Festo SPC11 User Manual

Supplementary

manual

Drive-specific

supplement for

operating the

SPC11 with the

drive type

DGCI/DDLI

Manual

549167

en 1406d

[8037996]

SPC11 Soft Stop

Contents and general safety instructions

I

Festo P.BE-SPC11-DG CI-E N en 1406d

Original de.......................................

Edition en 1406d..................................

Designation P.BE-SPC11-DGCI-EN.....................

Order -no. 549167..................................

© (Festo AG & Co., D-73726 Esslingen, Germany, 2012)

Internet: http://www.festo.com

E-Mail: service_international@festo.com

The copying, distribution and utilization of this document

as well as the communication of its contents to others with-

out expressed authorization is prohibited. Violations give

rise to compensation. All rights are reserved, in particular

the right to carry out patent, utility model or ornamental

design registration.

Contents and general safety instructions

II

Festo P.BE-SPC11-DG CI-E N en 1406d

Contents and general safety instructions

III

Festo P.BE-SPC11-DG CI-E N en 1406d

Contents

Designated use V........................................................

Service VI...............................................................

Target group VI..........................................................

Important user instructions VII..............................................

Product-specific terms and abbreviations IX...................................

Notesontheuseofthismanual X...........................................

1. Overview of components 1-1........................................

1.1 General information 1-3.............................................

1.2 System structure with the DGCI or DDLI 1-4.............................

1.3 Notes on installing the pneumatic components 1-5.......................

1.4 Instructions on converting systems 1-13................................

1.5 Notes on installing the electronic components 1-14.......................

2. Parameters of the SPC11 for the DGCI or DDLI 2-1.......................

2.1 SPC11 parameters 2-3..............................................

2.2 Setting parameters 2-5..............................................

2.3 Parameters for the DGCI/DDLI in horizontal mode 2-8.....................

2.3.1 DGCI-18-... in horizontal mode 2-8.............................

2.3.2 DGCI/DDLI-25-... in horizontal mode 2-13........................

2.3.3 DGCI/DDLI-32-... in horizontal mode 2-18........................

2.3.4 DGCI/DDLI-40-... in horizontal mode 2-23........................

2.3.5 DGCI/DDLI-63-... in horizontal mode 2-28........................

2.4 Parameters for the DGCI/DDLI in vertical mode 2-33.......................

2.4.1 DGCI-18-... in vertical mode 2-33...............................

2.4.2 DGCI/DDLI-25-... in vertical mode 2-38..........................

2.4.3 DGCI/DDLI-32-... in vertical mode 2-43..........................

2.4.4 DGCI/DDLI-40-... in vertical mode 2-48..........................

2.4.5 DGCI/DDLI-63-... in vertical mode 2-53..........................

Contents and general safety instructions

IV

Festo P.BE-SPC11-DG CI-E N en 1406d

A. Technical appendix A-1.............................................

A.1 Repetition accuracy A-3.............................................

A.2 Index A-5.........................................................

Contents and general safety instructions

V

Festo P.BE-SPC11-DG CI-E N en 1406d

Designated use

The SPC11 has been designed for fitting into a machine or an

automated system. In conjunction with permitted drives and

measuring systems as well as with a proportional directional

control valve type MPYE-5-... , the SPC11 enables:

– fast movement into the mechanical end positions and one

or two selectable intermediate positions

– manual movement between the end positions.

Depending on the drive used, fixed stops may be necessary

in order to protect the drive. The end positions can be set by

means of fixed stops. The end position cushioning, movement

to the intermediate positions and manual positioning are

electronically controlled. The SPC11 may only be used as

follows:

–asdesignated

– in its original state

– without any modifications by the user

– in faultless technical condition

– only in conjunction with permitted drive/measuring sys-

tem combinations.

When used together with commercially available compo-

nents, such as sensors and actuators, the specified limits

for pressures, temperatures, electrical data, torques etc.

must be observed. National and local safety regulations

must also be observed.

Contents and general safety instructions

VI

Festo P.BE-SPC11-DG CI-E N en 1406d

Service

Please consult your local Festo repair service if you have any

technical problems.

Targ et g ro up

This manual is directed exclusively at technicians trained in

control and automation technology.

Contents and general safety instructions

VII

Festo P.BE-SPC11-DG CI-E N en 1406d

Important user instructions

Danger categories

This manual contains instructions on the possible dangers

which can occur if the product is not used correctly. These

instructions are marked (Warning, Caution, etc), printed on

a shaded background and marked additionally with a picto-

gram. A distinction is made between the following danger

warnings:

Warning

... means that failure to observe this instruction may result

in serious personal injury or damage to property.

Caution

... means that failure to observe this instruction may result

in personal injury or damage to property.

Note

... means that failure to observe this instruction may result

in damage to property.

The following pictogram marks passages in the text which

describe activities with electrostatically sensitive compo-

nents.

Electrostatically sensitive devices: Incorrect handling can

result in damage to components.

Contents and general safety instructions

VIII

Festo P.BE-SPC11-DG CI-E N en 1406d

Identifying special information

The following pictograms mark passages in the text which

contain special information.

Pictograms

Information

Recommendations, tips and references to other sources of

information

Accessories:

Information on necessary or useful accessories for the

Festo product.

Environment:

Information on the environment-friendly use of Festo

products.

Text markings

•

The bullet indicates activities which may be carried out in

any order.

1. Figures denote activities which must be carried out in the

numerical order specified.

– Hyphens indicate general activities.

Contents and general safety instructions

IX

Festo P.BE-SPC11-DG CI-E N en 1406d

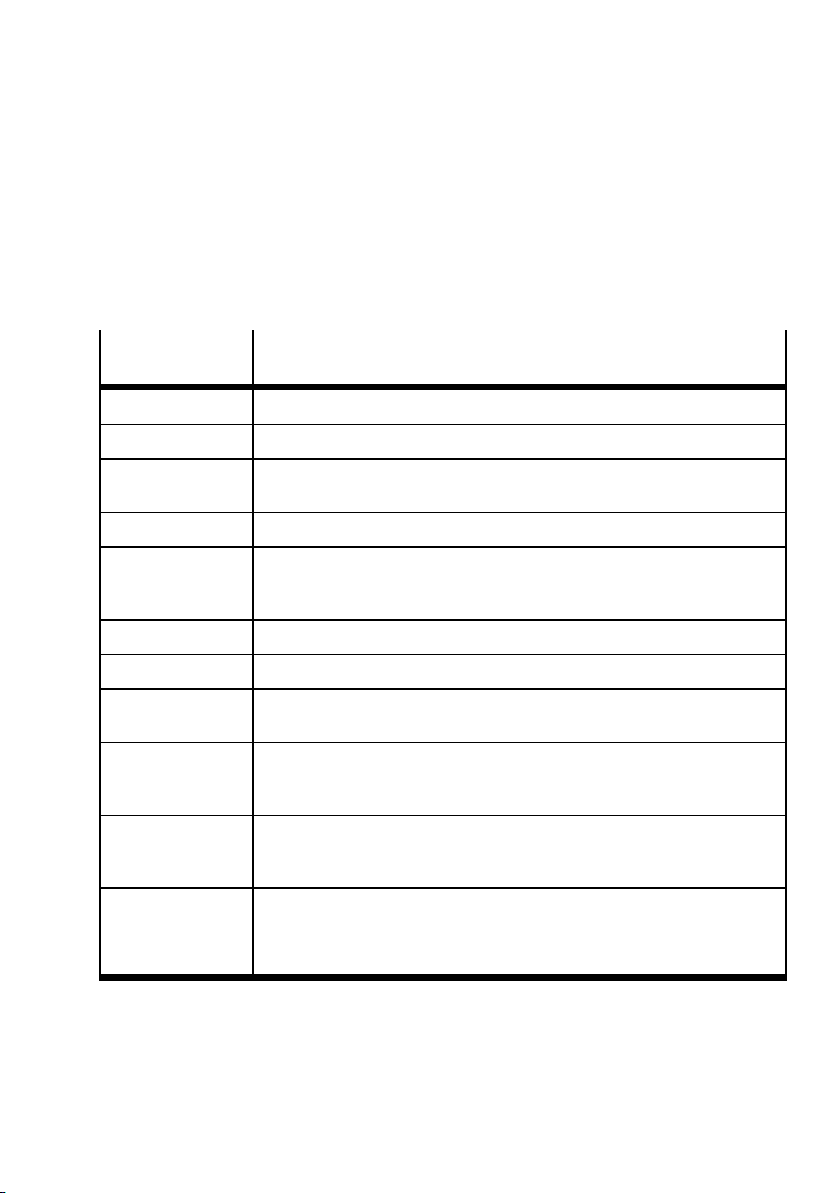

Product-specific terms and abbreviations

The following product-specific abbreviations are used in this

manual:

Term/abbrevi-

ation

Meaning

0-signal Input or output supplies 0 V

1-signal Input or output supplies 24 V

Drive The term drive is used in this manual for the linear unit (DDLI, DGCI-... or

DGP(I)(L)-...), cylinder ( DDPC, DNC...) or rotary drive (DSMI-...).

O Digital output

Cushioning stage The positioning behaviour is determined by the amplification and cushioning

stages. The cushioning stage serves to optimize the approach behaviour when

moving to the end positions.

I Digital input

PLC/IPC Programmable logic controller/industrial PC

System parameters Characteristic value which describes the system structure, the features and

components of the drive used.

Parameters Parameters which must be set in order that the system can be operated.

The amplification stage, the cushioning stage and the system parameter

belong here.

Teach procedure During the teach procedure the SPC11 checks the set parameters, learns the

position of the mechanical fixed stops as well as various characteristic system

values and saves them in the integrated EEPROM.

Amplification stage The amplification stage influences the acceleration behaviour of the drive,

for example. The amplification stage should usually be set as spec if ied in the

“Drive-Specific Supplement” manual. If the positioning behaviour is optim-

ized later, only the cushioning stage should be modified.

Contents and general safety instructions

X

Festo P.BE-SPC11-DG CI-E N en 1406d

Notes on the use of this manual

This manual contains special information on installing

and commissioning the SPC11 in conjunction with drive

DGCI or DDLI.

General basic information on the method of operation, fitting,

installing and commissioning pneumatic drives with the

SPC11 can be found in the system manual P.BE-

SPC11-SYS-... .

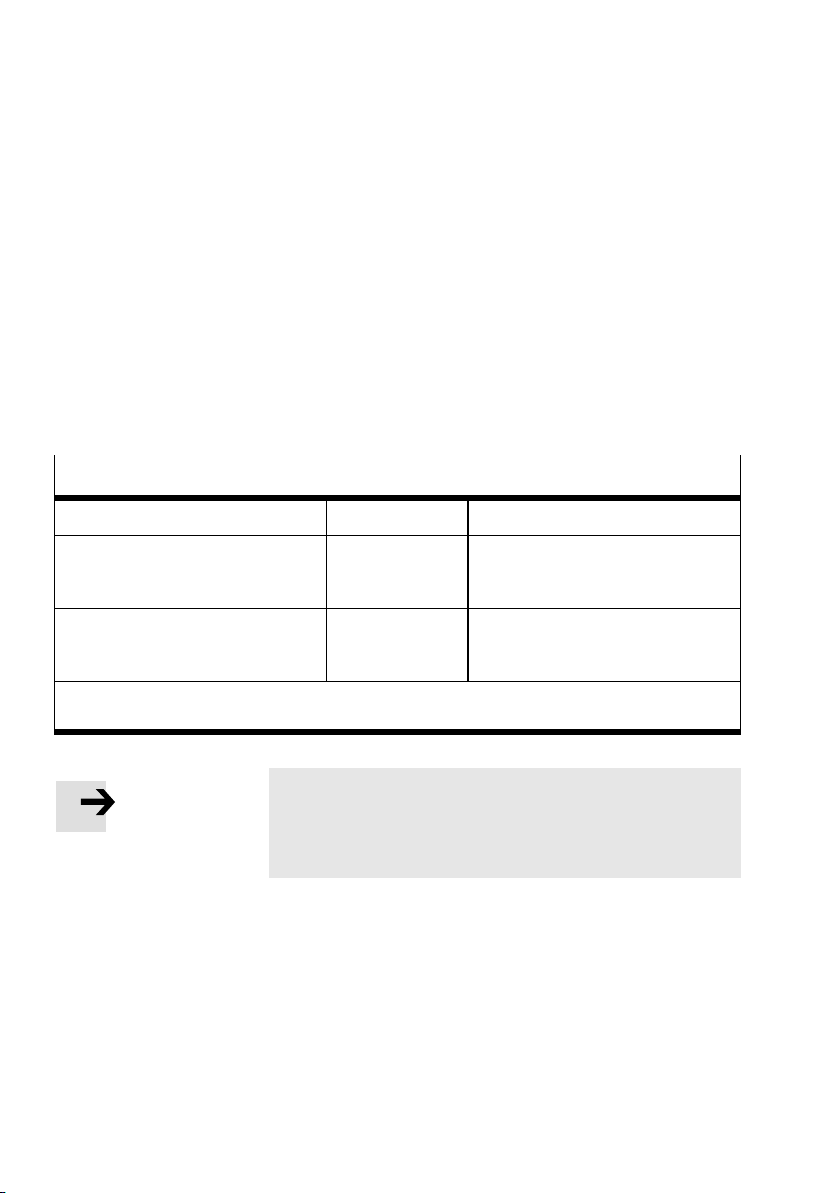

Manuals for the SPC11

Manual Designation Content

System Manual

Soft StopSPC11 Electronics/

Pneumatics

P.BE-SPC11-SYS... General instructions on installing and

commissioning

Drive-specific supplement for operat-

ing the SPC11 with a certain drive, e.g.

with the DGCI-... (e.g. this manual)

P.BE-SPC11-...-... Special installation and commission-

ing instructions as well as parameter

settings for the relevant drive

1)

1) These manuals contain the permitted drive-valve c ombinations, drive diameters and mass loads as

well asthe valid parameter settings of the SPC11.

Note

For installation and commissioning you will require the

System Manual as well as the “Drive-Specific Supplement”

manual for the drive used.

Installation instructions for th e DGCI or DDLI

1-1

Festo P.BE-SPC11-DG CI-E N en 1406d

Chapter 1

Installation instructions for the DGCI or DDLI

1. Installation instructions for the DGCI or DDLI

1-2

Festo P.BE-SPC11-DG CI-E N en 1406d

Contents

1.1 General information 1-3.............................................

1.2 System structure with the DGCI or DDLI 1-4.............................

1.3 Notes on installing the pneumatic components 1-5.......................

1.4 Instructions on converting systems 1-13................................

1.5 Notes on installing the electronic components 1-14.......................

1. Installation instructions for the DGCI or DDLI

1-3

Festo P.BE-SPC11-DG CI-E N en 1406d

1.1 General information

Warning

Faults in the system structure and incorrect parameters

cancausetheslidetomovetoanendpositionuncu-

shioned. The fixed stop or the drive may then be de-

stroyed. You must observe the following instructions

in order to prevent such damage.

•

Set up the system with great care. Always observe the

safety instructions and information in this manual as well

as in the system manual for type P.B E-SPC11-SYS... .

•

Use only the special matching components from Festo for

setting up and wiring the system. Only in this way can you

be sure that the system will function correctly.

Note

In order to operate the DGCI-... you will require the SPC11

type SPC11-MTS-AIF-2.

1. Installation instructions for the DGCI or DDLI

1-4

Festo P.BE-SPC11-DG CI-E N en 1406d

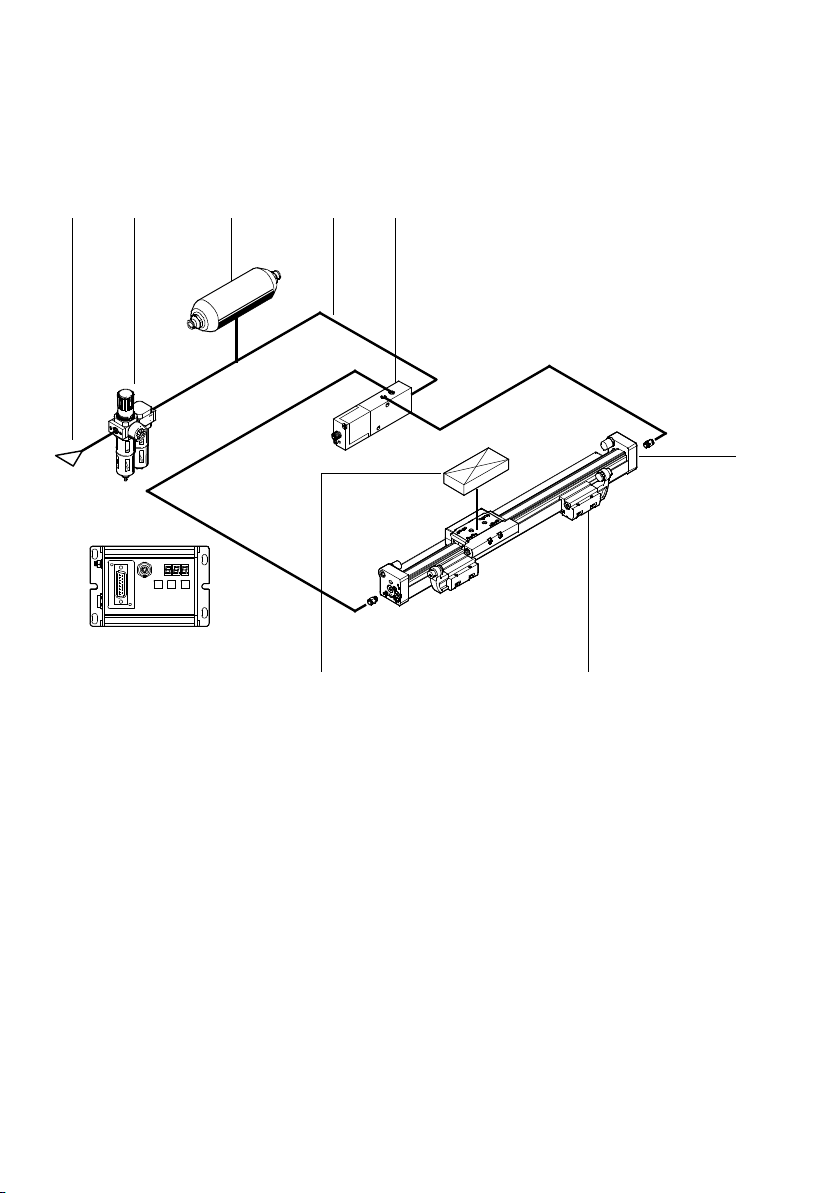

1.2 System structure with the DGCI or DDLI

The following diagram shows the basic layout of a drive with

the SPC11 using as an example drive type DGCI-... .

1

2

4

5

3

6

2

7

1

Drive (here type DGCI-... with built-on

measuring system)

2

Fixed stop (here e.g. B. KYC-...)

3

Measuring system connection

4

SPC11-MTS-AIF-2

5

Proportional directional control valve

type MPYE-5-...-010B

6

Service unit with 5 µm filter, without

lubricator

7

Compressed air source (5 to 7 bar)

Fig. 1/1: System structure of the SPC11

1. Installation instructions for the DGCI or DDLI

1-5

Festo P.BE-SPC11-DG CI-E N en 1406d

1.3 Notes on installing the pneumatic components

Caution

If the operating voltage is switched off while the com-

pressed air supply is still switched on, the actuators may

be triggered, resulting in unexpected movements which

may cause damage. Switch off the operating voltage and

the compressed air supply at the same time or in the fol-

lowing sequence:

1. the compressed air supply

2. the operating voltage

Note

Make sure that the compressed air supply and the operat-

ing voltage are switched off before starting installation and

maintenance work.

General rules for building up the system can be found in the

system manual type P.BE-SPC11-SYS... . Special instructions

on operation with linear unit type DGCI-... can be found in the

following sections:

Note

Observe the following instructions on installing the pneu-

matic components. Only then can you guarantee faultless

operation.

1. Installation instructions for the DGCI or DDLI

1-6

Festo P.BE-SPC11-DG CI-E N en 1406d

12 3 45

6

78

1

...

9

Instructions on installation see following pages

Fig. 1/2: Overview of pneumatic installation

Compressed air supply ( 1 )

See system manual type P.BE-SPC11-SYS...

Service unit ( 2 )

See system manual type P.BE-SPC11-SYS...

Compressed air reservoir ( 3 )

See system manual type P.BE-SPC11-SYS...

1. Installation instructions for the DGCI or DDLI

1-7

Festo P.BE-SPC11-DG CI-E N en 1406d

Compressed air tubing and screw connectors ( 4 )

See system manual type P.BE-SPC11-SYS...

•

Arrange the tubing between the valve (MPYE-5-...) and

the drive (DGCI/DDLI) symmetrically.

Recommendation: tubing length = drive length

•

Cut the tubing and the connectors to the required length

as shown in the following table.

Horizontal mounting position

Drive length in

mm

ValvetypeMPYE-...

Screw connectors for

Tube type

PUN

MPYE-... DGCI/DDLI-...

DGCI-18-...

100 ... 300 MPYE-5-M5-010B QSM-M5-6 QSM-M5-6 PUN-6x1

360 ... 1750 MPYE-5-1/8-LF-010B QS-1/8-6 QSM-M5-6 PUN-6x1

2000 MPYE-5-1/8-HF-010B QS-1/8-6 QSM-M5-6 PUN-6x1

DGCI/DDLI-25-...

100 ... 160 MPYE-5-1/8-LF-010B QS-1/8-6 QS-1/8-6 PUN-6x1

225 ... 300 MPYE-5-1/8-LF-010B QS-1/8-8 QS-1/8-8 PUN-8x1,25

360 ... 2000 MPYE-5-1/8-HF-010B QS-1/8-8 QS-1/8-8 PUN-8x1,25

DGCI/DDLI-32-...

100 MPYE-5-1/8-LF-010B QS-1/8-6 QS-1/8-6 PUN-6x1

160 ... 1000 MPYE-5-1/8-HF-010B QS-1/8-8 QS-1/8-8 PUN-8x1,25

1250 ... 2000 MPYE-5-1/4-010B QS-1/4-8 QS-1/8-8 PUN-8x1,25

DGCI/DDLI-40-...

100 ... 500 MPYE-5-1/8-HF-010B QS-1/8-8 QS-1/4-8 PUN-8x1,25

600 ... 750 MPYE-5-1/4-010B QS-1/4-8 QS-1/4-8 PUN-8x1,25

850 ... 2000 MPYE-5-1/4-010B QS-1/4-10 QS-1/4-10 PUN-10x1,5

1. Installation instructions for the DGCI or DDLI

1-8

Festo P.BE-SPC11-DG CI-E N en 1406d

Horizontal mounting position

Drive length in

mm

ValvetypeMPYE-...

Screw connectors for

Tube type

PUN

MPYE-... DGCI/DDLI-...

DGCI/DDLI-63-...

100 ... 300 MPYE-5-1/8-HF-010B QS-1/8-8 QS-3/8-8 PUN-8x1,25

360 ... 400 MPYE-5-1/4-010B QS-1/4-10 QS-3/8-10 PUN-10x1,5

450 ... 2000 MPYE-5-3/8-010B QS-3/8-12 QS-3/8-12 PUN-12x2

Vertical mounting position

Drive length in

mm

ValvetypeMPYE-...

Screw connectors for

Tube type

PUN

MPYE-... DGCI/DDLI-...

DGCI-18-...

100 ... 300 MPYE-5-M5-010B QSM-M5-6 QSM-M5-6 PUN-6x1

360 ... 1750 MPYE-5-1/8-LF-010B QS-1/8-6 QSM-M5-6 PUN-6x1

2000 MPYE-5-1/8-HF-010B QS-1/8-6 QSM-M5-6 PUN-6x1

DGCI/DDLI-25-...

100 ... 160 MPYE-5-1/8-LF-010B QS-1/8-6 QS-1/8-6 PUN-6x1

225 ... 750 MPYE-5-1/8-LF-010B QS-1/8-8 QS-1/8-8 PUN-8x1,25

850 ... 2000 MPYE-5-1/8-HF-010B QS-1/8-8 QS-1/8-8 PUN-8x1,25

DGCI/DDLI-32-...

100 MPYE-5-1/8-LF-010B QS-1/8-6 QS-1/8-6 PUN-6x1

160 ... 300 MPYE-5-1/8-LF-010B QS-1/8-8 QS-1/8-8 PUN-8x1,25

360 ... 1750 MPYE-5-1/8-HF-010B QS-1/8-8 QS-1/8-8 PUN-8x1,25

2000 MPYE-5-1/4-010B QS-1/4-8 QS-1/8-8 PUN-8x1,25

1. Installation instructions for the DGCI or DDLI

1-9

Festo P.BE-SPC11-DG CI-E N en 1406d

Vertical mounting position

Drive length in

mm

ValvetypeMPYE-...

Screw connectors for

Tube type

PUN

MPYE-... DGCI/DDLI-...

DGCI/DDLI-40-...

100 ... 225 MPYE-5-1/8-LF-010B QS-1/8-8 QS-1/4-8 PUN-8x1,25

300 ... 750 MPYE-5-1/8-HF-010B QS-1/8-8 QS-1/4-8 PUN-8x1,25

850 ... 1000 MPYE-5-1/8-HF-010B QS-1/8-10 QS-1/4-10 PUN-10x1,5

1250 ... 2000 MPYE-5-1/4-010B QS-1/4-10 QS-1/4-10 PUN-10x1,5

DGCI/DDLI-63-...

100 … 225 MPYE-5-1/8-LF-010B QS-1/8-8 QS-3/8-8 PUN-8x1,25

300 MPYE-5-1/8-HF-010B QS-1/8-8 QS-3/8-8 PUN-8x1,25

360 ... 450 MPYE-5-1/4-010B QS-1/4-10 QS-3/8-10 PUN-10x1,5

500 ... 2000 MPYE-5-3/8-010B QS-3/8-12 QS-3/8-12 PUN-12x2

1. Installation instructions for the DGCI or DDLI

1-10

Festo P.BE-SPC11-DG CI-E N en 1406d

Proportional directional control valve ( 5 )

See system manual type P.BE-SPC11-SYS...

The DGCI-... is suitable both for slide and yoke mode.

Work port 2 of the proportional directional control valve

must be connected to the drive conection which is on the

side with the electrical connection for the potentiometer.

1

1

Electrical connection

Fig. 1/3: Tubing connection for slide mode

1

1

Electrical connection

Fig. 1/4: Tubing connection for yoke mode

1. Installation instructions for the DGCI or DDLI

1-11

Festo P.BE-SPC11-DG CI-E N en 1406d

If the DGCI or DDLI is ordered with screw connectors – Stand-

ard (no modular system feature) or modular system feature

“QD” or “QR”:

•

Work port 2 of the proportional directional control valve

must be connected to the drive connection of the screw

connector with blue releasing ring.

•

Work port 4 of the proportional directional control valve

must be connected to the drive connection of the screw

connector with black releasing ring.

Linear drive type DGCI/DDLI ( 6 )

With the DGCI or DDLI, use only:

– drivesoftypeDGCIorDDLI.

– Permitted combinations of drives and valves, drive diam-

eter, drive lengths and mass loads, see “Parameters for

the DGCI or DDLI” in chapter 2.

– Drives with air supply on both sides (for good positioning

behaviour).

•

Fit the drive horizontally or vertically.

•

Connect the drive, the guide, the potentiometer and the

load free of play in the direction of movement and flush

with each other .

•

If necessary, provide a sufficiently large supply of energy

in order to minimize the effects of transverse forces on

the positioning behaviour.

•

Lubricate the guide of the drive at maintenance intervals

as specified in the operating instructions for the drive

(see operating instructions for the drive or the guide).

1. Installation instructions for the DGCI or DDLI

1-12

Festo P.BE-SPC11-DG CI-E N en 1406d

Fixed stops ( 7 )

With drives of type DGCI-... you can use as a fixed stop either

the integrated original stops, the shock absorber support

(without the shock absorber) type DADP-DGC-... together with

stops type KYC-... or suitable external stops.

The use of shock absorbers is not permitted.

1

2

2

3

1

1

Integrated original stops (drive end length)

2

Stop type KYC-...

3

Shock absorber support type DADP-DGC

Fig. 1/5: Fixed stops (Example DGCI)

With drives of type DDLI external fixed stops on the mounting

slide are required.

Mass load ( 8 )

Fit the mass load free of play. Use the compensating coupling

DARD from Festo.

Possible moving mass loads see “Parameters for the DGCI-...”

in chapter 2. The tables listed there contain all the permitted

combinations of drive, valve and mass load.

1. Installation instructions for the DGCI or DDLI

1-13

Festo P.BE-SPC11-DG CI-E N en 1406d

1.4 Instructions on converting systems

When converting systems you should use further the existing

drives. Only drives with air supply on one side are often avail-

able here.

The specified positioning times as well as optimum system

behaviour can only be achieved if the installation instructions

described in the previous section are observed.

Drives with compressed air supply on one side

Please observe the following when using drives compressed

air supply on one side:

– When compressed air is applied to port 4 of the propor-

tional directional control valve, the slide must move in

the direction of the measuring system zero point (electri-

cal connection of the measuring system).

If compressed air is applied to port 2, the slide must move

away from the measuring system zero point.

– The resulting positioning times may vary according to the

direction of the stroke.

1

1

Electrical connection (measuring system zero point)

Fig. 1/6: Tubing on the side with the measuring system zero

point.

1. Installation instructions for the DGCI or DDLI

1-14

Festo P.BE-SPC11-DG CI-E N en 1406d

If the DGCI or DDLI is ordered with screw connectors – modu-

lar design feature “QR:”

•

Work port 2 of the proportional directional control valve

must be connected to the drive connection of the screw

connector with blue releasing ring.

•

Work port 4 of the proportional directional control valve

must be connected to the drive connection of the screw

connector with black releasing ring.

1.5 Notes on installing the electronic components

Caution

Incorrect or missing earthing can cause interference.

Connect the DGCI-... drive with low impedance (short

cable with large cross-sectional area) to the earth poten-

tial, if the drive is not mounted on an earthed machine

stand.

Parameters of the SPC11 for the DGCI or DDLI

2-1

Festo P.BE-SPC11-DG CI-E N en 1406d

Chapter 2

Parameters of the SPC11 for the DGCI or DDLI

2. Parameters of the SPC11 for the DGCI or DDLI

2-2

Festo P.BE-SPC11-DG CI-E N en 1406d

Contents

2.1 SPC11 parameters 2-3..............................................

2.2 Setting parameters 2-5..............................................

2.3 Parameters for the DGCI/DDLI in horizontal mode 2-8.....................

2.3.1 DGCI-18-... in horizontal mode 2-8.............................

2.3.2 DGCI/DDLI-25-... in horizontal mode 2-13........................

2.3.3 DGCI/DDLI-32-... in horizontal mode 2-18........................

2.3.4 DGCI/DDLI-40-... in horizontal mode 2-23........................

2.3.5 DGCI/DDLI-63-... in horizontal mode 2-28........................

2.4 Parameters for the DGCI/DDLI in vertical mode 2-33.......................

2.4.1 DGCI-18-... in vertical mode 2-33...............................

2.4.2 DGCI/DDLI-25-... in vertical mode 2-38..........................

2.4.3 DGCI/DDLI-32-... in vertical mode 2-43..........................

2.4.4 DGCI/DDLI-40-... in vertical mode 2-48..........................

2.4.5 DGCI/DDLI-63-... in vertical mode 2-53..........................

Loading...

Loading...