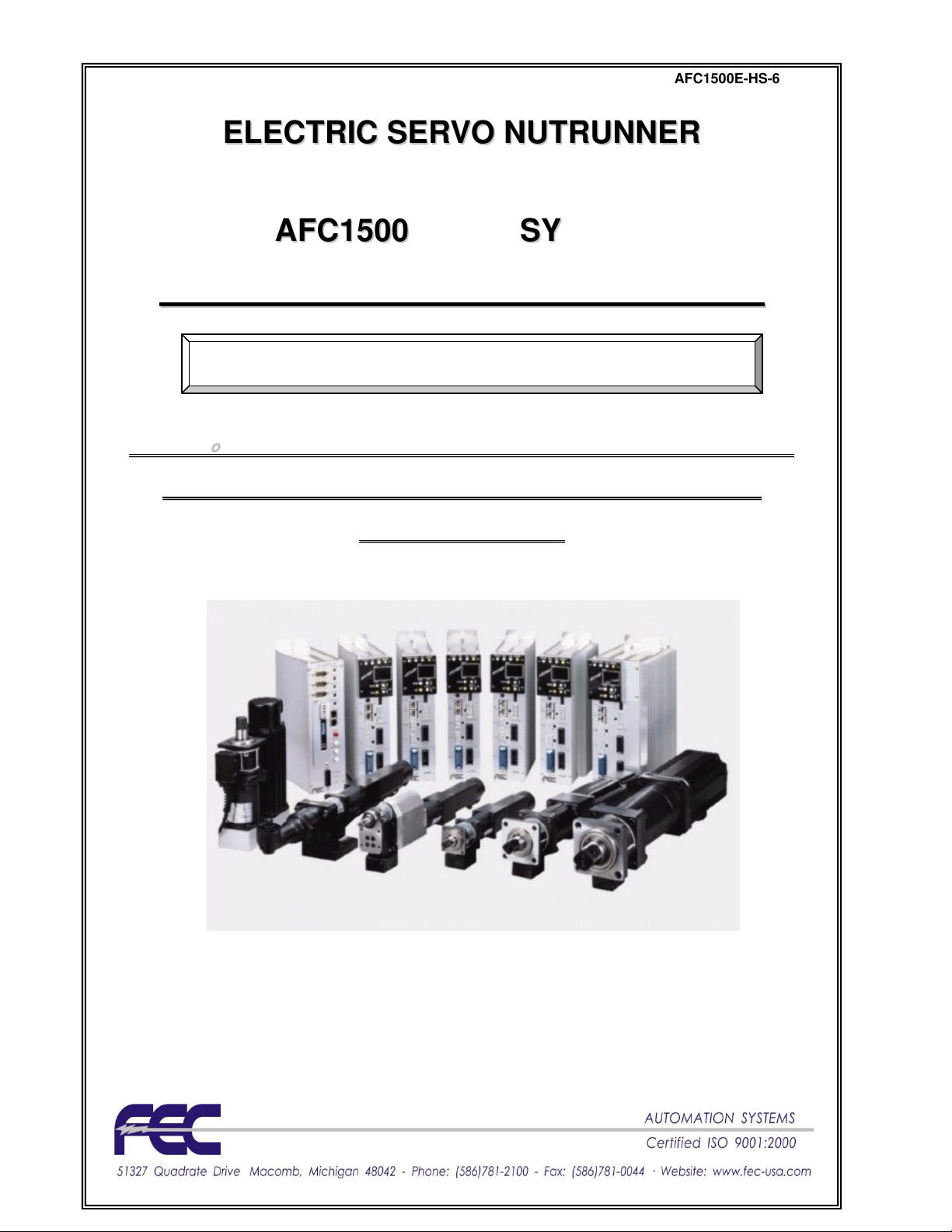

Page 1

SSAANN UUNNIITT OOPPEERRAATTIIOONN M

OOOO

rrrr

iiii

gggg

iiii

nnnn

aaaa

OOOO

rrrr

iiii

gggg

iiii

nnnn

aaaa

UUUU

pppp

UUUU

pppp

EELLEECCTTRRIICC SSEERRVVOO NNUUTTRRUUNNNNEERR

AAFFCC11550000 MMUULLTTII SSYYSSTTEEMM

MAANNUUAALL

SSttaanndd--AAlloonnee && MMUULLTTII TTyyppee

llll

MMMM

oooo

dddd

eeee

llll

ssss

----

SSSS

AAAA

NNNN

2222

----

1111

2222

MMMM

////

SSSS

AAAA

NNNN

2222

----

2222

4444

MMMM

////

SSSS

AAAA

NNNN

2222

----

4444

0000

MMMM

////

SSSS

AAAA

NNNN

llll

MMMM

oooo

dddd

eeee

llll

ssss

----

SSSS

AAAA

NNNN

2222

----

1111

2222

MMMM

////

SSSS

AAAA

NNNN

2222

----

2222

4444

MMMM

////

SSSS

AAAA

NNNN

2222

----

4444

0000

MMMM

////

dddd

aaaa

tttt

eeee

dddd

MMMM

oooo

dddd

eeee

llll

ssss

----

SSSS

AAAA

NNNN

3333

----

2222

4444

MMMM

////

SSSS

AAAA

NNNN

3333

----

4444

0000

MMMM

////

SSSS

AAAA

NNNN

3333

----

dddd

aaaa

tttt

eeee

dddd

MMMM

oooo

dddd

eeee

llll

ssss

----

SSSS

AAAA

NNNN

3333

----

2222

4444

MMMM

////

SSSS

AAAA

NNNN

3333

----

4444

0000

MMMM

////

SSSS

SSSS

AAAA

NNNN

3333

----

2222

4444

HHHH

MMMM

////

SSSS

AAAA

NNNN

3333

----

6666

SSSS

AAAA

NNNN

3333

----

2222

4444

HHHH

MMMM

////

SSSS

AAAA

Sixth Edition October 2009

0000

NNNN

3333

----

6666

0000

1111

AAAA

NNNN

3333

----

1111

HHHH

MMMM

HHHH

MMMM

2222

SSSS

AAAA

NNNN

2222

2222

0000

TTTT

MMMM

////

2222

0000

TTTT

MMMM

////

----

8888

0000

----

8888

0000

SSSS

SSSS

AFC1500E-HS-6

MMMM

////

SSSS

AAAA

NNNN

2222

MMMM

////

AAAA

NNNN

3333

AAAA

NNNN

3333

----

SSSS

AAAA

NNNN

2222

----

----

1111

2222

0000

WWWW

----

1111

2222

0000

WWWW

MMMM

MMMM

1111

2222

0000

MMMM

1111

2222

0000

MMMM

Page 2

WARNING

All applicable national and local codes must be followed when installing and operating the

equipment detailed in this manual.

FAILURE TO ABIDE BY THESE CODES AND THE SPECIFICATIONS DESCRIBED IN THIS

MANUAL CAN RESULT IN SERIOUS INJURY TO PERSONNEL AND/OR DAMAGE TO THE

EQUIPMENT!

Any questions regarding the contents of this document or any related matter should be directed

to FEC INC. at (586) 781-2100, faxed to (586) 781-0044 or emailed to support@fec-usa.com.

The information set forth in the following document is the property of FEC INC.

This document shall not be released to or copied for any person and/or organization

With out the expressed prior consent of FEC INC.

Unauthorized reproduction or distribution of this manual is strictly prohibited.

Please contact FEC INC. if you require additional copies.

Page 3

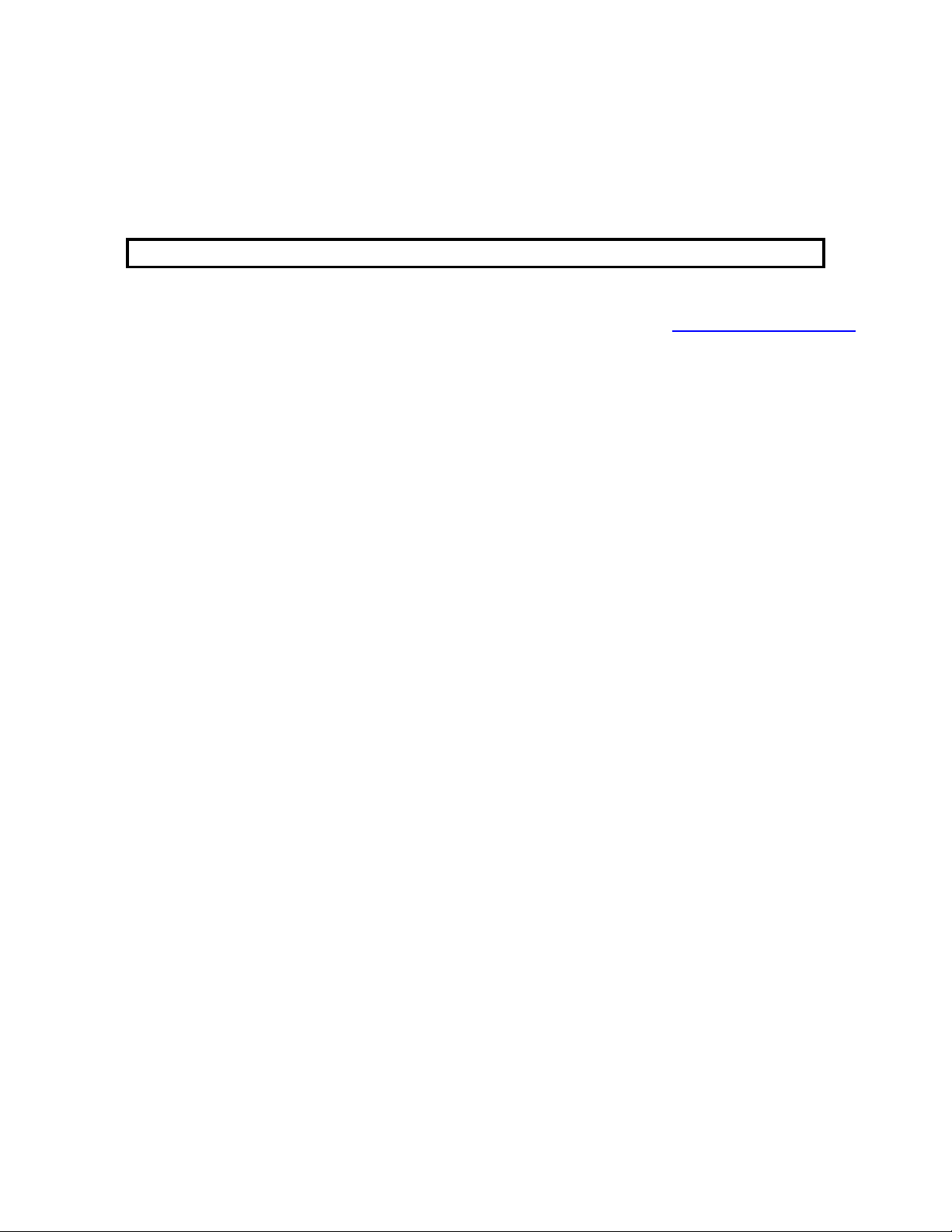

= SAN Unit Hardware Operation

FUSION

FUSIONFUSION

FUSION

= DC Hand Tool

Revision History

Revision

date

1998/01/12 First Edition Original Manual

Manual No. Content of revision

2002/01/12 Second Edition

2003/01/03 Second Edition Corrections to First Update (internally referred to as 3rd edition)

2007/01/30 AFC1500E-HS-4

2008/02/19 AFC1500E-HS-5

2009/10/30 AFC1500E-HS-6

DSP1500

DSP1500 = Servo Press

DSP1500DSP1500

DSP1500

DSP1500 = Servo Press

DSP1500DSP1500

AFC1500

AFC1500 = Nutrunner

AFC1500AFC1500

AFC1500

AFC1500 = Nutrunner

AFC1500AFC1500

FUSION

FUSION = DC Hand Tool

FUSIONFUSION

EEEE = English Version

SSSS = Spanish Version

****Japanese Version furnished by DDK

uses DDK numbering convention.

First update

First major revision.

Combination of SAN2 and SAN3 Servo Drive into a single Manual.

Combination of Stand-Alone and Multi Unit operation into a single Manual.

Updated for SAN3-24HM & SAN3-60HM models (High Speed motors)

Updated power consumption specifications

Updated for SAN3-DP1 &DP2 (including RTC setup for this)

Updated for special Dual Transducer setup

Various text, notes & edits

Manual Numbering Convention

AFC1500E-HS-6

Version Number

(Major Revision Level)

HS

HS

HSHS

Manual

HM

HM = Multi / Main Unit Hardware

HMHM

Operation Manual

HM

HM----ENET

ENET = Ethernet Manual for

HMHM

ENETENET

Multi / Main Unit

SW

SW = Software Manual

SWSW

Page 4

Introduction

Thank you for purchasing our Electric Servo Nutrunner - AFC1500 System.

This instruction manual describes the procedures for installation, wiring, and handling, and actions

to be taken in case of any failure.

◆

This instruction manual shall be delivered to the end user who operates the equipment.

◆

Read all instructions before use, and always keep this instruction manual with the equipment.

◆

Items not described in this instruction manual shall be considered “unavailable”.

◆

The product specification and appearance described in this instruction manual is subject to change

without notice.

◆

All rights reserved. Any disclosure, copying, distribution, or use of the information contained herein for

other than its intended purpose, is strictly prohibited.

◆

It is important for you to read all “Safety Precautions” before using the equipment, and

understand and observe all instructions and recommendations included in this manual.

◆

Read all instructions and recommendations included in this manual, understand the functions

and performance of this nutrunner, and correctly use this machine.

◆

Wirings and parameter settings shall only be conducted by a qualified professional.

◆

Never conduct a withstand voltage test or insulation resistance test on this equipment.

◆

Indicate the following on all instruction manuals that use this equipment.

”This equipment is capable of high voltages hazardous to human life.”

Please confirm the followings when unpacking this equipment.

◆

Ensure that you received the correct model, as ordered.

◆

Ensure that there are no missing parts.

◆

Check for any damage caused during transportation.

For the safety of operator and equipment

Points to check when unpacking

Page 5

Introduction

Warranty Period

FEC Inc. warrants that the equipment manufactured by it and delivered hereunder will be free of

defects in material and workmanship for a period of twelve (12) months from the date of placing the

equipment in operation, or eighteen (18) months from the date of shipment, or 500,000 machine

cycles - whichever shall first occur.

Provision of warranty

Should any failure to conform to this warranty be reported in writing to the company within said

period, the company shall at its option, correct such nonconformity by suitable repair to such

equipment or furnish a replacement part from FEC or an FEC approved facility, provided the

purchaser has stored, installed, maintained and operated such equipment in accordance with good

industry practices and has complied with specific requirements & recommendations of the

company. Accessories or equipment furnished by the company shall not be liable for any repairs,

replacements or adjustments to the equipment or any costs of labor performed by the purchaser or

others without the company's prior written approval.

The effects of corrosion, erosion and normal wear and tear are specifically excluded from the

company's warranty. Performance warranties are limited to those specifically stated within the

company's proposal. Unless responsibility for meeting such performance warranties are limited to

specified shop or field tests, the company's obligation shall be to correct in the manner and for a

period of time provided above.

THE COMPANY MAKES NO OTHER WARRANTY OR REPRESENTATION OF ANY KIND

WHATSOEVER, EXPRESSED OR IMPLIED, EXCEPT THAT OF TITLE, AND ALL IMPLIED

WARRANTIES, INCLUDING ANY WARRANTY OF MERCHANTABILITY AND FITNESS FOR A

PARTICULAR PURPOSE, ARE HEREBY DISCLAIMED.

Correction by the company of nonconformity's, whether patent or latent in the manner and for the

period of time provided above, shall constitute fulfillment of all liabilities of the company for such

nonconformity's, whether based on contract, warranty negligence, indemnity, strict liability or

otherwise with respect to, or arising out of such equipment.

The following are defined as non-warranty situations that are outside the scope of warranty

provided;

• Product is out of the warranty period as determined by FEC serial number tracking.

• Any cause external to the equipment, including but not limited to any act of God, lighting or power

surges, abuse, negligence, accident or failure to maintain the proper operating environment.

• Use of equipment or adjustments or devices not approved by the manufacturer and FEC.

• Cosmetic damage to unit or any of the parts

• Consumable parts - for example; sockets, rest/wear pads, bushings, etc.

• Physical damage (example - damage caused by dropping, cut cables, etc.)

• Field Service required on a Warranty Part - FEC warranty covers the parts and labor only onsite

at FEC.

Extended warranties are available as an addition to the standard warranty period outlined above - for all

FEC Inc. systems. Please contact FEC if you are interested in an extended warranty.

Warranty

Page 6

ead all instructions before operating the

manual carefully

Safety precautions in this manual

To prevent danger to the user and other persons as well as property damage

with the symbols

This instruction manual uses the

caused when the instruction is not observed.

nstructions that are marked with

marked with the above symbols

marked with

the following additional

This symbol indicates that failure to observe instr

with this symbol

This symbol indicates that failure to observe instruction marked

with this symbol

damage.

Electric shock

Fire

Safety Precautions

equipment safely and

the equipments functions, safety

are marked with two symbols

nstruction

two symbols according to the degree of damage that may be

may result in severe damage

. For your safety, f

that shall be observed.

may result in severe personal injury or death.

personal injury or

F

ire

Electric shock

Caution:

High Temperature

R

Prior to use, read this instruction

precautions and instructions.

[Caution].

observed are marked

◆

Even i

observed according to conditions.

Warning

Caution

equipment in order to use this

below.

following

and fully understand

may result in minor

Caution

, i

correctly.

[Warning] and

s that must be fully

uction marked

material

if they are not

Contents

instructions and especially those

◆

This instruction manual uses

Warning:

Caution:

Prohibited

Required

are very important instructions

these symbols.

symbols for instructions

Warning:

Caution:

Do not disassemble

Ground

ollow all

Page 7

and gear case

output spindle may rotate and cause injury.

Do not repair, disassemble, or modify the equipment

this instruction may cause

Never operate the equipme

Failure to observe

Keep fingers away from the

the equipment is turned OF

operation and maintenance work shall be conducted by a

this instruction may cause

Turn OFF the power when conducting wiring operation

this instruction may cause

damage the cables, apply excess

Never use damaged cables.

this instruction may cause

3 grounding of FG terminals.

this instruction may cause

abnormal odor, noise, or operation error

source.

device

this instruction may cause

emergency stop circuit

Failure to observe

Keep away from the equipment

fter

this instruction may cause

Safety Precautions

individual components of the system.

injury, electric shock, fire, and malfunction.

atmosphere

for a while after

electric shock

professional.

the cables.

stop operation

injury and fire.

peration

, and

suddenly restart.

Warning

Do not remove the motors

The tool

Failure to observe

or flammable gases.

Wiring

Failure to observe

Failure to observe

Never

Conduct type Failure to observe

Failure to observe

In case of an

and turn OFF the power

Install a Power shutdown

Failure to observe

Install an

promptly.

measures are conducted a

Failure to observe

s of tools while power is applied..

nt where it is exposed to water, near a corrosive

this instruction may cause fire.

connectors while the equipment is turned ON and

F. Failure to observe this instruction may cause

qualified

electric shock and injury.

and maintenance.

electric shock and injury.

stress to cables, or squeeze

electric shock and fire.

electric shock.

occurrence,

Failure to observe this instruction may cause

in order to ensure the safety of equipment.

injury.

on the outside of equipment in order to stop o

this instruction may cause injury.

during recovery from a temporary blackout

restarting the equipment. The equipment may

injury.

.

.

immediately

ensure safety

Page 8

Transport the equipment properly according to its weight.

this instruction may cause

The conditions when transporting the equipment by ship is as below.

-

0% RH or lower

Rust prevention measure: Apply grease or oil on tools.

this instruction may cause

Do not hold cables and output spindles when t

this instruction may cause

indictor on the

The indicator may come off and drop from the front panel.

this instruction may cause

The equipment shall be stored under the following conditions.

-

Ambient humidity: 90% RH or lower

Indoors (Avoid direct sunlight)

corrosive gases or flammable gases

No oil mist, dust, water, salt, iron powder

Avoid direct vibration or shocks

this instruction may cause

Safety Precautions

Transportation / Storage

Caution

Failure to observe

injury and malfunction.

◆

Ambient temperature:

◆

Ambient humidity: 5

◆

Package: Tight seal

◆

Failure to observe

Failure to observe

Do not hold the

5°C~+55°C (Avoid freezing)

(Avoid moisture)

earth leakage and malfunction.

ransporting the tools.

injury and malfunction.

front panel when transporting the AXIS Unit.

Failure to observe

injury and malfunction.

◆

Ambient temperature:

◆

◆

Atmosphere:

◆

Failure to observe

No

5°C~+55°C (Avoid freezing)

(Avoid moisture)

earth leakage and malfunction.

Page 9

where they can bear the maximum torque

this instruction may cause

inside the control panel using the specified screws.

this instruction may cause

Use the specified tool for the AXIS

this instruction may cause

Unit shall

this instruction may cause

ventilation hole

from entering

this instruction may cause

The power source shall be provided with safety measures

Failure to observe

(SAN)

this instruction may cause

get on the top of equipment or do not place heavy

this instruction may cause

equipment

this instruction may cause

Conduct wirings properly and firmly.

this instruction may cause

Operate the equipment within the specified power supply voltage

this instruction may cause

When operating the equipment in the following conditions,

electrical

where the equipment is subjected to

power wire.

this instruction may cause

Safety Precautions

Installation / Wiring

during operation.

and

fire and malfunction.

on the top of equipment.

, and malfunction.

hock, fire, and malfunction.

measures

magnetic field

injury, false operation, and malfunction.

Caution

Install all tools firmly

Failure to observe

Install the AXIS Unit firmly

Failure to observe

Failure to observe

The AXIS (SAN)

Failure to observe

Do not block the

Avoid any foreign body

Failure to observe

Failure to observe

circuit protectors.

Do not use tools or AXIS

Do not

Failure to observe

Do not subject the

Failure to observe

Failure to observe

Failure to observe

to shield the equipment.

◆

Location where

◆

Location

◆

Location near a high

Failure to observe

injury and malfunction.

malfunction.

(SAN) Unit.

fire and malfunction.

maintain the specified distance from other devices.

fire and malfunction.

of the AXIS (SAN) Unit.

inside the equipment.

fire and malfunction.

this instruction may cause

Units that are damaged or missing parts.

fire, injury, and malfunction.

injury, and malfunction.

to excess shock and impact.

malfunction.

injury, false operation

injury, electric s

noise is generated

a strong electric field or

such as breakers

objects

take sufficient

.

Page 10

Never operate the equipment with wet hands.

this instruction may cause electric shock.

Keep fingers away from the

is turned ON or for a while after the equipment is turned OFF. These parts may become very

this instruction may cause burns.

Use the equipment under the following conditions.

0°C

Ambient humidity: 90% RH or lower

Indoors (Avoid direct sunlight)

corrosive gases or flammable gases

No oil mist, dust, water, salt, iron powder

Avoid direct vibration or s

this instruction may cause

ll parameters before operation

movement of the equipment.

this instruction may cause injury,

adjustments or setting changes that may cause instability of

this instruction may cause injury,

The equipment may restart suddenly

Always ensure that the start signal is OFF before resetting the equipment.

instruction

Do not turn ON and OFF the equipment repeatedly.

instruction

equipment at torque higher than

Failure to observe this instruction may shorten

due to the high temperature caused by overload.

mality occurs,

and restarting the equipment.

Failure to observe this instruction may cause injury.

Safety Precautions

Operation

/ Adjustment

tool motors while the equipment

in order to prevent unexpected

and malfunction.

and malfunction.

is reset with the start signal ON.

or cause malfunction

remove the cause and ensure safety before resetting

Caution

Failure to observe

AXIS (SAN) Unit radiating fin and

hot. Failure to observe

◆

Ambient temperature:

◆

◆

Atmosphere:

◆

Failure to observe

Confirm and adjust a

Failure to observe

Never conduct extreme

Failure to observe

Failure to observe this

Failure to observe this

Do not use the

In case any abnor

No

~

+45°C (Avoid freezing)

(Avoid moisture)

hocks

earth leakage and malfunction.

when the equipment

may cause injury.

may cause malfunction.

the maximum torque.

equipment life

false operation

false operation

operation.

Page 11

Table of Contents

Chapter 1: Outline

1-1

Chapter 2: Specifications

2-1

Chapter 3: System Description

3-1

Chapter 4: System Setup and Wiring

4-1

1.1 About This operations manual 1-2

1.2 Features 1-3

1.3 Functions 1-5

1.4 System requirements 1-7

2.1 Main Specifications 2-2

2.2 Duty Cycle Calculation 2-3

2.3 SAN Unit Specifications 2-4

2.4 Capability. 2-5

2.4.1 Nutrunner Tool Specification Table 2-6

2.4.2 Nutrunner Decimal Point Display Table 2-7

3.1 System Block Diagram 3-2

3.1.1 Multi System Block Diagram Description 3-2

3.1.2 Stand Alone System Block Diagram Description 3-4

3.2 AFC1500 SAN UNIT Front panel 3-6

3.2.1 AFC1500 Front Panel Switches and Connectors 3-6

3.2.2 AFC1500 Status LED and Bypass Switch Description 3-7

3.3 AFC1500 Keyboard-Display description - SAN DP1/DP3 3-8

3.4 AFC1500 Keyboard-Display description - SAN DP2/DP4 3-9

3.4.1 SAN-DP2/DP4, SAN3-DP1/DP2 Serial Pin out 3-9

3.4.2 SAN DP2/DP4, SAN3-DP1/DP2 Communication Protocol 3-10

3.4.3 SAN DP2/DP4, SAN3-DP1/DP2 Communication Format 3-10

3.4.4 SAN DP2/DP4, SAN3-DP1/DP2 Communication Format Description 3-11

3.4.5 Cable Connection to SAN DP2/DP4, SAN3-DP1/DP2 3-12

3.5 Nutrunner (Tool) Unit 3-13

Page

4.1 Design and Build Procedure 4-2

4.2 Component Dimensions 4-3

4.2.1 SAN Controller Unit Dimensions 4-3

4.3 Unit Arrangement 4-4

4.4 Nutrunner (Standard Tool) Dimensions 4-5

4.4.1 Straight Tool 4-5

4.4.2 Offset Tool 4-7

4.4.3 High Speed Tool – SA Version 4-8

4.4.4 High Speed Tool – SS Version 4-9

4.4.5 Mounting Plate Design Requirements 4-10

4.4.6 Locating Procedure for Fixtured Multi-Spindled Powerhead 4-10

4.5 Wiring Diagrams 4-12

4.6 Power Requirements and Connections 4-13

4.6.1 SAN 4-13

4.6.2. Calculating Circuit Protection 4-14

4.7 Wiring PLC I/O 4-15

4.7.1 Explanation of SAN Unit I/O 4-16

4.7.2 Work / Parameter Select Table 4-18

4.7.3 Bank Select Table 4-19

4.7.4 Bank Output Servo Error Table 4-21

Page 12

4.7.5 PLC Wiring Sample 4-22

Chapter 5: Power Up and

Initial Checks

5-1

Chapter 6: Fastening Instructions

6-1

Chapter 7: System Operations

7-1

4.7.6 Synchronized Fastening Operation(Without MULTI UNIT) 4-23

4.7.7 Signal Timing Chart 4-24

4.8 RS-485 Data communication ports. 4-26

4.9 MON. Connector -Torque/Angle/Current/Speed OUTPUT 4-27

4.9.1 Monitoring connector Output Circuit. 4-28

4.10 SAN Unit DIP Switch setting. 4-29

4.10.1 SAN Unit DIP switch positions 1 ~ 3 4-29

4.10.2 SAN Unit DIP switch positions 4 ~ 8 4-30

4.11 Tool Connection (cabling) 4-31

4.11.1 Cable Installation Guidelines 4-32

4.11.2 Considerations for Cable Trolleys 4-33

4.11.3 Considerations for Flexible Cable Tracks 4-33

4.11.4 Considerations for Cable Trays and Ladders 4-33

4.11.5 Preamplifier connector. 4-34

4.11.6 Motor connector 4-34

4.11.7 Resolver connector 4-35

4.12 Firmware Flash Connector (CN8). 4-36

5.1 Before Powering On 5-2

5.2 Initial Data Setting 5-3

6.1 Fastening Control 6-2

6.1.1 Torque Control Method 6-2

6.1.2 Angle Control Method 6-6

6.2 Monitoring Functions 6-12

6.2.1 Peak Torque Monitoring 6-12

6.2.2 Final Torque Monitoring 6-14

6.2.3 Angle Monitoring 6-16

6.2.4 Point-to-Point Torque Rate Monitoring 6-18

6.2.5 Time Monitoring 6-20

6.3 Speed Functions 6-21

6.4 Reverse Functions 6-23

6.5 Torque Recovery 6-24

6.6 Added Functions 6-25

6.6.1 Current Monitor / Control 6-25

6.6.2 Offset Check / Offset Correct 6-26

6.6.3 Angle Correction 6-26

6.6.4 One Pulse Reverse Function 6-26

6.6.5 Quarter Torque Recovery 6-27

6.6.6 Reduced Fastening Reaction 6-27

6.6.7 Varispeed 6-27

6.6.8 Rundown Revolution Limits 6-28

6.6.9 Torque Inhibit Function 6-28

6.6.10 Fastening End by Self Check Off Signal 6-28

7.1 AFC1500 Detachable Display and Programming unit operation. 7-2

7.1.1 Manual Fastening controls for Display Programming (DP) Unit 7-2

7.1.2 Fastening Preset Results Display 7-3

7.1.3 Fastening Presetting / Result Display Controls 7-3

7.2 Run State Modes. 7-4

7.2.1 Display indication modes. 7-4

Page 13

7.2.2 Real-time display indication mode. 7-5

Chapter 8:

Maintenance and Inspection

8-1

Chapter 9: Troubleshooting

9-1

7.2.3 Fastening results display mode. 7-6

7.2.4 Parameter display mode 7-7

7.2.5 Parameter Data List 7-9

7.2.6 Status Display 7-22

7.3 Download / Setup Mode Operation. 7-23

7.3.1 Download Mode selection 7-23

7.3.2 Setup Mode selection 7-24

7.3.3 Parameter # Selection. 7-25

7.3.4 Data # selection 7-26

7.3.5 Data Edit Mode Operation 7-27

7.3.6 Parameter Copy 7-28

7.3.7 I/O Enable (Stand Alone or Multi Configuration) 7-29

7.3.8 Dual Transducer Set-up 7-30

8.1 Inspection Items 8-2

8.1.1 Nutrunner (Tool) 8-2

8.1.2 Spindle Assembly 8-2

8.1.3 Homerun cables 8-2

8.1.4 SAN unit 8-3

8.1.5 Air Handling Units (Air Conditioner, Heat Exchanger, etc.) 8-3

8.2 Basic operational tests 8-4

8.2.1 Torque transducer. 8-4

8.2.2 Resolver. 8-4

8.2.3 Motor. 8-4

8.2.4 Transmission Disassembly and Inspection 8-6

8.3 Replacements 8-9

8.3.1 SAN Unit Replacement 8-9

8.3.2 Replace Nutrunner (tool) 8-10

8.3.3 Replace Homerun cables 8-10

9.1 Abnormal Conditions. 9-2

9.2 Torque Transducer Origin Error, Cal Check Error. 9-3

9.2.1 Code 1-0 Torque transducer / Zero Voltage error. 9-3

9.2.2 Code 1-1 Torque transducer / Cal Voltage error. 9-3

9.2.3 Code 1-2 Torque transducer / Zero check error. 9-3

9.2.4 Code 1-3 Torque transducer / Cal self-check error. 9-4

9.2.5 Code 1-4 Torque transducer / Started on Zero condition error. 9-4

9.2.6 Code 1-5 Torque transducer / Started on Cal condition error 9-4

9.2.7 Code 1-6 Torque transducer / Zero Level Self Check Error 9-4

9.3 Torque Over Abnormals 9-5

9.3.1 Code 2-0 Torque Over Abnormal / Offset Torque 9-5

9.3.2 Code 2-1 Torque Over Abnormal / Torque Inhibit High Limit 9-5

9.4 Tool EEPROM Errors 9-6

9.4.1 Code 3-0 Preamplifier / Tool ID Checksum error 9-6

9.4.2 Code 3-1 Preamplifier / Tool type error 9-6

9.4.3 Code 3-2 Preamplifier / Started without tool connected 9-6

9.4.4 Code 3-3 Preamplifier / Tool is not connected 9-6

9.5 System Memory Errors 9-7

9.5.1 Code 4-0 system memory error / Flash ROM write error 9-7

9.5.2 Code 4-1 system memory error / Flash ROM read error 9-7

9.5.3 Code 4-2 system memory error / Servo Amp Flash ROM error 9-7

9.6 Servo Amplifier Response / Resolver 9-8

Page 14

9.6.1 Code 5-0 Servo Amplifier reply error / No reply from Resolver 9-8

Appendix A

RMA Supplement.

A-2

Data Parameter

Setting Blank Form.

A-3

Tool List (Straight, Offset, U

-

Tools)

A-4

Tool List (Right Angle tools)

A-5

AFC1500 SAN2 with MULTI UNIT

- Cable Map.

A-6

AFC1500 SAN3 with MULTI2 UNIT

- Cable Map.

A-7

AFC1500 SAN2 Axis Unit Connection Reference.

A-8

AFC1500

SAN3 Axis Unit Connection Reference.

A-9

AFC1500 Transformer.

A-10

AFC1500 SAN / Multi Power Cable.

A-11

AFC1500 SAN3

-

120WM Power Cable.(RM5)

A-12

AFC1500 System Motor / Resolver Cables.(RM1,2,3,4)

A-13

AFC1500 System Pre

-

Amp Cable.(RM1,2,3,4,5)

A-14

AFC1500 System Motor Cable.(RM5)

A-15

AFC1500 System Resolver Cable.(RM5)

A-16

AFC1500 System Motor / Resolver Ext. Cables.(RM1,2,3,4)

A-17

AFC1500 System Pre

-

Amp Ext. Cable.(RM1,2,3,4,5)

A-18

AFC1500 System Motor Ext. Cable.(RM5)

A-19

AFC1500 System

Comm. Cable (RS232/422 Converter).

A-20

AFC1500 Comm. Cable (Axis to Axis unit).

A-21

AFC1500 MULTI Unit Null Modem Cable

A-22

AFC1500 SAN2 Unit I/O cable

A-23

AFC1500 SAN3 Unit I/O cable

A-24

AFC1500 SAN2 ~ SAN3 Adapter Cable

A-25

AFC1500 SAN3 ~

SAN2 Adapter Cable

A-26

AFC1500 System Motor/Resolver/Preamp Cable (RH1,3)

A-27

AFC1500 System Motor/Resolver/Preamp Ext. Cable (RH1,3)

A-28

9.7 Servo Type Error 9-9

9.7.1 Code 6-0 Servo Type error / Servo Type mismatch 9-9

9.8 Internal Error 9-10

9.8.1 Code 7-0 Internal error / Internal power supply abnormal 9-10

9.8.2 Code 7-1 Internal error / Signal Timing Error 9-10

9.9 Servo Amplifier Error 9-11

9.9.1 Code 8-1 Servo Amplifier error / Servo is over heated 9-11

9.9.2 Code 8-4 Servo Amplifier error / Over current 9-11

9.9.3 Code 8-5 Servo Amplifier error /Internal power supply. 9-11

9.9.4 Code 8-6 Servo Amplifier error / Input Voltage abnormal 9-12

9.9.5 Code 8-9 Servo Amplifier error / Over speed. 9-12

9.9.6 Code 8-10 Servo Amplifier error / over load ( I square T) 9-12

9.9.7 Code 8-11 Servo Amplifier error / Resolver Signal Error . 9-12

9.10 Parameter Error 9-13

9.10.1 Code 9-0 Parameter Error / Missing speed preset. 9-13

9.10.2 Code 9-1 Parameter Error/ Missing Speed or Time 9-13

9.10.3 Code 9-2 Parameter Error/ Parameter Select Error 9-13

9.10.4 Code 9-3 Parameter Error/ Missing Reverse Speed 9-13

9.10.5 Code 9-4 Parameter Error/ Torque Speed not set 9-13

9.10.6 Code 9-5 Parameter Error/ Torque Setup Error 9-14

9.10.7 Code 9-6 Parameter Error/ Angle Setup Error 9-14

9.10.8 Code 9-7 Parameter Error/ Reverse Torque over. 9-14

9.11 AFC1500 SAN Unit Fastening Faults and Causes 9-15

9.11.1 Accept Conditions 9-15

9.11.2 Torque Reject Conditions 9-15

A-1

Page 15

FEC AFC1500 Operations Manual Chapter 1: Outline (Rev. 6: 10/09)

Chapter 1: Outline

Page 1-1

Page 16

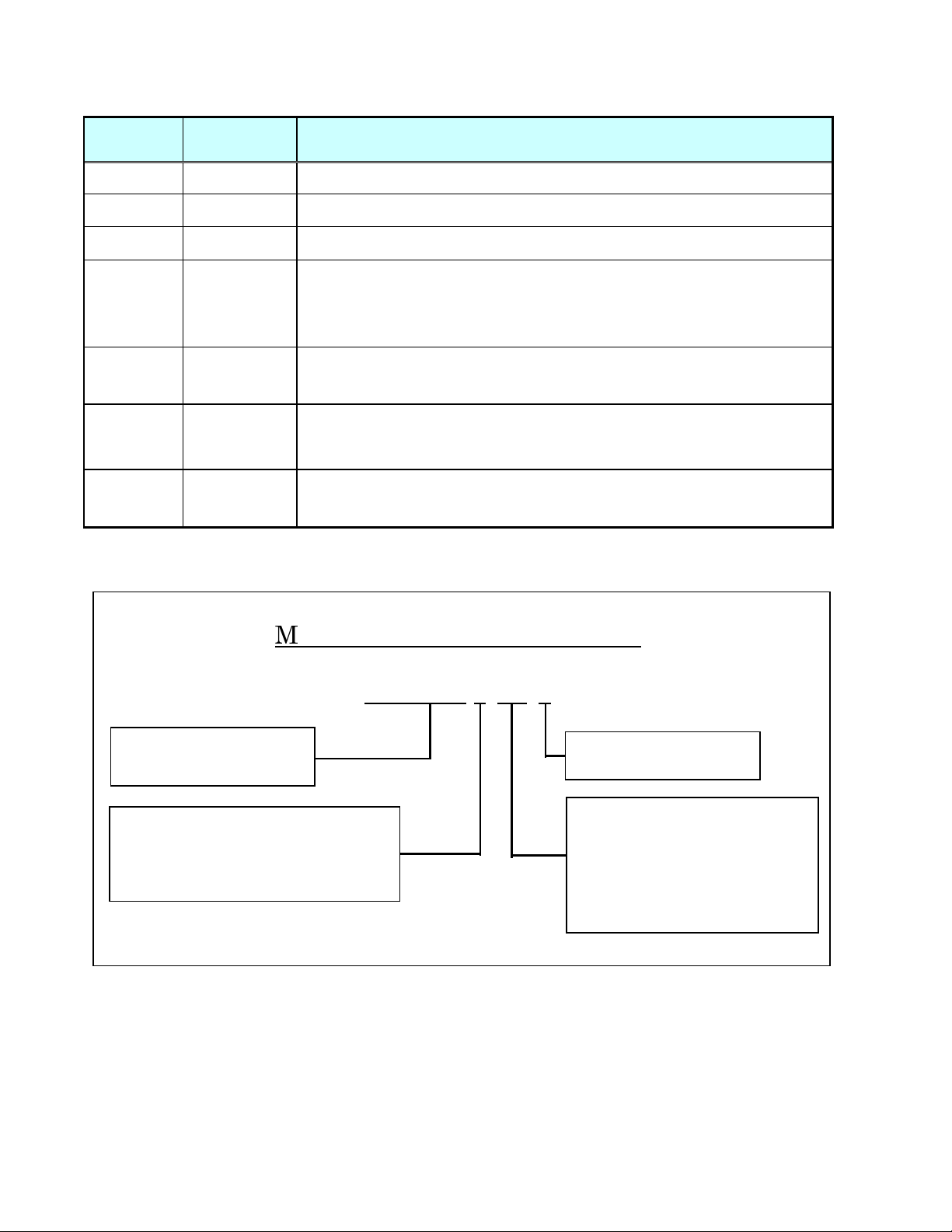

Chapter 1: Outline

Chapter

Item

Contents

1.1 About This operations manual

This manual details the configuration, components, specifications, and the operation of the

AFC1500 Fastening System.

The following table outlines the contents of each chapter:

Chapter 1 Outline Basic characteristics and requirements of the AFC1500

System.

Chapter 2 Specifications General specifications of the AFC1500 System.

Chapter 3 System Description Description of standard and optional system compo-

nents.

Chapter 4 System Setup and Wiring Equipment installation procedure, dimensions, Input

and Output signal descriptions and requirements for

PLC programming.

Chapter 5 Power Up and Initial Checks Preliminary power on and operational tests.

Chapter 6 Fastening Instructions Basic fastening operations and presetting procedures.

Chapter 7 System Operations Instructions for the input of preset data and monitoring

explanations.

Chapter 8 Maintenance and Inspection Guide for preventive maintenance.

Chapter 9 Troubleshooting Descriptions of fastening rejects, abnormal operation

faults, and corrective actions.

Appendix A Reference Drawings Electrical reference drawings of standard cables and

connections.

Related Instruction Manuals

AFC1500 Multi Unit Manual

AFC1500 Multi-2 Manual

AFC User Console Manual

Page 1-2

Page 17

FEC AFC1500 Operations Manual Chapter 1: Outline (Rev. 6: 10/09)

1.2 Features

The AFC1500 Fastening System is a culmination of over thirty years of electric fastening expertise integrated with the latest electronic technology. The system is designed with modular construction in

mind. Configuration can be as simple as a single spindle controlled from a PLC, or a group of up to

31 spindles controlled from one main controller, the Multi Unit. The Multi Unit can be added to any

spindle(s) to perform the function of Sequencing, I/O Control, and Data Reporting for the spindles

connected to it. This drastically reduces the number of I/O required and simplifies PLC logic.

The basic elements of this system are:

1) A brushless, Resolver Based permanent magnet motor

2) Durable Planetary Gear Transmission

3) Reliable intelligent torque Transducer

2) A combination Fastening Controller / Digital Servo Amplifier (SAN unit)

• Compact Design

As the result of miniaturization circuit technology, the compact SAN units (Controller) maintain a maximum width as little as 60 mm in spite of the built-in power source and Servo Amplifier.

System components are Back Panel mounted.

• Detachable Front Keypad-Display.

A Hot Swap-able front keypad display is available as an optional component for programming

single units and/or monitoring the fastening results and status conditions in the system. The system

can operate without the display.

• Multiple Condition Display

The system features a set of LED's that light to indicate the status of the System.

• Parameter Selection

Totally digitized system eliminates analog potentiometers.

Up to 16 different sets of parameters can be stored into Flash ROM for each spindle.

No battery-backup of memory is required.

• Available AFC User Console Programming Software

The AFC User Console Software incorporates the user interface as an integral part of the total system configuration. Nutrunner programming and data collection can be performed via the userfriendly AFC software. Functions such as Preset Parameter programming, Fastening data monitoring

and Fastening data analysis can be performed on multiple connected spindles using this software.

With the addition of a Multi Unit main controller, Fastening Sequencing and Fastening data

output can be programmed and controlled from the Single (Multi Unit) connection point. Typically this

software is installed in an industrial computer touch screen integrated into the system, but can also be

utilized through a detachable PC.

• Communication Interface

For Stand-Alone operation external communication is available through an integrated RS-485

port or via an optional Keypad Display (DP2 or DP4). The DP2 and DP4 units provide individual

spindle RS232 ASCII data output. Additional Communication options are available when configured

with the AFC1500 Multi Unit (Refer to related instruction manuals).

• Motor

A permanent magnet DC motor provides for improved fastening control. The sealed design

of the motor provides greater protection from contamination without generating excess heat. The resolver is uniquely designed to withstand harsh environments and provide high resolution control / angular feedback signals.

Page 1-3

Page 18

Chapter 1: Outline

• Data Storage

Each SAN3 unit stores approximately the last 12,300 fastening results in memory as well as

the last 256 Abnormal conditions. (SAN2 units DO NOT support data storage). Data is erased as a

result of FIFO (First In First Out) or via the AFC user console. Date stamping of data does not take

place in the Stand alone SAN units unless new SAN-DP1 display is connected (DP1 which supports

the clock function) or when stored data is collected via a Multi Unit configured system. The data list

that is stored in a Stand-alone SAN3 –xxx unit is as

follows;

1. Cycle Count 9. Final Torque

2. Date (only with new SAN-DP1 display connected) 10. Final Angle

3. Time (only with new SAN-DP1 display connected) 11. Cycle Time

4. Fastening Method 12. 1st Rate

5. Fastening Steps 13. 2nd Rate

6. Judgment 14. 3rd Rate

7. Parameter Number 15. Snug Torque

8. Peak Torque

• Preamplifier

Quality control of the tool torque transducer is accomplished electronically (digitally) through

the EEPROM (Electrically Erasable Programmable Read Only Memory) in the preamplifier. During

factory setup of the torque transducer, the unit is Dead Weight and dynamically tested against Standards that are certified and traceable to the National Institute of Standards and Technology. The resultant data is then programmed into the preamplifier where it is stored on non volatile EEPROM.

• Servo Amplifier (Servo Drive)

Reduced equipment size with improved drive circuit strength is the result of incorporating Insulated Gate Bipolar Transistor (IGBT) technology into the drive System. SAN units are available in

several models. The Servo Amplifier housed in each SAN unit determines the model type. The Servo Amplifier also dictates the nutrunner (tool) models that can be supported by the SAN unit.

• Plug-In Firmware Update System

The SAN Firmware is stored in Flash ROM and can be rewritten with future Firmware updates via a plug-in connector located on each unit. There is no need to remove the unit or disassemble the unit for any Firmware upgrades.

• Motor and Resolver Combined Cable

A combined motor and resolver cable reduces the number of cables in the system. The torque

signal cable is separate for better torque signal management.

• Multi Unit Connectivity

A main controller or Multi Unit can be connected to a single spindle or group of up to 31 spindles to control all spindle(s) from a single point of I/O. The Multi Unit assumes all fastening sequencing, fastening data monitoring / analysis and all data communication. Without the use of the Multi

Unit, individual spindle sequencing is limited to basic multi step operations.

• Network Connectivity

Connection to an Ethernet network can be accomplished via the addition of the Multi Unit. For

specific capabilities related to Ethernet protocols, please contact FEC Inc.

Page 1-4

Page 19

FEC AFC1500 Operations Manual Chapter 1: Outline (Rev. 6: 10/09)

1.3 Functions

• Fastening function.

The following fastening control methods can be selected for either clockwise (CW) or counterclockwise (CCW) operation:

Torque Control / Angle Monitoring

Angle Control / Torque Monitoring

Current (Amp) Torque Control (NRT – Transducerless tools only)

Current (Amp) Angle Control (NRT - Transducerless tools only)

The SAN unit used as a standalone unit (without the Multi Unit) has capability for one, two & three

step fastening. With the addition of the Multi Unit, one - three step fastening is possible and may be

repeated (using the sequence function) over multiple steps allowing for a multitude of fastening sequence possibilities.

As stand alone units, SAN Units can perform synchronized fastenings using the SYNC I/O signals,

which controls the simultaneous synchronization of all spindles. Thus, each spindle stops and waits

when they reach the previously defined step value. When all connected spindles have reached the

same step value, they will simultaneously start again and rundown to the next step value. When

configured with a Multi Unit, spindle synchronization is a standard function in the fastening sequence

set-up.

Note: With the use of a Multi Unit, fastening steps may be performed repeatedly in up to 99 fastening

steps in the fastening sequence.

Torque rate monitoring is available in any configuration.

• Self-Check Disable Function

The Self Check can be disabled by an external PLC signal. If the self check signal is "high"

(inactive) before the cycle starts, the check is done automatically. The zero voltage level of the torque transducer and the CAL voltage levels are verified to within +/- 4%. When the torque transducer's automatic check is not required, this function can be disabled by activating the SELF CHECK

signal before the cycle starts. The fastening cycle will then be performed without the self check.

• Reject / Abnormal Condition Display

When a fastening Reject has occurred, the tool stops, outputs the appropriate signal and displays the resultant data in the Detachable Keypad-Display unit if it is connected. Upon a fastening reject, the unit will not require resetting prior to the next cycle.

The System will output an Abnormal signal when it detects there is a problem (Zero Check out of limits, incorrect component connection, etc.) within the system itself. The output will be displayed as a

code on the affected Axis unit. Refer to Chapter 9 Troubleshooting for more details. Correction of

the abnormal cause and reset of the system is required on an abnormal before normal operation can

resume.

• Axis Bypass Function

When a PLC Bypass input signal is activated or when the RUN/BYPASS switch on the front

panel is switched to the Bypass position, the Bypass output signal is activated. In this condition, the

spindle will not START, REVERSE, CAL OR RESET. The SYNC signal will be bypassed to avoid affecting synchronized operations. When the Axis unit is in the bypass mode, the "Bypass" LED on the

front panel of the Axis unit will blink. When configured with a Multi Unit, the bypassed spindle is ignored as if it doesn’t exist in the multiple spindle configurations.

Page 1-5

Page 20

Chapter 1: Outline

• Tool Type Check Function

The AFC1500 tools have an EEPROM in the preamplifier that contains tool data specific for

each tool. The Tool type check function reads the information of the tool EEPROM and compares it

to the information of the Axis (SAN) unit; any mismatch is reported as a Tool Type Error Abnormal.

The tool type check is performed during the following times:

1) When the equipment is powered on.

2) When preset data is downloaded from a user console to the Axis unit.

3) When a tool is changed

Page 1-6

Page 21

FEC AFC1500 Operations Manual Chapter 1: Outline (Rev. 6: 10/09)

1.4 System requirements

To ensure the most effective and extended use of all equipment, adhere to the following specifications:

• Tool Installation

Tools generate a great amount of torque during operation, and the reaction force is applied to

the mounting area of the tool. Therefore, tools must be installed in the proper positions and with adequate bolts. Use the supplied bolts to prevent the tool from loosening due to vibration. A minimum of

2mm of clearance is required between tools, with nothing touching a mounted tool that will impact

free movement for torque reaction (or improper torque readings will result). The tool assembly contains precision parts and electronic components, and must not be subject to excessive shocks or

stresses.

Keep in mind that the torque transducer is a strain gage based instrument and, although it

has been designed to withstand sudden shock, repeated shock (over time) could damage the transducer. Therefore, cylinder cushions or shock absorbers should be used to decelerate spindle slides

and prevent excessive (hard stop) vibration, particularly in short cycle time applications operating at

high speeds.

• Fastening Operation

Avoid fastening beyond the full scale torque. Do not use a duty cycle (the ratio of the tool ro-

tating time to the machine cycle time) higher than 60%, even when the torque is below the full scale

value.

• Cable Wiring

Use the specified cables for all System connections.

Circuit breakers or fuses are required on branch circuit power feeds to the controllers.

Do not use a high voltage circuit as a frame ground (FG). Also, the frame ground should be

separate from the power ground.

When multiple Axis units are used, ensure that each unit is connected to its matching num-

bered tool, and that all connectors are locked.

PLC I/O cables must be run separate from any high voltage power sources or cabling, and

must not exceed 50 feet in length.

• Control Equipment (Axis units) Installation Environment

Controllers should be located in a NEMA 12 enclosure.

Controller units must be located a minimum of 600 mm from high transient voltage sources

such as transformers, motor starters, AC inverters and AC contactors. If it cannot be avoided,

the units must be properly shielded.

Do not use at the following locations.

Areas under direct sunlight.

Areas where the environmental temperature is out of the 32 °~122° F range.

Areas where the relative humidity is above the 90% range.

Areas where the temperature changes quickly, which may cause moisture.

Areas where conductive powder, oil mist, saline, or organic solvents exist.

Areas that have corrosive or combustible gases.

Areas that have strong electric or magnetic fields.

Areas where a strong vibration or shock could be transmitted directly to a Controller unit or

tool.

Page 1-7

Page 22

Chapter 1: Outline

• Static Electricity

AFC1500 System construction incorporates many electronic Surface Mounted Devices.

(SMD) It is advisable to strictly adhere to practices for safe electrostatic discharge in order to prevent

damage to the System when handling the units.

• Cleaning

Do not use any organic solvents, such as thinner, to clean an Axis unit or a tool. The solvent

could melt the surface paint, or penetrate inside and cause damage. A cloth dampened with alcohol

or warm water should be used to lightly wipe the components.

• Handling and Shipping

It is critical that AFC1500 System components are properly handled and shipped in order to

maintain the System's integrity. Adhere to the following requirements for shipping and handling:

Loose AFC1500 System components must be individually packaged in an approved anti-

static container or wrap to prevent damage from electrostatic discharge.

Tighten mounting screws on all back panel mounted fastening controllers.

Tool assemblies not vertically mounted must be removed from the powerhead during ship-

ment to prevent damage to the transducer assembly.

Enclosures must be protected with shrink wrap.

Enclosures and System components should be shipped on an air ride trailer whenever possi-

ble.

All non-painted metal parts (except for the tool motor and connectors) must be greased or

oiled to prevent rust.

Adhere to Chapter 2 Specifications for environmental requirements.

Page 1-8

Page 23

FEC AFC1500 Operations Manual Chapter 2: Specifications (Rev. 6: 10/09)

Chapter 2: Specifications

Page 2-1

Page 24

Chapter 2: Specifications

2.1 Main Specifications

{{{{ Power Supply Voltage

P 180~242 VAC, 3-Phase, 50/60 Hz

{{{{ Operating Power Requirements

PPPP See section 2.3 - SAN Unit Specifications

{{{{ Installation Requirement

P NEMA 12 enclosure (minimum).

{{{{ Range of Operation

P Duty cycle below 60% (reference Section 2.2 Duty Cycle Calculation)

P Additional specifications will be provided for nutrunners greater than 50 Kgm.

{ Operating Conditions (may be met by incorporating an Air Handling Unit into System)

P Temperature: 0° ~ 50°C (32° ~ 122°F) Humidity: 20% ~ 90%, no moisture

{ Motor Max. Operating Case Temperature

P Temperature: 70°C (158°F)

{{{{ Storage Conditions

P Temperature: -5° ~ 55°C (23° ~ 131°F) Humidity: Below 90%, no moisture

{{{{ Shipping Conditions

P Temperature: -5° ~ 55°C (23° ~ 131°F) Humidity: Below 90%, no moisture

Page 2-2

Page 25

FEC AFC1500 Operations Manual Chapter 2: Specifications (Rev. 6: 10/09)

2.2 Duty Cycle Calculation

Duty Cycle is rated as a percentage of the time the motor is running to the time the motor is

idle. This is an important factor in determining overload protection for Servo Amplifiers and

motors as it directly relates to the amount of power or heat dissipation of the motor / servo

package. The rated duty cycle for the AFC1500 System is calculated as follows:

Tool Rotation Time

Total Cycle Time (Tool Rotation + Tool Waiting)

Example: Tool Rotation Time = 3 Seconds x 100 = 25% Duty Cycle Percentage

Total Cycle Time = 12 Seconds

Duty cycle ratings vary between tools. As a general rule, however, it should not exceed 60%.

IF duty cycles remain above 60% for extended periods, a Servo Amplifier Error / Overload will

result (See abnormal CODE 8 -10). Protection for high duty cycle is a standard feature of the

Servo Amplifier to prevent servo or motor damage.

X 100 = Duty Cycle Percentage (%)

Page 2-3

Page 26

Chapter 2: Specifications

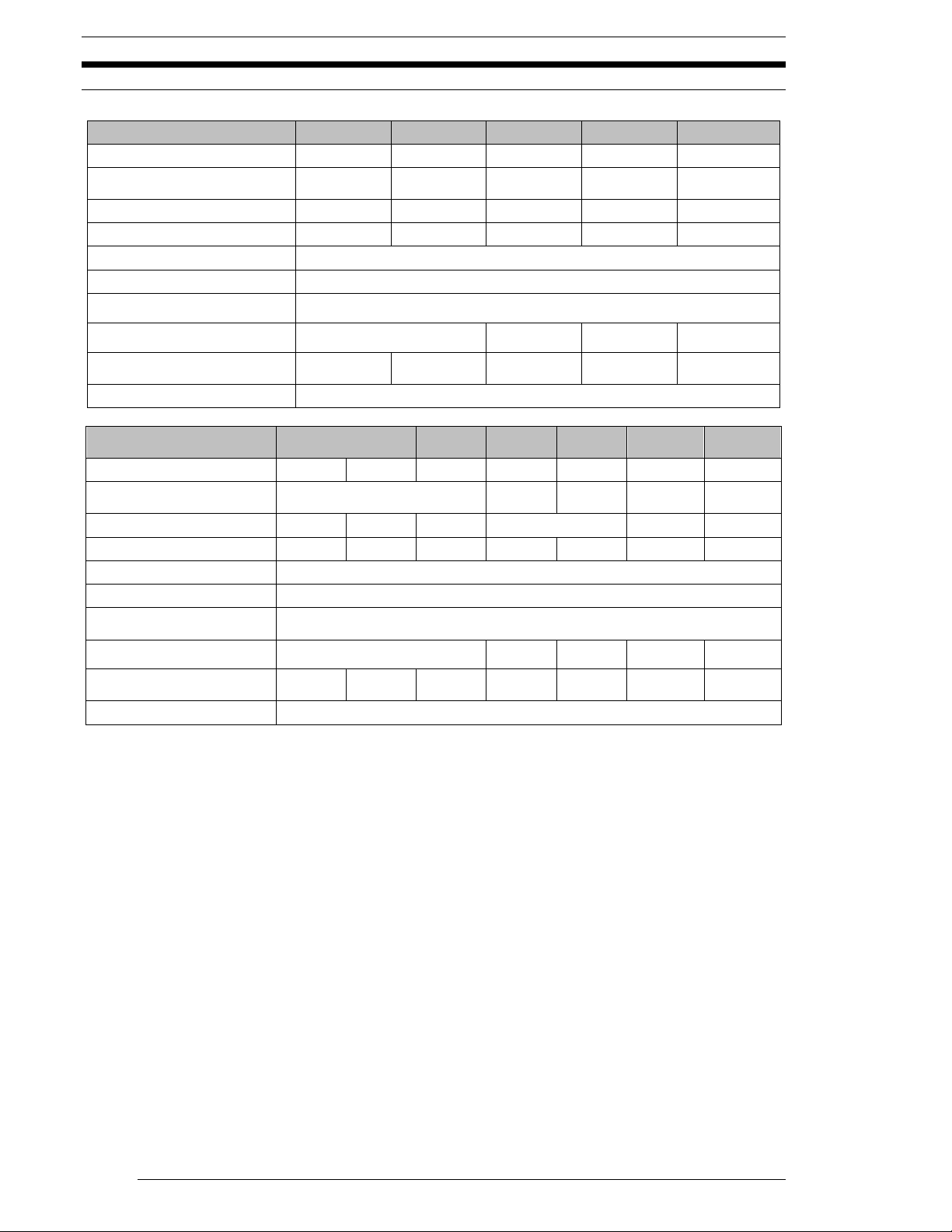

2.3 SAN Unit Specifications

ORIGINAL SAN UNIT TYPE SAN2 - 12 SAN2 - 24 SAN2 - 40 SAN2 - 80 SAN2 – 120

TOOL MOTOR TYPE RM1 RM2 RM3 RM4 RM5

TOOL MAX. TORQUE

MOTOR MAX. POW ER 60W 80W 200W 1500W 3000W

MOTOR RATED CURRENT 1A (RMS) 2A (RMS) 3A (RMS) 11A (RMS) 21A (RMS)

SAN INPUT POW ER 180-242VAC 50/60Hz

SAN IDLE POW ER

CONSUMPTION (watt/hour)

SAN AVERAGE POW ER

CONSUMPTION (watt/hour)*

SAN MAX. MOMENTARY

CURRENT (Inrush)

SAN UNIT OUTPUT POWER 270-300VAC PW M

4.0 Kgfm

(39Nm)

9.5A 18A 38.6A 79.2A 116.2A

4.0 Kgfm

(39Nm)

25wh 43wh 95wh 134wh

30.0 Kgfm

(294Nm)

18wh IDLE

80.0 Kgfm

(784Nm)

500 Kgfm

(4093Nm)

UPDATED SAN UNIT TYPE SAN3 - 24

TOOL MOTOR TYPE RM1 RM2 RH1 RM3 RH3 RM4 RM5

TOOL MAX. TORQUE

MOTOR MAX. POW ER 60W 80W 70W 200W 1500W 3000W

MOTOR RATED CURRENT 1A (RMS) 2A (RMS) 2A (RMS) 3A (RMS) 6A (RMS) 11A (RMS) 21A (RMS)

SAN INPUT POW ER 180-242VAC 50/60Hz

SAN IDLE POW ER

CONSUMPTION (watt/hour)

SAN AVERAGE POW ER

CONSUMPTION (watt/hour)*

SAN MAX. MOMENTARY

CURRENT (Inrush)

SAN UNIT OUTPUT POWER

*

Watt hours measured using the SAN unit at 60% duty/95% torque capacity

9.5A 18A 19A 38.6A 53.7A 79.2A 116.2A

4.0 Kgfm

(39Nm)

25wh 43wh 112wh 95wh 134wh

SAN3 –

24HM

SAN3 - 40

30.0 Kgfm

(294Nm) (200Nm)

18wh IDLE

270-300VAC PW M

SAN3 –

60HM

SAN3 –

120TM

80.0 Kgfm

(784Nm)

SAN3 –

120WM

500 Kgfm

(4093Nm)

CAUTION: If the equipment is powered on and off repeatedly, internal circuit protection devices may trip due to high in-rush current overload. It may take up to five minutes of “off” time to clear the self-protection circuit.

{{{{ Controller Processor: 32-bit RISC (Reduced Instruction Set CPU)

{ Parameter / Firmware Storage: Flash ROM

{ Fastening Method: Torque, Angle and Current Control Method

{ Torque Rate Calculation: 3 ranges

{{{{ Data Communications: (2) - RS485 communication ports: (1) for AFC User

Console Software and (1) for Multi Unit Communications

Page 2-4

Page 27

FEC AFC1500 Operations Manual Chapter 2: Specifications (Rev. 6: 10/09)

2.4 Capability

{{{{ Fastening Accuracy (Torque):

From 1/4 to 1/2 full scale torque: 3 sigma scatter less than 4% of target torque.

From 1/2 to full scale torque: 3 sigma scatter less than 3% of target torque.

{{{{ Torque resolution: Full Scale Torque x 1/1000.

{{{{ Torque Display Resolution: 4-digit display with floating decimal point

(In detachable display unit)

{{{{ Angle Resolution: 1024 pulses per motor rev.

{{{{ Angle Display Resolution: 1 degree.

Forward Max. count 9999 degree

Reverse Max. count 1999 degree

{ Torque transducer accuracy: (0 - Full Scale) ±1%

{ Linearity of torque transducer: ± 0.5% of Full Scale value (Maximum).

Page 2-5

Page 28

Chapter 2: Specifications

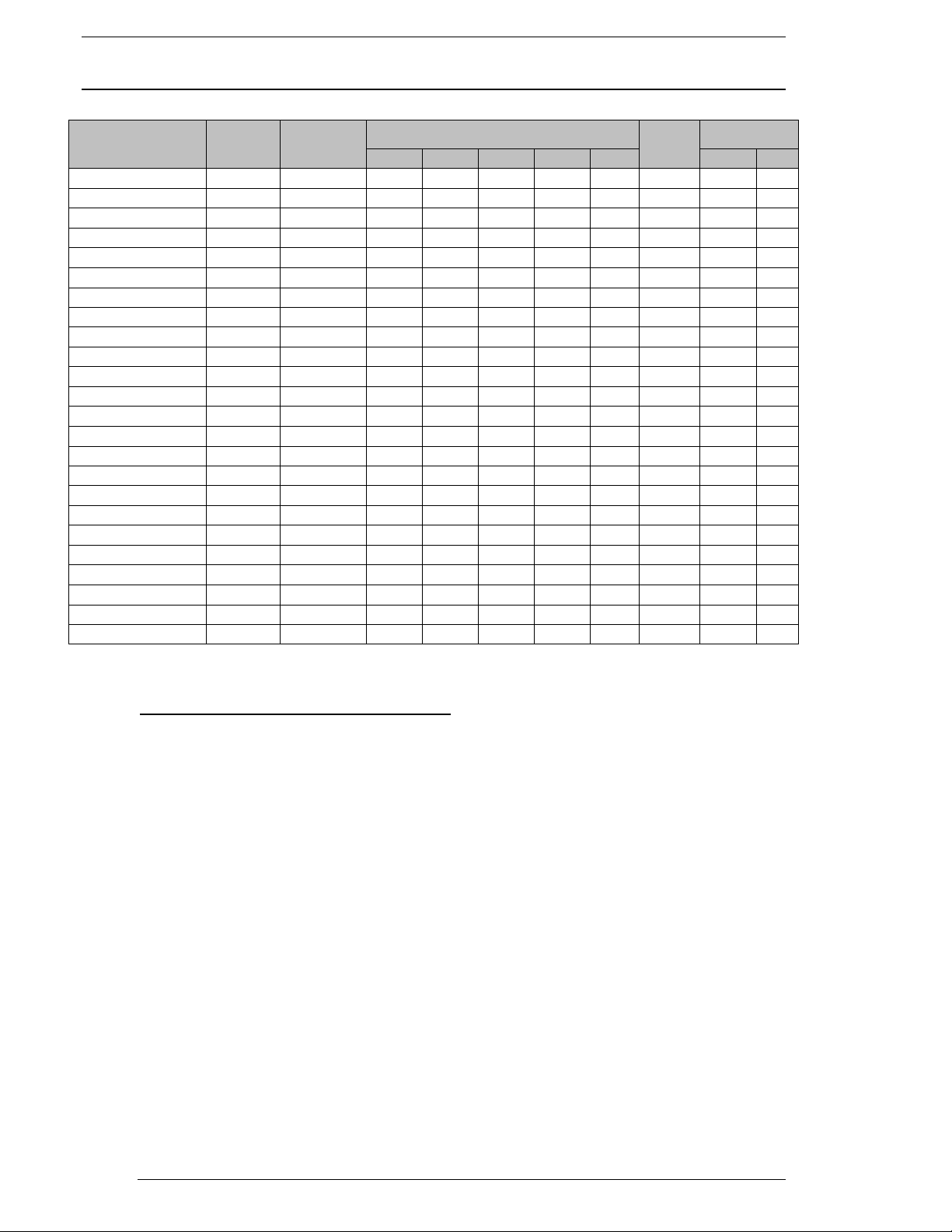

2.4.1 Nutrunner Tool Specification Table

TOOL TYPE

NFT-051RM1(A) –S1 SAN2-12 SAN3-24 4.9 0.5 50 3.6 43 19.8 :1 500 1

NFT-051RM1(A) -S SAN2-12 SAN3-24 4.9 0.5 50 3.6 43 9 :1 1,100 2

NFT-101RM1(A) –S/O SAN2-12 SAN3-24 9.8 1.0 100 7.2 86 9 :1 1,100 2

NFT-201RM1(A) –S/O SAN2-12 SAN3-24 19.6 2.0 200 14.4 173 19.8 :1 500 1

NFT-211RH1(x)-S N/A SAN3-24H 20.6 2.1 210 15.2 182 - 1220 1

NFT-301RM2(A) –S/O SAN2-24 SAN3-24 29.4 3.0 300 21.7 260 19.8 :1 600 1

NFT-311RH1(x)-S N/A SAN3-24H 30.4 3.1 310 22.4 269 - 855 1

NFT-401RM1(A) –S/O SAN2-12 SAN3-24 39.2 4.0 400 28.8 346 39.6 :1 250 1

NFT-411RH1(x)-S N/A SAN3-24H 40.2 4.1 410 29.6 356 - 635 1

NFT-401RM3(A) –S/O

NFT-601RM3(A) –S/O

NFT-801RM3(A) –S/O

NFT-801RH3(x)-S N/A SAN3-60H 78.4 8.0 800 57.6 693 - 1000 1

NFT-132RM3(A) –S/O

NFT-132RH3(x)- N/A SAN3-60H 127.4 13.0 1,300 94.0 1,127 - 580 1

NFT-152RM3(A) –S/O

NFT-202RM3(A) –S/O

NFT-202RH3(x)-S N/A SAN3-60H 196.0 20.0 2,000 144.0 1,734 - 408

NFT-302RM3(A) –S/O

NFT-502RM4(A) –S/O SAN2-80 SAN3-120TM 490 50 5,000 361 4,337 66.6 : 1 155

NFT-802RM4(A) –S/O SAN2-80 SAN3-120TM 785 80 8,000 578 6,938 40:1 100

NFT-103RM5 –S SAN2-120 SAN3-120WM 981 100 10,000 723 8,680 65:1 60

NFT-203RM5-S SAN2-120 SAN3-120WM 1961 200 20,000 1445 17,343 65:1 60

NFT-303RM5-S SAN2-120 SAN3-120WM 2942 300 30,000 2168 26,019 101:1 25

ORIGINAL

SERVO

TYPE

SAN2-40

SAN2-40

SAN2-40

SAN2-40

SAN2-40

SAN2-40

SAN2-40

UPDATED

SERVO

TYPE

SAN3-40 39.2 4.0 400 28.8 346 12.6 : 1 790 1

SAN3-40 59 6.0 600 43 520 12.6 : 1 790 1

SAN3-40 78.4 8.0 800 57.6 693 19.8 :1 500 1

SAN3-40 127.4 13.0 1,300 94.0 1,127 25.2 :1 395 1

SAN3-40 147 15.0 1,500 108 1,301 31.5 : 1 317 1

SAN3-40 196.0 20.0 2,000 144.0 1,734 45.0 :1 220

SAN3-40 294 30.0 3,000 226 2,716 64.8 : 1 150

NM KGM KGCM FTLB INLB MAX MIN

FULL SCALE TORQUE

GEAR

RATIO

CONVERSION GUIDE: 1 KGM = 100 KGCM = 9.8 NM = 7.2 FTLB = 86.7 INLB

Tool Assembly Model Number Breakdown

Example: NFT-801RM3A-S

NFT: AFC1500 Series Tool

801: 8.0 Kgm tool capacity (last digit indicates decimal position from left)

RM3: Resolver Motor (Model 3) RHx = High Speed Resolver Model

A: “A” motor has bulkhead connector, “ “ (blank) is pigtail style connection

“A” on an RHx(A) motor - cable exits towards end of tool

“B” on an RHx(B) motor - cable exits towards Square Drive

S: S = Straight, O = Offset, SU = “U” style, S1 = Straight Special, A = Angled Head

(Straight, Offset and “U” style tools have the same operational characteristics but are

physically configured to accommodate different space restrictions)

(Special and Angled Head tools have differing operational Characteristics / Capabilities

than Standard tools – Please contact FEC for specifications for these types of tools)

The tool lists located throughout this manual identify the specifications for standard

tools used with the AFC1500 System. Additional tools up to 5000Nm are available. If

additional capacity, information or special needs are required, please contact FEC INC.

SPEED

RPM

1

1

1

1

1

1

1

1

Page 2-6

Page 29

FEC AFC1500 Operations Manual Chapter 2: Specifications (Rev. 6: 10/09)

TORQUE

TORQUE RATE

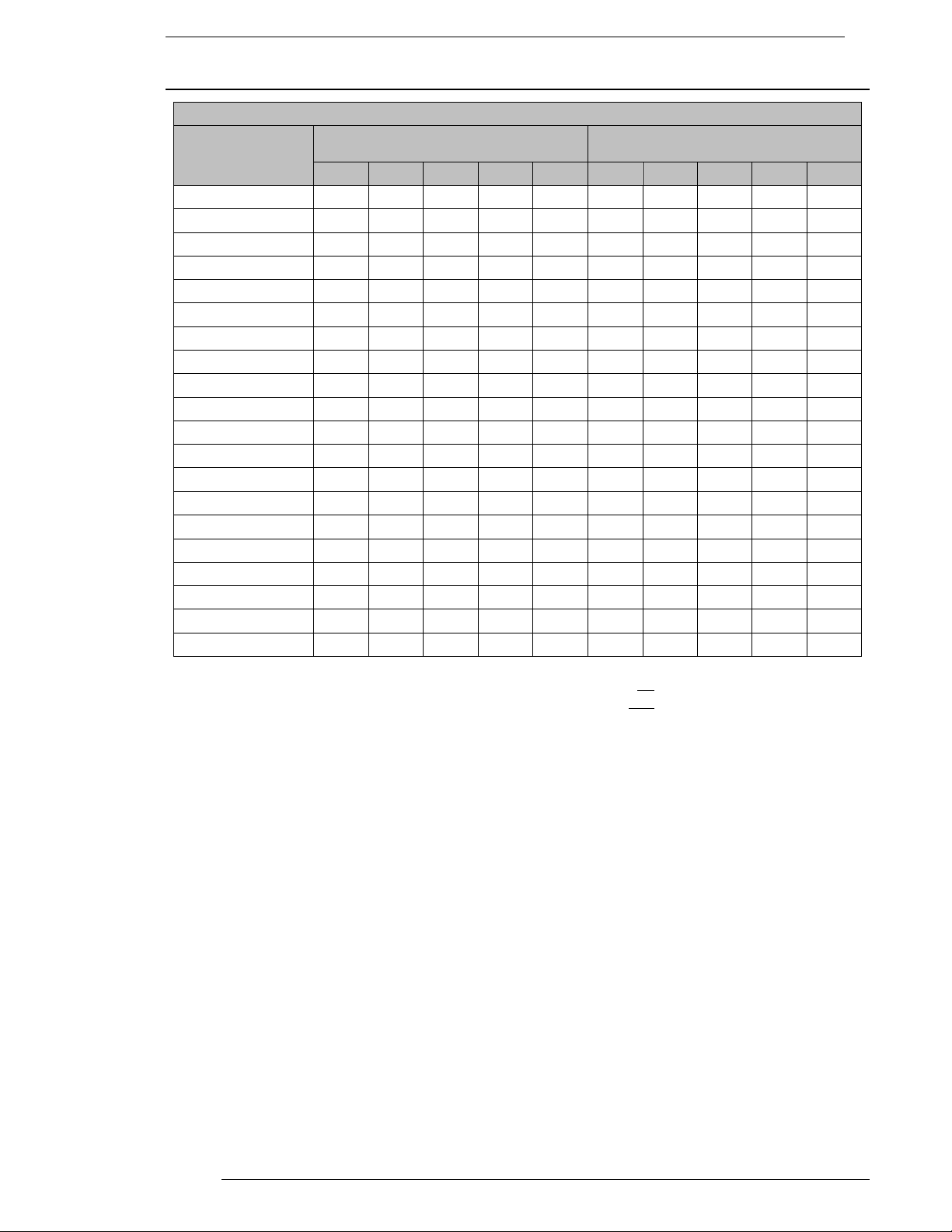

2.4.2 Nutrunner Decimal Point Display Table

POSITIONS FOR DECIMAL POINT DISPLAY

TOOL TYPE

DECIMAL POINT DISPLAY

DECIMAL POINT DISPLAY

NM KGM KGCM FTLB INLB NM KGM KGCM FTLB INLB

NFT-051RM1-x 2 3 1 3 1 3 3 3 3 3

NFT-101RM1-x 2 3 1 3 1 3 3 3 3 3

NFT-201RM1-x 2 2 0 2 1 3 3 2 3 2

NFT-211RH1x-S 2 2 0 2 1 3 3 2 3 2

NFT-301RM2-x 2 2 0 2 1 3 3 2 3 2

NFT-311RH1x-S 2 2 0 2 1 3 3 2 3 2

NFT-401RM1/2-x 1 2 0 2 0 3 3 2 3 2

NFT411RH1x-S 1 2 0 2 0 3 3 2 3 2

NFT-601RM3-x 1 2 0 2 0 3 3 2 3 2

NFT-801RM3-x 1 2 0 2 0 2 3 1 2 1

NFT-801RH3x-S 1 2 0 2 0 2 3 1 2 1

NFT-132RM3-x 1 2 0 1 0 2 3 1 2 1

NFT-132RH3x-S 1 2 0 1 0 2 3 1 2 1

NFT-152RM3-x 1 2 0 1 0 2 3 1 2 1

NFT-202RM3-x 1 2 0 1 0 2 3 1 2 1

NFT-202RH3x-S 1 2 0 1 0 2 3 1 2 1

NFT-302RM3-x 1 2 0 1 0 2 3 1 2 1

NFT-502RM4-x 1 2 0 1 0 2 3 1 2 1

NFT-802RM4-x 1 2 0 1 0 1 2 0 1 0

NFT-103RM5-S 0 1 0 0 0 1 2 0 1 0

Example: NFT-201RM1-S Torque Display = 19.00 NM (2 positions)

Torque Rate Display = 1.999 NM/degree (3 positions)

Page 2-7

Page 30

Chapter 2: Specifications

[Blank Page}

Page 2-8

Page 31

FEC AFC1500 Operations Manual Chapter 3: System Description (Rev. 6:10/09)

Chapter 3: System Description

Page 3-1

Page 32

3.1 System Block Diagram

3.1.1 Multi System Block Diagram Description

{ Spindles can be configured as stand alone units (with independent I/O) or combined in a

multiple spindle configuration controlled by one main controller (Multi Unit) using one set of

I/O to control the group of spindles. This configuration is referred to as a “Multi System”.

{ In a Multi System, communication and spindle control for up to 31 SAN Units (Spindle Con-

trollers) is accomplished through the Multi Unit via an RS485 Daisy chain connection on the

front of each Axis unit.

{ Spindle programming / monitoring is accomplished through either a detachable Laptop PC

or an embedded HMI PC, running the AFC User Console software package, for simultaneous

uploading / downloading of up to 31 spindles.

{ A “Hot -Swap” detachable keypad/display can be used on each SAN Unit to monitor the individual spindle status.

{ The use of a Multi Unit provides one set of PLC I/O for controlling multiple spindle fastening operations. Fieldbus interfaces are available for direct connection to networks such as

Profibus, DeviceNet, AB Remote I/O, CCLink, Ethernet I/P, etc.

Chapter 3: System Description

{ Discrete 24 VDC (Sinking) I/O on the SAN unit provides direct communications with the

PLC for limited individual spindle control when the system is configured with a Multi Unit. The

individual spindle I/O can provide individual spindle status when required.

{ Dedicated communications with the system is provided via communications ports available

directly on the Multi Unit. Once configured, the system is not dependent on a PC or software

package to receive or transmit data from/to an external device.

{ A detachable or embedded PC running the AFC User Console software can be connected

to the Multi Unit for increased data communications or manipulation capabilities.

Page 3-2

Page 33

FEC AFC1500 Operations Manual Chapter 3: System Description (Rev. 6:10/09)

Multi2 Only

– (1) RS422

User Console

Detachable Laptop

OR

User Console HMI

Embedded

AFC User Console Communication

Multi-RS485

Multi2-RS232 Null Modem or

Ethernet

Serial display panel

RS232 Barcode input

Serial Output (2) Ports

Serial Printer

Discrete

PLC I/O.

Optional

Fieldbus

RS485 communications

Misc. Serial Device

RS485 communications

RS485 communications

RS485 communications

Individual

Spindle PLC

I/O

1 ~ 31 Spin-

Motor/Resolver,

& Transducer

Tool Cables

FIG. 3-1-1 AFC1500 Block Diagram with Multi Unit connection

Page 3-3

Page 34

3.1.2 Stand Alone System Block Diagram Description

{ Spindles can be combined in a multiple spindle configuration controlled by one main controller (Multi Unit) using one set of I/O to control the group of spindles. When communications requirements, spindle sequencing requirements or spindle quantities are limited, a simpler configuration without a Multi Unit can be set up. This configuration is referred to as a

“Stand Alone” system.

{ In a Stand Alone System, simultaneous communication for up to 31 SAN Units (Spindle

Controllers) can only be accomplished via an RS485 Daisy chain connection on the front of

each Axis unit. The AFC User Console software must be used in conjunction with a PC to

collect and manipulate data from multiple spindles.

{ Additionally, a “Hot -Swap” detachable Keypad/Display can be used on each SAN Unit to

program and monitor the individual spindles.

{ Discrete 24 VDC (Sinking) I/O on the SAN unit provides direct connection with the PLC for

complete individual spindle control when the system is configured as a Stand Alone System.

The spindle I/O for each SAN unit must be individually controlled and monitored

{ Dedicated serial communications with each SAN unit can be provided via an individual

communications port available directly on the optional Keypad/Display Unit (DP2, DP4) that

can be connected to a single SAN unit. Once configured, the system is not dependent on a

PC or software package to transmit data to an external device.

Chapter 3: System Description

{ A detachable or dedicated PC running the AFC User Console software can be connected

to the multiple spindles in a Stand Alone system for increased data communications or manipulation capabilities.

Page 3-4

Page 35

FEC AFC1500 Operations Manual Chapter 3: System Description (Rev. 6:10/09)

Serial Data output via a

SAN-DP2, SAN3

-

DP2 or

Serial display panel

Individual Spindle

Serial Output (1) Port

Per Display Unit (RS232)

Serial Printer

Misc. Serial Device

User Console De-

tachable Laptop

OR

User Console

User Console HMI

Embedded

RS485

*Use cable FEB-1266

RS232/RS485 convertor cable assembly

SAN-DP4 unit is available as a single spindle output only. When multiple spindle data is required

an Embedded PC with the AFC Userconsole software or a MULTI unit must be used.

RS485 communications

RS485 communications

RS485 communications

Individual

Spindle

PLC I/O

1 ~ 31 Spin-

Motor/Resolver,

& Transducer

Tool Cables

FIG. 3-1-2 AFC1500 Block Diagram with out Multi Unit connection (Stand-Alone)

Page 3-5

Page 36

3.2 AFC1500 SAN UNIT Front panel

ITEM AS MARKED

DESCRIPTION

M O T O R

T / D

R S

B Y P A S S

S

1

P O W E R

B U S Y

A

C .

J .

R E S

L V E

3.2.1 AFC1500 Front Panel Switches and Connectors

AAAA

FFFF

CCCC 1111

5555 0000

0000

C O N 1

S V .

A B N .

R U N

4 8 5

M O N .

P L C

FEC

R

A C 2 0 0 - 2 2 0

SAN3-24M

ON UNIT

CON1

For Display Unit (SAN-DP*) connection. (Section 3.3 & 3.4)

SW1

Sets Spindle number for communications and special configuration features. (Section 4.10)

Controller Enable/Disable switch.

BYPASS/RUN

RUN: Enable

BYPASS: Bypass mode

RS485

Bi-directional Communication ports.

RESOLVER

Resolver connection for tool Motor /

Resolver cable.

(Angle of Rotation input)

Monitor Output

MON.

Torque Analog Voltage and Angle

Pulse output connection for connection to independent monitor device.

T/D

Connection for tool Transducer cable.

(Torque signal input)

MOTOR

Motor Connection for tool Motor/Resolver cable. (Motor Drive)

Connection for Inputs and Output

PLC

signals. Available signal vary depending on Stand alone or Multi operation.

AC 200 ~ 220

Connection for Input Power.

(+/- 10%)

3 phase, 180-242VAC, 50/60Hz

FIG. 3-2-1 Axis unit Front panel controls

Chapter 3: System Description

Page 3-6

Page 37

FEC AFC1500 Operations Manual Chapter 3: System Description (Rev. 6:10/09)

ASS

1

SV.

ABN

.

REJ

.

ACC

.

POWER

BUS

Y

CON

1

1

2

3

4

5

6

3.2.2 AFC1500 Status LED and Bypass Switch Description

Located on the front of each SAN Unit are status indicators as well as a manual spindle bypass

switch. The indicators provide diagnostics and overall status, while the bypass switch provides a manual method to bypass a spindle when it is part of a multiple spindle configuration. This allows other

spindles to continue operation without the bypassed spindle.

SW

BYP

7

RUN

Fig. 3-2-2 Status LED and Bypass switch.

ITEM ON UNIT DESCRIPTION

1 POWER

2 BUSY

3 SV (SERVO)

4 ABNORMAL

5 ACCEPT

6 REJECT

BYPASS SWITCH

7

INDICATOR

(Yellow ). Indicates the power is on.

(Orange). Lights when the unit is powering on or performing a fastening operation.

Flashes when operating in reverse.

(Red). Lights if an Abnormal condition is detected in the Servo section of the control circuit. See troubleshooting section for more information

(Red). Lights to indicate that some component of the spindle (SAN unit, Nutrunner Tool,

etc.) is in an Abnormal state, and the fastening cycle has been interrupted.

A failed Cal Check or Zero Check will also display as an ABNORMAL.

Flashes when a Current warning has been detected.

See troubleshooting section for more information.

(Green) Lights to indicate that the spindle has completed an acceptable fastening, Zero

Check, or Cal Check.

(Red). Indicates the spindle performed a rejected fastening, out of the operation limits.

Flashes fast indicating an Angle reject. ( on 100 msec – off 300 msec)

Flashes Slow indicating a Torque rate or time reject. (on 100 msec – off 700 msec)

(Red) The LED mounted in the handle of the switch flashes when the unit is in Bypass

mode. The system will not operate in this mode. If connected to the Multi Unit, the spindle

is ignored, and the remaining spindles in the configuration will be judged as if the bypassed spindle does not exist.

Detailed information of the System status can be obtained through the Keyboard-display unit.

Page 3-7

Page 38

Chapter 3: System Description

REV

3.3 AFC1500 Keyboard-Display unit - SAN DP1/DP3 – SAN3-DP1

The SAN(3)-DP1 display unit is a “hot-swappable” detachable display also incorporating programming and monitor functions as well into this optional unit. It attaches directly to the front of the SAN

unit through connector CON1 and can be removed or attached with power on. It is not required for

the system to operate. Programming of parameters can be accomplished using the programming

keys. For multiple spindle applications the AFC User Console Programming software is more efficient

method of programming.

NOTE: Refer to Chapter 7 for detailed operation using the SAN(3)-DP units.

START

CAL

RESET

DATA

PARM

SET

D-NO

DATA

Mounting

flange on

DP3 and

DP4 only

FIG. 3-3 SAN - DP1 Keyboard -Display unit

ITEM AS MARKED ON UNIT DESCRIPTION

START Manual fastening start pushbutton.

REV Manual reverse pushbutton.

CAL Manual Calibration (CAL) Check pushbutton

RESET Manual Zero Check and System reset pushbutton.

DATA Four digit display where function is dependent upon the D-NO selected.

PARM

D-NO

Displays two-digit parameter number and, as required, will override Parameter output to display an Abnormal code.

Display number that indicates which data in the "DATA" display field is

being displayed and as required, will display an Abnormal Sub-code.

UP Data change increase pushbutton.

DOWN Data change decrease pushbutton.

MODE Display mode selection pushbutton.

SET Data change confirmation set pushbutton.

The SAN display units come in (2) different widths

to allow mounting to the SAN Units

SAN-DP1 & DP2 can be used on the following SAN

Units:

• SAN2-12, SAN2-40,

SAN3-24(H), SAN3-40, SAN3-60H

SAN-DP3 & DP4 can be used on the following SAN

Units;

• SAN2-80, SAN2-120,

SAN3-120T, SAN3-120W

(These units have a wider mounting flange)

SAN3-DP1 & DP2 units were introduced in 2009

and are RoHs compatible replacements of the 1st

generation SAN-DP units. These units also include

the addition of a real time clock (RTC) function for

stand-alone systems. (see 7.2.5 Parameter Data

List for clock setup)

SAN3-DP1 & SAN3-DP2 can now be used on ALL

SAN units. (DP2 has a serial port)

Page 3-8

Page 39

FEC AFC1500 Operations Manual Chapter 3: System Description (Rev. 6:10/09)

PIN SIGNAL

DESCRIPTION

1

NOT USED

2 RXD

NOT USED

3 TXD

TRANSMIT DATA

4 DTR

DATA TERMINAL READY (ALWAYS ON)

5 GND

SIGNAL GROUND

6 DSR NOT USED

7 RTS REQUEST TO SEND (ALWAYS ON)

8 CTS CLEAR TO SEND

9

NOT USED

1

5

69

SAN-DP2

3.4 AFC1500 Keyboard-Display Unit - SAN DP2/DP4 – SAN3-DP2

The SAN(3)-DP2 has the same function as the DP1 unit with the added function of a serial RS232

port for output of fastening data from a stand alone single SAN Unit. If the SAN unit is part of a multiple spindle configuration, then the fastening data would be output from the Multi Unit and this display

would not be required for this purpose. All button functions are identical to the DP1 Unit.

NOTE: Refer to Chapter 7 for detailed operation using the SAN(3)-DP units.

The SAN display units come in (2) different widths

to allow mounting to the SAN Units

SAN-DP1 & DP2 can be used on the following SAN

Units:

• SAN2-12, SAN2-40,

SAN3-24(H), SAN3-40, SAN3-60H

• SAN2-80, SAN2-120,

SAN3-120T, SAN3-120W

Mounting

flange on

DP3 and

DP4 only

SAN-DP3 & DP4 can be used on the following SAN

Units;

(These units have a wider mounting flange)

SAN3-DP1 & DP2 units were introduced in 2009

and are RoHs compatible replacements of the 1st

generation SAN-DP units. These units also include

the addition of a real time clock (RTC) function for

stand-alone systems. (see 7.2.5 Parameter Data

List for clock setup)

SAN3-DP1 & SAN3-DP2 can now be used on ALL

SAN units. (DP2 has a serial port)

Fig. 3-4 SAN - DP2 Unit

3.4.1 SAN(3)-DP2/DP4 Serial Pin out

Connector: DB-9P (Male)

Mating Connector: DB-9S (Female)

Note: The CTS signal needs to be activated in order for the fastening data to be output. If it is

not activated, up to 16KB of data will be stored in the output buffer. Once the buffer is full, the

data will be overwritten in a First In, First Out (FIFO) process. The CTS signal may be connected to the RTS signal if data is to be “dumped” at every fastening.

Page 3-9

Page 40

Chapter 3: System Description

TQ

ASCII

ASCII

TQ

ASCII

49

ASCII

ASCII

3.4.2 SAN(3)-DP2/DP4 Communication Protocol

Communication protocol from the SAN(3)-DP2/DP4 is as follows;

Speed: 9600bps

Parity: NONE

Data Bits: 8 Bit

Stop Bit: 1 Bit

3.4.3 SAN(3)-DP2/DP4 Communication Format

The data output from the SAN(3)-DP2/DP4 is a formatted ASCII output. This can be connected to a

serial printer, computer or other peripheral device. 78 bytes of data is output per fastening. The data

format is described in the table below.

Byte 1

Desc.

Hex

Data 0

Byte 17 18

2

3

4

5

6

7 8

9 10 11 12 13 14 15 16

Cycle Count

30H 30H 30H 31H 20H 20H 30H 31H 20H 20H 20H 20H 31H 20H 20H 30H

0

0

1

19 20 21 22 23 24 25 26 27 28 29 30 31 32

Spindle

Number

0 1

Parameter

Number

1

0

PK

Desc.

Peak Torque (PK TQ)

31H 2EH 33H 34H 4CH 20H 20H 20H 35H 30H 20H 20H 20H 31H 2EH 33H

Hex

Data 1

Byte 33

Desc.

Hex

Data

Byte

Desc.

Hex

Data

Byte

Desc.

.

3

34 35 36 37 38 39 40 41 42 43 44 45 46 47 48

FN

Judge 1st Rate

34H 4CH 20H 30H 2EH 31H 32H 33H 20H 20H 30H 2EH 31H 32H 33H 20H

4 L

50 51 52 53 54 55 56 57 58 59 60 61 62 63

3rd Rate

20H 30H 2EH 31H 32H 33H 20H 20H 20H 31H 30H 2EH 30H 20H 20H

0

.

64 65 66 67 68 69 70 71 72 73 74 75 76 77 78

2nd Time

Judge

Final Angle

Judge

4 L 5 0

Judge

2nd Rate

0

.

1

2 3

Judge

1st Time

1

2

3

Judge

1

Judge

0

0 . 0

CR LF

Final Torque (FN TQ)

.

1 2

Judge

1

.

3

Judge

3

20H 20H 32H 2EH 30H 20H 20H 20H 20H 58H 20H 20H 20H 0DH 0AH

Hex

Data

2

.

0

Total Judgment: “X” = 58h, “O” = 4Fh

Page 3-10

X

Page 41

FEC AFC1500 Operations Manual Chapter 3: System Description (Rev. 6:10/09)

3.4.4 SAN(3)-DP2/DP4 Data Format Description

The table below describes the data convention output from the SAN(3)-DP2/DP4 serial port.

Non-data bytes will be occupied by the hex character 20H.

Data Name

Byte # Data Format

Description

Cycle Count

Spindle Number

Parameter Number

Peak Torque

Peak Torque Judgment

Final Angle

Final Angle Judgment

Final Torque

Final Torque Judgment

1st Rate

1st Rate Judgment

2nd Rate

2nd Rate Judgment

3rd Rate

3rd Rate Judgment

1st Time

1st Time Judgment

2nd Time

2nd Time Judgment

Total Judgment

Carriage return 77 ODH

1 ~ 4 0000-9999

7 ~ 8 01 – 31

12 ~ 13 1 – 16

16 ~20 01.34

21

23 ~ 26 1234

27

29 ~ 33 01.34

34

36 ~ 40 01.23

41

43 ~ 47 01.23

48

50 ~ 54 01.23

55

57 ~ 61 123.4

62 H: High Reject

64 ~ 68 123.4

69 H: High Reject

73

H: High Reject

L: Low Reject

H: High Reject

L: Low Reject

H: High Reject

L: Low Reject

H: High Reject

L: Low Reject

H: High Reject

L: Low Reject

H: High Reject

L: Low Reject

O: Accept

X: Reject

Number is reset at Power Off

Maximum 31 spindles

Maximum 16 parameters

Decimal point location may change based

upon the tool type and torque unit.

ASCII space (20H) will apply if judgment is

accepted

4 digit number. No decimal point used

ASCII space (20H) will apply if judgment is

accepted

Decimal point location may change based

upon the tool type and torque unit.

ASCII space (20H) will apply if judgment is

accepted

Decimal point location may change based

upon the tool type and torque unit.

ASCII space (20H) will apply if judgment is

accepted

Decimal point location may change based

upon the tool type and torque unit.

ASCII space (20H) will apply if judgment is

accepted