Page 1

Ferm B.V. • P.O. Box 134 • 8280 AC Genemuiden NL • Web: www.ferm.com 0107/18

USERS MANUAL

Metal turning lathe 02

BEDIENUNGSANLEITUNG

Metalldrehmaschine 11

GEBRUIKSAANWIJZING

Metaaldraaibank 21

MODE D’EMPLOI

Tour à métaux 31

BRUKSANVISNING

Vinkelslipmaskin 20

KÄYTTÖOHJE

Kulmahiomakone 24

BRUKSANVISNING

Vinkelsliper 29

BRUGER VEJLEDNING

Vinkelslibere 33

Art.nr: 330950

Art.nr. 330960

GB

D

NL

F

MD-350/MD-500

Page 2

Ferm 51

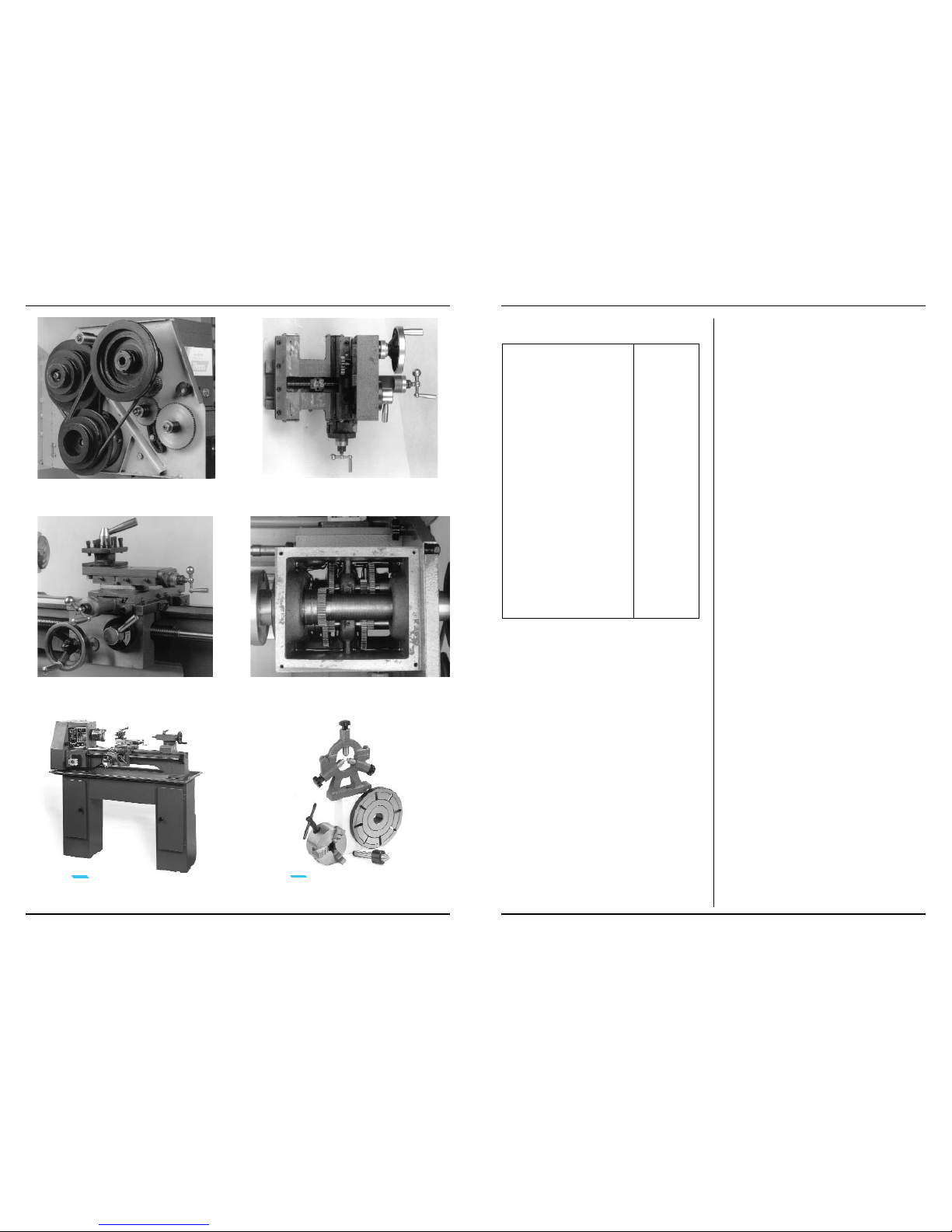

BENCH LATHE MD-350 / MD 500

CAREFULLY READ THE INSTRUCTIONS BEFORE

YOU USE THE BENCH LATHE!

Carefully read this manual before using the machine. Make sure that you know how the machine functions and how

to operate it. Maintain the machine in accordance with the

instructions to make sure it functions properly. Keep this

manual and the enclosed documentation with the machine.

USE

The metal lathe has been designed for processing, mechanically removing metal, of ferrous and non-ferrous metals, synthetics and wood. The metal lathe is meant for semi-professional use and for leisure interests.

SAFETY INSTRUCTIONS

When using electric machines always observe the

safety regulations applicable in your country to reduce the risk of fire, electric shock and personal injury.

Read the following safety instructions and also the

enclosed safety instructions.

Keep these instructions in a safe place!

At the design of the machine is made allowance for the requirements for a safe use. Every change, adaptation, reconstruction or other adaptation use can cancel the safety

of the object. Besides the guarantee will expire through

this.

Before, after and during working with the lathe a number of

safety rules have to be taken. By the presence of turning

parts and sharp objects very severe injury can arise. Especially the bits of the turning chuck are very dangerous.

1. The lathe has been designed for manufacturing unruly

material and so it has to be able to develop a lot of power.

That is why touching turning parts is perilous. For this

reason unlawfully, undesirably or unintentionally switching on the machine has to be prevented, for example

by the pushed in locking of the emergency stop valve

by means of a small padlock.

2. By the elastic working of the chisel metal parts can

be shoot away with a big power at the most unexpected moments.

- Protection of the eyes is very important. Make it a habit

to wear special safety glasses when you are in the

space where the lathe stands. Buy yourself a professional and tested copy which you can wear for a long time and if need be for visitors a cheaper one, but this

one also has to be a good performance.

- If you take care of a cheerful workshop you can prevent

for example gripping in the machine or falling by stumbling over flinging about material.

3. Be very careful when you make turning pieces of

work with the hands.

- When you want to polish a surface turning, then take a

long piece of polish paper which you can place half

around the piece of work, with the ends to your direction.

- Never turn the ends around the fingers, never push

sand-paper on the piece of work with your hands.

- By turning, edges of the piece of work exist which are

sharp as a razor. These edges have to be smoothed off

with a file or a trimming hook.

4. Never remove chipcurls with your hands

Use a little hook which has been made by yourself of

thread or buy a professional chips hook.

5. Never grip over the turning machine or chuck

when during turning something falls in or behind

the bed.

Always first stop the machine. See that the covering

plate lies on the opening in the bed.

6. A good lighting prevents that you operate the machine from too close by.

- If you apply strip light you have to make allowance for

the so-called strobosto scopic effect. Through this a

turning object seems to stand still. A solution is the use

of double armatures by which a phase shifting of the

two strip lights has been accomplished.

7. Emergency stop

If a dangerous situation arises unexpectedly, for example if a badly exerted piece of work seems to get loose during turning, you van use the emergency stop by

giving a tap on the yellow cover of the safety switch,

marked “STOP”. The machine now stops without pushing in the switch button yourself.

GB

English

2 Ferm

SPARE PARTS FOR MD-350/MD-500

REF. NR. DESCRIPTION FERM NR.

0.01 Shears 400311

0.02 Intermediate gear spindle 400312

1.01 Locking handle 400300

1.03 Clamping nut 400301

1.05 Spindle 400302

1.06 Spindle bearing 400303

1.07 Handwheel for support 400304

1.08 Cover plate 400305

1.09 Spindle nut 400306

1.10 Tail stock 400307

1.11 Pinole MT-2 400308

1.12 Baseplate / bedplate 400309

1.13 Locking bolt 400310

2.02 Press handle 400313

2.03 Holder complete 400314

2.04 Axle pin tool holder 400315

2.05 Tool support (top) 400316

2.06 Sunk key 400317

2.09 Spindle 400318

2.14 Handle 400319

2.16 Nut (tool slide) 400320

2.17 Tool slide (under) 400321

2.18 Locking bolt 400322

2.20 Turning pin 400323

2.21 Key cross slide 400324

3.01 Handle 400325

3.04 Spindle 400326

3.05 Spindle nut 400327

3.10 Baseplate cross slide 400328

3.11 Hollow key 400329

3.13 Longidutinal direction spindle 400330

3.15 Hand wheel 400331

3.17 Half nut lever 400332

3.18 Half nut mechanism 400333

3.21 Longiditunal direction spindle (internal) 400334

3.22 Bearing 400335

4.03 Motor 400336

4.04 Motor pulley 400337

4.07 Headstock with cover 400338

4.08 Main spindle 400339

4.10 Main spindle pulley 400340

4.11 Intermediate pulley 400341

4.12 Tension roller 400342

4.16 Switch 400343

4.17 Bearing (lead screw) 400344

4.23 Thrust bearing 400345

4.24 Rack MD-350 400346

4.24 Rack MD-500 400367

4.24 Rack 400366

5.01 Gear 51 400347

5.02 Gear 68 400348

5.03 Gear 25 400349

5.04 Gear 75 400350

5.05 Gear 76 400351

5.06 Gear 24 400352

5.07 Gear 24 400353

5.08 Gear 76 400354

5.09 Gear 56 400355

5.10 Gear 56 400356

5.11 Change wheel 30 400357

5.12 Change wheel 42 400358

5.13 Change wheel 49 400359

5.14 Change wheel 28 400360

5.15 Change wheel 63 400361

5.16 Change wheel 70 400362

5.17 Change wheel 84 400363

5.18 Change wheel 98 400364

5.19 Change wheel 105 400365

- Center MC-3 400368

- Center MC-2 400369

- 3-Jaw chuck 400370

- 4-Jaw chuck 400371

- V-belt tension roller 400372

- Micro switch for door 400373

- V-Belt Z31 (10 x 790) 800114

- V-Belt Z28 (10 x 710) 800170

- V-Belt Z35 (10 x 890) 800197

- The reference numbers refer to the 5 annexes indicated

with the numbers 0, 1, 2, 3, 4, 5.

The number in front of the point refers to the Annex, the

number behind the point refers to the part.

So, reference 4.07 refers to Annex 4, part 7

- Die Referentienummer referieren auf 5 Beilage die Mittels

den Nummern 0, 1, 2, 3, 4 und 5 angegeben werden.

Die Nummer vor dem Punckt verweißt auf die Beilage, die

Nummer hinter dem Punckt auf das Unterteil. So die Verweißung 4.07 referiert auf Beilage 4, Unterteil 7.

- De Referentienummers verwijzen naar de 5 bijlagen aangegeven met de nummers 0, 1, 2, 3, 4 en 5.

Het nummer voor de punt verwijst naar de bijlage, het nummer achter de punt naar het onderdeel

Referentie 4.07 verwijst dus naar bijlage 4, onderdeel 7.

- Les numéros de reference se référent à les 5 annexes, indiquées avec les numéros 0, 1 ,2 ,3, 4 et 5. Le numéro devant

le point se réfère à l’annexe, le numéro à derrière le point se

réfère à la pièce détachée. Par conséquant la référence

4.07 se réfère à annexe n°4, pièce détachée n°7.

Page 3

R

R

R

R

R

R

50 Ferm

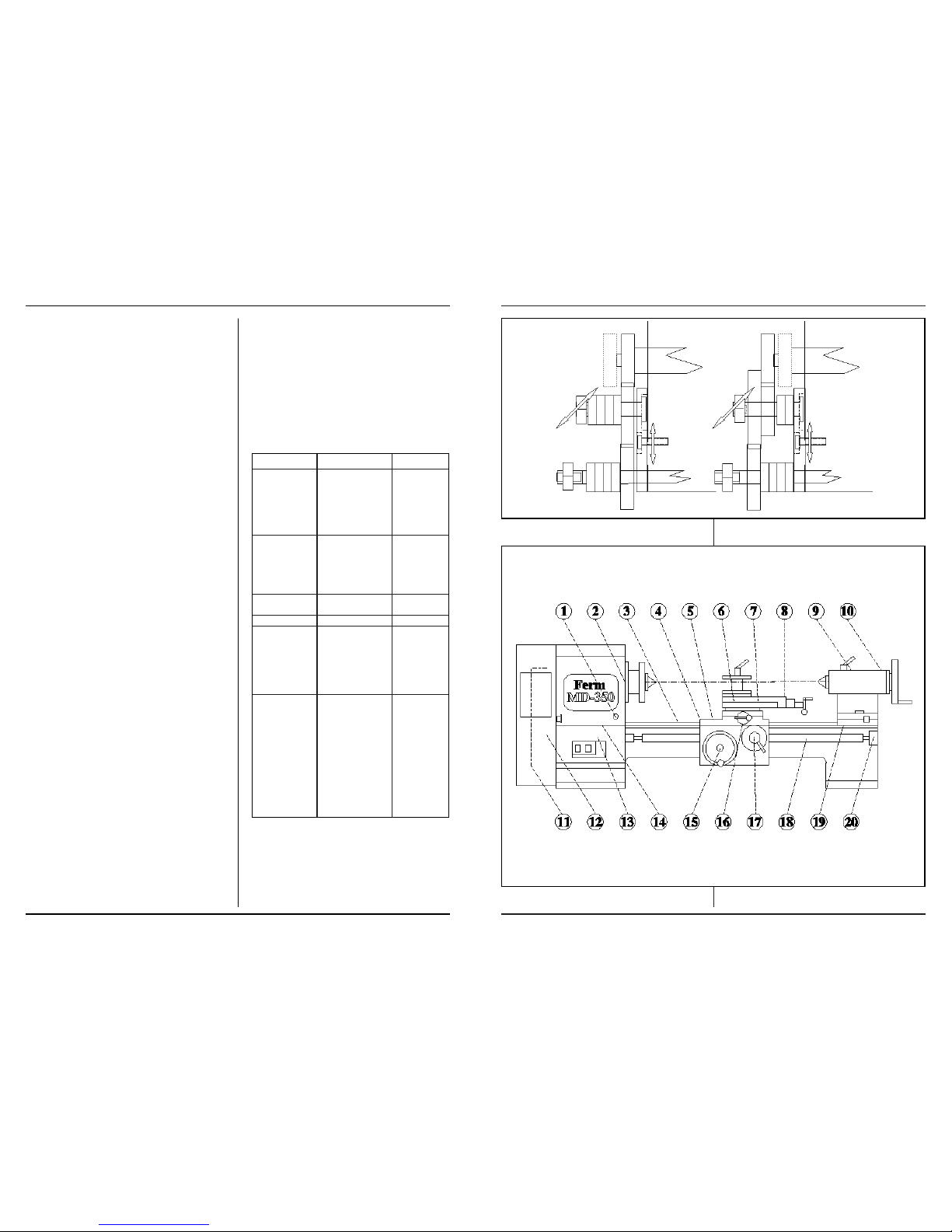

TECHNICAL SPECIFICATIONS

Mains voltage 230 Volt

Mains frequency 50 Hz

Absorbed power 375 Watt

Center height 110 mm

Center distance MD-350 350 mm

Center distance MD-500 500 mm

Max. turndiameter above bed 200 mm

Max. turndiameter above support 115 mm

Culvert and recording main shaft 18 mm, MT-3

Number of speeds main shaft 6

No load speeds main shaft 120-2.000/min.

Automatic start 11 mm; 0,04 - 0,3

Thread cutting (right) 11 mm; M0,4 - M3

Distance toolholder centerline -

measured vertically 15 mm

Rotating plate movement: 3600

Graduation rotating plate: ± 450

Movement tool cut 70 mm

Movement cross slide 115 mm

Movement end slide 350 mm

Graduation slide screws 0,04 mm

Recording and stroke slide tube 50 mm; MT-2

Graduation slide tube 0,05 mm

Weight MD-350 110 kg

Weight MD-500 130 kg.

Sound pressure L

wa

70 dB(A)

Vibration value 2,8 m/s

2

THE MD-350 AND THE MD-500 ARE DELIVERED IN

THE FOLLOWING BASE PERFORMANCE.

Machinebed with prism conductor, ferme head with main

shaft and drive for automatic longitudinal feed and thread

cutting, tail stock with sliding tube and transverse adjustment, electro motor with start/stop- and sense of rotation

switch, support with lock case, combined with

starting/lead screw, cross slide with rotating plate and tool

slide, fourfold tool holder with index pin, 3-chuck with extra

exterior basins and measuring certificate, drive protection

case, 7 change wheels, 3 driving-belts, 2 centers, 3 openend spanners, 2 socket head wrenches, catch pin and a

tightening-wrench chuck.

Excluded under-carriage (art. nr.330957).

INSTALLATION

SPACE.

Next to a good maintenance it is very important the machine is installed drily, as the machine has been built up for de

biggest part of metal. Spaces can become moist by insufficient or a wrong ventilation, burning not regularly or by

raced walls and lifting moisture. Condensation of moisture

on the metal is caused by suddenly raising the temperature in a cold space. See that the temperature is equable.

UNPACKING AND INSTALLING

The machine is packed in a strong case which you can dismantle to six flat parts which can be put away easily. These

parts can be saved in case you have to transport the lathe,

for example for repair or for a removal. After you have opened the case the lathe has to be detached from the pallet.

For this you have to remove two nuts, in each bedfoot one.

Later the nuts can be used again. For lifting up the lathe

you may call in the help of an assistent, this depends on the

weight. Before you begin you have to arrange how to lift

the machine. You should rather put the machine from the

pallet on the permanent destination at one go. The best

thing is to grip the machine at the ends of the bed, so do not

grip it on the heads, transporter, change wheel case or

motor! The apparatus weights roughly 110 kg. For reducing the weight temporary a number of parts can be removed carefully, like the tail stock, the turning plate with building and the discs from iron cast. The lathe has to be level

and it has to be installed on a strong bottom. If you make an

under-carriage yourself you can use a steel U-profile of

sufficient lenght, on which you can sold or screw a leg construction. You can also use a strong wooden lower case

with a strengthened and flat upper blade, for example by

means of a piece of multiple worktop. The conditi on is that

the formation has to be stiff in every directions and that it

cannot fling about, bend or wobble. The lathe is fixed with

two bolts M10 in the special gaps in both bottom plates.

TIP:

You can take the following precautionary measures

for preventing that small roughnesses still cause tension

on the bed if you tighten the two bolts. You draw the place

of the two bottom platesand the two assembling gaps and

you assemble two bolts M10 in the foundation. Put on the

drawn places a layer epoxy filling. Install a plastic foil on

this. See that the bolts stay clear! Then install the workbench on the drawn place. Use the two bolts for this as the

conductor. Let down the bed on the foil and then harden

the filling. After that you can provide the bolts with the nuts

which are also used for the transport, and then you can

tighten these ones again.

ELECTRICAL CONNECTION

After the motor has been installed permanently a connection to the electrical installation has to be made. The machine has been made for use on the existing 230 Volts alternating current mains and hasn’t a power bigger than other big household equipment with a motor. Have an eart-

Ferm 3

Floor Stand / Unterschrank / Onderstel /

Bas de casse. Art.nr.: 330957

Accessories/Unterteile / Onderdelen /

Accessoires

V-Belt / Riemen / V-Snaar / Courroies t

rapézoïdales

Bottom side Support/Unterseite Support / Onderzijde support / Surface inférieure de support

The Suppory/Das Support / Het support /

Le support

Oil bath in gearbox/Ölbad im Zahnräderkasten

Oliebad in de tandwielkast/ Bain d’huile de boîte d’engrenage

Page 4

Ferm 49

hed power point installed in the nearness of the machine

and see that the lead can be guided to the contact without

cracks and pulls. If need be an earthed extension cable

can be used, but see that the cable is unrolled entirely and

that it is not in the way.

ELECTRICAL SAFETY

Always check that the power supply corresponds to the

voltage on the rating plate.

REPLACING CABLES OR PLUGS

Immediately throw away old cables or plugs when they have been replaced by new ones. It is dangerous to insert the

plug of a loose cable in the wall outlet.

BEFORE OPERATION

For transport the machine has been greased with a layer

which prevents rust. This layer has no greasing function

and has to be removed with clothes. You can do this with a

solvant which is not aggressive, for example turpentine or

petroleum. When you are acquainted with metal-working

machines you can dismantle, control and oil several spare

parts with a light and universel machine-oil, for example

sewing-machine oil (sour free). Afterwards you finish the

complete maintenance table of chapter 14 ‘maintenance’.

ADJUSTMENT

The lathe has been adjusted to a minimum margin by the

factory. Because of transport some adjustments can be

changed. On the other hand the machine has been designed in such a way that any appearing margin can be lifted. This margin is also caused by wear end tear as a consequence of an intensif use. If re-adjustment does not have an effect anymore, the part is worned and has to be moved.

SPARE PART

Spindle tool slide

Tool slide

Spindle cross

slide

Cross slide

Transmission/

starting shaft

Tailstock

LIFTING A MARGIN

Loosen the front lock

nut, distort the back

lock nut clockwise,

until margin is minimum, turn back a

fourth part and tighten

the front lock nut

Loosen the lock nuts,

tightening the

adjusting nuts

clockwise until margin

is minimum, tighten

lock nuts

Watch spindle tool

support

Watch tool slide idem

Loosen front lock nut

and tighten hindmost

lock nut until margin is

no longer noticeable,

turn back a quarter

part and tighten the

front lock nut

Loosen clamping nut,

unscrew both adjusting nuts on both sides

a quarter part.

Move head with

adjusting screws until

the mark signs on the

right side of the head

correspond, tighten

the adjusting screws

again a bit without

moving the head, fixing the clamping nut.

RECOURCES

2 hook

spanners

screw-driver,

open end

wrench

idem

idem

idem

screw-driver,

open end

wrench

4 Ferm

Page 5

48 Ferm

If all preparations have been done the machine can be

connected to the mains by putting the plug into the power

point. Beforehand check if the mains switch is “OFF” and

check if the turning directions is “RIGHT”. Watch the gauge once more and see if the oil level has not changed and if

necessary you have to fill it till the gauge half-full. See that

there is no paper or cleaning-rag for the ventilati on openings of the motor. Check the three-jaw and see that the

basins cannot come out of the jaw.

PUT THE JAW-WRENCH ON A PERMANENT

PLACE!

Open the protection case and check the position

and tension of the belts. For running on trial the lowest turning speed has to be chosen. You may shift the front belt,

watch fig.5 and 15.

Push in the switch and have the machine turned during 20

minutes. Check regularly if the head bearings in the headstock and the motor do not become hot by stopping the

machine and putting a hand on both side of the headstock

and on the motor body. Immediately stop if you hear a deviating noise and if you feel an abnormal heath development( more than handwarm) and first con tact your supplier.

Then switch over to a higher speed and have the machine

also function a few minutes on this speed. Do this again

with a reversed turning direction. If no problems have arisen, the machine is ready for use.

WORKING METHOD

Removing metal takes place by pushing under control a

chisel point or a boring point in the piece of work through

which small pieces of material - chips - are cut away. For

this the piece of work has to make a turning movement between two fixed turning points- the headstock and the tail

stock (watch fig.1) - which lie on a very precise, imaginary

line: the centerline(4). This can be turned off paral lelly to

the centerline over the whole lenght, by carrying the chisel

which has been fixed on the support(5) in a certain tempo

along the turning piece of work. This has to be done in a

straight line, with the hands or automatically with the transmission(6).

For removing material of the piece of work, power is needed. This power is transmitted from the motor to an empty

shaft in the headstock: the main shaft (2). In connection

with the maximum motorcapacity the quantity material

which has to be taken - the chip thickness and the width of

chip- has to be adapted. If the number of revolutions lowers too much, the starting depth or the rate of speed has

to be lowered. Otherwise there is a chance of motor damage, shorter tool life of the chisel or the chisel rupture. The

diameter of the piece of work is also influences this. If you

have a diamter of 100 mm more power is needed for cutting a chip of 1 mm than at a diameter of 10 mm.

When the tail stock (8) is placed next to the centerline because of cross adjustment, an outward conical plane is turned. An extra processing possibility over the lenght axle is

cutting a screw-thread. A special chisel cuts a spiral deepening in the outline of the piece of work. A part of the out-

line keeps on standing and this height difference forms the

ultimate screw-thread. Next to turning over the lenght axle, the ends of a piece of work can also be processed, for

example for making them flat and straight. Short pieces of

work can be fixed at one side in a fixed turning-point, the three-jaw chuck, and on the other side be processed at right

angles to the centerline. The basins of the chuck see to

maintenance of an imaginary centerline. By having occurred the chisel replace ment under an angle by adjustment

of the chuck, inward and outward conical planes can be

turned. With this strain borings can also be made in levelled surfaces. For that a drill chuck has to be bought separately. This drill chuck with morse cone peg has to be installed in the sliding tube (7) of the tail stock. Then the gaps

can be screwn out until the desired depht, diameter and

form.

IMPORTANT:

The precision of the pieces of

work is first and particularly depen dant of expertness and experience. During turning many

factors can influence the end result, like the sort and the

condition of the chisels, the nature of the material you want

to process, the turn and starting speed, the fixation of the

piece of work, the drafting and the condition of the machine. With the MD-350 it is possible to manufacture prolonged pieces of work with a big accuracy, if all circumstances

are perfect.

FOR THE BEGINNING TURNER.

During turning big powers on certain parts can be developed. If you use the machine incorrect these parts can be

damaged or deformed and wear end tear faster, even if

they have been made and designed very expertly and carefully. Through this the accuracy of the machine will decrease strongly, which directly influences the quality and

tahe preciseness of your pieces of work. So it is important

that the apparatus is tended in an expert way. Recommended is, if you are not a skilled turner, to start with simple pieces of work and to try the different possibilities of the lathe

with trial pieces of work. It is instructive to look at skilled turners, because you are not that fast a perfect turner! For pre

venting disappointments you have to become familiar with

the basic principles of turning. Turning is not for nothing a

profession. You can find referencebooks about metal working and metal turning in the library or in a book-shop. Besides model-building magazines write about this subject regularly. The best is getting into possession of a, if need be

obsolete, technical text-book. In this book is told about the

general principles of turning and many things worth knowing and handy summaries of problems with possible

causes and solutions.

FUNCTION OF THE MACHINE.

For a good understanding of the working of the machine

this one can for conve nience sake be divided in a number

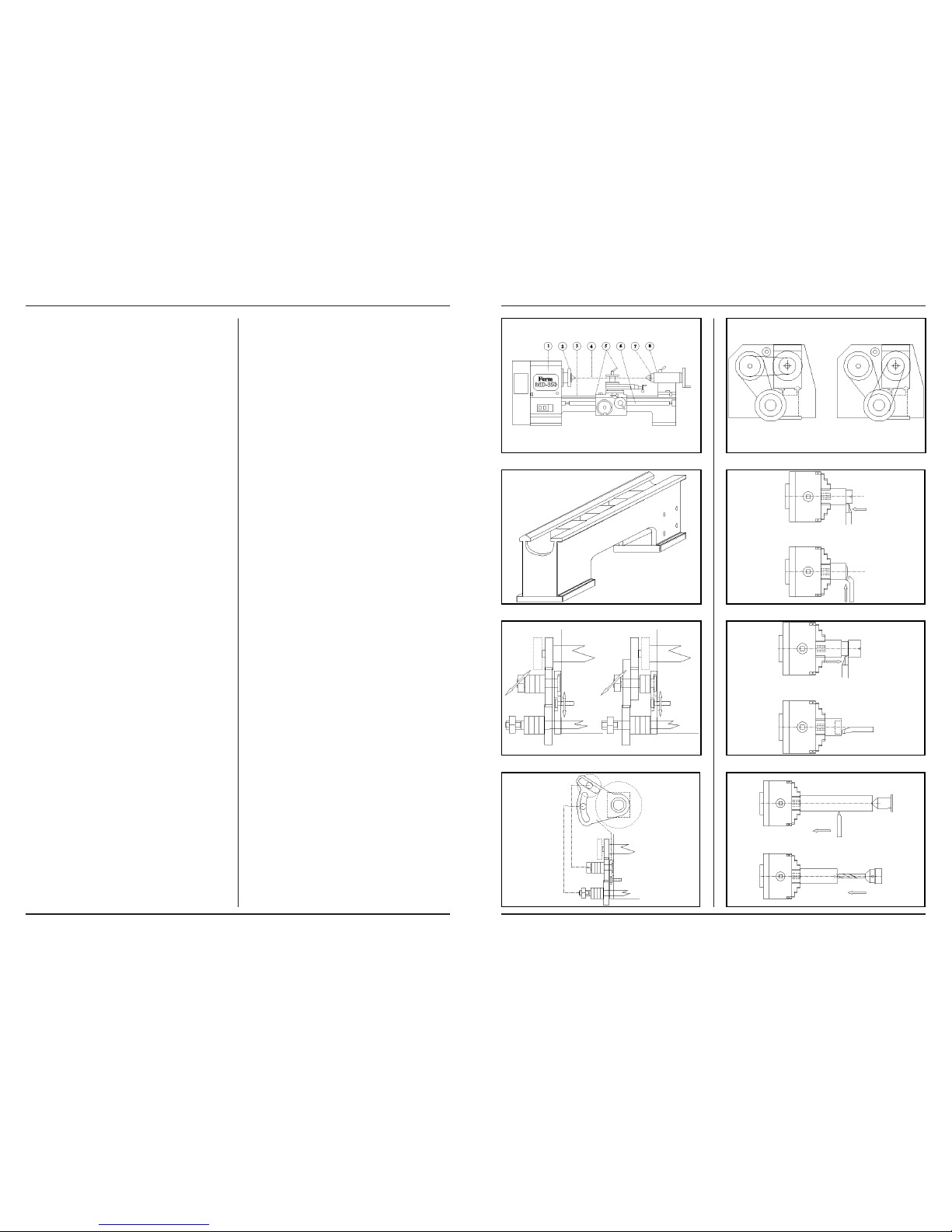

of main groups and components, all with a special function. Watch fig.1.

Ferm 5

Page 6

Ferm 47

THE MACHINE BED

The machine bed connects all these parts and has next to

it also other important functions. The bed (3) has been manufactured of highgrade grey cast iron and it is provided

with several filled cross ties. Because of the design and

the applied sorts of material tremblings are better absorbed and deforming because of charge is minimum. The

bed is provided with two sliding surfaces sharpened very

precisely, for the conducting of support and tail stock. These conduc tings, one prismatic and one flat, see to maintenance of the centerline(4).watch fig.2.

THE MOTOR

The attached alternating current motor is a carbon brushless 1-phase squirrel- cage motor with starting condenser.

The motor is maintenancefree and does not need a special treatment. By means of V-belts and plural belt discs,

the pulleys, the movement of the motor is transmitted to

the mains axis.

THE HEADSTOCK

The poured headstock(1) has been fixed on the bed with a

prism conducting and two face plates. On the back side is

an oil draining nut. The cover is remo vable for inspection

and for putting oil. At the bottom of the head you can find a

system of turning axis and toothed wheels. Because of

these toothed wheels the speed of the main shaft is retarded and transmitted to a double, coaxial output axis. On

this axis you can find the driving gear for the start and the

driving gear for the thread-cutting, watch fig.3. In the head

you can find the most important part of the machine, the

main shaft(2).

This one has been fixed revolving with two conical roller

bearings in an O- drafting. All turning parts in the head are

lubricated by means of an oil bath. The level of this is readable in the window on the front side. The main shaft has

been provided with a going on boring with on the right side

a fixing flange and a morse cone, for respectively the

chucks and the center.

THE SUPPORT

On the sliding surfaces on the bed the support(5) has been

fixed which sees that conducting tools along the piece of

work is checked. First the support consists of a bed slide

with lock case. This slide lies on the bed and serves as movement in the lenght direction. This movement can occur

with the hands or automatically by the transmission/feeding axis(6). In the last case the coach bolt has to be closed in the lock case. On the bed slide a second slide has

been installed which takes care of the chisel movement in

cross direction. By means of a spindle with follow nut this

slide can be moved or adjusted. On the cross slide a chuck

has been installed. With this the upper slide or tool slide

can be adjusted under an angle. The third and upper slide,

tool slide, can be replaced in any desired direction over a

distance of 70 mm and it follows every movement of all underlying slides also the chuck. On top of the tool slide a tool

holder has been installed. In this tool can be exerted to a

point height of maximum 15 mm, the vertical distance to

the centerline. The tool holder has a fourfold absorption

and has an indexing pin with four click points. Through this

can be changed of chisel very fast without having to adjust

again.

THE TAIL STOCK

The end of the centerline is formed by the tail stock (8). The

axis of the fixed and tail stock are exactly in each others extension. Depending on the lenght of the piece of work the

head can be moved over the bed and it can be fixed. With

the slide bush (7), in which a center has to be installed, the

piece of work can be exerted fixed and revolving right on

the centerline. If you turn back the slide bush, the center is

automatically untied. The body of the head has been divided. The upper part can be adjusted sideways with regard

to the upper part by means of adjusting screws. Through

this an adjustment next to the centerline can be obtained.

Normal movements in the lenght direction do not have

side ways adjustments as a consequence.

THE COMBINED TRANSMISSION/STARTING AXLE

For a good surface quality a correct and particularly a constant rate of turnover in the longitudinal direction is important. For longer pieces of work this is almost impossible

with your hands. By closing the lock nut the support is

coupled with the thread on the transmission. When the

transmission has been switched on this one has been

coupled to the main shaft in his turn. With this a coupling is

made with an intermediate wheel between the drive wheel

of the transmission and the drive wheel for the longitudinal

feed on the headstock. This happens because of an adjustment of the change wheel scissors, watch fig. 3 and 4.

At each rotation of the main shaft the support will move itself over a certain distance along the bed. This distance

depends on the wire haste and the chosen wheel change

on the transmission. By chosing another wheel change

the star ting speed can be adapted.

With thread-cutting the same happens in principle, however with a much bigger support movement with a much lower main shaft speed. In this case a coupling has to be made with the thread-cutting driving gear of the headstock.

The positioning of the gear wheels happens by the installation of the rings on the starting axle and intermediate

wheel axle of the scissors. In this case change of the change wheel on the transmission makes possible a choice of

the haste of the thread which has to be cut. On the transmission is no automatic cut out. So switch this one off for

preventing that the chisel runs against the chuck.

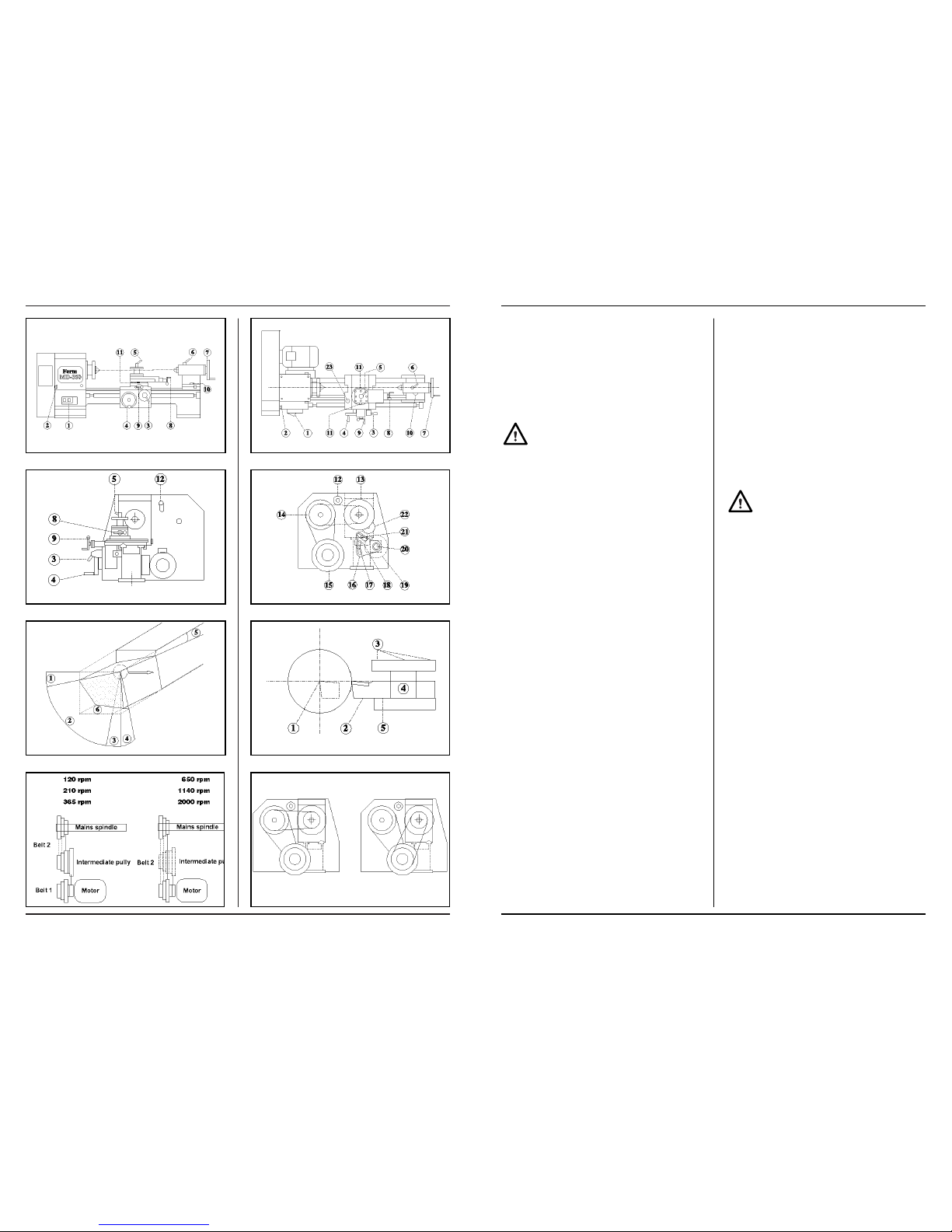

THE DRIVE

Since the applied motor has a fixed and relatively high

number of revolutions the transmission has been done in

such a way that this reduces the numbers of revolutions at

the same time. Besides, with the application of plural pulleys and an intermediate pulley this number of revolutions

is variable in six successive steps.

For lifting up possible belt tension differences the bearingmounted belt pressure roll has been made variable.

Watch fig.5. For reaching the three highest spindle

6 Ferm

Page 7

46 Ferm

speeds the front belt has to be shifted from the intermediate-pulley to the motor pulley. The intermediate gear keeps

driven and serves as flywheel for catching load variations.

BASIC PRINCIPLES OF THE TURNING

Before you can start turning, you have to know the most

important basic under standings. Otherwise there is a

change that the wrong turning speed or the wrong chisel is

chosen. With a number of tables and rules making the machine ready for turning is easier.

CLAMPING

Clamping the piece of work has to happen with care. Put

the piece of work in the chuck as far as possible and clamp

this one with the tightening wrench. If you clamp too hard

the chuck, basins or the piece of work can be damaged.

The same applies for the sliding tube. Tighten this one with

your hands, strong but not by force. Some clamping examples by which also the use of bores and chisel is made

clear, can be seen in fig.6, 7 and 8.

The represented standard three-chuck is self-centring.

Through this the axis of a small piece of work falls exactly

on the centerline, even if the dead centre is not used. With

a chuck belongs an inside basin (represented) and an

outside basin. These ones are used for inside clamping of

bigger diameters. Every basin has in the chuck the same

place. Place and basin are numbered!

In fig.6 a right side cutting chisel (up) and a right bended

roughing tool is used. The arrows indicate the starting direction. The roughing tool can be used in longitudinal direction and in cross direction and is often used for quickly

elimina ting many material. Fig 7. shows the use of a left

side cutting chisel and a blind boring chisel. Fig.8 shows a

clamp with dead center in a tail stock. A pointed chisel has

been used for an egal finish. Under this figure a clamping is

represen ted for making a bore with a spiral drill. Beforehand you have to pre-drill with a center bore. This is a bore

from which the shank is much thicker than the crossing

frog. The boring gap which arises through that serves as a

center gap for both the center and the bore!

OPERATION OF MD-350 AND MD-500

Survey of the operation points with corresponding function (see fig.9,10 11 and 12).

1 Combined on/of direction of rotation switch with

emergency feature blocked.

Switching on the motor and chancing the direction of

stop rotation, the valve kan be blocked with a lock.

2. Drive cupboard closing

For opening and closing of the case

3. Carriage nut handle

By closing the carriage nut, the

automatic starting is

switched on.

4. Handwheel longitudinal adjustment.

For quickly moving the support to the left and to the

right. On the nonius can be written how big the adjustment is in steps of 0,04 mm.

5. Clamping handle tool holder

By unloading the handle the bit block can be turned in

steps of 90 °

6. Clamping handle sliding bush.

For fixing the sliding bush.

7. Handwheel sliding bush

By turning the piece of work can be clamped between

the chuck and the center; also used for boring; on the

nonius can be written how big the adjustment is in

steps of 0.05 mm.

8. Handwheel crank tool slide

for the longitudinal adjustment of the tool slide; on the

nonius can be written how big the adjustment is in

steps of 0.04 mm.

9. Handwheel crank cross slide

for the longitudinal adjustment of the cross slide; on

the nonius can be written how big the adjustment is in

steps of 0.04 mm.

10 Clamping nut tail stock

for clamping the tail stock to the bed; for clamping the

upper part to the bottomplate.

11 Clamping nuts rotary plate

After the desired corner has been adjusted the rotary

plate parts can be clamped on each other with this.

12 V-belt tension roller

Makes it possible to change V-belts, to clamp and shift

them without dismantling the pulleys.

13 Main shaft pulley

Adjusting rotary speed.

14 Intermediate pulley

Adjusting rotary speed.

15 Motor pulley

Adjusting rotary speed.

16 Scissor

for assembling an intermediate change wheel and being able to adjust this in three directions. Coupling

transmission

17 Clamping bolt link adjustment

By adapting the position of the quadrant the intermediate drive wheel and the transmission change wheel

Ferm 7

Annex 5/Anlage 5

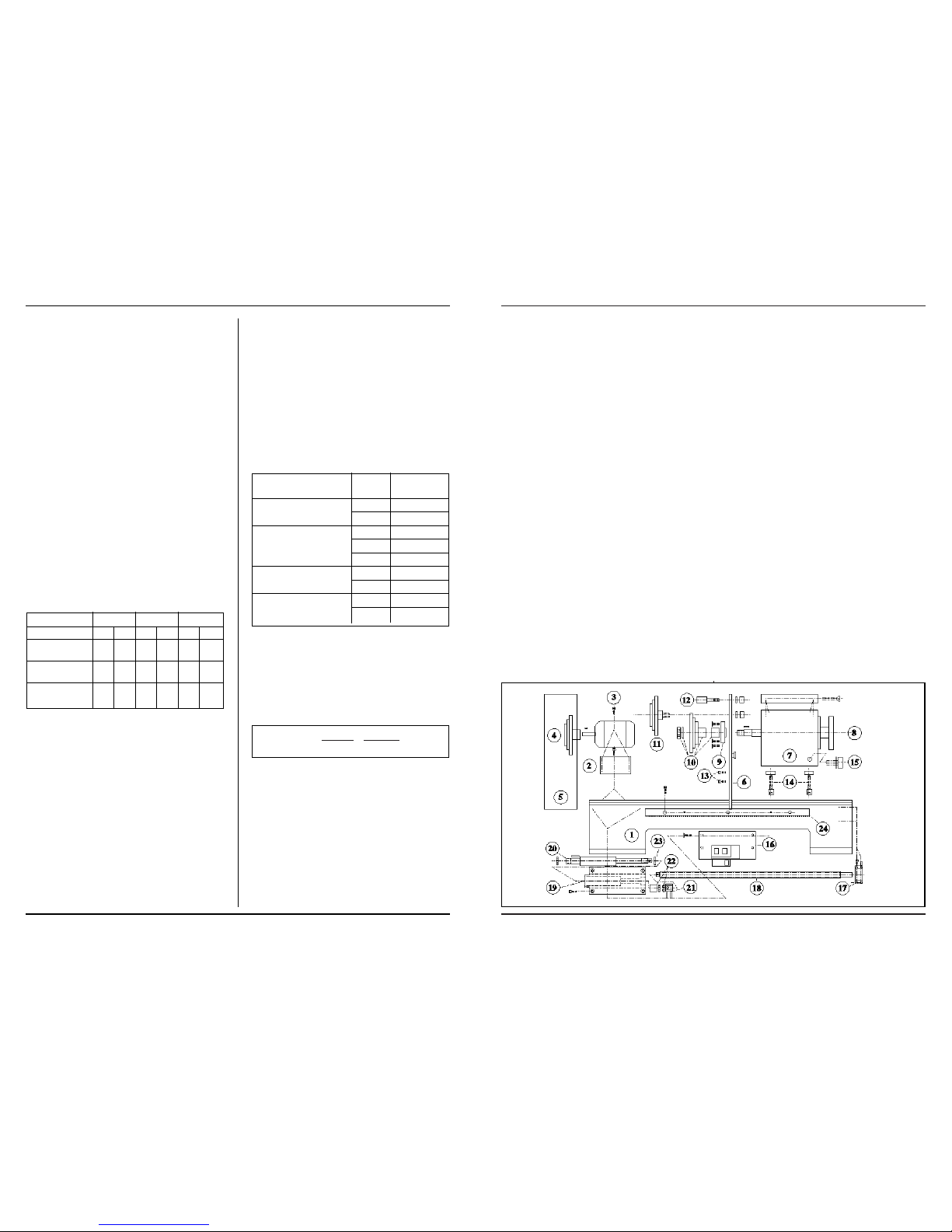

GEAR WHEEL, SPINDLE AND WASHERNUT DATA

ANGABEN ZU ZAHNRAD, SPINDEL UND UNTERLEGMUTTER

Nr. Parts/tooth Pitch/mod. Spec./Dim.

Nr. Zubehörteil/Zähne Gew. St. Bes./Abm.

MAIN SHAFT/HAUPTWELLE

1 Gear wheel/Zahnrad/51 /1 /D8

2 Gear wheel/Zahnrad/68 /1 /D8

3 Gear wheel/Zahnrad/25 /1 /D8

4 Gear wheel/Zahnrad/75 /1 /D8

5 Gear wheel/Zahnrad/76 /1 /D8

6 Gear wheel/Zahnrad/24 /1 /D8

7 Gear wheel/Zahnrad/24 /1 /D8

8 Gear wheel/Zahnrad/76 /1 /D8

9 Gear wheel/Zahnrad/56 /1 /D8

10 Gear wheel/Zahnrad/56 /1 /D8

CHANGE WHEELS/WECHSELRÄDERN

11 Gear wheel/Zahnrad/30 /1 /D8

12 Gear wheel/Zahnrad/42 /1 /D8

13 Gear wheel/Zahnrad/49 /1 /D8

14 Gear wheel/Zahnrad/28 /1 /D8

15 Gear wheel/Zahnrad/63 /1 /D8

16 Gear wheel/Zahnrad/70 /1 /D8

17 Gear wheel/Zahnrad/84 /1 /D8

18 Gear wheel/Zahnrad/98 /1 /D8

19 Gear wheel/Zahnrad/105 /1 /D8

SUPPORT/SUPPORT

20 Gear wheel/Zahnrad/17 /1 /D8

21 Gear wheel/Zahnrad/51 /1 /D8

22 Gear rack/Zahnstange /2 *) /L425

23 Gear wheel/Zahnrad/17 /2 *) /D8

24 Lock nut/Schloßmutter M3/ *) /L30

25 Starting shaft/Anlaufwelle *) /L425

26 Washer nut/Unterlegmutter M2/ *)

27 Spindle/Spindel *)

28 Washer nut/Unterlegmutter M2/ *)

29 Spindle/Spindel *)

TAILSTOCK/REITSTOCK

30 Washer nut/Unterlegmutter M2/ /L27 *)

31 Spindle/spindel /L50 *)

*) This parts are already mentioned in the list op parts.

*) Diese Teile sind bereits im Zubehörverzeichnis erwähnt.

Bijlage 5/Pièce annexe 5

TANDWIEL-, SPINDEL- EN VOLGMOERGEGEVENS

ROUE DENTÉE, BROCHE ET DONNÉES D'ÉCROUS D'ORDRE

Nr Onderdeel/tanden spoed/Mod. bijz./afm.

N° Pièce detachee/N° dents urgence/mod. part./dim.

HOOFDAS/ESSIEU PRRINCIPAL

1 tandwiel/roue dentée/ 51 /1 /D8

2 tandwiel/roue dentée/ 68 /1 /D8

3 tandwiel/roue dentée/ 25 /1 /D8

4 tandwiel/roue dentée/ 75 /1 /D8

5 tandwiel/roue dentée/ 76 /1 /D8

6 tandwiel/roue dentée/ 24 /1 /D8

7 tandwiel/roue dentée/ 24 /1 /D8

8 tandwiel/roue dentée/ 76 /1 /D8

9 tandwiel/roue dentée/ 56 /1 /D8

10 tandwiel/roue dentée/ 56 /1 /D8

WISSELWIELEN/ROUES DE RENVOI

11 tandwiel/roue dentée/ 30 /1 /D8

12 tandwiel/roue dentée/ 42 /1 /D8

13 tandwiel/roue dentée/ 49 /1 /D8

14 tandwiel/roue dentée/ 28 /1 /D8

15 tandwiel/roue dentée/ 63 /1 /D8

16 tandwiel/roue dentée/ 70 /1 /D8

17 tandwiel/roue dentée/ 84 /1 /D8

18 tandwiel/roue dentée/ 98 /1 /D8

19 tandwiel/roue dentée/ 105 /1 /D8

SUPPORT/SUPPORT

20 tandwiel/roue dentée/ 17 /1 /D8

21 tandwiel/roue dentée/ 51 /1 /D8

22 tandheugel/crémaillère /2 *) /L425

23 tandwiel/roue dentée/ 17 /2 *) /D8

24 slotmoer/écrou de verrouillage M3/ *) /L30

25 aanzetas/arbre d'entraînement *) /L425

26 volgmoer/écrou d’orde M2/ *)

27 spindel/broche *)

28 volgmoer/écrou d’ordre M2/ *)

29 spindel/broche *)

LOSSE KOP/CONTRE-POUPÉE

30 volgmoer/écrou d’ordre M2/ /L27 *)

31 spindel/broche /L50 *)

*) Deze onderdelen staan reeds vermeld in de onderdelentabel.

*) Ces pièces détachées sont déjà mentionnées dans le tableau

des pièces

5

Page 8

Ferm 45

can be placed. Switching the transmission on and off.

18 Intermediate change wheel

Direction of rotation transmission; adjusting the transmission ratio

19 Chance wheel transmission.

Adjusting transmission ratio; by means of placing filling rings the wheel can be adjusted in axial

direction(fig.3)

Longitudinal motion support

20 Transmission/lead screw

fixation intermediate change wheel; by means of installing the filling rings he wheel is axial adjustable and

with the lowest shaft nut the wheel is adjustable sideways

21 Intermediate change wheel.

In front of the thread-cutting wheel, behind the starting

wheel

22 Drive gear wheels for start.

by using this clamping device for surfacing and threadcutting the lock nut can stay open and the support

does not slip away; spindle and nut are less charged

then.

23 Clamping bolt cross slide.

CHISELS

During turning a chip is cut out of the piece of work. For this,

chisels have to be sharpened in a special and sharp form.

This form depends on the chisel material and on the material you want to cut. Watch the next table.

On the basis of fig. 13 the corners of this table can be taken

over on a little piece square high-speed steel for making or

re-sharpening your own chisel. In this example we are talking about a straight, right roughing tool. The dotted lines

indicate the original form of the bar. The sum of the angles

1,2 and 3 is always 90°. Angle 1 is the cutting-edge side rake, angle 2 the wedge angle and angle three the clearance

angle. For keeping the friction as low as possible, two extra clearance angles have been sharpened: angle 4 and

angle 6. Besides, a slope angle 5 has been installed. The

arrow indicates the starting direction. The front face is called the minor cutting face. The main cutting face is the part

on which the arrow has been drawn. In this way all possible

chisels can sharpen themselves, by which you have to say

where the main cutting face has to be and what the turning

material has to be.

A perfectly sharpened chisel has to be placed in the tool

holder in the right way now. Fig.14 indicates a correct pla-

cing of a pointed chisel. Point 1 is the center line. The tip of

the chisel has to stand exactly that high. If not, you have to

use bearing plates(5). The chisel always has to be placed

against the block body(4) and cannot extend farther than 1

to 1.5 time the tool shank thickness(2).

It goes without saying that all clamping bolts (3) have to be

tightened strongly.

TURNING SPEED

If the chisel have been sharpened and put, the piece of

work has been clamped well, the speed of the main shaft

has to be adjusted with the V-belts, watch fig. 15 and 16. In

the subjoined table some machining speeds which happen many times are indicated for different sorts of chisels

and materials.

With this table you can chose yourself for any diameter the

right speed. The only thing you have to do is fill in the desired speed in the following formule.

v = cutting speed in meters per minute

d = diameter of the piece of work in mm

n = number of revolutions in revolutions per minute

π = constant, nl. 3,14

Calculation example:

1. A round piece of silver steel of 100 mm has to be turned

with a HSS chisel. You can find in the table that silver

steel has to be turned with 32m/min, v=32

Divide 32.000 by 100 gives a number of revolutions of

320 revolutions per minute. We put belt 2 on the hindmost discs of the intermediate and main shaft pulley.

2. A piece of copper of 10 mm is turned with a HM-chisel.

v=200 and through that “n” comes far above the maximum number of revolutions. The highest number of revolutions can be adjusted. Belt two is layed on the

hindmost disc of the motor and main shaft pulley.

v =

π ¥ d ¥ n =v ¥ 1000

1000 π ¥ d

Turning material Chissel Turning speed

material REV/MIN

Unalloyed structural steel HSS 40 - 60

(9S20k - 60S20k) P10 140 - 160

Alloyed structural steel HSS 32

Tool steel P10 112

(C80= Silversteel)

Cast Iron HSS 40

K10 100

Non-Ferrous HSS 45 - 80

(Cupper, Aluminium) K10 140 - 280

Chisel corners Light cut Normal cut Heavy cut

HSS HM HSS HM HSS HM

cutting-edge

side rake

12 10 10 5 5 0

Clearance

angle

867564

Wedge

angle

70 74 73 80 79 86

8 Ferm

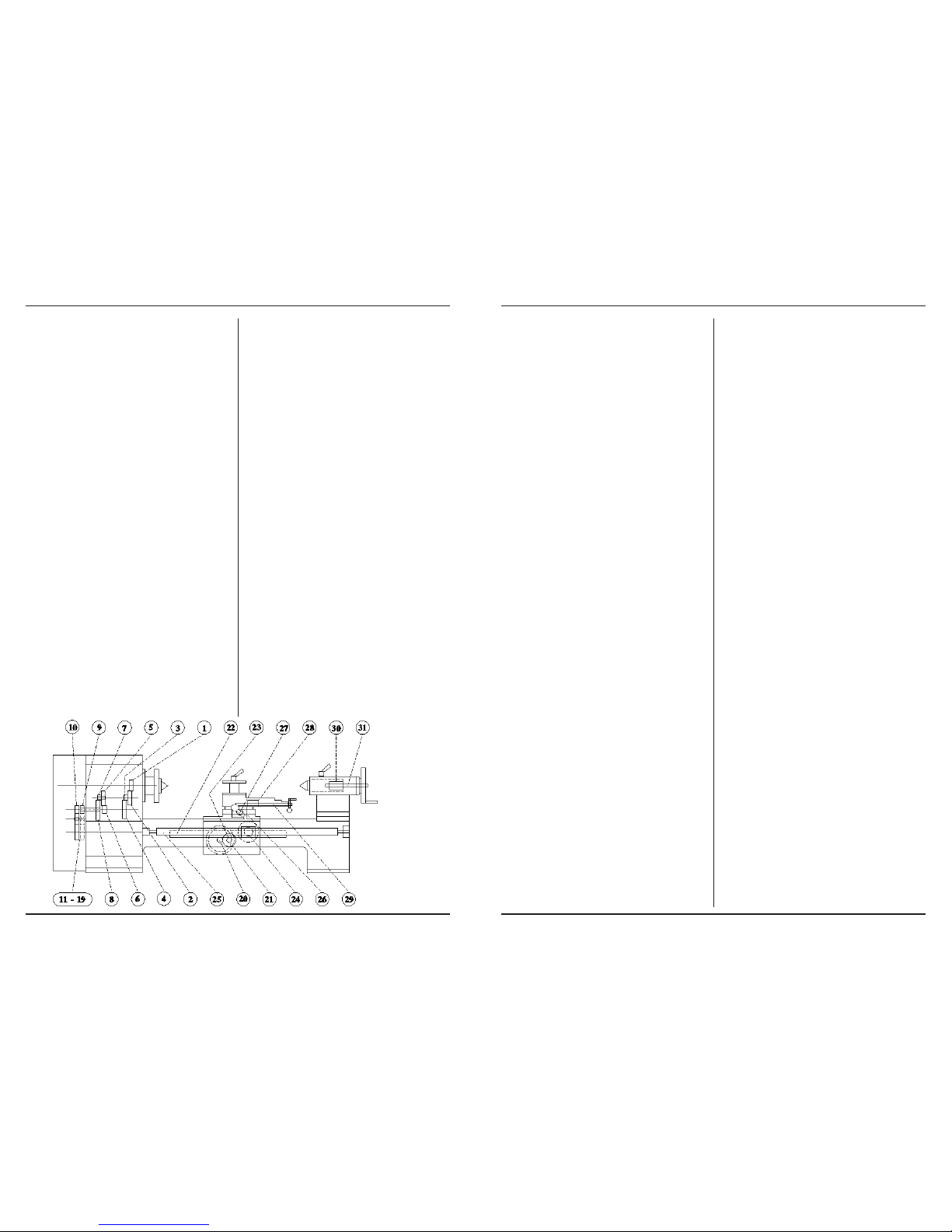

Annex 4

List of parts

BED/HEADSTOCK

Nr. Part

1. Bed

2. Motor base plate

3. Motor

4. Motor pulley

5. Guard

6. Mounting plate

7. Headstock with cover

8. Mains spindle

9. Bearing cover

10. Main spindle pulley

11. Idler

12. Tension pulley

13. Bolts with ring

14. Chuck headstock

15. Oil cup

16. Switch

17. Longitudinal and traerse

motion bearing

18. Longitudinal traverse (lathe

spindle

19. Bearing housing drive shaft

20. Drive shaft longitudinal and

transverse motion

21. Bush

22. Castle locking nuts

23. Axial thrust bearing

24. Gear rack

Anlage 4

Zubehörverzeichnis:

MASCHINENBETT/

SPINDELSTOCK

Nr. Zubehörteil

1. Maschinenbett

2. Motorstellplatte

3. Motor

4. Motorriemenscheibe

5. Schutzkasten

6. Befestigungsplatte

7. Spindelstock mit Deckel

8. Hauptwelle

9. Lagerdecke

10. Hauptwellenriemenscheibe

11. Zwischenriemenscheibe

12. Spannrolle

13. Bolzen mit Ring

14. Spannplatten Spindelstock

15. Ölstopfen

16. Schalter

17. Fördererlager

18. Längsvorschub (Leitspindel)

19. Lagergehäuse Antriebswelle

20. Antriebswelle Fördere

21. Kupplungsschale

22. Kronensicherungsmuttern

23. Axialdrucklager

24. Zahnstange

Bijlage 4

Onderdelenoverzicht

Bed/Vaste kop

Nr.

Onderdeel

1 bed

2 motorstelplaat

3 motor

4 motorpoelie

5 beschermingskast

6 bevestigingsplaat

7 vaste kop met deksel

8 hoofdas

9 lagerdeksel

10 hoofdaspoelie

11 tussenpoelie

12 spanrol

13 bouten met ring

14 spanplaten vaste kop

15 oliedop

16 schakelaar

17 transporteur-lager

18 langsvoeding (leispindel)

19 lagerhuis aandrijfas

20 aandrijfas transporteur

21 koppelbus

22 kroonborgmoeren

23 axiaal druklager

24 tandheugel

Pièce annexe 4

Aperçu pièces détachées:

Banc/Poupée fixe

N° pièce détachée

1. banc

2. plaquette de réglage moteur

3. moteur

4. poulie de moteur

5. boîte de protection

6. plaquette de fixation

7. poupée fixe avec couvercle

8. essieu principa

9. couvercle de roulement

10. poulie de l'essieu principal

11. poulie intermédiaire

12. galet de tension

13. boulons avec rondelle

14. plaques de tension

poupées fixe

15. bouchon de vidange d'huile

16. commutateur

17. roulement de transport

18. avance longitudinale (broche de guidage)

19. arbre d'entraînement de

boîte de roulement

20. arbre d'entraînement transporteur

21. douille de connexion

22. écrous de blocage à créneauxt

23. butée à vis sans fin

24. crémaillère

4

Page 9

44 Ferm

THREAD-CUTTING

Next to the usual turning work you do with the MD-350 you

can also cut screw- thread with this machine. For this special chisel have to be used. The technique of thread-cutting is not very simple. For reaching a correct fit with thread-cutting, both the thread profile and the minor and outside diameter have to be very accurate. Therefore many

turners use existing machine screw taps. Screw plates

can be used in the same way, however a fitting holder has

to be made yourself. Cutting takes place with very low

numbers of revolutions( often 70 revolutions per minute)

or if need be by cranking, turning the main shaft with your

hands.

For the cutting of inchthread, a separate set of gears

is required. This set is not included. This set is available at your dealer under Nr. 330961.

The continuously repeating distance between two permanent points of a screw thread is called the thread haste. If

you are going to cut you always have to adjust this thread

haste. This happens by chosing a certain change wheel

com bination on the scissors. In fig.17 on the left side a

single transmission for thread-cutting is indicated ( a socalled single work) and on the right side a double transmission for the automatical starting is indicated( so-called

double work). Through this the support is moved over a

certain distance during a rotation of the main shaft. In the

headstock two fixed transmission have been builded in,

namely 1 : 4 for thread haste and 1 : 40 for starting, which

decide the number of revolutions of the coaxial datum

axis. From this datum the end transmission has to be calculated. For calculating this some formulas exist, but for

the sake of convenience we already indicated the most

current thread haste dimensions in the subjoined table. All

indicated wheels are delivered automatically with the machine! Installing or adjusting the change wheels happens

by shifting the scissors and the intermediate wheel axle

and by placing the filling rings. Adjust the change cogwheels margin.

Besides, in the table - second column- is mentioned how

the starting size by means of the same change wheels can

be adjusted.

INCH

nABC

48 70 79

40 70 84 79

32 105 98 49

24 98 40

20 70 84 40

16 56 84 40

14 49 105 50

12 49 98 40

11 49 105 39

8 50 105 28

Pitch Starting Nr. of teeth per wheel

(mm) (mm) A B C

0.4 0.04 49 - 105

0.5 0.05 70 - 84

0.7 0.07 70 98 84

0.8 0.08 105 98 49

1.0 0.1 98 - 42

1.25 0.125 84 105 42

1.5 0.15 105 - 28

1.75 0.175 84 98 28

2.0 0.2 49 98 42

2.5 0.25 63 105 28

3.0 0.3 49 105 30

Ferm 9

Annex 3

TRAVERSING SLIDE/APRON

Nr. Part

1. Handwheel lever

2. Socket head screww

3. Spindle Bearing

4. Spindle

5. Spindle nut

6. Castle locking nut

7. Vernier

8. Socket head screws

9. Socket head screws

10. Cross slide base

11. Key

12. Apron

13. Shaft for left and right hand

motion

14. Bearing cover plate

15. Handwheel

16. Bearing cover plate

17. Half nut lever

18. Half nut mechanism

19. Leadscrew and half nut

guide

20. Eye bolts and keys

21. Shaft for left and right hand

motion/ring

22. Bearing with 2 socket head

bolts

23. Gear wheel for left and right

hand motion

Anlage 3

LÄNGSSCHLITTEN/

SCHLOßKASTEN

Nr. Zubehörteil

1. Handradkurbel

2. Inbusbolzen

3. Spindellager

4. Spindel

5. Spindelmutter

6. Kronensicherungsmutter

7. Nonius

8. Inbusbolzen

9. Inbusbolzen

10. Querschlittenunterteil

11. Achsnagel

12. Schloßkasten

13. Welle Längsverstellung

14. Lagerabdeckplatte

15. Handrad

16. Lagerabdeckplatte

17. Schloßmutterkurbel

18. Schloßmuttermechanismus

19. Leitspindel- und Schloßmutterführung

20. Achsnagelinbusbolzen

21. Welle Längsverstellung

22. Lager

23. Zahnrad Längsverstellung

Bijlage 3

LANGSSLEDE/SLOTKAST

Nr. Onderdeel

1 Handwielkruk

2 Inbusbouten

3 Spindellager

4 Spindel

5 Spindelmoer

6 Kroonborgmoer

7 Nonius

8 Inbusbouten

9 Inbusbouten

10 Dwarsslede onderstuk

11 Spie

12 Slotkast

13 As langsverstelling

14 Lagerafdekplaat

15 Handwiel

16 Lagerafdekplaat

17 Slotmoerkruk

18 Slotmoermechanisme

19 Leispindel- en slotmoerge-

leider

20 Spie-inbusbouten

21 As langsverstelling en ring

22 Lager met 2 inbusbouten

23 Tandwiel langsverstelling

Pièce annexe 3

CHARIOT LONGITUDINAL/PALASTRE

N° Pièce

1. manivelle

2. boulons à 6 pans

3. roulement de broche

4. broche

5. écrou de broche

6. écrou de blocage à creneaux

7. vernier

8. boulons à 6 pans

9. boulons à 6 pans

10. chariot transversal

11. clavette

12. palastre

13. réglage longitudinal

14. plaquette de protection de

roulement

15. roue à mains

16. plaquette de protection de

roulement

17. poignée à écrous de verrouillage

18. mécanisme d'écrous de

verrouillage

19. broche glissière et conducteur

20. boulons à 6 pans de clavette

21. essieu de réglage longitu-

dinal

22. roulement

23. roue dentée réglage longitudinal

3

Page 10

R

R

R

R

R

R

Ferm 43

MAINTENANCE

Make sure that the machine is not live when carrying out maintenance work on the benchlathe

Lubricating schedule (watch also fig.18.)

Maintenance of the machine happens for preventing rust

and wear end tear. The maintenance consists mainly of

clearing and oiling. It certainly is not sufficient to handle

only the oil-syringe. Chips and waste of the machine parts

have to be removed very regularly, often more times during turning. Otherwise there is the possibility it lands between moving, slipping and turning parts. For this reason

chips bulldozers on the cross slide have been placed.

watch fig.18.

Critical places are the upper bed sliding surfaces(3), the

thread part on the transmission/starting shaft(18), the

spindles(6, 16), all sliding surfaces and pins of the slidings(7, 16), the bottom plate tail stock (19).

Remove chips with a cloth or a brush. Do not use compressed air, with this you press the chips only farther in the angles. Regularly dismantle chips bulldozers and brush clean

the felt. This normal maintenance of the machine can be

done by the user himself. If the subjoined schedule is

handled for this, making a mistake or forgetting something

is excluded. The machine need not be dismantled. All oiling points are easily attainable. In certain cases it may be

advisable still dismantling the parts of the machine, for

example if many fine chips have landed on the chisel and

cross slide at a certain slide position. In that case the best

you can do is separating the concerning part entirely, cleaning the parts, oiling the parts and putting it together again.

However the part will have to be adjusted again.

TROUBLESHOOTING

At troubleshooting you have to watch first if the lathe is in a

good condition of maintenance. If it is and you cannot find

a demonstrable reason for the troubleshooting, then get in

touch with your Ferm dealer.

ACCESSORIES AND SPARE PARTS

If you would like to ask something about the lathe or other

Ferm products, you can get into touch with your Ferm

dealer. This also applies for repeated orders of spare parts

and/or accessories.

With the MD-350/500 a number of accessories are deliverable from stock.

With this it is possible to equip the machine exactly as you

want. You can order these accessories via your Ferm

dealer.

GUARANTEE

The guarantee conditions can be found on the separately

enclosed guarantee card.

ClEl

■

DECLARATION OF CONFORMITY

(GB)

We declare under our sole responsibility that this

product is in conformity with the following

standards or standardized documents

prEN12840, EN60204-1, EN55014-1, EN61000-3-2,

EN61000-3-3, EN55014-2, EN292-1, EN292-2

in accordance with the regulations.

73/23/EEC

89/336/EEC

98/37/EEC

from 11-02-2000

GENEMUIDEN NL

G.M. Ensing

Quality department

PART

Roller bearing

main shaft

Bearings and

cog wheels of

speed reduction

axles in the

headstock (2)

Bearings V-belt

roller and axle

mediate

Thrust bearing

mission (13)

Change gear

wheels (12)

Gear wheels lock

with gear

rack(15)

Gear wheel

bearings lock

case, lock nut

mechanism (17)

Transmission/

starting axle (18)

Sliding surfaces

off the bed (3)

Support spindles

(8, 16)

All ball nipples

the (5,6,9,14 and

20)

Felt in chips

bulldozers (4)

All remaining

white parts

without cover

layer

TIME/INTERVAL

After first 10 days

after 20 days and

then each 60 days

Annually

Annually

At change or

Weekly

Weekly

Daily

The same

The same

The same

The same

The same

Weekly

Lubricant

Transmission oil

SAE90:

till sight-glass is

half-full(1) or

lowest cog-wheels

just in the oil

The same

Universel gear

The same

Fine lubricating oil

The same

The same

The same

The same

The same

Vaseline

10 Ferm

Annex 2

LIST OF PARTS:

TOOLSLIDE

Nr. Part

1. Clamping screws

2. Clamp lever

3. Tool post

4. Tool post pin

5. Tool slide top

6. Key

7. Adjusting bolt

8. Spindle nut

9. Spindle

10. Sunk key

11. Spindle Bearing

12. Socket head screws

13. Castle locking nut

14. Handwheel lever

15. Vernier

16. Driving plate lock nut

17. Tool slide base

18. Clamping bolt

19. Driving plate base

20. Pin driving plate

21. Cross slide key

Anlage 2

ZUBEHÖRVERZEICHNIS

WERKZEUGSCHLITTEN

Nr. Zubehörteil

1. Klemmschrauben

2. Spannhebel

3. Werkzeughalter

4. Drehstift Werkzeughalter

5. Werkzeugschlitten oberteil

6. Achsnagel

7. Stellbolzen

8. Spindelmutter

9. Spindel

10. Einlegekeil

11. Spindellager

12. Inbusbolzen

13. Kronensicherungsmutter

14. Handradkurbel

15. Nonius

16. Drehplattenklemmmutter

17. Werkzeugschlittenunterteil

18. Klemmbolzen

19. Unterteil Drehplatte

20. Drehstift Drehplatte

21. Achsnagel Querschlitten

Bijlage 2

ONDERDELEN OVERZICHT:

BEITELSLEDE

Nr. Onderdeel

1. Klemschroeven

2. Klemhendel

3. Beitelhouder

4. Draaipen beitelhouder

5. Beitelslede bovenstuk

6. Spie

7. Stelbout

8. Spindelmoer

9. Spindel

10. Inlegspie

11. Spindellager

12. Inbusbouten

13. Kroonborgmoer

14. Handwielkruk

15. Nonius

16. Draaiplaatklemmoer

17. Beitelslede onderstuk

18. Klembout

19. Onderstuk draaiplaat

20. Draaipen draaiplaat

21. Spie dwarsslede

Pièce annexe 2

APERÇU DES PIÈCES

DÉTACHÉES:

CHARIOT PORTE-OUTILS

N° Pièce

1. vis de serrage

2. levier de serrage

3. porte-outils

4. pivot du porte-outils

5. pièce du dessus chariot

porte-outils

6. clavette

7. boulon de réglage

8. écrou de broche

9. broche

10. clavette normale

11. roulement de broche

12. boulons à 6 pans

13. écrou crénelé de blocage

14. poignée de roue à mains

15. vernier

16. écrou de serrage de plaque

17. pièce de dessous chariot

18. écrou de serrage

19. pièce de dessous plaque

tournante

20. pivot plaque tournante

21. clavette de chariot transversal

2

Page 11

42 Ferm

METALLDREHMASCHINE

MD-350 / MD 500

LESEN SIE DIESE GEBRAUCHSANWEISUNG GUT

DURCH, BEVOR SIE DIE METALLDREHMASCHINE

BENUTZEN.

Lesen Sie diese Betriebsanleitung aufmerksam, bevor

Sie die Maschine in Betrieb nehmen. Machen Sie sich vertraut mit der Funktionsweise und der Bedienung. Warten

Sie die Maschine entsprechend den Anweisungen, damit

sie immer einwandfrei funktioniert. Die Betriebsanleitung

und die dazugehörende Dokumentation müssen in der

Nähe der Maschine aufbewahrt werden.

GEBRAUCH

Die Metalldrehmaschine wurde zum Bearbeiten von Eisen- und Nicht-Eisen-Metallen, Kunststoffen und Holz

entworfen und ist für Hobbyzwecke bestimmt.

SICHERHEITSVORSCHRIFTEN

Beachten beim Benutzen von Elek tromaschinen

immer die örtlichen Sicherheitsvorschriften bezüglich Feuerrisiko, Elektroschock und Verletzung.

Lesen Sie außer den folgenden Hinweisen ebenfalls

die Sicherheitsvorschriften im einschlägigen Sonderteil.

Die Hinweise müssen sicher aufbewahrt werden!

SPEZIELLE SICHERHEITSVORSCHRIFTEN.

Bei der Konstruktion der Maschine wurden die Anforderungen an eine sichere Benutzung berücksichtigt. Jede

Veränderung, Anpassung, Umbau oder anderer Einsatz

kann die Sicherheit der Konstruktion aufheben. Außerdem verfällt dadurch die Garantie.

Vor, während und nach dem Arbeiten mit der Drehmaschine müssen eine Anzahl Sicherungsmaßnahmen vorgenommen werden.

Durch das Vorhandensein drehender Teile und scharfer

Gegenstände können sehr ernste körperliche Verletzungen entstehen. Vor allem die Spannbacken des runddrehenden Spannfutters sind sehr gefährlich.

1. Die Drehmaschine wurde entworfen, um widerstandsfähiges Material zu bearbeiten, und somit

in der Lage zu sein, viel Kraft zu entfalten.

Das Berühren drehender Teile ist darum lebensgefährlich. Aus diesen Gründen muß auch das nichtgestattete, ungewünschte oder ungewollte Einschalten der Maschine verhindert werden, zum Beispiel

durch das eingedrückt Blockieren der Notstoppklappe

mit Hilfe eines kleinen Hängeschlosses.

2. Durch die federnde Arbeitsweise des Drehstahls

können Metallteilchen mit großer Kraft in höchst

unerwarteten Momenten geradezu weggeschossen werden.

- Die Beschützung der Augen ist darum auch sehr

wichtig. Machen Sie es sich zur Gewohnheit, um

immer in dem Raum, in dem die Drehmaschine aufgestellt ist, eine speziell erhältliche Sicherheitsbrille zu tragen. Kaufen Sie für sich selbst eine professionelle und getestete Brille, die Sie länger hintereinander tragen können, und für Besucher nötigenfalls eine etwas preiswertere, aber ebenfalls gute

Ausführung.

- Durch einen aufgeräumten Arbeitsplatz vermeiden

Sie zum Beispiel, in die Maschine zu greifen oder zu

fallen, weil Sie über rumfliegendes Material stolpern könnten.

3. Seien Sie sehr vorsichtig beim manuellen Bearbeiten drehender Werkstücke.

- Wenn Sie eine Oberfläche drehend feinschleifen

wollen, nehmen Sie dann ein ausreichend langes

Stück Schleifpapier, das Sie halb um das

Werkstück legen und mit den Enden zu Ihnen.

- Die Enden nie um die Finger wickeln, nie mit der

Hand Schleifpapier auf das Werkstück drücken.

- Durch das Drehen entstehen messerscharfe Rän-

der am Werkstück. Diese Ränder erst mit einer Feile oder einem Abgrater abgraten.

4. Während des Drehens nie mit den Fingern

Drehspäne entfernen

Benutzen Sie hierzu einen aus Draht selbst gefertigten Spänehaken oder kaufen Sie einen professionellen Spänehaken.

5. Falls während des Drehens etwas in oder hinter

das Bett fällt, nie über die drehende Maschine oder

das Spannfutter hinweg greifen.

Immer erst die Maschine abschalten. Sorgen Sie

dafür, daß das Abdeckplättchen auf der Öffnung im

Bett liegt.

6. Gute Beleuchtung verhindert, daß Sie die Maschine von zu nahe bedienen.

- Bei Einsatz von Leuchtstoffröhren muß mit dem

sogenannten stroboskopischen Effekt gerechnet

werden. Hierdurch kann ein sich drehender Gegenstand optisch stillstehen. Eine Lösung ist der Einsatz doppelter Armaturen, wobei eine Phasenverschiebung beider Leuchtstoffröhren zustandegebracht ist.

7. Notstopp.

Wenn sich unerwartet eine gefährliche Situation ergibt, zum Beispiel, wenn ein nicht gut eingespanntes

Werkstück sich während des Drehens zu lösen droht,

können Sie den Notstopp gebrauchen, indem Sie einen leichten Schlag auf den gelben Deckel des Sicherheitsschalters (mit STOP gekennzeichnet) geben. Hierdurch stoppt die Maschine, ohne daß Sie den

Schalterknopf selbst eindrücken müssen.

Deutsch

D

Ferm 11

Annex 1

LIST OF PARTS:

TAILSTOCK/SHEARS

TAILSTOCK

Nr. Part

1. Clamp lever

2. Ball nipples

3. Clamping nut

4. Locking screw

5. Spindle

6. Spindle bearing

7. Handwheel

8. Cover plate

9. Spindle nut

10. Tailstock

11. Sliding bush

12. Bed

13. Clamping bolt

14. Adjusting screws

15. Nut

SHEARS

1. Shears

2. Idler shaft

3. Locking Bolt

4. Spacing ring

Anlage 1

ZUBEHÖRVERZEICHNIS

REITSTOCK/SCHERE

REITSTOCK

Nr. Zubehörteil

1. Spannhebel

2. Kugelnippel

3. Klemmutter

4. Sicherungsschraube

5. Spindel

6. Spindellager

7. Handrad

8. Abdeckplatte

9. Spindelmutter

10. Reitstock

11. Pinole

12. Fußplatte

13. Klemmbolzen

14. Stellschrauben

15. Mutter

SCHERE

1. Schere

2. Zwischenradwelle

3. Klemmbolzen

4. Distanzring

Bijlage 1

ONDERDELEN OVERZICHT: LOSSE KOP/SCHAAR

LOSSE KOP

Nr. Onderdeel

1. Klemhendel

2. Kogelnippels

3. Klemmoer

4. Borgschroef

5. Spindel

6. Spindellager

7. Handwiel

8. Afdekplaat

9. Spindelmoer

10. Losse kop

11. Schuifbus

12. Voetplaat

13. Klembout

14. Stelschroeven

15. Moer

SCHAAR

1. Schaar

2. Tussenwielas

3. Klembout

4. Afstandsring

Pièce annexe 1

APERÇU DES PIÈCES

DÉTACHÉES: CONTREPOUPÉE/CISAILLES

CONTRE-POUPÉE

N° Pièce

1. levier de serrage

2. douilles à bille

3. écrou de serrage

4. vis de blocage

5. broche

6. roulement de broche

7. roue à mains

8. plaque de couverture

9. écrou de broche

10. contre-poupée

11. douille coulissante

12. plaque à pied

13. écrou de serrag

14. vis de réglage

15. boulon

CISAILLES

1.Cisailles

2.Essieu intermédiaire

3.Boulon de serrage

4.Rondelle d'écartement

1

Page 12

SPARE PARTS SURVEY

ONDERDELENOVERZICHT

ZUBEHÖRVERZEICHNIS

APERÇU DES PIÈCES DÉTACHÉES

ACCESSORIES AND SPARE PARTS

ACCESSORY NR FUNCTION

Lower case 330957 with store possibilitiesand cutting

tray

3-Jaw chuck 330955 clamping pieces of work which

are round

4-Jaw chuck 330956 clamping pieces of work which

are not round

Steady rest 330962 turning long pieces of work

Follow rest 330965 turning long and thin pieces of

work

Face plate 330968 Fixing pieces which are not round

Accessories-set 400375 as delivered with machine

Center 400368 MT-3

Center 400369 MT-2

Inside basin 3-jaw 400377 set

Outside basin 3-jaw 400376 set

V-belt tension 400374 complete

Gear rack 400346 steel

Gear rack 400366 synthetic

Inch gear wheel set 330961 Thread cutting

Change wheel scissors 40031 steel

Handwheel 400404 synthetic for longitudinal adjust-

ment

Motor 400336 complete

V- belt 800170 10 x 710 mm

V- belt 800114 10 x 790 mm

V- belt 800197 10 x 890 mm

Switch 400343 complete unit with relay

Transmission/lock nut *)

Slide spindles, slide nuts *)

Ball- and roller bearings *)

Revolving center 330557 MT-2

Drill chuck 13 mm 330240 self-stretching, J2 connection

Drill chuck 16 mm 330250 self-stretching B-18 connection

Adaptor B-18/MT-2 330297 for drill chuck 16 mm

Chisels 10 x 10 mm 331466 5 parts HM, lenght 160 mm

Chisels 12 x 12 mm 331464 5 parts HM, 180 mm

Chisels 16 x 16 mm 331465 5 parts HM, 180 mm

Taper shank drills 332407 9 parts: MT-2: 14.5, 16, 18, 20

and 22 mm.

MT-3: 24, 26, 28, 30 mm.

Taper shank drills 332409 10 parts: MT-2: 14.5, 15, 16, 17,

18, 19, 20, 21, 22 and 23 mm

Morse taper 330180 from MT-4 to MT-3

Morse taper 330185 from MT-3 to MT-2

Morse taper 330190 from MT-4 to MT-2

*) These part are not always in stock. Ask your local Ferm-dealer.

Ferm 41

TECHNISCHE DATEN

Netzspannung 230 Volt

Netzfrequens 50 Hz

Leistungsaufnahme 375 Watt

Körnerspitzenhöhe 110 mm

Körnerspitzen distanz MD-350 350 mm

Körnerspitzen distanz MD-500 500 mm

Max.Drehdurchmesser über bett 200 mm

Max. Drehdurchmesser über Support 115 mm

Durchlaß und Aufnahme Hauptspindel 18 mm, MT-3

Geschwindigkeiten Hauptspindel 6

Umdrehungen Hauptspindel 120-2.000/min

Automatisher Vorschub 11 mm; 0,04 - 0,3

Gewinde schneiden (rechtsum) 11 mm; M0,4 - M3

Abstand Spannklaue Zentrierlinie

Vertikal gemessen 15 mm

Drehteilbewegung 3600

Gradeinteilung Drehteil ± 450

Verschiebung Oberschlitten 70 mm

Querschlitten 115 mm

Längsschlitten 350 mm

Gradeinteilung Schlittenspindeln 0,04 mm

Aufnahme und Windung Reitstockspitze 50 mm; MT-2

Gradeinteilung 0,05 mm

Gewicht MD-350 110 kg

Gewicht MD-500 130 kg

Geräuchspegel L

wa

70 dB(A)

Vibrationspegel 2,8 m/s

2

DIE MD-350 UND MD-500 WIRDEN GELIEFERT IN DIE

FOLGENDE BASISAUSFÜHRUNG.

Die MD-350 und MD-500 werden in der folgenden Basisausführung geliefert: Maschinenbett mit Prismenbett,

Spindelstock mit Hauptspindel und Antrieb für automatischen Längsvorschub und Gewindeschneiden, Reitstock

mit Reitstockspitze und Querverstellung, Elektromotor

mit Start- / Stopp- und Drehrichtungsschalter, Werkzeugschlitten (Support) mit Schloßplatte, kombinierter Längsvorschub, Querschlitten mit Drehplatte und Oberschlitten, Vierfachstahlhalter mit Indexstift, Dreibackenfutter

mit extra Spannbacken und Meßzertifikat, Antriebsschutzkasten, 7 Wechselrädern, 3 Antriebsriemen, 2 Körnerspitzen, 3 Steckschlüsseln, 2 Inbusschlüsseln, Mitnehmerstift und einem Spannfutterschlüssel.

Ohne Untergestell (Artikelnummer: 330957)

INSTALLATION

AUFSTELLRAUM

Da die Maschine zum größten Teil aus Metall gebaut ist,

ist neben gutem Unterhalt die Aufstellung in trockener

Umgebung nötig. Räume können durch unvollständige

oder verkehrte Ventilation, nicht regelmäßiges Heizen

oder durchschlagende Mauern oder aufsteigende Nässe

feucht werden. Kondensation durch Feuchtigkeit auf Metall entsteht durch zu plötzliche Temperaturerhöhung in

einem kalten Raum, zum Beispiel, wenn man in diesem

Raum arbeiten will. Sorgen Sie für eine gleichmäßige

Temperatur.

AUSPACKEN UND AUFSTELLEN.

Die Maschine ist in einer robusten Kiste verpackt, die Sie

in 6 flache, bequem unterzubringende Teile zerlegen können. Diese Teile können Sie für den Fall bewahren, daß

Sie die Drehmaschine transportieren müssen, z. B. zu Reparatur oder Umzug. Nachdem Sie die Kiste geöffnet haben, muß die Drehmaschine von der Palette gelöst werden. Hierzu entfernen Sie zwei Muttern, in jedem Bettfuß

eine. Die Muttern können Sie später erneut gebrauchen.

Zum Hochheben der Drehmaschine sollten Sie mit Rücksicht auf das Gewicht die Hilfe einer zweiten Person in

Anspruch nehmen. Sprechen Sie vorher genau ab, wie

Sie hochheben wollen. Die Drehmaschine sollte am besten ohne Absetzen von der Palette auf den definitiven

Standort gesetzt werden. Sie können die Maschine am

besten bei den Enden des Bettes packen, also nicht an

den Stöcken, Vorschub, Wechselradkasten oder Motor!

Die Maschine wiegt ca. 110 kg. Um das Gewicht zeitweise

zu vermindern, können einige Unterteile erst vorsichtig

entfernt werden, wie der Reitstock, die Drehplatte mit Aufbau und die gußeisernen Riemenscheiben. Die Drehmaschine muß waagerecht und auf einem soliden Untergrund aufgestellt werden. Beim Selbstbau eines Untergestells können Sie zum Beispiel stählerne U-Profile von

ausreichender Länge benutzen, an die Sie eine Fußkonstruktion schweißen oder schrauben. Auch können Sie einen kräftigen hölzernen Unterkasten mit einem verstärkten und flachen Oberblatt benutzen, z.B. einem Stück

Kunststoff-Anrichtblatt. Bedingung ist in jedem Fall, daß

die Konstruktion in allen Richtungen versteift sein muß.

Sie darf weder schlingern, noch durchbiegen oder wackeln.

Die Drehmaschine wird mit zwei M10 Bolzen in den speziellen Löchern in beiden Fußplatten festgeschraubt.

TIP: Um zu verhindern, daß geringe Unebenheiten beim

Festziehen der zwei Bolzen doch noch Spannungen am

Bett verursachen können, können Sie die folgenden Vorsorgemaßnahmen treffen. Sie zeichnen den Platz der beiden Fußplatten und der zwei Montagelöcher an und Sie

montieren zwei Bolzen M10 in den Untergrund. Legen Sie

auf die angezeichneten Stellen eine Lage Epoxyfüllmittel.

Bringen Sie hierauf eine Plastikfolie an. Sorgen Sie dafür,

daß die Bolzen sauber bleiben! Stellen Sie die Drehma-

12 Ferm

Page 13

ENTRETIEN

L’entretien de la machine sert à prévenir la corrosion et

l’usure. Les travaux d’entretien sont principalement le nettoyage et l’huilage. Mais il ne suffit absolument pas d’utiliser exclusivement l’injecteur à huile. Très régulièrement souvent plusieurs fois pendant le tournage - il faut enlever

soigneusement les copeaux et les déchets de la machine.

Sinon il y a le risque qu’ils entrent entre les pièces mouvantes, glissantes et tournantes de la machine. Pour cette

raison des chasse-copeaux ont été montés par exemple

sur le chariot longitudinal. Voir fig.18. Les endroits critiques sont les surfaces de glissement supérieures du banc

(3), la partie filetée du transporteur, l’axe d’avance (18),

les vis (6, 16), toutes les surfaces de glissement et les clavettes des chariots (7, 16), le socle de la contre-poupée

(19).

Vous pouvez enlever les copeaux à l’aide d’un chiffon ou

d’une brosse. N’utilisez pas l’air comprimé qui presserait

les copeaux encore plus loin dans les coins. Démontez régulièrement les chasse-copeaux et nettoyez le feutre à

l’aide d’une brosse. Ces travaux d’entretien normal peuvent être effectués par l’utilisateur lui-même. Si vous utilisez le schéma qui se trouve ci-dessous, les erreurs ou les

négligences sont exclues. Il n’est pas nécessaire de démonter la machine. Tous les points de graissage sont facilement accessibles. En certains cas il pourrait être recommandable de démonter pourtant certaines pièces de la

machine, par exemple si beaucoup de copeaux fins sont

tombés, dans une certaine position du chariot, sur la vis du

chariot porte-outil et du chariot transversal. Dans ce cas-là

nous vous conseillons de démonter entièrement la pièce

en question de la machine, de la nettoyer - en vous servant

maintenant d’air comprimé! - d’huiler et de monter de nouveau les pièces. Il faudra cependant régler de nouveau la

pièce.

Assurez-vous que la machine n’est pas sous

tension si vous allez procéder à des travaux

d’entretien dans son système mécanique.

PANNES

En cas de panne survenue par exemple à la suite de l’usure d’une pièce, contactez votre distributeur Ferm local.

Au dos de ce mode d’emploi, vous trouverez un dessin

des pièces avec les pièces dont vous pouvez renouveler

la commande.

GARANTIE

Pour les conditions de garantie, lisez le certificat de garantie joint à part.

ClE l

■

DÉCLARATION DE CONFORMITÉ

(F)

Nous declarons sous notre propre responsabilité

que ce produit est en conformité avec les normes

ou documents normalisés suivants

prEN12840, EN60204-1, EN55014-1, EN61000-3-2,

EN61000-3-3, EN55014-2, EN292-1, EN292-2

conforme aux réglementations:

73/23/CEE

89/336/CEE

98/37/CEE

dès 11-02-2000

GENEMUIDEN NL

G.M. Ensing

Quality department

40 Ferm

schine auf die angezeichnete Stelle. Benutzen Sie hierzu

die beiden Bolzen als Führung. Lassen Sie das Bett auf

die Folie sacken und das Füllmittel aushärten. Danach

können Sie die Muttern, die auch für den Transport verwendet wurden, auf die Bolzen drehen und festziehen.

ELEKTRISCHE SICHERHEIT

Überprüfen Sie immer, ob Ihre Netzspannung der des Typenschilds entspricht.

AUSTAUSCHEN VON KABELN ODER STECKERN

Entsorgen Sie alte Kabel oder Stecker, unmittelbar nachdem Sie durch neue ersetzt sind. Das Anschließen eines

Steckers eines losen Kabels an eine Steckdose ist gefährlich.

ELEKTRISCHER ANSCHLUß

Nachdem die Maschine endgültig aufgestellt ist, muß ein

Anschluß an die Elektroinstallation erfolgen. Die Drehmaschine ist für das bestehende 230 Volt Wechselstromnetz

ausgelegt und hat kein größeres Vermögen als andere

große Haushaltsapparate mit Motor. Lassen Sie eine

geerdete Wandsteckdose in unmittelbarer Nähe der

Drehmaschine installieren und sorgen Sie dafür, daß das

Elektrokabel der Maschine ohne Knicke oder Spannungen zur Steckdose geführt werden kann. Nötigenfalls

kann ein geerdetes Verlängerungskabel benutzt werden.

Achten Sie aber darauf, daß das Kabel vollständig ausgerollt ist und es nicht im Weg liegt oder hängt.

VOR IN BETRIEBNAHME.

Zum Transport wurde die Maschine mit einer speziellen

rostabwehrenden Lage eingeschmiert. Diese Lage hat

keine schmierende Wirkung und muß mit Lappen entfernt

werden. Sie können dies mit einem nicht agressiven Lösemittel tun, z. B. Terpentin oder Petroleum. Abhängend von

Ihrer Kenntnis von Metallbearbeitungsmaschinen können Sie die verschiedenen Unterteile demontieren, kontrollieren und mit einem leichten Maschinenöl (zum Beispiel säurefreiem Nähmaschinenöl) einölen. Danach führen Sie die komplette Unterhaltstabelle aus Kapitel 13

“Unterhalt” sorgfältig aus.

AUFSTELLUNG

Wenn alle Vorbereitungen getroffen sind, kann die Maschine durch Einstöpseln des Steckers in die Steckdose

ans Stromnetz angeschlossen werden. Kontrollieren Sie

vorab, ob der Netzschalter AUS und die Drehrichtung

ERSATZTEIL

Spindel

oberschlitten

Oberschlitten

Spindel

Querschlitten

Querschlitten

Vorschub/

leitspindel

Reitstock

SPIEL AUFHEBEN

Vordere Sicherungsmutter

lösen, hintere Sicherungsmutter im Uhrzeigersinn

verdrehen, bis Spiel minimal

ist, Vierteldrehung zurückdrehen und vordere

Sicherungsmutter andrehen.

Sicherungsmuttern lösen,

Stellschrauben im Uhrzeigersinn andrehen, bis Spiels

minimal ist.

Sicherungsmuttern anziehen.

Siehe spindel

Drehstahlsupport

Siehe Oberschlitten

Vordere Sicherungsmutter

lösen und hintere Sicherungsmutter andrehen, bis

Spiel nicht mehr merkbar ist,

Viertelschlag zuruckdrehen

und vordere Sicherungsmutter anziehen.

Klemmmutter lösen, beide

Stellschrauben an beiden

Seiten der Fußplatte einen

Viertelschlag losdrehen, Reitstock mit Stellschrauben verschieben, bis die Markierungen auf der rechten Seite

des Reitstocks übereinstimmen, Stellschrauben wieder

leicht andrehen, ohne den

Reitstock zu verschieben,

Klemmutter festklemmen.

RECOURCES

2 hook

spanners

screwdriver, open

end wrench

idem

idem

idem

screwdriver, open

end wrench

Ferm 13

Page 14

MAINTENANCE

Make sure that the machine is not live when carrying out maintenance work on the benchlathe

TABLEAU DE GRAISSAGE (VOIR AUSSI LA FIG.1

PIÈCE

Paliers à rouleaux

de la broche

Paliers et roues

dentées des axes