light brown. For covering DOMINO milled holes.

201499

201354

201355

201356

DOMINO connector Systainer DominoVerb Sort SV-SYS D14

32 anchor bolts S V-AB D14, 16 double-headed bolts SV-DB D14, 128 domino

connector covers for increasing transverse load transfer from the anchor bolts and

double-headed bolts, 32 expansion bolts SV-SA D14, 64 transverse anchors SV-QA

D14 including studs, 4 mm stud spanner for tightening studs, 64 connector covers

SV-V D14 for widening 32 transverse anchors, 32 cover caps each in the colours silver,

dark brown and light brown (SV-AK D14 slr, SV-AK D14 brn1 and SV-A K D14 brn2),

32 dominos D14 x 75, Beech.

201353

Page 99

7

Supplementary system accessories

9796

Page 100

7.1 Mobile dust extractors

Any Festool mobile dust extractor with an extractor hose diameter of 27 mm can be attached to the DOMINO joining machine extrac tor stub. The Festool

system of fer s numerous mobile dust extractors with a wide variety of volumes, with or without automatic AUTOCLEAN cleaning technology and in

different dust categor ies. We therefore only present a small selection of our range here. Your specialist retailer can give you all the information you need

on mobile dust extractors, items included and dust categories, or go to www.festool.co.uk

CT 26 | 36 | 48

The all-rounder.

In three sizes to meet every need: the all-rounder for the construction

site or body shop.

CT 26 E AC | CT 36 E AC | CT 48 E AC

With dedusting.

With automatic, infinitely var iable AUTOCLEAN filter dedusting for

constant extraction performance: perfect for large quantities of fine

dust.

CT 48 E LE EC

For continuous operation.

With a durable, brushless EC-TEC drive concept: for tough continuous

operation and work in quasi-stationary mode at the energy box.

Loading...

Loading...