Page 1

C 12

Instruction manual

Page 2 - 7

IMPORTANT: Read and understand

all instructions before using.

Guide d’utilisation

Page 8 - 13

IMPORTANT: Lire et comprendre

toutes les instructions avant de

démarrer les travaux.

Manual de instrucciones

Página 14 - 19

IMPORTANTE: Lea y comprende

todas las instrucciones antes de usar.

469 038_002

Cordless Drill /

Screwdriver

Perceuse visseuse á

accumulateur

Taladradora-atornilladora

con acumuladores

1

Page 2

GENERAL SAFETY RULES

Read and understand all instruc-

tions. Failure to follow all instructions listed below

may result in electric shock, fi re and/or serious

personal injury.

SAVE THESE INSTRUCTIONS

1) Work area safety

a) Keep work area clean and well lit. Cluttered

and dark areas invite accidents.

b) Do not operate power tools in explosive

atmospheres, such as in the presence of fl ammable liquids, gases or dust. Power tools create

sparks which may ignite the dust or fumes.

c) Keep children and bystanders away while

operating a power tool. Distractions can cause

you to lose control.

2) Electrical safety

a) Power tool plugs must match the outlet.

Never modify the plug in any way. Do not use

any adapter plugs with earthed (grounded)

power tools. Unmodifi ed plugs and matching

outlets will reduce risk of electric shock.

b) Avoid body contact with earthed or

grounded surfaces such as pipes, radiators,

ranges and refrigerators. There is an increased

risk of electric shock if your body is earthed or

grounded.

c) Do not expose power tools to rain or wet

conditions. Water entering a power tool will in-

crease the risk of electric shock.

d) Do not abuse the cord. Never use the cord

for carrying, pulling or unplugging the power

tool. Keep cord away from heat, oil, sharp

edges or moving parts. Damaged or entangled

cords increase the risk of electric shock.

e) When operating a power tool outdoors,

use an extension cord suitable for outdoor

use. Use of a cord suitable for outdoor use reduces

the risk of electric shock.

f) Hold power tool by insulated gripping surfaces only, when performing an operation

where the cutting accessory may contact

hidden wiring or its own cord. Cutting acces-

sory contacting a „live“ wire may make exposed

metal parts of the power tool „live“ and shock the

operator.

3) Personal safety

a) Stay alert, watch what you are doing and

use common sense when operating a power

tool. Do not use a power tool while you are

tired or under the infl uence of drugs, alcohol

or medication. A moment of inattention while

operating power tools may result in serious personal injury.

b) Use safety equipment. Always wear eye

protection. Safety equipment such as dust mask,

non-skid safety shoes, hard hat, or hearing protection used for appropriate conditions will reduce

personal injuries.

c) Avoid accidental starting. Ensure the

switch is in the off position before plugging

in. Carrying power tools with your fi nger on the

switch or plugging in power tools that have the

switch on invites accidents.

d) Remove any adjusting key or wrench before turning the power tool on. A wrench or a

key left attached to a rotating part of the power

tool may result in personal injury.

e) Do not overreach. Keep proper footing and

balance at all times. This enables better control

of the power tool in unexpected situations.

f) Dress properly. Do not wear loose clothing or jewellery. Keep your hair, clothing

and gloves away from moving parts. Loose

clothes, jewellery or long hair can be caught in

moving parts.

g) If devices are provided for the connection

of dust extraction and collection facilities,

ensure these are connected and properly

used. Use of these devices can reduce dust re-

lated hazards.

4) Tool use and care

a) Do not force the power tool. Use the correct power tool for your application. The cor-

rect power tool will do the job better and safer at

the rate for which it was designed.

b) Do not use the power tool if the switch

does not turn it on and off. Any power tool that

cannot be controlled with the switch is dangerous

and must be repaired.

c) Disconnect the plug from the power

source before making any adjustments,

changing accessories, or storing power tools.

Such preventive safety measures reduce the risk

of starting the power tool accidentally.

d) Store idle power tools out of the reach of

children and do not allow persons unfamiliar

with the power tool or these instructions to

operate the power tool. Power tools are danger-

ous in the hands of untrained users.

e) Maintain power tools. Check for misalignment or binding of moving parts, breakage of

parts and any other condition that may affect

the power tools operation. If damaged, have

the power tool repaired before use. Many ac-

cidents are caused by poorly maintained power

tools.

f) Keep cutting tools sharp and clean. Properly maintained cutting tools with sharp cutting

edges are less likely to bind and are easier to

control.

g) Use the power tool, accessories and tool

bits etc., in accordance with these instructions and in the manner intended for the particular type of power tool, taking into account

the working conditions and the work to be

performed. Use of the power tool for operations

different from those intended could result in a

hazardous situation.

2

Page 3

5) Battery tool use and care

a) Ensure the switch is in the off position

before inserting battery pack. Inserting the

battery pack into power tools that have the switch

on invites accidents.

b) Recharge only with the charger specifi ed

by the manufacturer. A charger that is suitable

for one type of battery pack may create a risk of

fi re when used with another battery pack.

c) Use power tools only with specifi cally designated battery packs. Use of any other battery

packs may create a risk of injury and fi re.

d) When battery pack is not in use, keep it

away from other metal objects like paper

clips, coins, keys, nails, screws, or other

small metal objects that can make a connection from one terminal to another. Shorting

Various dust created by power sanding, sawing, grinding, drilling and other construction activities contains chemicals known (to the State of California) to cause cancer, birth defects

or other reproductive harm. Some examples of these chemicals are:

• lead from lead-based paints,

• crystalline silica from bricks and cement and other masonry products, and

• arsenic and chromium from chemically-treated lumber.

The risk from these exposures varies, depending on how often you do this type of

work.

To reduce your exposure to these chemicals: work in a well ventilated area, and work

with approved safety equipment, such as dust masks that are specially designed to

fi lter out microscopic particles.

the battery terminals together may cause burns

or a fi re.

e) Under abusive conditions, liquid may be

ejected from the battery; avoid contact. If

contact accidentally occurs, fl ush with water. If liquid contacts eyes, additionally seek

medical help. Liquid ejected from the battery

may cause irritation or burns.

6) Service

a) Have your power tool serviced by a qualifi ed repair person using only identical replacement parts. This will ensure that the safety

of the power tool is maintained.

To reduce the risk of injury,

user must read and understand instruction

manual.

Technical data

Cordless drill/screwdriver C 12

Motor voltage 12 V

Idle-running speed: 1. speed / 2. speed 0 – 450 rpm / 0 – 1500 rpm

Max torque: soft case / hard case 18 Nm / 30 Nm

Adjustable torque: 1. speed / 2. speed 2 – 7 Nm / 0.5 – 2.5 Nm

Chuck capacity 1.5 – 13 mm

Max. drill diameter for metal / wood 14 mm / 25 mm

Tool fi tting in chuck 1/4 "

Weight without battery pack 0.96 kg (2.1 lbs)

Charger LC 45

Supply voltage (input) / line frequency 120 V ~ / 60 Hz

Charging voltage (output) 7.2 - 18 V (DC)

Charging current

• Quick charge max. 3 A

• Compensation charge, pulsating app. 0.06 A

Charging time for • NiCd 1.3 Ah app. 30 min

• NiCd 2.4 Ah app. 50 min

• NiMH 3.0 Ah app. 70 min

Battery pack BPS 12 C NiCd BPS 12 S NiCd BPS 12 S NiMH

Order number 493 348 492 268 491 821

Voltage 12 V 12 V 12 V

Capacity 1.3 Ah 2.4 Ah 3.0 Ah

Temp. range for charging 5 - 45 °C 5 - 45 °C 5 - 45 °C

Monitoring of charge by means of NTC thermistor

Weight 0.56 kg (1.2 lbs) 0.73 kg (1.6 lbs) 0.75 kg (1.7 lbs)

3

Page 4

Symbols

V volts

A amperes

Hz hertz

W watt

~ alternating current

n

no load speed

0

Class II Construction

rpm revolutions per minute

Intended use

Cordless drills are suitable for drilling metal, wood,

plastics and similar materials, as well as tightening and screwing in screws (into wood, up to a

diameter of 6 mm).

The LC 45 battery charger is designed for recharging the battery pack listed.

The user will be liable for damage

due to improper use.

Wall mounting LC 45

The charger LC 45 has two longitudinal slots on its

rear by which it can be suspended on walls using

two screws (e.g. button-headed or fl at head screw

with a shaft diameter of 5 mm). Screw both screws

into the wall 96 mm apart until the screwhead is

protruding from the wall by approx. 4 mm.

Machine settings

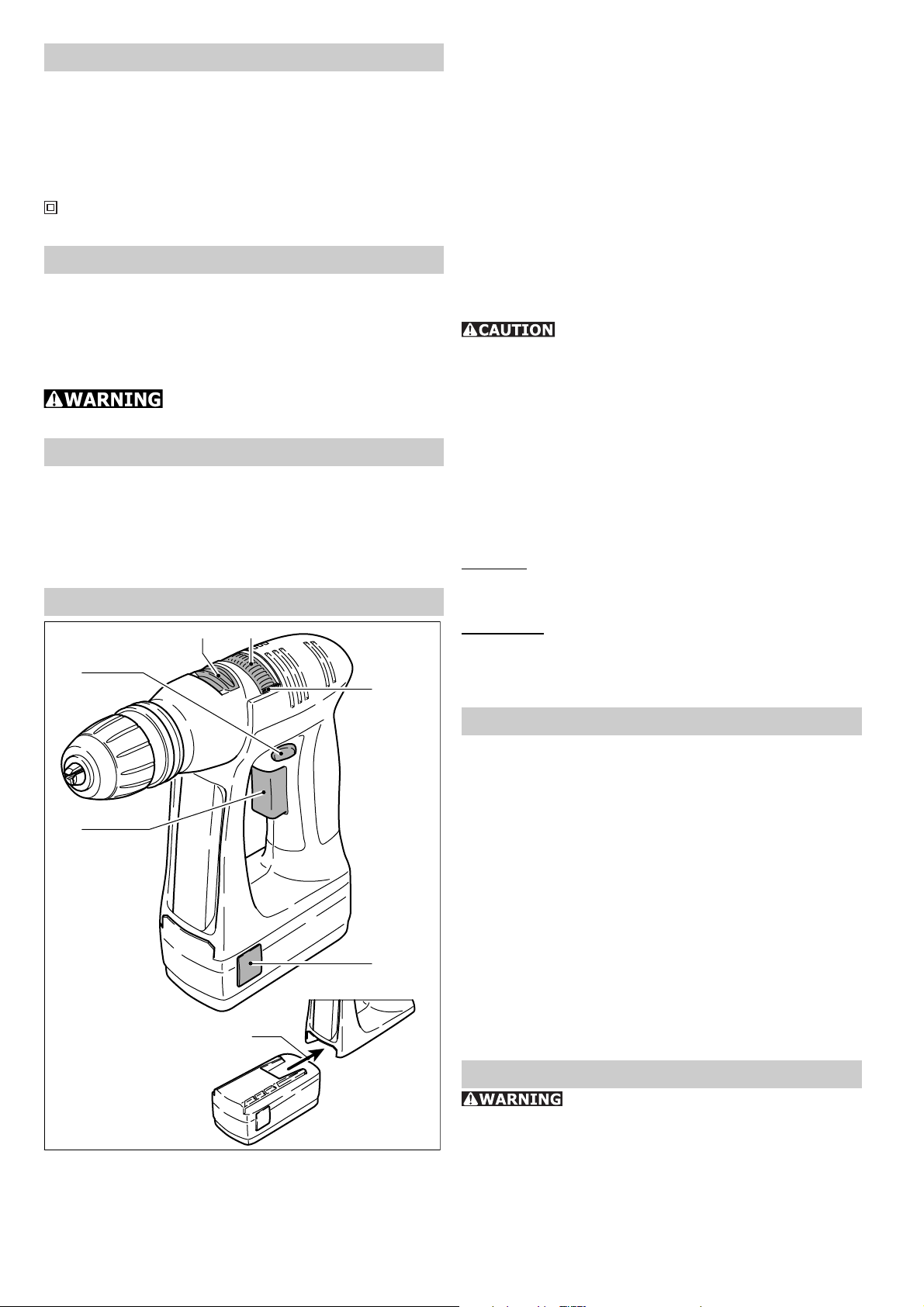

1.3 1.4

1.2

1.5

- Inserting battery pack: Slide the battery pack

into the holder on the underside of the handle

until it latches into place (1.7).

To change the direction of rotation

The selector button (1.2) determines the direction

of rotation.

• Turn button from right to left = clockwise rotation.

• Turn button from left to right = anticlockwise

rotation.

• Selector button in central position = circuit interlock.

Shifting speeds

Change only when completely

stopped!

Using the shift lever (1.3), the speed can be

changed.

• 1. Speed: Lever forward - Figure 1 is visible.

• 2. Speed: Lever backwards - Figure 2 is vis-

ible.

Torque adjustment

By turning the adjustment ring (1.4) the required

torque can be adjusted. The arrow (1.5) aligns

with the adjusted state.

Drilling:

Drilling symbol on adjustment ring aligns with the

arrow = maximum torque.

Screwing:

Torque corresponding to setting:

• Position 1 = low torque

• Position 20 = high torque

1.1

1.6

1.7

Exchanging the battery pack

- Removing battery pack: Press the two buttons

(1.6) and slide the battery pack forwards to

remove.

Operation

Turn on by pressing button (1.1). Depending on

the pressure exerted on the button, the adjustment of running speed can be varied infi nitely.

Turn off by releasing the button (1.1). After releasing the button, the chuck is stopped and therefore,

after-running of the equipment is prevented.

Warning signal

With the following operational statuses, the

machine sounds an acoustic warning signal and

switches off:

Peep at regular intervals

- Battery empty

Triple peep at regular intervals

- Excessive load (torque)

- Machine too warm.

Tool holding fi xture, attachments

Make sure that the machine is

switched of and the battery block has been removed before changing the tool holding fi xture,

attachments and tools.

4

Page 5

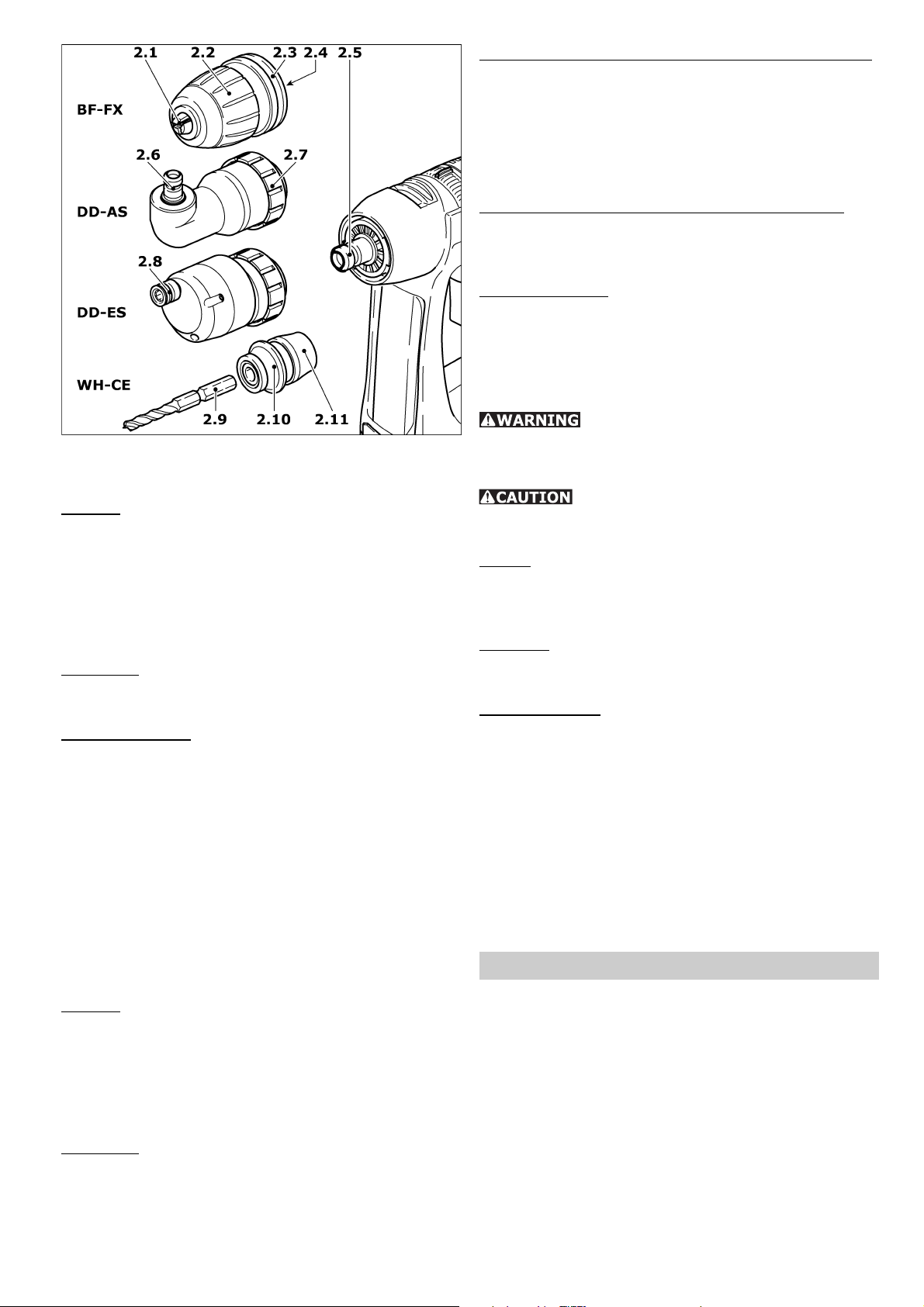

Chuck BF-FX

The chuck is used to clamp drills and bits.

Fitting:

- Place the chuck on the drill spindle (2.5) and

twist until the hexagon key (2.4) of the chuck

latches into the hexagon socket of the drill

spindle.

- Pull the unlocking ring (2.3) forwards, press the

chuck onto the drill spindle up to the stop and

release the unlocking ring.

Removal:

- Pull the unlocking ring forwards and remove

the chuck.

Changing tools:

- Turn the clamping sleeve (2.2) anti-clockwise

to open the clamping jaws (2.1)

(Note: the spindle is automatically locked when

the machine is switched off).

- Insert the tool into the chuck.

- Clamp the tool by turning the clamping sleeve

clockwise. Always make sure that the tool is

clamped centrally in the chuck.

Angle attachment DD-AS

The angle attachment permits work (drilling,

screwing) vertical to the machine’s longitudinal

axis.

Fitting:

- Place the angle attachment on the drill spindle

and turn until it catches in the desired position

(Note: The angle attachment can be fi tted in

16 different angle settings).

- Lock the angle attachment by turning the fastening ring (2.7) tightly clockwise.

Removal:

- Turn the fastening ring anti-clockwise up to the

stop and remove the angel attachment.

Fitting / removal of chuck on angle attach ment:

The chuck is fi tted on the shaft (2.6) of the angle

attachment in the same way as on the drill spindle

of the machine.

Eccentric attachment DD-ES

The eccentric attachment is used to hold bits. It

allows screwing close to edges.

Fitting / removing the eccentric attach ment:

The eccentric attachment is fi tted / removed in

the same was as the angle attachment (see DDAS).

Changing tools:

Pull the unlocking ring (2.8) back and remove the

tool and/or insert the new tool.

CENTROTEC WH-CE toolholder

The CENTROTEC toolholder enables rapid changes

of tools with CENTROTEC shafts.

Danger of injury! When changing

tools, handle the tool and its sharp cutters with

special care and wear protective gloves, if necessary.

Do not fi t CENTROTEC tools at the

round shaft section in a conventional chuck to

prevent damage to the shaft.

Fitting

- Pull the release ring (2.11) forwards, place the

toolholder as far as it will go on the drill spindle

(2.5) and let go of the release ring.

Removal

- Pull the release ring forwards and take off the

toolholder.

Changing tools

- To insert or remove a tool with CENTROTEC

shaft, pull the green release ring (2.10) back.

On inserting the tool, turn it until its hex shank

arbour (2.9) locks in place in the hexagonal

shank of the drill spindle, and push the tool into

the toolholder as far as it will go.

Tool holding fi xture in the drill

spindle

Bits can be fi tted directly in the hexagon socket

holder of the drill spindle (2.5) to make the machine lighter and shorter.

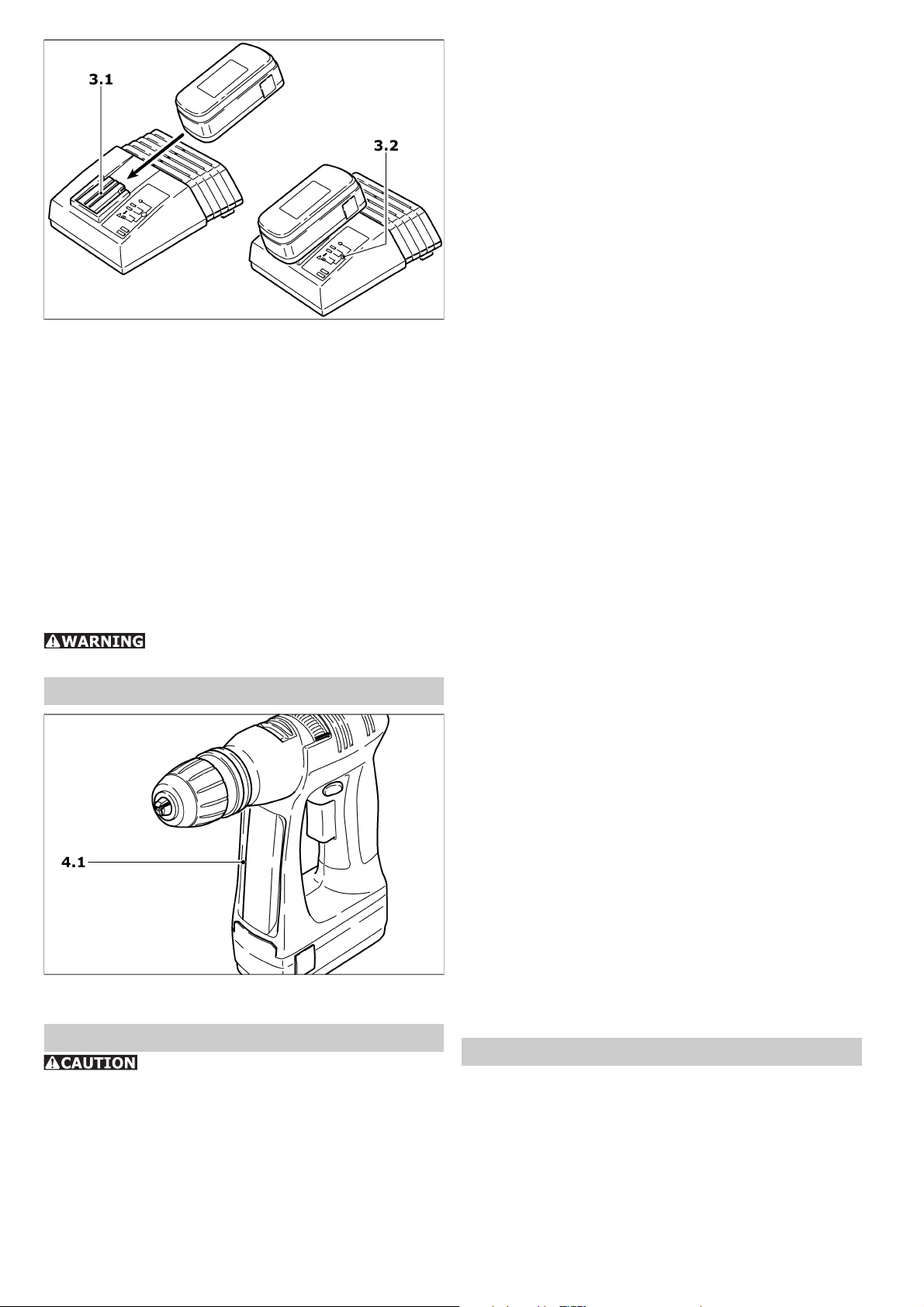

Charge battery pack

To load the battery pack, push it into the holder

(3.1) on the charger up to the stop. Perform this

in reverse to remove the battery pack from the

charger.

The battery type used (NiCd or NiMH) is detected

automatically. Charging is controlled by a microprocessor.

If a warm NiMH battery pack (>37° C) is inserted, charging will only be carried out at a lower

charge current. In this case, the charging time is

extended.

5

Page 6

The LED (3.2) indicates the respective charging state of the charger.

LED yellow – steady:

charger is ready for use.

LED green – fl ashing:

battery pack being charged.

LED green – steady:

battery pack fully charged, conservation charge

on.

LED red – fl ashing:

general malfunction, e. g. full contact not being

made, short-circuit, battery pack faulty.

LED red – steady:

temperature of battery pack is outside permis-

sible limit.

It is essential that you read the in-

structions in the Chapter „Maintenance - Care“.

Bit storage well

You can insert several bits or bit extensions into

the bit magazine (4.1) with magnetic holder.

Maintenance and care

Pay attention to the following instructions. Otherwise there is a risk of damage to the

tool, charger or battery pack.

• Repairs may only be performed by authorised

technicians. LC 45 charging device: Even after

disconnection from the mains, there is still a

high capacitor voltage on the power output

component on the inside of the device.

• Keep the air vents of the electronic equipment

and the charger clean to guarantee the air circulation for cooling.

• No metal objects (metal chips) should enter the

charger at the contact points as well as through

the cooling slits into the equipment (danger of

short circuit).

• Only use original Festool battery packs. Do not

use spent and recycled battery packs. The user

shall be liable for damages if Festool original

battery packs are not used.

• Keep the connection contacts of electronic

equipment, charger and battery pack clean.

• By keeping the battery pack in a ready for use

charger, the battery pack will be kept in a state

of readiness by fl oat charging conservation.

• Do not keep discharged battery pack (maximum

one month) attached to charger whenever charger is detached from the power supply (danger

of deep discharging).

• A new battery pack or a battery pack not used

for a longer period of time reaches it full capacity after about 5 charging and discharging

cycles.

• Battery packs should, before charging, be fully

discharged if possible. Continuous starting of

the charging process shortens the lifespan of

the batteries.

• A considerably reduced time of operation per

charging shows that the battery pack is used

up an should be replaced by a new one.

• NiCd battery packs that are not used for longer periods should be stored in a discharged

state.

Special instructions for NiMH battery

packs:

• The output of NiMH battery packs drops noticeably at ambient temperatures below 0° C or

above 45° C.

• Do not overload the tool (do not load the tool

excessively so that it comes to a standstill).

• Even if NiMH battery packs are not used, recharge them approx. every 4 months so that

they retain their full capacity.

• NiMH battery packs should be left for 60 min.

in the charger after every 10th fast charge to

compensate any differences in capacity between the cells.

• Because NiMH battery packs discharge automatically, store them preferably at ambient

temperatures of between 0° C and 25° C.

Recycling battery packs

Never throw spent battery packs into domestic waste containers! Return spent or defective

battery packs to dealers, the Festool after-sales

service department or approved waste disposal

facilities. This ensures that they are correctly

recycled.

6

Page 7

Accessories, tools

For safety reasons, only use original

Festool accessories and tools!

The accessory and tool order number can be found

in your Festool catalog or on the Internet at www.

festool-usa.com.

Warranty

Conditions of 1+2 Warranty

You are entitled to a free extended warranty (1

year + 2 years = 3 years) for your Festool power

tool. Festool shall be responsible for all shipping

costs during the fi rst year of the warranty. During the second and third year of the warranty the

customer is responsible for shipping the tool to

Festool. Festool will pay for return shipping to the

customer using UPS Ground Service. All warranty

service is valid 3 years from the date of purchase

on your receipt or invoice.

Festool Limited Warranty

This warranty is valid on the pre-condition that the

tool is used and operated in compliance with the

Festool operating instructions. Festool warrants,

only to the original consumer purchaser, that the

specifi ed tool will be free from defects in materials and workmanship for a term of one year from

the date of procurement. Festool makes no other

warranty, express or implied, for Festool portable

power tools. No agent, representative, distributor,

dealer or employee of Festool has the authority

to increase or otherwise change the obligations

or limitations of this warranty. The obligations of

Festool in its sole discretion under this warranty

shall be limited to the repair or replacement of

any Festool portable power tool that is found to be

defective as packaged with the User Manual.

Excluded from coverage under this warranty are:

normal wear and tear; damages caused by misuse,

abuse or neglect; damage caused by anything

other than defects in material and workmanship.

This warranty does not apply to accessory items

such as circular saw blades, drill bits, router bits,

jigsaw blades, sanding belts, and grinding wheels.

Also excluded are “wearing parts”, such as carbon

brushes, lamellas of air tools, rubber collars and

seals, sanding discs and pads, and batteries.

Festool portable power tools requiring replacement

or repair are to be returned with the receipt of

purchase to Festool (call 800-554-8741 for address details).

IN NO EVENT SHALL FESTOOL BE LIABLE

FOR ANY CONSEQUENTIAL OR INCIDENTAL

DAMAGES FOR BREACH OF THIS OR ANY

OTHER WARRANTY, EXPRESSED OR IMPLIED

WHATSOEVER. ALL WARRANTIES IMPLIED

BY STATE LAW, INCLUDING THE IMPLIED

WARRANTIES OF MERCHANTABILITY AND

FITNESS FOR A PARTICULAR PURPOSE, ARE

HEREBY LIMITED TO THE DURATION OF

THREE YEARS.

Some states in the U.S. and some Canadian provinces do not allow the limitations on how long an

implied warranty lasts, so the above limitation may

not apply to you. With the exception of any warranties implied by state or province law as hereby

limited, the foregoing express limited warranty

is exclusive and in lieu of all other warranties,

guarantees, agreements and similar obligations

of Festool.

This warranty gives you specifi c legal rights and

you may also have other rights which vary from

state to state in the U.S. and province to province

in Canada.

7

Page 8

RÈGLES DE SÉCURITÉ GÉNÉRALES

Assurez-vous de lire et de

bien com prendre toutes les instructions. Le

non-respect, même partiel, des instructions cidessous peut entraîner un risque de choc électrique, d’incendie et/ou de blessures graves.

CONSERVEZ CES INSTRUCTIONS

1) Sécurité de aire de travail

a) Maintenez l’endroit de travail propre et

bien éclairé. Un lieu de travail en désordre ou

mal éclairé augmente le risque d’accidents.

b) N’utilisez pas l’appareil dans un environnement présentant des risques d’explosion et

où se trouvent des liquides, des gaz ou poussières infl ammables. Les outils électroportatifs

génèrent des étincelles risquant d’enfl ammer les

poussières ou les vapeurs.

c) Tenez les enfants et autres personnes

éloignés durant l’utilisation de l’outil électroportatif. En cas d’inattention vous risquez de

perdre le contrôle sur l’appareil.

2) Sécurité électrique

a) La fi che de secteur de l’outil électroportatif doit être appropriée à la prise de courant.

Ne modifi ez en aucun cas la fi che. N’utilisez

pas de fi ches d’adaptateur avec des appareils

avec mise à la terre. Les fi ches non modifi ées

et les prises de courant appropriées réduisent le

risque de choc électrique.

b) Evitez le contact physique avec des surfaces mises à la terre tels que tuyaux, radiateurs, fours et réfrigérateurs. Il y a un risque

élevé de choc électrique au cas où votre corps

serait relié à la terre.

c) N’exposez pas l’outil électroportatif à la

pluie ou à l’humidité. La pénétration d’eau dans

un outil électroportatif augmente le risque d’un

choc électrique.

d) N’utilisez pas le câble à d’autres fi ns que

celles prévues, n’utilisez pas le câble pour

porter l’appareil ou pour l’accrocher ou encore pour le débrancher de la prise de courant. Maintenez le câble éloigné des sources

de chaleur, des parties grasses, des bords

tranchants ou des parties de l’appareil en

rotation. Un câble endommagé ou torsadé aug-

mente le risque d’un choc électrique.

e) Au cas où vous utiliseriez l’outil électro-

portatif à l’extérieur, utilisez une rallonge

autorisée homologuée pour les applications

extérieures. L’utilisation d’une rallonge électri-

que homologuée pour les applications extérieures

réduit le risque d’un choc électrique.

f) Ne tenez l‘outil qu‘à l‘aide des poignées

isolées, lorsque vous êtes susceptibles de

toucher des lignes électriques cachées ou

votre propre câble électrique, lorsque vous

travaillez avec des outils de tronçonnage. Si

des outils de tronçonnage touchent des lignes électriques, des pièces métalliques de l‘outil peuvent

être mises sous tension et asséner une décharge

électrique à l‘utilisateur.

3) Sécurité des personnes

a) Restez vigilant, surveillez ce que vous

faites. Faites preuve de bon en utilisant

l’outil électroportatif. N’utilisez pas l’appareil lorsque vous êtes fatigué ou après avoir

consommé de l’alcool, des drogues ou avoir

pris des médicaments. Un moment d’inattention

lors de l’utilisation de l’appareil peut entraîner de

graves blessures sur les personnes.

b) Portez des équipements de protection.

Portez toujours des lunettes de protection.

Le fait de porter des équipements de protection

personnels tels que masque anti-poussières,

chaussures de sécurité antidérapantes, casque

de protection ou protection acoustique suivant le

travail à effectuer, réduit le risque de blessures.

c) Evitez une mise en service par mégarde.

Assurez-vous que l’interrupteur est effectivement en position d’arrêt avant de retirer

la fi che de la prise de courant. Le fait de porter

l’appareil avec le doigt sur l’interrupteur ou de

brancher l’appareil sur la source de courant lorsque

l’interrupteur est en position de fonctionnement,

peut entraîner des accidents.

d) Enlevez tout outil de réglage ou toute clé

avant de mettre l’appareil en fonctionnement. Une clé ou un outil se trouvant sur une

partie en rotation peut causer des blessures.

e) Ne surestimez pas vos capacités. Veillez

à garder toujours une position stable et

équilibrée. Ceci vous permet de mieux contrôler

l’appareil dans des situations inattendues.

f) Portez des vêtements appropriés. Ne portez pas de vêtements amples ni de bijoux.

Maintenez cheveux, vêtements et gants

éloignés des parties de l’appareil en rotation. Des vêtements amples, des bijoux ou des

cheveux longs peuvent être happés par des pièces

en mouvement.

g) Si des dispositifs servant à aspirer ou à

recueillir les poussières doivent être utilisés,

vérifi ez que ceux-ci soient effectivement raccordés et qu’ils sont correctement utilisés.

L’utilisation de tels dispositifs réduit les dangers

dus aux poussières.

4) Utilisation et entretien des outils

a) Ne surchargez pas l’appareil. Utilisez

l’outil électroportatif approprié au travail à

effectuer. Avec l’outil électroportatif approprié,

vous travaillerez mieux et avec plus de sécurité à

la vitesse pour laquelle il est prévu.

b) N’utilisez pas un outil électroportatif dont

l’interrupteur est défectueux. Un outil élec-

troportatif qui ne peut plus être mis en ou hors

fonctionnement est dangereux et doit être réparé.

c) Retirer la fi che de la prise de courant avant

d’effectuer des réglages sur l’appareil, de

changer les accessoires, ou de ranger l’appareil. Cette mesure de précaution empêche une

mise en fonctionnement par mégarde.

8

Page 9

d) Gardez les outils électroportatifs non utilisés hors de portée des enfants. Ne permettez

pas l’utilisation de l’appareil à des personnes

qui ne se sont pas familiarisées avec celui-ci

ou qui n’ont pas lu ces instructions. Les outils

électroportatifs sont dangereux lorsqu’ils sont

utilisés par des personnes non initiées.

e) Prenez soin des outils électroportatifs.

Vérifi ez que les parties en mouvement fonctionnent correctement et qu’elles ne soient

pas coincées, et contrôlez si des parties sont

cassées ou endommagées de telle sorte que

le bon fonctionnement de l’appareil s’en

trouve entravé. Faites réparer les parties

endommagées avant d’utiliser l’appareil. De

nombreux accidents sont dus à des outils électroportatifs mal entretenus.

f) Maintenez les outils de coupe aiguisés et

propres. Des outils soigneusement entretenus

avec des bords tranchants bien aiguisés se coincent moins souvent et peuvent être guidés plus

facilement.

g) Utilisez les outils électroportatifs, les accessoires, les outils à monter etc. conformément à ces instructions et aux prescriptions

en vigueur pour ce type d’appareil. Tenez

compte également des conditions de travail

et du travail à effectuer. L’utilisation des outils

électroportatifs à d’autres fi ns que celles prévues

peut entraîner des situations dangereuses.

5) Utilisation et emploi soigneux

des appareils sans fi l

a) Vérifi ez que l‘appareil est effectivement en

position d‘arrêt avant de monter l‘accumulateur. Le fait de monter un accumulateur dans un

outil électroportatif en position de fonctionnement

peut causer des accidents.

b) Ne chargez les accumulateurs que dans

des chargeurs recommandés par le fabricant.

Un chargeur approprié à un type spécifi que d‘accumulateur peut engendrer un risque d‘incendie

lorsqu‘il est utilisé avec d‘autres accumulateurs.

c) Dans les outils électroportatifs, n‘utilisez

que les accumulateurs spécialement prévus

pour celui-ci. L‘utilisation de tout autre accumu-

lateur peut entraîner des blessures et des risques

d‘incendie.

d) Tenez l‘accumulateur non-utilisé à l‘écart

de toutes sortes d‘objets métalliques tels

qu‘agrafes, pièces de monnaie, clés, clous,

vis ou autres, étant donné qu‘un pontage

peut provoquer un court-circuit. Un court-cir-

cuit entre les contacts d‘accu peut provoquer des

brûlures ou un incendie.

e) En cas d‘utilisation abusive, du liquide

peut sortir de l‘accumulateur. Evitez tout

contact avec ce liquide. En cas de contact

par mégarde, rincez soigneusement avec de

l‘eau. Au cas où le liquide rentrerait dans les

yeux, consultez en plus un médecin. Le liquide

qui sort de l‘accumulateur peut entraîner des irritations de la peau ou causer des brûlures.

6) Entretien et réparation

a) Ne faites réparer votre outil électroportatif que par un personnel qualifi é et seulement

avec des pièces de rechange d’origine. Ceci

permet d’assurer la sécurité de l’appareil.

Pour réduire le risque de

dommages, l'utilisateur doit lire et comprendre le manuel d'instruction.

Certaines poussières créées par le ponçage mécanique, le sciage, le meulage,

le perçage et autres activités reliées à la construction contiennent des substances chimiques connues (dans l’État de la Californie) comme pouvant causer le cancer, des anomalies congénitales ou

représenter d’autres dangers pour la reproduction. Voici quelques exemples de telles substances:

• plomb provenant de peintures à base de plomb,

• silice cristallisée utilisée dans les briques, le ciment et autres matériaux de maçonnerie, et

• arsenic et chrome du bois d’œuvre traité avec un produit chimique.

Le risque d’exposition à de tels produits varie selon la fréquence à laquelle vous faites

ce genre de travail. Pour réduire les risques d’exposition à ces substances chimiques:

travaillez dans un endroit adéquatement ventilé et utilisez un équipement de sécurité

approuvé, tel que masques antipoussières spécialement conçus pour fi ltrer les particules microscopiques.

Caractéristiques techniques

Perceuse-visseuse C 12

Tension du moteur 12 V

Vitesse à vide: 1 ère vitesse / 2 ème vitess 0 – 450 tr/min / 0 – 1500 tr/min

Couple max.: vissage faciles / vissage diffi ciles 18 Nm / 30 Nm

Réglage de couple: 1 ère vitesse / 2 ème vites 2 – 7 Nm / 0.5 – 2.5 Nm

Capacité mandrin 1.5 – 13 mm

Maxi capacité de perçage, métal / bois 14 mm / 25 mm

Fixation de la broche 1/4 "

Poids sans accumulateur 0.96 kg (2.1 lbs)

9

Page 10

Chargeur LC 45

Tension / fréquence secteur (entrée) 120 V ~ / 60 Hz

Tension de charge (sortie) 7.2 - 18 V (DC)

Courant de charge: • Charge rapide 3 A max.

• Charge de maintien à impulsions 0.06 A env.

Durée de charge pour: • NiCd 1.3 Ah 30 min env.

• NiCd 2.4 Ah 50 min env.

• NiMH 3.0 Ah 70 min env.

Accumulateur BPS 12 C NiCd BPS 12 S NiCd BPS 12 S NiMH

Référence 493 348 492 268 491 821

Tension 12 V 12 V 12 V

Capacité 1.3 Ah 2.4 Ah 3.0 Ah

Plage de temp. de charge 5 - 45 °C 5 - 45 °C 5 - 45 °C

Contrôle d’état de charge via résistance NTC

Poids 0.56 kg (1.2 lbs) 0.73 kg (1.6 lbs) 0.75 kg (1.7 lbs)

Symbole

V Volt

A Ampère

Hz Hertz

W Watt

~ Tension alternative

n

Vitesse de rotation à vide

0

Classe II conception

tr/min tours par minute

Utilisation prévue

La perceuse-visseuse sans fi l est adaptée au perçage du métal, du bois, des plastiques et matériaux similaires, ainsi qu’au vissage (vis jusqu’à

un diamètre de 6 mm dans le bois).

Le chargeur LC 45 convient au chargement de la

batterie utilisée.

Seul l’utilisateur est tenu

responsable des dommages qui résulteraient d’une

utilisation non conforme aux prescriptions.

Fixation au mur LC 45

Le chargeur LC 45 dispose sur son dos de deux

trous oblongs par l’intermédiaire desquels il peut

être fi xé au mur par deux vis (par ex. vis à tête

conique ou ronde avec un diamètre de la partie

lisse de la tige de 5 mm). Vissez les deux vis en

respectant un intervalle de 96 mm au mur, de

manière à ce qu’il reste encore un espace de 4

mm entre la tête de vis et le mur.

• Bouton poussé de droite vers la gauche = marche à droite.

• Bouton poussé de gauche vers la droite = marche à gauche.

• Bouton en position centrale = verrouillage de

mise en marche.

1.3 1.4

1.2

1.5

1.1

1.6

1.7

Réglages de la machine

Remplacer la batterie

- Retrait de la batterie : appuyez sur le deux

touches (1.6), et enlevez la batterie en la tirant

vers l’avant.

- Installation de la batterie : enfoncez la batterie

dans le logement par le dessous de la poignée

jusqu’à ce qu’elle soit bien enclenchée (1.7).

Commutation du sens de rotation

Le bouton de commutation (1.2) sert à déterminer

le sens de rotation.

Commutation de l’engrenage

Procéder à la commutation uni-

quement à l’arrêt ou en fi n de roulement!

Le curseur de commutation (1.3) permet de com-

muter l’engrenage.

• 1ère vitesse: Curseur de commutation vers

l’avant - le chiffre 1 est visible.

• 2ème vitesse: Curseur de commutation vers

l’arrière - le chiffre 2 est visible.

10

Page 11

Réglage du couple de rotation

Il est possible de faire varier le couple de rotation

en tournant la bague de réglage (1.4). La fl èche

apposée (1.5) indiquera l’état réglé.

Perçage

Couple de rotation maximal - la fl èche est pointée

sur le symbole de perçage

Vissage

Couple de rotation en fonction du réglage:

• Position sur 1 = couple de rotation réduit

• Position sur 20 = couple de rotation élevé

Utilisation

Mise en marche en appuyant sur la touche de commutation (1.1). La vitesse de rotation peut être

progressive-ment réglée, en fonction du mode de

pression sur la touche de commutation.

Mise à l’arrêt en relâchant la touche de commutation (1.1). Une fois que la touche de commutation

est relâchée, la broche de travail (mandrin) est

freinée, ce qui empêche ainsi une poursuite de

rotation par inertie de l’outil.

Signal d’alerte

Dans les situations de fonctionnement suivantes,

la machine émet un signal d’alerte et s’arrête :

Bip sonore intermittent

- Batterie déchargée

3 bips sonores intermittents

- Charge (couple) trop importante

- Machine trop chaude.

Porte-outil, groupes d’appui

Montage :

- Placez le mandrin de perceuse sur l'axe (2.5)

puis tournez-le jusqu'à ce que le six pans (2.4)

du mandrin de perceuse s'enclenche dans le

logement de l'axe.

- Tirez la bague de déverrouillage (2.3) vers

l'avant, enfoncez le mandrin de perceuse jusqu'à la butée sur l'axe puis relâchez la bague

de déverrouillage.

Démontage :

- Tirez la bague de déverrouillage vers l'avant

puis enlevez le mandrin de perceuse.

Changement d'outil :

- Tournez la douille de serrage (2.2) dans le sens

contraire des aiguilles d'une montre pour ouvrir

les mâchoires de serrage (2.1)

(Remarque : A machine inactivée, l'axe est

automa-tiquement verrouillé).

- Placez l'outil dans le mandrin de perceuse.

- Serrez l'outil à fond en tournant la douille de

serrage dans le sens des aiguilles d'une montre.

Ce faisant, veillez toujours à ce que l'outil soit

serré au centre du mandrin.

Appui angulaire DD-AS

L'appui angulaire permet de travailler (percer, visser) à la verticale par rapport à l'axe longi-tudinal

de la machine.

Montage :

- Placez l'appui angulaire sur l'axe et tournez-le

jusqu'à ce qu'il s'enclenche dans la position

souhaitée (Remarque : L'appui angulaire peut

s'enclencher dans 16 positions angulaires différentes).

- Verrouillez l'appui angulaire en tournant fermement la bague de fi xation (2.7) dans le sens

des aiguilles d'une montre.

Démontage :

- Tournez la bague de fi xation dans le sens contraire des aiguilles d'une montre jusqu'à la

butée puis enlevez l'appui angulaire.

Montage / démontage du mandrin de perceuse

sur l'appui angulaire :

Le mandrin de perceuse doit être fi xé de la même

manière sur l'arbre (2.6) de l'appui angu-laire que

sur l'axe de la machine.

A chaque remplacement du

porte-outil, du groupe d’appui et de l’outil, assurez-vous que la machine est convenablement

inactivée et que l’accumulateur est enlevé.

Mandrin de perceuse BF-FX

Le mandrin de perceuse sert à serrer les forets et

les embouts.

Appui excentrique DD-ES

L'appui excentrique sert à la réception d'embouts.

Il permet de visser à proximité du bord.

Montage / démontage de l'appui excentrique :

Le montage / démontage de l'appui excentrique

s'opère de la même manière que pour l'appui angulaire (cf. DD-AS).

Changement d'outil

- Tirez la bague de déverrouillage (2.8) vers

l'arrière puis enlevez l'outil ou resp. mettez un

outil en place.

11

Page 12

Porte-outil CENTROTEC-WH-CE

Le porte-outil CENTROTEC permet un changement rapide d’outils avec arbre CENTROTEC.

Risque de blessure ! Mani pulez

très prudemment l’outil aux arêtes tranchan tes

lorsque vous procédez à un échange d’outil, portez

éventuelle-ment des gants de protection.

Ne serrez pas les outils CENTROTEC au niveau du manche dans un mandrin

de serrage traditionnel pour ne pas endommager

le manche.

Montage

- Tirez la bague de déverrouillage (2.11) vers

l’avant, enfoncez le porte-outil jusqu’en butée

sur l’axe (2.5) puis relâchez la bague de déverrouillage.

Démontage

- Tirez la bague de déverrouillage vers l’avant et

enlevez le porte-outil.

Changement d’outillage

- Pour placer ou enlever un outil avec arbre CEN-

TROTEC, retirez sur la bague de déverrouillage

verte (2.10). Pour mettre un outil en place,

tournez jusqu’à ce que son arbre hexagonal

(2.9) s’engage dans le logement hexagonal de

l’axe et poussez l’outil à fond dans le porteoutil.

La DEL (3.2) indique à chaque fois l’état de

service du chargeur.

DEL jaune - éclairage continu:

le chargeur est prêt à fonctionner.

DEL verte - éclairage clignotant:

L’accumulateur est en train d’être chargé.

DEL verte - éclairage continu:

L’accumulateur est chargé; la charge de main-

tien est active.

DEL rouge - éclairage clignotant:

indication d’erreur générale, par exemple pas

de mise en contact complète, court-circuit,

défectuo-sité de l’accumulateur

DEL rouge - éclairage continu:

température de l’accumulateur au-delà des

valeurs limites admissibles.

Nous vous recommandons de

respecter les instructions décrites dans le chapitre

intitulé „Entretien - Maintenance“.

Bit-Depot

Porte-outil sur l'axe

Afi n que la machine devienne plus légère et plus

courte, les embouts peuvent être mis en place

directement dans le logement six pans de l'axe

(2.5).

Charger l’accumulateur

Pour le chargement, vous devez pousser la batterie dans le logement (3.1) du chargeur jusqu’à

la butée. A l’inverse, il est possible de retirer la

batterie chargée du chargeur.

Le type d’accumulateur utilisé (NiCd ou NiMH)

est identifi é automatiquement. La procédure de

charge est contrôlée par microprocesseur.

Si vous utilisez un pack d’accumulateurs NiMH

chaud (>37°C), il sera seulement chargé avec un

courant de charge réduit. Dans ce cas, le temps

de charge sera prolongé.

Les porte-embouts (4.1) à support magnétique

peuvent accueillir plusieurs embouts ou prolongateurs.

Entretien - Maintenance

Il est indispensable d’obser-

ver les consignes suivantes, sinon, la machine,

le chargeur ou l’accumulateur risque d’être

endommagé(e).

• Les réparations doivent être uniquement réa-

lisées par un spécialiste. Dans le chargeur LC

45, la tension au condensateur à l’intérieur de

l’appareil reste élevée même après le débranchement du réseau.

• Veiller à ce que les ouvertures d’aération sur

l’outil électrique et sur le chargeur soient toujours propres afi n que la circulation de l’air de

refroidissement soit assurée.

• Sur le chargeur, aucune pièce métallique (co-

peaux métalliques) ne doit pénétrer dans les

compartiments de réception des accumulateurs

et par les fentes d’aération (risque de courtcircuit).

• N’utiliser que des accumulateurs d’origine Fes-

tool et ne pas utiliser non plus d’accumulateurs

usagés ou remis en état. En effet, seul l’utilisateur sera tenu responsable en cas d’apparition

12

Page 13

de dommages résultant d’une violation de cette

prescription.

• Veiller à ce que les contacts de raccordement

sur l’outil électrique, sur le chargeur et sur

l’accu-mulateur soient toujours propres.

• En laissant l’accumulateur dans le chargeur prêt

à fonctionner, l’accumulateur est conservé en

état chargé grâce à un chargement de maintien

permanent.

• Ne pas laisser les accumulateurs vides enfi chés

pendant plus d’un mois env. dans le chargeur

lorsque le chargeur est coupé du secteur (risque

de décharge profonde).

• Un accumulateur neuf ou n’ayant pas été utilisé

pendant une longue période n’atteint sa pleine

capacité qu’au bout de 5 cycles de charge et

de décharge environ.

• Il faudrait, dans la mesure du possible, que les

accumulateurs soient entièrement déchargés

avant d’être rechargés. En effet, un démarrage

réitéré de l’opération de charge d’accumulateurs chargés diminue leur durée de vie.

• Une durée de fonctionnement considérable ment

plus réduite à la suite de chaque recharge indique que l’accumulateur est usé et qu’il doit par

conséquent être remplacé par un neuf.

• Les batteries NiCd, qui ne sont pas utilisées

pendant une période plus longue, doivent être

rangées dans leur état déchargé.

Consignes particulières concernant les accumulateurs NiMH :

• En présence de températures ambiantes inférieures à 0° C ou supérieures à 45° C, la

puissance des accumulateurs NiMH diminue

nettement.

• Ne pas surcharger la machine (ne pas solliciter

la machine à un tel point qu’elle s’immobilise).

• Chargez les batteries NiMH environ tous les

4 mois, même en cas de non-utilisation, afi n

d’exploiter au mieux toute leur capacité.

• Après chaque 10ème cycle de charge, les packs

d’accumulateurs NiMH doivent rester 60 min

supplémentaires dans le chargeur après la

charge rapide, afi n de compenser d’éventuelles

différences de capacité entre les éléments.

• Rangez de préférence les batteries NiMH, suite

à leur déchargement, à des températures ambiantes comprises entre 0° C et 25° C.

Recyclage des accumulateurs

Ne pas jeter les accumulateurs usagées dans

les ordures ménagères. Les accumulateurs

usagés ou défectueux doivent être rendus aux

revendeurs, au service après-vente Festool ou aux

installations d’élimination publiques prescrites. Les

accumulateurs seront ainsi soumis à un recyclage

approprié.

Accessoires, outils

Pour des raisons de sécurité,

il faut utiliser exclusivement des accessoires et

outils d’origine Festool!

Les références des accessoires et outils fi gurent

dans le catalogue Festool ou sur Internet sous

www.festool-usa.com.

Garantie

Conditions de la garantie (1+2 ans)

Vous avez droit à une prolongation de garantie

gratuite (1 an + 2 ans = 3 ans) sur votre outil

électrique Festool. Festool assumera tous les

coûts d’expédition pendant la première année de

la garantie alors que les deuxième et troisième

années, les coûts devront être assumés par le

client. Festool paiera les frais de retour de l’outil

au client par service de livraison terrestre UPS.

La garantie est valable pour une période de 3 ans

à compter de la date d’achat indiquée sur votre

reçu ou votre facture.

Garantie limitée de Festool

Cette garantie est valable à condition que l’outil

soit utilisé conformément aux instructions de

Festool. Festool garantit, à l’acheteur initial seulement, que l’outil indiqué sera exempt de tout

défaut de matériau et de fabrication pendant un

an à compter de la date d’achat. Festool ne donne

aucune garantie supplémentaire, implicite ou explicite, sur les instruments portables électriques

Festool. Aucun agent, représentant commercial,

distributeur, vendeur ou employé de Festool n’est

autorisé à prolonger ou à modifi er les obligations

ou restrictions de la présente garantie. Les obligations de Festool sont, à son entière discrétion,

limitées à la réparation ou à l’échange des outils

portables électriques Festool trouvés défectueux

dans le présent emballage, tels que fournis avec

le présent Guide d’utilisation.

Cette garantie exclut l’usure normale, les dommages causés par un usage impropre, les abus

ou la négligence, ou tout dommage autre que

ceux attribuables à des défauts de matériau et

de fabrication. Cette garantie ne s’applique pas

aux accessoires tels que lames de scie circulaire,

mèches de perceuse et vilebrequin, lames de scie

sauteuse, bandes abrasives et meules. Sont également exclues les pièces d’usure, telles que balais

de charbon, lamelles pour outils à air comprimé,

joints et manchons de caoutchouc, disques et

patins ponceurs, ainsi que les piles.

Les outils électriques portables Festool à remplacer

ou à réparer doivent être retournés avec le reçu

d’achat à Festool (appelez au 800-554-8741 pour

connaître l’adresse d’expédition).

FESTOOL N’EST EN AUCUN CAS RESPONSABLE

DES DOMMAGES DIRECTS OU INDIRECTS,

IMPLICITES OU EXPLICITES, DÉCOULANT

DE LA RUPTURE DE CETTE GARANTIE OU

DE TOUTE AUTRE GARANTIE. TOUTES

13

Page 14

LES GARANTIES IMPLICITES, Y COMPRIS

LES GARANTIES IMPLICITES DE QUALITÉ

MARCHANDE ET D’ADÉQUATION À UN

USAGE PARTICULIER, SONT LIMITÉES À UNE

PÉRIODE DE TROIS ANS.

Certains états américains et certaines provinces

canadiennes ne permettent pas la limitation des

garanties implicites; il se pourrait donc que les

limites indiquées ci-dessus ne s’appliquent pas

dans votre cas. À l’exception de certaines garanties

implicites des provinces ou des états indiquées

ici, la présente garantie est exclusive et remplace

toute autre garantie, convention et obligation similaire de Festool.

Cette garantie vous confère des droits légaux

spécifi ques, et vous pouvez aussi avoir d’autres

droits pouvant varier d’un état à l’autre, ou d’une

province à l’autre au Canada.

NORMAS GENERALES DE SEGURI-

DAD

Lea y entienda todas las ins-

trucciones. El incumplimiento con las instruccio-

nes aquí referidas puede resultar en una descarga

eléctrica, fuego y/o lesiones personales serias.

CONSERVE ESTAS INSTRUCCIONES

1) Seguridad del espacio de trabajo

a) Mantenga limpio y bien iluminado su puesto de trabajo. El desorden y una iluminación

defi ciente en las áreas de trabajo pueden provocar

accidentes.

b) No utilice la herramienta eléctrica en un

entorno con peligro de explosión, en el que

se encuentren combustibles líquidos, gases

o material en polvo. Las herramientas eléctricas

producen chispas que pueden llegar a infl amar los

materiales en polvo o vapores.

c) Mantenga alejados a los niños y otras personas de su puesto de trabajo al emplear la

herramienta eléctrica. Una distracción le puede

hacer perder el control sobre el aparato.

2) Seguridad eléctrica

a) El enchufe del aparato debe corresponder a la toma de corriente utilizada. No es

admisible modifi car el enchufe en forma alguna. No emplear adaptadores en aparatos

dotados con una toma de tierra. Los enchufes

sin modifi car adecuados a las respectivas tomas

de corriente reducen el riesgo de una descarga

eléctrica.

b) Evite que su cuerpo toque partes conectadas a tierra como tuberías, radiadores,

cocinas y refrigeradores. El riesgo a quedar

expuesto a una sacudida eléctrica es mayor si su

cuerpo tiene contacto con tierra.

c) No exponga las herramientas eléctricas a

la lluvia y evite que penetren líquidos en su

interior. Existe el peligro de recibir una descarga

eléctrica si penetran ciertos líquidos en la herramienta eléctrica.

d) No utilice el cable de red para transportar

o colgar el aparato, ni tire de él para sacar el

enchufe de la toma de corriente. Mantenga

el cable de red alejado del calor, aceite, esquinas cortantes o piezas móviles. Los cables

de red dañados o enredados pueden provocar una

descarga eléctrica.

e) Al trabajar con la herramienta eléctrica

en la intemperie utilice solamente cables de

prolongación homologados para su uso en

exteriores. La utilización de un cable de prolon-

gación adecuado para su uso en exteriores reduce

el riesgo de una descarga eléctrica.

f) Sujete la máquina únicamente por las empuñaduras aisladas si durante los trabajos las

herramientas para separar pueden entrar en

contacto con conducciones eléctricas ocultas

o incluso con el cable de la corriente. Cuando

las herramientas para separar entran en contacto

con conducciones eléctricas bajo tensión, las partes metálicas de la máquina pueden adquirir esta

tensión y transmitir, de ese modo, una descarga

eléctrica al usuario.

3) Seguridad personal

a) Esté atento a lo que hace y emplee la herramienta eléctrica con prudencia. No utilice

la herramienta eléctrica si estuviese cansa-

14

Page 15

do, ni tampoco después de haber consumido

alcohol, drogas o medicamentos. El no estar

atento durante el uso de una herramienta eléctrica

puede provocarle serias lesiones.

b) Utilice un equipo de protección y en todo

caso unas gafas de protección. El riesgo a le-

sionarse se reduce considerablemente si, dependiendo del tipo y la aplicación de la herramienta

eléctrica empleada, se utiliza un equipo de protección adecuado como una mascarilla antipolvo,

zapatos de seguridad con suela antideslizante,

casco, o protectores auditivos.

c) Evite una puesta en marcha fortuita del

aparato. Cerciorarse de que el aparato esté

desconectado antes conectarlo a la toma de

corriente. Si transporta el aparato sujetándolo

por el interruptor de conexión/desconexión, o si

introduce el enchufe en la toma de corriente con

el aparato conectado, ello puede dar lugar a un

accidente.

d) Retire las herramientas de ajuste o llaves

fi jas antes de conectar la herramienta eléctrica. Una herramienta o llave colocada en una

pieza rotante puede producir lesiones al ponerse

a funcionar.

e) Sea precavido. Trabaje sobre una base

fi rme y mantenga el equilibrio en todo momento. Ello le permitirá controlar mejor la he-

rramienta eléctrica en caso de presentarse una

situación inesperada.

f) Lleve puesta una vestimenta de trabajo

adecuada. No utilice vestimenta amplia ni joyas. Mantenga su pelo, vestimenta y guantes

alejados de las piezas móviles. La vestimenta

suelta, las joyas y el pelo largo se pueden enganchar con las piezas en movimiento.

g) Siempre que sea posible utilizar unos

equipos de aspiración o captación de polvo,

asegúrese que éstos estén montados y que

sean utilizados correctamente. El empleo de

estos equipos reduce los riesgos derivados del

polvo.

4) Uso y cuidado de la herramienta

a) No sobrecargue el aparato. Use la herramienta prevista para el trabajo a realizar. Con

la herramienta adecuada podrá trabajar mejor y

más seguro dentro del margen de potencia indicado.

b) No utilice herramientas con un interruptor

defectuoso. Las herramientas que no se puedan

conectar o desconectar son peligrosas y deben

hacerse reparar.

c) Saque el enchufe de la red antes de realizar un ajuste en el aparato, cambiar de accesorio o al guardar el aparato. Esta medida

preventiva reduce el riesgo a conectar accidentalmente el aparato.

d) Guarde las herramientas fuera del alcance

de los niños y de las personas que no estén

familiarizadas con su uso. Las herramientas uti-

lizadas por personas inexpertas son peligrosas.

e) Cuide sus aparatos con esmero. Controle

si funcionan correctamente, sin atascarse,

las partes móviles del aparato, y si existen

partes rotas o deterioradas que pudieran

afectar al funcionamiento de la herramienta. Si la herramienta eléctrica estuviese

defectuosa haga repararla antes de volver a

utilizarla. Muchos de los accidentes se deben a

aparatos con un mantenimiento defi ciente.

f) Mantenga los útiles limpios y afi lados. Los

útiles mantenidos correctamente se dejan guiar y

controlar mejor.

g) Utilice herramientas eléctricas, accesorios,

útiles, etc. de acuerdo a estas instrucciones y

en la manera indicada específi camente para

este aparato. Considere en ello las condiciones de trabajo y la tarea a realizar. El uso de

herramientas eléctricas para trabajos diferentes de

aquellos para los que han sido concebidas puede

resultar peligroso.

5) Trato y uso cuidadoso de aparatos accionados por acumulador

a) Antes de montar el acumulador cerciorarse

de que el aparato esté desconectado. La inser-

ción del acumulador en una herramienta eléctrica

conectada puede causar un accidente.

b) Solamente cargar los acumuladores con

los cargadores recomendados por el fabricante. Existe riesgo de incendio al intentar cargar

acumuladores de un tipo diferente al previsto para

el cargador.

c) Solamente emplee los acumuladores previstos para la herramienta eléctrica. El uso de

otro tipo de acumuladores puede provocar daños

e incluso un incendio.

d) Si no utiliza el acumulador, guárdelo separado de clips, monedas, llaves, clavos, tornillos o demás objetos metálicos que pudieran

puentear sus contactos. El cortocircuito de los

contactos del acumulador puede causar quemaduras o un incendio.

e) La utilización inadecuada del acumulador puede provocar fugas de líquido. Evite

el contacto con él. En caso de un contacto

accidental enjuagar el área afectada con

abundante agua. En caso de un contacto con

los ojos recurra además inmediatamente a un

médico. El líquido del acumulador puede irritar la

piel o producir quemaduras.

6) Mantenimiento

a) Únicamente haga reparar su herramienta

eléctrica por un profesional, empleando exclusivamente piezas de repuesto originales.

Solamente así se mantiene la seguridad de la

herramienta eléctrica.

Para reducir el riesgo de le-

sión, el usuario debe leer y entender el manual de instrucción.

15

Page 16

Algunos polvos creados por lijadoras mecánicas, aserraderos, trituradores, perforadoras y otras actividades de construcción contienen sustancias químicas que se sabe (en el Estado

de California) causan cáncer, defectos de nacimiento u otros daños al sistema reproductivo. Algunos

ejemplos de estas sustancias químicas son:

• Plomo de las pinturas con base de plomo

• Sílice cristalino de los ladrillos y cemento y otros productos de mampostería, y

• Arsénico y cromo de madera tratada con sustancias químicas

El riesgo de exposición a estas sustancias varía, dependiendo de cuantas veces se hace

este tipo de trabajo. Para reducir el contacto con estas sustancias químicas: trabaje

en un área con buena ventilación y trabaje con equipo de seguridad aprobado, como

mascarillas para el polvo diseñadas espe cí fi camente para fi ltrar partículas microscópicas.

Datos técnicos

Taladro atornillador C 12

Potencia del motor 12 V

Velocidad en vacío: 1ª marcha / 2ª marcha 0 - 450 rpm / 0 - 1500 rpm

Par de apriete máximo: en lugares blandos / duros 18 Nm / 30 Nm

Par de apriete regulable: 1ª marcha / 2ª marcha 2 - 7 Nm / 0.5 - 2.5 Nm

Alcance del portabrocas 1.5 - 13 mm

Diámetro máx. perforación en metal / madera 14 mm / 25 mm

Alojamiento de herramientas en el eje 1/4“

Peso con acumulador 0.96 kg (2.1 lbs)

Cargador LC 45

Tensión / frecuencia de la red (entrada) 120 V ~ / 60 Hz

Tensión de carga (salida) 7.2 - 18 V (DC)

Corriente de carga:

• Carga rápida max. 3 A

• Carga de mantenimiento por impulsos aprox. 0.06 A

Tiempo para recargar para: • NiCd 1.3 Ah aprox. 30 min

• NiCd 2.4 Ah aprox. 50 min

• NiMH 3.0 Ah aprox. 70 min

Juego de acumuladores BPS 12 C NiCd BPS 12 S NiCd BPS 12 S NiMH

Nº de pedido 493 348 492 268 491 821

Voltaje 12 V 12 V 12 V

Capacidad 1.3 Ah 2.4 Ah 3.0 Ah

Margen de temp. de carga 5 - 45 °C 5 - 45 °C 5 - 45 °C

Control de estado de carga por resistencia NTC

Peso 0.56 kg (1.2 lbs) 0.73 kg (1.6 lbs) 0.75 kg (1.7 lbs)

Símbolos

V voltios

A amperios

Hz hertzios

W vatios

~ rensión alterna

n

revoluciones sin carga

0

Clase II Construcción

rpm revoluciones por minuto

Utilización adecuada

Los taladros atornilladores Akku son apropiados para taladrar en metal, madera, plásticos y

materiales similares, así como para atornillar y

apretar tornillos (hasta un diámetro de 6 mm en

madera)

El cargador LC 45 está destinado para cargar los

acumuladores especifi cados.

El usuario se responsabiliza de

los daños debidos a un uso inadecuado.

Sujeción a la pared LC 45

El cargador LC 45 tiene en su parte posterior dos

agujeros alargados para poder ser colgado a la

pared usando dos tornillos (por ej. tornillos de

cabeza plana o algo redondeada con 5 mm de

diámetro del vástago). Para ello, atornillar los dos

tornillos separados 96 mm a tal profundidad que

la cabeza de tornillo todavía sobresalga unos 4

mm de la pared.

16

Page 17

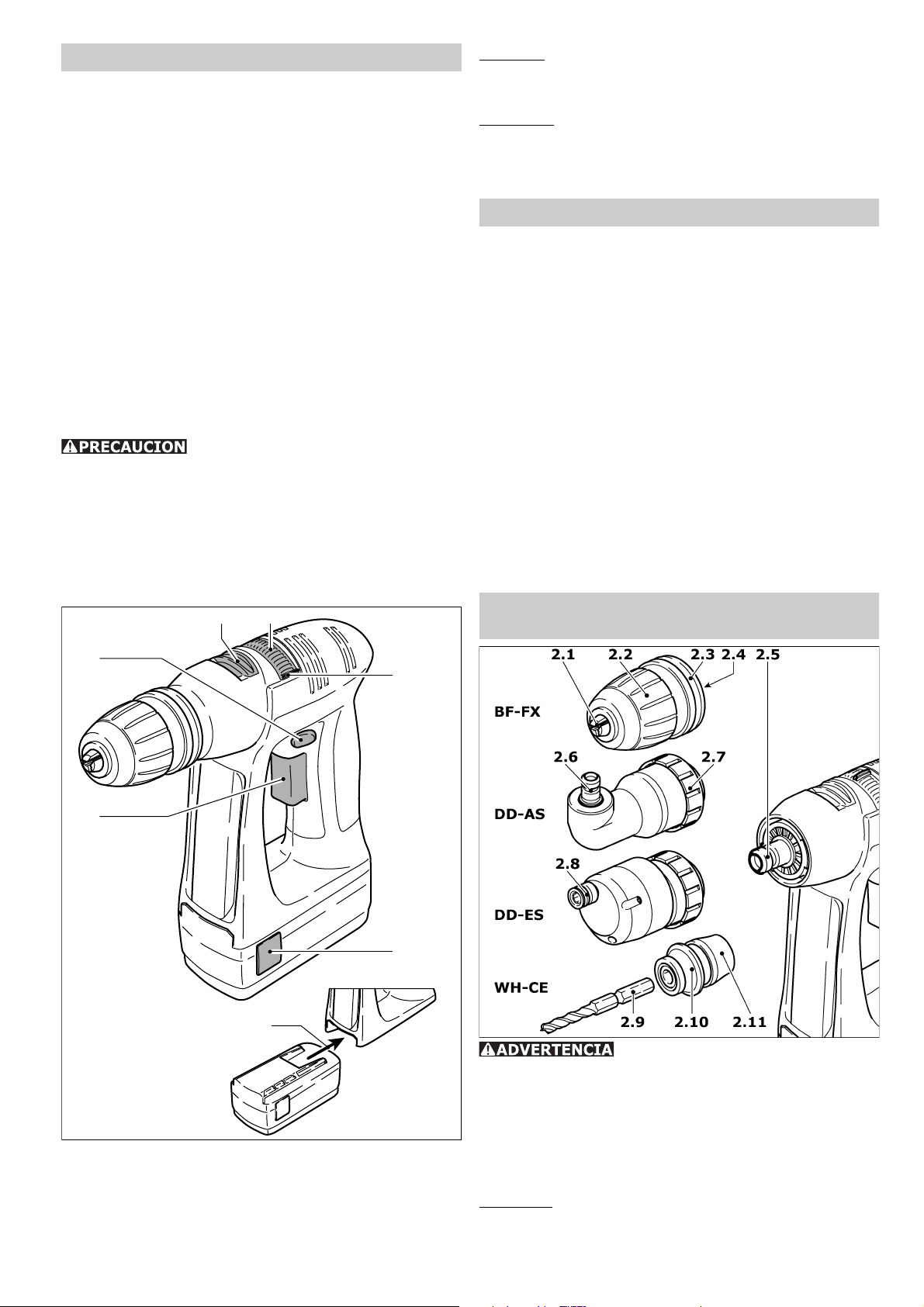

Ajustes en la máquina

Cambiar el acumulador

- Retirar el acumulador: pulsar las dos teclas

(1.6) y extraer el acumulador tirando hacia

delante.

- Colocar el acumulador: insertar el acumulador

hasta que se enclave en el soporte en la parte

inferior del mango (1.7).

Cambiar el sentido de giro

El botón (1.2) sirve para determinar el sentido

de giro.

• Botón apretado de derecha a izquierda = el

taladro atornillador gira hacia la derecha;

• Botón apretado de izquierda a derecha = el

taladro atornillador gira hacia la izquierda;

• Botón en posición media = bloqueo de conexión.

Conmutación del engranaje

¡Conectarlo sólo con la máquina

parada!

Con el interruptor desplazable (1.3) se conecta

el engranaje.

• 1ª marcha: Interruptor hacia adelante - se ve

la cifra 1.

• 2ª marcha: Interruptor hacia atrás - se ve la

cifra 2.

1.3 1.4

Tal adrar

La fl echa de marca mira hacia el símbolo de tala-

drar = par de apriete máximo.

Atornillar

Par de apriete según el ajuste:

• Posición en 1 = par de apriete bajo

• Posición en 20 = par de apriete alto

Funcionamiento

Ponerlo en funcionamiento con el pulsador (1.1).

Según la presión que se ejerza sobre el pulsador

varía la velocidad de giro del taladro atornillador.

Para desconectarlo basta con soltar el pulsador

(1.1). Después de soltar el pulsador, se frena el

eje (portabrocas) impidiendo que la máquina siga

girando por inercia.

Señal de advertencia

En los estados de funcionamiento indicados a

continuación la máquina emite una señal acústica

de advertencia y se apaga:

Pitidos a intervalos regulares

- Acumulador vacío

Triple pitido a intervalos regulares

- Carga (par de apriete) demasiado alta

- Máquina demasiado caliente.

Toma de herramienta, grupos adi-

cionales

1.2

1.1

1.5

1.6

1.7

Asegúrese en cada cambio de

toma de herramienta, grupo adicional y herramienta que la máquina esté apagada y el bloque

de acumulador quitado.

Regulación del par de apriete

Girando la rueda de ajuste (1.4) se puede regular

el par de apriete. La marca con la fl echa (1.5)

indica el estado ajustado en cada momento:

Portabrocas BF-FX

El portabrocas sirve para sujetar las brocas y las

puntas de destornillador.

Montaje:

- Coloque el portabrocas en el husillo portabro cas

(2.5) y gírelo hasta que la clavija hexagonal

17

Page 18

(2.4) del portabrocas se enclave en la toma

hexagonal interior del husillo portabrocas.

- Estire la anilla de desbloqueo (2.3) hacia adelante, apriete el portabrocas sobre el husillo

portabrocas hasta el tope y suelte la anilla de

desbloqueo.

Desmontaje:

- Estire la anilla de desbloqueo hacia adelante y

quite el portabrocas.

Cambiar la herramienta:

- Gire el manguito de sujeción (2.2) en contra

del sentido de las agujas del reloj para abrir las

mordazas de apriete (2.1)

(Nota: Cuando la máquina está parada, el hu-

sillo está bloqueado automáticamente).

- Introduzca la herramienta en el portabrocas.

- Apriete bien la sujeción de la herramienta girando el manguito de apriete en el sentido de

las agujas del reloj.

enga siempre en cuenta que la herramienta esté

sujetada de forma céntrica en el portabrocas.

Ángulo adicional DD-AS

El ángulo adicional facilita el trabajo (taladrar,

atornillar) vertical con respecto al eje longitudinal

de la máquina.

Montaje:

- Coloque el ángulo adicional sobre el husillo

portabrocas y gírelo hasta que se enclave en

la posición deseada (Nota: El ángulo adicional

se puede enclavar en 16 posiciones angulares

distintas).

- Bloquee el ángulo adicional girando la anilla de

sujeción (2.7) en el sentido de las agujas del

reloj hasta que quede apretada.

Desmontaje:

- Gire la anilla de sujeción en el sentido contrario

a las agujas del reloj hasta llegar al tope y quite

el ángulo adicional.

Montar / desmontar el portabrocas en el ángulo

adicional:

El portabrocas se sujeta de la misma manera en

el eje (2.6) del ángulo adicional que en el husillo

portabrocas de la máquina.

Pericolo di lesioni! Maneggiare

l'attrezzo e i relativi taglienti affi lati con particolare scrupolo durante la sostituzione e indossare

gli appositi guanti da lavoro.

Non fi ssare gli attrezzi CENTROTEC

sulla parte tonda del codolo in un mandrino tradizionale, al fi ne di evitare danni al codolo stesso.

Montaggio

- Spostare in avanti l'anello di sblocco (2.11),

inserire il portautensili fi no a battuta sul mandrino portapunte (2.5) e rilasciare l'anello di

sblocco.

Smontaggio

- Spostare in avanti l'anello di sblocco ed estrarre

il portautensili .

Sostituzione dell'utensile

- Per inserire e/o disinserire un utensile con

gambo CENTROTEC, spostare indietro l'anello

di sblocco di colore verde (2.10). Quando si

inserisce l'utensile, avvitare fi nché il suo gambo di forma esagonale (2.9) non si innesta

nell'alloggiamento di forma esagonale del

mandrino portapunte e spingere l'utensile fi no

a battuta nel portautensili.

Toma de herramienta en el husillo

portabrocas

Para que la máquina sea más corta y más ligera

las puntas de destornillador se pueden introducir

directamente en la toma hexagonal interior del

husillo portabrocas (2.5).

Cargar el juego de acumuladores

Excéntrica adicional DD-ES

La excéntrica adicional sirve para la toma de puntas de destornillador. Permite atornillar cerca de

los bordes.

Montar / desmontar la excéntrica adicional:

El montaje / desmontaje de la excéntrica adicional

se realiza de la misma manera que el montaje y

desmontaje del ángulo adicional (véase DD-AS).

Cambiar la herramienta:

- Estire la anilla de desbloqueo (2.8) hacia atrás

y saque o bien introduzca la herramienta.

Portautensili CENTROTEC WH-CE

Il portautensili CENTROTEC consente di effettuare

un rapido cambio degli utensili con gambo CENTROTEC.

Para cargar es preciso empujar el acumulador

hasta el tope en el soporte (3.1) del cargador. En

dirección opuesta, el acumulador cargado puede

extraerse del cargador.

El tipo de acumulador empleado (NiCd o NiMH) lo

detecta el cargador automáticamente. El proceso

de carga lo controla un micro-procesador.

Si se emplea un acumulador de NiMH en estado

caliente (>37°C), se carga sólo con corriente de

carga reducida. En este caso se alarga el tiempo

de recarga.

El diodo luminoso (LED) (3.2) indica el estado

actual del cargador.

LED amar. – permanente:

18

Page 19

El cargador está listo para ser usado.

LED verde – intermitente:

El juego de acu-muladores está cargado.

LED verde – permanente:

Juego de acumuladores cargado; cargador con

carga de matenimiento.

LED rojo – intermitente:

Indicación general de error, por ej. mal puesto,

defectuoso, o cortocircuito.

LED rojo – permanente:

Temperatura de acumuladores superior a valo-

res permitidos.

Observar obligatoriamente las

indicaciones en el capítulo "Mantenimiento - Cuidado".

Depósito para destornilladores

En los depósitos de destornillador (4.1) con soporte magnético se pueden incorporar más puntas

de destornillador o prolongaciones de destornillador.

Mantenimiento - Cuidados

Tenga en cuenta las indicaciones

que se ofrecen a continuación. En caso de inobservancia existirá peligro de dañar la máquina, el

cargador o el acumulador.

• Sólo técnicos especializados pueden llevar a

cabo las reparaciones. Con el cargador LC 45,

continúa habiendo una tensión del capacitor

elevada en el interior del aparato después de

separarlo de la red.

• Mantener limpias las ranuras de la herramien-

ta eléctrica y del cargador para que el aire de

refrigeración circule sin problemas.

• En el interior del cargador no debe penetrar

ningún trozo de metal (viruta metálica) a través

de las aberturas para los acumuladores ni de

las ranuras de ventilación (peligro de cortocircuito).

• Emplee sólo juegos de acumuladores de Fes-

tool. No emplee juegos de acumuladores ya

desgastados y preparados de nuevo para poder

ser usados. El usuario se responsabiliza de los

posibles daños por el uso de juegos de acumuladores no originales de Festool.

• Mantener limpios los contactos de conexión de

la máquina, del cargador y del juego de acumuladores.

• Guardando el juego de acumuladores en un

cargador listo para ser usado, el juego de acumuladores se mantiene siempre cargado debido

a la carga de mantenimiento.

• No dejar los acumuladores vacíos durante más

de 1 mes en el cargador si éste está separado

de la red (peligro de descarga total).

• Un juego de acumuladores nuevo o que no

haya sido utilizado en mucho tiempo alcanza su

capacidad total después de aproxi-madamente

5 ciclos de carga y descarga.

• Los juegos de acumuladores deberían estar descargados prácticamente por completo antes de

volver a ser cargados. Si se carga reptidamente

un juego de acumuladores no desgastado del

todo, se reduce su vida útil.

• Una capacidad de funcionameniento bastante

más corta por cada carga indica que el acumulador està gastado y que debe ser sustituido

por uno nuevo.

• Los acumuladores NiCd que no se utilicen durante un período prolongado deberían guardarse completamente descargados.

Indicaciones especiales para los acu-muladores NiMH:

• Cuando la temperatura ambiente está por debajo de los 0° C o bien por encima de los 45° C,

el rendimiento del acumulador NiMH disminuirá

considerablemente.

• No deberá sobrecargarse la máquina (no cargar la máquina tanto como para que llegue a

pararse).

• Los acumuladores NiMH deberán recargarse

cada 4 meses aunque no se utilicen para mantener toda su capacidad.

• Los acumuladores de NiMH deberían permanecer todavía 60 minutos más en el cargador tras

cargarse por décima vez en el modo de carga

rápida. Así se compensan las posibles diferencias de capacidad de las células.

• Debido a que se descargan solos, los acumuladores NiMH deben guardarse preferentemente

en lugares con una temperatura ambiente entre

0° C y 25° C .

Reciclaje de los juegos de acumu-

ladores

No tire a la basura el juego de acumuladores

ya desgastado. Devuelva los juegos de acu-

muladores utilizados o defectuosos al comercio

especializado, al servicio de postventa de Festool

o a los centros municipales de recogida de basura

especial. De esta manera se facilita un reciclaje

correcto de los acumuladores.

Accesorios, herramientas

¡Por razones de seguridad, solamente deben emplearse accesorios y herramientas

originales de Festool!

Los números de pedido para los respectivos accesorios y herramientas se encuentran en su catálogo Festool o en Internet en la dirección www.

festool-usa.com.

19

Page 20

Garantiá

Condiciones de la Garantía 1 + 2

Usted tiene derecho a una garantía extendida

gratuita (1 año + 2 años = 3 años) para su herramienta mecánica Festool. Festool se hará responsable por los gastos de envío durante el primer

año de garantía. Durante el segundo y tercer año

de garantía el cliente es responsable por el costo

del envío de la herramienta a Festool. Festool

pagará el embarque de regreso al cliente usando

UPS Ground Service. Todo el servicio de garantía

es válido por 3 años desde la fecha de la compra

de acuerdo a la fecha de su recibo o factura de

compra.

Garantía limitada de Festool

Esta garantía es válida con la condición previa de

que la herramienta se usa y opera de conformidad

con las instrucciones de operación de Festool. Festool garantiza, sólo al comprador original, que la

herramienta especifi cada estará libre de defectos

de fabricación y materiales durante un periodo

de un año a partir de la fecha de compra. Festool

no otorga otras garantías, ni explícitas ni implícitas para ninguna de las herramientas mecánicas

portátiles Festool. Ningún agente, representante,

distribuidor, comerciante o empleado de Festool

está autorizado para extender o modifi car de

cualquier manera las obligaciones o limitaciones

de esta garantía. Las obligaciones de Festool, a

su propia entera discreción, están limitadas a la

reparación o sustitución de cualquier herramienta

portátil Festool que se encuentre estar defectuosa en el momento de ser embalada junto con el

manual de usuario.

Quedan excluidos de la cobertura en esta garantía: el desgaste normal; los daños causados por

uso indebido, el abuso o negligencia; los daños

causados por cualquier otra causa que no sean

defectos del material o de la fabricación. Esta

garantía no aplica a accesorios como cuchillas de

sierras circulares, brocas de taladro, barrenas de

buriladora, cuchillas de sierra, cuchillas para sierras de calado, correas de lijadoras y ruedas de

esmeril. También se excluyen las “partes que se

desgastan” como cepillos de carbón, laminillas de

herramientas de aire, collarines de hule y sellos,

discos y cojines de lijado, y baterías.

Las herramientas mecánicas portátiles Festool que

requieran de reemplazo o reparación deben devolverse con el recibo de compra a Festool (llame al

800-554-8741 para los detalles de la dirección).

EN NINGÚN CASO FESTOOL SE HARÁ

RESPONSABLE POR LOS DAÑOS SECUNDARIOS

O CONSECUENTES OCASIONADOS POR

LA VIOLACIÓN DE ESTA O CUALUQUIER

OTRA GARANTÍA, SEA EXPLÍCITA

O IMPLÍCITA. TODAS LAS GARANTÍAS

IMPLICADAS POR LEYES ESTATALES,

INCLUYENDO LAS GARANTÍAS IMPLICADAS

DE COMERCIALIZACIÓN Y ADECUACIÓN

A UN PROPÓSITO PARTICULAR, QUEDAN

LIMITADAS A TRES AÑOS DE DURACIÓN.

Algunos estados de EE.UU. y algunas provincias

de Canadá no permiten las limitaciones en cuanto

a la duración de las garantías implícitas, de modo

que la limitación arriba indicada puede que no

le afecte. A excepción de algunas garantías

implicadas por leyes estatales o provinciales,

limitadas por la presente, la anteriormente citada

garantía, expresamente limitada, es exclusiva y

sustituye a cualquier otra garantía, acuerdo u

obligación similar de Festool.

Esta garantía le concede derechos legales específi cos y usted podría tener otros derechos legales

que varían de estado a estado en EE.UU. y de

provincia a provincia en Canadá.kjgph

20

Loading...

Loading...