Page 1

Domino® DF 500

Tenon Joiner

Tenon Joiner

Supplemental User’s Manual

WARNING To reduce the risk of serious injury, read and understand all safety

precautions and instructions in this manual before using this tool.

Page 2

Limited Warranty

30 Day Money Back Guarantee

We are so confident that you will thoroughly enjoy our tools, that

we offer a 30 day money back guarantee. If you are not

1+2 Limited Warranty

Festool USA offers a 3-year limited warranty, one of the longest

in the industry. This warranty is valid on the pre-condition that

the tool is used and operated in compliance with the Festool

Conditions of 1+2 Limited Warranty

You are entitled to a free extended limited warranty (1 year + 2

years = 3 Years) for your Festool power tool. Festool USA is

responsible for all shipping costs during the first year of the

warranty. During the second and third year of the warranty, the

customer is responsible for shipping the tool to Festool. Festool

will pay for return shipping to the customer using UPS Ground

Service. All warranty service is valid 3 years from the date of

purchase on your receipt or invoice.

Excluded from the coverage under this warranty are: normal

wear and tear, damages caused by misuse, abuse, or neglect;

damage caused by anything other than defects in material and

workmanship. This warranty does not apply to accessory items

such as circular saw blades, drill bits, router bits, jigsaw blades,

sanding belts, and grinding wheels. Also excluded are "wearing

parts," such as carbon brushes, lamellas of air tools, rubber

collars and seals, sanding discs and pads, batteries, and Festool

gear (hats and t shirts).

The obligations of Festool USA in its sole discretion under this

warranty shall be limited to repair or replacement or a refund of

the purchase price for any Festool portable power tool that is

found to have a defect in materials or workmanship during the

completely satisfied, your full purchase price will be refunded,

excluding all freight charges.

operating instructions. Festool USA warrants that the specified

tool will be free from defects in materials and workmanship for a

term of 3 years from the date of purchase.

warranty period. FESTOOL USA SHALL NOT BE LIABLE FOR ANY

CONSEQUENTIAL, INCIDENTAL OR SPECIAL DAMAGES

REGARDLESS OF THE THEORY OF LAW ON WHICH THE CLAIM IS

BASED. ALL WARRANTIES IMPLIED BY STATE LAW, INCLUDING

THE IMPLIED WARRANTIES OR MERCHANTABILITY AND FITNESS

FOR A PARTICULAR PURPOSE ARE HEREBY LIMITED TO THE

DURATION OF THREE YEARS.

Some states in the U.S. and some Canadian provinces do not

allow the limitations on how long an implied warranty lasts, so

the above limitation may not apply to you. This warranty gives

you specific legal rights, and you may also have other rights that

vary from state to state in the U.S. and from province to province

in Canada.

With the exception of any warranties implied by state or province

law as limited above, the foregoing express limited warranty is

exclusive and in lieu of all other warranties, guarantees,

agreements, and similar obligations of Festool USA. Festool USA

makes no other warranty, express or implied, for Festool portable

power tools. No agent, representative, distributor, dealer, or

employee of Festool USA has the authority to increase or

otherwise change the obligations or limitations of this warranty.

Repairs

If your Festool power tools require repair, you must contact our

Service Department at (800) 554-8741 for authorization and

address details. No collect shipments will be accepted. No Festool

hats, t-shirts or other wearables may be returned. Also contact

our Service Department at the telephone number listed above if

you have any questions about warranty claim procedures.

Returns

If you need to return your Festool tools for any reason, please return it to the dealer from which you originally bought the tool.

Liability Statement

This product has been built to the high standards of Festool.

Please do not attempt to operate or repair this equipment without

adequate training. Any use, operation, or repair in contravention

of this document is at your own risk. By acceptance of this

system you hereby assume all liability consequent to your use or

misuse of this equipment. Festool USA assumes no liability for

incidental, special, or consequential damage of any kind.

Equipment specifications, applications, and options are subject to

change at the sole discretion of Festool USA without notice.

Proprietary Notice

All drawings and information herein are the property of Festool,

TTS Tooltechnic Systems AG & Co. KG. All unauthorized use and

reproduction is prohibited.

Written and Illustrated by Rick Christopherson.

© 2007-2008 TTS Tooltechnic Systems AG & Co. KG

All rights reserved. Printed in the United States of America and

Germany.

2 Domino DF 500 Tenon Joiner

Festool USA is a division of Tooltechnic Systems, LLC.

Festool is a trademark and service mark of TTS Tooltechnic

Systems AG & Co. KG

Domino, Plug-It, and Systainer are registered trademarks of TTS

Tooltechnic Systems AG & Co. KG

www.festoolusa.com

Page 3

Contents

Limited Warranty .............................................2

30 Day Money Back Guarantee......................... 2

1+2 Limited Warranty..................................... 2

Conditions of 1+2 Limited Warranty.................. 2

Repairs ......................................................... 2

Returns......................................................... 2

Liability Statement ......................................... 2

Proprietary Notice........................................... 2

About This Manual............................................3

Tool Symbols................................................. 3

General Power Tool Safety Warnings ...............4

Work Area Safety........................................ 4

Electrical Safety.......................................... 4

Personal Safety........................................... 4

Power Tool Use and Care.............................. 4

Service...................................................... 5

Specific Safety Rules for Tenon Joiners .............. 5

Respiratory Exposure Safety Warnings .............. 5

Tool Description...............................................5

Technical Specifications................................... 5

Intended Use................................................. 5

Functional Description..................................... 6

Setup................................................................7

Setting Up a New Domino Joiner....................... 7

Setting the Fence Angle................................... 7

Setting the Fence Height ................................. 8

Setting the Mortise Width ................................ 8

Setting the Mortise Depth................................ 9

Changing the Mortising Bit............................... 9

Operation.......................................................10

Overview, General Notes, and Tips.................. 10

Plug-It® Power Cord...................................... 10

Turning On the Joiner.................................... 11

Using Dust Extraction.................................... 11

Using the Locating Pins or Edge Stop Dogs....... 11

Disabling/Retracting the Edge Stop Dogs.......... 12

Using the Base Support Bracket...................... 12

Using the Optional Narrow Frame Fence........... 12

Using the Optional Outrigger Guides................ 13

Applications ...................................................13

Edge Joining Boards...................................... 13

Making Butt Box Joints .................................. 14

Making Miter Box Joints................................. 15

Making Lock Tenon Joints .............................. 15

Making Frame Joints ..................................... 16

Making Carcase Butt Joints............................. 17

Making Three-Way Lock Miter Joints................ 18

Shortening a Domino Tenon’s Length............... 19

Creating Special Plunge Depths....................... 19

Tips for Applying Glue ................................... 19

Maintenance...................................................20

Routine Maintenance..................................... 20

Calibrating the Locating Pins or Edge Stop Dogs 21

Adjusting the Locating Pin........................... 21

Removing and Adjusting the Edge Stop Dogs.21

Calibrating the Horizontal Position Gauge......... 22

Accessories ....................................................23

Systainer (System Container)......................... 24

Troubleshooting.............................................25

About This Manual

Save These Instructions

It is important for you to read and understand this manual. The

information it contains relates to protecting YOUR SAFETY and

PREVENTING PROBLEMS. The symbols below are used to help you

recognize this information.

Indicates a potentially hazardous

WARNING!

CAUTION!

NOTICE:

Note:

situation which, if not avoided, could

result in death or serious injury.

Indicates a potentially hazardous

situation which, if not avoided, could

result in minor or moderate injury.

Indicates a potential situation which, if

not avoided, can result in property

damage or damage to the tool.

Indicates information, notes, or tips for

improving your success using the tool.

Instruction Manual 3

Tool Symbols

V Volts

W Watts

Hz Hertz

~ Alternating Current (AC)

n

No-load Speed

o

Ø Diameter

Class II Double Insulated

Page 4

General Power Tool Safety Warnings

WARNING! Read all safety warnings and instructions.

Failure to follow the warnings and instructions may result in

electric shock, fire, and/or serious injury.

Save all warnings and instructions for future

reference.

Work Area Safety

► Keep your work area clean and well lit. Cluttered or

dark work areas invite accidents.

► Do not operate power tools in explosive atmospheres,

such as in the presence of flammable liquids, gases,

or dust. Power tools create sparks which may ignite the

dust or fumes.

► Keep children and bystanders away while operating a

power tool. Distractions can cause you to lose control.

Electrical Safety

► Power tool plugs must match the outlet. Never modify

the plug in any way. Do not use any adapter plugs

with earthed (grounded) power tools. Unmodified plugs

and matching outlets will reduce risk of electric shock.

► Avoid body contact with earthed or grounded surfaces

such as pipes, radiators, ranges and refrigerators.

There is an increased risk of electric shock if your body is

earthed or grounded.

► Do not expose power tools to rain or wet conditions.

Water entering a power tool will increase the risk of electric

shock.

► Do not abuse the cord. Never use the cord for

carrying, pulling, or unplugging the power tool. Keep

cord away from heat, oil, sharp edges or moving

parts. Damaged or entangled cords increase the risk of

electric shock.

► When operating a power tool out doors, use an

extension cord suitable for outdoor use. Use of a cord

for outdoor use reduces the risk of electric shock.

► If operating a power tool in a damp location is

unavoidable, use a ground fault circuit interrupter

(GFCI) protected supply. Use of a GFCI reduces the risk

of electric shock.

► Never use an extension cord that is damaged,

including cuts, exposed wires, or bent/missing

prongs. Damaged extension cords increase the risk of fire

or electric shock.

► Use only extension cords rated for the purpose.

► Use only extension cords rated for the amperage of

this tool and the length of the cord. Using too small of

an extension cord can cause the cord to overheat.

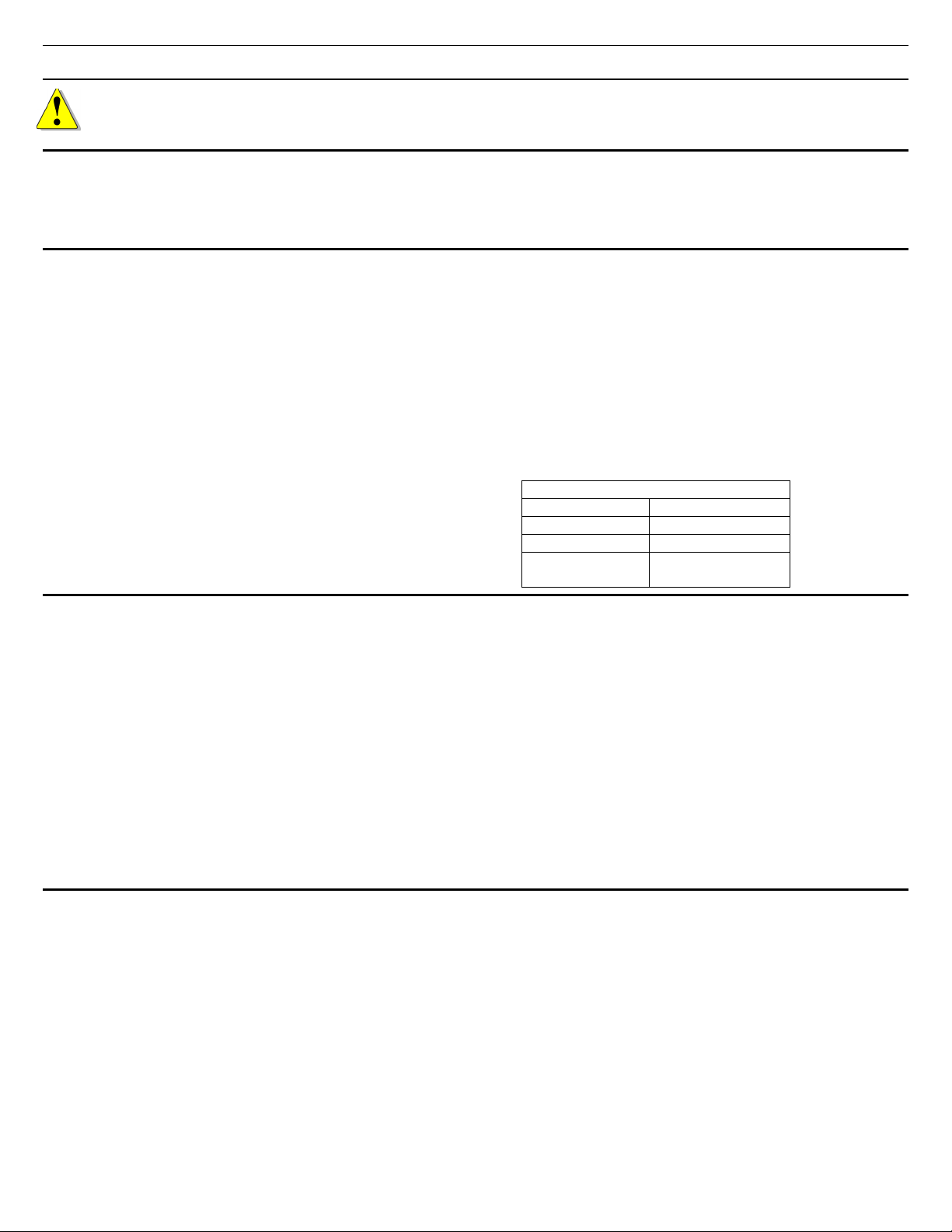

Extension Cord Ratings

Cord Length Size (AWG)

<50 Ft. 14

50-100 Ft. 12

>100 Ft. Not

recommended

Personal Safety

► Stay alert, watch what you are doing, and use

common sense when operating a power tool. Do not

use a power tool while tired or under the influence of

drugs, alcohol, or medication. A moment of inattention

while operating power tools may result in serious personal

injury.

► Use personal protective equipment. Always wear eye

protection. Protective equipment such as dust mask, nonskid safety shoes, hard hat, or hearing protection used for

appropriate conditions will reduce personal injuries.

► Prevent unintentional starting. Ensure the switch is in

the off-position before connecting to power source,

picking up, or carrying the tool. Carrying power tools

with your finger on the switch or energizing power tools that

have the switch on invites accidents.

► Remove adjusting key or wrench before turning the

power tool on. A wrench or a key that is left attached to a

rotating part of the tool may result in personal injury.

► Do not overreach. Keep proper foot i ng and balance at

all times. This enables better control of the tool in

unexpected situations.

► Dress properly. Do not wear l oose clothing or jewelry.

Keep your hair, clothing, and gloves away from

moving parts. Loose clothes, jewelry, or long hair can be

caught in moving parts.

► If devices are provided for the connection of dust

extraction and collection facilities, ensure these are

connected and properly used. Use of dust collection can

reduce dust-related hazards.

► Always wear safety glasses complying with ANSI

Z87.1. Ordinary glasses are not proper protection.

Power Tool Use and Care

► Do not force the power tool. Use the correct power

tool for your application. The correct power tool will do

the job better and safer at the rate for which it is designed.

► Do not use the power tool if the switch does not turn

it on and off. Any power tool that cannot be controlled with

the switch is dangerous and must be repaired.

► Disconnect the plug from the power source before

making any adjustments, changing accessories, or

storing the tool. Such preventive safety measures reduce

the risk of starting the tool accidentally.

► Store idle tools out of reach of children and do not

allow persons unfamiliar with the power tool or these

instructions to operate the power tool. Power tools are

dangerous in the hands of untrained users.

► Maintain power tools. Check for misalignment or

binding of moving parts, breakage of parts and any

other condition that may affect the power tool’s

operation. If damaged, have the power tool repaired

before use. Many accidents are caused by poorly

maintained power tools.

► Keep cutting tools sharp and clean. Properly maintained

tools with sharp cutting edges are less likely to bind and are

easier to control.

► Use the power tool, accessories, and tool bits etc. in

accordance with these instructions, taking into

account the working conditions and the work to be

performed. Use of the power tool for operations different

from those intended could result in a hazardous situation.

► To reduce the risk of serious injury, never alter or

misuse the power tool.

4 Domino DF 500 Tenon Joiner

Page 5

Service

► Have your power tool serviced by a qualified repair

person using only identical replacement parts. This

Specific Safety Rules for Tenon Joiners

► Mortising bits must be rated for at least the speed

recommended on the tool. Mortising bits running over

rated speed can fly apart and cause injury.

► Always use the fence. The fence protects the operator

from unintentional contact with the mortising bit. When the

fence is removed from the joiner, the spinning and

oscillating cutter is exposed and can cause serious injury.

► Keep hands away from the cutting area. Never place

your hand on the front face of the fence while the tool is

running.

► Use only Festool authorized mortising bits. Non-

approved mortising bits can come loose during operation.

► Never use dull or damaged mortising bits. Dull or

damaged mortising bits can cause the tool to lurch sideways

unexpectedly and lead to a loss of control of the power tool.

Respiratory Exposure Safety Warnings

Substantial or repeated inhalation of dust and other airborne

contaminants, in particular those with a smaller particle size,

may cause respiratory or other illnesses. Various dusts

created by power sanding, sawing, grinding, drilling and other

construction activities contain chemicals or substances known

(to the State of California and others) to cause cancer, birth

defects or other reproductive harm. Some examples of these

chemicals/substances are:

► lead from lead-based paints;

► crystalline silica from bricks, cement, and other masonry

products;

will ensure that the safety of the power tool is maintained.

► Do not operate the tool if the spring-loaded fence

does not return to its forward rest position. The fence

covers the mortising bit and prevents accidental contact. If

the slides of the fence do not move freely, have the tool

serviced immediately.

► Wait for the cutter to stop before setting the tool

down. An exposed cutter may engage the surface leading

to possible loss of control and serious injury.

► Use clamps or other practical way to secure and

support the workpiece to a stable platform. Holding the

work by hand or against your body is unstable and may lead

to loss of control.

► arsenic and chromium from chemically-treated lumber; and

► some wood dusts, especially from hardwoods, but also from

some softwoods such as Western Red Cedar.

The risk from these exposures varies, depending on how

often you do this type of work. To reduce your exposure to

these chemicals: work in a well ventilated area and use a

properly functioning dust extraction system. When the

inhalation of dust cannot be substantially controlled, i.e.,

kept at or near the ambient (background) level, the

operator and any bystanders should wear a respirator

approved by NIOSH for the type of dust encountered.

Tool Description

Technical Specifications

Power Consumption 420 Watts (3.5 amps @ 120 volts)

Motor Speed 25,500 RPM (no load)

Mortising Depth, Max. 28mm (1.1“)

Mortising Width, Max. 23mm (0.9”) + bit diameter

Mortising Bit Range 5mm, 6mm, 8mm, 10mm

Spindle Thread M6 x 0.75

Weight 3.2 kg (7 lbs)

Intended Use

The Domino tenon joiner is designed to produce mortises

in soft and hard wood, chip board, plywood and fiber

boards. All applications beyond this are regarded as

improper use. The tool should not be altered or used for

any other purpose other than as specified in these

operating instructions. Using the tool in contravention to

All metric dimensions are controlling. Mortising

bit dimensions are critical for safe operation,

and are presented in metric units only.

this manual may lead to injury and will void your

warranty. The user shall be responsible and liable for

accidents, injury, and property damage resulting from

misuse or abuse of this tool.

Instruction Manual 5

Page 6

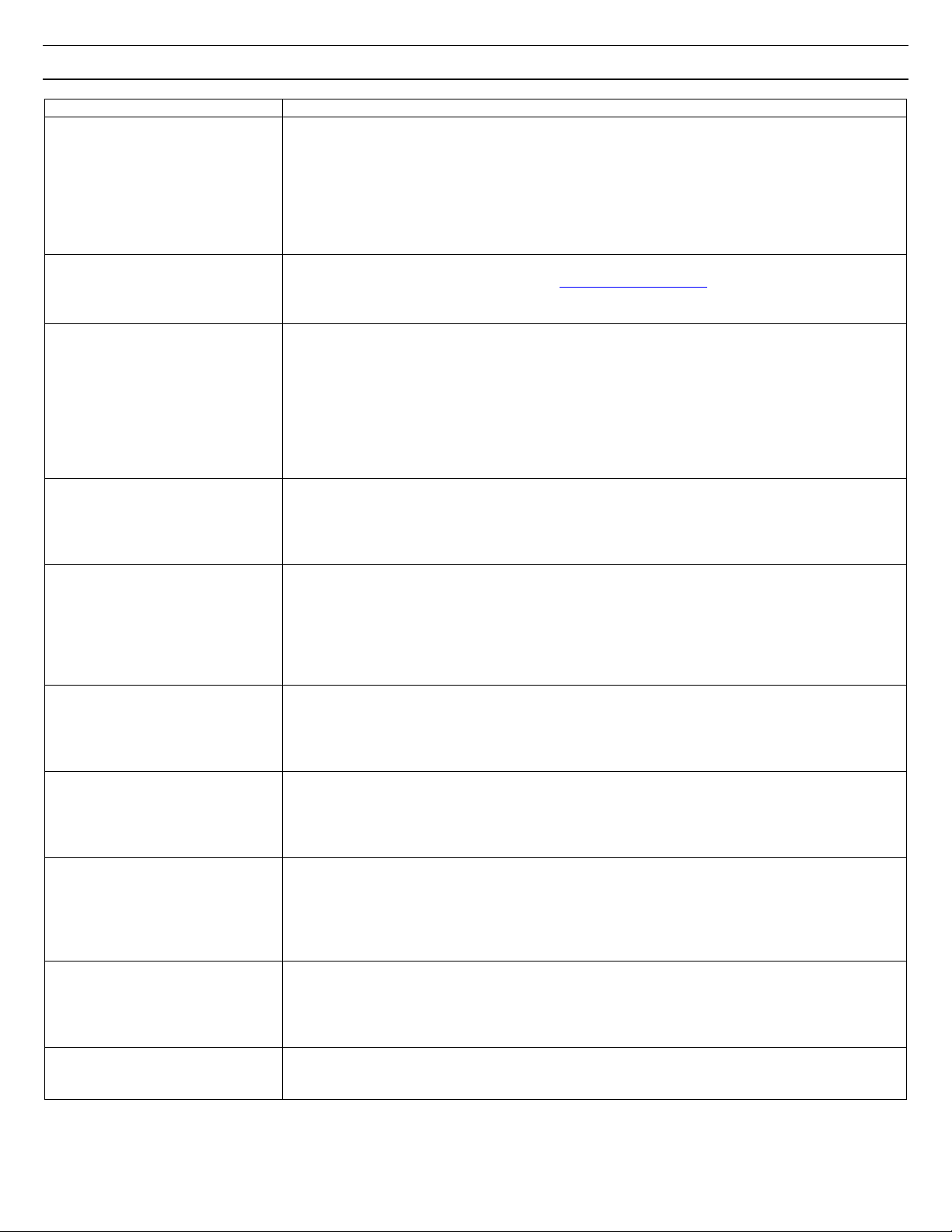

Functional Description

The Domino DF 500 Tenon Joiner is used to cut mortises in

wood for floating tenon joinery. Mortise and tenon joinery

is one of the oldest and strongest methods of joining

pieces of wood together. The Domino tenon joiner greatly

simplifies the task of cutting mating mortises in

workpieces to be connected together. A rotating and

oscillating cutter sweeps across the workpiece to quickly

and effortlessly cut a uniform mortise, in which a Domino

floating tenon is inserted.

Note: For newer models, the

locating pins are replaced with Guide

Item Name or Description Ref. Page(s)

Stop Dogs, as shown to the far right.

A Fence Body 9, 20

B Motor Housing 9, 20

C Auxiliary Handle 14, 15

D Fence Height Gauge 8, 14, 15

E Mortise Width Dial 8, 13

F Fence Height Locking Lever 8

G Power Switch 11

H Main Handle (barrel grip) ---

I Plug It® Power Inlet 10

J Depth Adjust Lever 8

K Depth Adjust Lock 8

M Board Thickness Gauge 8

Item Name or Description Ref. Page(s)

N Fence Angle Locking Lever 7

P Fence Angle Gauge 7, 15

Q Dust Extraction Port 11

R Baseplate 7, 17

S Outrigger Mounting Slot 12

T1 Locating Pins (qty. 2) 9, 11

T2 Edge Stop Dogs (qty. 2) 9, 11

U Mortising Bit Throat Opening ---

V Friction Pads (qty. 2) 25

W Horizontal Position Gauge 22, 12, 15

X Adjustable Fence Face 7, 8, 15

Y Fence Body Release Lever 9

Z Spindle Lock 9

6 Domino DF 500 Tenon Joiner

Page 7

Setup

Setting Up a New Domino Joiner

Congratulations on your purchase of a new Festool Domino

Tenon Joiner. The Domino joiner is the finest portable

loose tenon joiner in the world. Before using your new

Domino joiner, make sure you fully read and understand

all of the precautions and safety information presented in

this manual.

WARNING! To reduce the risk of injury from

contact with a moving part, always unplug the

joiner before making any inspections or

adjustments, or before installing or removing any

accessory!

1. With the joiner unplugged, inspect the mortising bit.

Make sure it is not bent, chipped, or otherwise

damaged, and make sure the bit is fully tightened on

the spindle. (Refer to "

page 9 for more information).

CAUTION! Check regularly whether the

mortising bit is in good condition. Mortising bits

that are bent or damaged can break, and should

no longer be used.

2. Peel off the protective film from the bottom of the

joiner baseplate.

3. Set up the joiner for the appropriate type of operation

as described throughout the remainder of this section.

Changing the Mortising Bit" on

4. Make sure that the fence height and angle locking

levers are properly tightened.

5. Install the power cord into the Plug-It receptacle on the

joiner (refer to page 10 for more information).

6. Before you use the joiner, make sure to read the

Overview, General Notes, and Tips section on page 10.

Setting the Fence Angle

Some joints require the fence to be set to an angle from

the mortising bit. The most common application is for

making a mitered joint (see page 15).

1. Unplug the joiner for safety.

2. Loosen the fence angle locking lever by rotating it

counterclockwise about ¼-turn.

3. Rotate the fence face to the desired angle, and tighten

the locking lever.

Notes:

► The fence has detent stops at 22½, 45, 67½, and 90

degrees.

► Use the gauge pointer for setting the fence to angles

other than the ones listed above.

► For greater stability, the locking lever clamps down on

both right and left sides of the fence.

The table below provides some common miter angles for

easy reference.

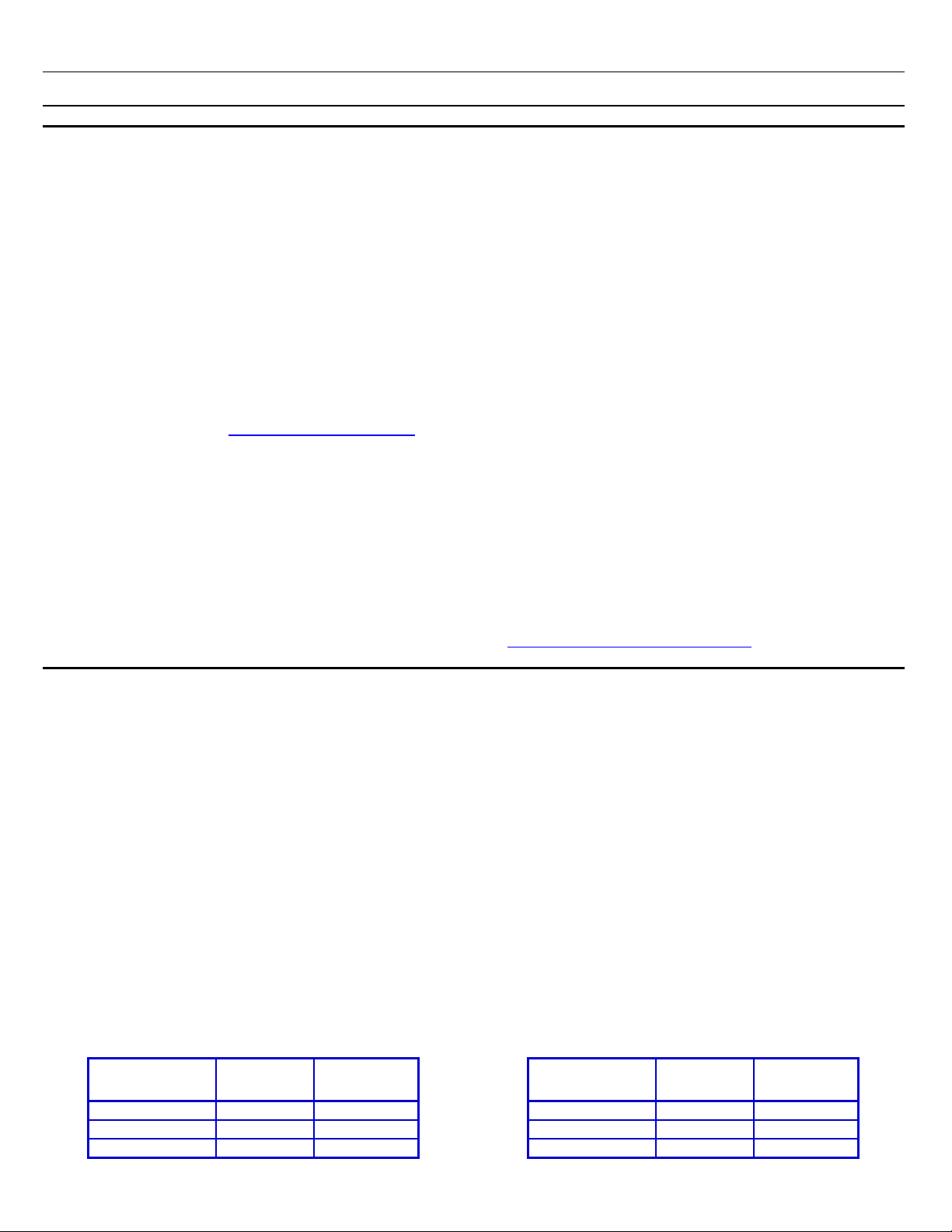

Number of

Equal Sides

3 – Triangle 60 30

4 – Square 45 45

5 – Pentagon 36 54

Mitersaw

Angle

Domino

Angle

Number of

Equal Sides

6 – Hexagon 30 60

7 – Heptagon 25.7 64.3

8 – Octagon 22.5 67.5

Mitersaw

Angle

Domino

Angle

Instruction Manual 7

Page 8

Setting the Fence Height

The height of the fence needs to be adjusted

depending on the type of joint being made and the

thickness of the material being joined. Refer to the

Applications section beginning on page 13 for more

information about the optimal fence height for the

specific application. There are two features available

for setting the fence height; the height gauge and the

board thickness gauge.

Note: It is not necessary to set the mortise

position to be exactly in the center of a

board. See the

on page 13 for more information about

mortise position.

Height Gauge

The height gauge shows the distance between the

bottom of the fence face and the centerline of the

mortising bit. Use this gauge to set the mortise height

relative to the surface of the workpiece.

Note: Make sure to retract the Board

Thickness Gauge to its lowest setting when

using the Height Gauge.

Applications section beginning

2. To use the board thickness gauge:

a. Raise the fence above the board thickness gauge.

b. Slide the gauge in or out until the thickness of the

workpiece (in mm) is shown in the window.

c. Lower the fence down until it touches the gauge.

d. Tighten the locking lever.

3. To use the height gauge:

a. Make sure the board thickness gauge is retracted out of

the way.

b. Raise or lower the fence until the pointer is pointing to

the desired height on the gauge.

c. Tighten the locking lever.

Board Thickness Gauge

The numbers printed on the gauge represent the

thickness of the workpiece (in mm) and the mortise

height will be centered in the workpiece. Use this

gauge for setting the fence height based on the

thickness of the workpiece without needing to

calculate the center distance.

Note: Do not use the board thickness gauge

for mitered joints, because this will place the

mortise too close to the edge of the joint.

1. Loosen the fence height locking lever by turning it

¼-turn counterclockwise.

Setting the Mortise Width

The width of the mortise slot can be increased to permit some

side-to-side flexibility in the tenon position. The mortise width

dial has three positions. In the standard (smallest) position,

the Domino tenon will fit snugly into the mortise slot. In the

middle position, the mortise slot will be 6 mm wider than the

Domino tenon. In the widest position the mortise slot will be

10 mm wider than the Domino tenon.

Important Notes

NOTICE: To avoid damaging the tool, follow

the notes below.

► Never force the dial to turn.

► Rotate the adjustment dial only when the motor is running.

► Never rotate the dial during a plunging operation. This can

bend or break the mortising bit, and can also damage the

machine.

8 Domino DF 500 Tenon Joiner

Page 9

Setting the Mortise Depth

The mortising depth determines how deep into the

workpiece the mortising bit penetrates. This needs to be

adjusted for different sized tenons. In most cases, the

tenon should be centered across the joint, and the depth

of the mortise should be ½ the length of the tenon.

However, in some cases you may want to have more of

the tenon in one piece than the other (lower Domino tenon

pictured below). In this case, the sum of the two depths

must equal the length of the tenon. (In the offset tenon

example below, the Domino tenon is 40 mm long, the left

mortise is 28 mm deep, and the right mortise is 12 mm

deep.)

1. Press in on the depth adjust lock.

2. Move the depth adjust lever to the stepped position of

the desired depth.

3. Release the depth adjust lock.

Changing the Mortising Bit

Different mortising bits are available for a variety of

Domino tenon sizes. The DF500 comes equipped with a

5mm bit, and 6, 8, and 10 mm bits are available as an

option.

WARNING! To reduce the risk of injury from

contact with a moving mortising bit, always

unplug the tool before changing mortising bits or

removing the fence body from the motor

housing.

1. Using the provided 8mm wrench, pry up on the fence

body release lever, and slide the fence body off the

motor housing. (The inset photograph on page 6 shows

the fence body and motor housing when separated.)

2. Press and hold the spindle lock button. This stops the

spindle from turning while you loosen the mortising bit.

3. Loosen the mortising bit by turning it counterclockwise

(standard right-hand thread).

4. Insert a new mortising bit, and start the threads by hand

to avoid cross-threading.

5. Press in on the spindle lock while tightening the bit. Do

not over tighten the bit.

6. Carefully reinstall the fence body onto the motor

housing, and push the fence body in until the latch

clicks.

► Make sure there is no sawdust inside the guide tubes

(hollow tubes) before inserting the fence body.

► Be careful not to damage the linear bearings (inner

surface of guide tube) when reinstalling the fence

body. If it does not slide on easily, it means the fence

is skewed with respect to the bearings.

Instruction Manual 9

Page 10

Operation

Overview, General Notes, and Tips

Getting Started

Because the look and feel of the Domino joiner may already

be familiar to you, or similar to other tools you may have

used in the past, you might be tempted to forego a basic

introduction to using the tool. However, unlike other tools of

similar look and feel, the Domino machine is extremely

precise in its operation. For this reason, it is recommended

that you spend some time practicing using the Domino joiner

before you begin using it for your fine woodworking projects.

For best results, observe the following tips:

► Always secure the workpiece firmly.

► Hold the Domino Joiner firmly by the handles and keep it

flat against the workpiece.

► Plunge the mortising bit into the workpiece with a slow and

steady pace.

Choosing the Right Domino Tenon Size

guidelines of mortise and tenon joinery. Here are some

guidelines to assist you in making your choices:

► When the strength of your workpieces is comparable

to the strength of the Domino tenon (e.g. general

hard woods) then the thickness of the Domino tenon

should be approximately 1/3 the thickness of the

workpieces.

► It is acceptable to use a tenon that is slightly thicker

than 1/3 when the width of the Domino tenon is

relatively narrow compared to the width of the joint.

This is why 8mm Domino tenons are the most

common for joining ¾-inch lumber.

► For softer woods, such as pine, the joint will be

stronger when the tenon is 1/3 or slightly less.

► For plywoods, especially low-grade constructi on

plywoods, the Domino tenon is much stronger than

the surrounding wood, so it is best to maximize the

strength of the substrate by minimizing the

thickness of the tenon.

Because the Domino system is a form of the classic mortise

and tenon joinery, it should follow much of the same

Domino Tenon Placement Guidelines

There are no steadfast rules on where tenons should be placed,

especially when they are used for alignment purposes. For edge

joining boards, a typical placement might be 6 to 8 inches apart.

However, when tenons are used to strengthen a joint, you might

be tempted to place the tenons too close together. This can

actually weaken the joint by removing too much of the substrate

material.

► A wide mortise weakens the substrate, so it is better to have

several narrow mortises with uncut space in between, than it

is to have a single wide mortise with several tenons side-byside.

► When placing several tenons close together, leave at least

twice the tenon thickness between mortise holes. As a

general rule, this means the minimum tenon spacing should

be about 10 mm to 20 mm, but they can be spaced much

wider.

► When creating stacked mortises for extra thick lumber, an

extension of the “1/3 rule” mentioned above still applies.

Specifically, the distance between mortises, and the distance

between a mortise and the wood surface should all be equal

to (or larger than) the thickness of the tenon.

Plug-It® Power Cord

The Domino joiner comes equipped with a removable

Plug-It power cord. To install the power cord, insert the

cord into the inlet on the tool with the key and keyway

aligned, and twist the locking ring. Reverse the

procedure to remove the cord.

Note: Turn the outer locking ring ¼-turn to

fully engage or disengage the cord. If the lock

is not fully engaged, the cord may fall out of

the socket.

10 Domino DF 500 Tenon Joiner

Page 11

Turning On the Joiner

WARNING! To reduce the risk of injury from

contact with moving parts, never turn on the tool

when the fence body is removed or does not

automatically return to its forward rest position.

The power switch for the Domino joiner locks into the On

position when activated. When working with the tool for

Using Dust Extraction

The Domino joiner is intended to be used with a dust

extraction system. Using the machine without dust

extraction will cause it to clog with wood chips.

When installing a Festool dust extraction hose onto the

dust port of the machine, it is easiest to insert the hose

at an angle and then push it on the rest of the way as

shown to the right.

Note: If you have a non-Festool vacuum

system and your vacuum hose does not fit the

dust extraction port, a Festool vacuum hose will

fit many other brands of vacuums.

the first time, it is recommended that you become familiar

with the operation of the switch before you plug the tool

into a power outlet.

To turn the joiner on, push forward and down on the

power switch. To turn the joiner off, press down on the

back of the power switch to release the latch.

Using the Locating Pins or Edge Stop Dogs

On the front of the fence are a pair of either locating pins

or edge stop dogs, depending on the manufacturing date

of the joiner. These are used to register the tool against

the edge of the workpiece or against a previously

machined mortise slot, and provide rapid and precise

placement of the tool on the workpiece.

► The distance between the locating pin/dog and the

center of the mortise slot is 37mm (1-7/16 inch).

Instruction Manual 11

► When the locating pin is against the edge of the

workpiece, the edge of the workpiece will be visible in

the center of the guide window on the top of the fence

(refer to right hand image below)

► The edge stop dogs can be locked in the retracted

position when not needed. Refer to page 12 for more

information. (The locating pins cannot be locked in the

retracted position.)

Page 12

Disabling/Retracting the Edge Stop Dogs

The edge stop dogs can be locked in their retracted

position so they don’t push the fence away from the

workpiece when not being used. To retract the dogs

1. Raise the fence to expose the dog’s limit position

setscrew.

2. Press the dog into its retracted position, and gently

tighten the setscrew using the provided 2mm hex

key. Take care to avoid over tightening the setscrew

any more than necessary to keep the dog retracted.

Using the Base Support Bracket

The base support bracket stabilizes the joiner when

mortising on the face of a narrow board as shown to the

right. The base support bracket mounts to the underside

of the joiner with two thumbscrews. Before tightening the

thumbscrews, check to make sure the face of the support

bracket is flush with the face of the joiner.

Using the Optional Narrow Frame Fence

The optional narrow frame fence (also called the trim stop)

is used to securely hold small workpieces for cutting

mortises.

Installing the Narrow Frame Fence

1. With the fence tilted to 90 degrees, slide the narrow

frame fence over the fence face of the Domino joiner as

shown. Make sure the narrow frame fence is fully

seated onto the joiner’s fence.

2. Slide the two latch tabs inward.

3. Tighten the two thumbscrews.

Setting the Fence Width

1. Loosen the two green thumbscrews on the bottom of

the fence.

2. Place the workpiece between the two guides and slide

the guides inward.

3. Use the position gauge on the Domino joiner fence face

to center the workpiece.

4. With the side guides tight to the workpiece and the

workpiece centered in the position gauge, tighten the

two thumbscrews.

5. Hint: Make note of where the workpiece lines up on

the horizontal position gauge, and use the position

gauge when cutting the mortise on the mating frame

for a T-joint frame.

12 Domino DF 500 Tenon Joiner

Page 13

Using the Optional Outrigger Guides

The optional outrigger guides extend the position of the

locating pins/dogs for wider tenon spacing. These are also

adjustable so the spacing can be tailored to the needs of

the specific application.

Note: The two outriggers are specific for right and

left-hand mounting, such that the locking levers

point toward the rear when locked. If you install the

adjustable locating pins backward, the locking

levers will point forward when locked, and this will

interfere with the workpiece. If this happens,

remove the locating pins from the outrigger arms

and turn them around.

Setup

measurement on the outrigger arm.

5. For most applications, make sure both right and left

locating pins are the same distance from the joiner.

6. As shown in the lower right photograph, the outrigger

locating pin can be used to register a mortise from the

edge of a previous mortise.

1. With the locking handle rotated toward the front of the

joiner (as shown in the upper photograph) insert the

mounting pin into the slot from below.

2. Turn the locking lever toward the rear to lock the

outrigger to the base of the joiner.

3. Loosen the clamping knob on the adjustable locating

pin and slide the pin to the desired position.

4. Before tightening the clamping knob, make sure both

pointers on the locating pin are pointing to the same

Applications

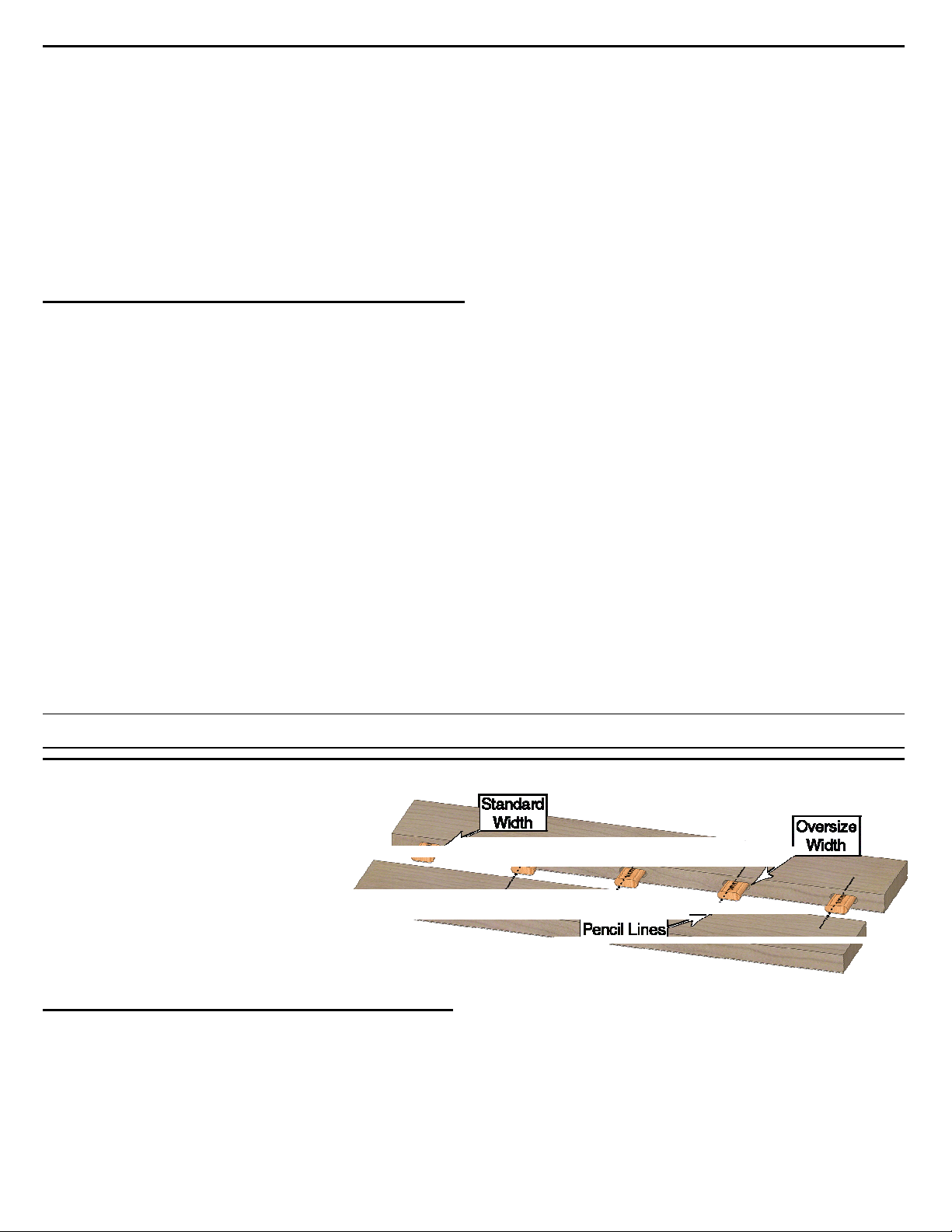

Edge Joining Boards

Edge joining boards is a common

method for creating wide boards from a

series of narrower boards. The Domino

tenons add strength to the joint and

also assist in aligning the boards to be

flush.

For edge joining boards, a series of

tenons are placed down the length of

the joint. The first tenon is used to register the two boards

horizontally, so it is milled at standard width. The remaining tenons

align the boards flush and may be milled with an oversize width.

► Place the mortise slots 6 to 12 inches apart for standard

Tips for Successful Joining

► Use the locating pins (page 11) for the first mortise

slot with the mortise width dial set to the narrow

setting (page 8).

► For subsequent mortise slots you can keep the

mortise width at the minimum setting, but you may

find it easier to set the mortise width dial to the next

widest setting.

Instruction Manual 13

joints, but this spacing should be decreased for joining

plywoods or when a stronger joint is needed.

► Instead of marking the mortise placements with pencil

lines, you can use the optional outrigger guides (page 12)

to evenly space the mortises down the length of the

boards. To do this, use the outrigger locating pin in the

previous mortise slot.

Page 14

Making Butt Box Joints

Butt box joints are typically used in general box

construction or for drawer construction. The Domino

tenons strengthen the joint without the need for additional

fasteners. The example below highlights drawer

construction, but the same techniques are used on other

types of box construction.

Construction Tips

► For drawer construction with a separate drawer front,

the front and rear of the box should be Captive, as

shown below.

► The drawer front is installed onto the drawer box

after the box has been assembled.

► This increases the strength of the drawer because

the tenons are in shear (perpendicular) to the

operation of opening and closing the drawer.

► The ends of the side boards are concealed by the

separate drawer front.

► For drawer construction without a separate drawer

front, the Sides should be Captive and the Front/Rear

should be the Caps (the reverse of the image below).

► For cabinet carcase construction, the Top/Bottom of the

carcase should be Captive (also see

Butt Joints

on page 17).

Making Carcase

5. Align the tenon position using the locating pins (refer to

the picture on page 11).

6. Grasp the Domino joiner by the auxiliary handle, hold it

firmly down to the workpiece, and slowly plunge the

cutter into the edge of the workpiece.

Machining the Cap-Side Tenons

1. Don’t change the fence height from the previous

operation. It is used to register the mortise placement

from the edge of the board.

2. Install the Base Support Bracket as described on page

12.

Machining the Captive-Side Tenons

1. Choose a Domino tenon size to be less than or equal to

1/3 of the board’s thickness.

2. Set the height of the fence so the Domino tenons are in

the center of the board’s thickness.

3. Set the mortise depth according to the instructions on

page 9.

► Note that if your workpieces are thin, you may need

to offset the tenon from center as shown in the

picture on page 9.

► For very thin material that you use frequently for

drawer sides, you may consider setting up a special

plunge depth stop described on page 19.

4. Clamp the Captive boards flat to your workbench.

3. If necessary, change the mortise depth setting.

4. Clamp the workpiece in a vertical position as shown.

5. When plunging, grasp the Domino joiner at the Base

Support Bracket and hold it firmly against the face of

the workpiece.

WARNING! To reduce the risk of injury from

contact with a moving mortising bit, keep hands

clear of the back of the workpiece in case the

mortising bit cuts all the way through the board.

14 Domino DF 500 Tenon Joiner

Page 15

Making Miter Box Joints

Generally miter box joints are fairly weak because the joint

is predominately endgrain to endgrain. Tenons significantly

increase the strength of the joint and make it easier to

assemble and clamp the pieces.

Setup and Machining

1. Tilt the fence to the appropriate angle. (Refer to the

table on page 7 for miter angles for multi-sided boxes.)

Construction Tips

► For thinner materials, keep the mortise close to the

inside corner. This minimizes the chances for boring all

the way through the workpiece.

► For very thin materials, it may be necessary to shorten

the Domino tenon length as described on page 19.

► For thicker materials, stacked mortises can be used as

shown in the picture to the right.

2. Lower the fence to the desired height. Note that the

mortise should be close to the inside corner to avoid

penetrating through the workpiece.

Tip: Before milling the mortise, double check your

depth settings to ensure you don’t cut all the way

through.

3. Plunge the joiner as shown below.

► The stacked mortises are used for thicker stock.

► Grasp the joiner by the auxiliary handle for best

control.

Making Lock Tenon Joints

A locked tenon joint is any type of joint with two or more

tenons at opposing angles. Once the opposing tenon(s)

are inserted, the joint cannot be disassembled. With the

exception of the Three-way Locked Miter Joint (page 18)

at least one of the tenons must be exposed so it can be

inserted after the joint is assembled. This is referred to as

the Locking Tenon.

There are many variations of a locked tenon joint, but the

simplest involve a mitered corner in a box or flat frame.

The miter angle provides an easy reference for the two

tenon angles.

In the example shown to the right, a standard miter joint

is constructed using a large Domino tenon for strength in

the main joint. The locking tenon is a 5mm x 30mm

Domino tenon.

The mortise for the locking tenon is milled with the joiner’s

plunge depth set to 28mm. This mortise is typically milled

after the joint is assembled, but it is possible to mill the

mortise in each piece separately.

Instruction Manual 15

Page 16

Making Frame Joints

Domino tenons can be used to quickly fabricate reinforced

frames of all types.

Butt Joint Frames

When making butt joint frames, such as cabinet

faceframes, use pencil lines to lay out the position of the

tenons. Use the sight gauge (see page 22 for more

information) on the joiner’s fence to position the joiner

over the pencil line.

Mitered Frames

When making mitered frames, position the tenon closer to

the inside corner. This reduces the likelihood of cutting the

mortise all the way through the workpiece.

For narrow frame stock, the optional narrow frame fence

(also called the trim stop) can be used to securely hold the

workpiece (shown below).

Cope and Stick (Stile and Rail) Frames

Domino tenons can also be used to strengthen cope and

stick frame construction too (bottom right picture). This is

typically found in raised panel door frames.

Make sure to securely clamp the workpiece to the bench

when mortising a mitered joint.

It is important to note that the two frame pieces overlap,

so the depth of the mortise needs to be extended. The

amount that each mortise needs to be extended is onehalf the amount of overlap.

Example: A typical stile and rail router bit set has a

profile width (overlap) of 3/8-inch (about 10mm). For a

40mm long tenon, instead of plunging 20mm deep, you

should increase this to 25mm for both workpieces.

16 Domino DF 500 Tenon Joiner

Page 17

Making Carcase Butt Joints

Using tenoned butt joints is an effective method for

constructing a cabinet carcase. The tenons provide a

strong support for each of the horizontal partitions of the

cabinet. The simplicity of this method is that you use the

carcase components for aligning the joiner.

(continued) Because the mortises are registered

from the base of the Domino (fixed 10 mm

distance), the direction that you tip the shelf (either

toward the top or toward the bottom) depends on

how thick the shelf is. Use the following guidelines:

► If the shelf is thick (greater than 20mm), tip it

down with the top-side facing up.

► If the shelf is thin (less than 20mm), tip it down

with the bottom-side facing up.

4. Clamp the two pieces together to prevent them from

moving.

5. With the Domino baseplate resting on the face of the

side-piece, plunge the joiner into the edge of the shelf.

Do not use the fence for height positioning.

Setup and Machining

1. Lay the vertical side pieces on your workbench, and

draw lines across both left and right pieces to indicate

where the shelves will be located. Note that it is easier

to avoid mistakes later on by drawing double lines, with

one line above the shelf and one line below the shelf as

shown.

6. With the joiner standing upright and its baseplate

against the edge of the shelf, plunge downward into

the side wall of the cabinet (see image below).

7. Repeat these steps for each of the shelves.

8. When you repeat this process for the other side wall,

make sure you keep the same side of the shelf facing

up.

2. For reference, label the top and bottom face of each

shelf. This is so your left- and right-hand mortises are

referenced from the same face of each shelf.

3. Working with one shelf at a time, lay the shelf on top of

the side piece so its edge lines up with the outside

pencil line for that shelf location.

Note: To help you remember how to position the

shelves for mortising, simply stand the shelf up

vertically between the pencil lines, and then gently

tip it over so it is laying flat against one pencil line.

Instruction Manual 17

Page 18

Making Three-Way Lock Miter Joints

Three-way miter joints (also called a parson’s joint) have

been around for ages as a way of creating a corner joint

without having any endgrain visible. Using the Domino

Tenon Joiner, you can create easy to construct, locking,

parson’s joints.

The key to these joints is that they require floating tenons at

45 degrees to the main body of the wood. Unlike non-locking

joints, no single piece can be removed from the joint without

separating all three pieces. The joint must be assembled or

disassembled all at once.

The first step in creating the joint is creating the frame

stock. Each piece of the frame must be square in profile. In

this example, the frame stock is 2 inches by 2 inches.

Smaller stock can be used, but you may have to trim the

corners of the tenons where they intersect (the transparent

image in the middle-right shows the Domino tenons just

barely touching).

The square frame stock then needs to be mitered. Each

piece is mitered at 45 degrees from two different faces,

creating a pointed, double miter.

With the frame stock cut and mitered, set up the Domino

joiner. The following settings are based on using 8x40mm

tenons in 2-inch by 2-inch frame stock:

1. Set the fence height between 8mm and 10mm.

2. Set the plunge depth to 20mm.

3. Set the mortise width to the minimum setting.

4. Using a sharp pencil, mark each mortise location at

45mm (1¾ inch) from the point of the miter (see image

below).

5. Plunge a mortise slot at the pencil line of each piece.

6. Assemble all three frame members simultaneously.

18 Domino DF 500 Tenon Joiner

Page 19

Shortening a Domino Tenon’s Length

There may be times when you need a large Domino tenon,

but the length of the tenon does not fit your application. It

is important to firmly and safely hold the tenon while you

cut it to length.

WARNING! Never attempt to cut a Domino

tenon’s length without using a mechanical

holder. Holding the tenon with your hand poses

an extremely serious risk of personal injury.

To make the simple tenon holder shown to the right, mill a

full-depth tenon slot into the end of a board, and then cut

out a notch in the side of the holder. This notch allows you

to push the shortened tenon out of the mortise slot after it

has been cut to length. Cut the tenon to the desired length

with either a hand saw or miter saw.

Creating Special Plunge Depths

Sometimes it may be necessary to use a plunge depth

different from the normally available depth settings. One

example of this is creating a Butt Box Joint (see page 14) for

thin drawer material. This can also be used for inlaying

decorative faux through tenons or other inlay work. Custom

limit stops can be made from ½-inch PVC tube purchased at

your local hardware store.

► Make sure to use a soft plastic such as PVC to prevent

scratching the stainless steel linear rail.

► Separate the fence body from the motor housing (see

page 9), insert the PVC tube over the linear rail, and

reinstall the fence on the motor housing.

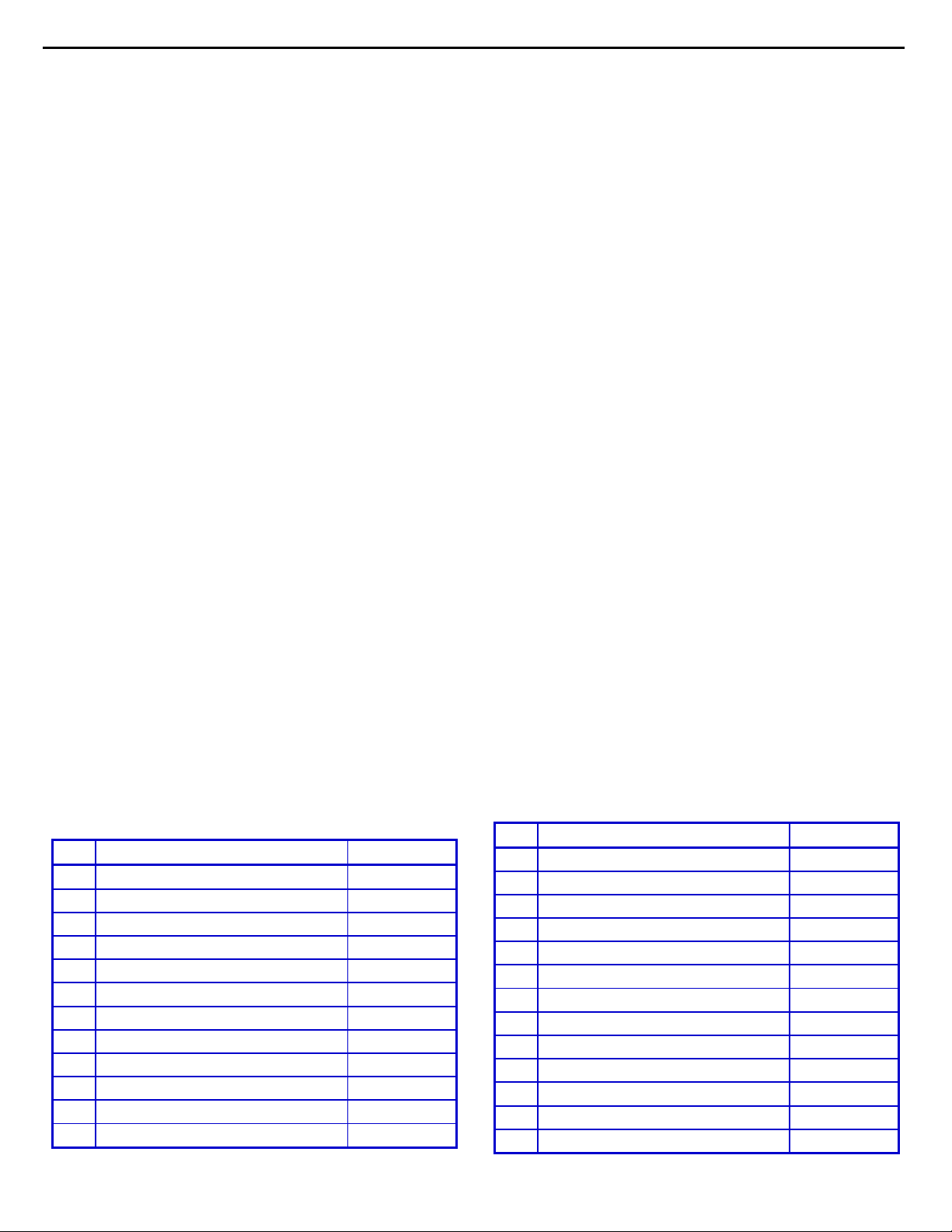

► The length of the tube needs to be 28 mm (1

minus the desired plunge depth. So for a 10 mm plunge,

you would need an 18 mm sleeve (⅜” plunge =

sleeve).

Plunge

Depth

Sleeve

Length

Plunge

Depth

Sleeve

Length

Plunge

1/4 27/32 11/32 3/4 7/16 21/32

9/32 13/16 3/8 23/32 15/32 5/8

5/16 25/32 13/32 11/16

3

/32 inch)

23

/32”

Sleeve

Depth

Length

1/2 19/32

Tips for Applying Glue

There are many different ways to apply glue to joints;

however, how you apply glue can have an impact on the

quality of the joint or the ease of assembly.

► For a longer glue open-time on complex assemblies,

apply the glue generously to the workpieces. The

thicker the glue, the longer the time it will take to skin

over (see image below). Excess glue can be cleaned off

after completion.

► Apply glue to the workpiece face and the mortise slots

before inserting the tenons into the slots.

Instruction Manual 19

► When applying glue for the tenons, you can either

apply glue into the mortise slots, spread a thin layer

across the Domino tenons, or both.

► When the tenon is the primary structure holding the

joint together, you should apply the glue at least to the

tenon (or both). The Domino tenons have small glue

pockets and ridges that will hold glue as the tenon

slides into the mortise

slot.

► When applying glue to

the mortise slot, take

care not to use too much

glue, as there is not

enough space for the

excess glue to squeeze

out past the tenon.

Page 20

Maintenance

WARNING! Any maintenance or repair work that

requires opening of the motor or gear housing

should be carried out only by an authorized

Customer Service Center (see your dealer for

information on locating a service center).

Maintenance or repair work carried out by an

unauthorized person can lead to improper

connection of electrical wires, misadjustment, or

damage to components, which can result in

electric shock or other injury.

WARNING! To reduce the risk of electrocution or

other personal injury, always unplug the tool from

the power supply outlet before performing any

maintenance or repair work on the tool.

Routine Maintenance

The Domino tenon joiner does not require much routine

maintenance except for cleaning. For best performance

and long life of the Domino tenon joiner, keep the machine

clean.

► To ensure proper cooling of the tool and motor, the

cooling vents in the motor housing must always be kept

clear and clean. Keep the motor cooling inlets at the

back of the handle clean and free from sawdust.

► Always use the Domino joiner with a dust collection

system (see page 11).

► Keep the linear rails, guide tubes, and linear bearings

clean and free from sawdust.

► Never store the joiner with the fence body separated

from the motor housing, as this can permit dust and

debris to enter the guide tubes.

► Periodically inspect the mortising bit(s) for damage,

wear, or dullness. Re-sharpen or replace the bits as

necessary.

► Never attempt to sharpen the mortising bits yourself.

The mortising bits should be sharpened only by a

qualified sharpening service.

► For best results, only the tip of the bit should be

ground, not the sides.

► The maximum tip material removal from sharpening

before the bit must be replaced is approximately

1mm. Any more than this and the bit will be too

short for proper fit of the tenons.

NOTICE: Do not use compressed air to clean the

motor housing of the tool, as you could inject

foreign objects into the motor through the

ventilation openings. Low-pressure (30 psi)

compressed air may be used on other

components, but personal safety apparel should

be worn (i.e. hearing, eye, and respiratory

protection).

NOTICE: Certain cleaning agents and solvents are

harmful to plastic parts. Some of these include,

but are not limited to: Gasoline, Acetone, Methyl

Ethyl Ketone (MEK), Carbonyl Chloride, cleaning

solutions containing Chlorine, Ammonia, and

household cleaners containing Ammonia.

a. With a soft cotton cloth, wipe down the linear rails.

b. With low-pressure compressed air, blow out any

dust from inside the guide tubes.

c. With a soft cotton cloth, wipe down the i n terior of

the linear bearings (interior of the guide tubes).

4. With a clean cotton cloth (not the same cloth used

previously), apply a coating of light-weight machine oil

to the linear rails and/or linear bearings.

► Use a lightweight machine oil such as “sewing

machine” oil or pneumatic tool oil.

► Do not use a penetrating oil as these may contain

solvents and detergents that can remove the

impregnated lubricant from the linear bearings.

► Do not use a rust inhibiting fluid/oi l (such as a water

displacement product) as these have limited

lubrication properties, and can also remove the

impregnated lubricant from the linear bearings.

5. Replace the fence body, and with the plunge depth set

to maximum, plunge the joiner in and out several times

to spread the lubricant into the internal linear bearings.

6. Remove the fence body from the motor housing and

wipe off the excess oil from the linear rails.

7. Replace the fence body onto the motor housing.

Cleaning and Maintenance

1. Blow off the exterior of the machine with low-pressure

compressed air to remove sawdust, but do not blow air

directly into the air cooling vents on the back of the

motor as this can drive debris into the motor.

2. Blow out impacted sawdust from the mortising bit area.

NOTICE: To avoid getting debris inside the guide

tubes, do not remove the fence body from the

motor housing when the joiner is coated with

sawdust.

3. With the exterior of the joiner free from sawdust,

remove the fence body from the motor housing and

clean the slide components:

20 Domino DF 500 Tenon Joiner

Page 21

Calibrating the Locating Pins or Edge Stop Dogs

It is important that the two locating pins/dogs are perfectly

spaced from the center of the mortise hole for properly

aligned mortises. The right-hand locating pin is adjustable by

rotating the eccentric bushing, and the edge stop dogs are

adjustable by replacing one dog with an offset dog (a pair of

offset dogs are included with the Domino).

1. Using the procedure described in “Using the Locating Pins

or Edge Stop Dogs

” on page 11, plunge a left-hand and

right-hand mortise into two blocks of scrap wood. Make

sure the mortise width dial (see page 8) is set to the

smallest setting.

2. Insert a Domino tenon into the resulting mortise and fit

the two pieces together without glue.

3. Examine the alignment of the ends of the two blocks of

wood. Note that you are only concerned about the ends

where the locating pins were used.

► If the two ends are flush, no adjustment is necessary.

► In the example shown to the right, the adjustable pin

(or right-hand dog) is too close to the mortise;

increase the distance of the pin as described below.

4. If an adjustment is necessary, follow the applicable

procedure listed for either the pins or dogs.

5. Repeat the test process to verify that the adjustment is

correct.

2. Using a large screwdriver, rotate the eccentric

bushing to move the adjustable pin closer to or

farther from the mortise slot.

► It is necessary to depress the pin in order to

engage the screwdriver in the eccentric bushing.

► The factory default (neutral) setting is shown in

the image below. The screwdriver slot is in the

vertical position.

► Each hash mark represents 0.25mm (0.010 inch).

► Don’t turn the bushing any farther than ¼-turn to

the left or ¼-turn to the right from the neutral

position.

► Compare your test pieces to the image to the left,

and increase or decrease the distance of the right

hand pin accordingly.

3. Retighten the setscrew.

Removing and Adjusting the Edge Stop Dogs

Adjusting the Locating Pin

The right hand locating pin has an eccentric bushing that

changes the position of the pin as the bushing is rotated. Use

the following steps to adjust the position of the pin.

1. Loosen the bushing’s setscrew using a 2 mm hex key.

To adjust the edge stop dogs, you replace the standard

dog with one of the offset dogs. The offset dog is 0.006”

(0.15mm) narrower than the standard dog, and you

replace whichever dog resulted in the larger distance to

the mortise. In the example shown to the left, the lefthand dog needs to be replaced with the offset dog.

1. While holding the dog in the retracted position,

remove the position limiting setscrew from the dog.

2. While being careful to not lose the return spring,

rotate the dog to the top position as shown, and

then slide the dog out of the fence housing.

3. Reinstall the new dog in the reverse process.

4. Take care not cross the threads when installing the

setscrew.

5. Leave the head of the setscrew slightly proud of the

surface of the dog.

Instruction Manual 21

Page 22

Calibrating the Horizontal Position Gauge

The horizontal position gauge (also called the sight gauge)

is used for aligning Domino tenons to a pencil mark on the

workpiece. If the gauge is not perfectly centered over the

mortising slot, the two workpieces will not be aligned

when the joint is assembled.

Calibration Procedure

1. Take two pieces of scrap wood, and draw a thin line on

each piece where a tenon is to be placed.

2. Set the mortise slot width to the narrow setting (page

8).

3. With the middle line of the sight gauge lined up on the

pencil line, plunge a mortise slot into each piece of

wood.

4. Join the two pieces of wood together without glue, and

examine the alignment of the original pencil lines.

5. If the pencil lines are not aligned, loosen the two

screws on the sight gauge and slide the gauge

sideways as noted in the upper image.

22 Domino DF 500 Tenon Joiner

Page 23

Accessories

Mortising Bits:

Carbide Tipped. Sold separately or in a set of

all four.

Sizes

► 5 mm

► 6 mm

► 8 mm

► 10 mm

Domino Tenons:

Sold separately or in an assortment.

Sizes

► 5 mm x 30 mm

► 6 mm x 40 mm

► 8 mm x 40 mm

► 8 mm x 50 mm

► 10 mm x 50 mm

The assortment Systainer includes:

► 5 mm x 30 mm - 600 pieces

► 6 mm x 40 mm - 190 pieces

► 8 mm x 40 mm - 130 pieces

► 8 mm x 50 mm - 100 pieces

► 10 mm x 50 mm - 85 pieces

► Set of 4 mortising bits

► Systainer – size #2

Narrow Frame Fence:

The narrow frame fence (also called the Trim

Stop) is used to firmly hold smaller frame

pieces while milling Domino mortises.

Outrigger Guides:

The outrigger guides (also called the Cross

Stop) are used to extend the distance of the

locating pins for positioning Domino mortises

without needing to draw marking lines.

Dowel Guide:

The dowel guide (also called the Handrail

Fence) is used to center a round workpiece in

front of the cutter for mortising.

Instruction Manual 23

Page 24

Systainer (System Container)

Each Festool product is shipped in its own unique system container, called a "Systainer." This provides protection and

storage for the tool and accessories. All Systainers are stackable and can be interlocked together, including stacking and

locking atop Festool dust extractors.

Parts of the Systainer

► Carrying Handle. The carrying handle folds flat when

not in use.

► Cover Latches. The two green latches on the front of

the Systainer secure the cover. (These are also used for

stacking Systainers, as described below.)

► Stacking Latches. The two gray latches on the sides

of the Systainer are used for stacking one or more

Systainers together.

► Stacking Tabs. The stacking tabs are used to lock two

Systainers together. There are four sets of tabs (two on

the front and two on the sides) of each Systainer.

Stacking Systainers

For convenience in transporting Festool tools and

accessories, the Systainers can be stacked and locked

together. The Systainers are locked together using the

stacking tabs and latches.

1. Place one Systainer on top of the other.

2. Release all four latches on the lower Systainer by

pulling back at their top edges (step A to the right).

3. Slide all four latches upward (step B) as depicted by the

two views.

4. Snap all four latches back to their flat position (step C)

so they engage the stacking tabs of the upper

Systainer.

The image to the right shows two accessory Systainers

stacked together.

24 Domino DF 500 Tenon Joiner

Page 25

Troubleshooting

Symptom Possible Causes

Motor does not start ► Check that the cord is properl y plugged into an outlet.

► Make sure the Plug-i t connector is properly inserted and fully tightened.

► Make sure the outlet has power. Check the ci rcuit breaker or try another outlet.

► If used with a Festool dust extractor, make sure the selector switch is pointing to

"Auto". The auxiliary outlet on the dust extractor has power only when the selector

is at Auto.

► Inspect the power cord (incl uding extension cords) for damage or missing prongs.

► The motor brushes may have worn and need replacement.

Plunging action is not smooth ► Clean the l inear rails and bronze bearings of the plunge slide, and make sure they

are properly lubricated (refer to the

► Inspect the li near bearings for damage. Improper insertion of the fence body onto

the motor housing can damage the linear bearings.

Domino tenons are too loose ► Make sure you hold the Domino joiner firmly in position while plunging the mortise

slot.

► Make sure the mortise width setting is correct.

► Make sure you are using the correct morti sing bit for the size of the Domino tenon.

► The Domino tenons may have shrunk in an overly dry or warm environment. This is

normal wood movement.

► Check the mortising bit to ensure it is not bent. A bent bit will make a thicker and

wider mortise slot than desired.

► Plungi ng too fast can cause the mortise slot to be enlarged.

Domino tenons are too tight ► The most common cause for this is that the tenons are stored in a humid

environment, and they have swelled from moisture absorption. Store the tenons in

a cool dry environment.

► The mortisi ng bit may have been improperly sharpened or sharpened too many

times. Replace the bit.

Workpiece joints are

misaligned horizontally

► Make sure the workpiece is securely clamped before plunging.

► Check the cali bration of the locating pins.

► Check the cali bration of the horizontal position gauge (sight gauge).

► Don’t plunge the morti sing bit into the work too fast. This may cause the joiner to

move during the plunge.

► Make sure the friction pads on the front of the joiner are not worn, damaged, or

missing.

Workpiece joints are

misaligned vertically

► Take care not to tilt the joiner while plunging.

► If the mortise sl ots were registered from the bottom of the baseplate, make sure

there is no dust or debris under the joiner.

► Make sure the fence is properl y locked at the desired height setting.

► Inspect the fence height adjustment lock to ensure it is not broken (slipping).

Tilted or misaligned mortise

slots

► Make sure the fence is set to the correct angle (e.g. 90 degrees).

► Make sure to hold the Domino joiner firmly to the work surface.

► When tighteni ng the height adjustment clamp lever, make sure the fence is not

being skewed. Try wiggling the fence slightly as you tighten the clamping lever.

► Plunging too slow can cause the mortise slots to be tilted slightly.

Workpiece joint won’t close

(gaps between pieces)

► Make sure the proper plunge depth is set.

► Make sure the mortising bit is not broken.

► Make sure the joiner i s tight to the face of the workpiece.

► The mortisi ng bit may have been sharpened too many times and is too short.

► Excessive dust may be present i nside the linear slide.

► Excessive gl ue may be present at the bottom of the mortise.

Tearout or rough mortise slots ► Plunging speed too fast. Slow down the rate of your plunge.

► Low-grade materials and plywoods will tear out more than solid woods. Decreasing

your plunging speed will improve the results but may not eliminate the problem

completely.

► Dull or broken mortising bit.

Tapered mortise slot. The

Domino tenon fits only part

► The plunge speed is too fast and the bit is not cutting the sides properly. Slow

down the plunge speed.

way into the slot

Routine Maintenance instructions on page 20).

Instruction Manual 25

Page 26

26 Domino DF 500 Tenon Joiner

Loading...

Loading...